Patents

Literature

38results about How to "Fit precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

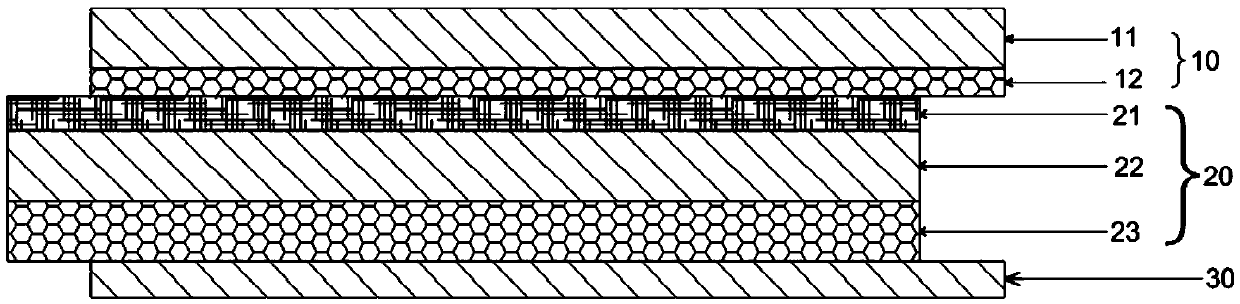

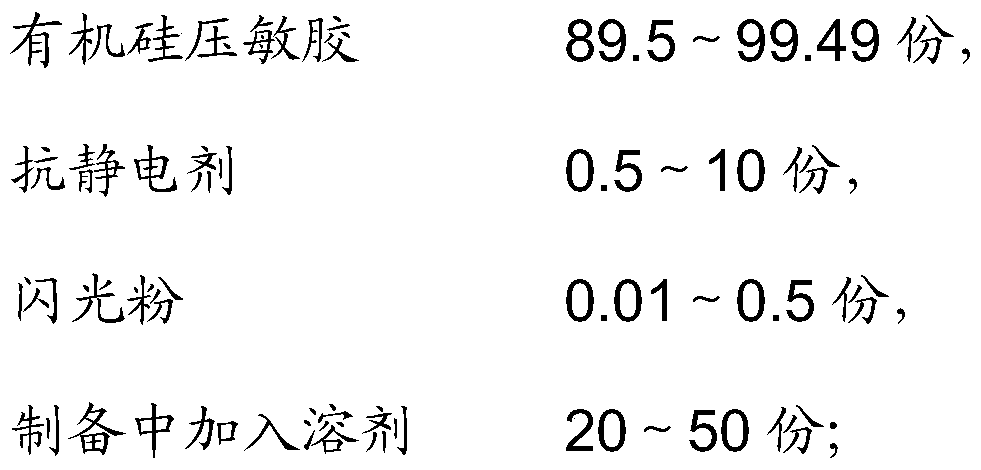

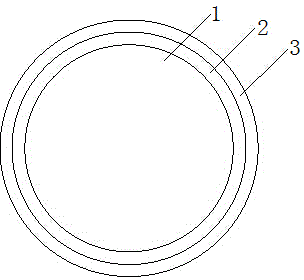

Hot-press molded protective film with shinning and antistatic effects and preparation method thereof

InactiveCN105522799AImprove the effect of hot pressingGuaranteed molding effectSynthetic resin layered productsAntistatic agentAcrylic resin

The invention discloses a hot-press molded protective film with shinning and antistatic effects and a preparation method thereof. The protective film can be used for comprehensively protecting a curved screen, and has an attractive appearance since shinning and antistatic effects are extra added. The protective film comprises a film protecting layer, an application layer and a release layer from top to bottom, wherein the application layer comprises a UV hardened layer, a base material A and an adhesive layer A; the principle component of the UV hardened layer is an acrylic resin layer, the base material A is a PET film, and the principle component of the adhesive layer is an organic silicone pressure-sensitive adhesive layer; and the thickness of the UV hardened layer is 2-10 mu m, the thickness of the base material A is 20-200 mu m, and the thickness of the adhesive layer A is 20-100 mu m. The hot-press molded protective film has shining and antistatic effects since shining particles and an antistatic agent are added into the application layer, and has high flexibility and cannot rebound after hot press since high-elasticity high-viscosity organic silicone pressure-sensitive adhesive is utilized in the adhesive layer.

Owner:NALI OPTICAL MATERIAL DONGGUAN

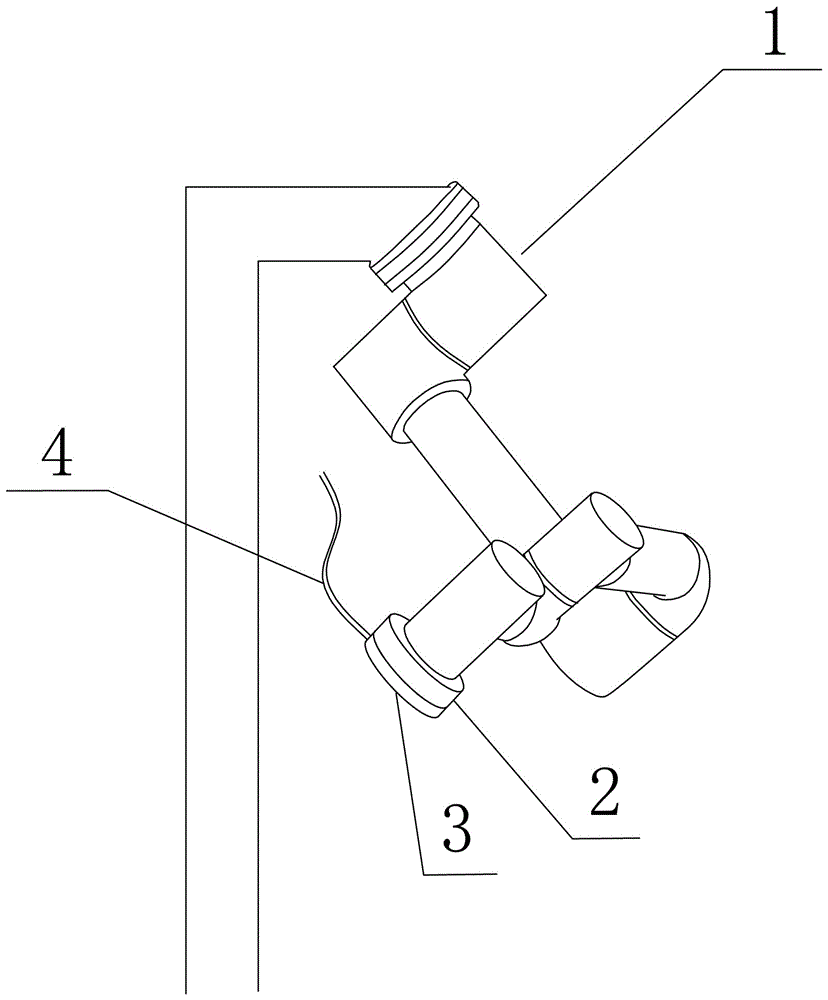

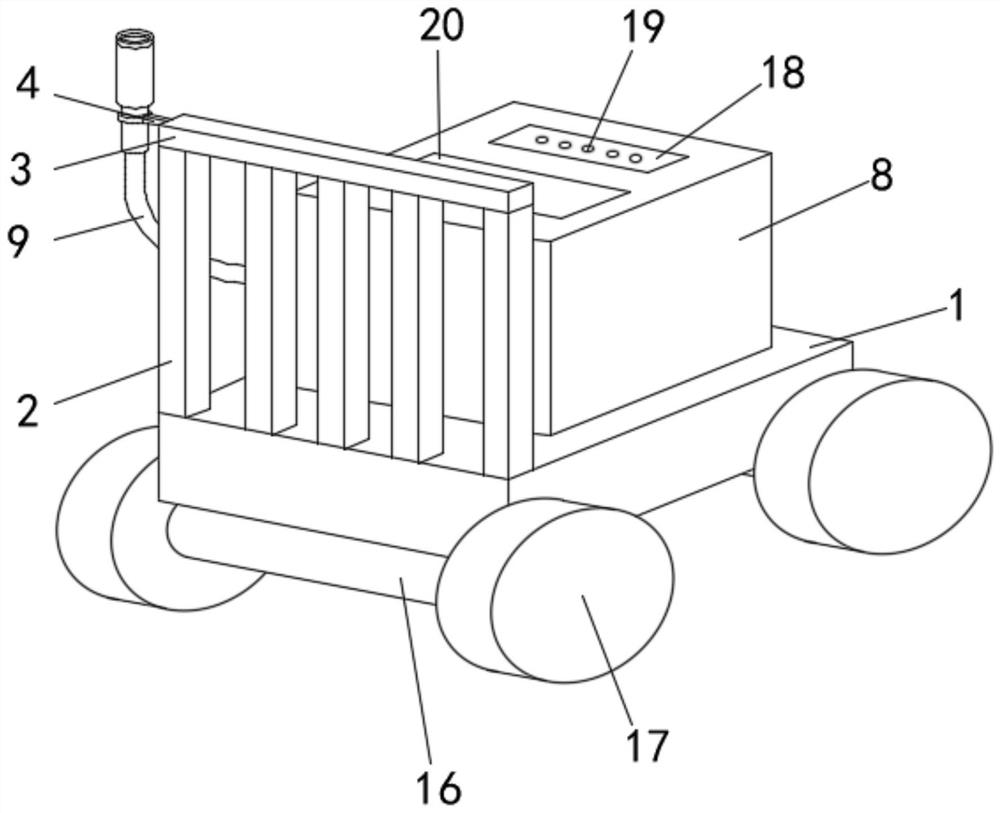

Sleeping intervention device for improving sleep quality and method thereof

ActiveCN106345059APrecise fitSolve the problem that the pressure sensor cannot be used to detect the fitting pressureElectrotherapyDiagnostic recording/measuringState of artEngineering

The invention provides a sleeping intervention device for improving sleep quality and method thereof, wherein sleeping intervention device for improving sleep quality comprises array bed, mechanical arm, brain wave detector, CPU and magnetic field stimulator arranged on the mechanical arm. The array bed comprises bed frame and a plurality of array element moved up and down by the control of the driving device; pressure detecting mechanism is arranged on the upper surface of each array element; the magnetic pad of the magnetic field stimulator is arranged on the free end of the mechanical arm; CUP is connected with Pressure detecting mechanism through information, connected with brain way detector through bi-directional information, respectively connected with mechanical arm, magnetic field stimulator and driving device. Compared to existing technology, sleeping intervention device for improving sleep quality of the invention has a much higher degree of automation; adverse effect on sleeping of the user caused by factors including working staff operation can be avoided. The device is excellent in using effect.

Owner:孙承业

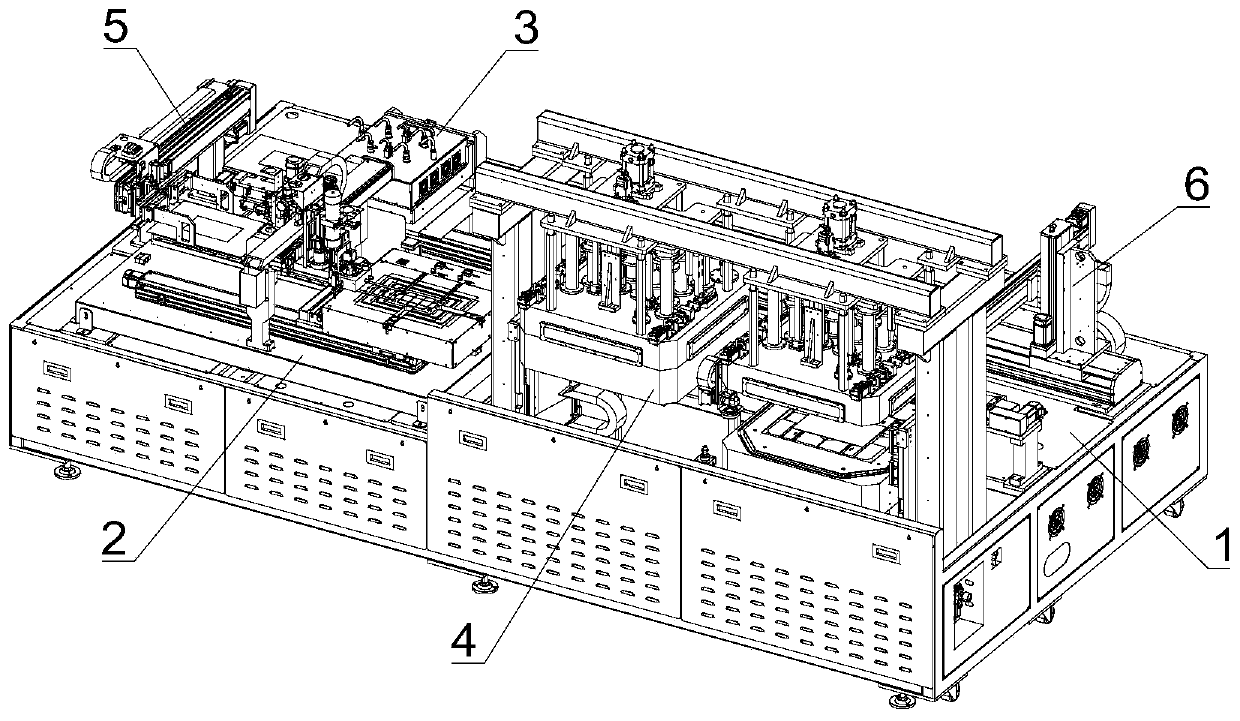

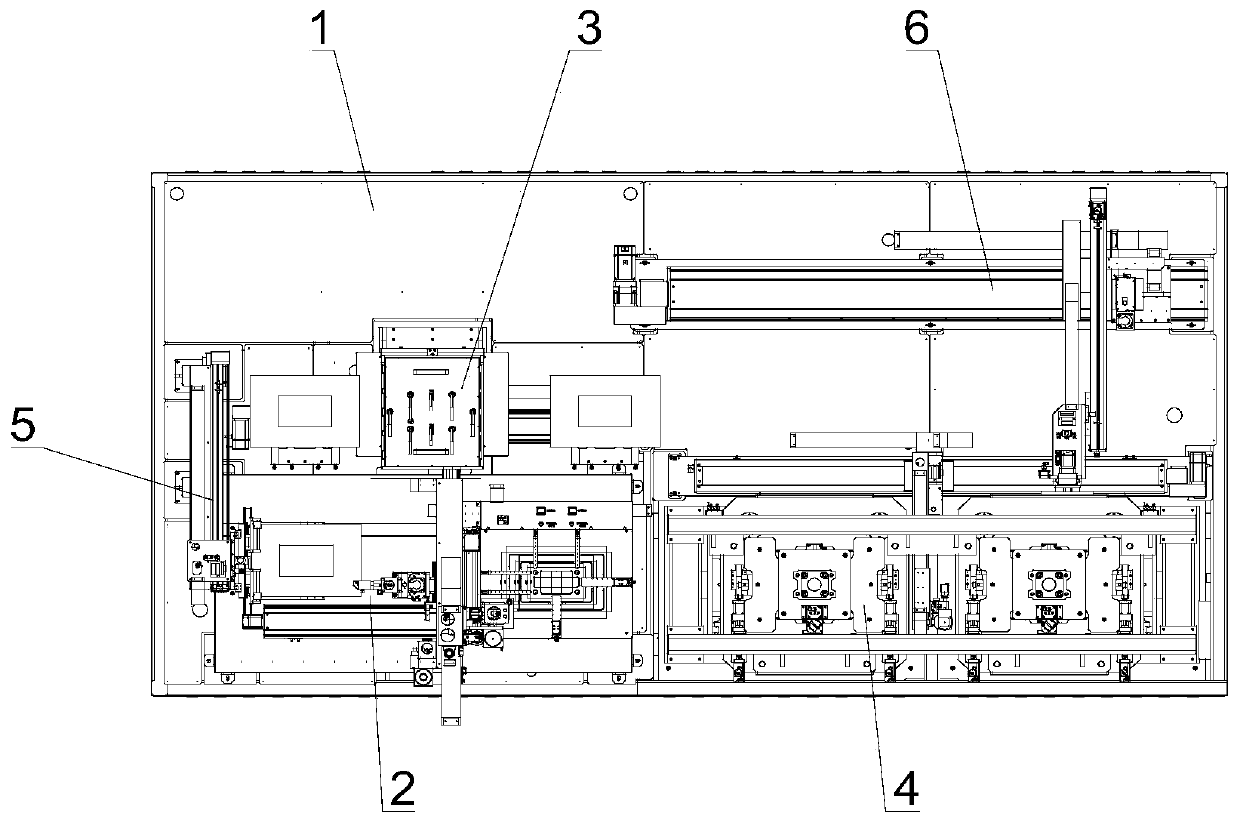

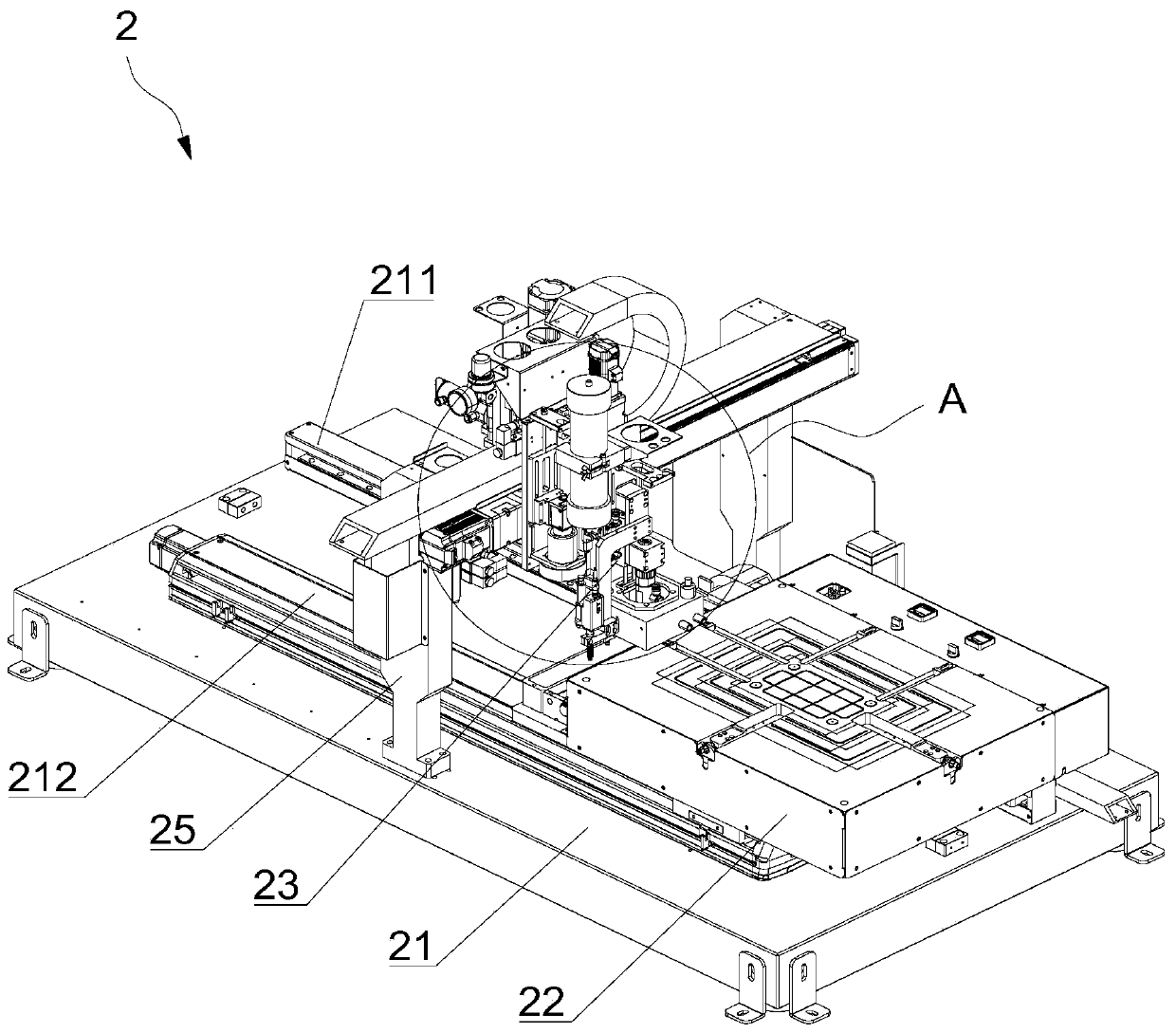

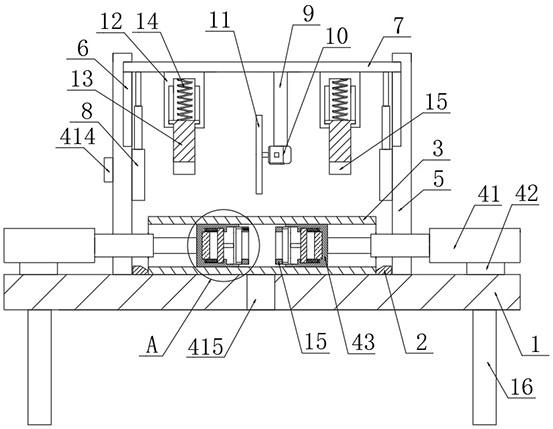

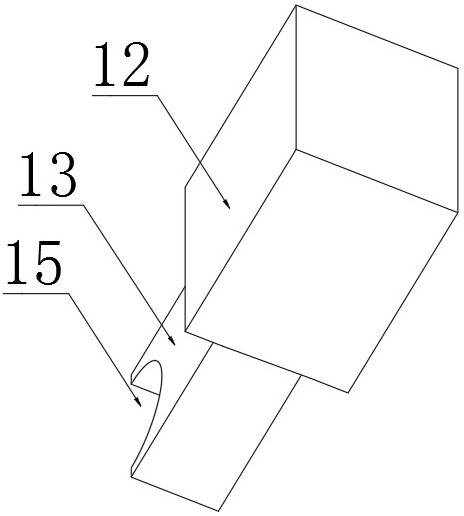

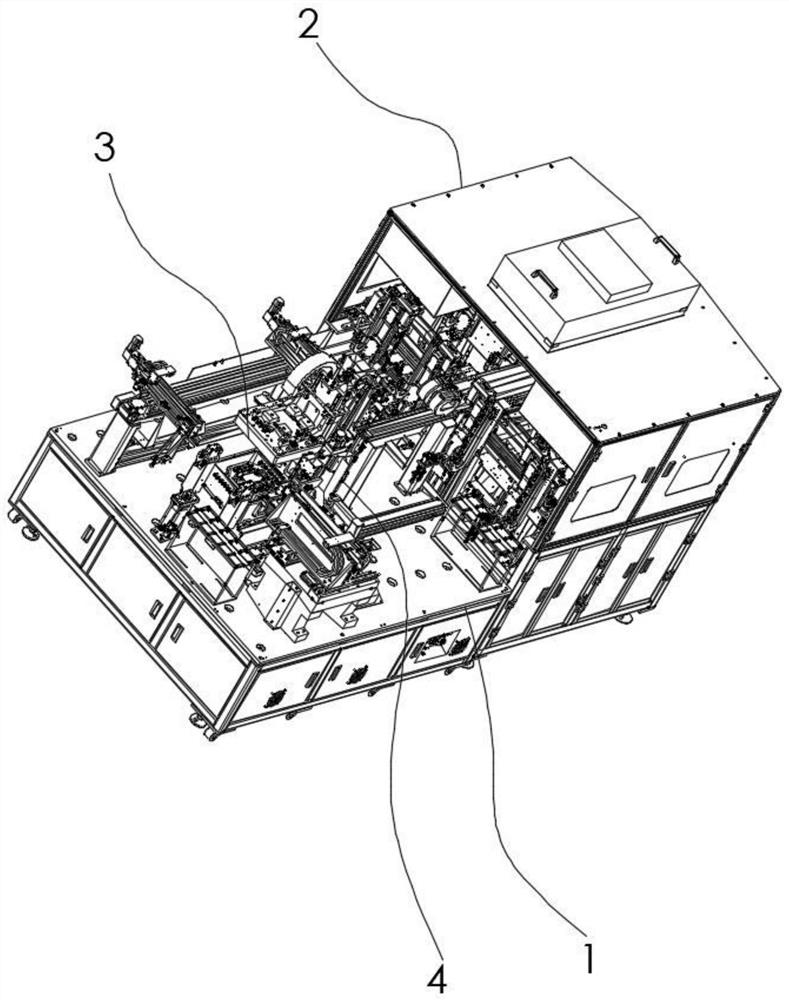

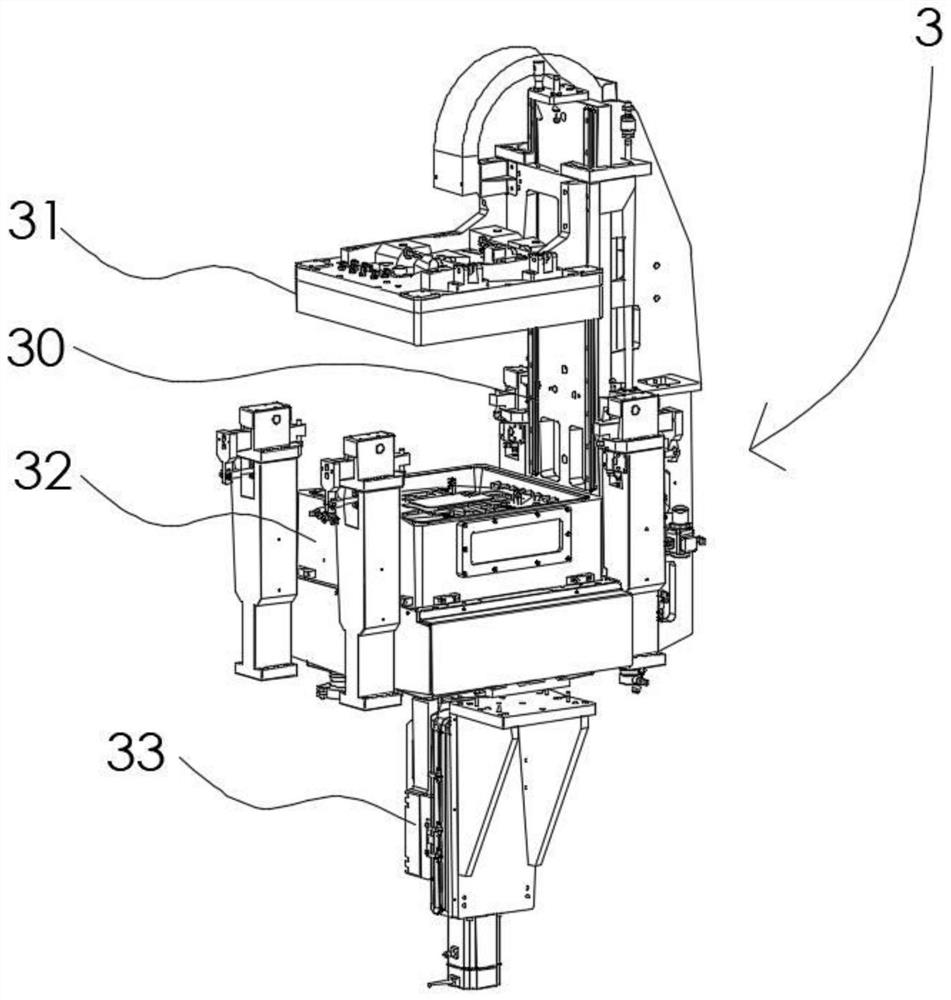

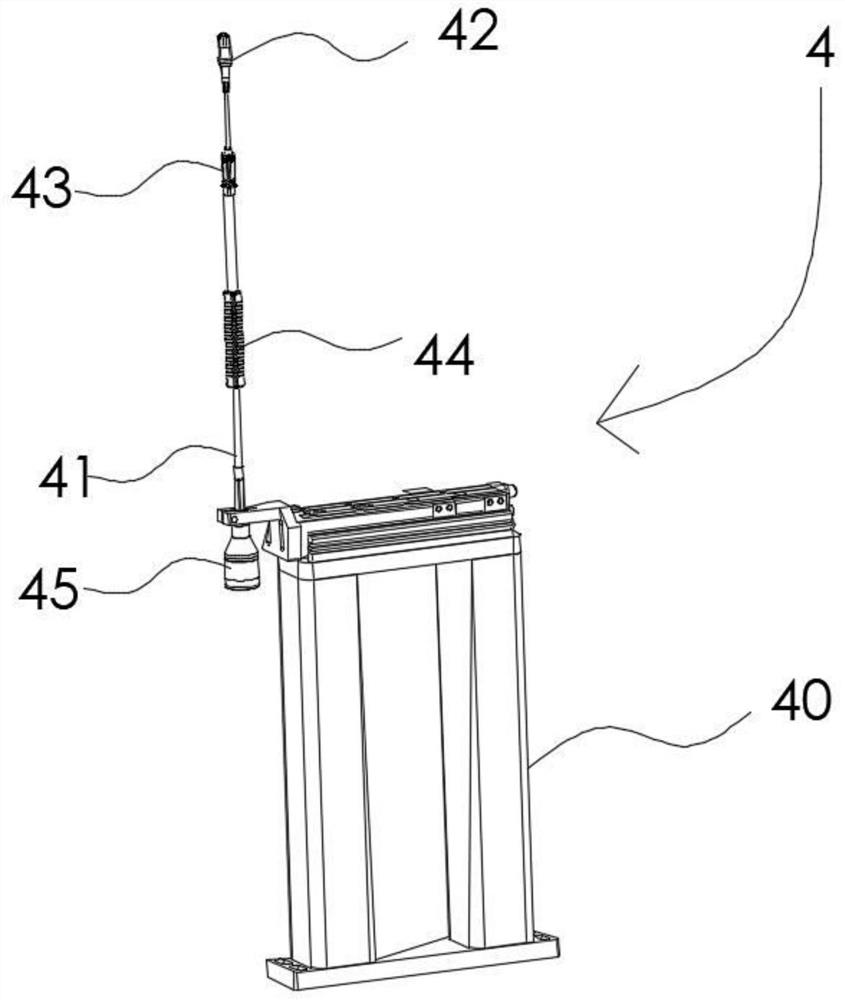

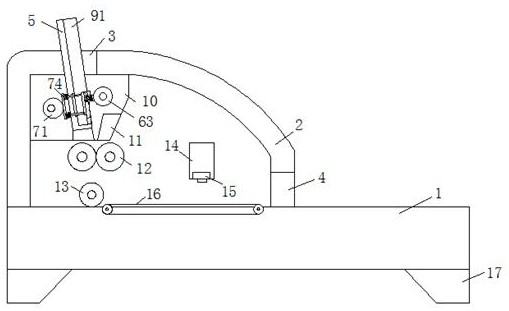

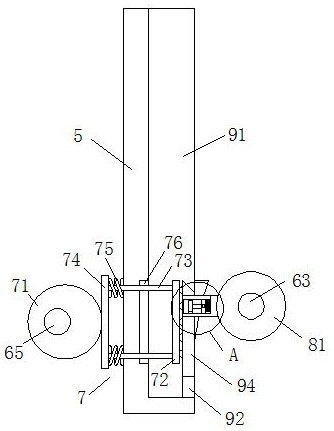

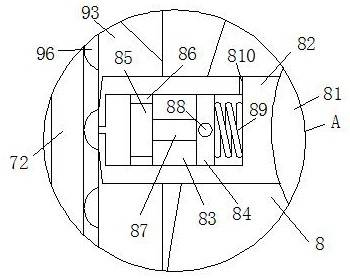

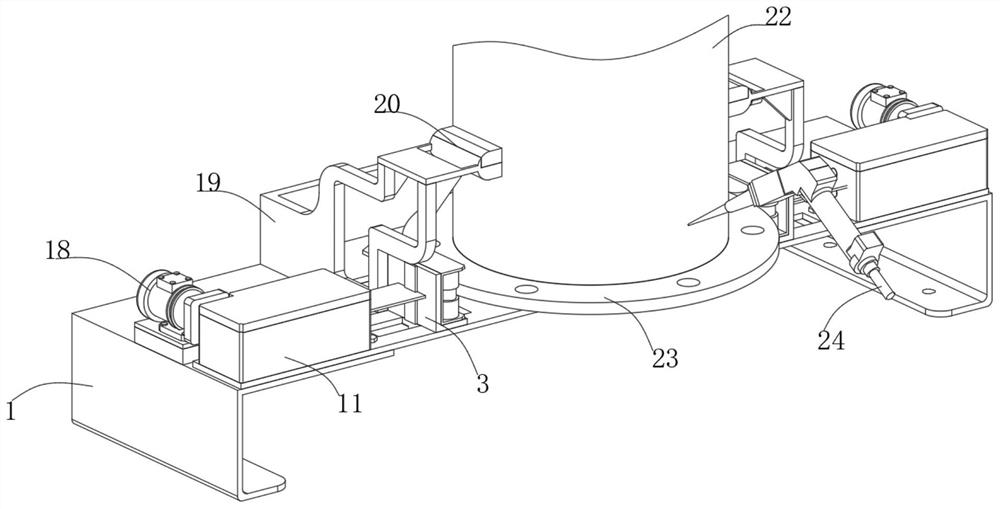

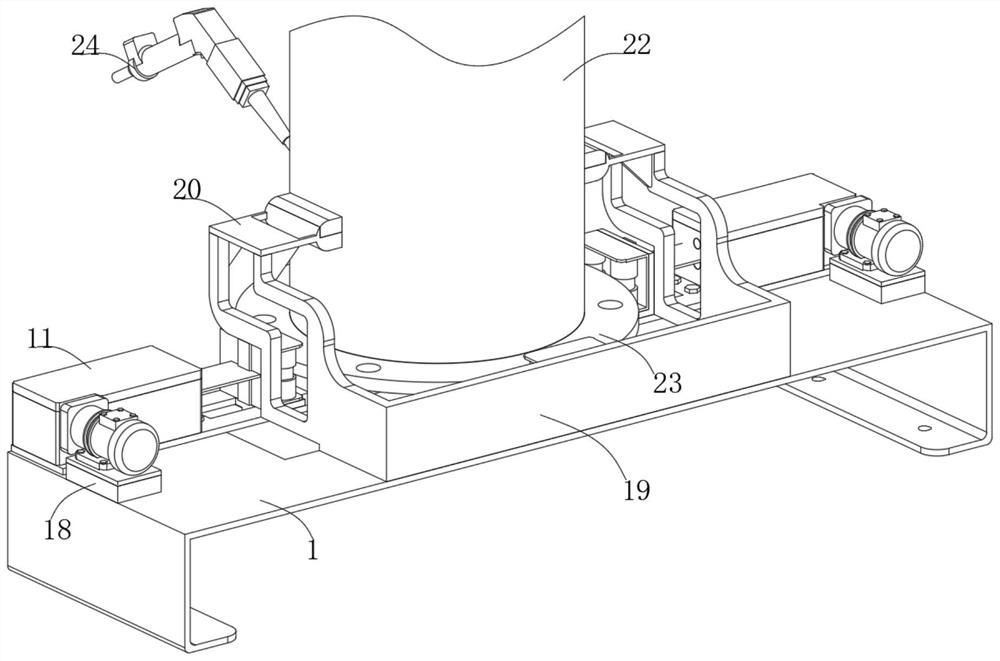

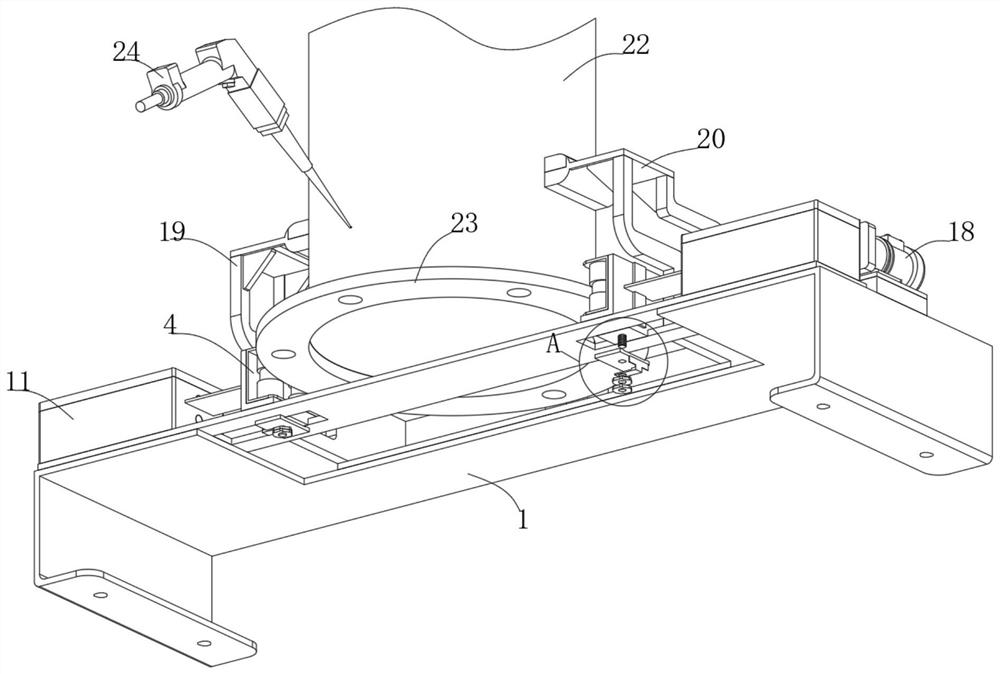

LOCA bonding machine

PendingCN109764040APrecise material transferFit precisionLiquid surface applicatorsCoatingsEngineeringFully automatic

The invention discloses an LOCA bonding machine comprising an installation platform, a dispensing station, a curing station, a bonding station, a first material moving and carrying part and a second material moving and carrying part. The dispensing station is used for conducting glue coating on a fed first workpiece. The curing station is used for conducting pre-curing on glue on the first workpiece. The bonding station is used for bonding the first workpiece and a fed second workpiece. The first material moving and carrying part is used for transferring the first workpiece to the curing station from the dispensing station. The second material moving and carrying part is used for transferring the first workipece to the bonding station from the curing station. By means of the LOCA bonding machine mentioned above, the fed first workpiece is sequentially subjected to the dispensing working procedure and the UV pre-curing working procedure and is then bonded together with the second workpiece, the whole process is fully automatic, material moving and carrying and bonding actions are accurate due to cooperation of image recognizing and positioning, the production efficiency is high, thebonding effect is good, and design requirements are met.

Owner:KUNSHAN SAMON AUTOMATION TECH

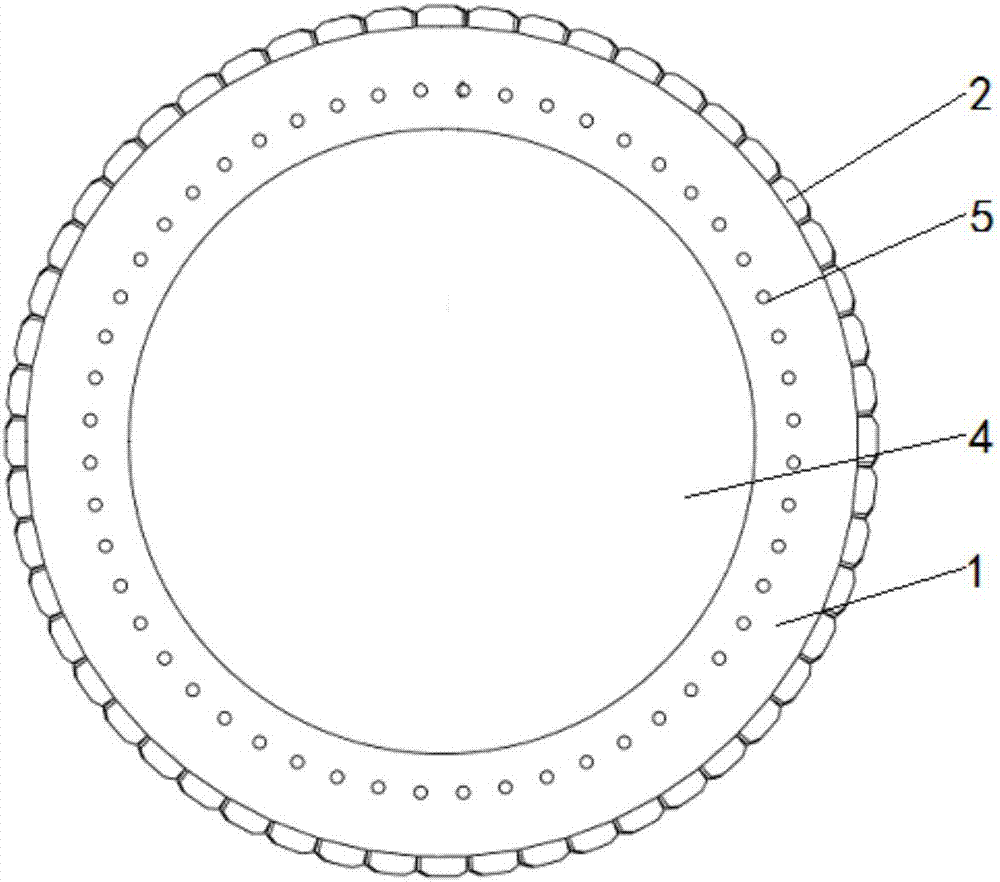

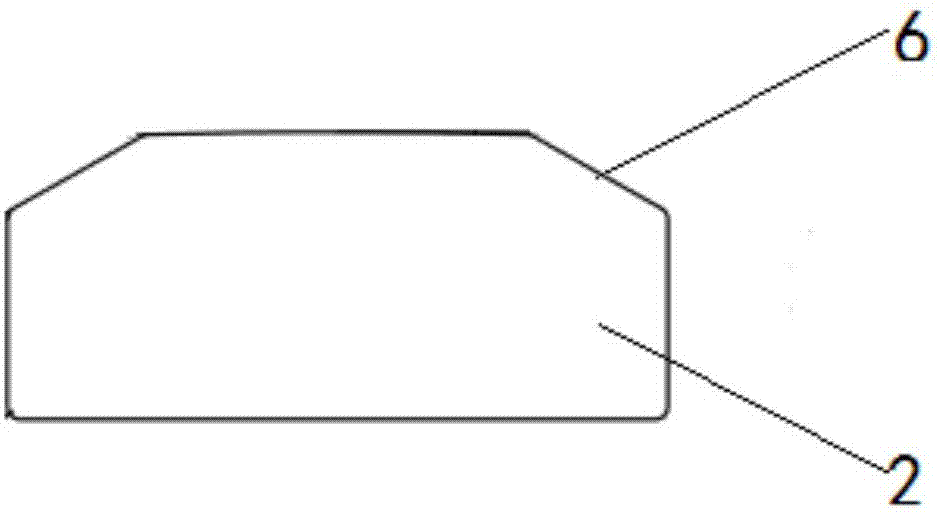

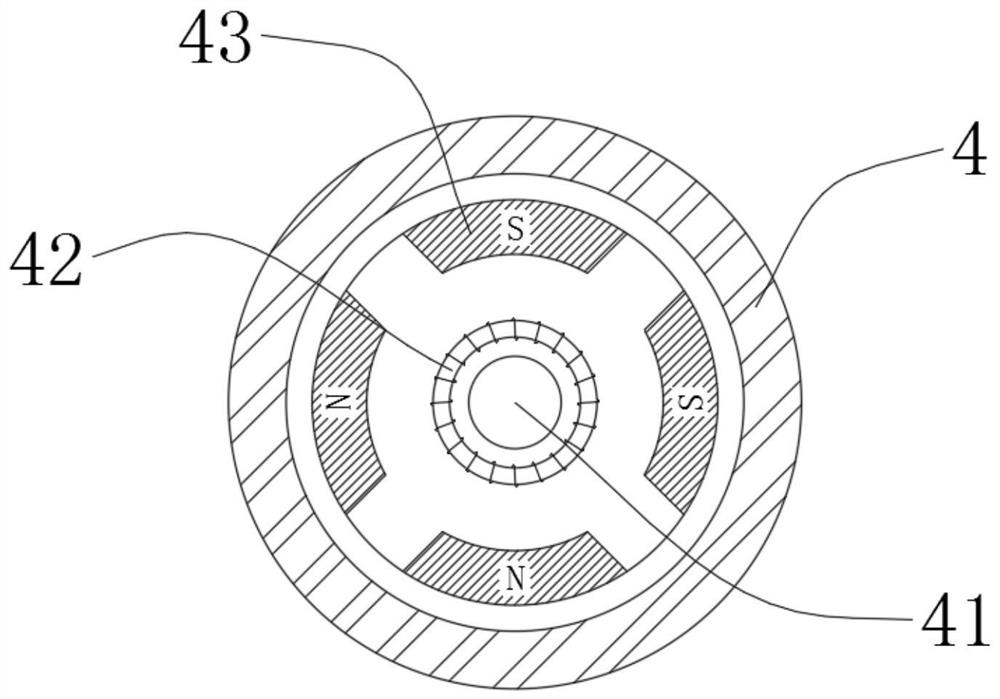

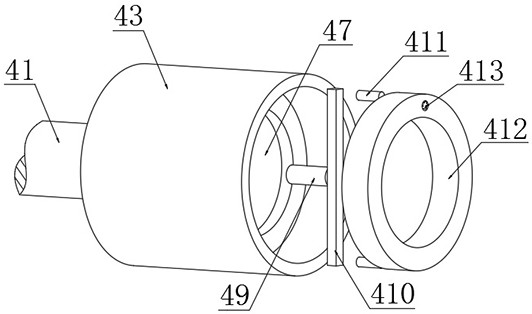

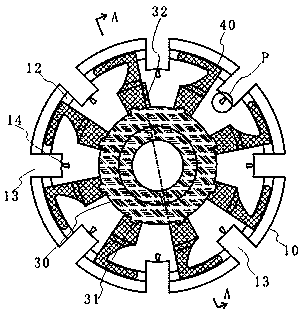

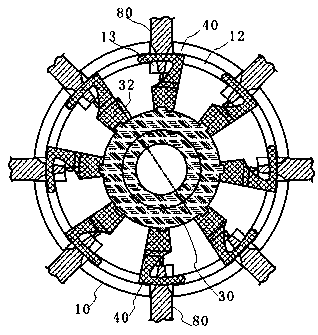

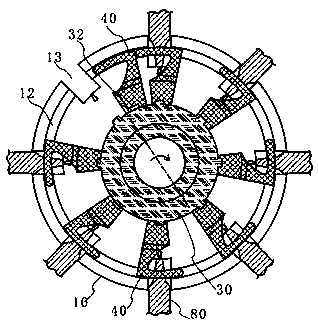

Motor rotor

PendingCN107508398AEasy to useSimple processMagnetic circuit rotating partsElectric machineClassical mechanics

The invention provides a motor rotor, which includes a rotor iron core and a permanent magnet. The permanent magnet is adhered to the surface of the rotor iron core. The rotor iron core is formed by lamination of rotor punching sheets. The side, adhered to the permanent magnet, of the rotor iron core is a regular polygon side, and the number of edges of the regular polygon equals the designed number 2P of magnetic poles of a motor. The center of the rotor iron core is equipped with a circular hole, and the circular hole matches a motor shaft. Positioning holes are evenly distributed in the circumference of the rotor iron core, and the number of the positioning holes also equals the designed number 2P of magnetic poles of a motor. The motor rotor is simple in process, and the labor cost is saved. In addition, the inclination angle precision is easy to control, and the use performance of a motor is guaranteed.

Owner:TIANJIN KANGTU TECH CO LTD

Manufacturing method for measurement clamp of steering column based on 3D printing technology

InactiveCN104484139APrecise positioningFit precisionDigital output to print unitsSteering columnPoint cloud

The invention discloses a manufacturing method for a measurement clamp of a steering column based on 3D printing technology. In order to prevent the steering column from rubbing in the installing process of the measurement clamp, the measurement clamp of the steering column is provided with a soft material and a metal shell. The 3D printing technology is used for scanning the measurement point of the steering column to obtain the origin point cloud data, the point cloud data of the soft material and the metal shell is obtained on the basis of the origin point cloud data, and the three-dimensional data of the measurement clamp of the steering column is obtained after the processing of matching, firing and the like, so that the 3D printing production of the measurement clamp of the steering column is performed. The origin point cloud data is obtained by scanning the measurement point of the steering column through the 3D printing, the point cloud data of the soft material and the metal shell is obtained on the basis of the origin point cloud data, the fitting degree of the measurement clamp is precision after the steering column is partially and reversely restored, and the measurement point of the steering column is positioned accurately. In addition, the installing repeatability is good and the front and back are uniform, so the production quality of the measurement clamp of the steering column is effectively improved.

Owner:JIANGXI HONGDU AVIATION IND GRP

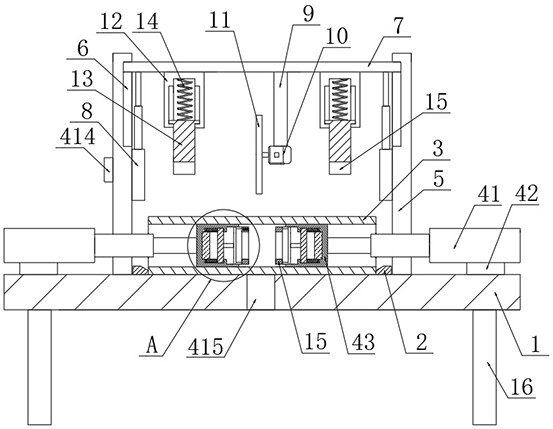

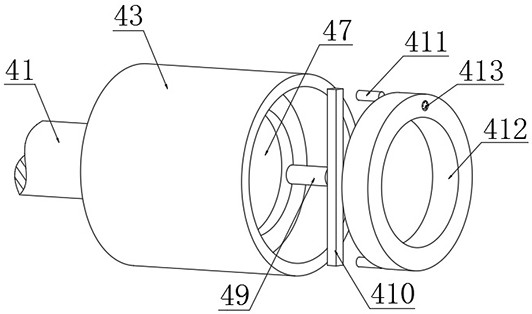

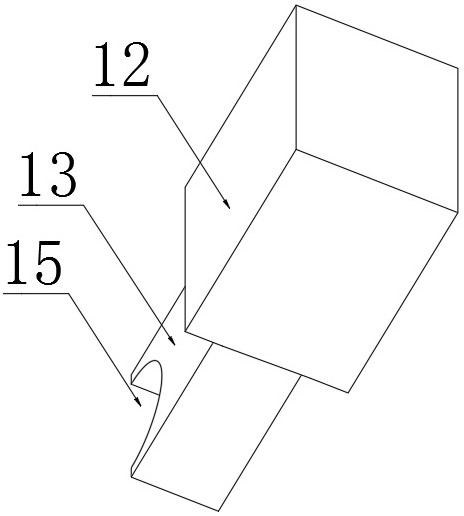

High-precision cutting device for winding pipe production and using method of high-precision cutting device

The invention discloses a high-precision cutting device for winding pipe production and a using method of the high-precision cutting device. The high-precision cutting device comprises a bottom plate, limiting blocks are fixedly arranged on the left side and the right side of the top of the bottom plate correspondingly, a pipe body is arranged between the two limiting blocks, a supporting mechanism is arranged at the top of the bottom plate, the supporting mechanism comprises two first air cylinders, the two first air cylinders are arranged on the left side and the right side of the top of the bottom plate correspondingly, heightening blocks are fixedly arranged at the bottoms of the first air cylinders, the bottoms of the heightening blocks are fixedly connected with the top of the bottom plate, and supporting blocks are fixedly arranged at the output ends of the two first air cylinders. According to the high-precision cutting device and the using method thereof, movement of the supporting blocks is controlled through the first air cylinders on the two sides, so that when a pipe body is cut by a blade, the supporting blocks are located in the pipe body and make contact with the inner wall of the pipe body, a stress point is provided for the two sides of the pipe body, the blade is prevented from extruding a pipe notch, deformation of the notch is avoided, and therefore the cutting precision and cutting quality of the pipe are improved.

Owner:RONGCHENG PIPE IND

Antimicrobial polymerizable ear piece material

ActiveUS20070088098A1Fit closelyImprove surface propertiesMouthpiece/earpiece sanitary/hygienic devicesAntifouling/underwater paintsSiliconeOrganosilicon

A two-component addition-crosslinking silicone comprises (a) 0.1-70% by weight polyorganosiloxanes containing at least two unsaturated groups in the molecule; (b) 0.1-15% by weight polyorganohydrogensiloxanes containing at least two SiH groups in the molecule; (c) 0.01-2.0% by weight noble metal catalyst; and (d) 0.1-5% by weight of a non-toxic antimicrobial additive or a combination of at least two non-toxic antimicrobial additives.

Owner:DREVE OTOPLASTIK

Glass punching device facilitating locating and machining

ActiveCN112976351AConvenient positioning and processingEasy to processWorking accessoriesStone-like material working toolsPunchingStructural engineering

The invention relates to the technical field of glass punching devices, and discloses a glass punching device facilitating locating and machining. The glass punching device facilitating locating and machining comprises a main plate and a punching device, wherein a support block I and a support block II are fixedly installed on the upper wall surface of the main plate, and the punching device is fixedly connected with the lower wall surface of the support block I; and a main body is arranged at the position, corresponding to the punching device, above the support block I. According to the invention, when a functional block is driven by a threaded rod to move downwards, four connecting blocks move downwards in corresponding sliding holes, and meanwhile, the four connecting blocks pull corresponding ropes to move downwards, so that four fixing rods move towards the sides close to each other along with pulling of the corresponding ropes; and when the inner concave portions of the four fixing rods and the outer wall surface of a functional ring are clamped together, four reinforcing blocks extrude downwards a glass piece on the main body, so that a secondary fixing effect on the glass piece is achieved, and the problems that the glass piece shakes in a punching process, and then is punched and broken, resources are wasted, and the production efficiency is affected are solved.

Owner:福建灿丰玻璃有限公司

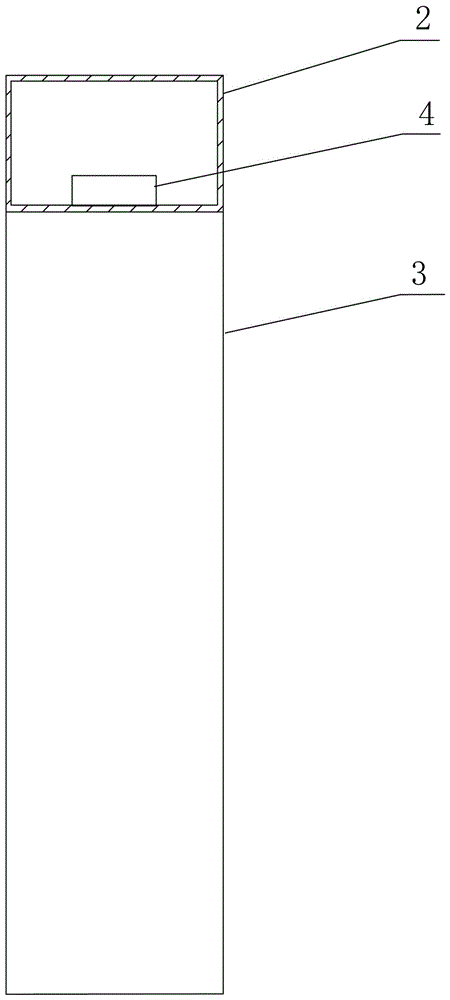

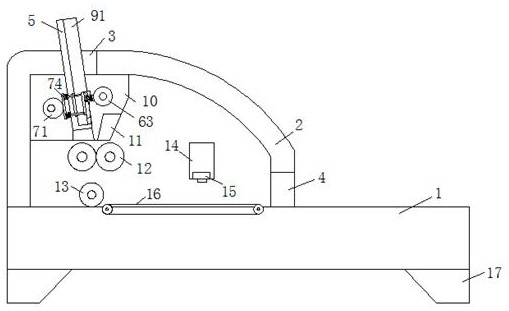

Paper feeding mechanism for invoice printer

ActiveCN112478843ARealize automatic paper feedingAvoid troublesome operationTypewritersOther printing apparatusComputer printingMechanical engineering

The invention relates to the field of printers, in particular to a paper feeding mechanism for an invoice printer. The paper feeding mechanism comprises a fixed base, a printer main body, a paper feeding hole, a paper discharging hole, a flow guide plate, a driving mechanism, an extrusion mechanism, a paper suction mechanism and a storage mechanism, the printer main body is fixedly connected to the upper end of the fixed base, and the paper feeding hole is formed in the upper end of the printer main body. A driving rotating shaft of the driving mechanism rotates to drive a paper suction rotating roller of the paper suction mechanism to rotate, a piston plate can slide in an air cavity through extrusion of a pull rod by an arc-shaped top plate, finally, an air pressure suction head sucks invoice paper to slide out of a front baffle of the storage mechanism, and the air pressure suction head is disconnected with the arc-shaped top plate through the pull rod, the air pressure suction headis disconnected from the invoice paper and enters the printer main body for printing, full-automatic paper feeding of the printer is achieved, the troublesome operation that invoices are manually fedto designated positions of the printer one by one is avoided, and the printing efficiency is improved.

Owner:NANJING HANMINGZHI INTELLIGENT TECHNOLOGY CO LTD

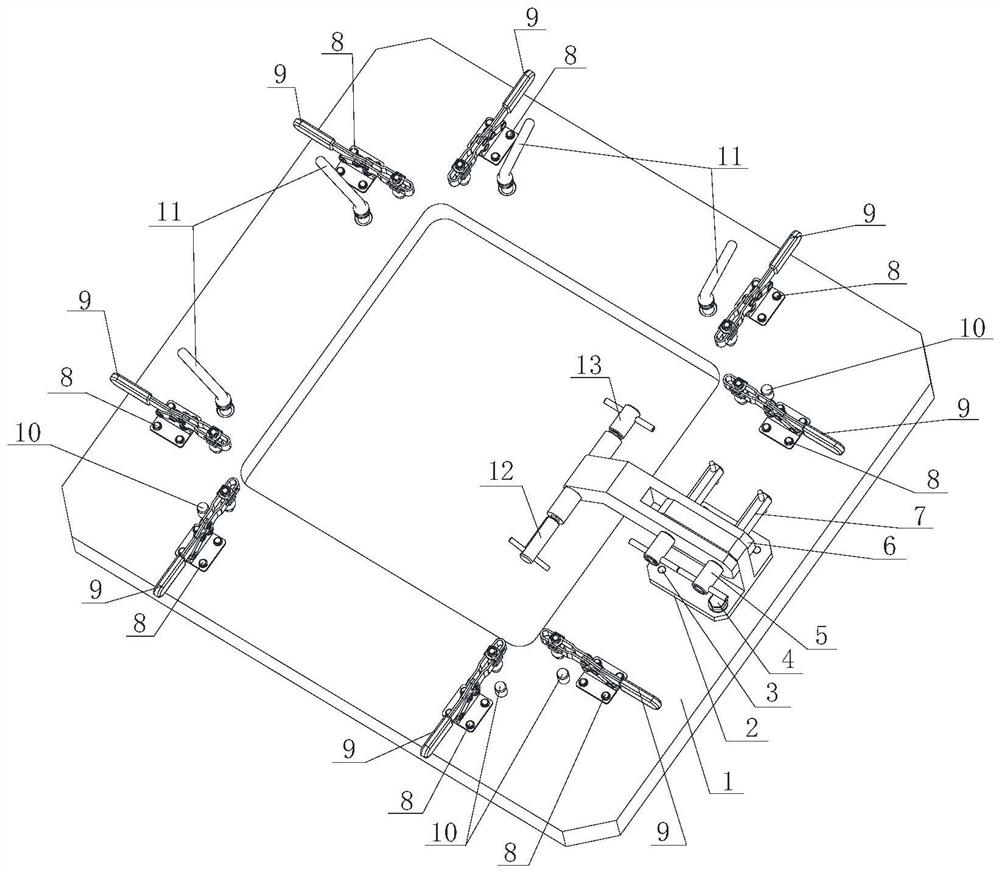

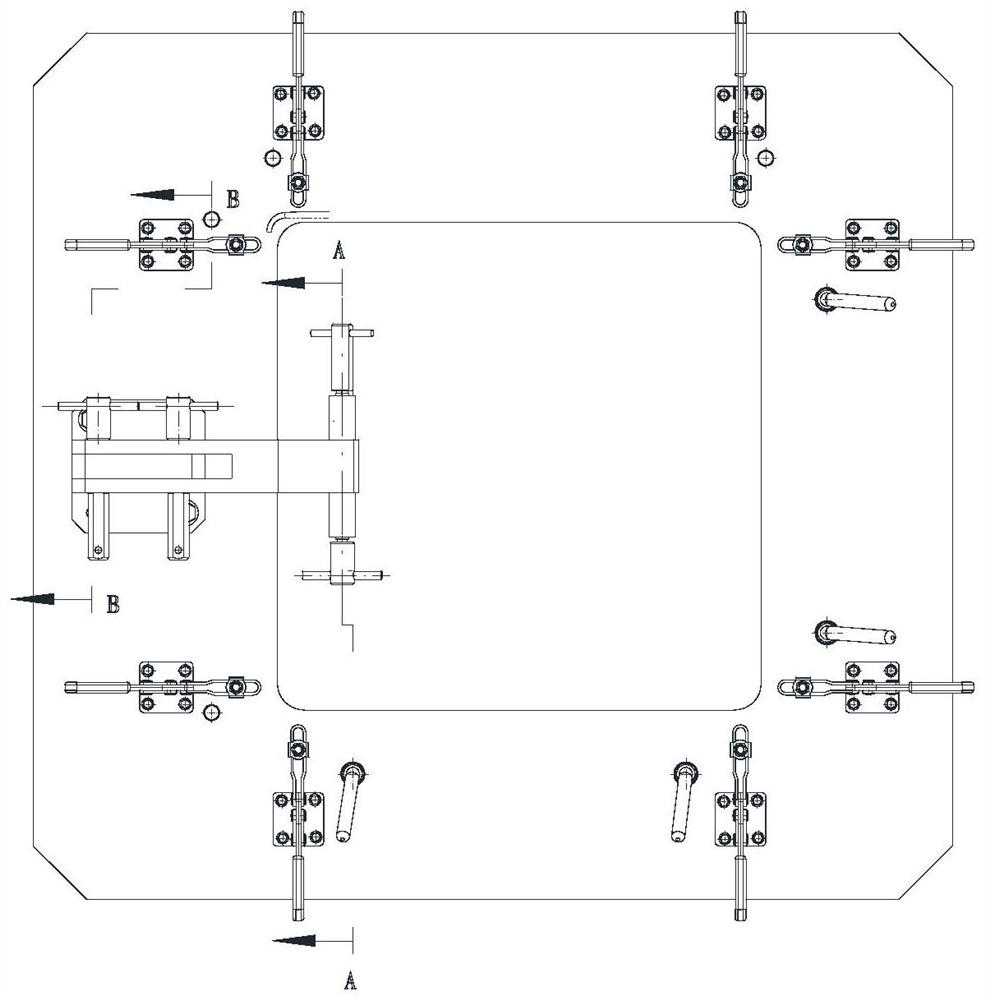

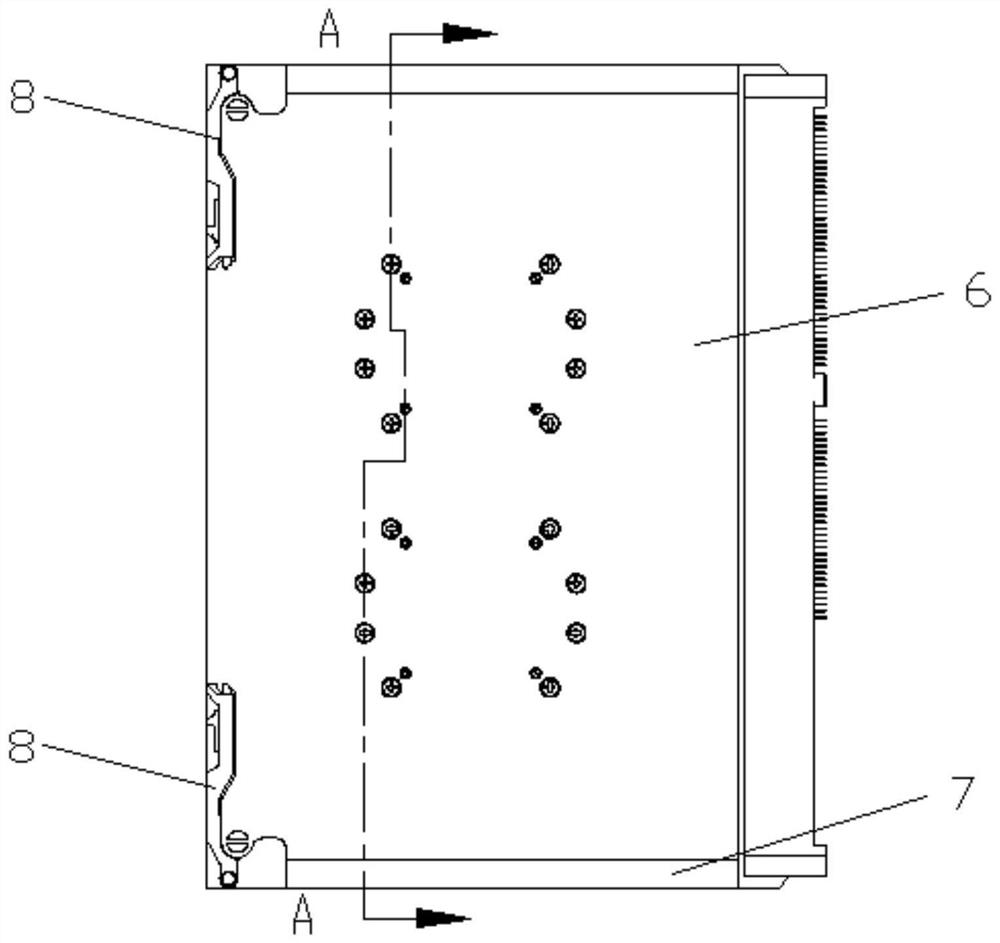

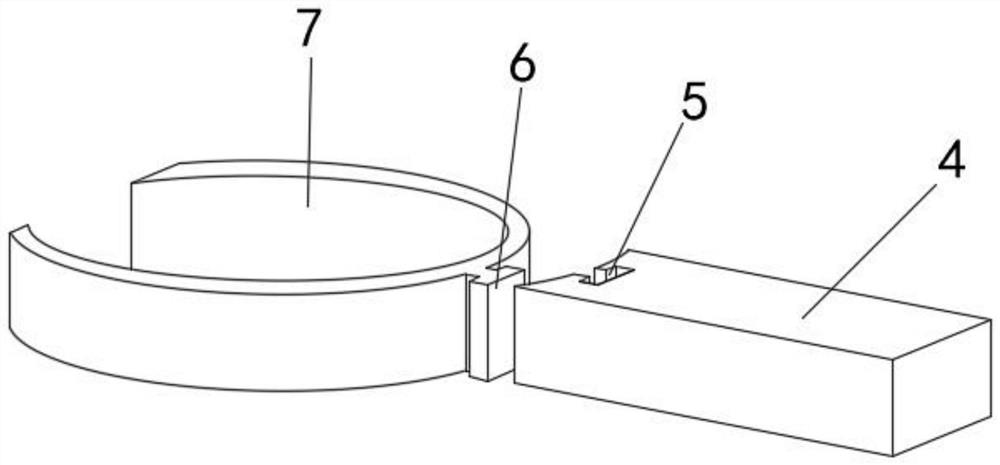

Supporting base and mouth frame locating device

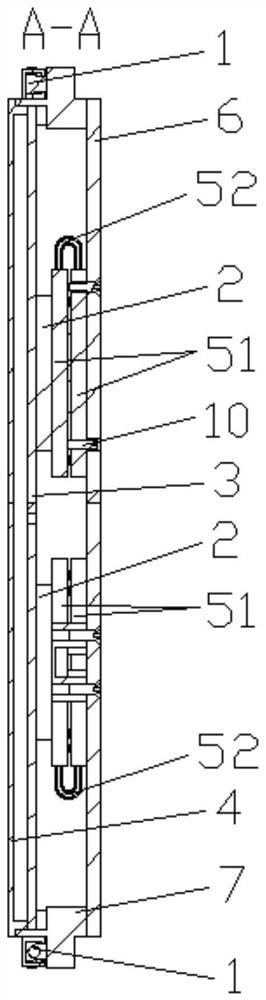

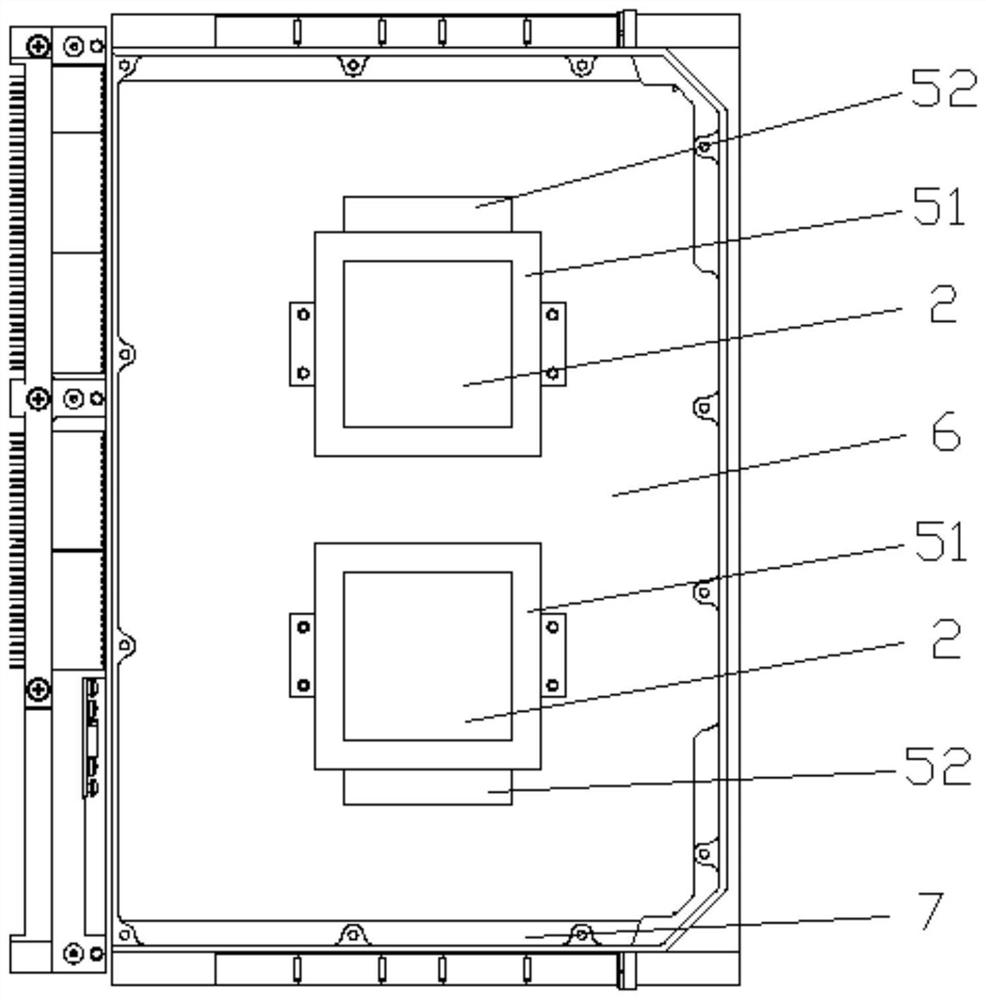

PendingCN113954006AReduce weightImprove work efficiencyWork holdersAircraft assemblyAirplaneStructural engineering

The invention provides a supporting base and mouth frame locating device comprising a locating plate (1), a base (2), a locating piece (6), pressing clamps (9), second cylindrical pins (10) and bent handle plug pins (11). A plurality of pressing pliers (9), a plurality of second cylindrical pins (10) and a plurality of bent handle plug pins (11) are fixedly arranged on the locating plate (1), and the pressing clamp (9), the second cylindrical pins (10) and the bent handle plug pins (11) are used for clamping the mouth frame on the locating plate (1); the base (2) is further fixedly arranged on the locating plate (1), and the locating piece (6) is fixedly connected to the base (2); and the supporting base is fixedly connected to the locating piece (6). The locating device is simple in structure, practical, convenient in operation, good in stability, and accurate and reliable, and the operation intensity of an operator is reduced; deviations caused by human factors are reduced, and the assembly quality is improved; and the locating device is particularly suitable for locating and combining a curved surface mouth frame and a supporting base of an airplane.

Owner:SHAANXI AIRCRAFT CORPORATION

Antimicrobial polymerizable ear piece material

ActiveUS7718748B2Improve surface propertiesFit precisionMouthpiece/earpiece sanitary/hygienic devicesFibre treatmentSiliconeNoble metal

A two-component addition-crosslinking silicone comprises(a) 0.1-70% by weight polyorganosiloxanes containing at least two unsaturated groups in the molecule;(b) 0.1-15% by weight polyorganohydrogensiloxanes containing at least two SiH groups in the molecule;(c) 0.01-2.0% by weight noble metal catalyst; and(d) 0.1-5% by weight of a non-toxic antimicrobial additive or a combination of at least two non-toxic antimicrobial additives.

Owner:DREVE OTOPLASTIK

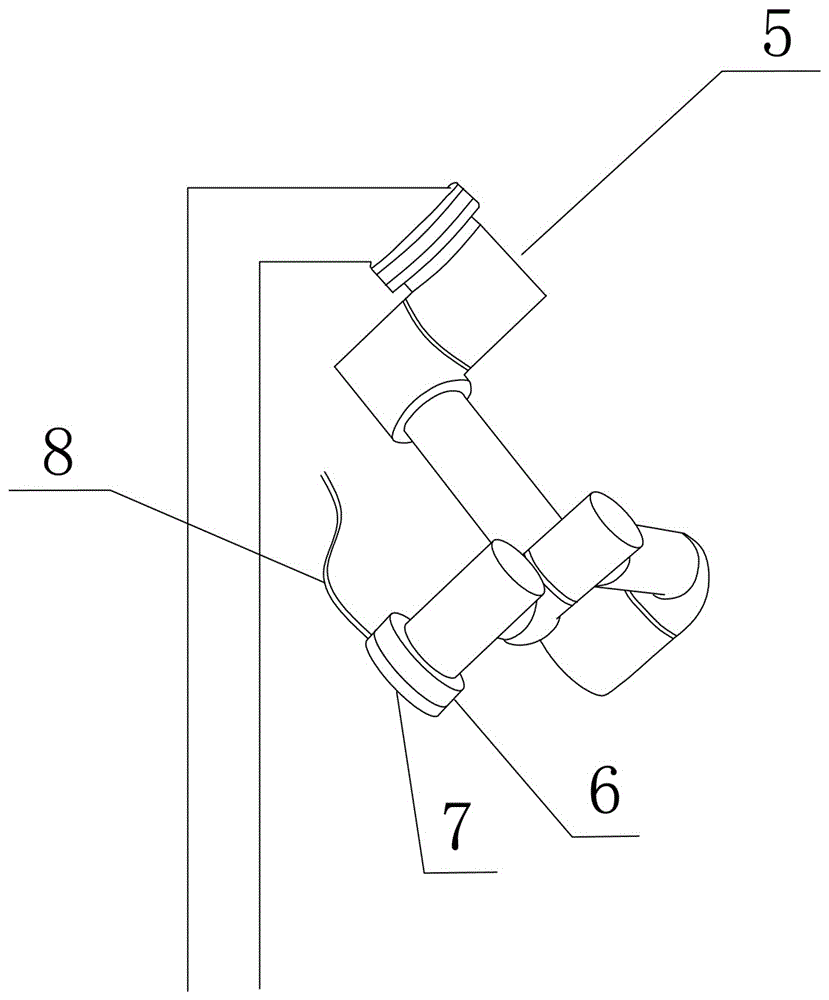

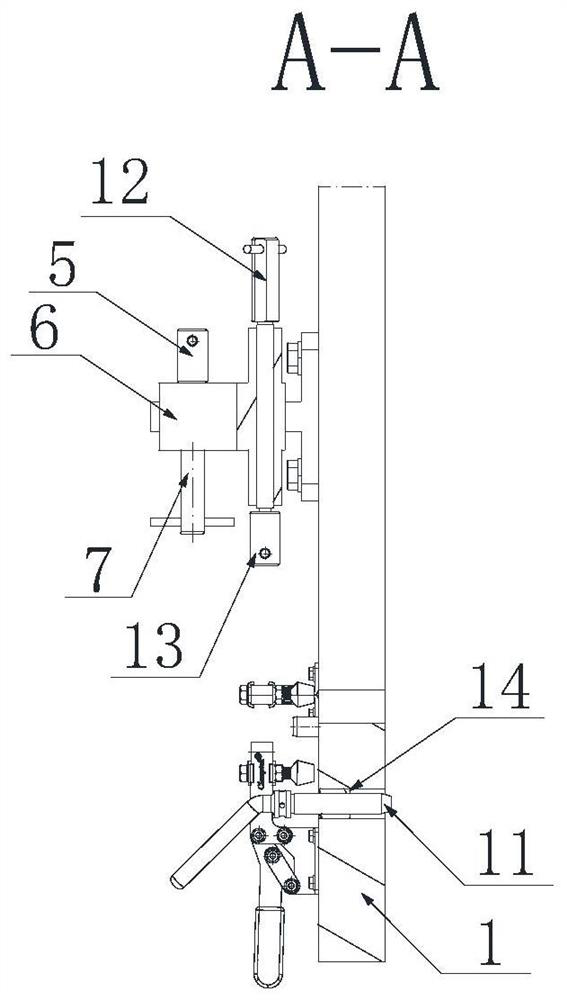

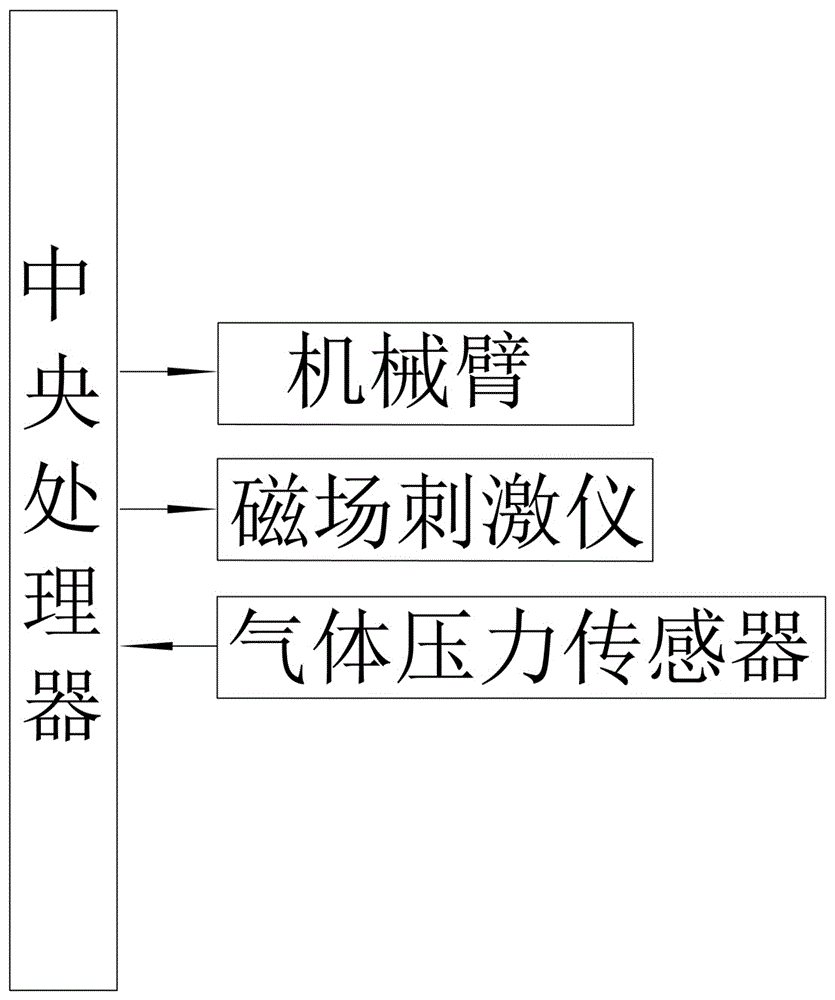

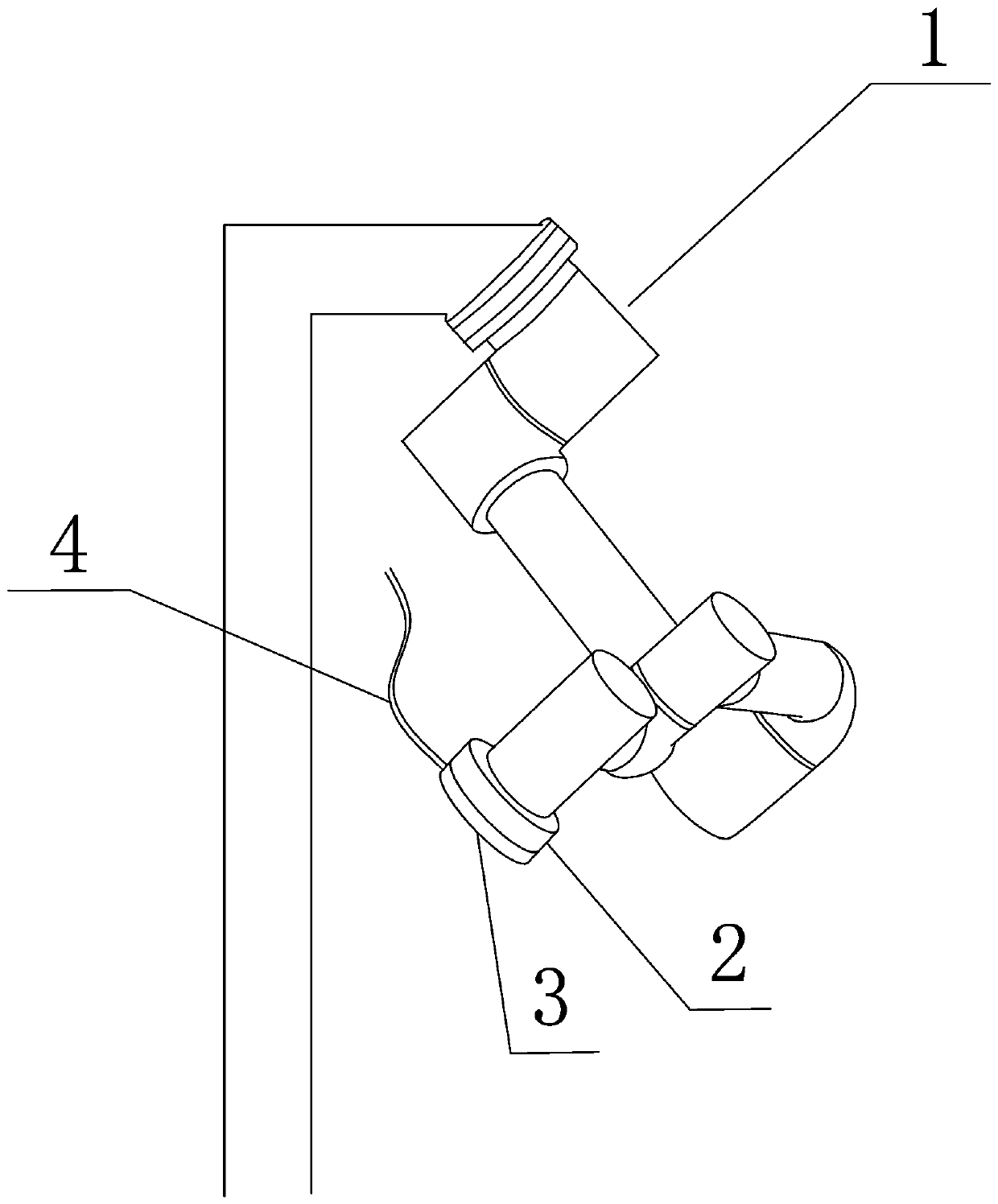

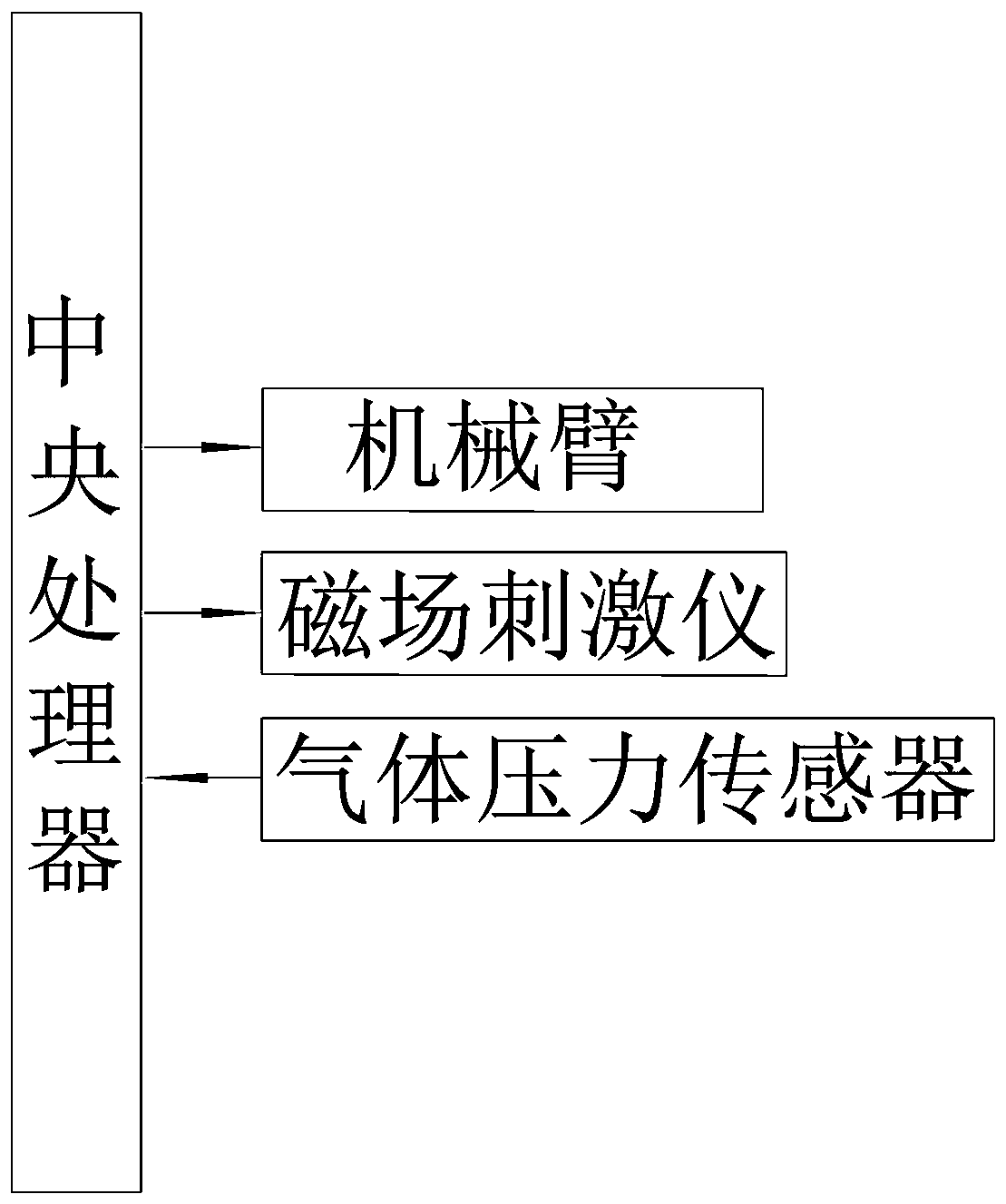

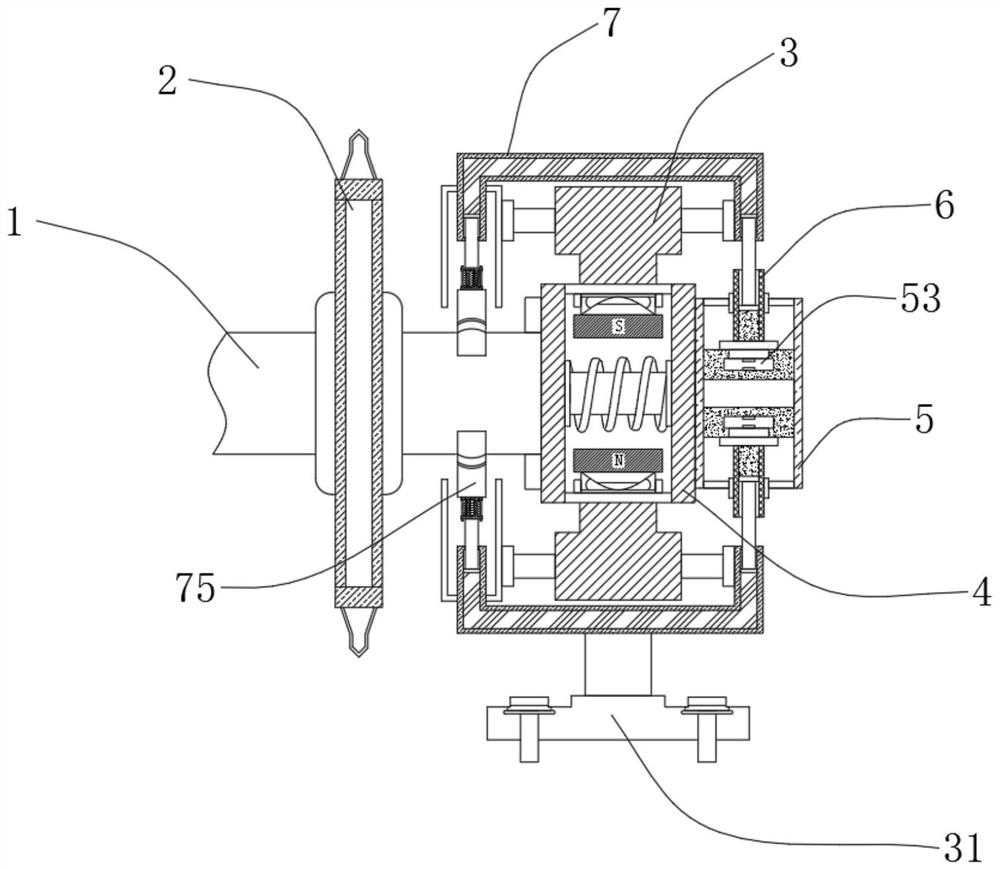

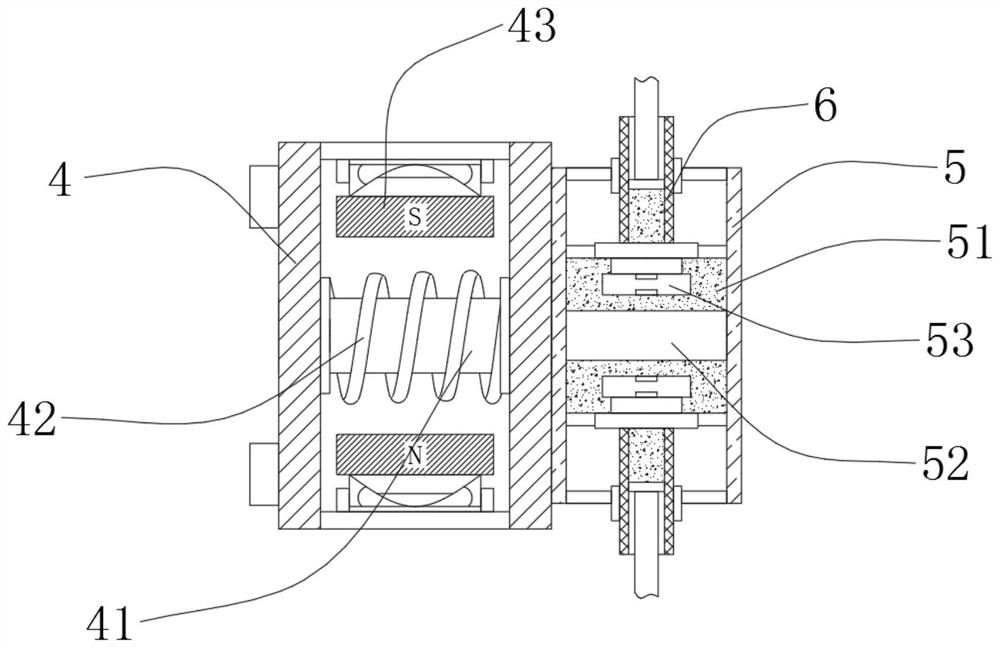

Magnetic-field stimulating device capable of improving sleep quality

ActiveCN106139403AEasy accessReduce adverse effectsElectrotherapyDiagnostic recording/measuringMicrochiropteraEngineering

The invention provides a magnetic-field stimulating device capable of improving sleep quality. The magnetic-field stimulating device comprises a mechanical arm used for being connected with a central processing unit and a magnetic-field stimulating instrument which is arranged on the mechanical arm and used for being connected with the central processing unit. The magnetic bat of the magnetic-field stimulating instrument is arranged at the free end of the mechanical arm. An air bag made of non-flexible materials is arranged on the outer side of the magnetic bat. The air bag comprises an air bag body and an air guide pipe. The detecting end of a gas pressure sensor used for being in information connection with the central processing unit is connected with the air guide pipe in a sealed manner. Compared with the prior art, the magnetic-field stimulating device has the advantages that automation level is increased greatly, adverse effects, caused by factors such as the manual action, for placing the magnetic bat to a head intervention position, of staff, the footstep sounds of the staff entering and leaving a room and sounds generated by door opening and closing, on the sleep-entering state of a user are avoided, and the device is quite good in use effect.

Owner:孙承业

Heat dissipation shell, processing method thereof and conduction heat dissipation module

InactiveCN114040641AImprove heat transfer performanceDissipate quicklySupport structure mountingModifications by conduction heat transferEngineeringMachining

The invention relates to a heat dissipation shell and a processing method thereof and a conduction heat dissipation module. The heat dissipation shell comprises a frame and a heat transfer bottom plate, wherein the heat transfer bottom plate is detachably installed on one side of the frame; the other side of the frame is fixedly connected with an extension part, and the extension part is used for fixing the PCB; and at least one thickness-adjustable flexible heat transfer device is detachably mounted on one side, close to the frame, of the heat transfer bottom plate. The heat dissipation shell also comprises a PCB and a chip. The processing method of the heat dissipation shell comprises the steps that the frame, the heat transfer bottom plate and the cover plate are sequentially machined and formed, and the other side of the frame extends outwards to form the extension part; and the heat transfer bottom plate is detachably installed on one side of the frame, and the flexible heat transfer device is detachably installed on the side, close to the frame, of the heat transfer bottom plate, so that the heat dissipation shell is formed. The heat dissipation shell is simple in structure, and the heat dissipation shell is designed in a split mode, so that the contact precision of the flexible heat transfer device and the chip is improved, standardized machining and production of a single component are achieved, the machining efficiency is greatly improved, and disassembly and assembly are convenient.

Owner:GUILIN CHANGHAI DEV

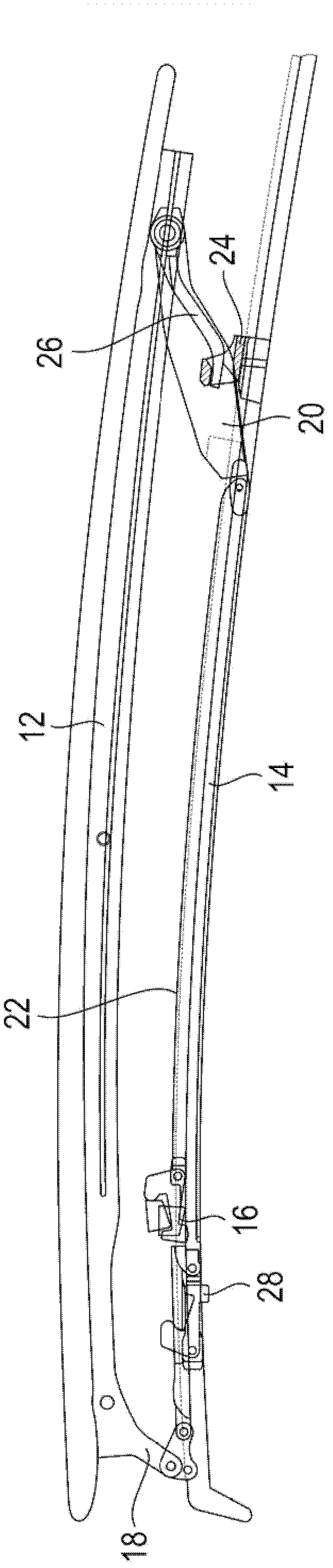

Sliding roof system

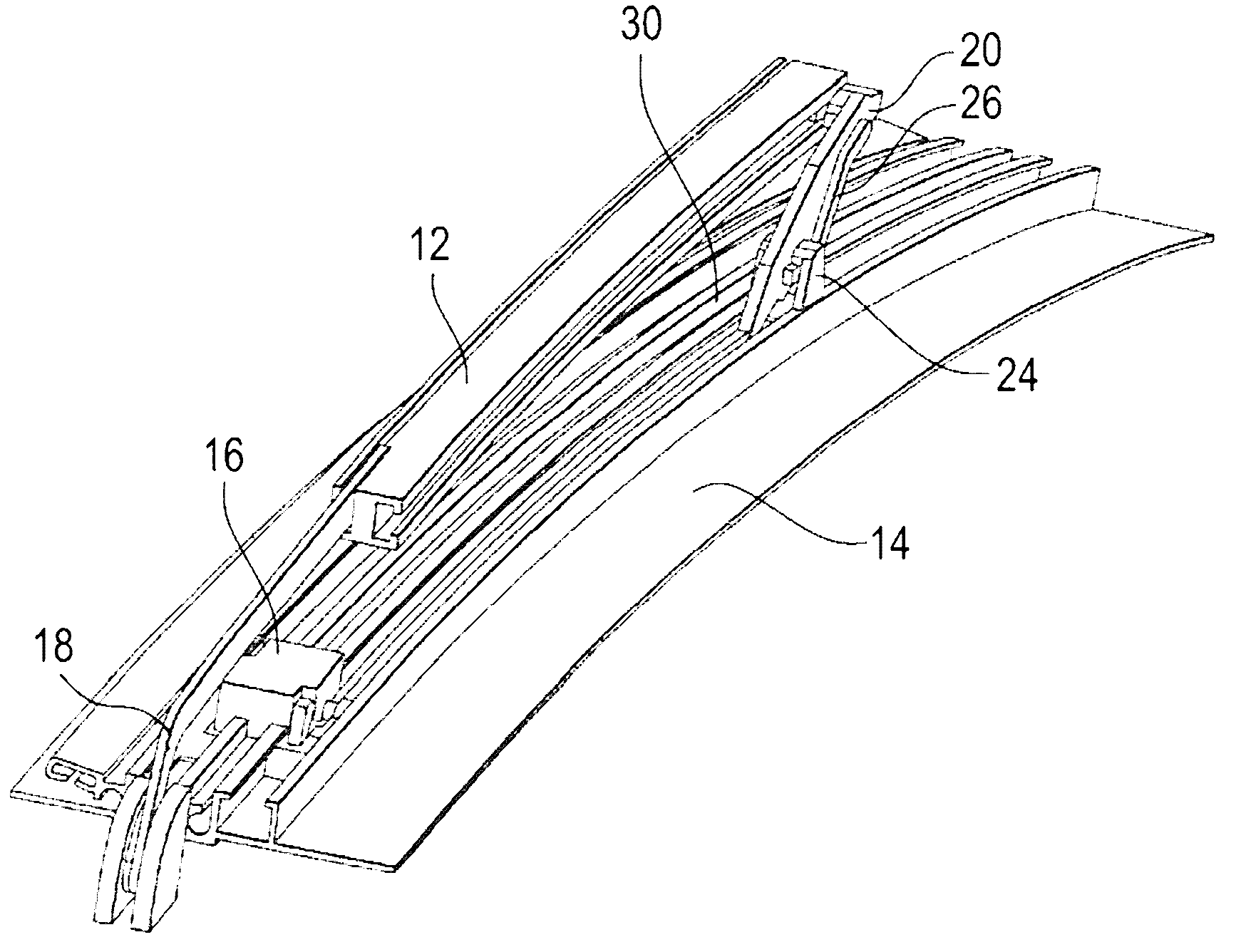

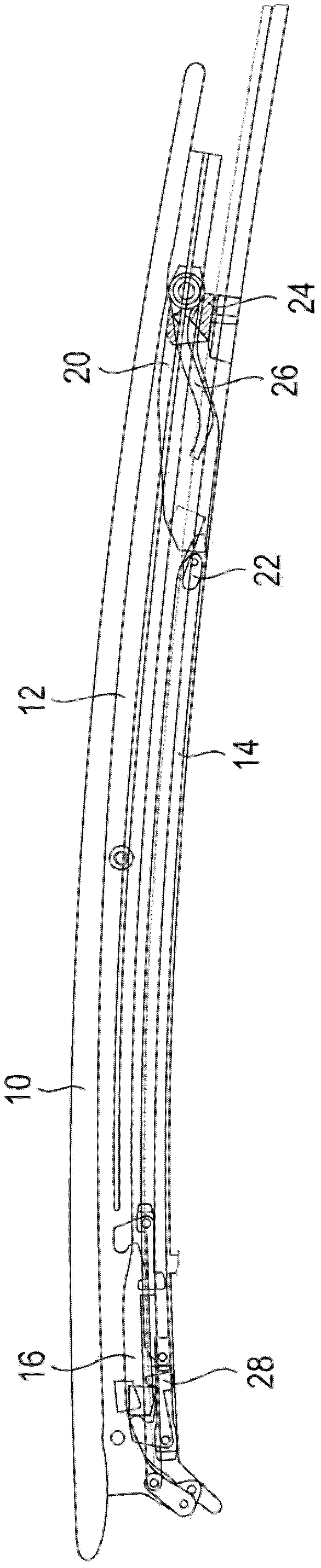

ActiveCN102673353AReliable applicationReduce widthEngine sealsVehicle sealing arrangementsEngineeringMechanical engineering

A sliding roof system, in particular for motor vehicles, with at least one guide rail (14), a carriage (16) which is shiftable in the guide rail (14), a guide element (18) located at the front, which can cooperate with a cover (10) of the sliding roof, and a swing-out lever (20) located at the rear, which likewise can cooperate with the cover (10) and can be moved by the carriage (16) from a starting position into a position swung out, is wherein the swing-out lever (20) is mounted on the guide rail (14) with a fixed swivel axis (32) and that at least in the starting position the end of the swing-out lever (20) associated to the cover (10) lies on the side of the swivel axis (32) facing the carriage (16).

Owner:DAIMLER AG

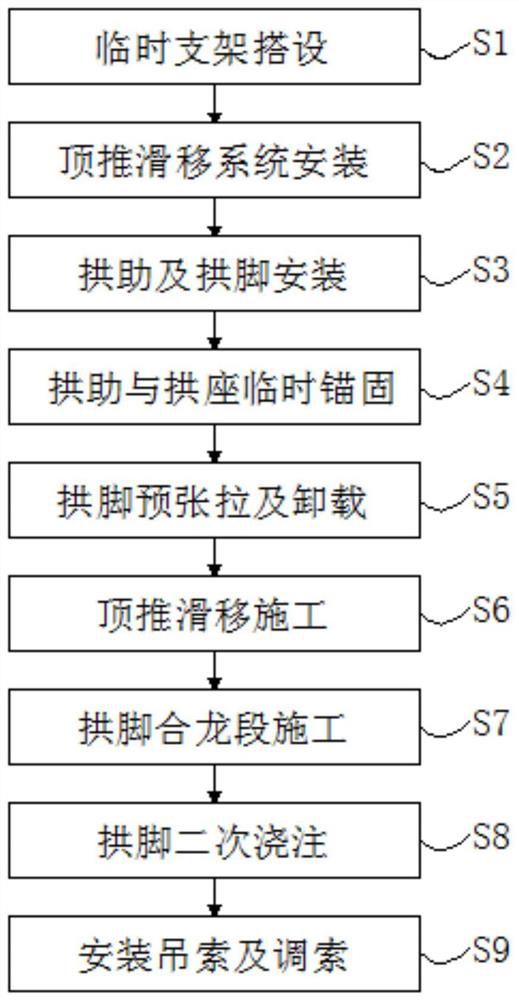

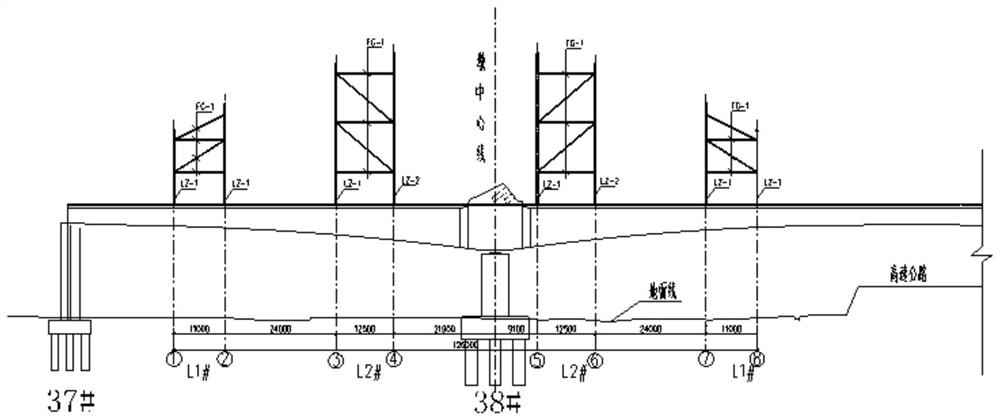

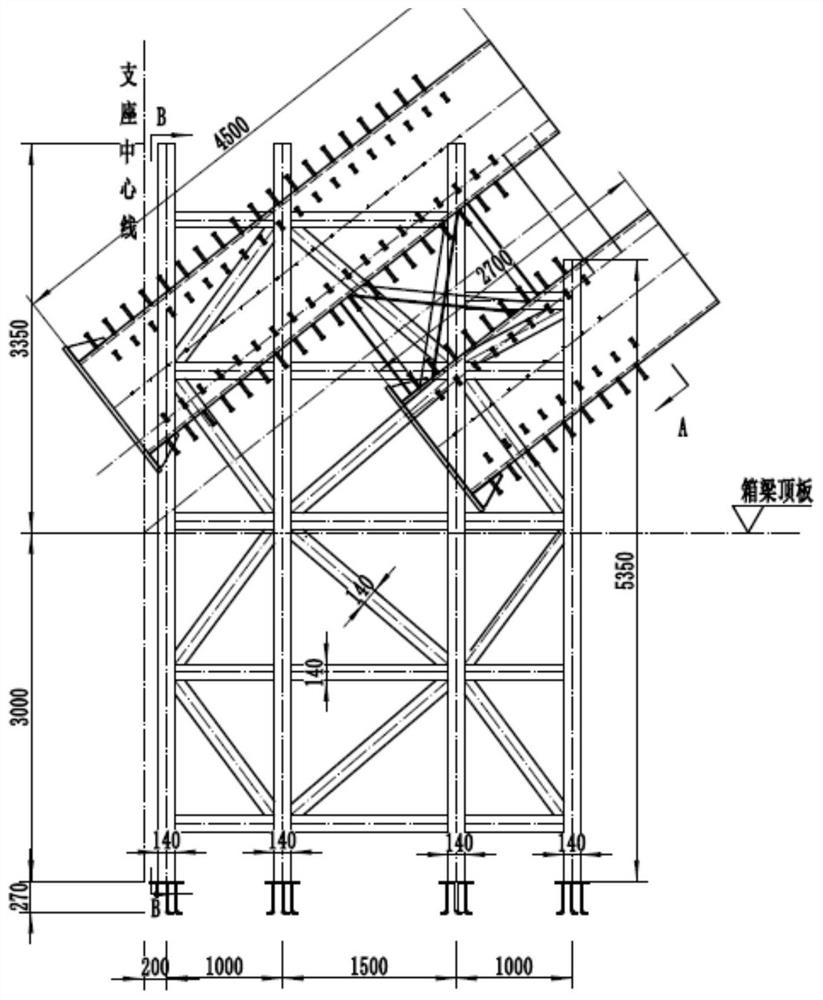

Arch stiffening continuous beam steel pipe arch crown pushing construction technology

PendingCN113250085AShorten construction timeReduce the impact of trafficBridge erection/assemblySupporting systemPre stress

The invention discloses an arch stiffening continuous beam steel pipe arch crown pushing construction technology. The construction technology comprises the following steps that S1, a temporary support is erected; s2, a pushing sliding system is installed; s3, arch supports and arch feet are mounted; s4, the arch supports and an arch seat are temporarily anchored; s5, the arch feet are pre-tensioned and unloaded; s6, pushing and sliding construction is carried out; s7, an arch foot closure section is constructed; s8, the secondary pouring of the arch feet is conducted; and S9, a sling is mounted and the sling is adjusted. The construction technology has the advantages that the influence of in-situ assembly of the arch ribs and the supports on the existing underpass expressway is solved by adopting the construction method of 'different-position assembly and integral pushing', and the construction time of the overpass expressway can be greatly shortened by adopting different-position assembly and integral pushing sliding construction, so that the influence on passing of expressway traffic is reduced. Meanwhile, after arch rib sections are assembled, prestress is applied to the arch feet, a supporting system is removed after the arch feet are pre-tightened, and the problems that in the sliding process, the stability of the arch ribs on the two sides is poor, and the arch feet are not restrained are solved.

Owner:CHINA RAILWAY BEIJING ENG BUREAU GRP NO 2

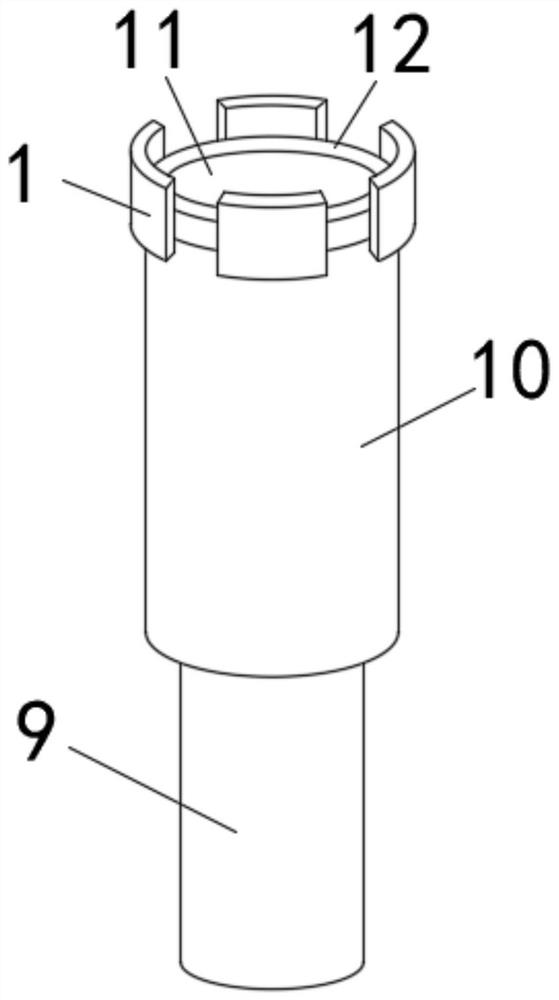

Ultrasonic bolt stress detection device

The invention discloses an ultrasonic bolt stress detection device which comprises a detection device base, one end of the detection device base is fixedly connected with a device handrail supporting rod, one end of the device handrail supporting rod is fixedly connected with a device transverse handrail, one end of the device transverse handrail is fixedly connected with a probe buckle fixing rod, one end of the probe buckle fixing rod is provided with a probe buckle clamping groove, one end of the probe buckle clamping groove is in buckle connection with a probe buckle convex block, and one end of the probe buckle convex block is fixedly connected with a probe buckle. According to the size and specification of a probe, the probe buckle with the appropriate specification is selected, the probe buckle convex block at one end of the probe buckle is buckled into the probe buckle clamping groove, and the probe buckle is buckled on the probe buckle fixing rod; and when the probe is not used, a probe wire penetrates through a circular opening in one end of the probe buckle, and an electromagnetic coil bin is placed on the probe buckle, so that the probe can be conveniently stored, and the use is convenient.

Owner:国能长源湖北新能源有限公司

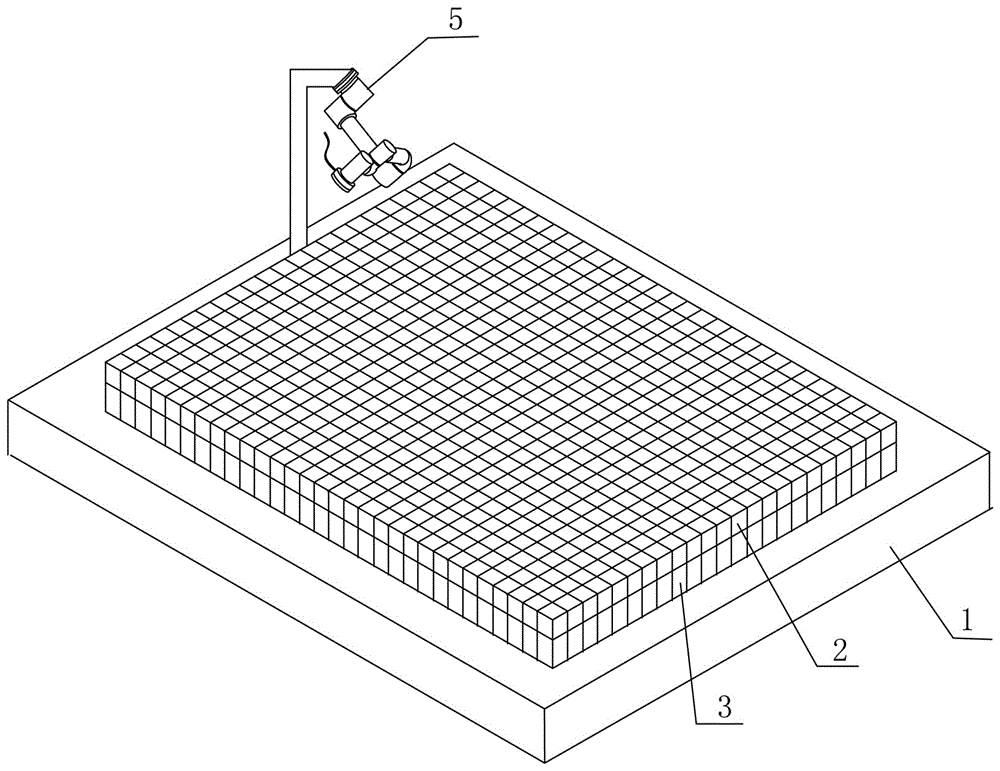

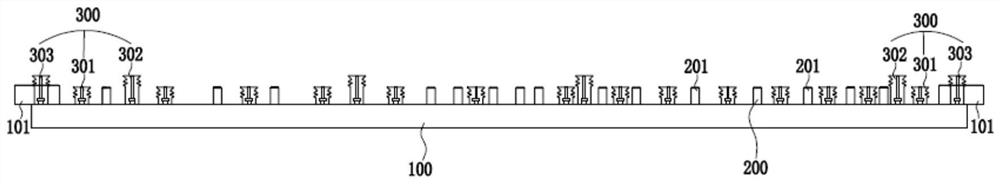

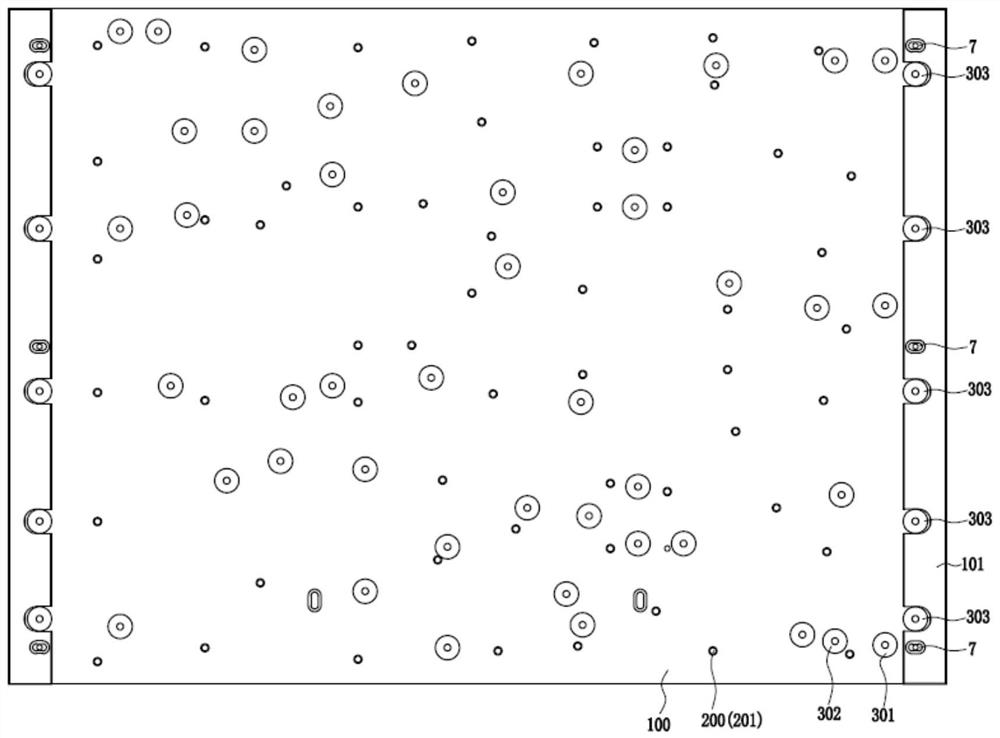

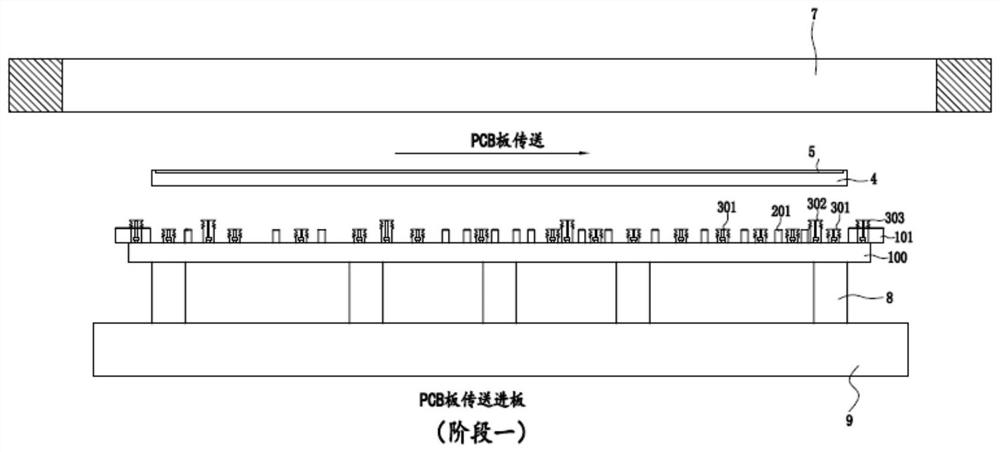

Vacuum platform for printing machine and using method of vacuum platform

PendingCN113733724AAvoid deformation effectsGuaranteed stabilityScreen printersConductive pattern formationEngineeringPrinting press

The invention discloses a vacuum platform for a printing machine and a using method of the vacuum platform, and relate to the technical field of printing machines. The vacuum platform for the printing machine comprises a main body platform, a supporting structure and a suction cup structure, the main body platform is fixed on a lifting workbench, the supporting structure comprises supporting ejector pins, and the suction cup structure comprises a PCB suction cup, a first steel mesh suction cup and a second steel mesh suction cup. When the vacuum platform is used, a PCB is jacked up through the supporting ejector pins, so that a gap is formed between the PCB and the inner bottom surface of a tool jig, and the PCB is prevented from being influenced by deformation of the bottom surface of the tool jig; then the PCB is adsorbed through the PCB suction cup, so that the PCB is tightly attached to the supporting ejector pins, and movement of the PCB is limited; a steel mesh is adsorbed through the first steel mesh suction cup and the second steel mesh suction cup, so that the steel mesh can be tightly and seamlessly attached to the PCB, then the phenomena of tin connection, tin shortage and the like of the PCB in the printing process are avoided, and the printing quality of the PCB can be effectively guaranteed.

Owner:HONGYI TECH AUTOMATION EQUIP HUIZHOU CO LTD

A magnetic field stimulation device for improving sleep quality

ActiveCN106139403BEasy accessReduce adverse effectsElectrotherapyDiagnostic recording/measuringEngineeringForce sensor

The invention provides a magnetic field stimulation device for improving sleep quality, which includes a mechanical arm for connecting with a central processing unit and a magnetic field stimulator set on the mechanical arm for connecting with the central processing unit. At the free end of the mechanical arm, an airbag made of non-stretchable material is arranged on the outside of the magnetic racket. The airbag includes a bag body and an air guide tube. The detection end of the gas pressure sensor used for information connection with the central processing unit is sealed with the air guide tube. connect. Compared with the existing technology, the invented magnetic field stimulation device for improving sleep quality has greatly improved the degree of automation, avoiding the actions of the staff manually placing the magnetic racket against the head intervention position, the sound of staff entering and leaving the room, opening and closing the door Factors such as the generated sound adversely affect the user's ability to go to sleep, and the effect of use is very good.

Owner:孙承业

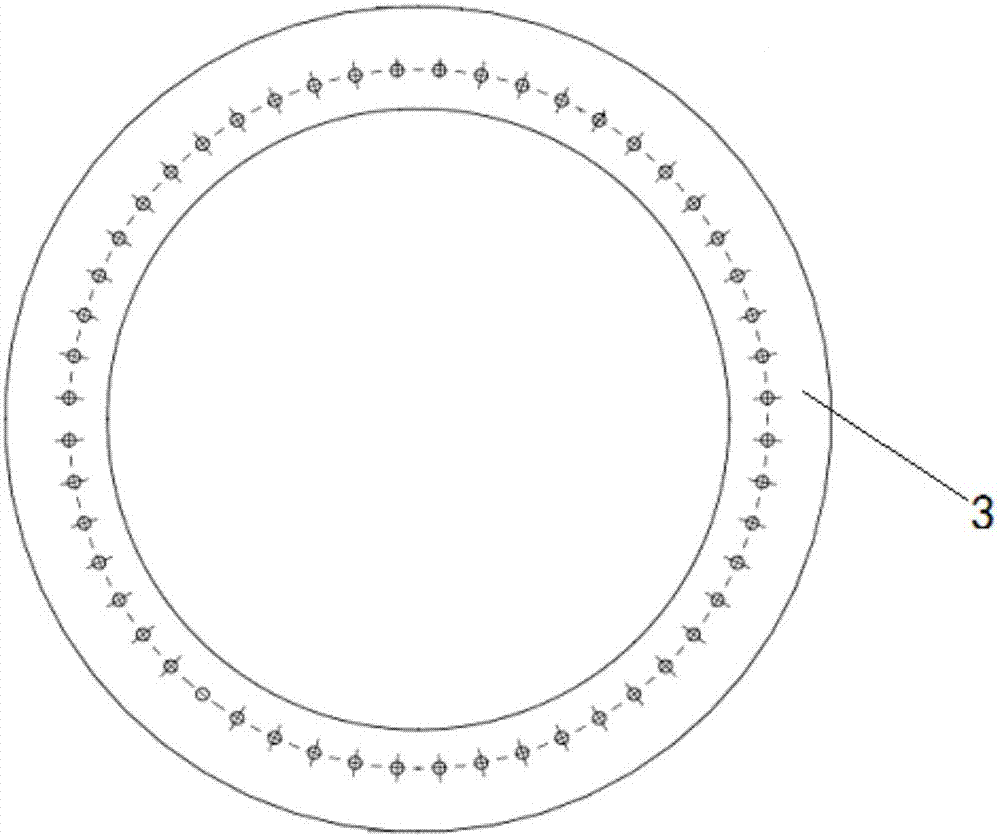

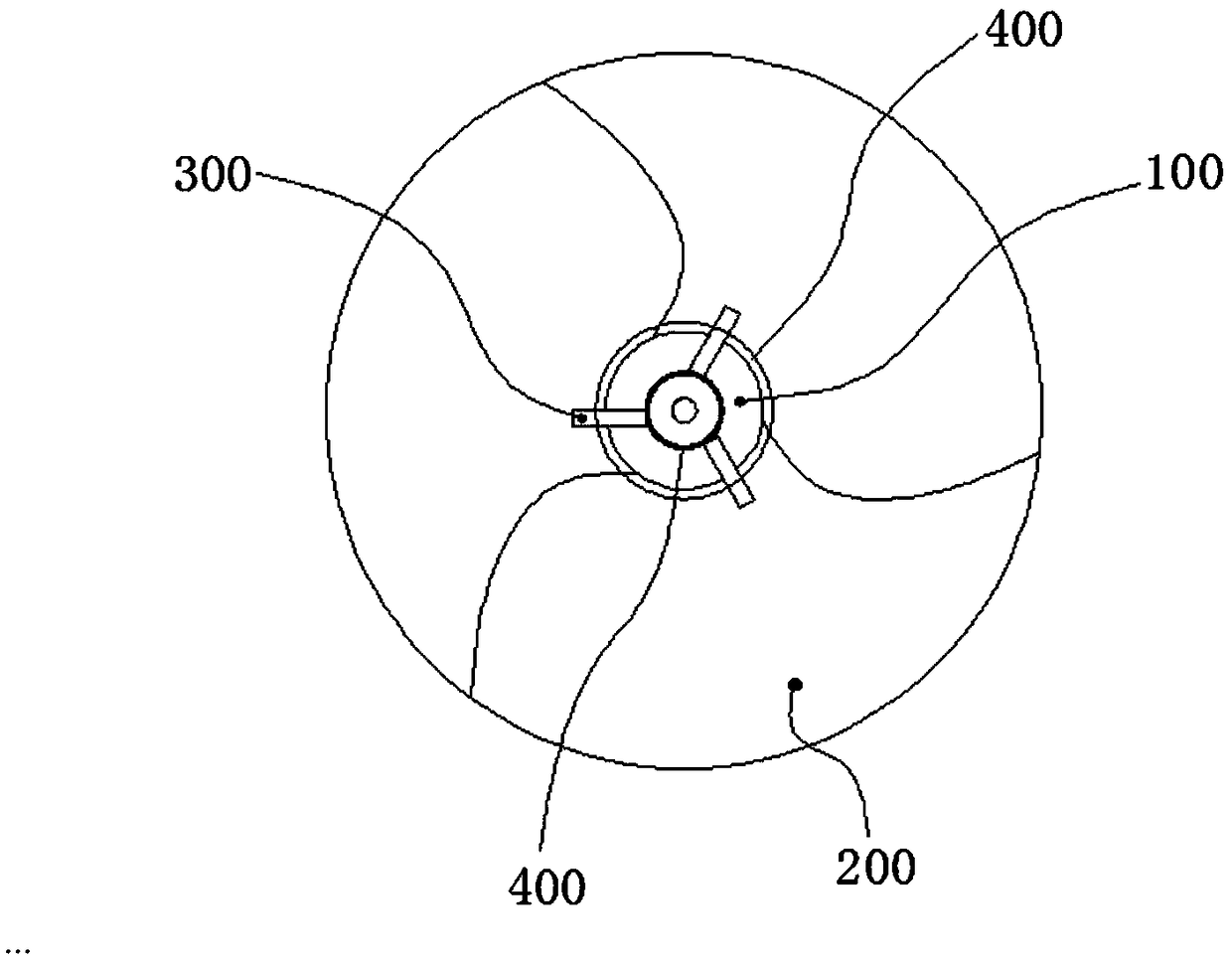

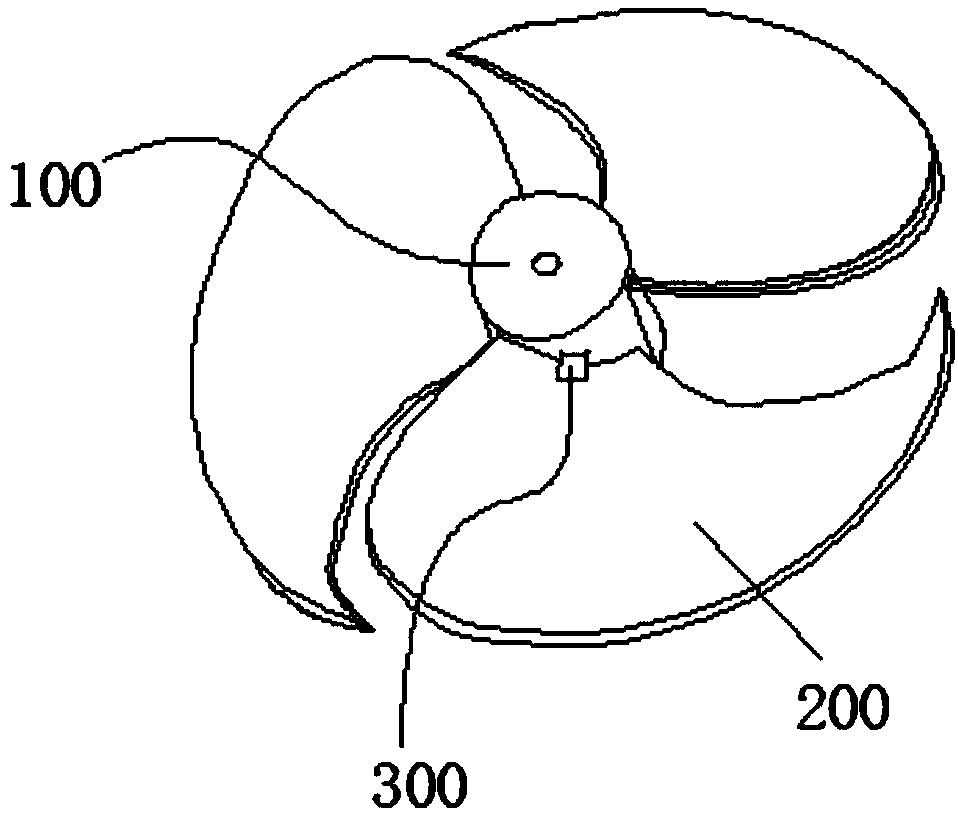

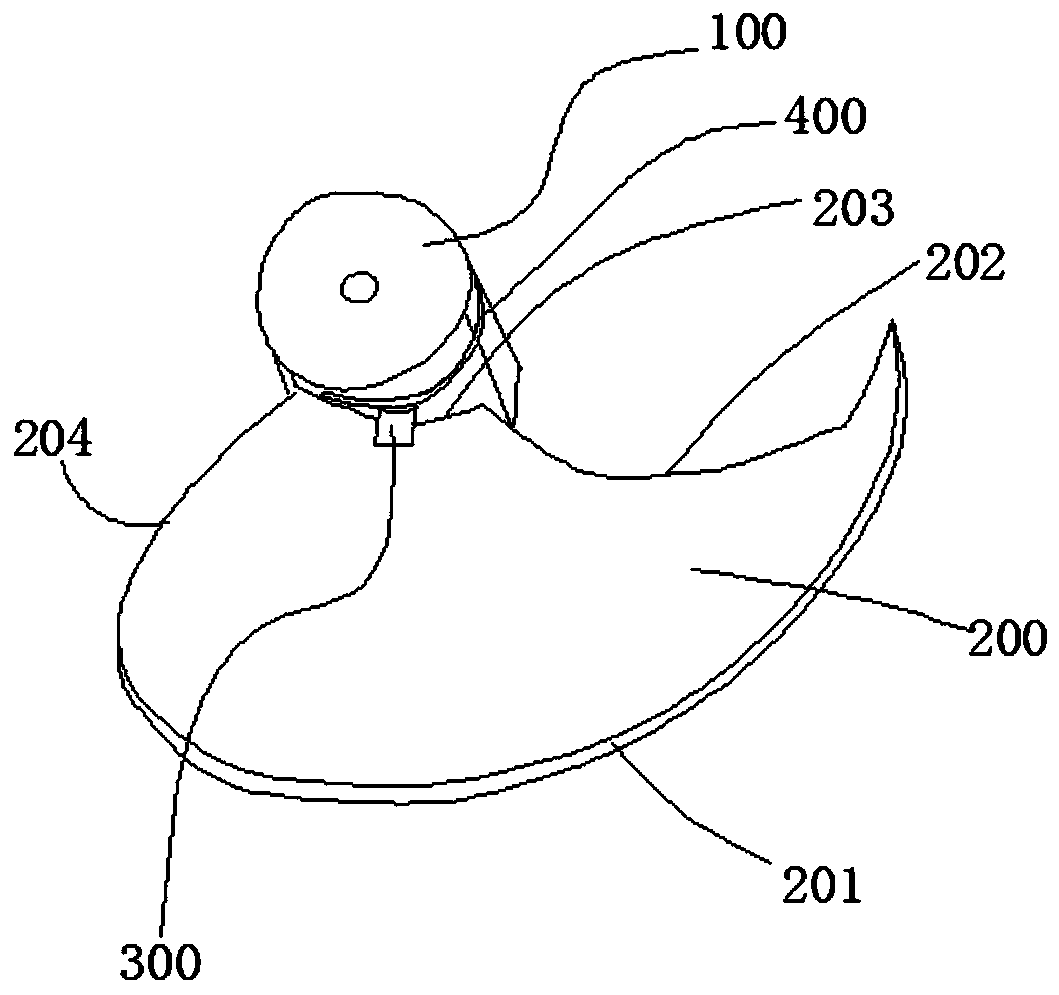

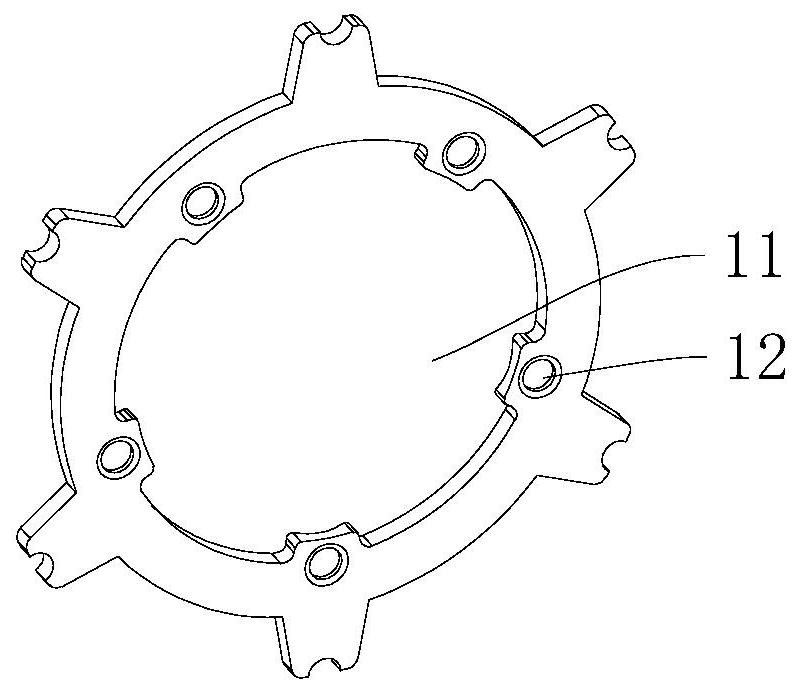

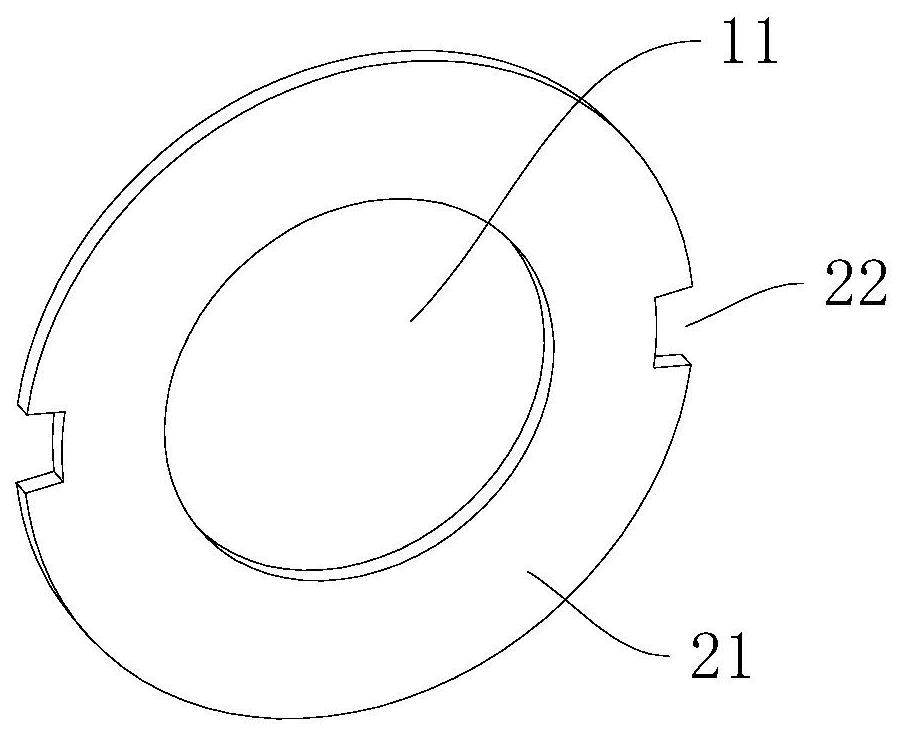

Weatherproof vanes with self-closing function

ActiveCN106438472BFit precisionRealize the effect of exhaustPump componentsPumpsStopped workEngineering

The invention discloses a weatherproof wind blade with an automatic closing function, and belongs to the field of wind dispelling or wind exhausting equipment. Staggering mechanisms are arranged on the blades; return mechanisms are arranged between main shafts and the blades; and when the blades are returned through the return mechanisms, and multiple blades are spliced as a complete closed circle, and are staggered through the staggering mechanisms, the blades are fixedly inclined on the main shafts to form a wind blade eddy current structure. The staggering mechanisms and the return mechanisms realize conversion of closing and unfolding states of the wind blades; when the wind blades work, the staggering mechanisms unfold the wind blades to form the wind blade eddy currents to realize the wind exhausting effect; and when the wind blades stop working, the return mechanisms return the wind blades to form a closed circle, and the adjacent blades are tightly bonded to realize a no-gap structure of an exhaust fan so as to achieve the weatherproof effect.

Owner:温岭市应达电器有限公司

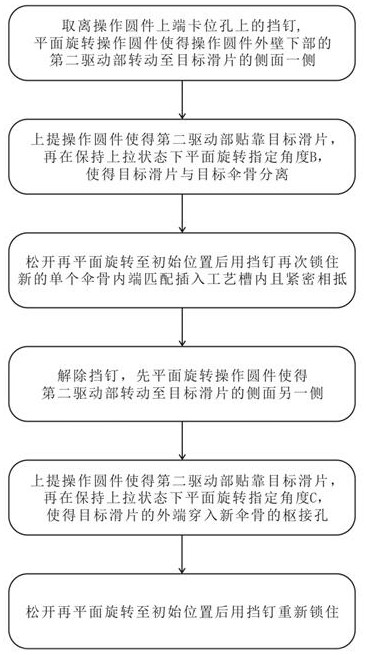

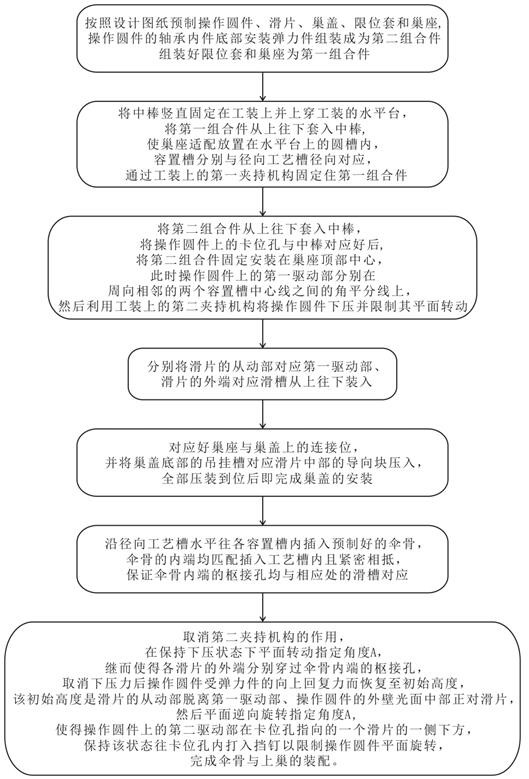

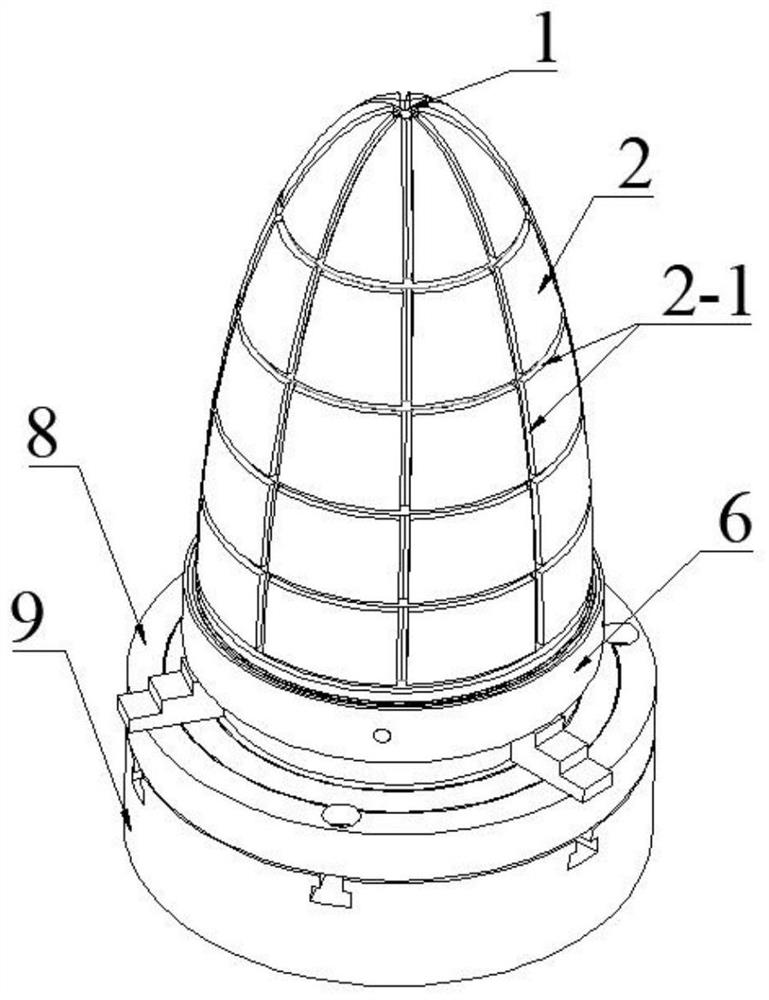

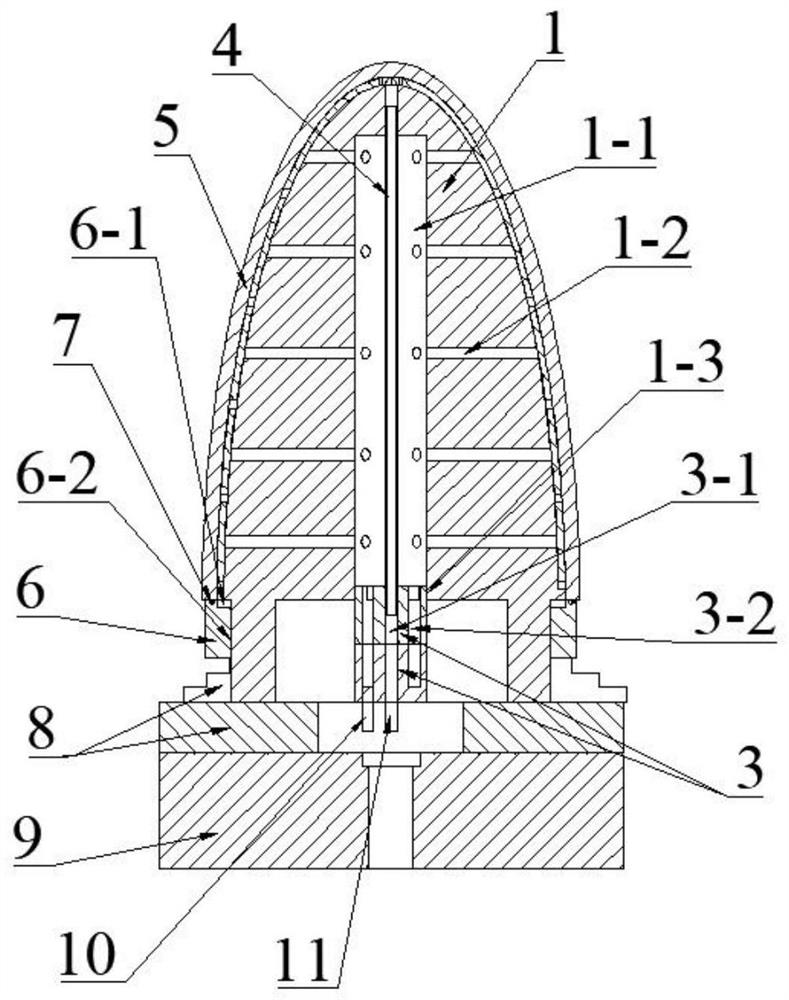

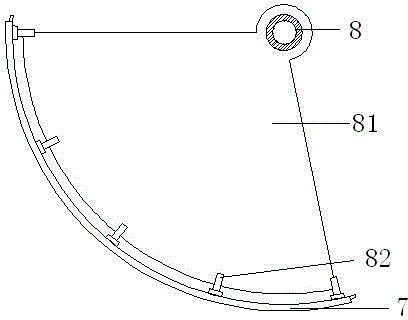

Disassembly and assembly process of umbrella rib and upper nest

ActiveCN110464090BHigh tensile strengthLittle artificial influenceWalking sticksClimate change adaptationStructural engineeringMechanical engineering

The invention relates to the disassembly and assembly process of the umbrella ribs and the upper nest, which is divided into the overall hanging process of completing the hanging of all the umbrella ribs at one time and the single bone disassembly and replacement process of separately dismantling and reassembling the umbrella ribs from the upper nest. The dismantling process specifically includes The steps are as follows: take out the retaining nail on the clamping hole, operate the round piece through plane rotation and lifting in turn, and then rotate the plane while keeping the pull up state to separate the target slide from the target rib; when installing a single rib, sequentially pass through Plane rotation and lifting operation The round part is then rotated in a plane while maintaining the pull-up state so that the outer end of the target slider penetrates the pivot hole of the new rib, and finally loosened and then rotated in a plane to the initial position and then locked again with a stopper . The overall hanging process includes rotating the plane of the operating circular piece at a specified angle while maintaining the pressed state with the aid of tooling, and then making the outer ends of each sliding piece pass through the pivot holes at the inner end of the umbrella ribs. The umbrella frame of the present invention can be fully assembled in place at one time, and can also be disassembled separately, has a stable structure, and is convenient for users to operate and use.

Owner:晋江集成轻工有限公司

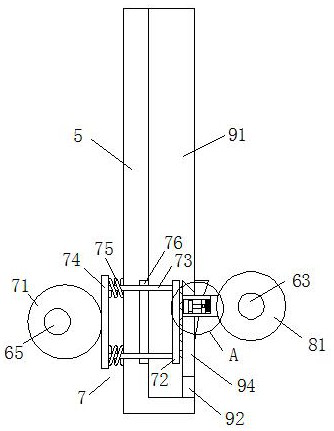

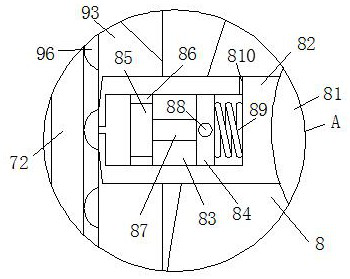

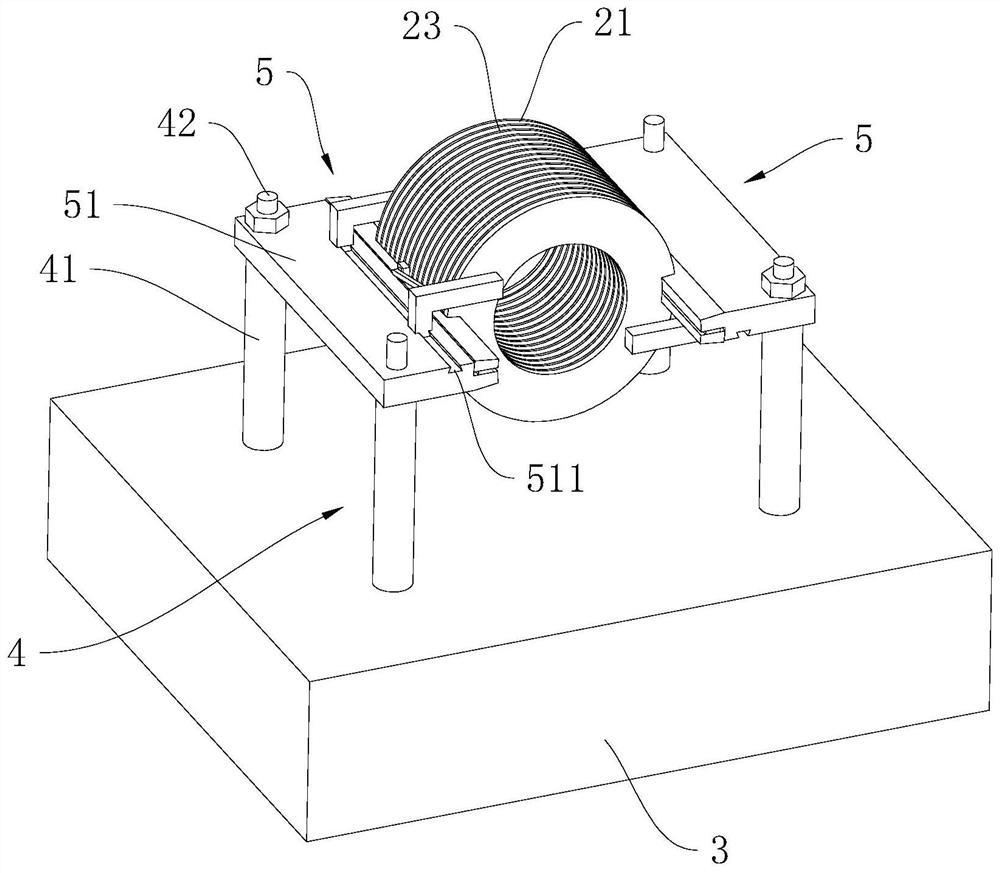

Safety device used for elevator and utilizing magnetorheological fluid for speed control

InactiveCN111981062AAvoid derailment or even breakageTo achieve the purpose of speed controlLiquid resistance brakesMagnetorheological fluidEngineering

The invention relates to the technical field of safety devices, and discloses a safety device used for an elevator and utilizing magnetorheological fluid for speed control. The safety device comprisesa driving roller, a supporting seat is arranged at one end of the driving roller, and the inner side wall of the supporting seat is fixedly connected with a roller seat; the interior of the roller seat is rotationally connected with a roller shaft, and one end of the roller shaft is fixedly connected with one end of the driving roller; and a first coil is wound on the outer side wall of the roller shaft. The rotating speed of the roller shaft is increased, a current generated by the first coil is also larger, thus a current on a second coil connected with the first coil is also increased accordingly, thus a magnetic field generated by the second coil and an iron core are also higher, according to the characteristic of the magnetorheological fluid, the larger the magnetic field around themagnetorheological fluid is, the larger the viscosity of the magnetorheological fluid is, thus the shearing stress needing to be overcome by a connecting shaft in the magnetorheological fluid is larger, the rotating speeds of the roller shaft connected with the connecting shaft and the driving roller are decreased, thus the purpose of speed control is achieved, and the phenomena that a chain runsoff a rail and is even broken are effectively avoided.

Owner:广州耀满科技有限公司

A high-precision cutting device for winding pipe production and its use method

The invention discloses a high-precision cutting device for winding pipe production and its use method. It includes a bottom plate, and limit blocks are fixed on the left and right sides of the top of the bottom plate, and a pipe body is arranged between the two limit blocks. The top of the bottom plate is provided with a support mechanism, the support mechanism includes two first cylinders, and the two first cylinders are respectively arranged on the left and right sides of the top of the bottom plate, and the bottom of the first cylinder is fixed with a heightening block. The bottom of the heightening block is fixedly connected to the top of the bottom plate, and the output ends of the two first cylinders are fixedly provided with support blocks. The invention controls the movement of the support block through the first cylinders on both sides, so that when the pipe body is cut by the blade, the support block is in the interior of the pipe body and in contact with its inner wall, providing a stress point for both sides of the pipe body and avoiding the impact of the blade on the pipe. The slit causes extrusion without causing deformation at the slit, thereby improving the cutting accuracy and cutting quality of the pipe.

Owner:RONGCHENG PIPE IND

OCR laminating machine internal height measurement assembly and height measurement method

ActiveCN112248606ASolve the problem of easy cracking and instability during useEasy to operateMeasurement devicesFinal product manufactureEngineeringStructural engineering

The invention discloses an OCR laminating machine internal height measurement assembly and height measurement method. The OCR laminating machine internal height measurement assembly comprises a rack main body and a feeding and discharging rack arranged at one side of the rack main body; the rack main body is provided with a laminating assembly; one side of the laminating assembly is provided witha height measurement assembly; the laminating assembly comprises a slide rail and a top carrier plate movably connected to the upper portion of the slide rail; a bottom carrier plate is movably connected the lower portion of the sliding rail; a lifting device is connected to the bottom of the bottom carrier plate; the height measurement assembly comprises a supporting rod installed on a bottom installation base; a first induction device is arranged at the upper end of the supporting rod; a second induction device is arranged below the first induction device; a third induction device is arranged below the second induction device; the first induction device, the second induction device and the third induction device are arranged corresponding to the bottom of the top carrier plate, the lowerportion of the bottom of the top carrier plate and the distance between the top carrier plate and the bottom carrier plate respectively. According to the OCR laminating machine internal height measurement assembly and height measurement method of the technical schemes, a parameterized and calculable laminating mode is realized, so that the laminating combination degree is normalized and more accurate.

Owner:深圳双十科技股份有限公司

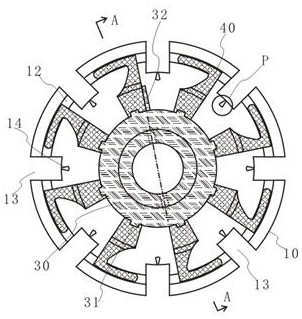

Improved upper nest structure for umbrella

PendingCN110326862AHigh tensile strengthLittle artificial influenceWalking sticksMechanical engineering

The invention relates to an improved upper nest structure for an umbrella. The improved upper nest structure for the umbrella comprises a nest seat and a nest cover. A seat hole and an operating roundpiece concentrically arranged outside the seat hole are arranged at the top center of the nest seat, a sliding groove and accommodating grooves are formed in the top edge of the nest seat, and sliding sheets are arranged between the operating round piece and the sliding groove; the outer ends of the sliding sheets are arranged in the sliding groove in an adaptive mode, driven parts are arranged at the inner ends of the sliding sheets, first driving parts matched with the driven parts are arranged on the upper part of the outer wall of the operating round piece, and second driving parts matched with the side surfaces of the sliding sheets are arranged on the lower part of the outer wall of the operating round piece; and bearing inner pieces are installed at the center of the bottom of theoperating round piece in an embedded mode, the bearing inner pieces and the nest seat are fixedly connected with elastic pieces, and when the elastic pieces are at the initial height, the second driving parts are located below the sliding sheets while the first driving parts are located above the sliding sheets. The nest cover is arranged at the top of the nest seat, limiting ring grooves and hanging grooves are formed in the bottom of the nest cover, upward pulling spaces are reserved between the nest cover and the operating round piece, and the upper end of the operating round piece penetrates through the nest cover. Umbrella ribs of the improved upper nest structure for the umbrella can be fully assembled in place at one time, or target ribs can further be separately disassembled and assembled, the structure is stable, and the operation and use by a user are convenient.

Owner:晋江集成轻工有限公司

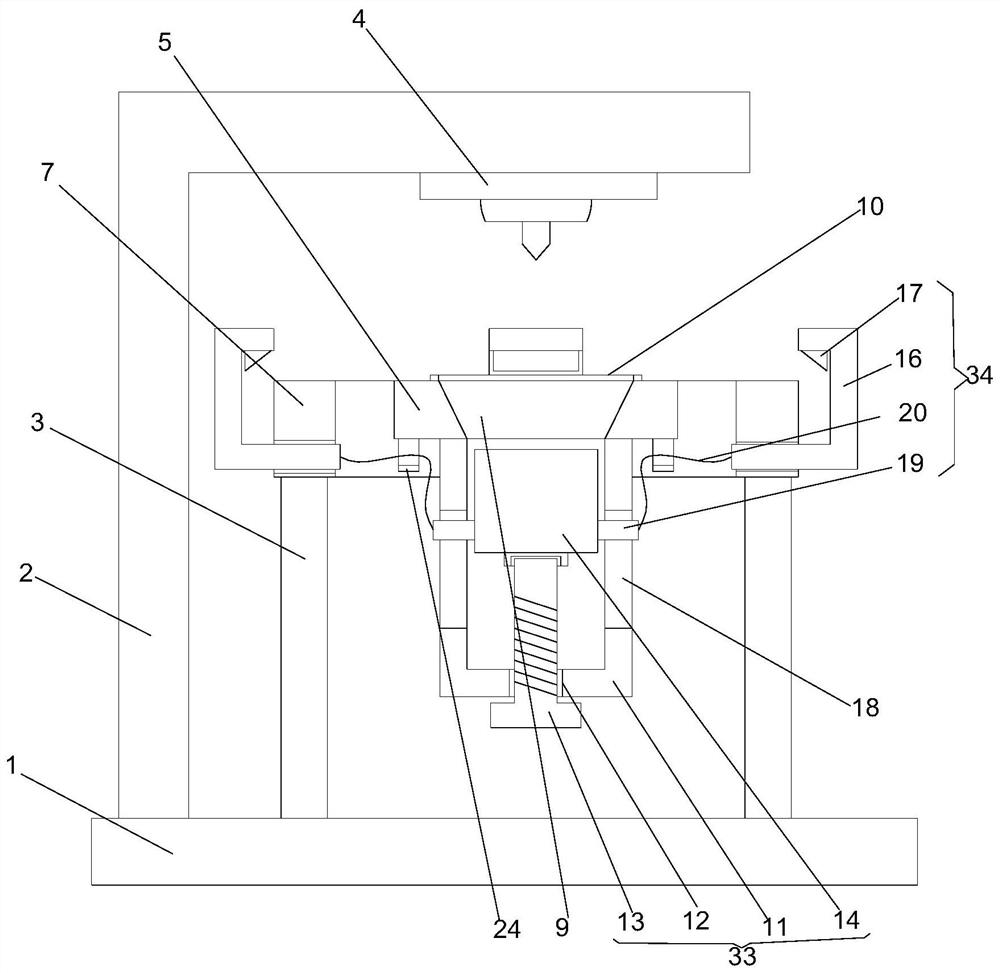

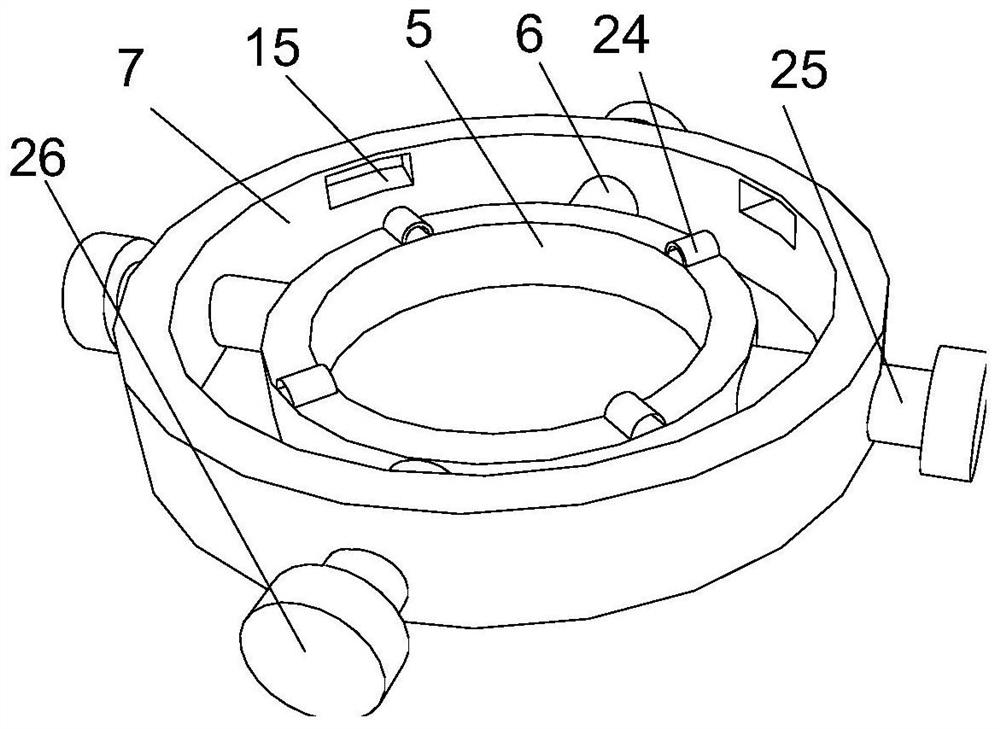

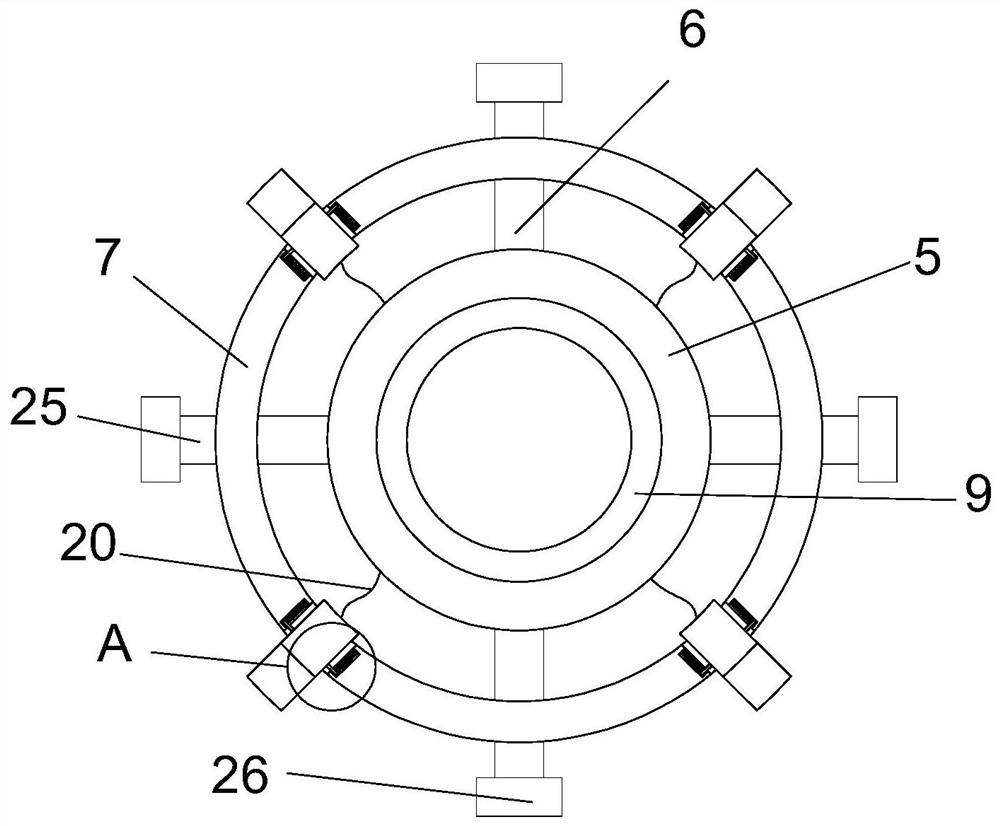

A self-adaptive flexible low-stress clamping device and clamping method for deep-sag aspheric elements

ActiveCN113211351BHigh precision requirementsHigh clamping precisionWork holdersSelf adaptiveMechanical engineering

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

Paper feeding mechanism for invoice printer

ActiveCN112478843BRealize automatic paper feedingAvoid troublesome operationTypewritersOther printing apparatusComputer printingMechanical engineering

The invention relates to the field of printers, in particular to a paper feeding mechanism for an invoice printer, which includes a fixed base, a printer body, a paper inlet hole, a paper outlet hole, a deflector, a driving mechanism, an extrusion mechanism, a paper suction mechanism and a storage mechanism. mechanism, the upper end of the fixed base is fixedly connected with a printer main body, and a paper feeding hole is opened at the upper end of the printer main body. Through the rotation of the active shaft of the driving mechanism, the paper suction roller of the paper suction mechanism can be driven to rotate, and the piston plate can slide in the air cavity through the extrusion of the arc-shaped top plate to the pull rod, and finally the air suction head can suck the invoice The paper slides out from the front baffle of the storage mechanism, and is disconnected from the arc-shaped top plate through the pull rod, so that the air pressure suction head is disconnected from the invoice paper, and enters the main body of the printer for printing, realizing automatic paper feeding by the printer. It avoids the troublesome operation of manually sending invoices one by one to the designated position of the printer, and improves printing efficiency.

Owner:NANJING HANMINGZHI INTELLIGENT TECHNOLOGY CO LTD

Brake disc processing technology and tooling

ActiveCN112935724BIncrease productivityImprove grinding efficiencyGrinding work supportsBrakePunching

This application relates to a brake disc processing technology and tooling. The processing technology includes blanking, car inner hole and grinding inner hole; step blanking: the sheet is placed on the workbench, and a circular shape is processed by cutting or punching. The base plate is processed with a positioning groove on the outer periphery of the base plate, and the positioning groove runs through the base plate along the thickness direction of the base plate; the inner hole of the step: clamp the outer periphery of the base plate, and turn the center hole on the base plate; the inner hole of the step grinding: multiple The base plates are coaxially stacked into a group, and the positioning grooves on each base plate are connected to each other. A set of base plates is installed on the tooling, and the grinding wheel rods are inserted into multiple center holes to grind the inner peripheries of the multiple center holes. Realize synchronous grinding of multiple basic center hole inner peripheries by using one grinding wheel rod, improve grinding efficiency, and further improve production efficiency of brake discs.

Owner:浙江隆中机械股份有限公司

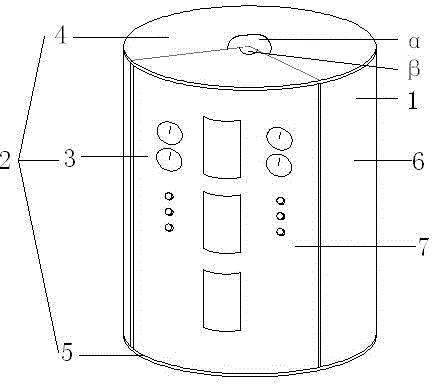

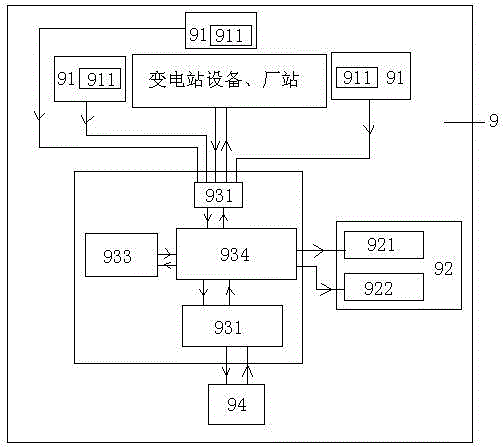

Transformer substation condition overhauling device based on three-dimensional visual intelligent platform

The invention provides a transformer substation condition overhauling device based on a three-dimensional visual intelligent platform. The device is simple in structure and reasonable in design, access and updating of historical and real-time data in data of power grid models such as transformer substation equipment, plant-stations and the like are realized, and manual monitoring is performed through cameras; through collection and analysis of the historical and real-time data in data of the power grid models such as the transformer substation equipment, the plant-stations and the like, the operation of the power grid models such as the transformer substation equipment, the plant-stations and the like can be diagnosed, monitoring, maintenance and overhauling are convenient, meanwhile, a cabinet adopted by the device is convenient and fast, has good dust prevention effect and is simple to overhaul.

Owner:JIANGSU PROVINCE XIDIAN ELECTRICAL

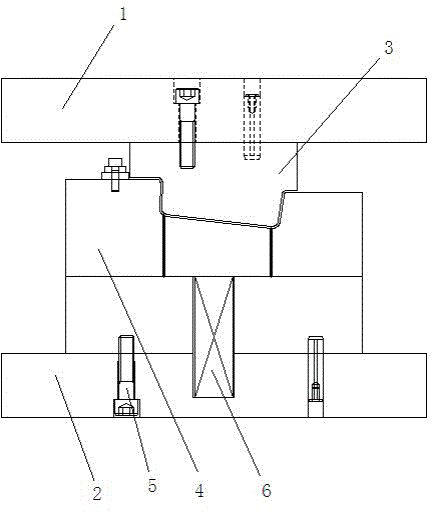

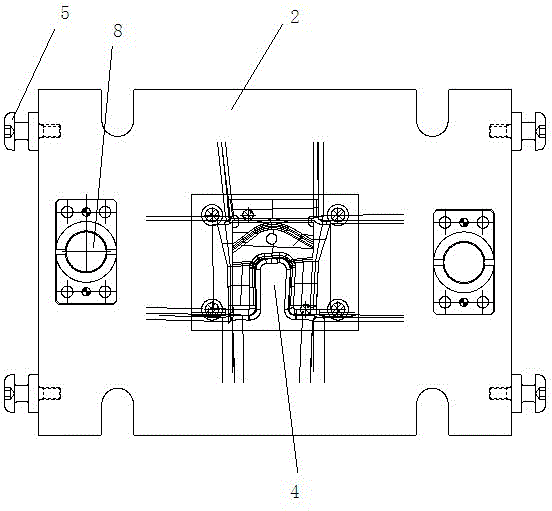

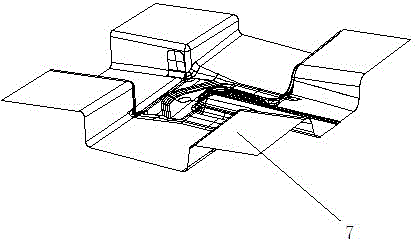

Stamping die for automobile left suspension installation inner-plate

The invention relates to an automobile part machining die, in particular to a stamping die for an automobile left suspension installation inner-plate. The stamping die for the automobile left suspension installation inner-plate is characterized by comprising an upper die plate and a lower die plate, wherein a male die is arranged at the lower part of the upper die plate, a female die which is provided with a positioning hole is arranged at the upper part of the lower die plate, and the positioning hole is matched with a positioning column arranged on the male die; and a spring is arranged between the female die and the lower die plate. According to the stamping die for the automobile left suspension installation inner-plate, the positioning hole is matched with the positioning column, so that an upper die and a lower die can be more precisely adhered, and the stamping machining efficiency is high.

Owner:WUHU BODA MACHINERY MFG

Gate valve rapid laser welding device

PendingCN113732501APrecise fitEfficient compressionLaser beam welding apparatusThreaded rodLaser soldering

The invention provides a gate valve rapid laser welding device, and relates to the technical field of welding equipment. The gate valve rapid laser welding device comprises a base and a laser welding device, wherein a mounting plate is fixedly connected to the top of the base, moving grooves are formed in the two sides of the center of the top of the mounting plate, a moving frame is slidably arranged in each moving groove, a mounting frame is fixedly connected to the top of each moving frame, mounting boxes are fixedly connected to the two corners of the front side of the top of the base, threaded rods are rotationally connected between the opposite inner surface walls of the two sides of each mounting box, a push plate is in threaded connection with the outer surface of each threaded rod, a sliding rod is fixedly connected to the inner surface wall of one side of each mounting box, the outer surface of each sliding rod is slidably sleeved with a limiting spring and a C-shaped top plate, and a supporting frame is fixedly connected to the top of the base. The welding device solves the problems that a traditional manual laser welding device is complex in operation process, and actual welding failure or flaws are prone to being caused.

Owner:YANCHENG JINGSHENG PETROCHEMICAL MASCH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com