Antistatic semiconductor UV viscosity-reducing adhesive layer and protective film

A technology of semiconductor and adhesive layer, which is applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, electric solid-state devices, etc. It can solve the problems of easy generation of static electricity, pollution of attached objects, and incomplete performance stability, etc., to extend the storage time , to avoid the effect of static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

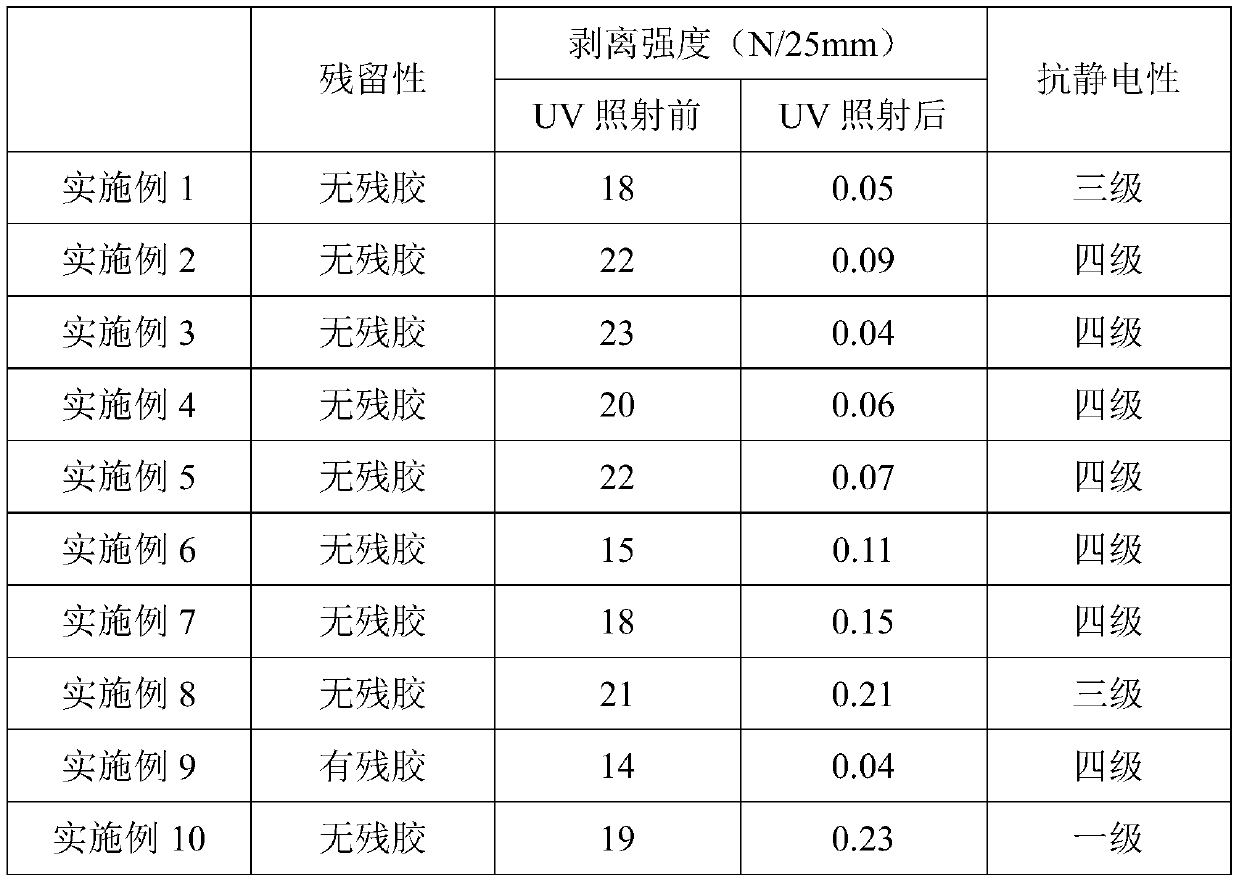

Examples

preparation example Construction

[0024] The preparation method of the cross-linked acrylic resin of the present invention comprises the following steps: adding di-trimethylolpropane tetraacrylate, methacrylic acid ester, and maleic anhydride in ethyl acetate, and then adding thermal trigger agent, mixed uniformly, and carried out free radical polymerization at 70-80°C to obtain the cross-linked acrylic resin;

[0025] The molar ratio of the two-trimethylolpropane tetraacrylate, methacrylate, and maleic anhydride is 1:22.5:4;

[0026] The content of described ethyl acetate is 35wt% of raw material gross mass;

[0027] The thermal initiator is tert-butyl peroxybenzoate; the content of the tert-butyl peroxybenzoate is 1 wt% of the total mass of raw materials.

[0028] In some preferred embodiments, the polymer with a cross-linked network system also includes a three-dimensional cross-linked network polymer; the raw materials for the preparation of the three-dimensional cross-linked network polymer include linea...

Embodiment 1

[0065] Embodiment 1 provides an antistatic semi-conductor UV viscosifying adhesive layer. In parts by weight, the raw materials for preparing the UV viscous adhesive layer include 40 parts of a polymer with a cross-linked network system, 0.1 part of an antistatic agent, 0.2 parts of photoinitiator, 0.5 parts of dispersant;

[0066] The polymer with a crosslinked network system includes a crosslinked acrylic resin; the preparation method of the crosslinked acrylic resin comprises the steps of: di-trimethylolpropane tetraacrylate, methacrylic acid Add ester and maleic anhydride to ethyl acetate, then add thermal initiator, mix uniformly, and carry out free radical polymerization reaction at 75°C to obtain the cross-linked acrylic resin; the bis-trimethylol The molar ratio of propane tetraacrylate, methacrylate and maleic anhydride is 1:22.5:4; the content of ethyl acetate is 35wt% of the total mass of raw materials; the thermal initiator is benzoic acid peroxide tert-butyl este...

Embodiment 2

[0079] Embodiment 2 provides an antistatic semi-conductor UV viscosifying adhesive layer. In parts by weight, the raw materials for preparing the UV viscous adhesive layer include 60 parts of a polymer with a crosslinked network system, 0.3 parts of an antistatic agent, 1 part of photoinitiator, 2 parts of dispersant;

[0080] The polymer with cross-linked network system is the same as embodiment 1;

[0081] The antistatic agent is a multi-walled carbon nanotube purchased from Jiangsu Xianfeng Nano Material Technology Co., Ltd.;

[0082] Described photoinitiator is with embodiment 1;

[0083] The dispersant is BYK-P104S, purchased from Foshan Qianyou Chemical Co., Ltd.;

[0084] The preparation method of the UV adhesive layer is the same as in Example 1.

[0085] An antistatic semi-conductor UV viscosity-reducing protective film comprises a substrate film, a UV-viscosity-reducing adhesive layer and a release film in sequence;

[0086] The thickness of the UV adhesive layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com