High-transparency acrylic acid pressure-sensitive adhesive and preparation method thereof

An acrylic pressure-sensitive adhesive technology with high light transmittance, which is applied in the field of pressure-sensitive adhesives, can solve problems such as unsatisfactory light transmittance and failure to use normally, and achieve strong adhesion, large peeling force, and high transparency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

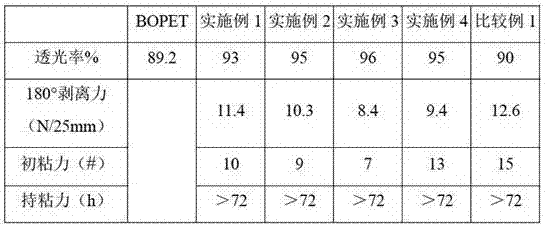

Examples

Embodiment 1

[0034] Prepare raw materials by the following parts by weight:

[0035] 5 parts of vinyl acetate, 20 parts of methyl methacrylate, 45 parts of butyl acrylate, 17 parts of 2-isooctyl acrylate, 4 parts of acrylic acid, 4 parts of hydroxyethyl acrylate, o-phenylphenoxyethyl acrylate 5 parts, 0.3 parts of azobisisobutyronitrile (AIBN), 150 parts of ethyl acetate.

[0036] 1) Mix vinyl acetate, methyl methacrylate, butyl acrylate, 2-isooctyl acrylate, acrylic acid, hydroxyethyl acrylate, and o-phenylphenoxyethyl acrylate to obtain a monomer mixture. 40% of the total amount of the monomer mixture and 40% of the total amount of the solvent ethyl acetate were poured into a four-necked flask with mechanical stirring, a thermometer, and a condenser tube, and heated to 80°C, and then 50% of the total amount of the initiator AIBN was poured into Into the reaction flask, start timing when reflux occurs in the condenser tube, and keep the temperature for 1h.

[0037] 2) After the reaction...

Embodiment 2

[0043] Prepare raw materials by the following parts by weight:

[0044] 5 parts of vinyl acetate, 20 parts of methyl methacrylate, 40 parts of butyl acrylate, 17 parts of 2-isooctyl acrylate, 4 parts of acrylic acid, 4 parts of hydroxyethyl acrylate, o-phenylphenoxyethyl acrylate 10 parts, 0.3 parts of azobisisobutyronitrile, and 150 parts of ethyl acetate.

[0045] 1) Mix vinyl acetate, methyl methacrylate, butyl acrylate, 2-isooctyl acrylate, acrylic acid, hydroxyethyl acrylate, and o-phenylphenoxyethyl acrylate to obtain a monomer mixture. 40% of the total amount of the monomer mixture and 40% of the total amount of the solvent ethyl acetate were poured into a four-necked flask with mechanical stirring, a thermometer, and a condenser tube, and heated to 80°C, and then 50% of the total amount of the initiator AIBN was poured into Into the reaction flask, start timing when reflux occurs in the condenser tube, and keep the temperature for 1h.

[0046] 2) After the reaction, ...

Embodiment 3

[0051] Prepare raw materials by the following parts by weight:

[0052] 5 parts of vinyl acetate, 20 parts of methyl methacrylate, 40 parts of butyl acrylate, 17 parts of 2-isooctyl acrylate, 4 parts of acrylic acid, 4 parts of hydroxyethyl acrylate, o-phenylphenoxyethyl acrylate 10 parts, 0.3 parts of azobisisobutyronitrile, and 150 parts of ethyl acetate.

[0053] 1) Mix vinyl acetate, methyl methacrylate, butyl acrylate, 2-isooctyl acrylate, acrylic acid, hydroxyethyl acrylate, and o-phenylphenoxyethyl acrylate to obtain a monomer mixture. 40% of the total amount of the monomer mixture and 40% of the total amount of the solvent ethyl acetate were poured into a four-necked flask with mechanical stirring, a thermometer, and a condenser tube, and heated to 80°C, and then 50% of the total amount of the initiator AIBN was poured into Into the reaction flask, start timing when reflux occurs in the condenser tube, and keep the temperature for 1h.

[0054] 2) After the reaction, ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com