Experiment hot press

A technology of a hot press and a hot press mechanism, applied in the field of sheet metal presses, can solve the problems of difficult and complicated setting of conditions, lack of sheet metal presses, and inability to set, and achieves the effects of simple structure, strong flexibility, and convenient movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the object, technical solution and effect of the present invention more clear and definite, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

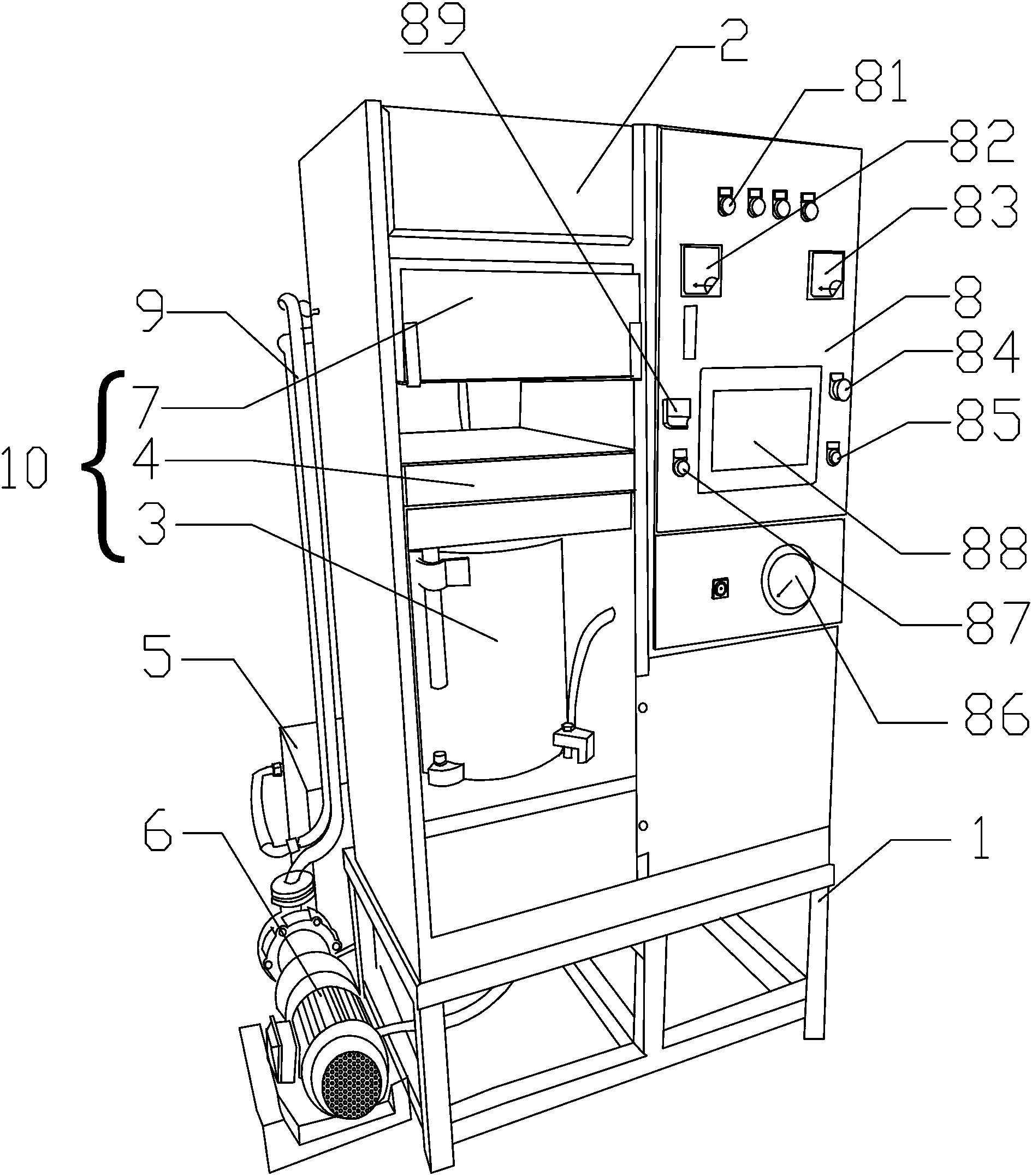

[0020] As shown in 1, the present invention discloses an experimental hot press comprising: a frame 1, a body 2, an electric heating box 5 and a lubricating oil circulation pump 6; wherein, the body 2 is placed on the frame 1, and the The electric heating box 5 and the lubricating oil circulating pump 6 are respectively arranged on the rear side of the frame 1 and the lower end of one side of the frame 1, and the body 2 also includes a heat press mechanism 10 and an electric control box 8; The electric control box 8 is connected to the hot pressing mechanism 10, the electric heating box 5 and the lubricating oil circulation pump 6 through cables; The electric control box 8 described above is installed on the other side of the body 2, occupyi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com