Steel belt hot press for artificial board hot pressing machining

A technology of wood-based panels and hot presses, which is applied in the direction of veneer presses, plywood presses, presses, etc., and can solve the problems of adhesive pollution on the hot-pressed steel belts of wood-based panels and the unsuitability of steel belt hot presses, etc. , to avoid corner cracking, good hot pressing effect, and improve the quality of the plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

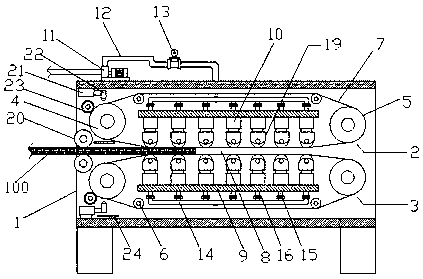

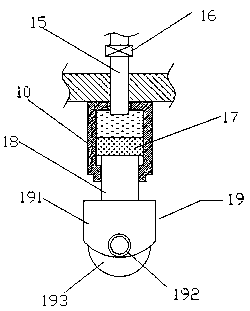

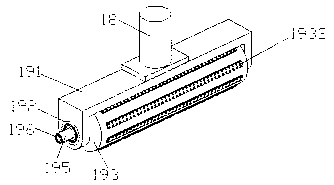

[0029]Embodiment 1 introduces a steel strip hot press for hot pressing of wood-based panels, the main structure includes a cabinet 1, an upper steel strip drive assembly 2, and a lower steel strip drive assembly 3, wherein the upper The belt drive assembly 3 is symmetrically arranged on the upper and lower ends of the cabinet 1, and the upper steel belt drive assembly 2 and the lower steel belt drive assembly 3 are composed of the same assembly, including a driving roller 4, a driven roller 5, a tension roller 6, Drive motor (not shown in the figure) and steel belt 7, wherein two driving rollers 4 are arranged on the left end of cabinet 1, and drive motor is arranged on the outer side of cabinet 1, and the output shaft of its drive motor stretches in the cabinet 1 and The driving rollers 4 are connected, and a pair of guide rollers 20 are arranged on the left side of the driving roller 4 on the cabinet 1, the two driven rollers 4 are arranged on the right end of the cabinet 1, ...

Embodiment 2

[0033] Embodiment 2 is a further improvement based on the basic solution of Embodiment 1 in order to prevent the surface of the steel strip from sticking to the hot melt adhesive. Its improvement points are: a release agent spraying device is provided on the chassis 1 above the upper steel belt drive assembly 2 or below the lower steel belt drive assembly 3, and the release agent spray device includes a storage tank 21, an air pump (not shown in the figure) output) and high-pressure nozzle 22, the high-pressure nozzle 22 is set facing the driving roller 4, and a coating roller 23 is arranged at the turning lower end of the driving roller 4, and a soft cotton cloth (not marked in the figure) is arranged on the coating roller 23 , by spraying the atomized release aid on the driving roller 4, and then spreading the release aid evenly through the coating roller 23, it can effectively prevent the steel strip from being polluted by too much adhesive and affecting the surface of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com