Patents

Literature

94results about How to "No glue residue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

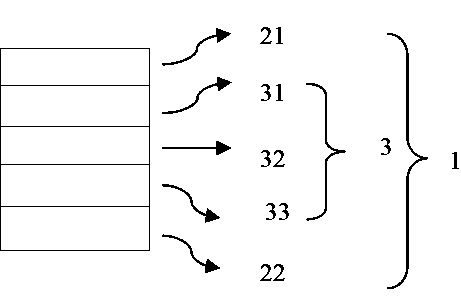

PET (polyethylene terephthalate) protective film for preparing flat-panel display

InactiveCN102134458AReduce polarityImprove cohesionFilm/foil adhesivesSynthetic resin layered productsTectorial membranePolyethylene terephthalate glycol

The invention discloses a PET (polyethylene terephthalate) protective film for preparing a flat-panel display, which is characterized by comprising an optical-level PET protective film base material and low-polarity pressure-sensitive adhesive, wherein the low-polarity pressure-sensitive adhesive is coated on the upper surface of the optical-level PET protective film base material. Since the pressure-sensitive adhesive has the characteristics of low polarity and high cohesive force, is inert, and can be instantaneously attached to the surface of the glass material of the flat-panel display, the protective film prepared from the pressure-sensitive adhesive, optical-level PET protective film and the like has the characteristics of no shedding, easy stripping after coating by vaporization, no adhesive residue, no pollution, high temperature resistance and static resistance, and can effectively avoid damaging the glass lens in the stripping process.

Owner:KUNSHAN BYE MACROMOLECULE MATERIAL CO LTD

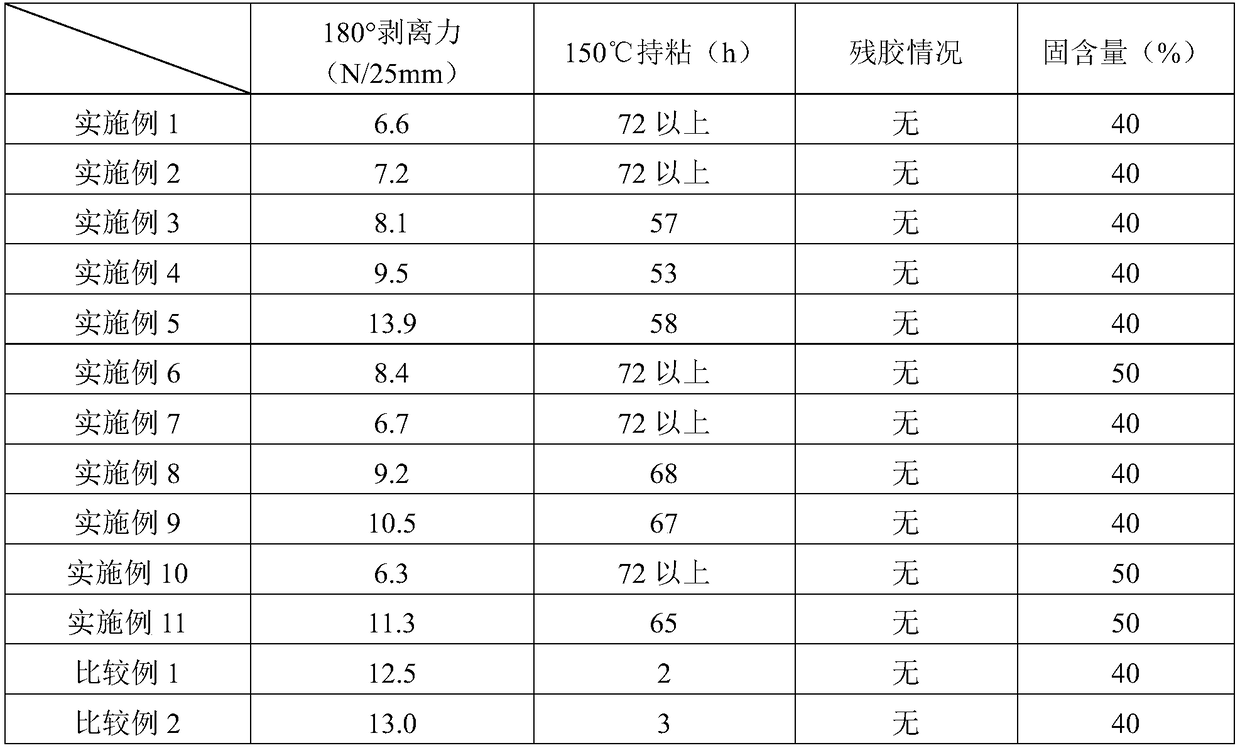

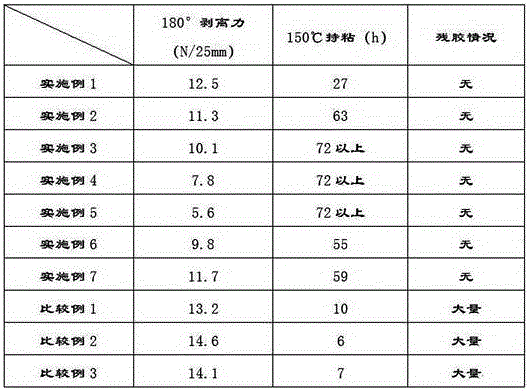

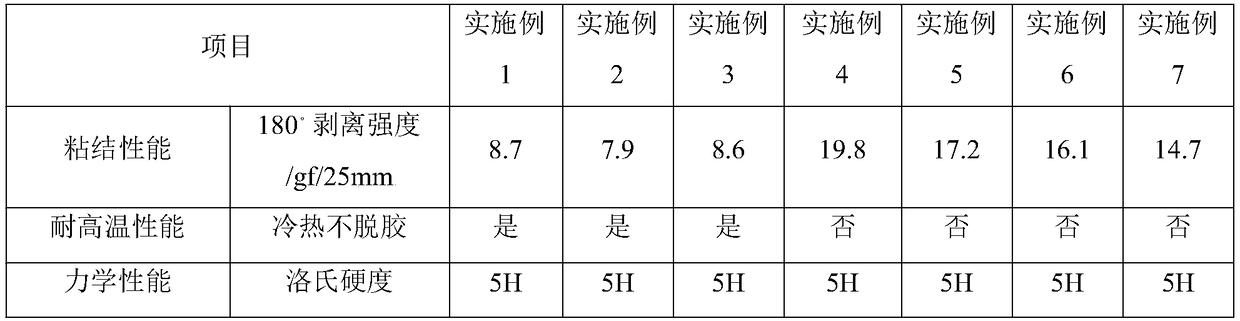

Organosilicon modified high-temperature-resistant acrylate pressure-sensitive adhesive and preparation method thereof

ActiveCN108410397AImprove temperature resistanceStrong adhesionEster polymer adhesivesGraft polymer adhesivesFunctional monomerSolvent

The invention discloses an organosilicon modified high-temperature-resistant acrylate pressure-sensitive adhesive and a preparation method thereof. The pressure-sensitive adhesive is prepared from, byweight, 2-8 parts of hard monomer, 70-90 parts of soft monomer, 2-8 parts of functional monomer, 5-10 parts of organosilicon modifying body, 0.1-0.8 part of initiator, 1-3 parts of curing agent and 100-150 parts of solvent. The pressure-sensitive adhesive is resistant to high temperature, high in adhesiveness, large in bonding power and free of residue when in use.

Owner:KUNSHAN ZLAN ELECTRONIC MATERIALS CO LTD

Hot-press molded protective film with shinning and antistatic effects and preparation method thereof

InactiveCN105522799AImprove the effect of hot pressingGuaranteed molding effectSynthetic resin layered productsAntistatic agentAcrylic resin

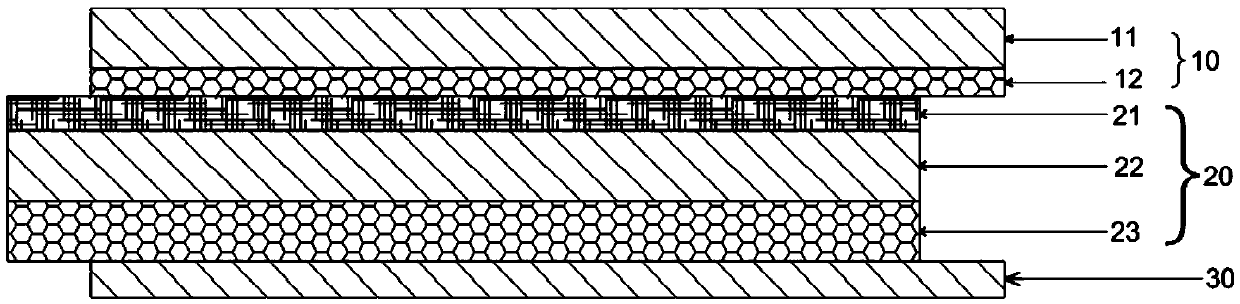

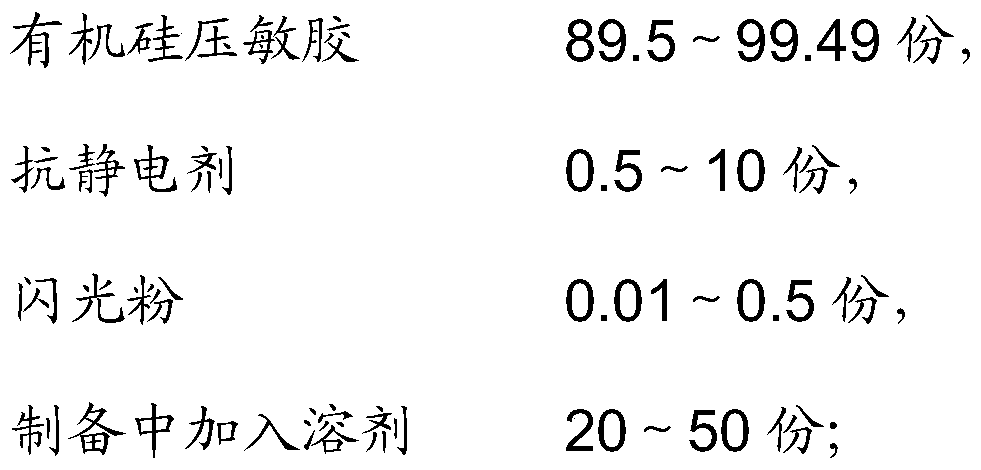

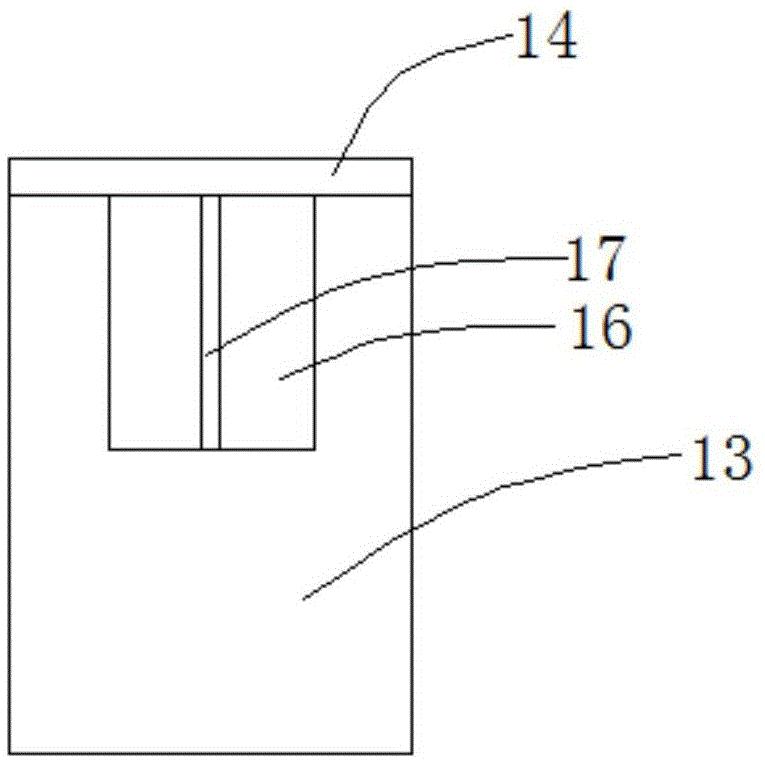

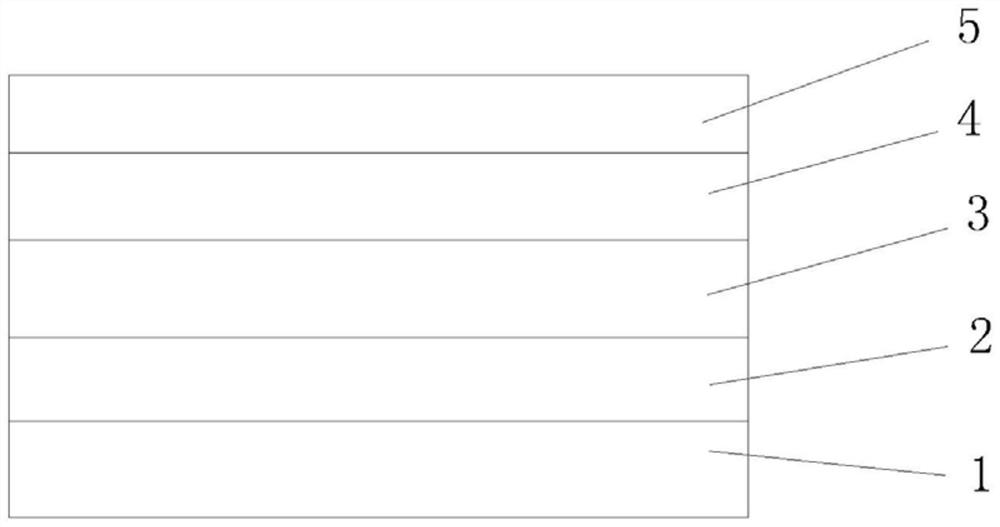

The invention discloses a hot-press molded protective film with shinning and antistatic effects and a preparation method thereof. The protective film can be used for comprehensively protecting a curved screen, and has an attractive appearance since shinning and antistatic effects are extra added. The protective film comprises a film protecting layer, an application layer and a release layer from top to bottom, wherein the application layer comprises a UV hardened layer, a base material A and an adhesive layer A; the principle component of the UV hardened layer is an acrylic resin layer, the base material A is a PET film, and the principle component of the adhesive layer is an organic silicone pressure-sensitive adhesive layer; and the thickness of the UV hardened layer is 2-10 mu m, the thickness of the base material A is 20-200 mu m, and the thickness of the adhesive layer A is 20-100 mu m. The hot-press molded protective film has shining and antistatic effects since shining particles and an antistatic agent are added into the application layer, and has high flexibility and cannot rebound after hot press since high-elasticity high-viscosity organic silicone pressure-sensitive adhesive is utilized in the adhesive layer.

Owner:NALI OPTICAL MATERIAL DONGGUAN

Re-peel-off type special double-faced adhesive sheet for fixing flexible printed circuit board

InactiveCN103834320AImprove yieldEasy to peel offFilm/foil adhesivesEster polymer adhesivesPolyesterAdhesive

The invention provides a re-peel-off type special double-faced adhesive sheet for fixing flexible printed circuit board. The double-faced adhesive sheet for fixing a flexible printed circuit board comprises a first core material layer, a first adhesive layer and a second adhesive layer, wherein the core material layer is arranged between the inner side of the first adhesive layer and the inner side of the second adhesive layer, the core material of the core material layer is a polyester film with thickness not more than 12 microns, the first adhesive layer is a re-peel-off layer, the second adhesive layer is a permanent fixing layer, the initial adhesive force of the first adhesive layer is not more than 700g / 20mm, and the adhesive force after being fixed is not less than 900g / 20mm, and the adhesive force of the second adhesive layer is not less than 900g / 20mm. The double-faced adhesive sheet is prepared by adopting special acrylic acid adhesive and can be re-peeled off within short time, and the re-work performance is good, the permanent adhesion and fixation after re-working and fixing can be satisfied, and the adhesive sheet cannot warp and deform after aging within a certain environment.

Owner:新纶电子材料(常州)有限公司

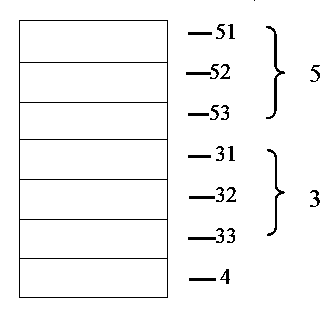

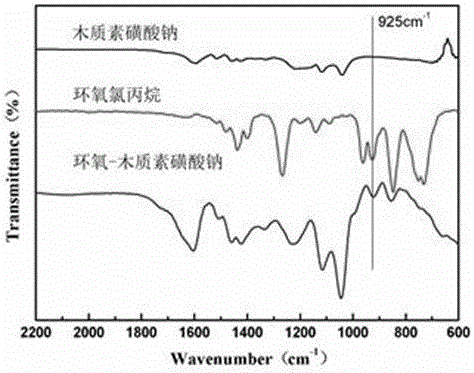

High-temperature-resistant solvent-type acrylate pressure-sensitive adhesive and preparation method thereof

ActiveCN106590478AImprove temperature resistanceStrong adhesionMacromolecular adhesive additivesEster polymer adhesivesBiological bodyFunctional monomer

The invention discloses a high-temperature-resistant solvent-type acrylate pressure-sensitive adhesive which is characterized by being synthesized from, by weight, 7-13% of hard monomer, 23-37% of soft monomer, 2-5% of functional monomer, 0.5-0.9% of heat-resistant monomer and 50% of solvent. The pressure-sensitive adhesive is high in resistance to high temperature, high in adhesiveness and high in adhesive force; when in use, there is no adhesive residue, and higher requirements of the present adhesive market on the pressure-sensitive adhesive are met with excellent performance; lignin which serves as the heat-resistant monomer is from an organism and belongs to renewable resources, so that the environment problem caused by utilizing petroleum resources is solved effectively.

Owner:ANHUI MINGXUN NEW MATERIAL TECH

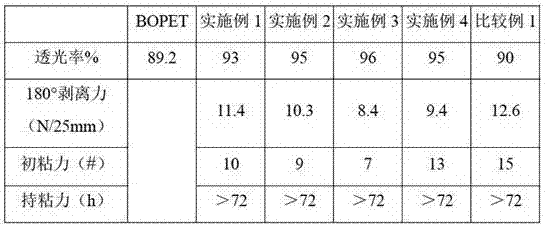

High-transparency acrylic acid pressure-sensitive adhesive and preparation method thereof

InactiveCN107057612AHigh refractive indexHigh light transmittanceEster polymer adhesivesFunctional monomerSolvent

The invention discloses a high-transparency acrylic acid pressure-sensitive adhesive. The acrylic acid pressure-sensitive adhesive is prepared from the following raw materials in parts by weight: 0-30 parts of cohesion monomers, 50-75 parts of adhesive monomers, 1-10 parts of functional monomers, 5-10 parts of o-phenylphenoxyethyl acrylate, 0.3-0.8 part of an initiator, 100-150 parts of a solvent and 0.1wt%-0.5wt% of a curing agent. The high-transparency acrylic acid pressure-sensitive adhesive provided by the invention has very high permeability (transparency being more than or equal to 93%), an adhesive remaining phenomenon does not occur in normal use and processing processes, the adhesive force is strong, the release force is high, and phenomena of adhesive failure and damaging of an adhesive layer and an interface do not occur in the use process, so that the adhesion problem in the fields of aerospace, electrons, electrical engineering and optical devices such as LCDs, PDPs and OLEDs is well solved.

Owner:HARBIN INST OF TECH WUXI RES INST OF NEW MATERIALS +1

Manufacturing method of heat-shrinkable auto-adhesive vacuum plating protective film

ActiveCN104788867AViscosity stabilityGood adhesionFlat articlesFilm materialEnvironmentally friendly

The invention discloses a manufacturing method of a heat-shrinkable auto-adhesive vacuum plating protective film. The manufacturing method comprises the following steps: (1) firstly, synthesizing polyvinyl polyacrylate; (2) then, performing melt blending on the polyvinyl polyacrylate, polyethylene resin, a first initiator and an antioxidant according to a weight proportion, extruding and granulating, and finally performing extrusion film blowing and UV curing to obtain the heat-shrinkable auto-adhesive vacuum plating protective film. The manufactured protective film wraps a local part, required to be protected, of a vacuum plating component in a heat shrinkage way; in a vacuum plating process, the surface of the film does not crease and deform, the adhesion force is stable, the attachment property is good, the re-peeling performance is excellent, the phenomenon of adhesive residue is avoided, and the barrier and mechanical properties are excellent; the heat-shrinkable auto-adhesive vacuum plating protective film is an excellent vacuum plating protective film material which is non-toxic, environmentally-friendly, safe and practical.

Owner:WUXI HAITE NEW MATERIAL RES INST

High temperature-resistant and UV (Ultraviolet)-resistant protective film and preparation method thereof

InactiveCN108707432AReduced shrinkage performancePrevent high temperature deformationNon-macromolecular adhesive additivesEster polymer adhesivesTectorial membraneDisplay device

The invention discloses a high temperature-resistant and UV (Ultraviolet)-resistant protective film and a preparation method thereof. The high temperature-resistant and UV-resistant protective film comprises a PE (Polyethylene)-based film layer and an adhesive layer, wherein the adhesive layer is formed by coating the surface of the PE-based film layer with a heat-resistant and UV-resistant pressure-sensitive adhesive and drying; the pressure-sensitive adhesive is prepared from the following raw materials in parts by weight: 25 to 35 parts of acrylate resin, 55 to 70 parts of ethyl acetate, 1to 2 parts of isocyanate curing agent, 0.1 to 0.5 part of UV absorbent and 0.4 to 0.7 part of free radial collecting agent. Compared with the prior art, the preparation method disclosed by the invention is reasonable in raw material proportioning and simple in preparation technology, and a release force of the high temperature-resistant and UV-resistant protective film provided by the invention ranges from 7N / m to 9N / m; after long-time irradiation under high temperature and UV, the release force of the high temperature-resistant and UV-resistant protective film changes within + / -35 percent, and the high temperature-resistant and UV-resistant protective film has no wrinkling, no degumming, no adhesive residue and no chromatic aberration after long-time irradiation under the UV; the high temperature-resistant and UV-resistant protective film can be used for protecting the surfaces of backlight displays in electronic products such as a computer, a television and a mobile phone and can beused for protecting an overlaid shipment transportation process of the backlight displays.

Owner:芜湖夏鑫新型材料科技有限公司

High temperature resistant crepe paper adhesive tape used for shoes

InactiveCN105331301AKeep dryImprove versatilityNon-macromolecular adhesive additivesFilm/foil adhesivesCross-linkCrêpe paper

The invention provides a preparation method of a high temperature resistant crepe paper adhesive tape used for shoes. The preparation method comprises a step of pressure sensitive adhesive preparation and a step of coating; according to the step of pressure sensitive adhesive preparation, methylbenzene is used for removing water in cross-linking agent dibenzoyl peroxide, and dibenzoyl peroxide is mixed with an organic silicon pressure sensitive glue at a certain ratio for uniform stirring, cross-linking agent diisocyanate of acrylic ester pressure sensitive glue is dissolved in methylbenzene, and is mixed with acrylic ester pressure sensitive glue; and at last crepe paper is coated with the mixtures of the two pressure sensitive glues so as to obtain a final product; wherein the final product possesses high temperature resistance, and no glue is left after removing from shoe materials.

Owner:SHANGHAI SMITH ADHESIVE NEW MATERIAL

Production method of PET (polyethylene terephthalate) protective film for manufacturing process of flat-panel display

InactiveCN102190979AAvoid damageSimple stepsFilm/foil adhesivesPretreated surfacesPolyethylene terephthalate glycolEngineering

The invention discloses a production method of a PET (polyethylene terephthalate) protective film for a manufacturing process of a flat-panel display, which comprises the following steps: (1) under Grade 1000 dust-free environmental conditions, coating low-polarity pressure-sensitive adhesive (19-20 g / m<2> weight, 18-19 mu m dry layer thickness) on the upper surface of an optical-level PET protective film substrate with a coating machine provided with on-line bifacial cleaning rollers by using a transfer coating method, and drying by heating to 120 DEG C; (2) laminating release film: laminating a release film on the upper surface of the low-polarity pressure-sensitive adhesive, and winding up; and (3) cutting: cutting the formed PET protective film on a special cutting machine to obtain the PET protective film for a manufacturing process of a flat-panel display. The invention has the advantages of simple steps and high production efficiency; and the product has the characteristics of no shedding, no pollution, high temperature resistance and static resistance, can be easily stripped after being coated by vaporization without leaving adhesive residues, and can avoid damaging the glass mirror in the stripping process.

Owner:KUNSHAN BYE MACROMOLECULE MATERIAL CO LTD

High-temperature-resistant modified acrylate pressure-sensitive adhesive and preparation method thereof

ActiveCN110698585ARaw materials are readily availableIncrease productivityEster polymer adhesivesPolymer scienceFunctional monomer

The invention discloses a high-temperature-resistant modified acrylate pressure-sensitive adhesive and a preparation method thereof, wherein the high-temperature-resistant modified acrylate pressure-sensitive adhesive comprises, by weight, 75-93 parts of a soft monomer, 3-8 parts of a hard monomer, 3-8 parts of a functional monomer, 2-10 parts of an organic boric acid modified monomer, 0.1-0.4 part of an initiator and 100-200 parts of a solvent. The invention further provides a preparation method of the high-temperature-resistant modified acrylate pressure-sensitive adhesive. According to theinvention, the preparation raw materials are easy to obtain, the production efficiency is high, the pressure-sensitive adhesive can be rapidly prepared, and the problems that the production cost is high, the operation is difficult and not easy to control, and the high-temperature stripping force of the pressure-sensitive adhesive is increased are effectively solved.

Owner:四川羽玺新材料股份有限公司 +1

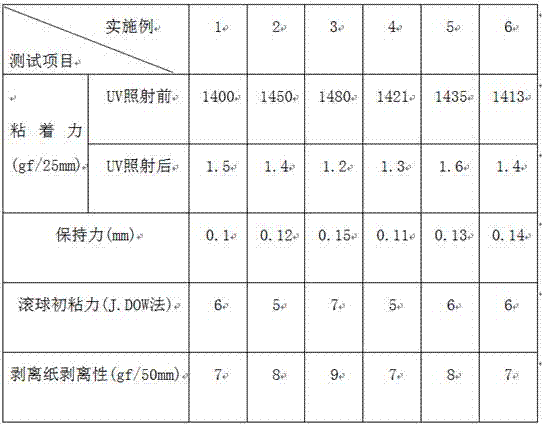

UV (ultraviolet) single-side adhesive tape with adhesive failure after ultraviolet irradiation and preparation method of adhesive tape

The invention discloses a UV (ultraviolet) single-side adhesive tape with adhesive failure after ultraviolet irradiation and a preparation method of the adhesive tape. The UV single-side adhesive tape comprises a transparent base film, a UV adhesive layer and a single-side release film, wherein the UV adhesive layer coats the surface of the transparent base film, the single-side release film covers the surface of the UV adhesive layer, and the UV adhesive layer comprises, in weight percentage, 38%-80% of UV adhesives, 0.5%-2.5% of curing additives, 9%-20% of ethyl ester and 10%-40% of methylbenzene. The UV adhesive layer is prepared by a specific formula, so that the UV single-side adhesive tape has high adhesive force, wafers cannot fly apart in cutting, grinding and the like, workpieces can be effectively protected, after UV irradiation, adhesive failure is rapid, adhesive failure effects are good, adhesive residues are omitted, and machining production operation is facilitated.

Owner:东莞市古川胶带有限公司

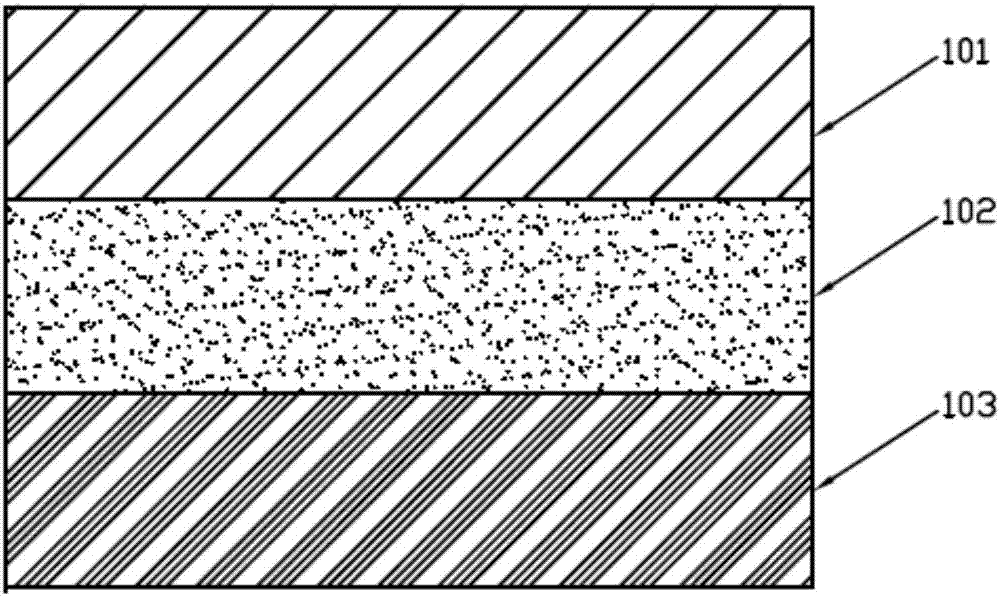

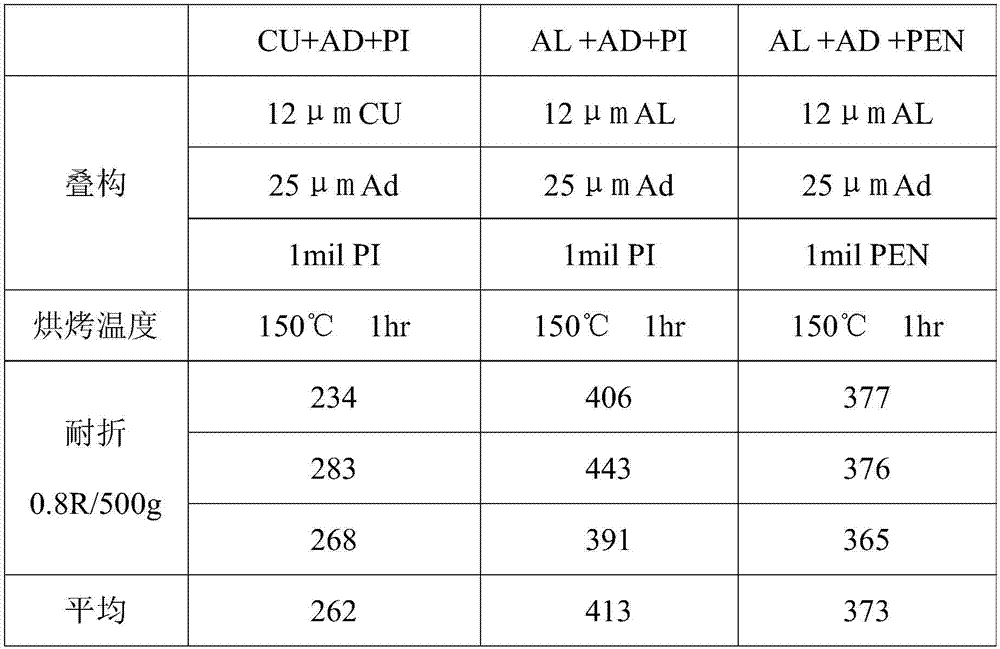

Aluminum-foil substrate applicable to flexible circuit board and manufacturing method of aluminum-foil substrate

InactiveCN106891586AIncrease productivityReduce manufacturing costInsulating substrate metal adhesion improvementPrinted circuit detailsFlexible circuitsMicrometer

The invention relates to an aluminum-foil substrate applicable to a flexible circuit board and a manufacturing method of the aluminum-foil substrate. The aluminum-foil substrate comprises aluminum foil, an insulating adhesive layer and a release layer, wherein the aluminum foil has a top surface and a bottom surface which are opposite to each other, the release layer is adhered to the bottom surface of the aluminum foil through the insulating adhesive layer, the aluminum foil is 12-50 micrometers in thickness, the insulating adhesive layer is 5-50 micrometers in thickness and the release layer is 30-200 micrometers in thickness. The aluminum-foil substrate has the advantages that the aluminum-foil substrate is simple in structure, quite light and thin and excellent in flexibility and bending resistance, production efficiency of clients and yield are increased by using the aluminum-foil substrate, and production cost is reduced.

Owner:SONGYANG ELECTRONICS MATERIAL KUSN

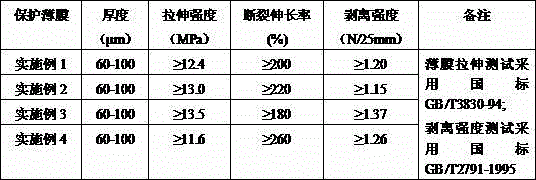

Degradable self-adhesive film material as well as preparation method and application thereof

ActiveCN112538321AExcellent adhesionGood adhesionMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesPolymer scienceAdhesive

The invention discloses a degradable self-adhesive film material as well as a preparation method and application thereof. The degradable self-adhesive film material is formed by compounding a surfacelayer and a self-adhesive layer, and preparation raw materials of the surface layer and the self-adhesive layer contain degradable resin. The self-adhesive film prepared by the method is good in adhesion effect with the surface of an adherend, strong in adhesive force, free of residual glue and easy to peel off, and the surface layer and the self-adhesive layer are not easy to adhere; good mechanical performance is achieved, and the tensile strength and the elongation at break are high; and the material has good biodegradability, avoids environmental pollution, is processed by a two-layer co-extrusion film blowing machine, and is simple in process and convenient for industrial popularization.

Owner:联泓(江苏)新材料研究院有限公司

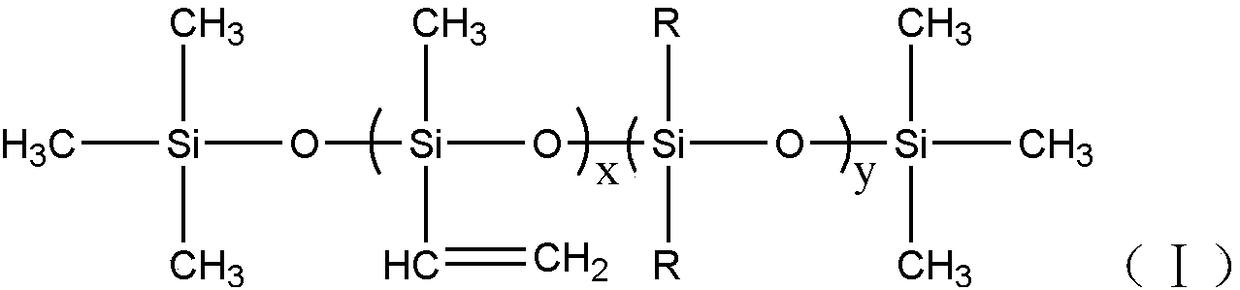

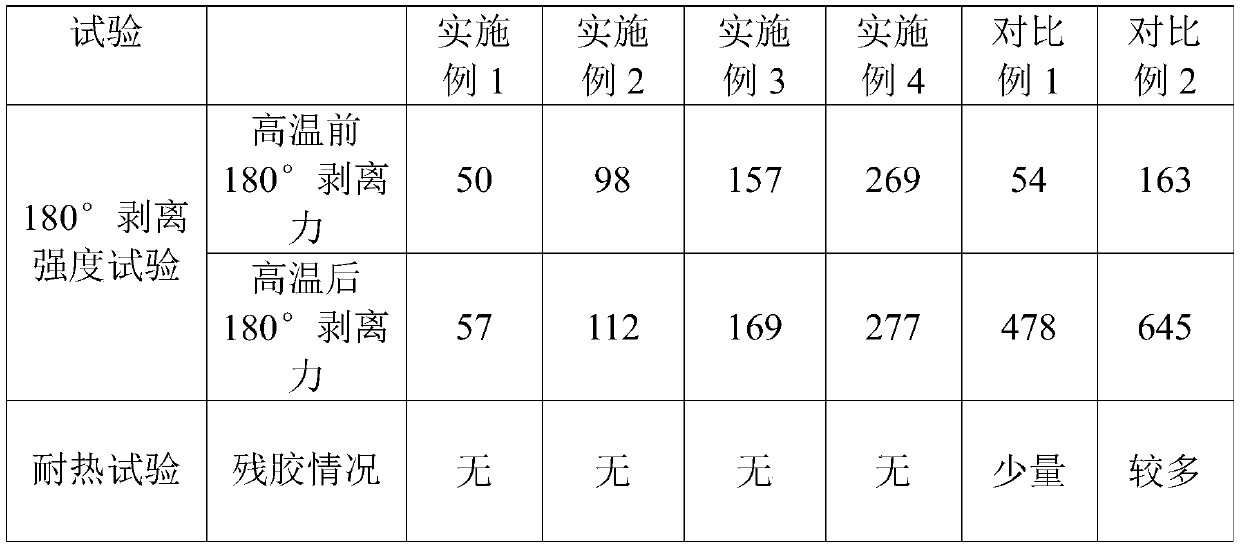

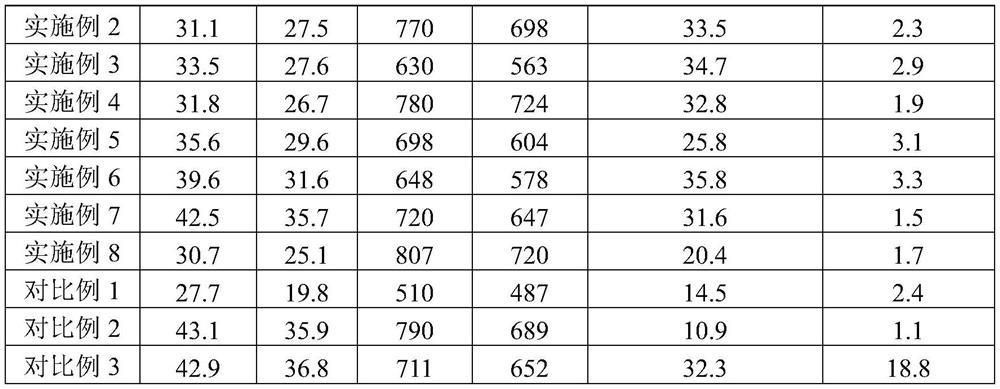

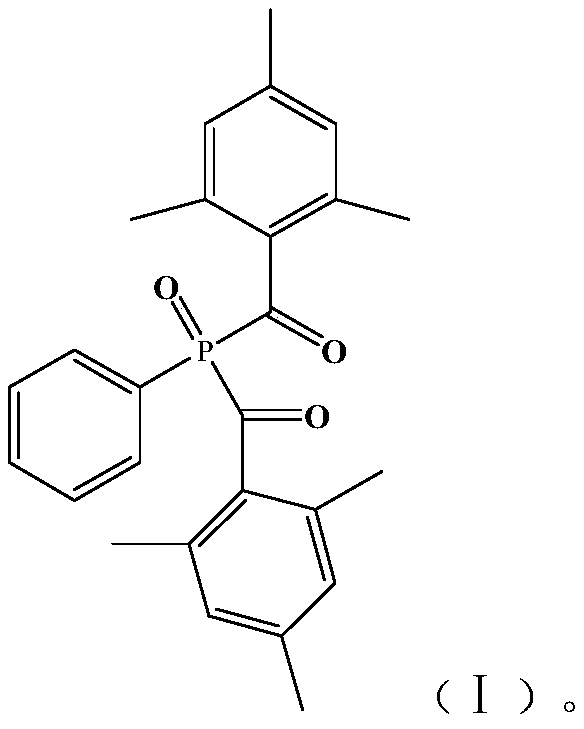

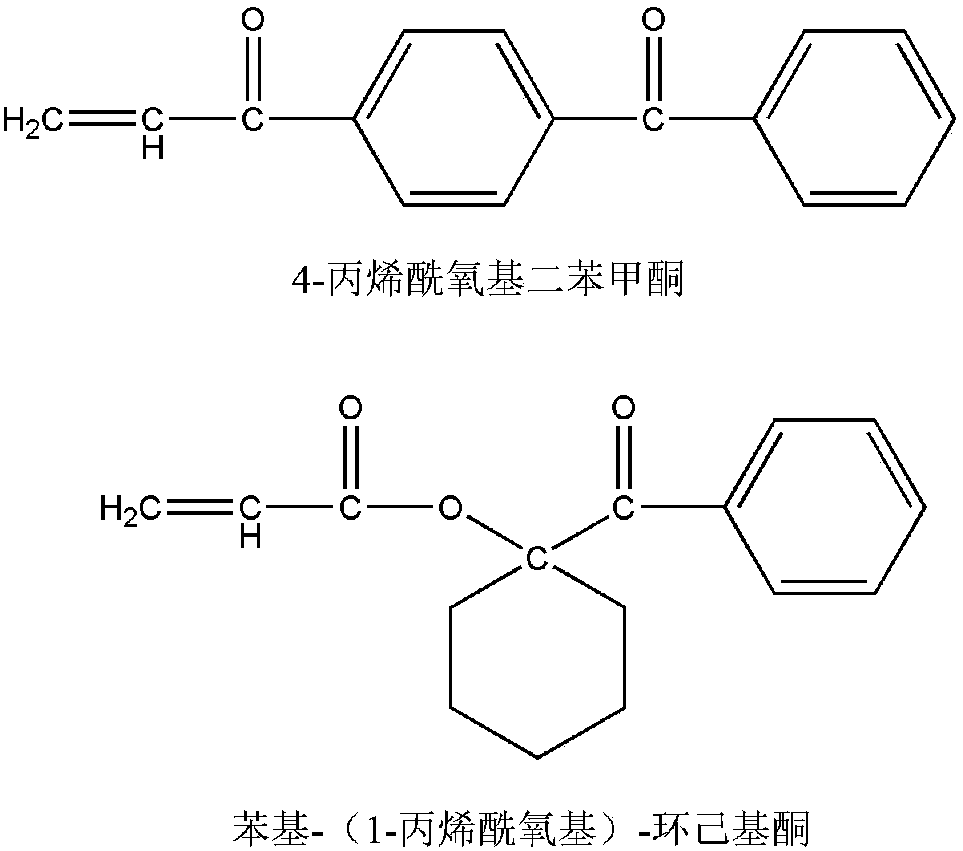

UV curing heat reducing adhesive, preparation method and application thereof

ActiveCN109749672AGood initial adhesionLower the starting temperatureFilm/foil adhesivesPolyureas/polyurethane adhesivesIsooctyl acrylatePolymer science

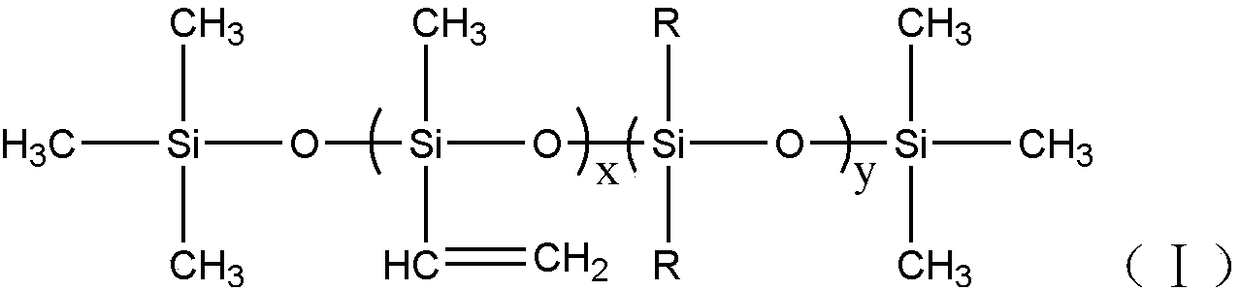

The invention discloses a UV curing heat reducing adhesive, a preparation method and an application thereof. Adhesive raw materials comprise prepolymer resin, polyurethane acrylate, a reactive diluent, a photoinitiator and thermal expansion microspheres. According to the mass percentage, the raw materials of the prepolymer resin comprise 60-94.5% of 2-ethylhexyl acrylate, 5-39.5% of (meth) acrylate and 0.01-1% of the compound shown in a formula (I), and the prepolymer resin are prepared by reacting the three raw materials. The preparation method includes, firstly, preparing the prepolymer resin, and then mixing the prepolymer resin with other raw materials of the adhesive to prepare the prepolymer resin. The invention discloses the application of a UV curing heat reducing adhesive tape made of the adhesive and the adhesive tape in the 2.5D and 3D glass edge sweeping processes. The adhesive has the advantages of excellent initial adhesive force, low initial temperature of thermal viscosity reduction and high viscosity reduction speed, and the heat reducing adhesive tape prepared from the adhesive does not have the phenomena of powder crumbs and residual glue in the use process, andthe adhesive has the advantages of low VOC, high coating production speed and the like.

Owner:CYBRID TECHNOLOGIES INC

High-barrier transparent flexible display material and preparation method thereof

ActiveCN108997753AHigh transparencyGood in-plane isotropyCoatingsIdentification meansPolymer scienceIn situ polymerization

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

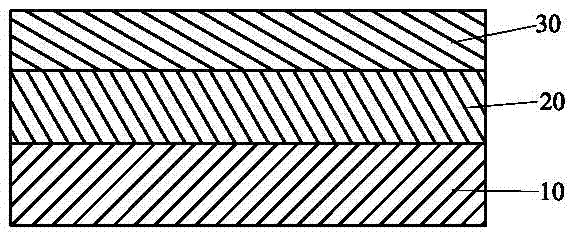

PET (polyethylene terephthalate) double-sided adhesive tape

InactiveCN106047213ANo glue residueNo warpingPressure sensitive film/foil adhesivesPolyethylene terephthalatePolyethylene terephthalate glycol

The invention discloses a PET (polyethylene terephthalate) double-sided adhesive tape. The PET double-sided adhesive tape comprises an outmost PET film layer, a middle adhesive layer and an inner substrate layer. The PET double-sided adhesive tape has advantages of freeness of adhesive residues, warping and shrinkage and high temperature resistance.

Owner:CHANGSHU CHANGJIANG TAPE

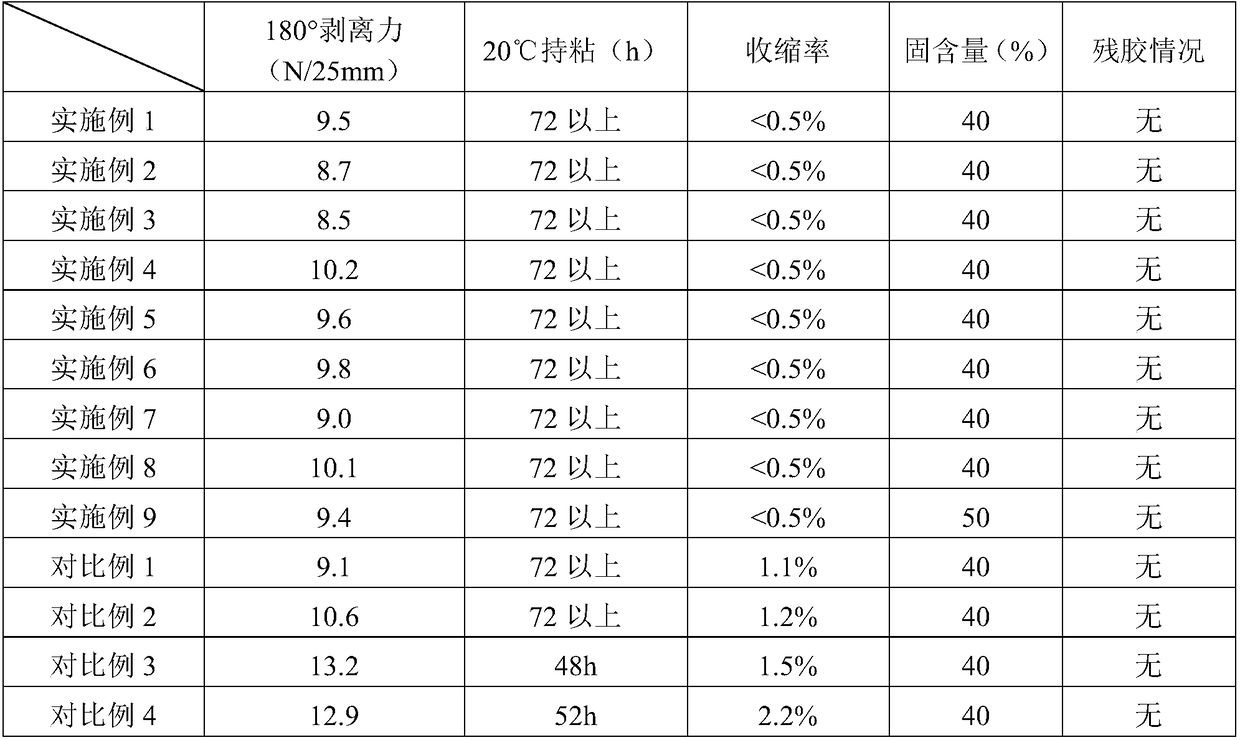

UV (Ultraviolet)-cured acrylate pressure-sensitive adhesive with low shrinkage rate and preparation method thereof as well as UV-cured acrylate pressure-sensitive adhesive tape with low shrinkage rate

ActiveCN108504312AImprove adhesionLow shrinkageMonocarboxylic acid ester polymer adhesivesEster polymer adhesivesPressure sensitiveSolvent

The invention discloses a UV (Ultraviolet)-cured acrylate pressure-sensitive adhesive with a low shrinkage rate and a preparation method thereof as well as a UV-cured acrylate pressure-sensitive adhesive tape with the low shrinkage rate. The UV-cured acrylate pressure-sensitive adhesive with the low shrinkage rate is characterized by being prepared from the following raw materials in parts by weight: 15 to 30 parts of a hard monomer, 30 to 60 parts of a soft monomer, 5 to 15 parts of a functional monomer, 0.3 to 0.5 part of an initiator, 0.2 to 0.8 part of a photo-curing agent, 13 to 20 partsof an expansion polymer and 100 to 160 parts of a solvent. In a synthesis process of the acrylate pressure-sensitive adhesive, the defect that a surface shrinkage phenomenon is generated in a UV photo-curing process is overcome; meanwhile, the pressure-sensitive adhesive disclosed by the invention has the advantages of great binding power, low shrinkage rate and no residual adhesive in an application process.

Owner:HARBIN INST OF TECH WUXI RES INST OF NEW MATERIALS +1

Manufacturing method of self-adhesive protective film for vacuum plating

The invention discloses a manufacturing method of a self-adhesive protective film for vacuum plating. The manufacturing method comprises the following steps: weighing the following raw materials in parts by weight: 100 parts of polyethylene resin, 2-15 parts of acrylate monomer, 0.2-5.0 parts of a first processing additive, and 0.2-1.0 part of a second processing additive; firstly, dissolving the acrylate monomer and the first processing additive in a solvent to obtain a solution, then uniformly mixing the solution with polyethylene resin and the second processing additive in a blender, realizing in-situ grafting and extrusion granulation in an extruder, finally film-forming the prepared grafted granules through a blow molding or tape-casting method directly. The manufacturing method is simple in process; the manufactured protective film is vacuum-plated in a local position, needing to be protected, of a part; during vacuum plating, the surface of the film has no wrinkle and no deformation, is stable in adhesion, good in attachment property and re-peeling performance, has no residue phenomenon; the protective film is excellent in barrier and mechanical properties, non-toxic, environment-friendly, safe and practical, and is an excellent vacuum-plated protective film material.

Owner:WUXI HAITE NEW MATERIAL RES INST

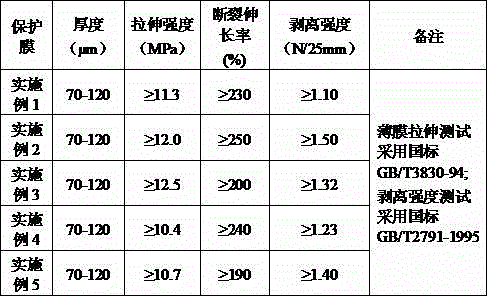

Online lamination protection film of light guide plate and preparation process of online lamination protection film

ActiveCN106142787AImprove fitRelatively difficult to shiftSynthetic resin layered productsLaminationElastomerTectorial membrane

The invention discloses an online lamination protection film of a light guide plate and a preparation process of the online lamination protection film. The online lamination protection film of the light guide plate comprises a base material surface layer, a core layer and an elastomer layer, wherein the core layer is arranged between the base material surface layer and the elastomer layer, and the base material surface layer, the core layer and the elastomer layer are integrally formed by virtue of a co-extrusion process. The protection film is stable in viscosity, good in light guiding property, excellent in high-temperature high-humidity aging resistance, and free from scratching a protected surface; and the viscosity of the protection film is not changed along with the temperature rising / lowering, can be repeatedly laminated and can avoid the adhesive residue phenomenon. Therefore, the protection film is very suitable for being used as the protection film of the light guide plate.

Owner:SHENZHEN FENGZHAO NEW MATERIAL CO LTD

Demolding liquid medicine and demolding method of aluminum stamping protective film

InactiveCN106929874AEfficient removalSimple processSurface reaction electrolytic coatingTectorial membraneAlcohol

The invention relates to demolding liquid medicine and a demolding method of an aluminum stamping protective film. The demolding liquid medicine is prepared from dichloromethane, methanoic acid and alcohol, wherein the proportion of the dichloromethane to the methanoic acid to the alcohol is (5 to 7):( 4 to 2):1, and raw liquid is used. The demolding method comprises the following steps of (1) soaking aluminum in the liquid medicine, wherein the temperature of the liquid medicine is 18 to 25 DEG C, and the soaking time is 7 to 9 min; (2) washing the aluminum with water until no liquid medicine exists on the surface of the aluminum. The demolding method has the advantages of simple process, mild conditions and short demolding time, manual tearing can be replaced to remove the protective film, and no adhesive residue or corrosion exists on the surface of a treated product.

Owner:弗勒伯特电子(江苏)有限公司

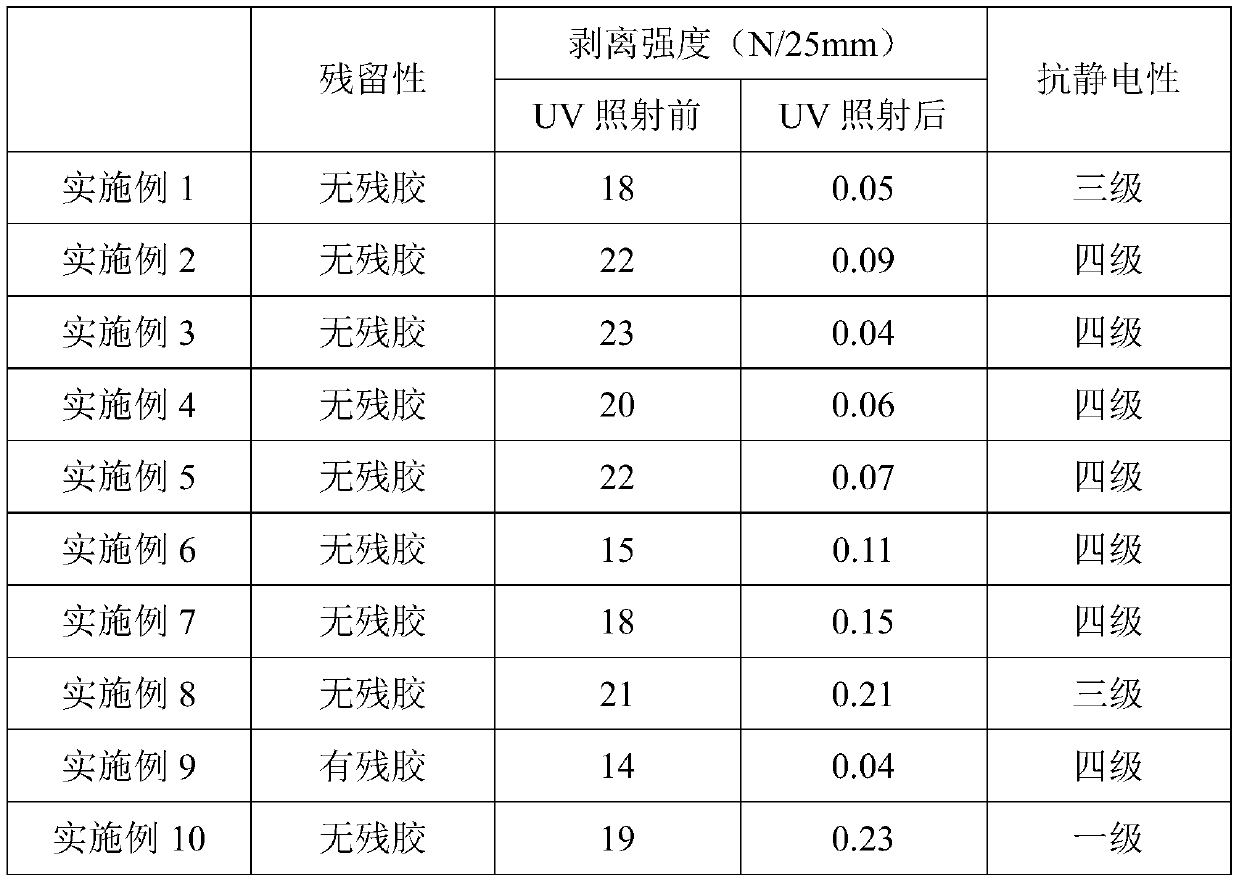

Antistatic semiconductor UV viscosity-reducing adhesive layer and protective film

ActiveCN111334225APrevent static electricityHigh peel strengthNon-macromolecular adhesive additivesSolid-state devicesPolymer sciencePhotoinitiator

The invention relates to the technical field of semiconductor protective films, in particular to an antistatic semiconductor UV viscosity-reducing adhesive layer and a protective film. The invention provides an antistatic semiconductor UV viscosity-reducing adhesive layer is prepared from the following raw materials, by weight: 40-60 parts of a polymer with a cross-linked network system, 1-5 partsof an antistatic agent, 1.5-8 parts of a photoinitiator and 0.5-2 parts of a dispersing agent. According to the antistatic semiconductor UV viscosity-reducing protective film, the protective film isfree of residual glue after being stored for six months, so that static electricity generated by the UV viscosity-reducing protective film due to the friction effect in the use process is avoided, thepeel strength of the UV viscosity-reducing protective film before UV irradiation can be improved, and the peel strength of the UV viscosity-reducing protective film after UV irradiation can be reduced.

Owner:广东硕成科技股份有限公司

Preparation method of high-performance low-viscosity glue for low-viscosity PET (polyethylene terephthalate) protective film

ActiveCN108864968AEasy to tear offImprove fitPolyureas/polyurethane adhesivesFilm/foil adhesive release linersOrganic solventPolyol

The invention provides a preparation method of high-performance low-viscosity glue for a low-viscosity PET protective film. The preparation method comprises the steps that macromolecular polyhydric alcohol is subjected to vacuum dehydration for 1-5 hours at the temperature of 100-120 DEG C, and then cooled to be 60-80 DEG C; isocyanate, an organic solvent and a catalyst are added, the mixture is subjected to thermostatic reaction for 2-6 hours under the condition of 500-1500 r / min; a chain extender is added to conduct chain extension reaction for 1-5 hours, and the product is cooled to be 30-50 DEG C; and a salt-forming agent and deionized water are added, high-speed shearing dispersing is conducted for 0.5-2 hours under the condition of 1000-3000 r / min, and the high-performance low-viscosity glue is obtained. The preparation technology is simple and easy to operate, and is suitable for industrialized production. The high-performance low-viscosity glue produced by adopting the method is applied to the PET protective film, so that the PET protective film has the characteristics of being low in viscosity, easy to tear, free of glue residue, good in adhesion, good in high temperatureresistance and excellent in mechanical performance.

Owner:NINGBO KELAIEN NEW MATERIAL TECH CO LTD

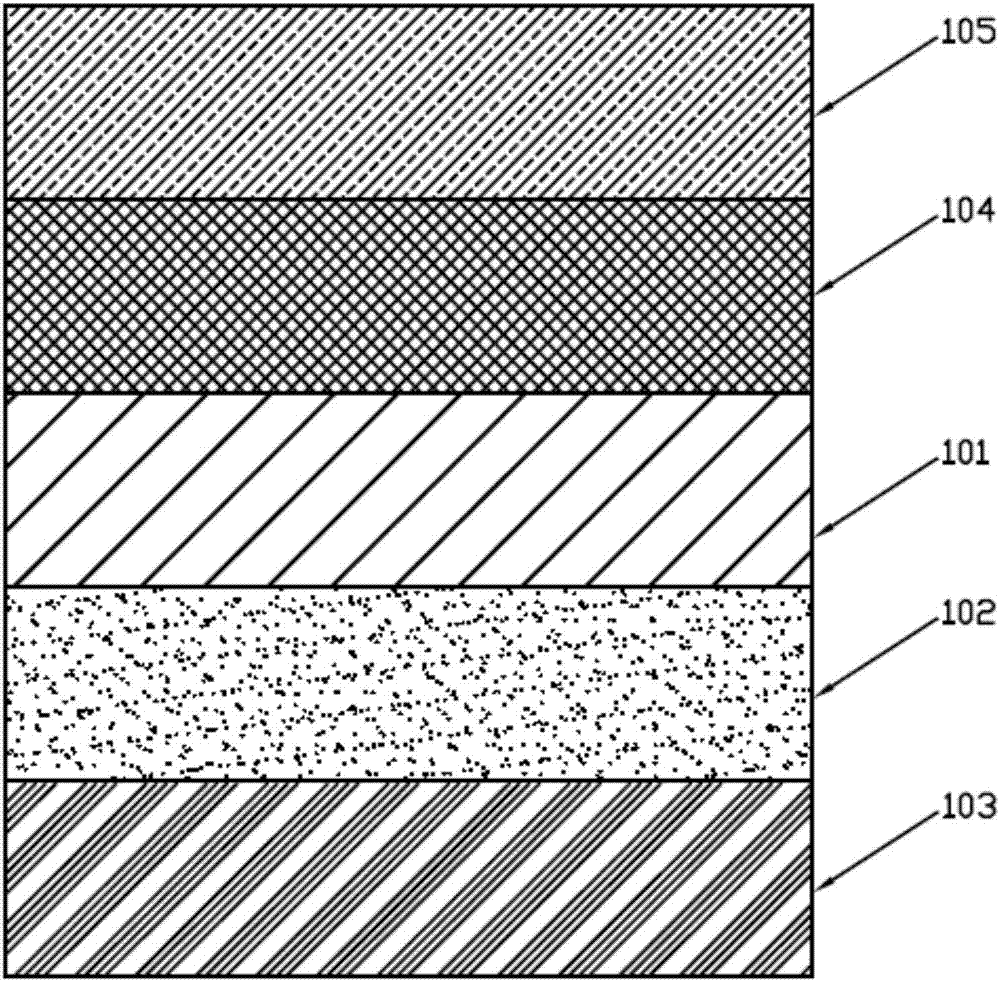

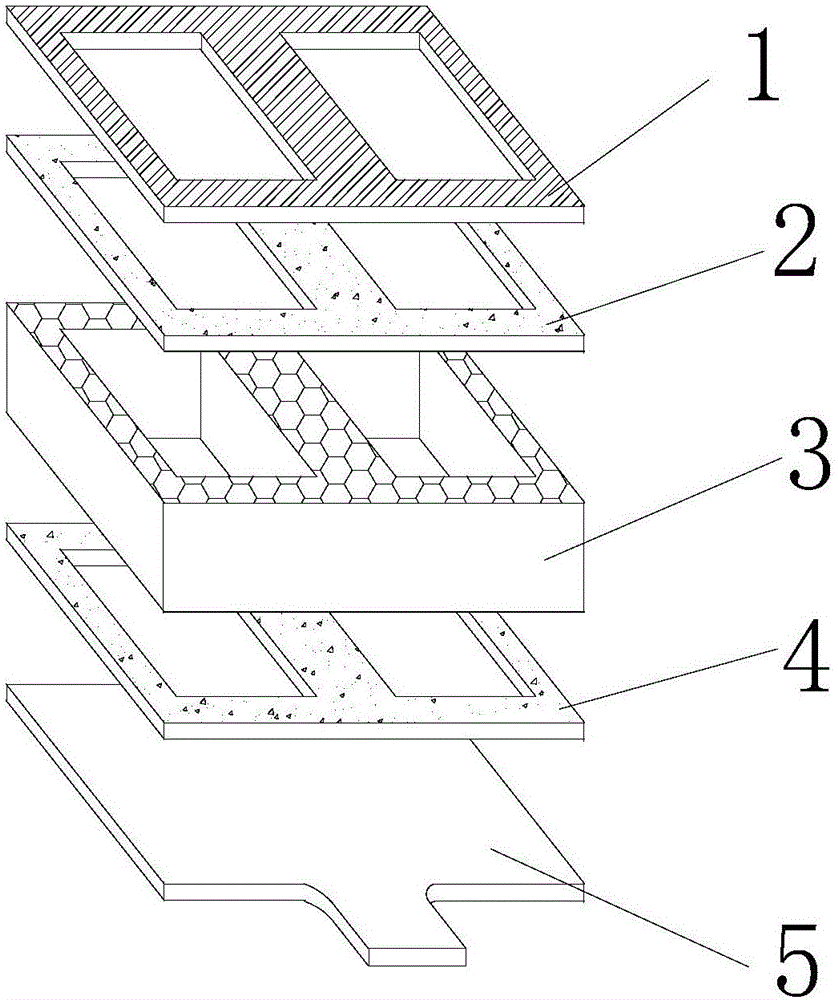

Camera protecting film and preparation process thereof

ActiveCN106183267AAvoid damageEasy to shapeLamination ancillary operationsProtective equipmentTectorial membranePolyethylene glycol

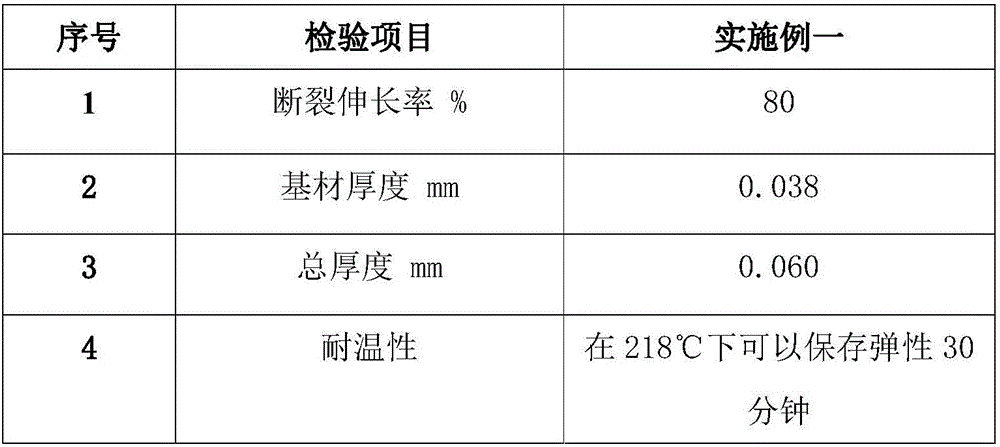

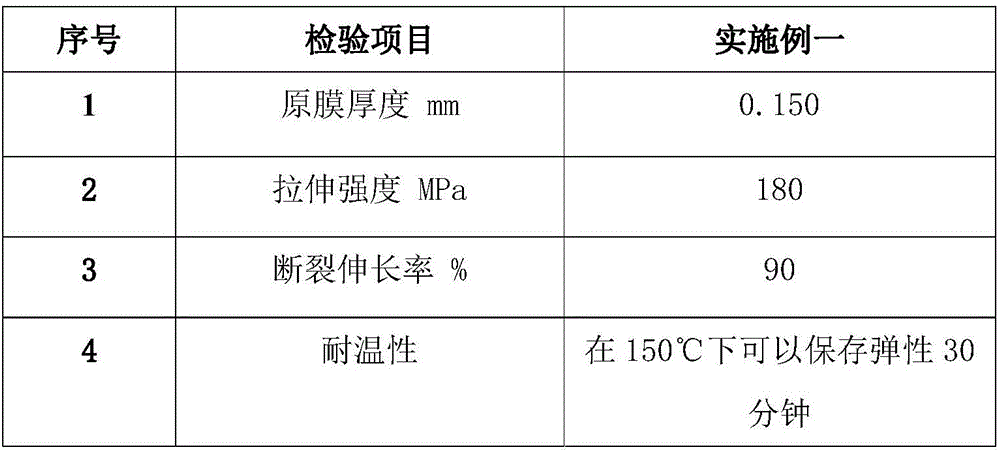

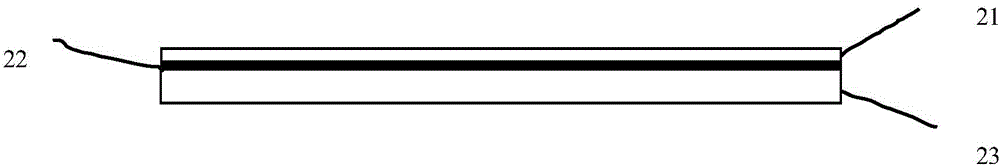

The invention discloses a camera protecting film and a preparation process thereof. The camera protecting film comprises a polyethylene protecting film layer, a stickup layer A, a foam superimposed layer, a stickup layer B and a polyethylene glycol terephthalate layer from top to bottom sequentially, wherein the stickup layer A and the stickup layer B are acryl glue layers, two hollow areas in the same size are arranged on each of the polyethylene protecting film layer, the stickup layer A, the foam superimposed layer and the stickup layer B, the acryl glue layers are 0.15 mm thick, a silica gel bonding layer is 0.02 mm thick, a base material in the polyethylene protecting film layer is 0.038 mm thick, the polyethylene glycol terephthalate layer is 0.15 mm thick, and the foam superimposed layer is 0.5 mm or 1.0 mm thick. The design idea of the camera protecting film is that multiple different materials are superimposed and glued to form a whole with a certain thickness, an outwards bulging camera can be well protected when used by a user, the requirement for high efficiency is met, the production time is saved, the cost is reduced, and the benefits are maximized.

Owner:苏州佳值电子工业有限公司

High-temperature-resistant mylar sheet and preparation method thereof as well as method for protecting wafer in wafer thinning process

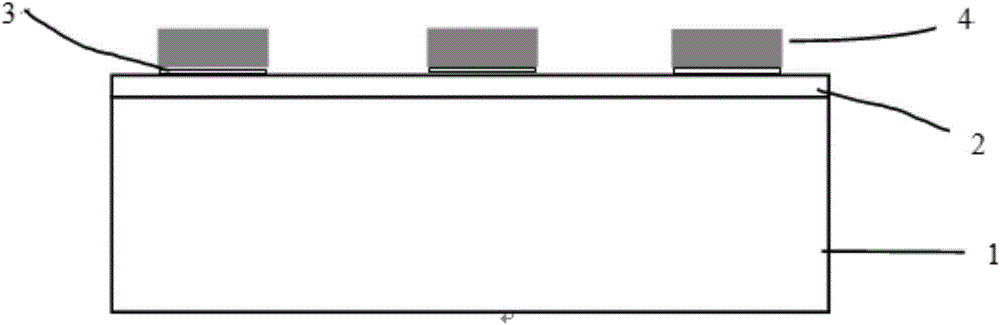

ActiveCN104403593AImprove protectionNo pollution in the processFilm/foil adhesivesSynthetic resin layered productsWaxProduction rate

The invention discloses a high-temperature-resistant mylar sheet and a preparation method thereof as well as a method for protecting a wafer in a wafer thinning process, and belongs to the field of semiconductor silicon device and integrated circuit manufacture. The high-temperature-resistant mylar sheet comprises a PET (polyethylene terephthalate) transparent release film, an acrylic acid type adhesive and a PET transparent film. In the wafer thinning process, the high-temperature-resistant mylar sheet is adhered to a ceramic plate and further is coated with low-temperature wax; and during wafer thinning, the high-temperature-resistant mylar sheet buffers hard-to-hard contact between a substrate and the ceramic plate and protects smoothness and flatness of the surface of the ceramic plate. The fragmenting rate during wafer thinning can be reduced, the chip productivity is improved, besides, wear of the ceramic plate can be reduced, the service life of the ceramic plate is prolonged, the production cost is reduced, the economic benefit is high, and the high-temperature-resistant mylar sheet is suitable for industrial application.

Owner:马鞍山太时芯光科技有限公司

Adhesive and production process thereof

InactiveCN106947417AThe glue is strong and reliableEasy removalMineral oil hydrocarbon copolymer adhesivesNatural rubber adhesivesAdhesivePolyresin

The invention provides an adhesive. The adhesive comprises the following components in parts by mass: 5-30 parts of natural smoked sheets, 20-50 parts of synthetic rubber elastomers, 30-50 parts of tackifying resin, 1-5 parts of an antiager, 3-8 parts of a rubber softener and 0.1-1 part of a light stabilizer, wherein the ratio of the synthetic rubber elastomers to tackifying resin is 1:(1-1.5). Owing to the formula, the provided adhesive is suitable for various complicated environments and firm and reliable in adhesion, can not slide or drop when stressed, and can be easily removed without residues when not in need, and an adhesive product prepared by the adhesive has outstanding weight loading ability.

Owner:SHANGHAI SMITH ADHESIVE NEW MATERIAL

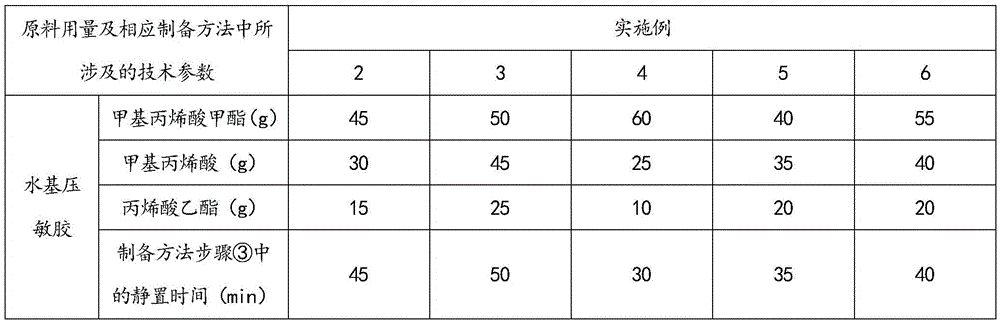

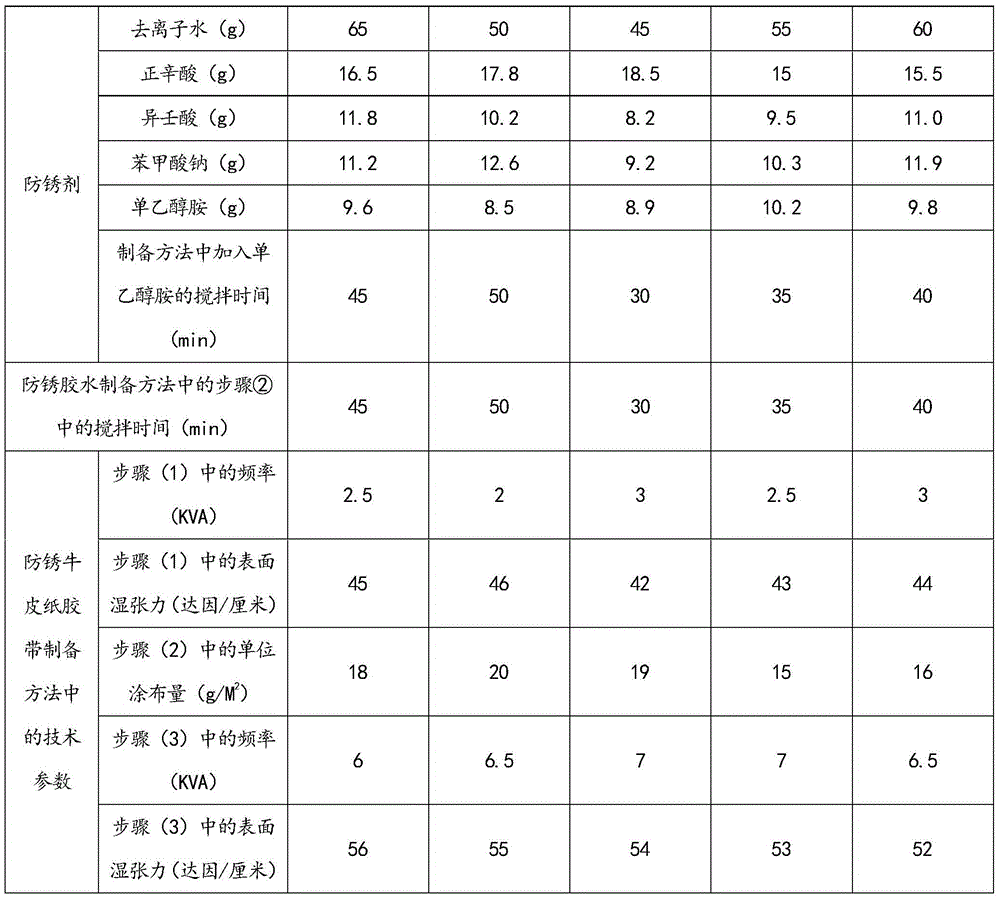

Bopp antirust adhesive tape, its preparation method and application

InactiveCN104479578BReduce viscosityNot subject to wear and tearNon-macromolecular adhesive additivesLamination ancillary operationsOxidation resistantPlastic film

Owner:SHANGHAI SANTAI WRAPPER

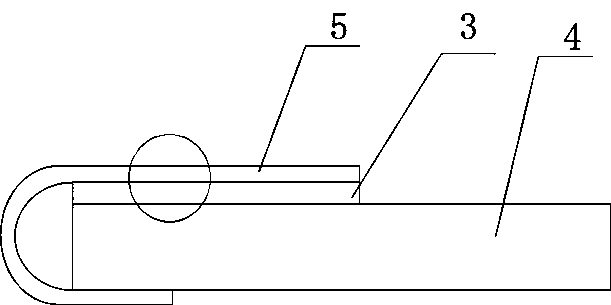

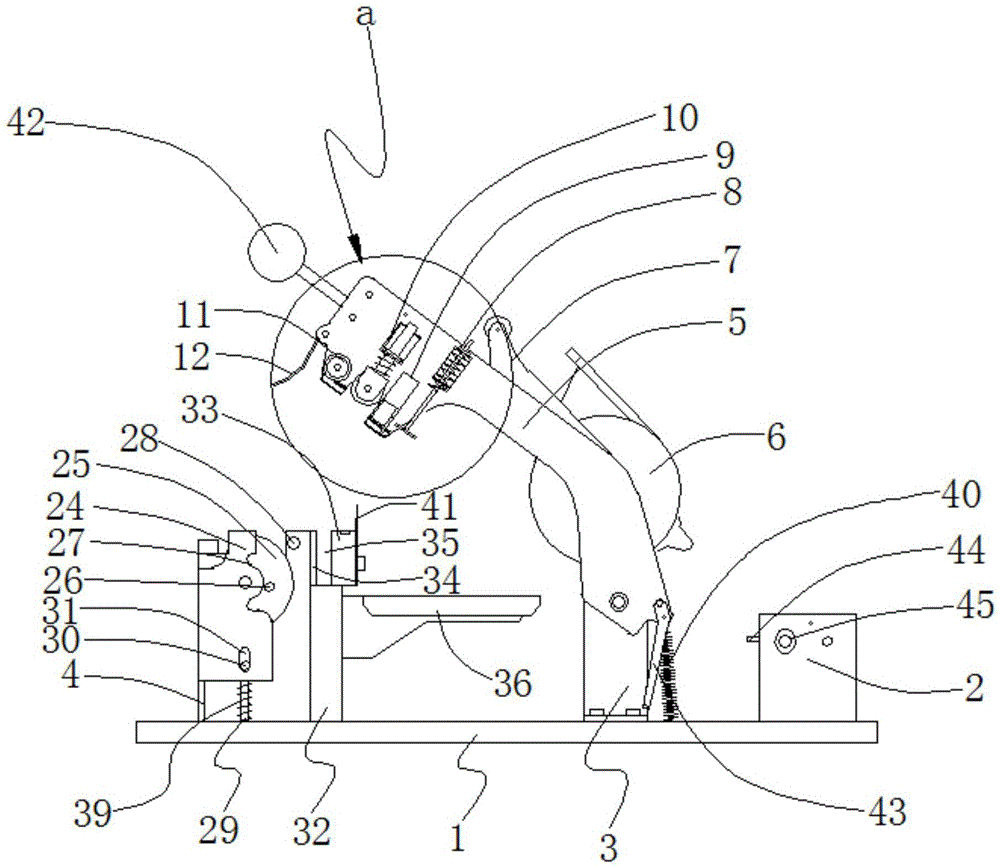

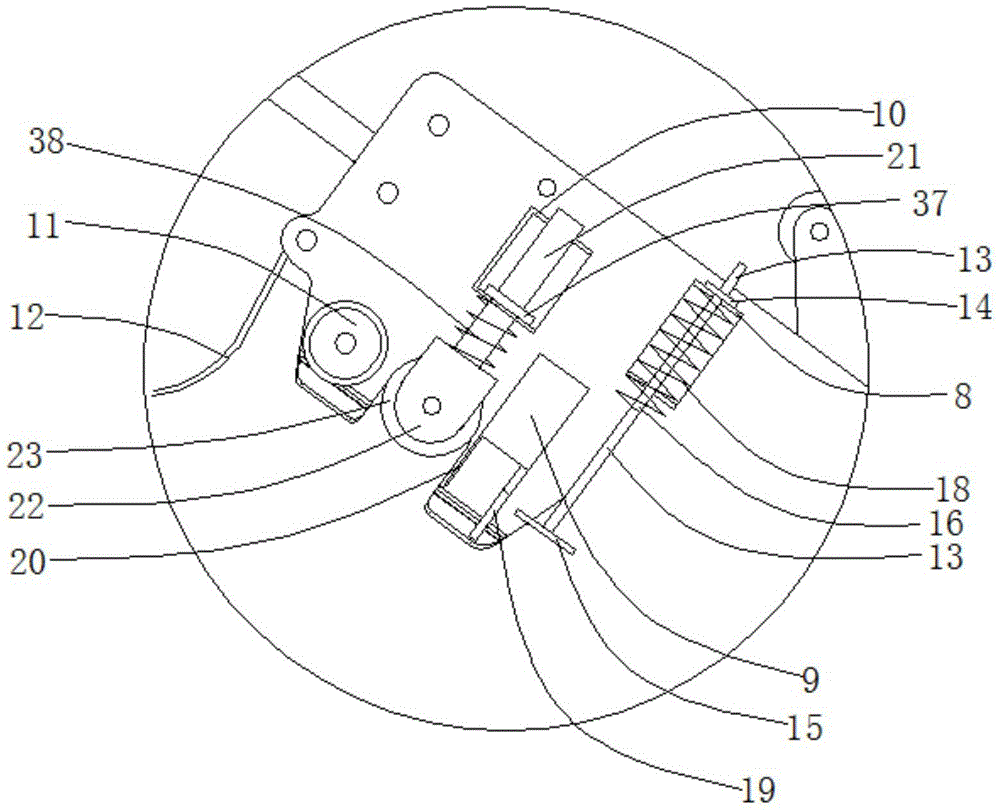

Vegetable binding machine

InactiveCN105599970ASimple structureEasy to useBundling machine detailsPackaging fruits/vegetablesMechanical engineering

The invention discloses a vegetable binding machine, which comprises a bottom plate (1), wherein the bottom plate (1) is fixedly provided with a power supply box (2), a handle seat (3) and a positioning seat (4) in sequence from one end to the other end; the two sides of the upper end of the handle seat (3) are symmetrically provided with handle racks (5) which are rotationally connected cooperatively with the handle seat; an adhesive tape disc (6) and a tape guide wheel bracket (7) are mounted at a middle part between the two handle racks (5); the other ends of the handle racks (5) are provided with a pressure applying box a corresponding to the positioning seat (4). The vegetable binding machine is simple in structure, and is convenient to use; as a burning sealing way is adopted to carry out fixation for the fixation way of a fixing tape, an adhesive tape without a gummed layer can be adopted integrally as the fixing tape to carry out burning sealing fixation; the integral connection effect is greatly improved; further, the binding is tight and reliable; the looseness is difficult; meanwhile, the fixing tape is the adhesive tape without the gammed layer; therefore, no glue is remained.

Owner:东莞市超卓包装设备有限公司

Pyrolysis adhesive film and production coating process thereof

InactiveCN111073538AEasy to produceEasy to useNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveChemistryFilm material

The invention discloses a pyrolytic adhesive film and a production coating process thereof, wherein the pyrolytic adhesive film at least comprises a release layer, a base material layer and a pressure-sensitive adhesive layer, wherein the release layer is a single-sided release film material and is used for winding the base material layer coated with the pressure-sensitive adhesive layer; and thepressure-sensitive adhesive layer is formed on the surface of the base material layer. The pyrolytic mucous membrane product is high in initial stripping force, a good fixing effect can be achieved onthe product, no residual adhesive is generated under high-temperature debonding, and stripping is easy. And meanwhile, the requirement on the debonding temperature does not influence the product.

Owner:江苏晶华新材料科技有限公司

Novel printable mobile phone rear cover inner explosion-proof membrane and preparation method thereof

ActiveCN113025227AImproves substrate adhesion propertiesImprove degumming problemNon-macromolecular adhesive additivesEster polymer adhesivesUltraviolet lightsUv absorber

The invention discloses a novel printable mobile phone rear cover inner explosion-proof film which sequentially comprises a PE protective film layer, a printable layer, a PET base material layer, an optical adhesive layer and a release film layer from bottom to top; the optical adhesive layer contains an epoxy curing agent, an ultraviolet absorber and a coupling agent; the ultraviolet light absorber is selected from one or more of an ultraviolet light absorber UV-P, an ultraviolet light absorber UV-234, an ultraviolet light absorber UV-329 and an ultraviolet light absorber UV-531, and the coupling agent is selected from one or more of a silane coupling agent KH-550, a silane coupling agent KH-560, a silane coupling agent KH-570 and a silane coupling agent KH-580. The explosion-proof film has high peel strength to mobile phone rear cover glass, the peel strength can reach 2000 gf / in or above, the explosion-proof film still has stable peel strength under the environments of high temperature, low temperature, 65 / 95, salt mist, QUV and the like, and no adhesive residue phenomenon is generated; the silane coupling agent is added into the optical adhesive layer, so that the base material adhesive force performance of the optical adhesive is greatly improved, and the degumming problem of the explosion-proof membrane is solved.

Owner:浙江日久新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com