Hot-press molded protective film with shinning and antistatic effects and preparation method thereof

A thermoforming and antistatic technology, which is applied to chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems of easy edge bending, high price, high manufacturing cost, etc., to ensure that the product Moldability, low cost of PET, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0077] Antistatic agent: AS-5 from Guangzhou Zhenke Technology Co., Ltd.;

[0078] Substrate: Toray's 50μm and 100μm PET substrates;

[0079] Glitter powder: golden glitter powder from Shantou Guansheng Plastic Co., Ltd.;

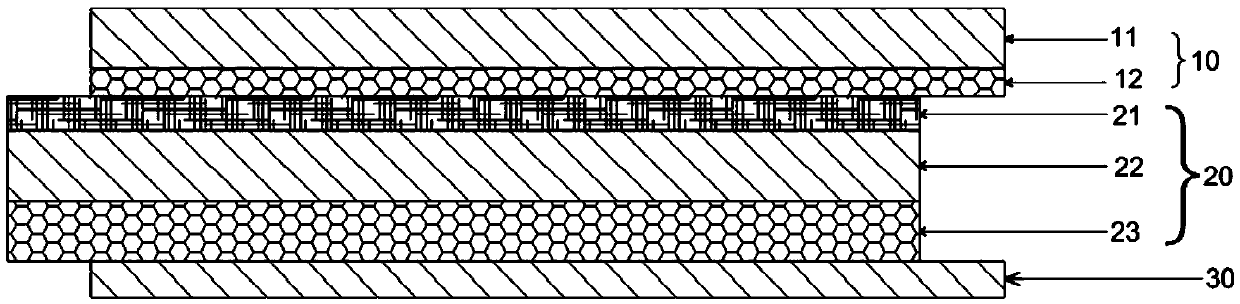

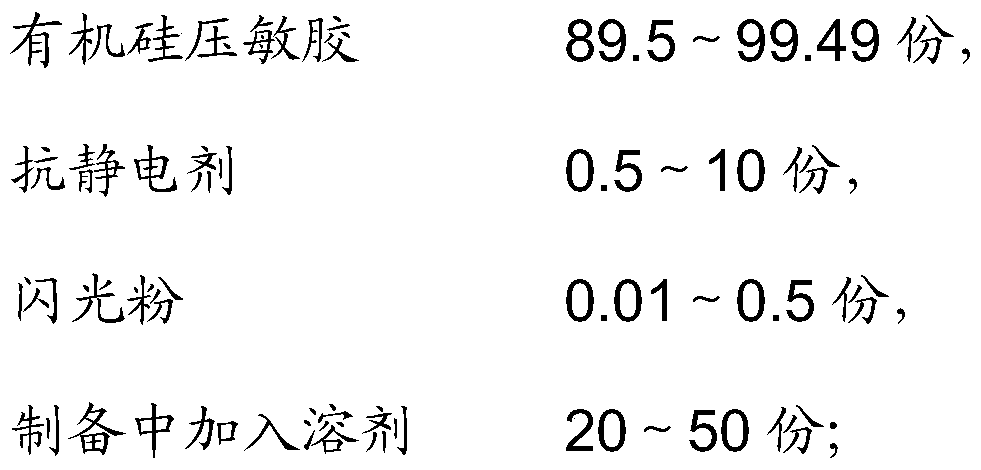

[0080] 5% by weight of antistatic agent AS-5 was added to the UV-type acrylic resin glue, and it was coated on the substrate A 22 by a micro-gravure roller. First bake at 80 for 60s, and then completely cure with UV lamp, the energy of UV lamp is 400mJ / cm2. Wherein the thickness of the UV hardening layer 21 is 5±1 μm, the thickness of the A substrate 22 is 100 μm, the haze is 0, and the light transmittance is 94%;

[0081] Add 1‰ golden glitter powder to the silicone pressure-sensitive adhesive, filter it through a 20μm filter element and a 5μm filter element, and then apply the glue on the other side of the A substrate 22 with a scraper, at 200°C Dry for 2 minutes, and cover with a release film as the release layer 30 to obtain a 2-layer composite film....

Embodiment approach 2

[0085] Antistatic agent: AC-1203 from Juli Chemical;

[0086] Substrate: Toray's 50μm and 100μm PET substrates;

[0087] Flash powder: pearlescent flash powder from Shantou Guansheng Plastic Co., Ltd.;

[0088] Apply the UV-type acrylic resin glue on the substrate A 22 through a micro gravure roller, bake it at 100°C for 45s, and then completely cure it with a UV lamp whose energy is 400mJ / cm2. Wherein the thickness of the UV hardening layer 21 is 7±1 μm, the thickness of the A substrate 22 is 100 μm, the haze is 0, and the light transmittance is 94%;

[0089] Add 5 / 10,000 pearlescent flash powder and 1% antistatic agent to the silicone pressure-sensitive adhesive, filter through two 5μm filter elements, and then apply the glue to the other side of the substrate A 22 with a scraper One side was dried at 200° C. for 2 minutes, and covered with a release film as the release layer 30 to obtain a two-layer composite film. Wherein the thickness of the adhesive layer 23 of A is 3...

Embodiment approach 3

[0093] Antistatic agent: AC-1203 from Juli Chemical;

[0094] Substrate: Toray's 50μm and 100μm PET substrates;

[0095] Flash powder: purple and silver flash powder from Shantou Guansheng Plastic Co., Ltd.;

[0096] 2% by weight of antistatic agent AC-1203 was added to the UV-type acrylic resin glue, and it was coated on the substrate A 22 by an anilox roller. First bake at 100°C for 45s, and then completely cure with UV lamp, the energy of UV lamp is 400mJ / cm2. Wherein the thickness of the UV curable layer 21 is 8±1 μm, the thickness of the A substrate 22 is 100 μm, the haze is 0, and the light transmittance is 94%;

[0097]Add 3 / 10000 weight ratio of silver, purple flash powder and 3% antistatic agent to the silicone pressure-sensitive adhesive, filter through a 20μm filter element and a 3μm filter element, and then apply the glue with a scraper On the other side of the substrate A 22, dry at 200° C. for 2 minutes, and cover with a release film as the release layer 30 to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com