Patents

Literature

159results about How to "Improve the effect of hot pressing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

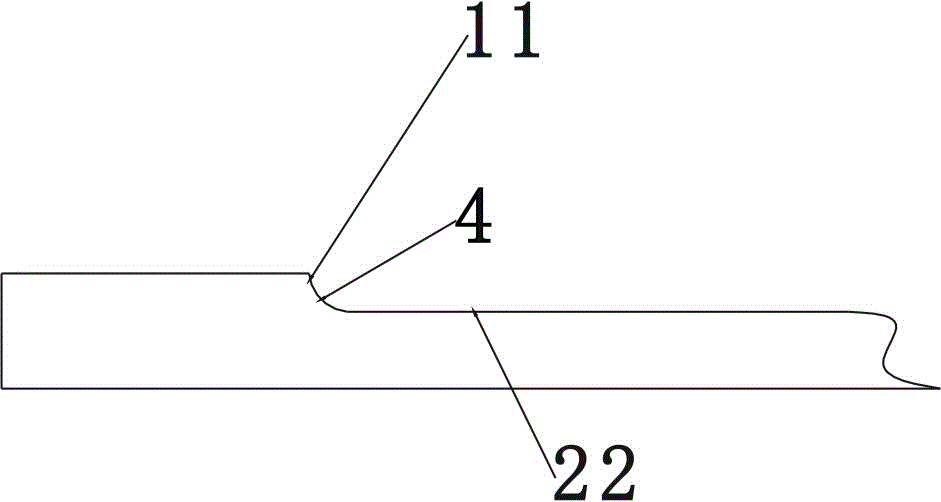

Veneering production process for artificial board

InactiveCN102896868AAvoid deformationGuaranteed quality and performanceLamination ancillary operationsLaminationChemistryEnvironmental geology

The invention relates to a veneering production process for an artificial board. The process comprises the following steps of: (1) treating an artificial board base material and a figured veneer at constant temperature and humidity to adjust water content, so that the water content of the artificial board base material is 6 to 10 percent, the water content of the figured veneer is 8 to 12 percent, and water is uniformly distributed; (2) completely removing a compact hardened layer from the surface of the artificial board base material to avoid warpage deformation or cracking caused by stress unbalance or environmental change in the veneering process of the figured veneer; (3) attaching the figured veneer to the surface, from which the compact hardened layer is removed, of the artificial board base material to form a semi-finished veneered decoration plate; and (4) and curing the semi-finished veneered decoration plate. By the process, the defects of dry shrinkage, bending, deformation, panel cracking and the like after the figured veneer is attached to the artificial board base material are overcome, and the quality of the veneered decoration plate is obviously improved; and compared with the traditional veneering process, the process has the advantage that quality loss is reduced by over 60 percent.

Owner:SHANTOU YIHUA FURNITURE +1

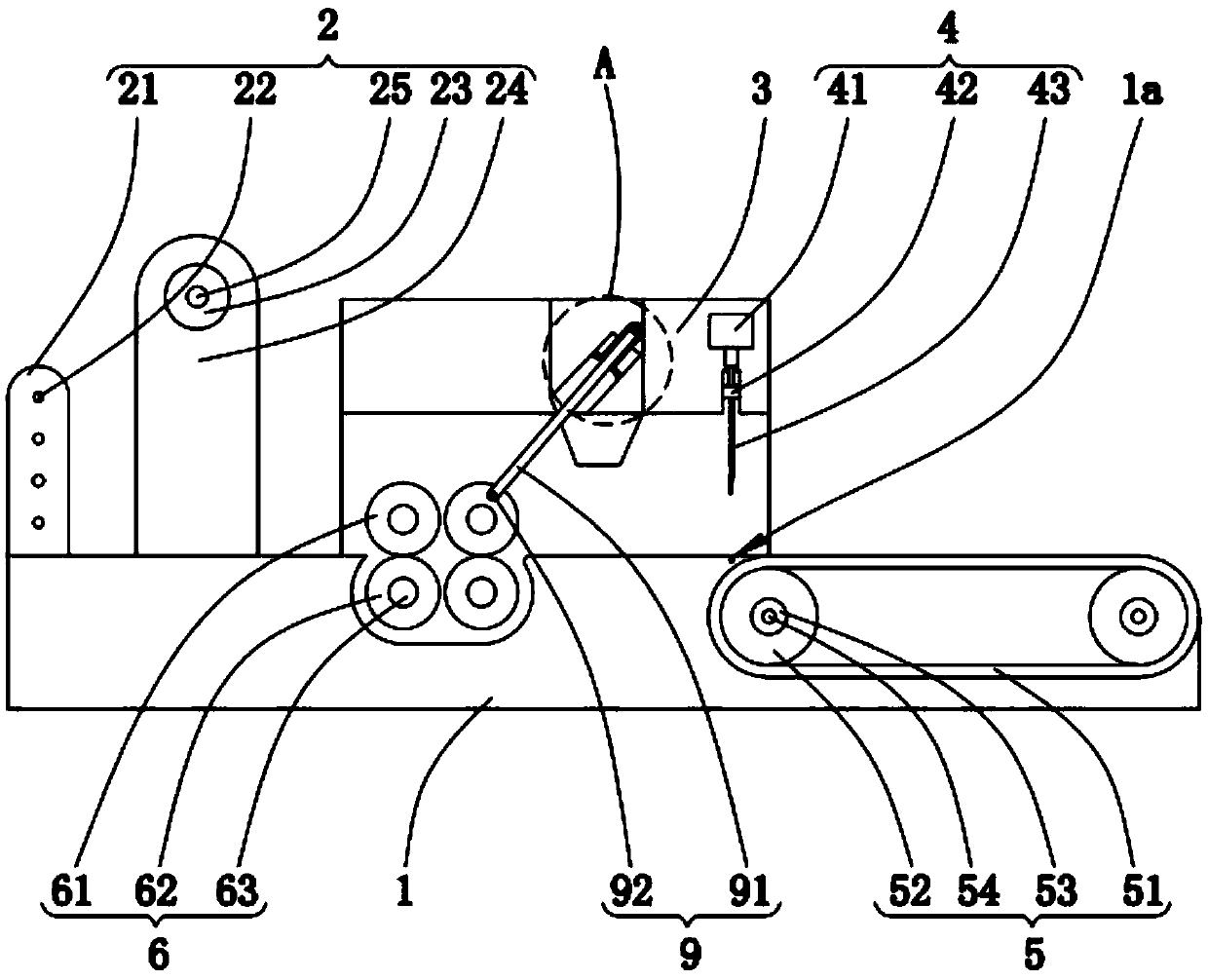

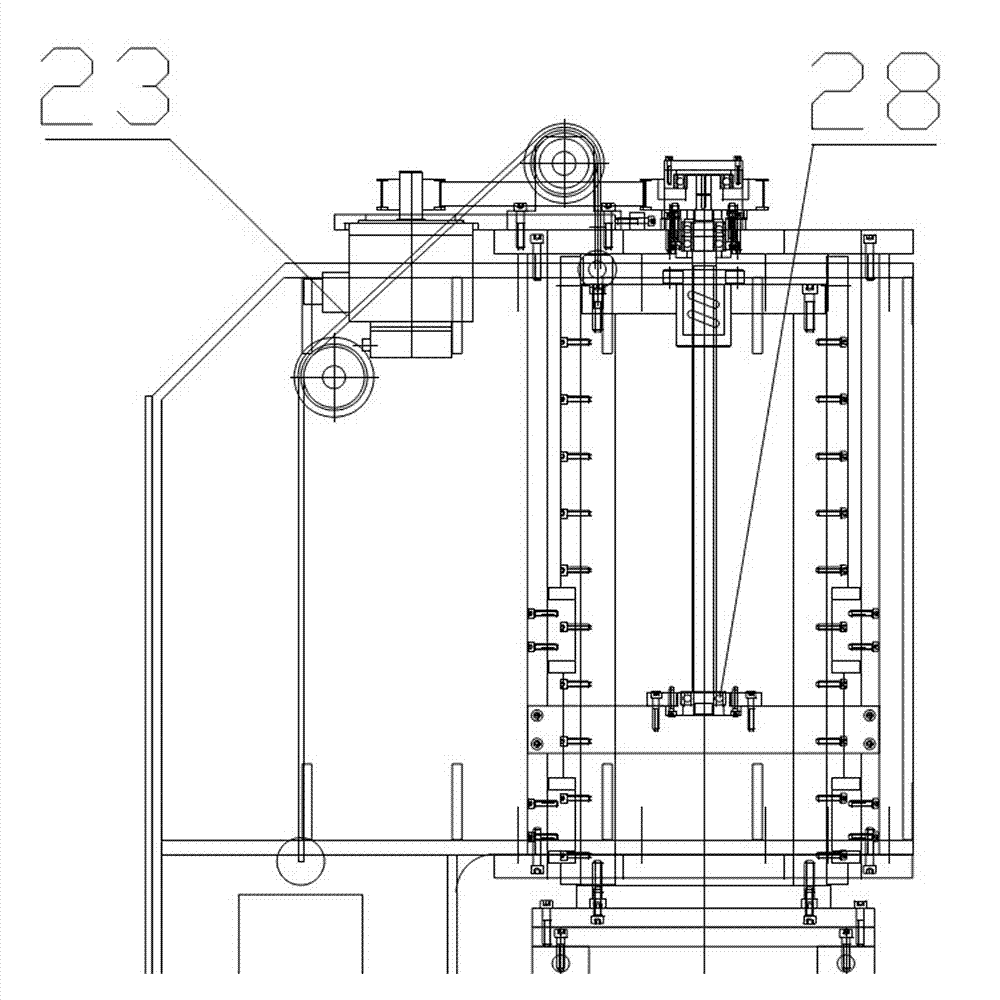

Bag making machine hot-sealing and hot-pressing mechanism capable of working stably

The invention discloses a bag making machine hot-sealing and hot-pressing mechanism capable of working stably. The mechanism comprises a fixing frame body, two guide sleeves, pull rods, a cutter fixing frame and a hot-sealing cutter. The upper ends of the pull rods are fixedly connected to the two ends of the cutter fixing frame respectively and each provided with an upper end abutting portion. The side wall of the upper portion of each pull rod is sleeved with a compression spring. The upper end and the lower end of each compression spring are connected to the corresponding upper end abutting portion and the top of the corresponding sleeve respectively in an abutting mode. At least one pull rod penetrates through the corresponding guide sleeve and then is in transmission connection with an intermittent motion mechanism. According to the bag making machine hot-sealing and hot-pressing mechanism, it can be ensured that the hot-sealing and hot-pressing positions and motion strengths of the hot-sealing cutter for air bubble films or pearl wool films under the hot-sealing and hot-pressing cutter are consistent all the time, and the hot-sealing cutter will not shift even if hot-sealing and hot-pressing are frequently and constantly carried out; accordingly, the working efficiency of the bag making machine hot-sealing and hot-pressing mechanism is greatly improved, and the service life of the bag making machine hot-sealing and hot-pressing mechanism is greatly prolonged.

Owner:洪东坡

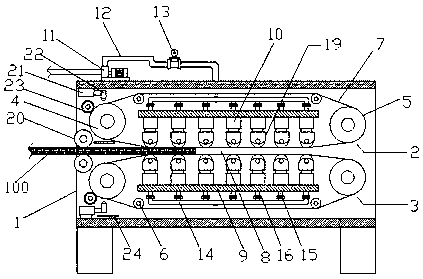

Bag machine with improved structure

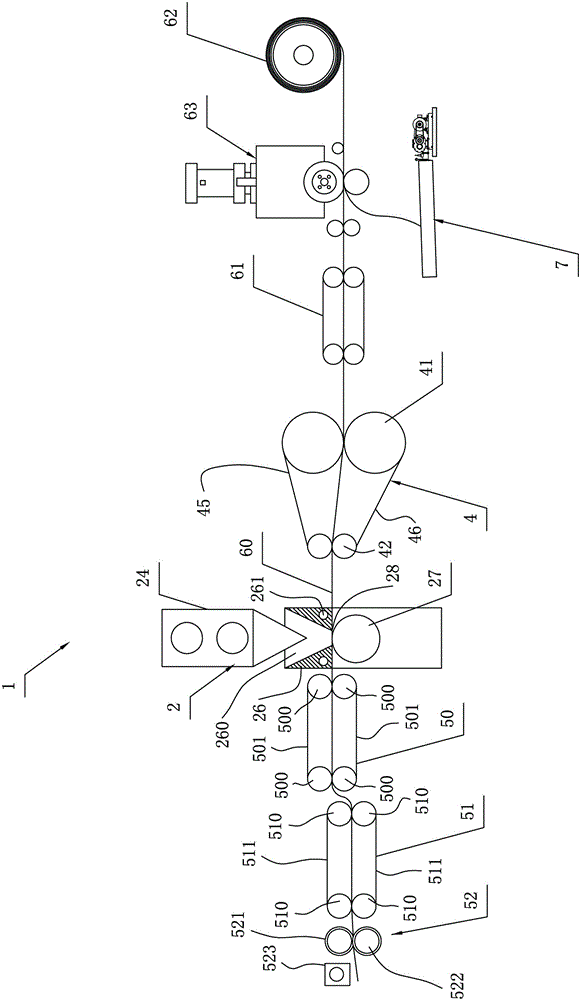

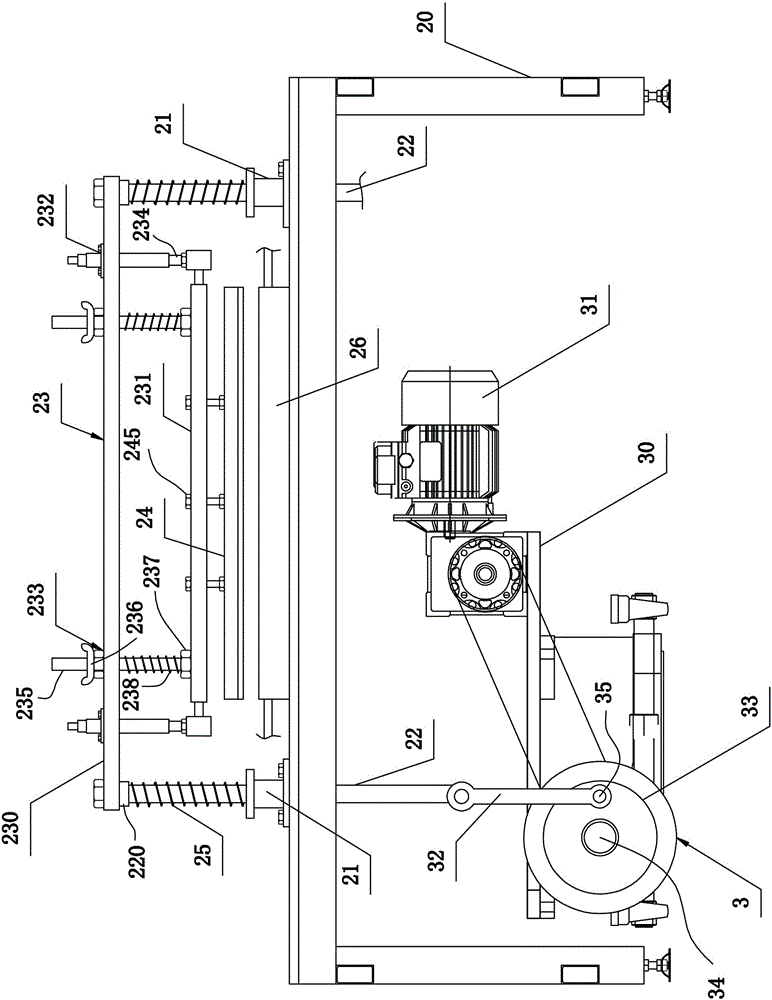

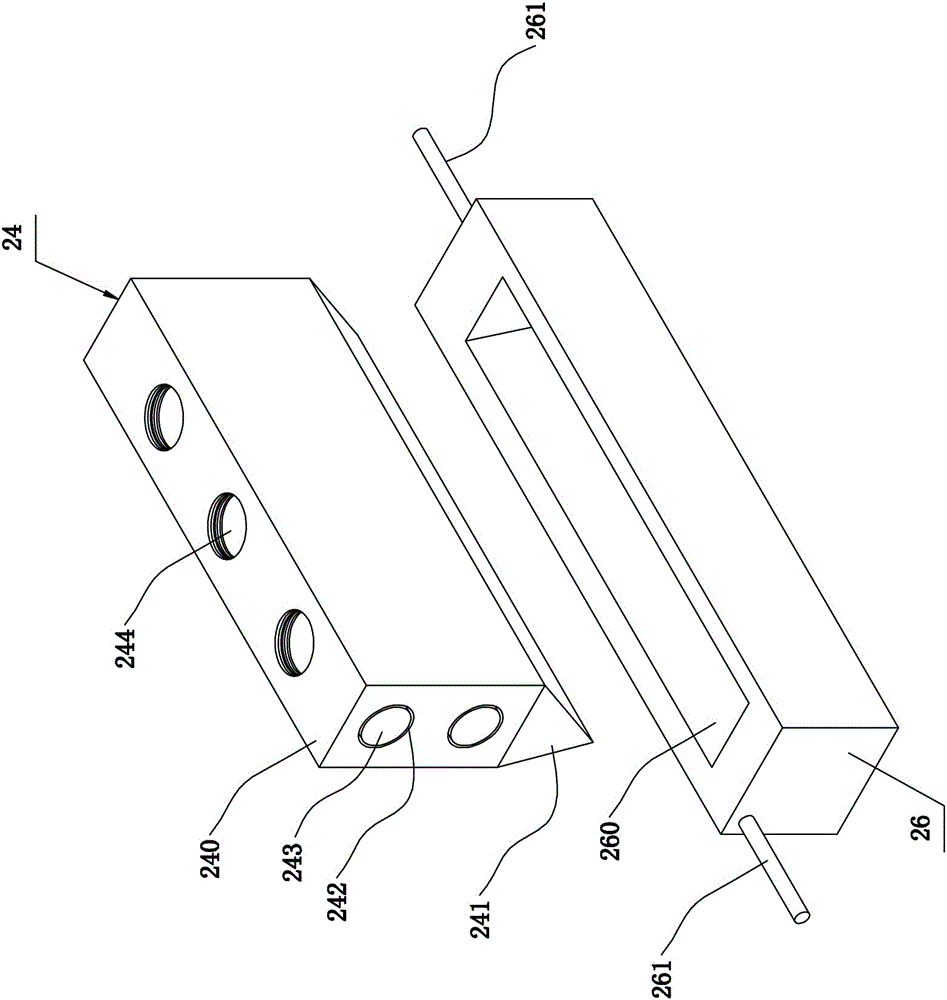

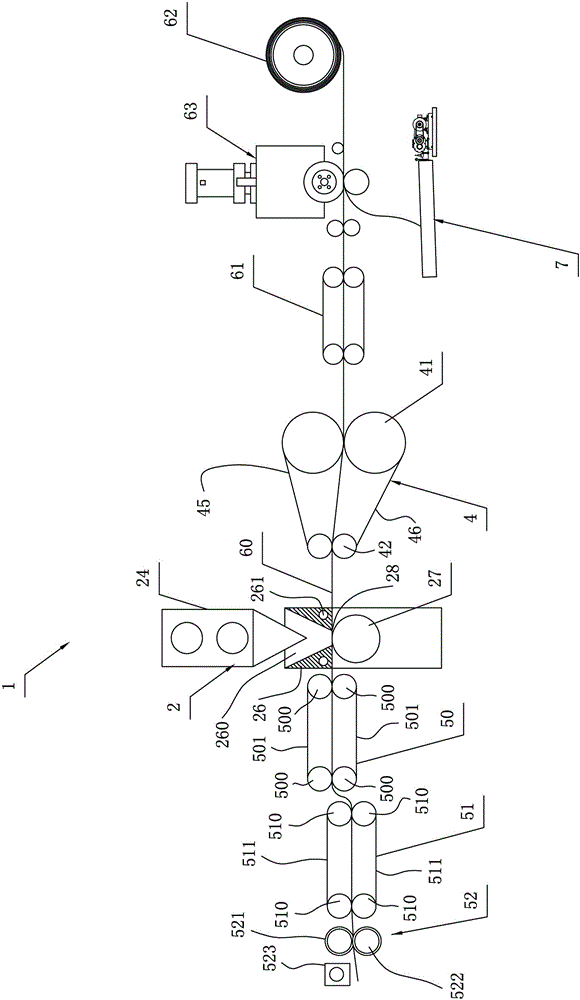

ActiveCN104985864AThere will be no offsetSimple structureBox making operationsPaper-makingEngineeringMechanical engineering

A bag machine with an improved structure comprises a convey assembly, a feed assembly, and a hot-sealing hot-pressing mechanism; the hot-sealing hot-pressing mechanism comprises a fixed rack, two guide sleeves, pull rods, a cutter fixing rack and a hot-sealing cutter; tops of each pull rod are respectively fixed on two ends of the cutter fixing rack; each pull rod is provided with a top abut portion; an upper side wall of each pull rod is sleeved by a compression spring; at least one pull rod penetrates the corresponding guide sleeve and is in transmission connection with an intermittence motion mechanism, wherein the intermittence motion mechanism is used for controlling the cutter fixing rack to complete up-down mobile motions in cycle in a fixed time. The bag machine can ensure the hot-sealing cutter to carry out hot-sealing hot-pressing for right blow bubble films or pearl cotton films with consistent positions and motion forces in each time; even under frequent continuously hot-sealing hot-pressing, no hot-sealing cutter offset condition is generated, thus greatly improving work efficiency and life of the bag machine.

Owner:洪东坡

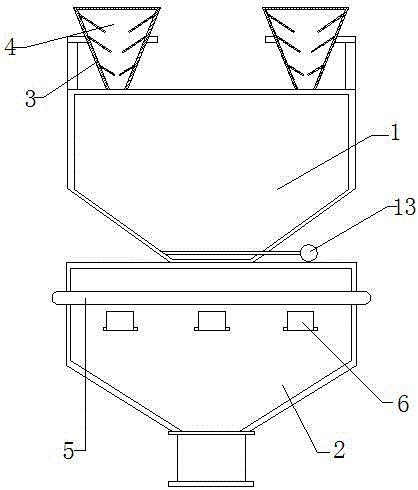

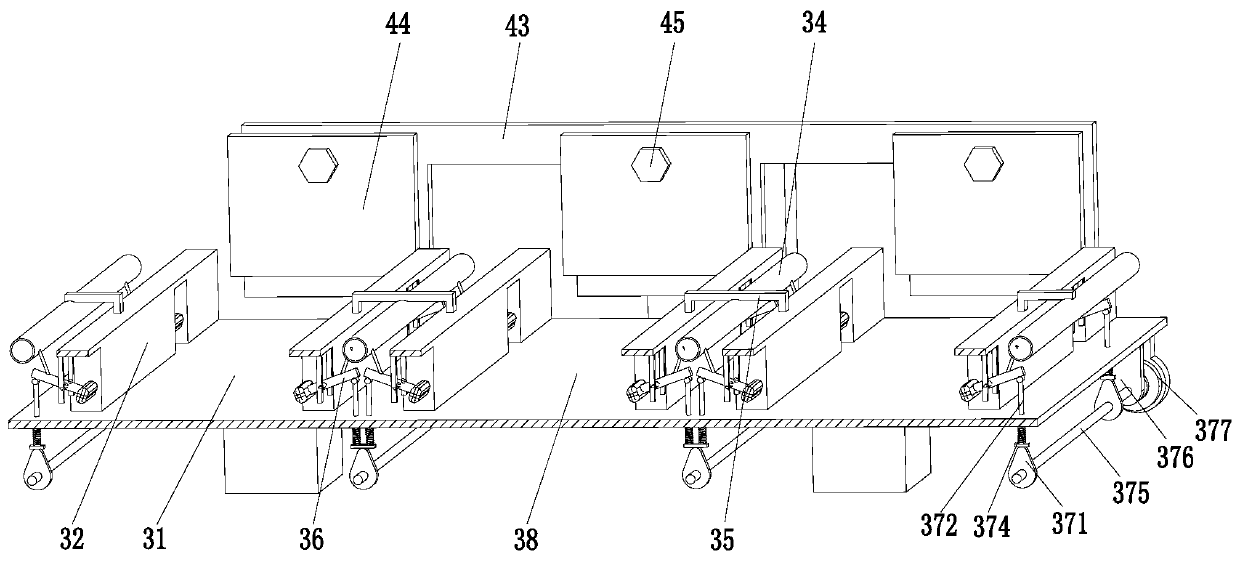

Multistation pattern ironing machine

InactiveCN101797832AAvoid misalignmentImprove work efficiencyTransfer printingThermographyEngineeringMechanical engineering

The invention relates to a multistation pattern ironing machine. The conventional double-station rocker-type hot-pressing pattern ironing machine is subject to further improve the efficiency and has complex structure and high cost. Therefore, the multistation pattern ironing machine comprises upper die assemblies and lower die assemblies, wherein each upper die assembly comprises a hot-pressing plate which is arranged on a lifting cylinder. The multistation pattern ironing machine is characterized in that the lifting cylinder is arranged on a transverse rail and provided with a transverse stepping driving device; 3-5 lower die assemblies are sequentially arranged below the transverse rail, and the upper die assemblies can sequentially move to the upper part of each lower die assembly under the driving of the transverse stepping driving device. The multistation pattern ironing machine has the advantages of simple structure, reliable operation and high working efficiency and is suitable for ironing figures and patterns on daily fabrics and various dress cloth, such as handkerchiefs, caps, and the like.

Owner:台州曼克斯机械有限公司

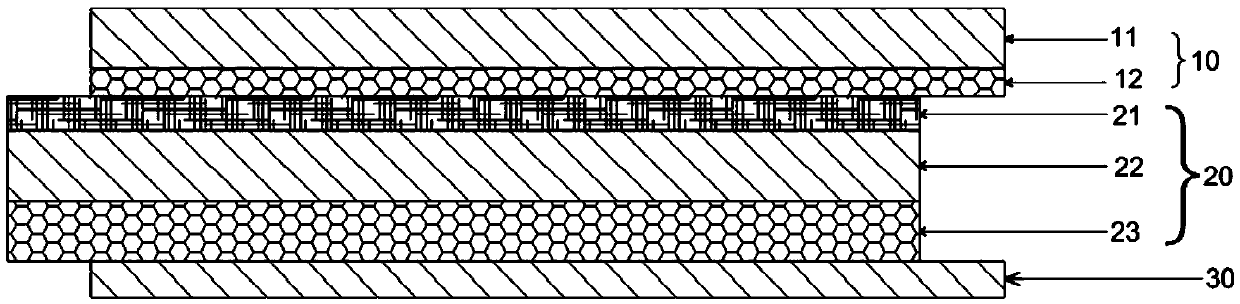

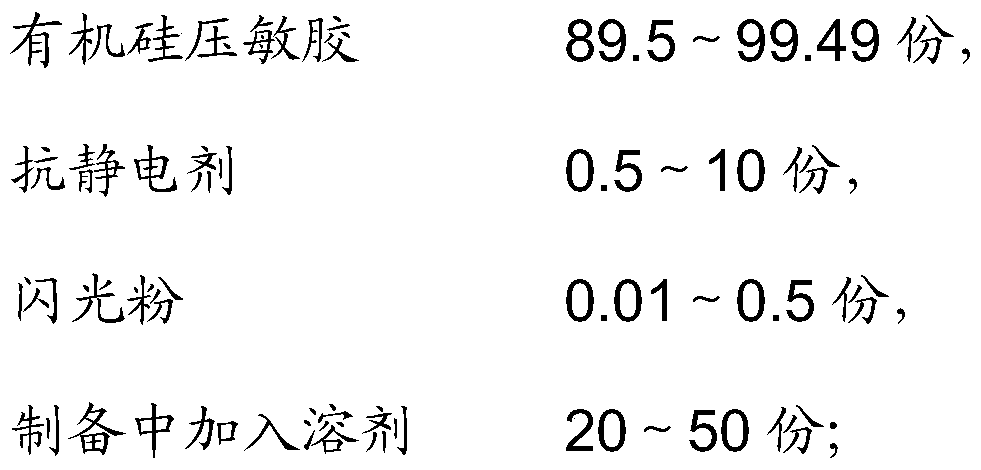

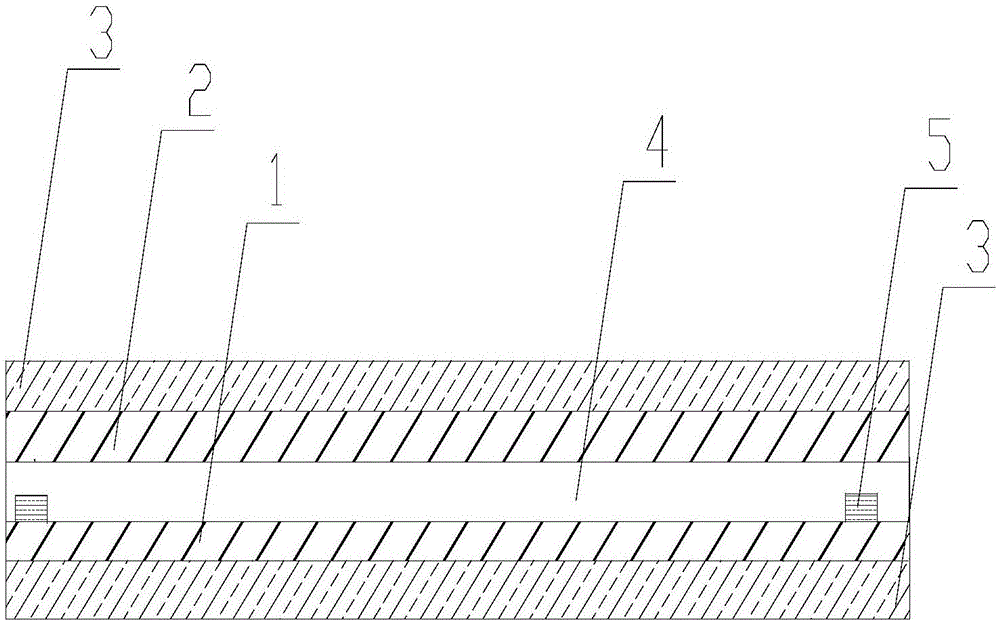

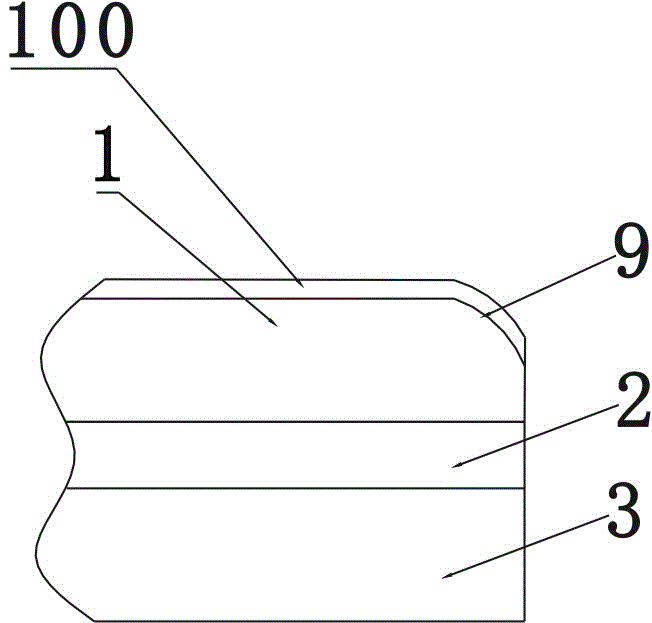

Hot-press molded protective film with shinning and antistatic effects and preparation method thereof

InactiveCN105522799AImprove the effect of hot pressingGuaranteed molding effectSynthetic resin layered productsAntistatic agentAcrylic resin

The invention discloses a hot-press molded protective film with shinning and antistatic effects and a preparation method thereof. The protective film can be used for comprehensively protecting a curved screen, and has an attractive appearance since shinning and antistatic effects are extra added. The protective film comprises a film protecting layer, an application layer and a release layer from top to bottom, wherein the application layer comprises a UV hardened layer, a base material A and an adhesive layer A; the principle component of the UV hardened layer is an acrylic resin layer, the base material A is a PET film, and the principle component of the adhesive layer is an organic silicone pressure-sensitive adhesive layer; and the thickness of the UV hardened layer is 2-10 mu m, the thickness of the base material A is 20-200 mu m, and the thickness of the adhesive layer A is 20-100 mu m. The hot-press molded protective film has shining and antistatic effects since shining particles and an antistatic agent are added into the application layer, and has high flexibility and cannot rebound after hot press since high-elasticity high-viscosity organic silicone pressure-sensitive adhesive is utilized in the adhesive layer.

Owner:NALI OPTICAL MATERIAL DONGGUAN

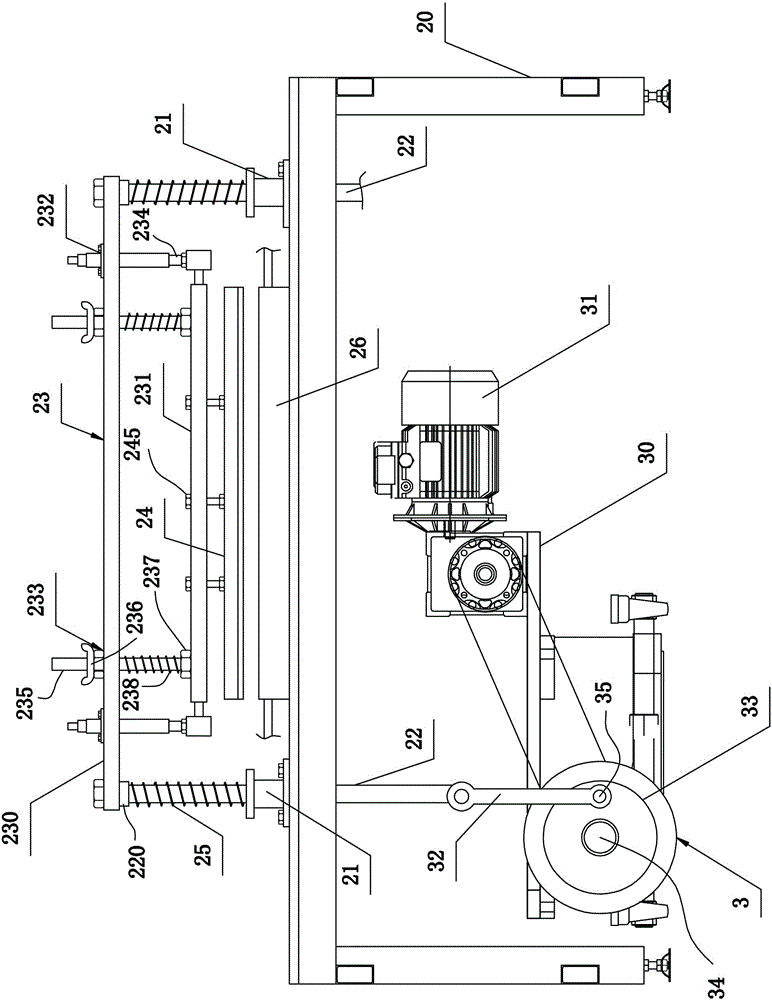

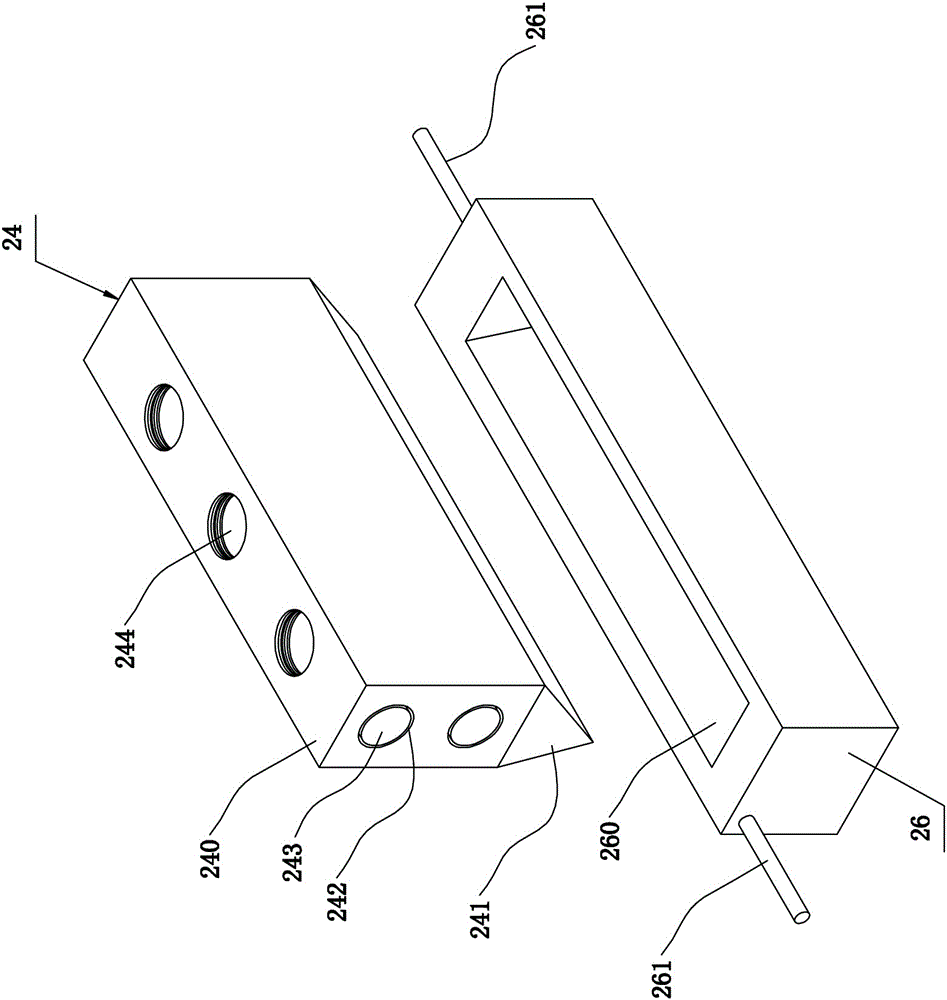

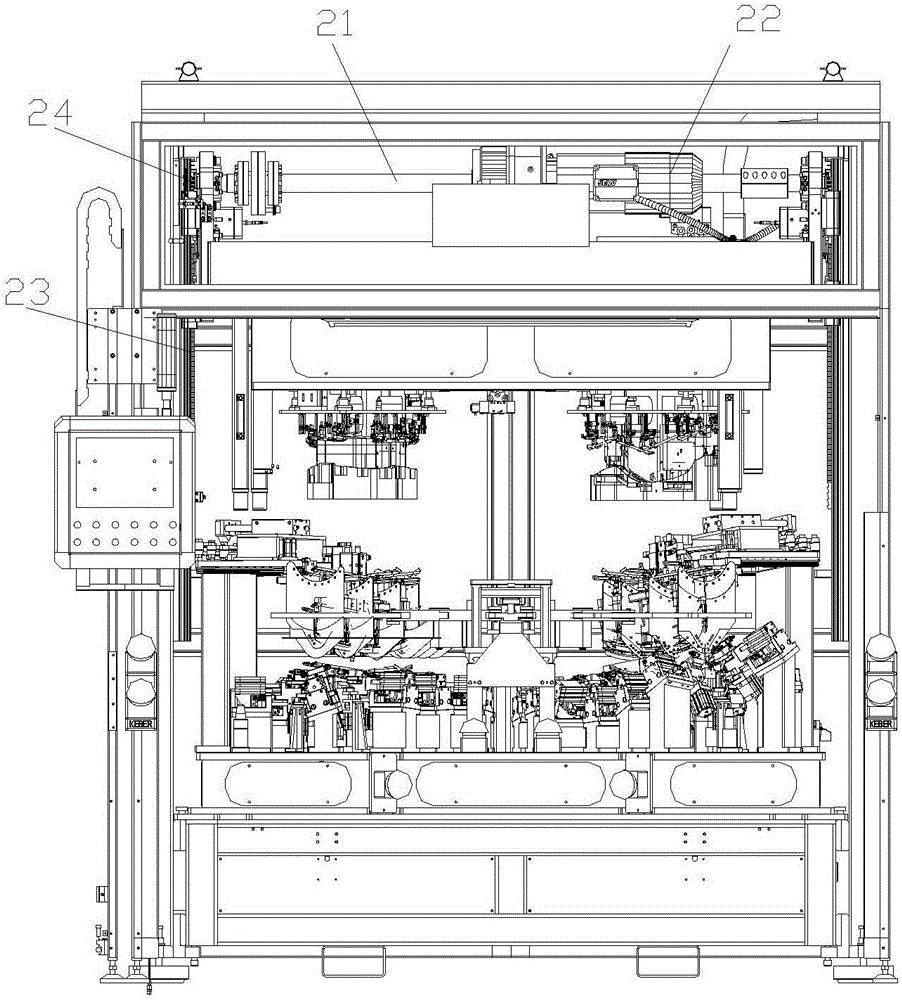

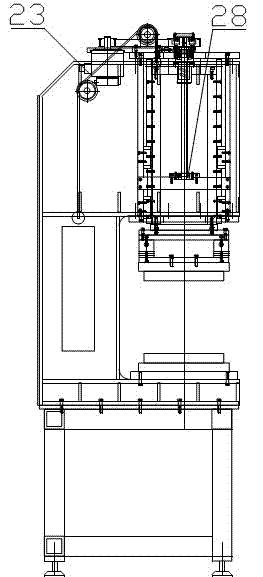

Automatic hot-pressing overlock machine

The invention discloses an automatic hot-pressing overlock machine and relates to the field of precision mechanical equipment. The automatic hot-pressing overlock machine comprises an upper mold device, a transmission device, a lower mold device and a baking device. The upper mold device is provided with a clamping mechanism for clamping an automobile armrest base plate. The lower mold device is provided with positioning needles for positioning and tightening a surface sheet. The baking device stretches to the part between the lower mold device and the upper mold device and meanwhile bakes and fuses solid glue on the surface sheet and solid glue on automobile armrest base plate. The transmission device drives the upper mold device to descend and to be pressed to the lower mold device so that the automobile armrest base plate can be attached to the surface sheet. The lower mold device is further provided with an overlock mechanism used for wrapping the surface sheet onto the overlock mechanism on the automobile armrest base plate. The automatic hot-pressing overlock machine can be adjusted according to different process parameters, and the problem of product hot-pressing overlaying with different configuration requirements is solved. Moreover, by means of double faces of baking and heating, the hot-pressing effect is better; and meanwhile, a positioning structure and an aligning structure on a bottom mold can accurately position a workpiece, and the working precision is guaranteed.

Owner:SUZHOU KEBER PRECISION MACHINERY

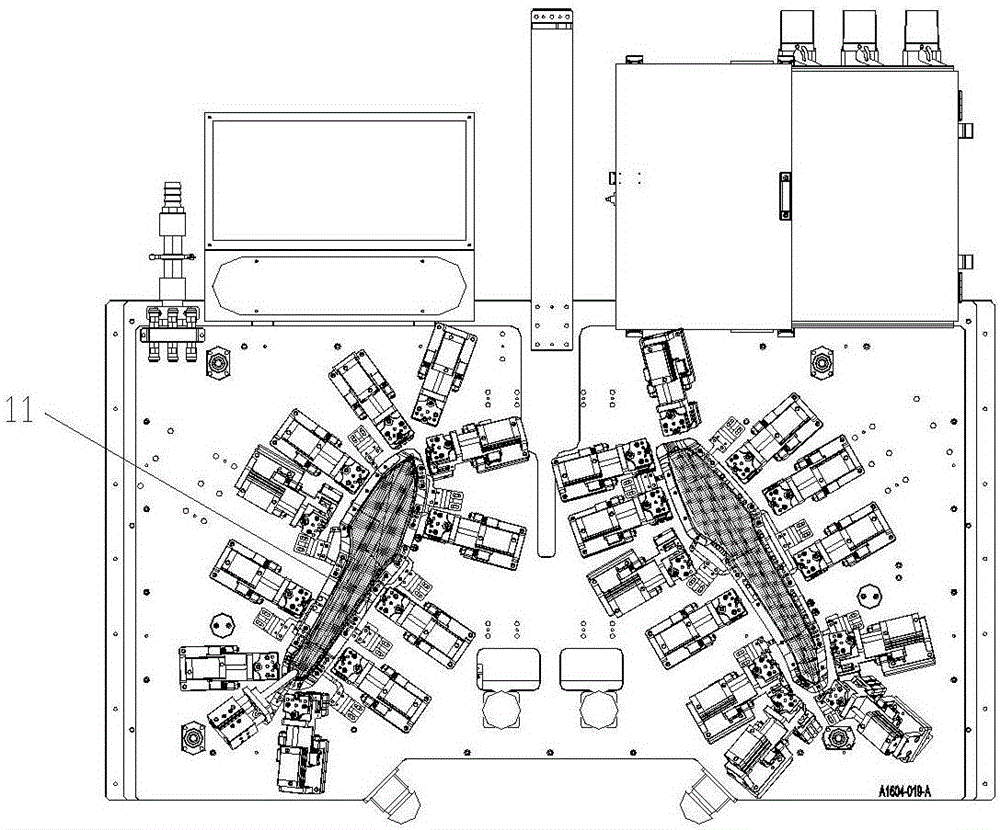

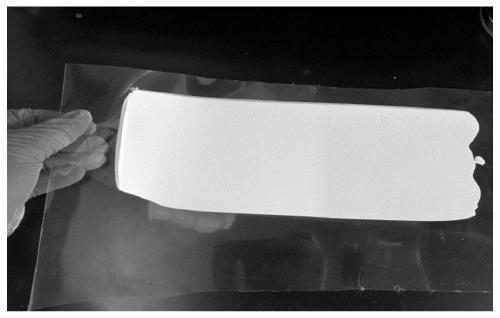

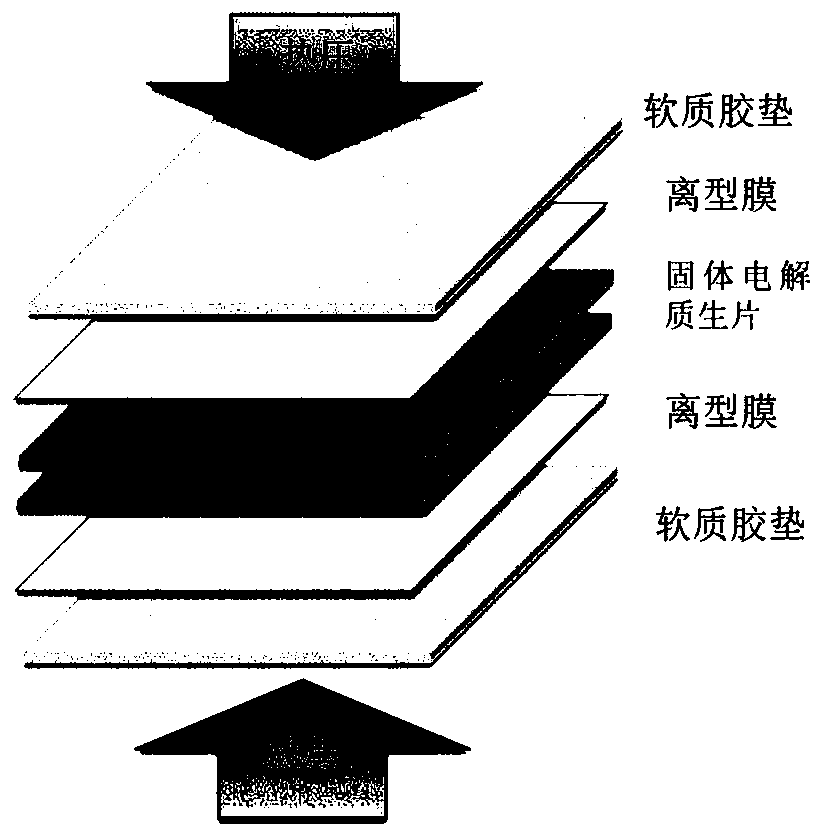

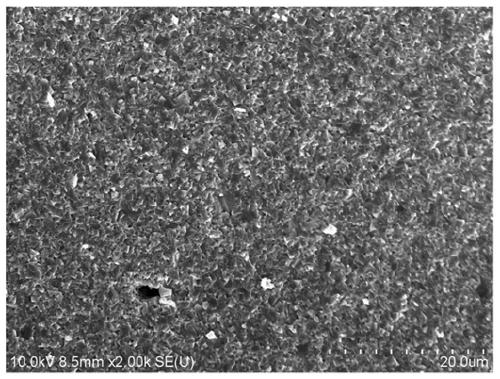

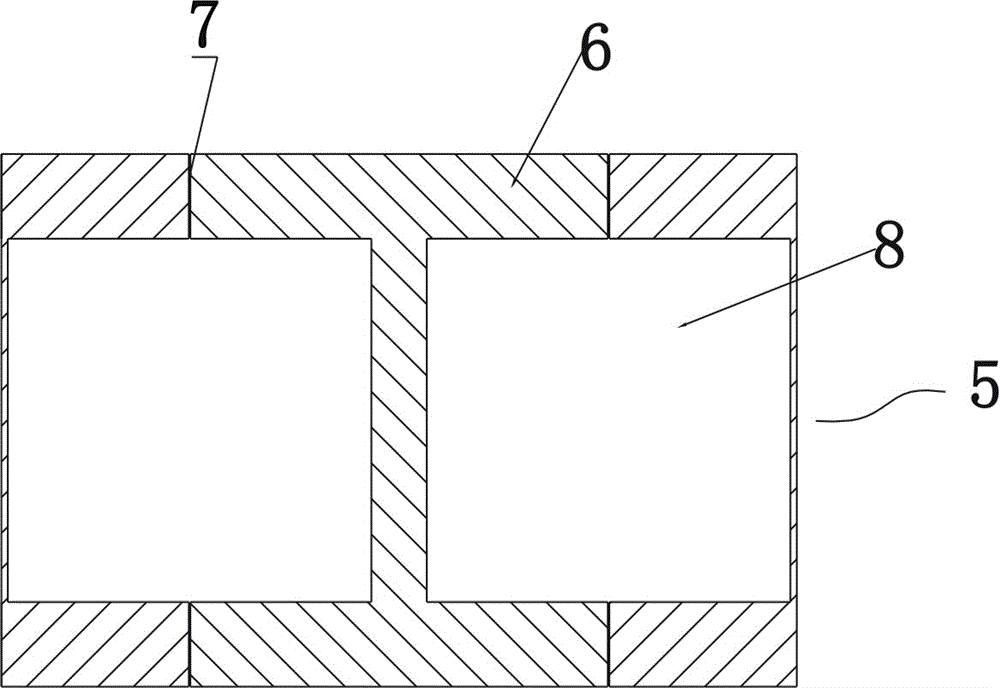

Oxide solid electrolyte sheet and preparation method and application thereof

ActiveCN111129560AImprove gas barrier sealing effectLarge area spanFuel and primary cellsFuel and secondary cellsPhysical chemistryThin sheet

The invention belongs to the technical field of solid electrolyte, and particularly relates to an oxide solid electrolyte sheet and a preparation method and application thereof. The method disclosed by the invention comprises the following step: laminating two or more layers of oxide solid electrolyte raw sheets into one layer in a thermocompression bonding manner. According to the invention, a double-layer or multi-layer hot-pressing compounding mode is adopted, so the through-hole-free compact oxide solid electrolyte sheet can be obtained, and the gas barrier sealing effect of the compact solid electrolyte sheet can be effectively improved.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

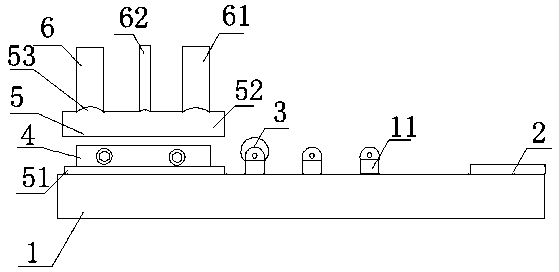

Flame-retardant carbon crystal heating plate and preparation method thereof

InactiveCN106162957AImprove the effect of hot pressingImprove securityHeating element materialsGraphite carbonHeat resistance

The invention discloses a flame-retardant carbon crystal heating plate which is prepared by the following steps: 1) fixing one end of a copper bar on the front of a first resin layer, and extending the other end to the outside of the first resin layer; 2) brushing graphite carbon slurry on the front of the first resin layer to form a graphite layer, and coating one end of the copper bar in the graphite carbon slurry; 3) hot pressing a second resin layer on the graphite layer to obtain a sandwich plate; and 4) hot pressing mica paper on both sides of the sandwich plate, and naturally cooling to obtain the flame-retardant carbon crystal heating plate. The flame-retardant carbon crystal heating plate has the advantages of long-time uniform heating, high-pressure resistance, good heat resistance and safety in use.

Owner:WUHU SAUNAKING ELECTRONICS TECH CO LTD

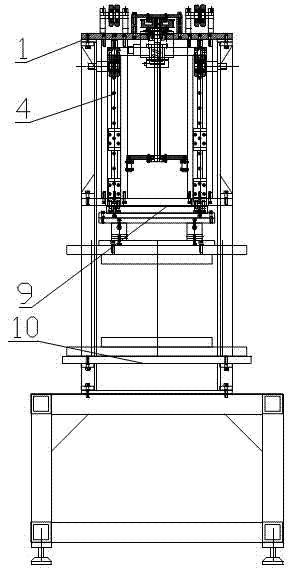

Hot press

InactiveCN104191476AImprove pressure performanceEvenly heatedPlywood pressesVeneer pressesAgricultural engineeringHot press

The invention relates to the field of hot-pressed shaping, in particular to a hot press. According to the technical scheme, the hot press comprises a frame, a vertical pressure transfer device and a horizontal pressure transfer device, wherein the vertical pressure transfer device is arranged on the frame and applies vertical pressure on materials, and the horizontal pressure transfer device is arranged on the frame and applies horizontal pressure on the materials. The vertical pressure transfer device comprises a lower pressure plate and an upper pressure plate, wherein the lower pressure plate is arranged on the frame, the upper pressure plate is arranged right above the lower pressure plate horizontally and can go up and down vertically, a middle partition plate and a heating pipe are arranged in the middle of the upper pressure plate in the vertical direction, the middle partition plate is parallel to the upper pressure plate, and a plurality of air holes are formed in the surface of the middle partition plate. The hot press is simple in structure and easy to implement, and specially-made hot-press board boards are adopted, so that products can bear force uniformly and be heated uniformly during hot press.

Owner:秦贵新

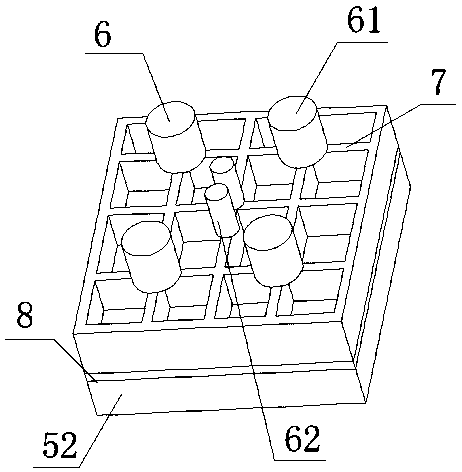

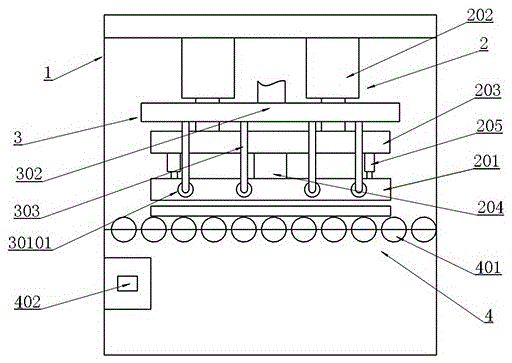

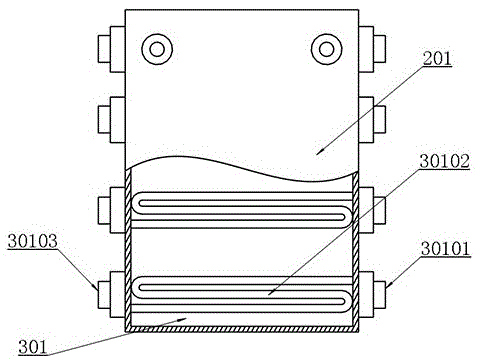

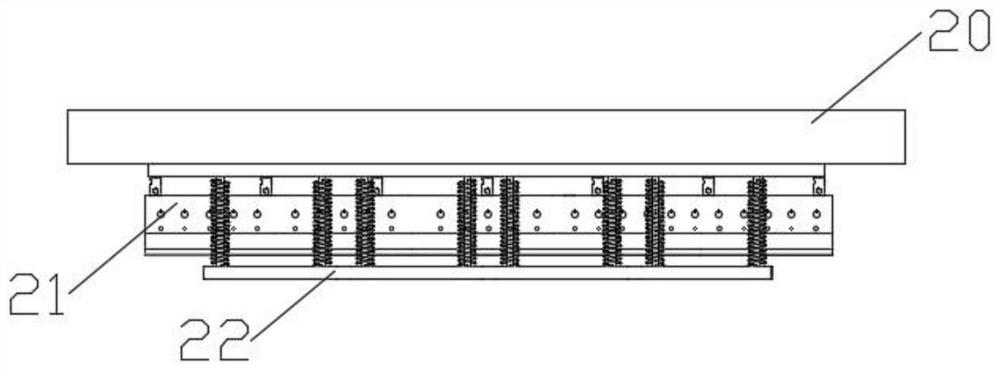

Hot press for consolidated composite floors

ActiveCN105538467AHigh bonding strengthThe overall structure is simple and reliableLaminationLamination apparatusManufacturing technologyEngineering

The invention belongs to the technical field of consolidated composite floor manufacturing and particularly relates to a hot press for consolidated composite floors. The hot press comprises a rack, a compaction unit and a heat supply unit, wherein the compaction unit is arranged in the rack, and the heat supply unit is arranged on the compaction unit. A conveying unit used for conveying the floors is arranged below the compaction unit. The compaction unit comprises a hot pressing plate, main air cylinders and a balance plate, wherein the balance plate is arranged between the hot pressing plate and the main air cylinders. The heat supply unit comprises multiple sets of heat supply pipelines which are independent of one another. The hot press is used for bonding of wearing layers, decoration layers and base layers in the consolidated composite floors and has the beneficial effects that the structure is simple and firm, the hot pressing effect is good, bonding strength among the wearing layers, the decoration layers and the base layers is high, and the hot press is convenient to operate.

Owner:蚌埠格识知识产权运营有限公司

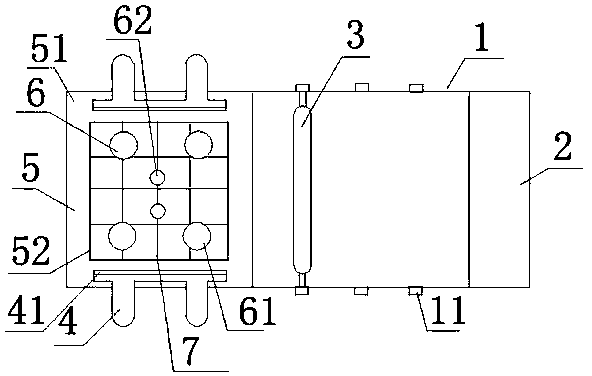

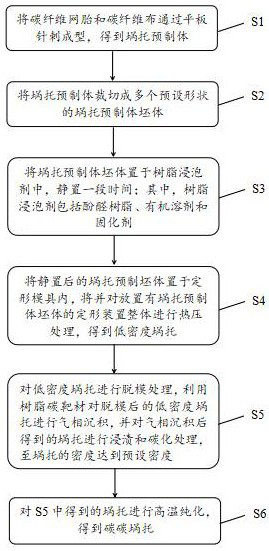

Carbon-carbon crucible support and preparation method thereof

PendingCN114379115AIncrease production speedReduce manufacturing costPolycrystalline material growthBy pulling from meltFiberCarbon fibers

The invention relates to the technical field of crucible supports, in particular to a carbon-carbon crucible support and a preparation method thereof.The method comprises the steps that a carbon fiber net tire and carbon fiber cloth are subjected to flat needling forming, and a crucible support prefabricated body is obtained; cutting the crucible support prefabricated body into a plurality of crucible support prefabricated body blanks with preset shapes; placing the crucible support preform blank in a resin soaking agent for standing; the crucible support prefabricated blank obtained after standing is placed in a shaping mold, a shaping device is integrally subjected to hot pressing treatment, and the low-density crucible support is obtained; performing demolding treatment on the low-density crucible support, performing vapor deposition on the demolded low-density crucible support by using a resin carbon target material, and performing impregnation and carbonization treatment on the crucible support obtained after vapor deposition until the density of the crucible support reaches a preset density; performing high-temperature purification on the obtained crucible support to obtain a carbon-carbon crucible support; the whole shaping mold can be placed in the drying oven for curing and shaping, operation is easy and convenient, and a good hot pressing effect can be achieved without a complex hot pressing process.

Owner:浙江德鸿碳纤维复合材料有限公司

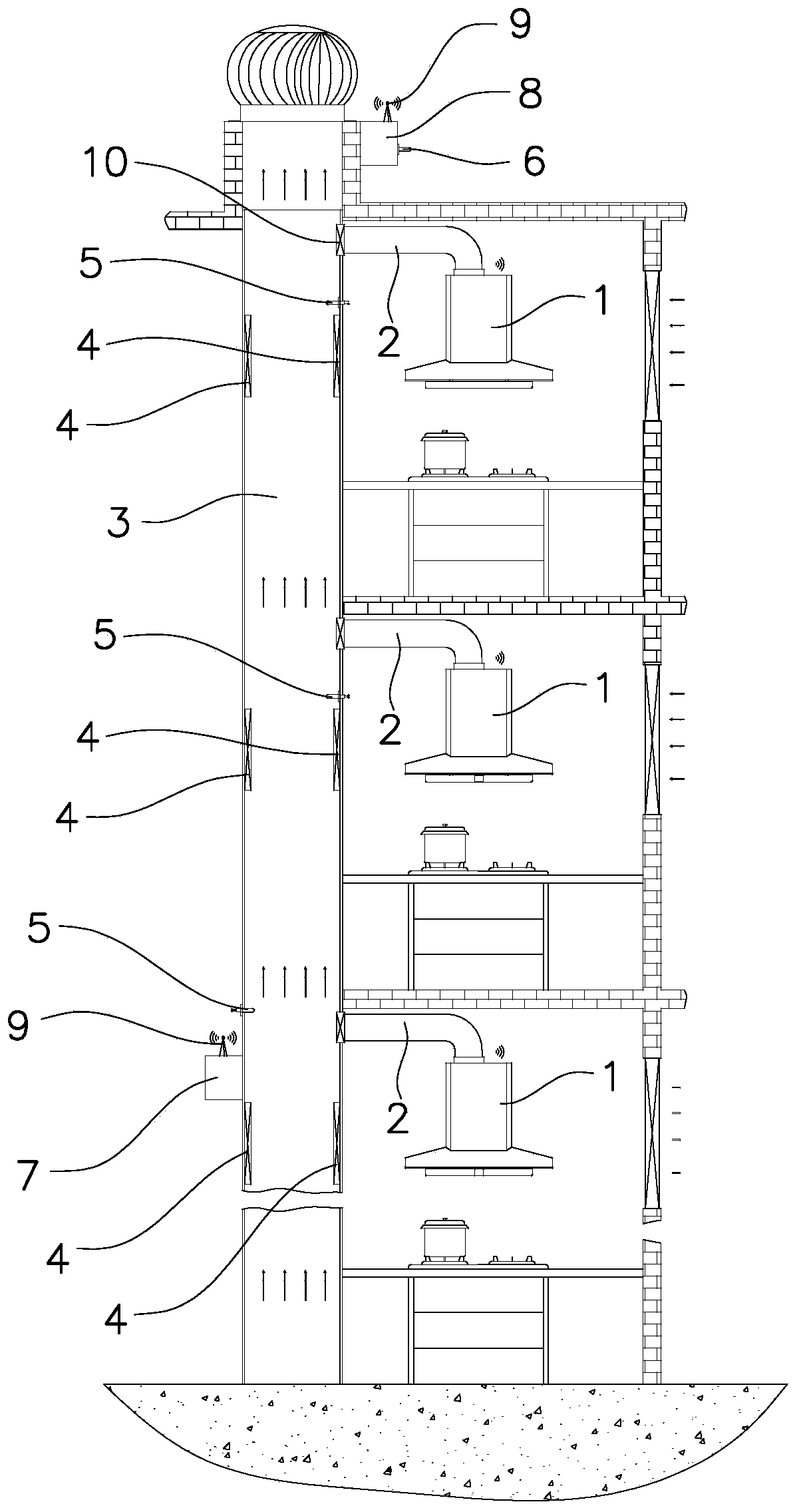

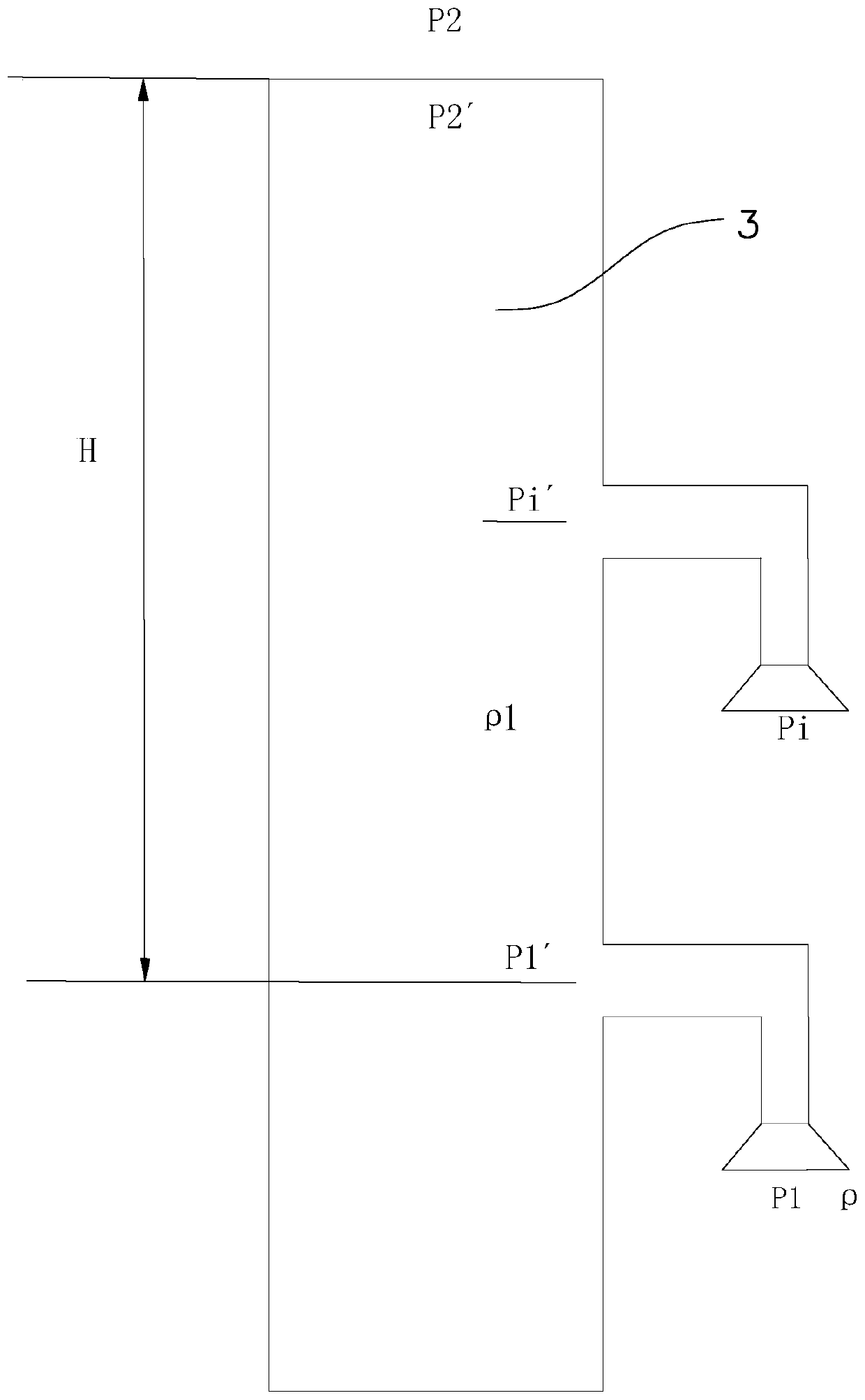

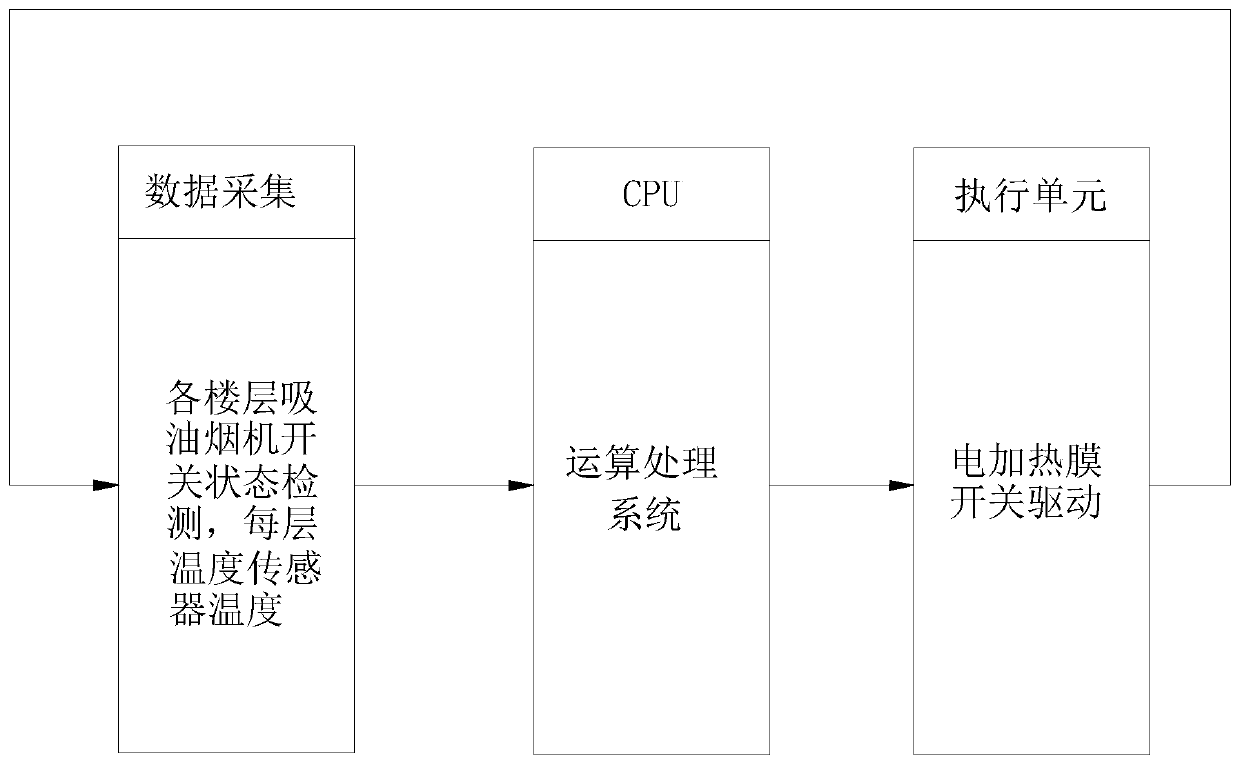

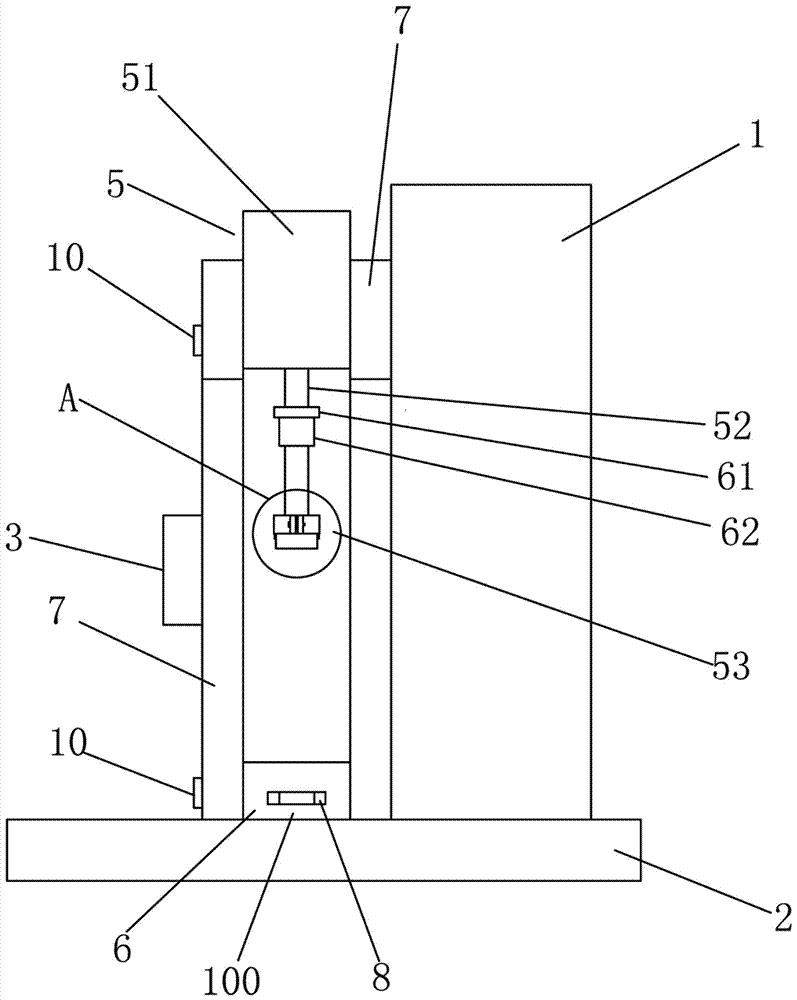

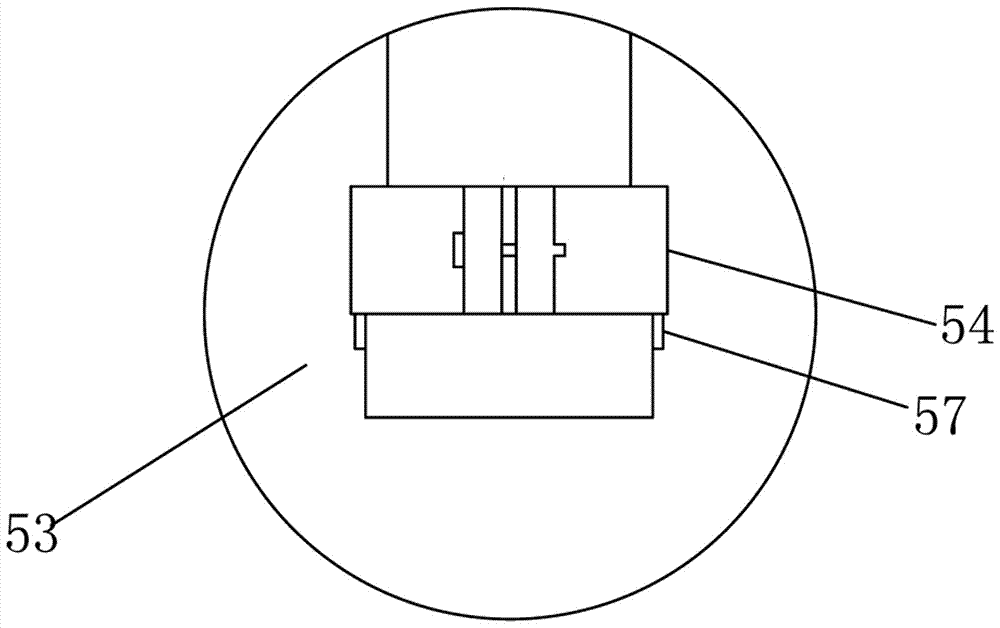

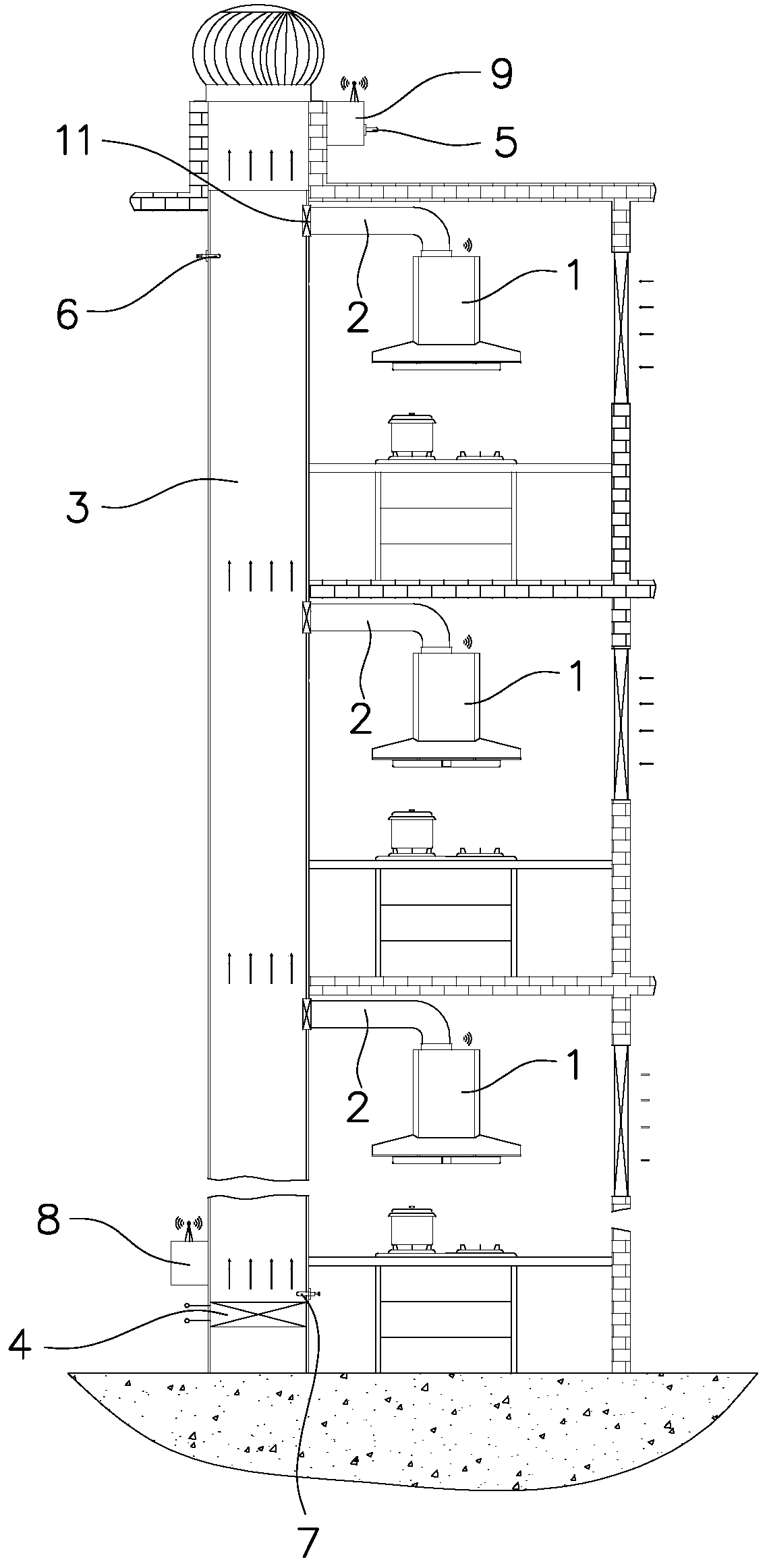

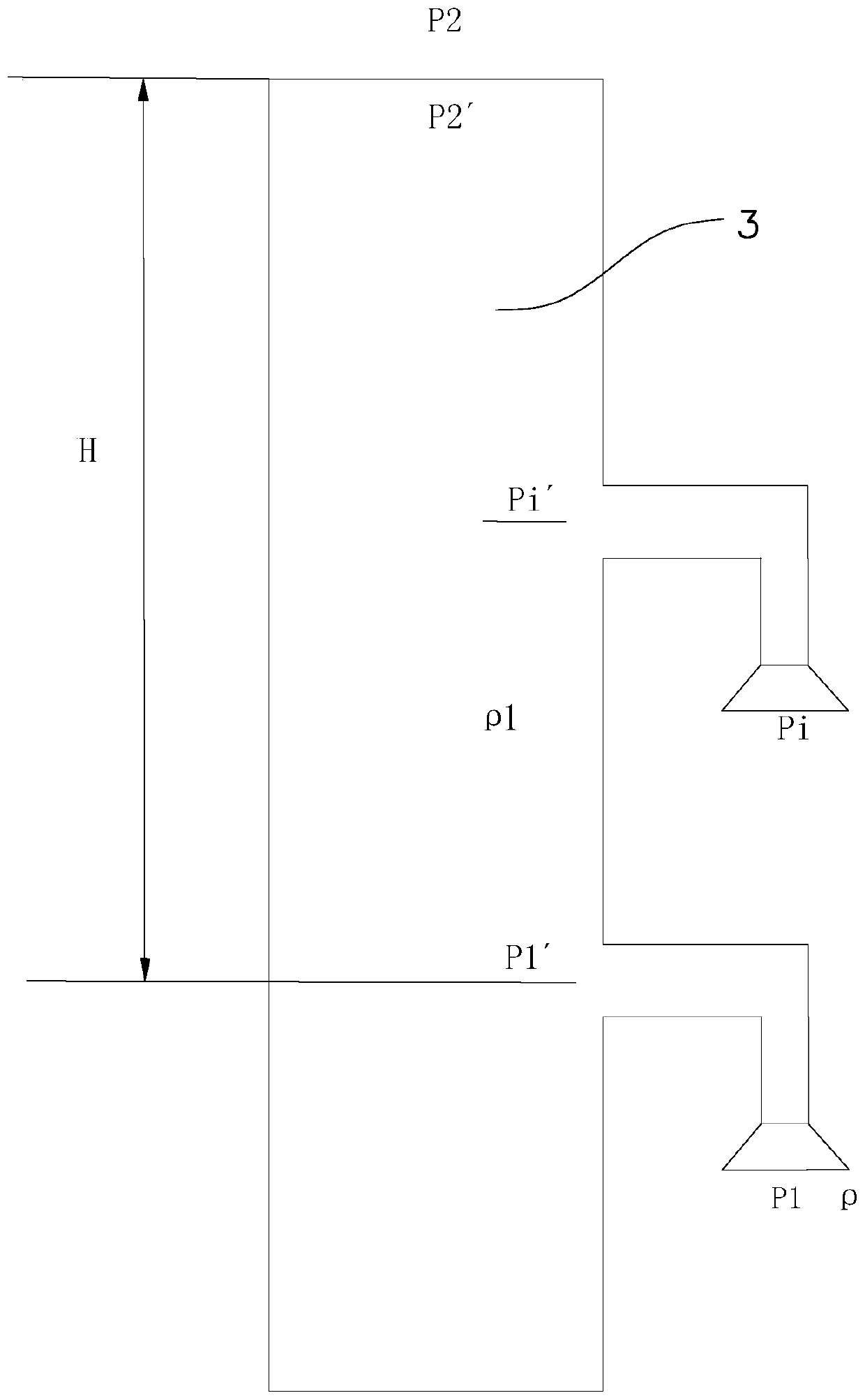

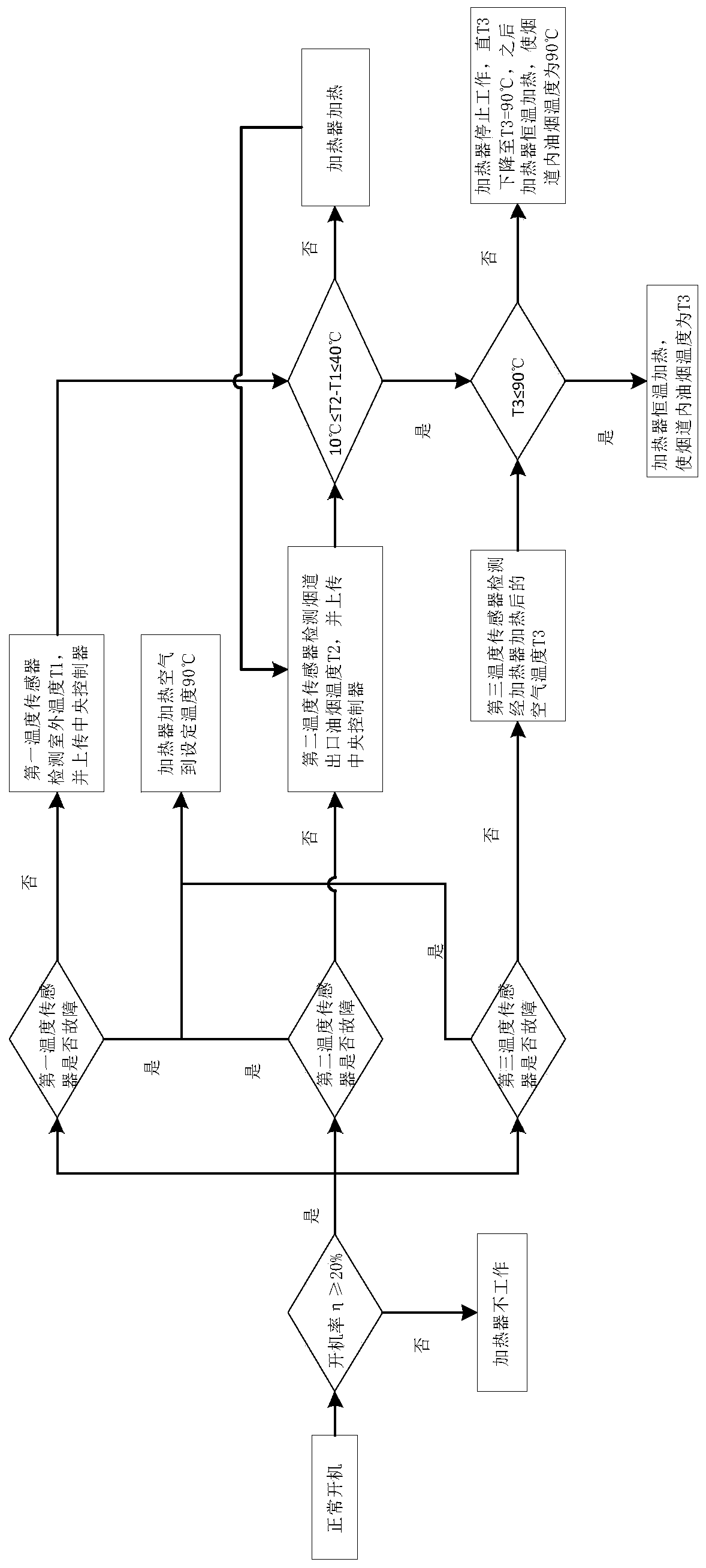

Smoke exhaust system for common flue of building and control method thereof

ActiveCN110274282AImprove the effect of hot pressingIncrease pressureDomestic stoves or rangesLighting and heating apparatusElectricityControl system

The invention relates to a smoke exhaust system for a common flue of a building. The system comprises a common flue and extractor hoods mounted in floors. An electric heating film is mounted on the inner wall of the common flue, a first temperature sensor for detecting the lampblack gas temperature of the flue is mounted in the common flue, and a second temperature sensor for detecting outdoor temperature is mounted on the roof. The smoke exhaust system also comprises an electric heating film control system and a master control system. The master control system can read the value of the second temperature sensor, the electric heating film control system can read the value of the first temperature sensor and the value of the second temperature sensor sent by the master control system, and can control an electric heating film according to a temperature difference value between the inner part of the common flue and the outdoor part. The smoke exhaust system has the advantages that the smoke exhaust system for the common flue of the building can change the temperature difference between the temperature of the lampblack gas in the flue and the outdoor environment by controlling the electric heating film, so that the hot pressing action of the flue is enhanced, the pressure distribution of the flue is enhanced, and the smoke exhaust capacity of the flue is improved.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Hot press molded melamine foam prepared by hot press molding and preparation method thereof

The present invention discloses a hot press molded melamine foam, and the melamine foam comprises, by weight, 100 parts of melamine resin, 1-10 parts of a surfactant, 5-40 parts of a foaming agent, 0-20 parts of an assistant, 5-20 parts of a catalyst, 0-30 parts of water, and 5-30 parts of hot pressing rubber powder particles. The invention also discloses a preparation method for the hot press molded melamine foam, and the method includes following steps: preparation of the melamine resin; preparation of a semi-finished product of the melamine foam: mixing raw materials uniformly to form a foaming solution, and subjecting the foaming solution to microwave action to obtain the semi-finished product; and preparation of a melamine foam finished product: spraying a liquid formed by dispersion of the hot pressing rubber powder particles during the moving of the semi-finished product of the melamine foam, and press-forming the dried foam by a thermo-compressor to obtain the melamine foam finished product. Reticular layer structures of the melamine foam are adhered together through melting of the hot pressing rubber powder particles in the method, and the melamine foam has good mechanical properties and flame retardance, and does not increase the formaldehyde content. The method is capable of continuous production.

Owner:成都玉龙超聚新材料有限公司

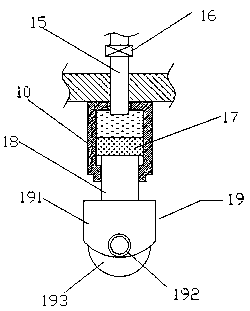

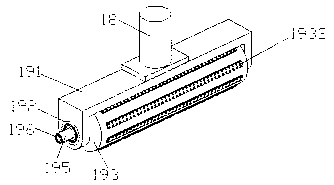

Portable Exhaust Valve Heat Press

ActiveCN105774044BReduce volumeImprove portabilityBag making operationsPaper-makingExhaust valveSolenoid valve

The invention relates to a convenient and portable exhaust valve heat press, which includes a control box, a base plate, an air pressure regulating device, a solenoid valve and an exhaust valve pressing device, and the base plate is provided with a connecting seat and two left and right curved arm plates , the connection seat is installed on the bottom plate, the left and right curved arm plates are respectively fixed on both sides of the connection seat in a parallel manner, and the control box, air pressure adjustment device, solenoid valve and exhaust valve pressing device are respectively fixed on the curved arm On the board, the bottom plate below the exhaust valve suppressing device is also provided with a valve body placement arm, one end of the valve body placement arm is connected with the connecting seat, and the other end is suspended, and there is a gap between the valve body placement arm and the bottom plate. The connection between the components of the present invention is tight, firm, and small in size, which improves portability and elastic deformation occurs between the valve body placement arm and the curved arm plate, so as to avoid head-to-head collision between the valve body placement arm and the die head of the exhaust valve pressing device "Contact, damage the mold head, improve the stability and service life of the exhaust valve heat press.

Owner:FOSHAN CITY SHUNDE DISTRICT HUAZHONG IND CO LTD

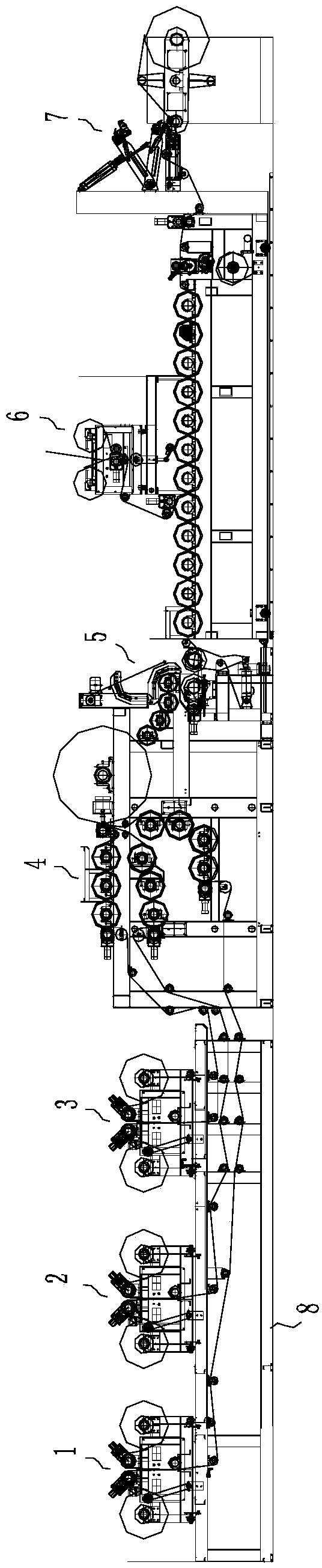

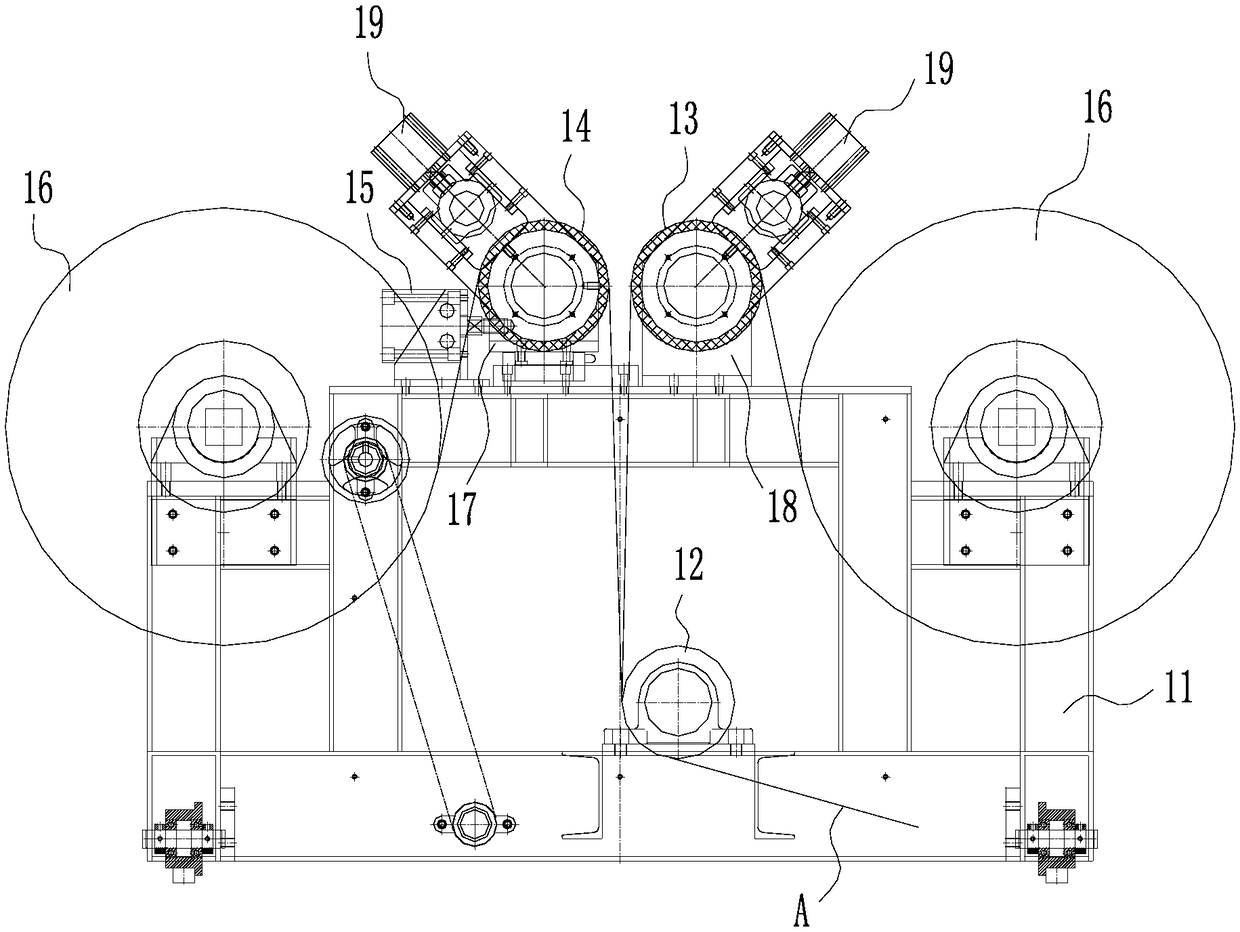

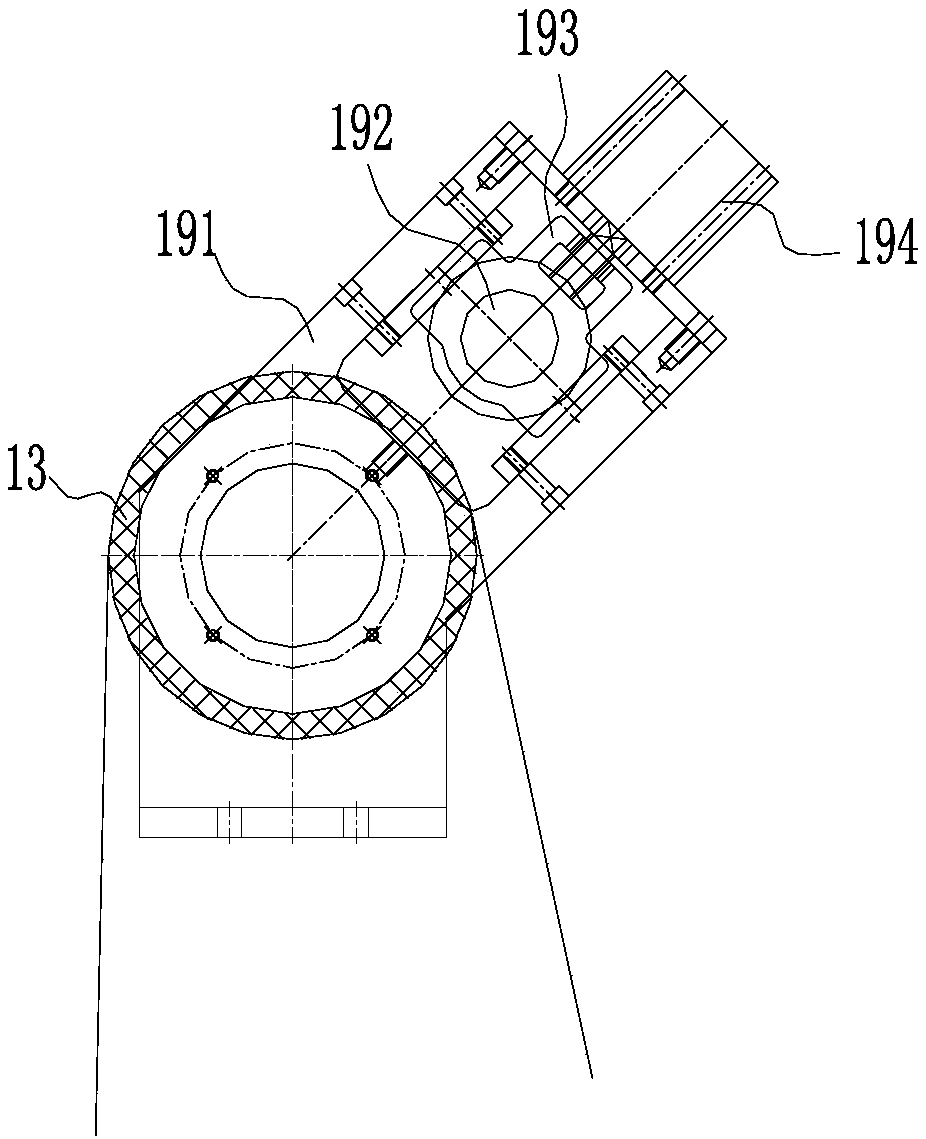

Multilayer film laminating machine

InactiveCN108861751AAdhere fullyEfficient removalLamination ancillary operationsLaminationComposite filmEngineering

The invention discloses a multilayer film laminating machine which comprises a first center unwinding machine, a second center unwinding machine, a third center unwinding machine, a primary laminatingdevice, an embossing device and a dual-station winding device, all of which are arranged on a rack in sequence. Films are output by the first center unwinding machine, the second center unwinding machine and the third center unwinding machine, various layers of films are subjected to primary pressing-laminating forming on the primary laminating device, the composite film is conveyed to the embossing device to be subjected to pattern hot pressing, and the finally-output composite film is wound on the winding device. According to the multilayer film laminating machine, through the primary laminating device, the multiple layers of films are subjected to primary laminating in the laminating device, bubbles are removed effectively, it is guaranteed that no gas exists in an interlayer, the various layers of films are fully laminated firmly, the laminating effect is improved, and the yield is increased.

Owner:佛山市高明正一机械设备有限公司

Corrugated board hot-pressing laminating machine

ActiveCN109591385AGood hot pressing effectEasy loadingMechanical working/deformationLaminationEngineeringHot press

The invention relates to the field of corrugated board hot-pressing devices, in particular to a corrugated board hot-pressing laminating machine. The corrugated board hot-pressing laminating machine comprises a fixed base, a feeding mechanism, a fixed shell, a cutting mechanism, a conveying mechanism, a hot-pressing mechanism, a lifting mechanism and driving mechanisms, wherein the feeding mechanism used for feeding is arranged on one side of the fixed shell on the fixed base, the hot-pressing mechanism used for performing hot pressing on a corrugated board so as the enable to the corrugated board is laminated is arranged in the fixed base and the fixed shell, the two driving mechanisms used for driving are connected to first corrugated rollers and second corrugated rollers correspondingly, the lifting mechanism used for driving the first corrugated rollers to ascend and descend is arranged on the fixed shell, the cutting mechanism used for cutting the corrugated board subjected to hotpressing is arranged in the fixed shell, and the conveying mechanism used for conveying the cut corrugated board is arranged on the fixed base. According to the corrugated board hot-pressing laminating machine, the distance and the hot-pressing force between the two corrugated rollers can be effectively controlled.

Owner:山东正夏自动化股份有限公司

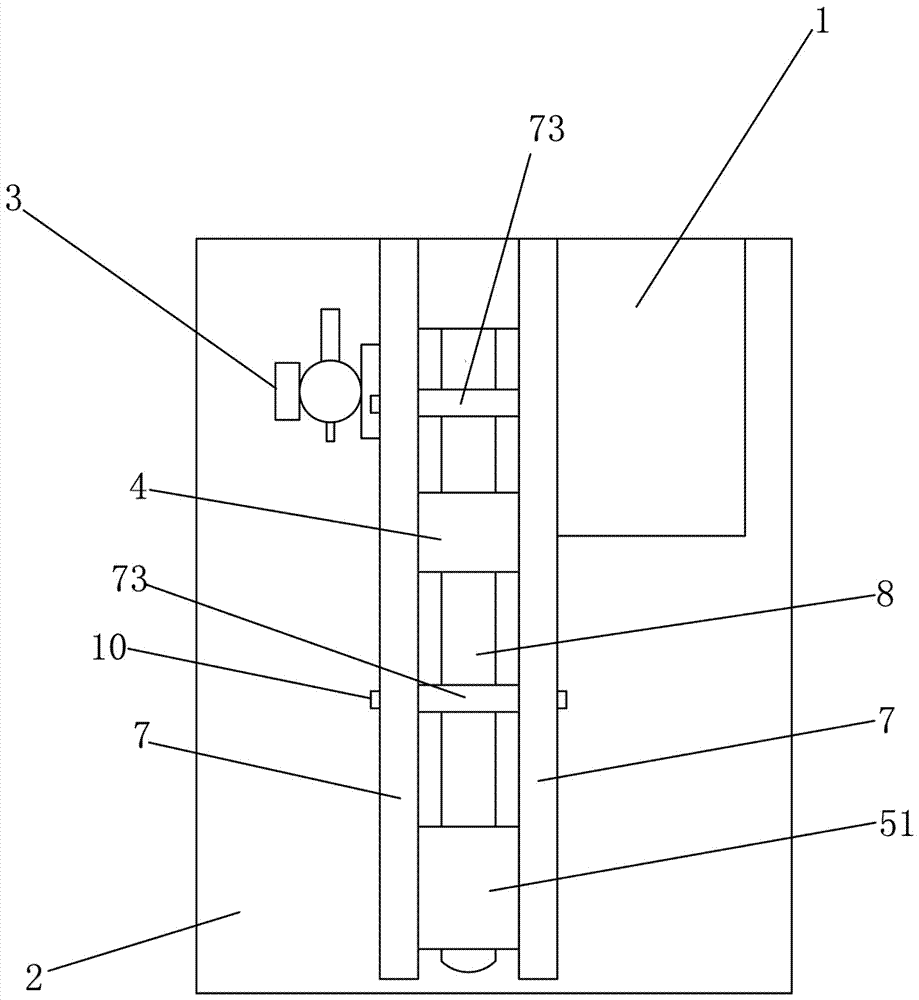

Building public flue smoke discharging system and control method thereof

ActiveCN110274284AImprove the effect of hot pressingIncrease pressureDomestic stoves or rangesLighting and heating apparatusControl systemTemperature difference

A building public flue smoke discharging system comprises a public flue and extractor hoods installed on various floors; a first temperature sensor used for detecting an outdoor temperature is installed on a roof; a heater, a second temperature sensor and a third temperature sensor are installed in the public flue; the second temperature sensor is used for detecting the lampblack temperature in the public flue; the third temperature sensor is used for detecting the temperature of gas after being heated by the heater in the public flue; a main control system reads the reading of the first temperature sensor; and a heater control system reads the reading of the second temperature sensor and the third temperature sensor and receives the reading, from the main control system, of the first temperature sensor, and thus can control the heater. The building public flue smoke discharging system has the beneficial effects that the building public flue smoke discharging system can change the temperature difference of the temperature of lampblack gas in the flue and the outdoor environment by controlling the heater, the flue heat pressure effect is enhanced, flue pressure distribution is improved, and the flue smoke discharging capacity is improved.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

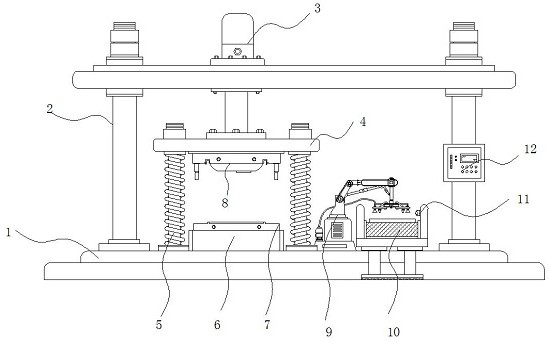

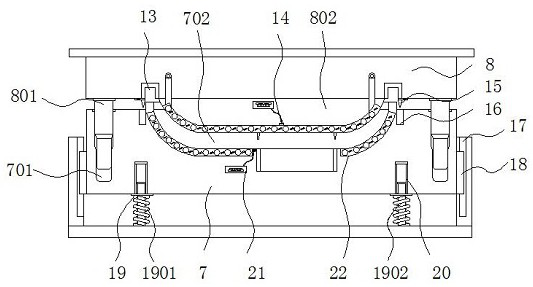

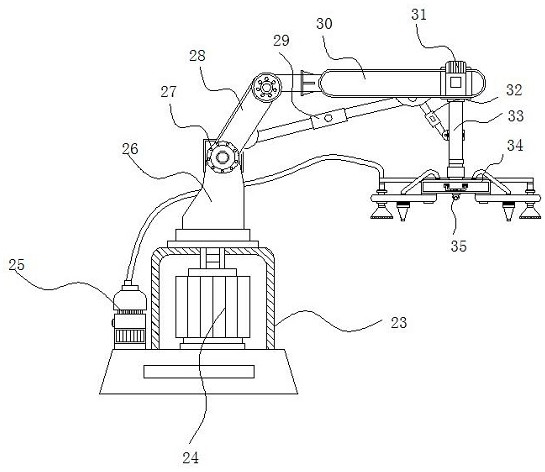

Automobile roof hot-press forming device with edge cutting function and automatic discharging function

InactiveCN112060552AEase of mass productionEasy to useDirt cleaningDomestic articlesHydraulic cylinderStructural engineering

The invention discloses an automobile roof hot-press forming device with an edge cutting function and an automatic discharging function. The automobile roof hot-press forming device specifically comprises a base, a lower die, an upper die, a transferring mechanism and a mounting arm, wherein a frame body is arranged at the top end of the base, and a control face plate is fixed to the middle position of one side of the frame body; and a hydraulic cylinder is arranged on the side, far away from the control face plate, of the top of the frame body, a pressing plate is arranged at the output end of the hydraulic cylinder, stamping guide columns penetrate through the four corners of the pressing plate, and the bottom ends of the stamping guide columns are connected with the base. According to the automobile roof hot-press forming device with the edge cutting function and the automatic discharging function, the transferring mechanism and a conveying belt are arranged, the transferring mechanism can suck materials to be hot-pressed through vacuum suckers and transfer the materials to be hot-pressed into a forming groove to achieve automatic feeding, formed automobile roofs can be automatically transferred back to the conveying belt to be conveyed out after hot pressing is completed, and manual carrying is not needed in the whole process, so that use is more convenient, and batch production of the automobile roofs is more convenient.

Owner:东莞市达盛机电设计有限公司

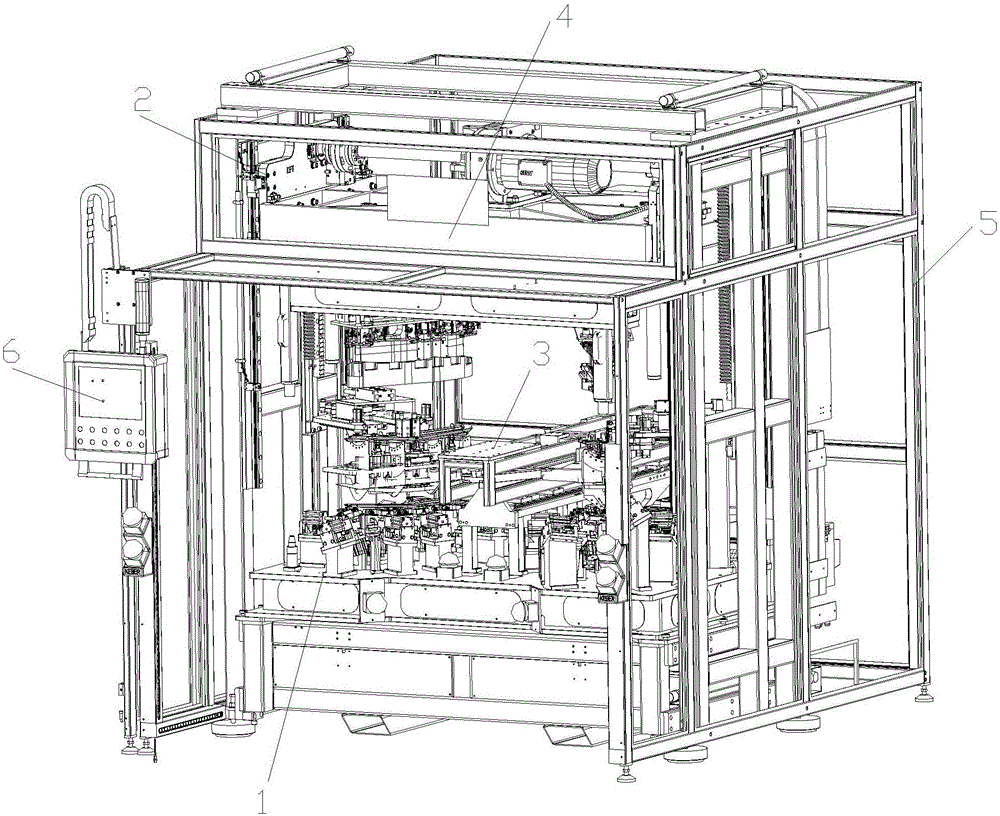

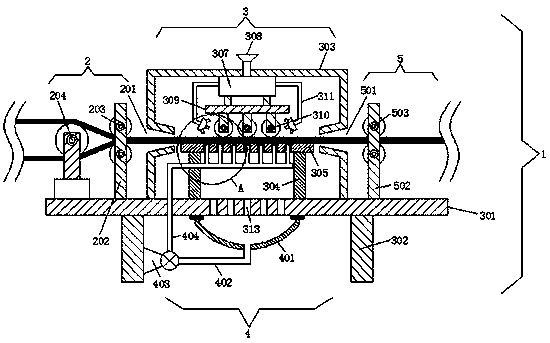

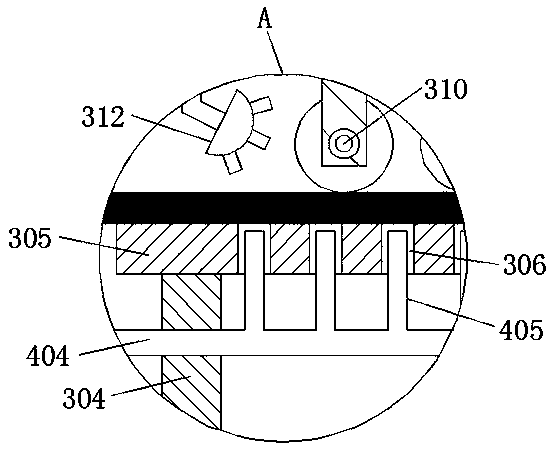

Intelligent hot press and hot pressing control method thereof

ActiveCN102729503AReduce defective rateImprove hot pressing performance and product qualityPress ramHot pressEngineering

The invention provides an intelligent hot press and a hot pressing control method thereof. The intelligent hot press comprises a rack, a control mechanism, a limiting mechanism, a locating and guiding mechanism, an upper workbench plate and a lower workbench plate, wherein the control mechanism is arranged on the rack and realizes segmental hot pressing control on a mold through a servo motor so as to form segmental hot pressing forming; the limiting mechanism is arranged on the rack and used for realizing limiting on the hot pressing position; the locating and guiding mechanism is fixed on the rack and used for realizing locating and guiding of a hot pressing route; the upper workbench plate is connected with the control mechanism and realizes downward pressing and backward pressing movement through the locating and guiding mechanism; and the lower workbench plate is fixedly arranged on the rack. According to the invention, segmental hot pressing control on the mold is realized through the servo motor of the control mechanism so as to form flexible and controllable segmental hot pressing forming, thus enabling hot-pressed products to have no breakage, greatly reducing the rejection ratio, improving the product quality and prolonging the service life.

Owner:SHENZHEN HOCHUEN TECH

Trademark leather and preparation method thereof

InactiveCN103061158AGood hot pressing effectGood tensile strength and elongationSynthetic resin layered productsTextiles and paperDimethyl formamideWax

The invention belongs to the technical field of synthetic leather, and particularly relates to trademark leather and a preparation method thereof. The trademark leather provided by the invention comprises a top layer, a discoloration layer and a bonding layer, wherein the discoloration layer is prepared by the following raw materials in part by weight: 20 to 25 parts of aliphatic dry PU (Polyurethane) resin, 20 to 30 parts of DMF (Dimethyl Formamide), 17 to 20 parts of acetic ether, 3 to 5 parts of high-modulus PU resin particles, 5 to 8 parts of gaseous phase silica and 30 to 40 parts of polypropylene wax powder. The preparation method of the trademark leather is as follows: complying with the traditional dry method process, i.e., performing process procedures of coating a top layer, drying, coating a discoloration layer, drying, coating a bonding layer and drying; and the preparation method is characterized in that through adjusting the parameter setting of each coating, the trademark leather with low cost, clear patterns after rolling, obvious difference with base color, scratch resistance and abrasion resistance can be prepared, and can be used for stamping a branch LOGO, a character and a pattern and the like.

Owner:HANGZHOU RAINBOW PIGMENT CO LTD

Abrasion-resistant S-shaped grinding wheel and hot-press forming technology thereof

ActiveCN105945741AImprove performanceReasonable ratioGrinding carriagesTransportation and packagingAlloyCopper

The invention discloses an abrasion-resistant S-shaped grinding wheel and a hot-press forming technology thereof. The abrasion-resistant S-shaped grinding wheel comprises the following main materials in volume fraction: 12 to 15% of diamond, 20 to 25% of copper, 40 to 45% of iron, 3 to 8% of tin, 5 to 8% of nickel, 5 to 8% of cobalt and 3 to 5% of auxiliary material alloy powder. The continuous tooth S-shaped grinding wheel is produced through the steps of batching, premixing, total mixing, cold pressing performing, hot pressing sintering, primary cooling, high frequency welding, secondary cooling, surface treatment, paint spraying, edging, and the like. According to the S-shaped grinding wheel produced through the formula and the technology, the strength is improved, the abrasion resistance is improved as well, the service life is prolonged in the actual use process, the production cost is greatly reduced, the resources are saved, and the technology is environment-friendly, sanitary and safe in the production process.

Owner:JIANGSU SUPER PEAK TOOLS CO LTD

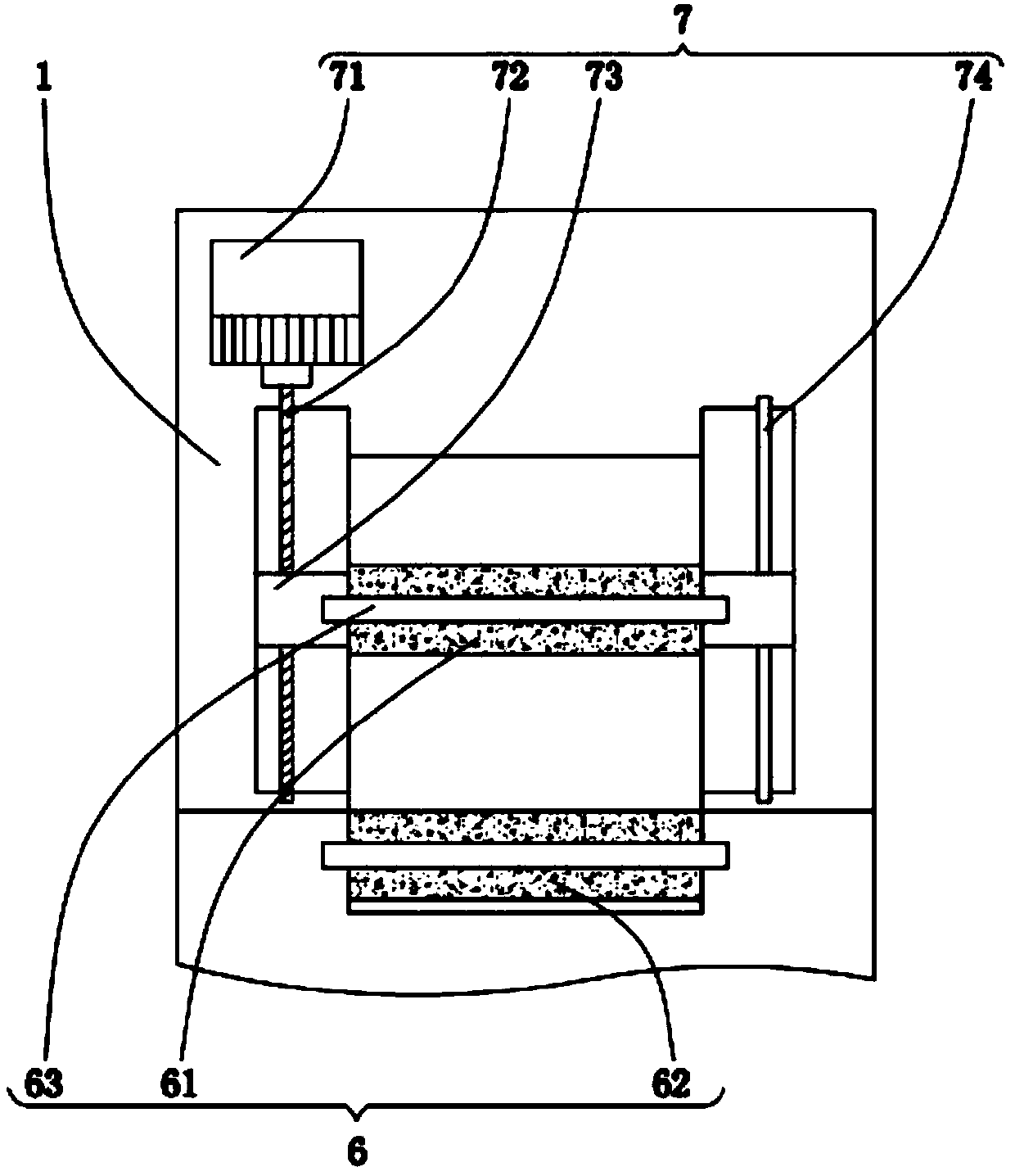

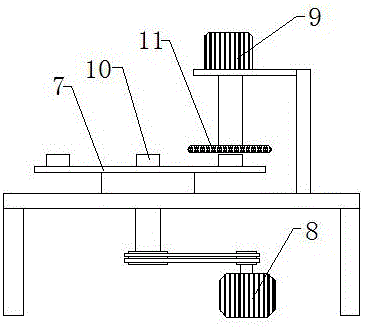

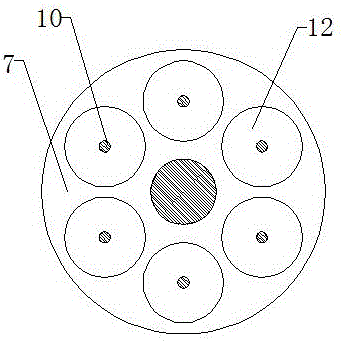

Hot pressing setting device and hot pressing setting method for ribbon fabric

InactiveCN110820191AEasy ironingImprove the effect of hot pressingHeating/cooling textile fabricsTextile treatment by spraying/projectingEngineeringMechanical engineering

The invention relates to a hot pressing setting device and hot pressing setting method for ribbon fabric. The hot pressing setting device for ribbon fabric comprises a bottom plate, a top plate, a hotsteaming device, leveling mechanisms, a pressing-down mechanism and an ironing mechanism; the top plate is arranged on a fixed surface, such as a wall surface, and the hot steaming device is arrangedabove the bottom plate; the bottom end of the hot steaming device is arranged in the middle of the top end of the bottom plate; the leveling mechanisms are symmetrically arranged on the left side andright side of the hot steaming device; the bottoms of the leveling mechanisms are mounted on the top end of the bottom plate; the top end of the pressing-down mechanism is mounted in the middle of the bottom end of the top plate and arranged on the upper left side of the bottom plate; the ironing mechanism is positioned below the pressing-down mechanism; the top end of the ironing mechanism is fitted on the bottom end of the pressing-down mechanism. The invention can solve the problems that, for instance, a ribbon cane not fully wetted by manual spraying wetting, and an iron easily scorches the part of the ribbon not fully wetted, so that product quality of the ribbon is affected, and that manual ironing of the ribbon has low production efficiency, so that the manual ironing is unable toadapt to large-scale production.

Owner:汪永超

Making process for lace bras

ActiveCN105533819ASimple processLow costFilm/foil adhesivesPolyureas/polyurethane adhesivesHot pressing

The invention relates to the technical field of female underwear and bras, in particular to a making process for lace bras. The method mainly comprises the following steps of A, selecting and making cup body molding materials and lace molding materials, which are in required shapes, and correspondingly tailoring stickers of which the shapes are consistent with those of the lace molding materials; B, adhering the lace molding materials to the corresponding positions of the outer surfaces of the cup body molding materials by virtue of the stickers, and performing hot pre-pressing fixation for 1 to 2 seconds under hot pre-pressing pressure of 1 to 2Pa and temperature of 115 to 120 DEG C; C, performing hot pressing forming on the hot pre-pressed cup body molding materials for 8 to 10 seconds to obtain lace cup bodies under hot pressing pressure of 4 to 6Pa and temperature of 125 to 130 DEG C; D, sewing the formed lace cup bodies into the lace bras. The method has the characteristics of simple process, low making cost, no reflection of adhesive films and high comfort degree and aesthetics.

Owner:HONGJI UNDERWEAR CO LTD

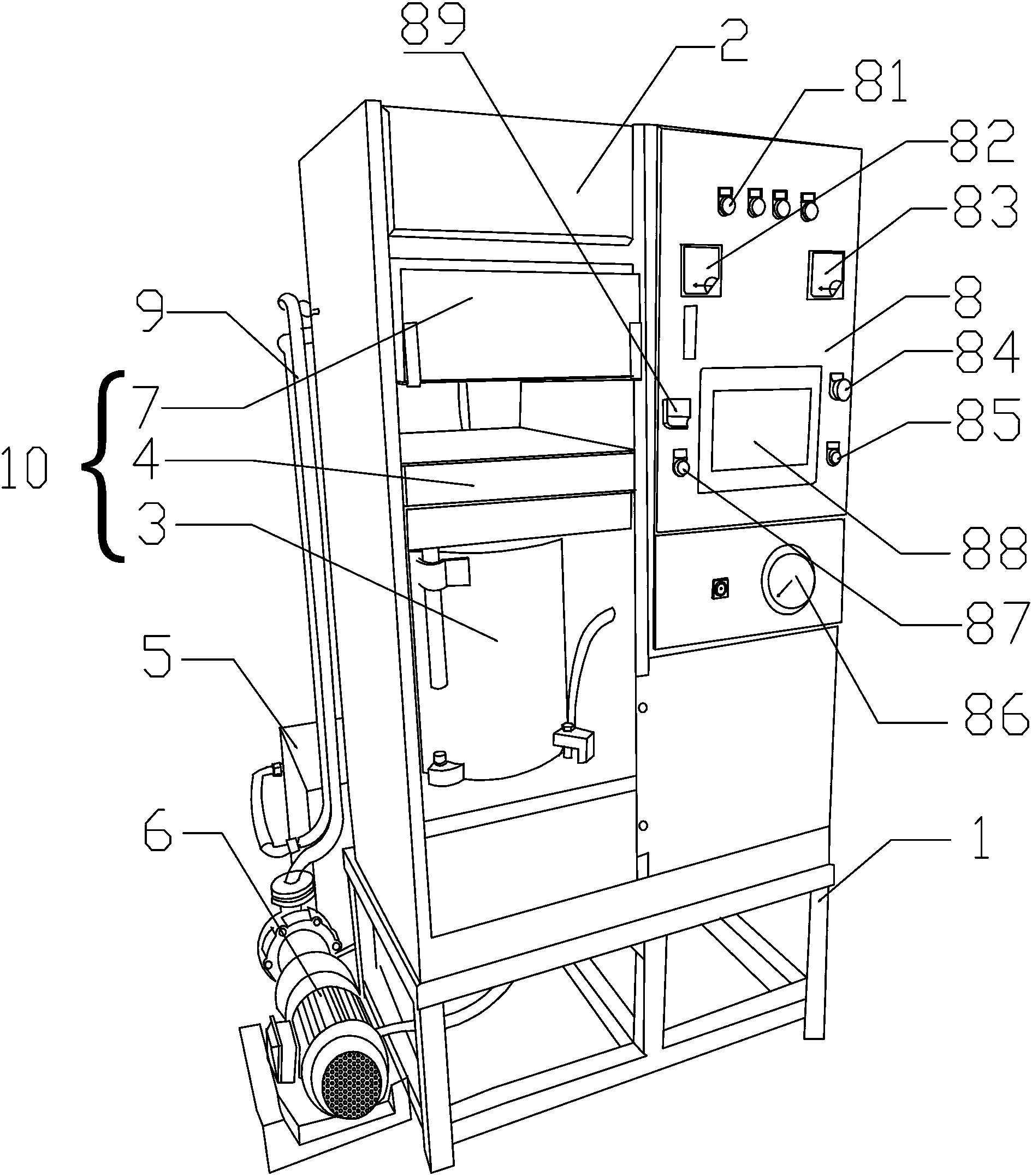

Experiment hot press

ActiveCN104044190AReduce manual operationsSimple controlPlywood pressesPreparing sample for investigationElectric heatingElectricity

The invention discloses an experiment hot press. The experiment hot press comprises a rack, a machine body, a lubricating oil circulation pump and an electric heating box, wherein the lubricating oil circulation pump is arranged on one side of the rack; the electric heating box is arranged on the back side of the rack; the machine body is arranged on the rack; the electric heating box is cyclically connected with the lubricating oil circulation pump by an oil pipe; a hot pressing mechanism is arranged on one side of the machine body; an electric control box is arranged on the other side of the machine body; the hot pressing mechanism also comprises a hot pressing plate, a workbench and an oil cylinder jack; the oil cylinder jack is arranged on the lower end of one side of the machine body; the oil cylinder jack is used for supporting the workbench by an oil jack; the hot pressing plate is arranged on the upper end of the machine body corresponding to the workbench; the lubricating oil circulation pump is used for conveying oil to the hot pressing plate by the oil pipe; the electric control box is respectively connected with the lubricating oil circulation pump, the electric heating box and the oil cylinder jack. According to the experiment hot press, the experiment condition of an experiment can be flexibly controlled, the consumed materials, the consumed manpower and the consumed time of the experiment are reduced, and the experiment hot press has the characteristics that the structure is simple, the operation is convenient, and the safety is high.

Owner:FOSHAN SANSHUI YUSN DECORATION IND

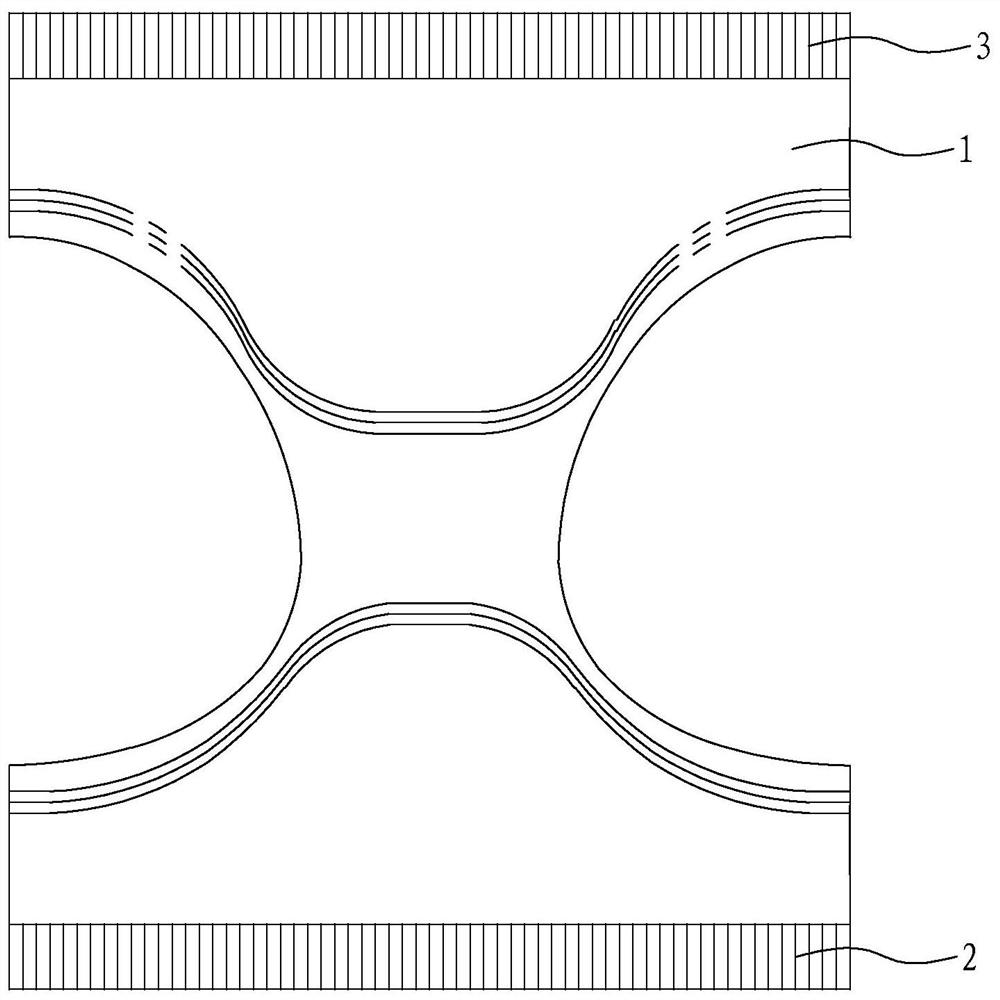

Production method for chamfering lock floor

ActiveCN104912297APrecise rounding processingImplement roundingLamination ancillary operationsLaminationEngineeringUV coating

The invention discloses a production method for a chamfering lock floor. The production method is characterized in that the production method comprises following steps: a, laying up all layers forming the floor in order; b, utilizing a chamfering template to the floor laid well in the step a to carry out chamfering operation in a hot-pressing state; c, adopting a rubber roll to carry out UV coating and curing operation to the surface of the floor obtained in the step b; d, slotting and mortising the floor obtained in the step c in order to obtain a finished product. The edge of the chamfering template is provided with a circular arc chamfer. The production method for the chamfering lock floor has following beneficial effects: with no chamfering tool at high production cost required, the lock floor which enables a wearing layer to be thinner has a larger and wider chamfering angle so that product quality is improved.

Owner:ZHEJIANG KINGDOM NEW MATERIAL GRP CO LTD

Multi-layer composite non-woven fabric processing method

ActiveCN108973300AImprove heating efficiencyImprove the effect of hot pressingLaminationLamination apparatusEngineeringNonwoven fabric

The invention discloses a multi-layer composite non-woven fabric processing method, comprising a processing device, a fabric feeding mechanism, a fabric feeding opening, a first wheel frame, first limiting wheels, a fabric feeding roller, a hot pressing mechanism, a bottom plate, support legs, a hot pressing bin, brackets, a hot press table, steam guide holes, a steam generator, a water supply pipe, a mounting frame, hot press rollers, a steam pipe, steam nozzles, ventilation holes, a circulation mechanism, an exhaust hood, an exhaust pipe, an exhaust machine, a steam guide pipe, branch pipes,a cloth discharge mechanism, a cloth outlet, a second wheel frame and second limiting wheels. A technical problem solved by the multi-layer composite non-woven fabric processing method is to overcomethe defects of low processing efficiency and poor effect of multi-layer non-woven fabric at the prior art. The multi-layer composite non-woven fabric processing method has the characteristics of simple operation, high processing efficiency, good effect, and energy conservation.

Owner:龙岩东腾再生资源科技有限公司

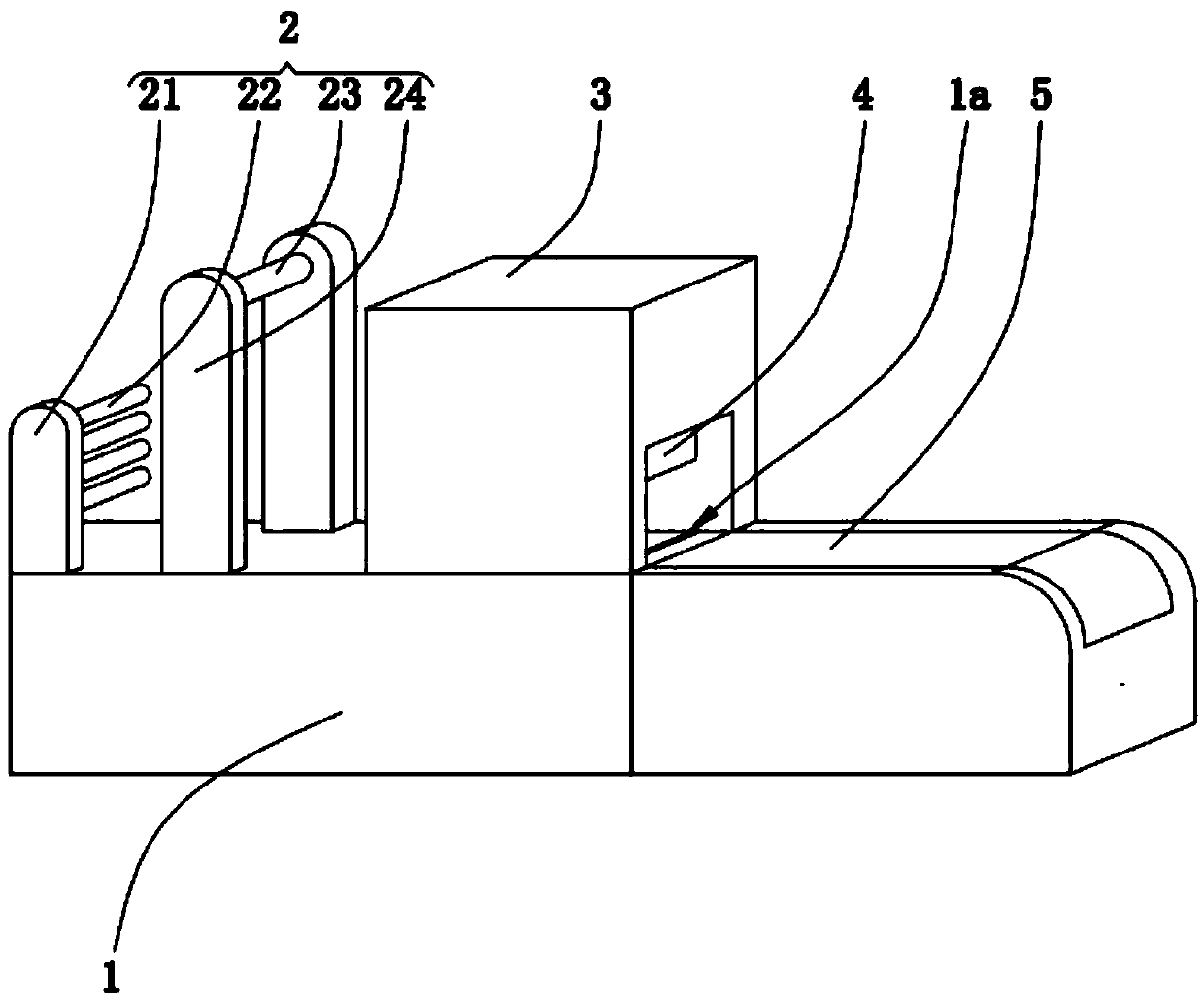

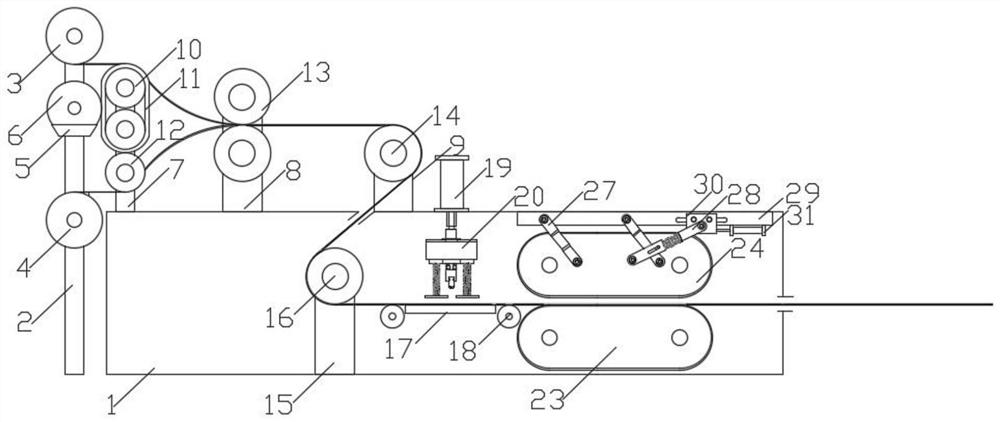

Breathable adult pull-ups and production process thereof

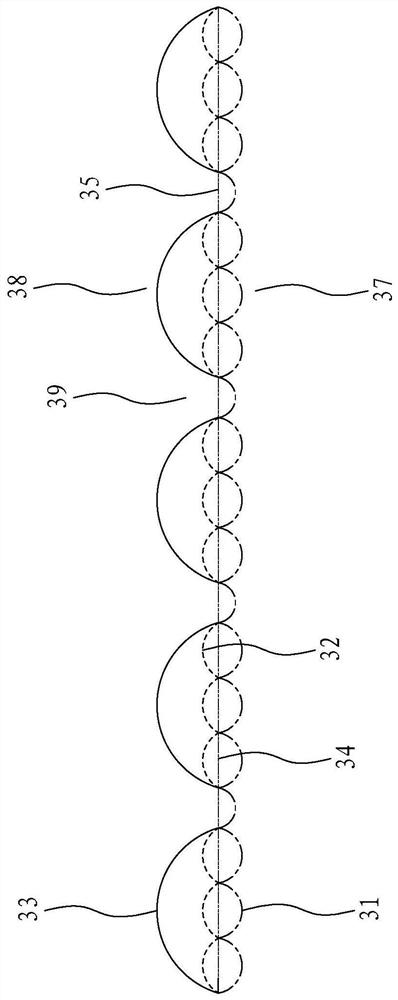

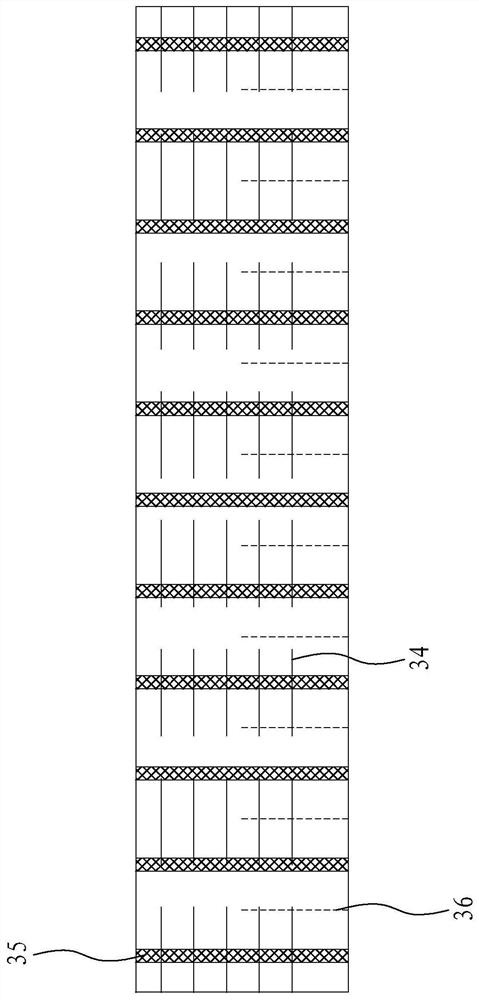

ActiveCN111821105ATightly boundRelieve tensionLaminationLamination apparatusMechanical engineeringWaist

The invention relates to the field of disposable sanitary products, in particular to breathable adult pull-ups. The breathable adult pull-ups comprise a body, a front waist and a back waist, the backwaist comprising an outer layer, a middle layer, an inner layer and elastic rubber strings, the elastic rubber strings are clamped between the outer layer and the middle layer, the elastic rubber strings are fastened to the outer layer and the middle layer, the lower end of the inner layer is lower than the lower end of the elastic rubber strings, and the inner layer is compounded with the middlelayer, a plurality of hot pressing parts are formed and extend in the vertical direction, when the elastic rubber strings contract, the outer layer and the middle layer form outer folding bulges withthe same folding state, the inner layer forms inner folding bulges, the width of the inner folding bulges in the transverse direction covers at least two outer folding bulges, and a ventilation channel is formed between two adjacent inner folding bulges. The breathable adult pull-ups solve the technical problems that existing pull-ups cause tightening marks at waist parts and have poor breathability. At the same time, a production process of the breathable adult pull-ups is provided.

Owner:FUJIAN HENGAN HLDG CO LTD +2

Medical environment-friendly degradable paper-plastic bag and preparation method thereof

InactiveCN111849037AGuaranteed waterproof performanceHigh affinityHollow articlesAdhesive gluePlastic bag

The invention discloses a medical environment-friendly degradable paper-plastic bag and a preparation method thereof. According to hot-pressing equipment, before hot pressing, glue is uniformly smeared on the surfaces of a film and kraft paper through an adhesive tape smearing roller and a glue smearing roller correspondingly, the glue on the bonding surface is uniform and sufficient when the filmand the kraft paper are hot-pressed, the hot pressing effect of the prepared paper-plastic bag is better; two pressing plates are designed, according to the paper-plastic bag cutting device, effective pressing and fixing are conducted when paper-plastic bags are cut, the situation that the cutting effect is affected due to wrinkles of the paper-plastic bags in the cutting process is avoided, meanwhile, through the design of the two conveying belts with the adjustable distance, the paper-plastic bags with different thicknesses can be conveyed, meanwhile, the paper-plastic bags are flatly pressed in the conveying process, and the flatness of the paper-plastic bags is guaranteed.

Owner:TONGCHENG ZHONGHUI PLASTIC IND CO LTD

Steel belt hot press for artificial board hot pressing machining

ActiveCN111300561AQuality improvementPrevent escapePlywood pressesVeneer pressesThick plateElectric machinery

The invention relates to the technical field of artificial board machining, in particular to a steel belt hot press for artificial board hot pressing machining. The steel belt hot press comprises a machine box, an upper steel belt driving assembly and a lower steel belt driving assembly, and is characterized in that the upper steel belt driving assembly and the lower steel belt driving assembly are symmetrically arranged at the upper end and lower end of the machine box, each of the upper steel belt driving assembly and the lower steel belt driving assembly comprises a driving roller, a drivenroller, a tensioning roller, a driving motor and a steel belt, the two driving rollers are arranged at the left end of the machine box, the two driven rollers are arranged at the right end of the machine box, the tensioning rollers are arranged at the right ends of the driving rollers, the steel belts are arranged between the driving rollers and the driven rollers, and a hot pressing gap is formed between the upper steel belt driving assembly and the lower steel belt driving assembly. According to the steel belt hot press, the quality problem caused by overlarge pressure when an existing hotpress conducts hot pressing on a thick plate can be effectively solved, and meanwhile the problem caused by steel belt gluing in the hot pressing process can be effectively solved.

Owner:铜陵万华禾香板业有限公司

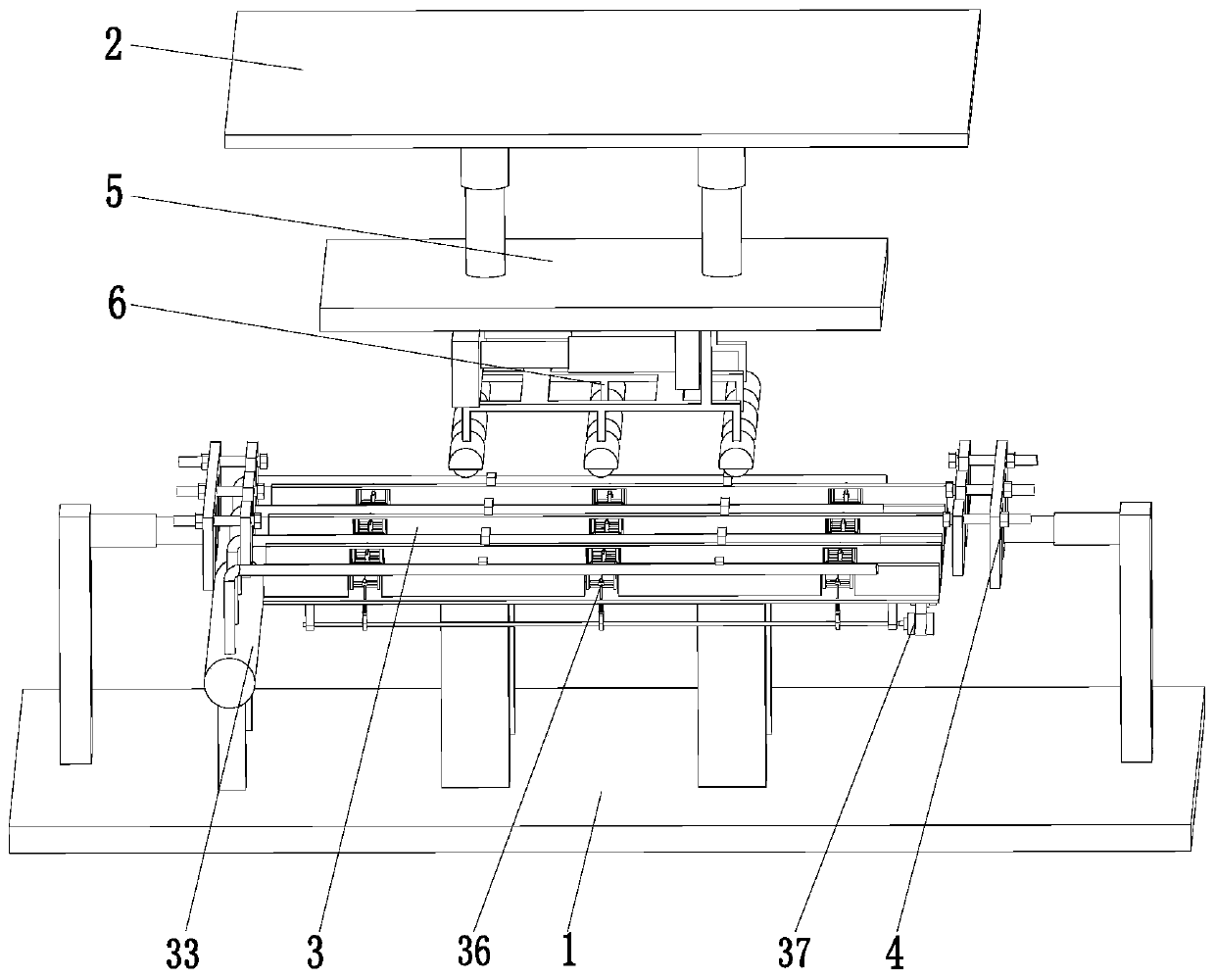

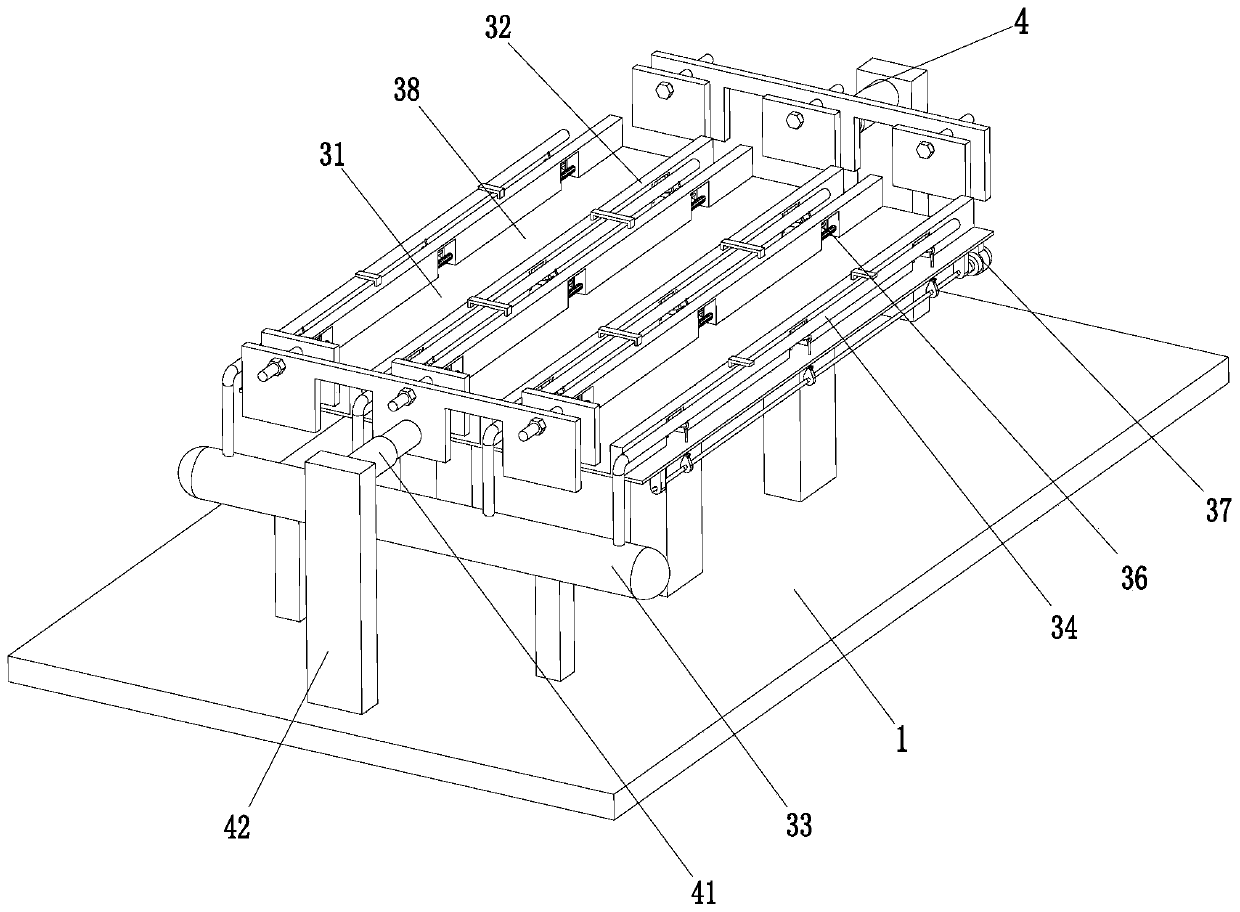

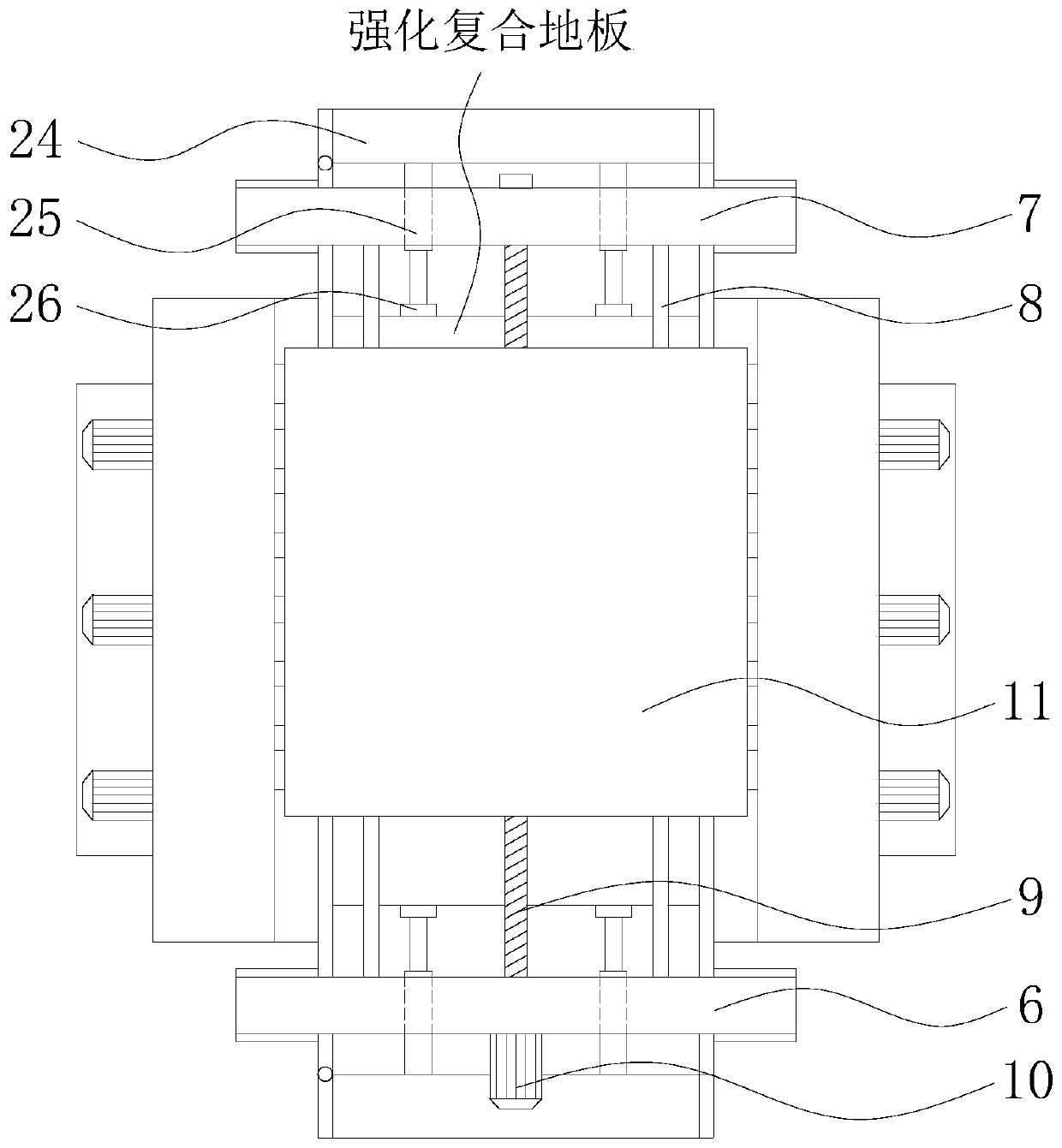

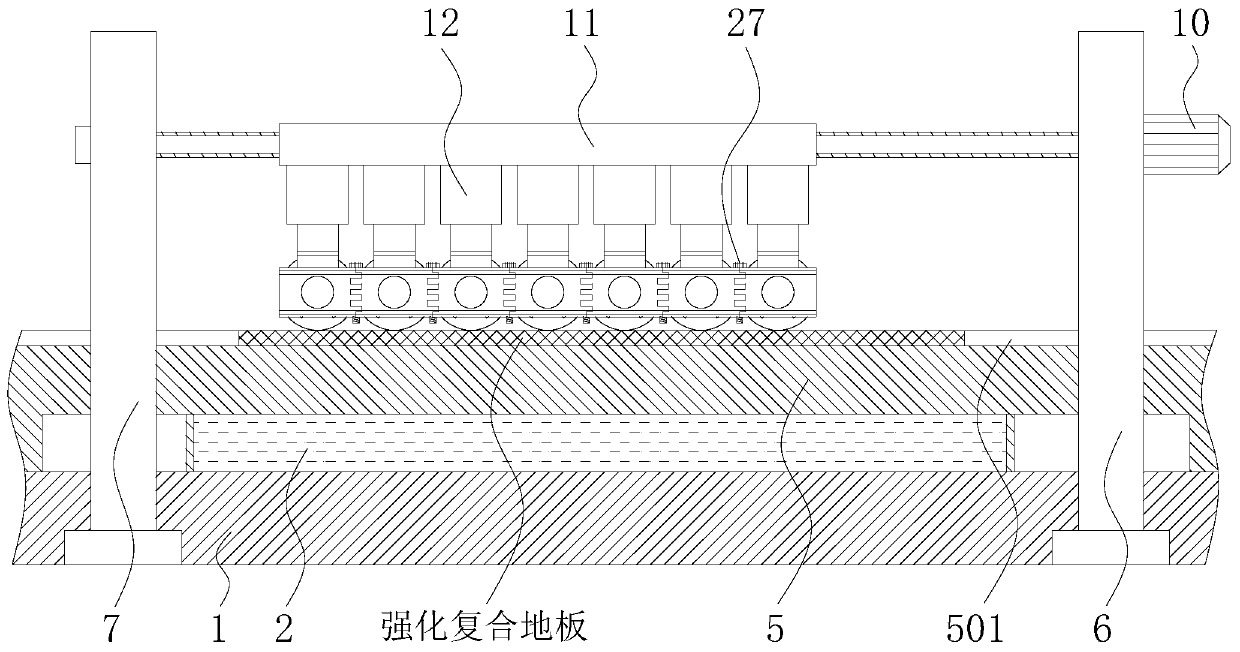

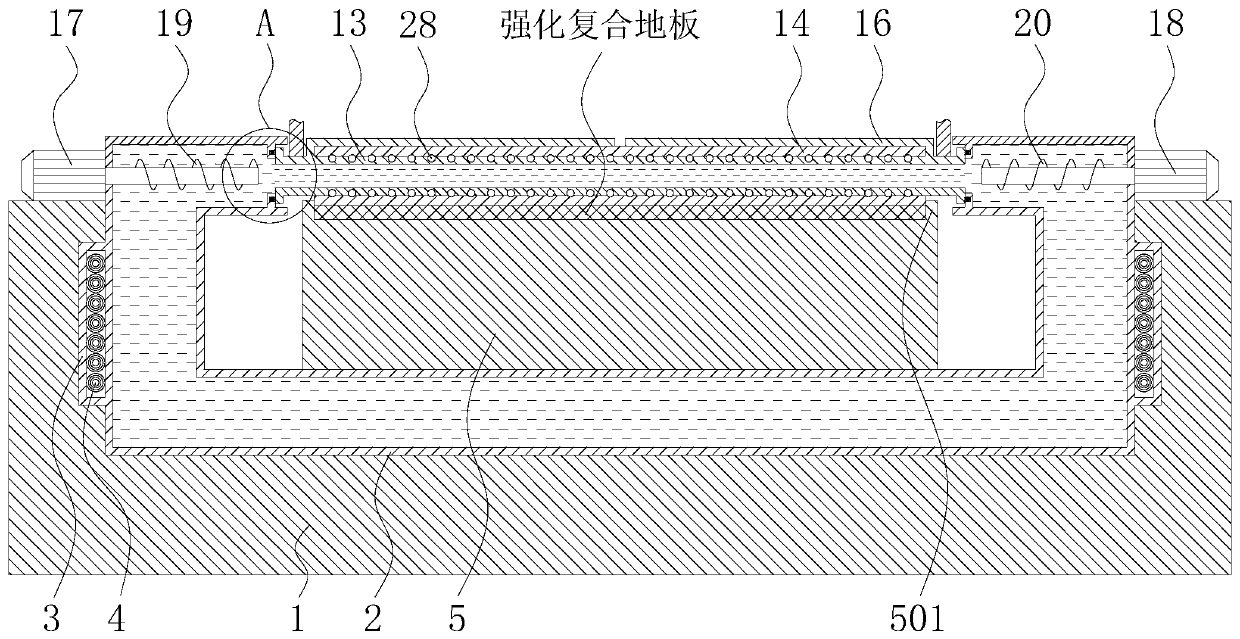

Reinforced composite floor hot press

InactiveCN110614682AImprove the effect of hot pressingUniform surface temperature distributionPlywood pressesVeneer pressesFuel tankEngineering

The invention belongs to the technical field of floor manufacturing equipment, and particularly relates to a reinforced composite floor hot press. The reinforced composite floor hot press comprises abase, an oil storage tank is fixedly installed on the base, and through holes are formed in the two end surfaces of the oil storage tank. A pressure-bearing platform is fixedly installed on the base,and a guiding rail is arranged on the pressure-bearing platform. A first bracket and a second bracket are fixedly arranged on the base, a limiting rod and a lead screw are connected between the firstbracket and the second bracket, and an installation plate parallel to the top surface of the pressure-bearing platform is matched with the lead screw in a threaded mode. A first air cylinder is installed on the bottom surface of the installation plate, the end part of a piston rod of the air cylinder is clamped to the two ends of a hot oil pipe, and a pressing roller is rotatably matched with theouter side wall of the hot oil pipe. The two ends of the hot oil pipe are fixedly connected with a sealing plate mutually matched with the end surface, and an opening with the same size as the longitudinal section of the hot oil pipe is formed in the middle part of the sealing plate. According to the reinforced composite floor hot press, a hot pressing roller is adopted to replace a traditional hot pressing plate to conduct the hot pressing on the reinforced composite floor, and a better hot pressing effect is achieved.

Owner:上海军裕实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com