Patents

Literature

85results about How to "Avoid deformation effects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

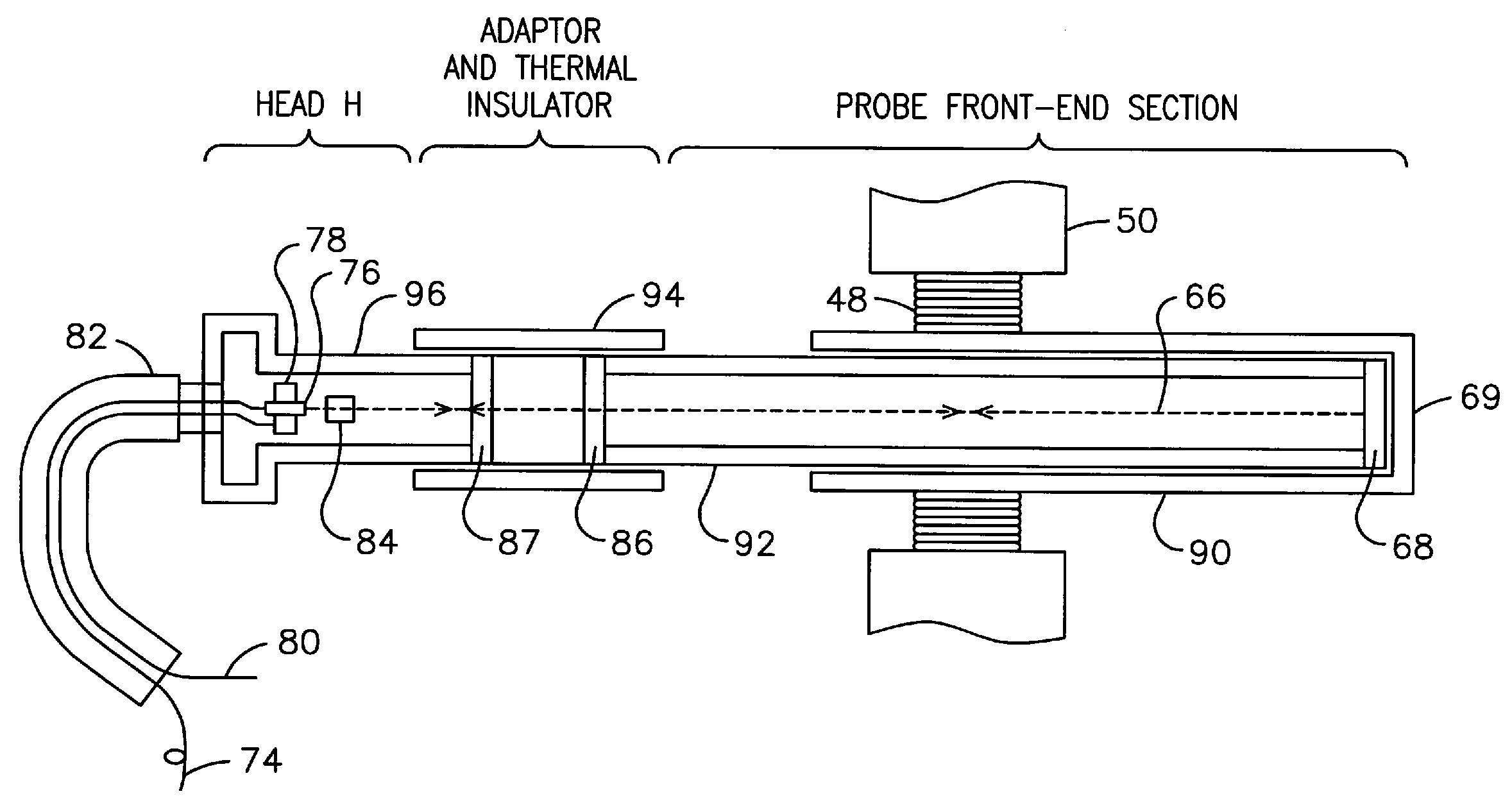

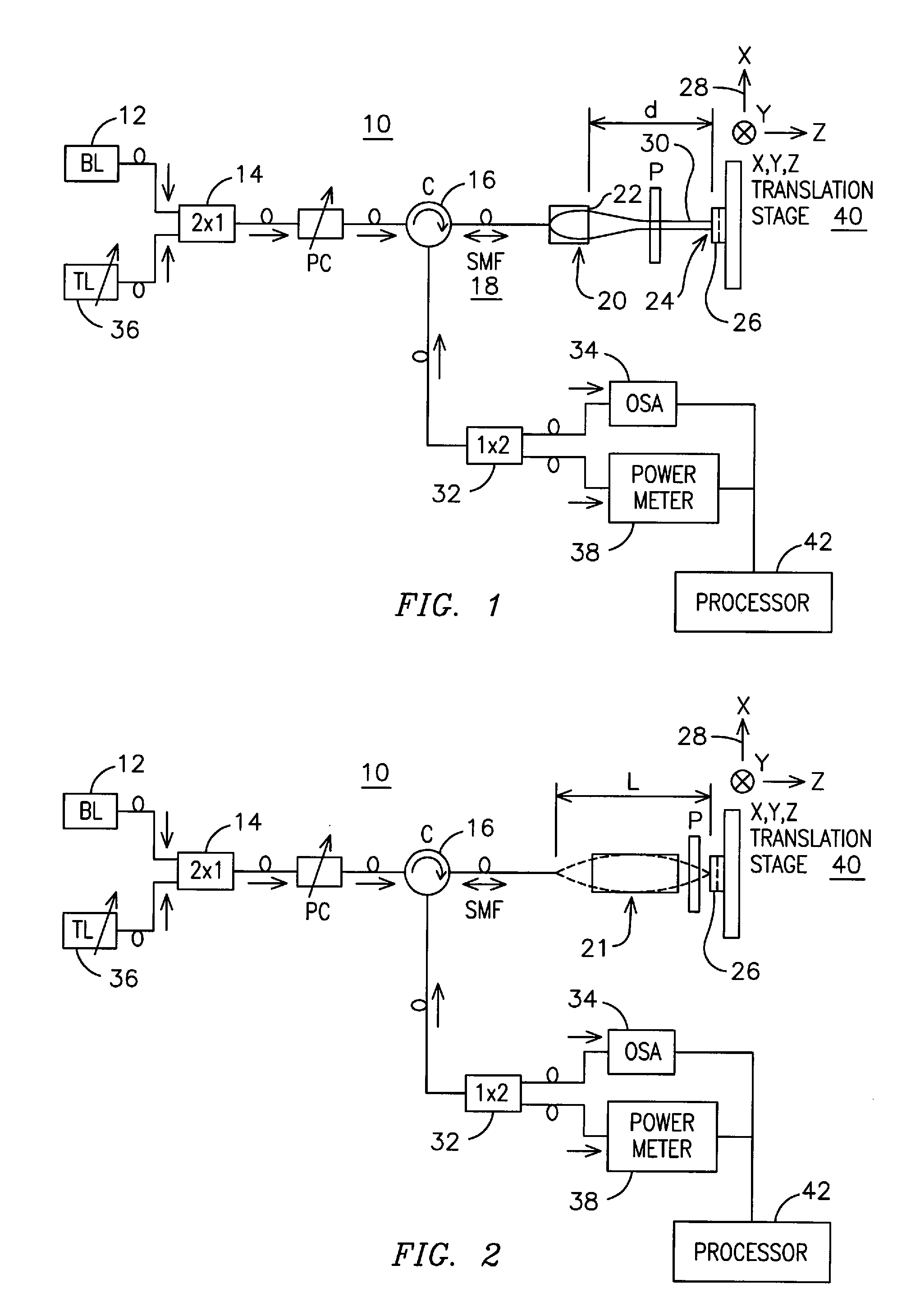

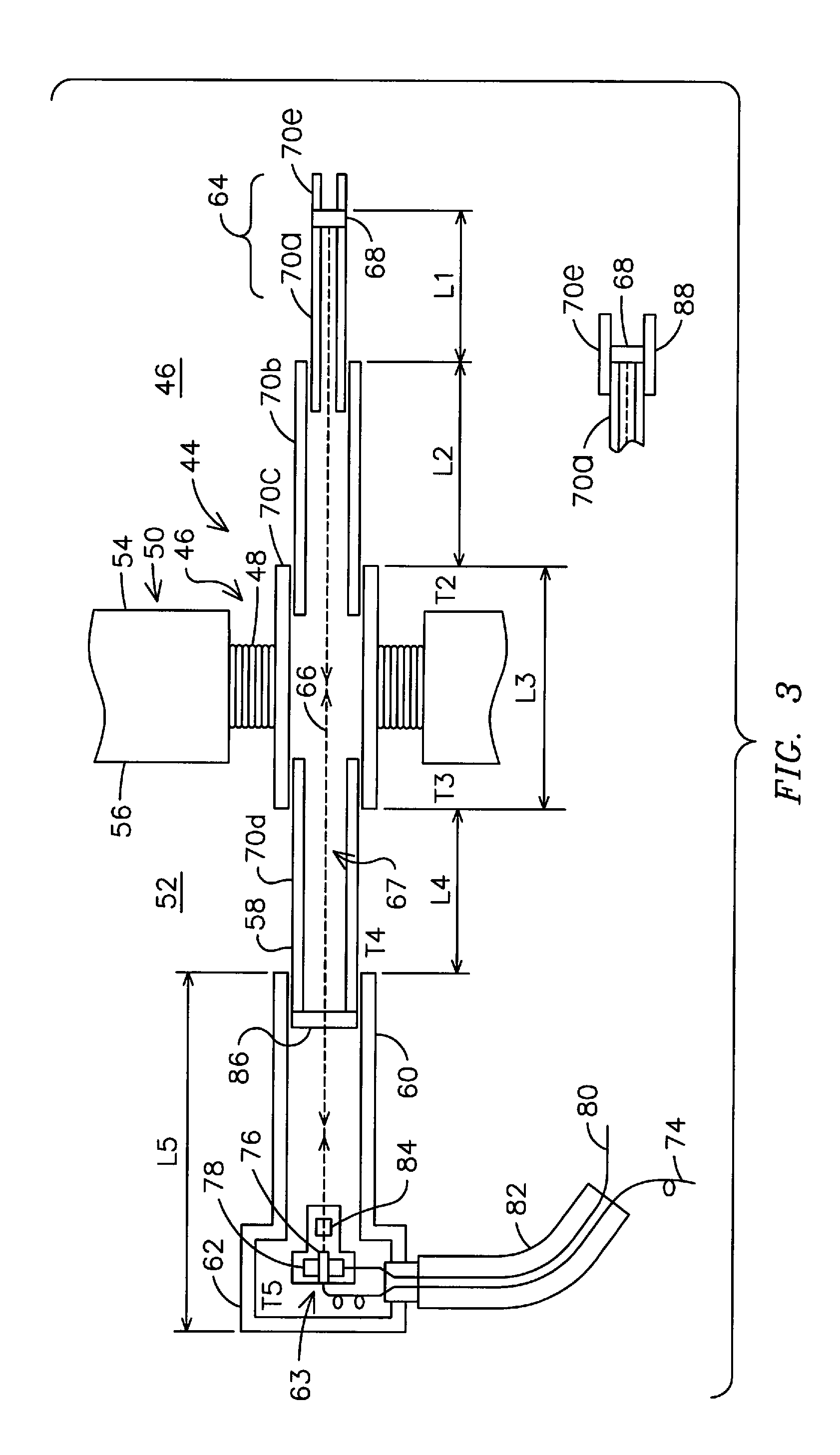

Optical Sensor For Extreme Environments

InactiveUS20080297808A1Low costGreat spatial coherenceInterferometersUsing optical meansLight beamOptical sensing

An optical sensing probe includes a tube having a tip portion configured for placement in an environment in which conditions are to be sensed and an etalon having a known characteristic disposed proximate the tip portion. The tube also includes a head portion remote from the tip portion containing a light directing element for directing light beams at the etalon and receiving reflected light beams from the etalon wherein the received reflected light beams are used for determining an environmental condition proximate the tip portion. A method for measuring a thickness of the etalon may include directing a light beams at different frequencies at the etalon and receiving the light beams from the etalon. The method may also include identifying conditions of the respective light beams condition received from the etalon and then calculating a first thickness of the etalon responsive to the respective conditions and the known characteristic.

Owner:NUSENSORS +2

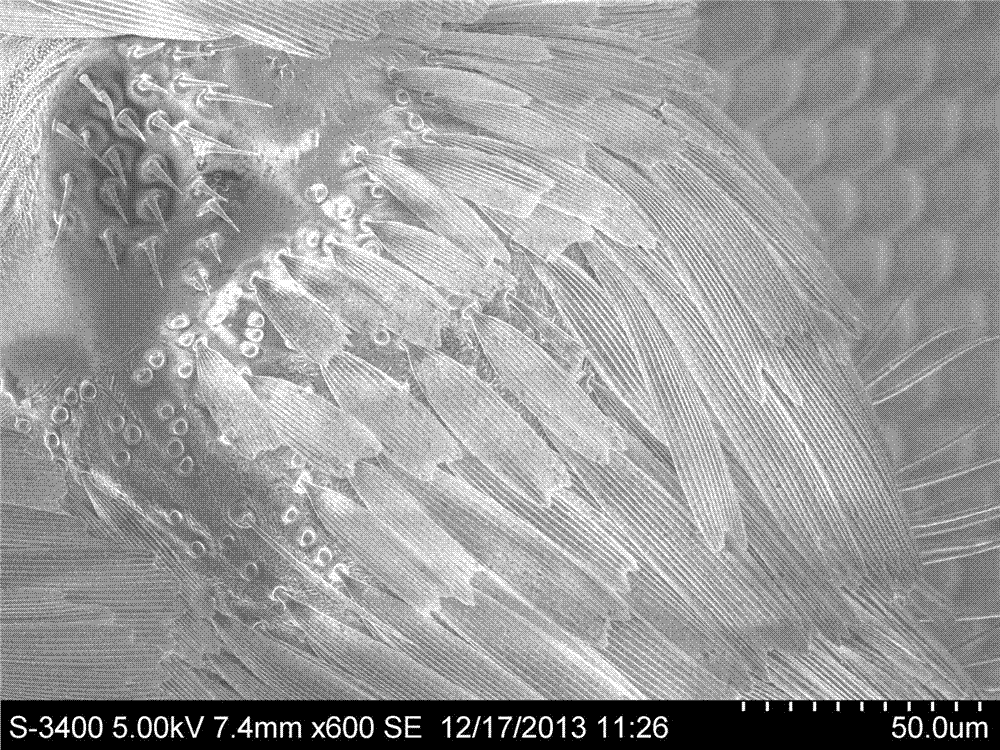

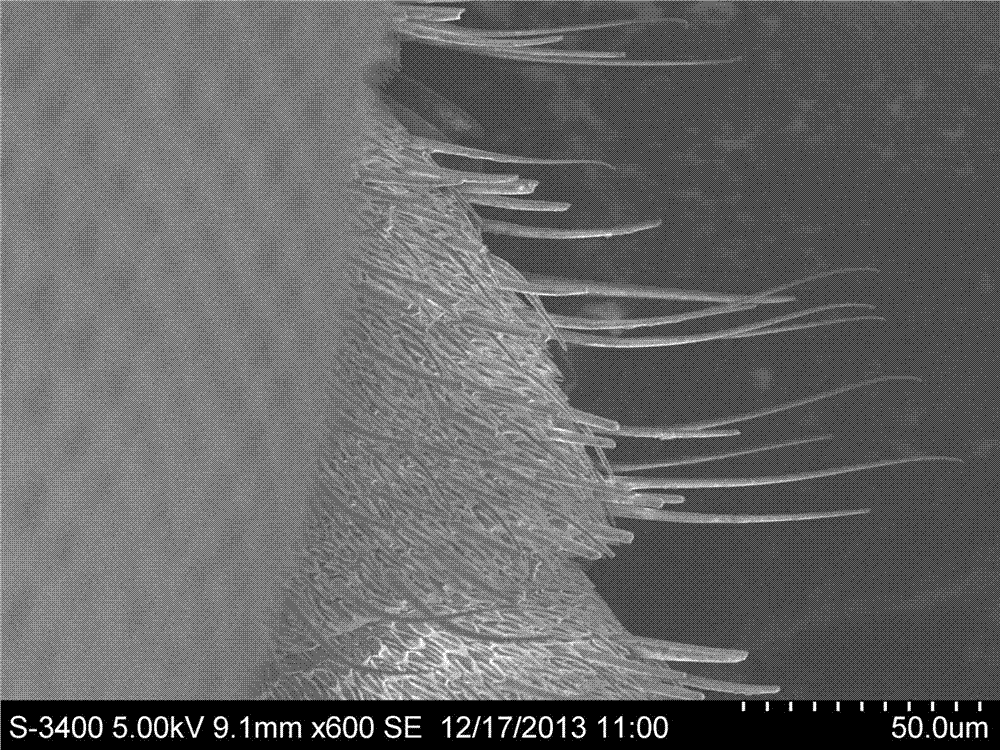

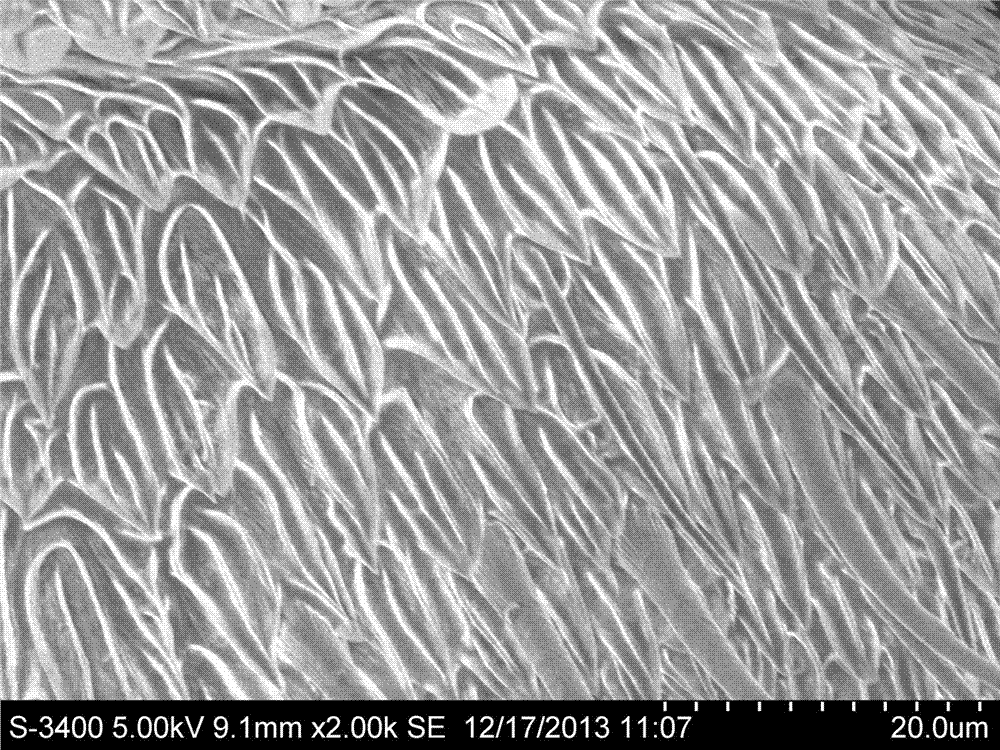

Treatment method of scanning electron microscope samples of insect tentacles and appendages

ActiveCN103868768ALow priceEasy to operatePreparing sample for investigationPhosphateScanning electron microscope

The invention relates to a treatment method of scanning electron microscope samples of insect tentacles and appendages, and belongs to the technical field of treatment of experimental samples. The treatment method provided by the invention comprises the steps of anaesthetizing and dissecting insects, fixing a sample through a glutaraldehyde-formaldehyde phosphate buffer, cleaning the sample and performing gradient dehydration with ethyl alcohol on the sample so as to obtain a scanning electron microscope sample before loading. The treatment method provided by the invention has the advantages that the problems that in the earlier stage treatment of the scanning electron microscope samples of the tentacles and appendages, scales of tentacles and appendages are not fully removed, the surface of the sample is not fully cleaned, the sample is hard to soak in a fixing solution thoroughly, and the sample is crisp and is easy to snap are solved, the surface structure of the treated sample is good, the deformation and pollution are not generated, a tissue surface is fully revealed, the sample has a good conductive property, and the real condition of the surface of the sample is effectively reflected.

Owner:INST OF PLANT PROTECTION HENAN ACAD OF AGRI SCI

Machining process of middle-long thin-wall blades

ActiveCN103008741AReduce cumulative errorReduce processing stress deformationMilling equipment detailsEngineeringMachining process

The invention discloses a machining process of middle-long thin-wall blades, which belongs to the technical field of machining of blades. The machining process is implemented by a detailed process of integrated rough machining and integrated fine machining, wherein the integrated rough machining comprise the specific steps of rough machining of each surface of a blade tip, each surface of a blade root and a molded surface of a steam passage; and the integrated fine machining comprises the specific steps: semifinishing of each surface of the blade tip and each surface of the blade root, fine machining of each surface of the blade tip, each surface of the blade root and each residue, semifinishing of the steam passage and fine machining of the steam passage. According to the machining process of the middle-long thin-wall blades, the operation is simple and convenient, the use is convenient and fast, the cost is low, the machining efficiency is high, and the operation is easy and labor-saving; and the deformation of the middle-long thin-wall blades is controlled within 0 to 0.8mm, the normal machining of a subsequent mold correction process is facilitated, and the machining of each blade is finished once.

Owner:SICHUAN MIANZHU XINKUN MACHINERY MAKING

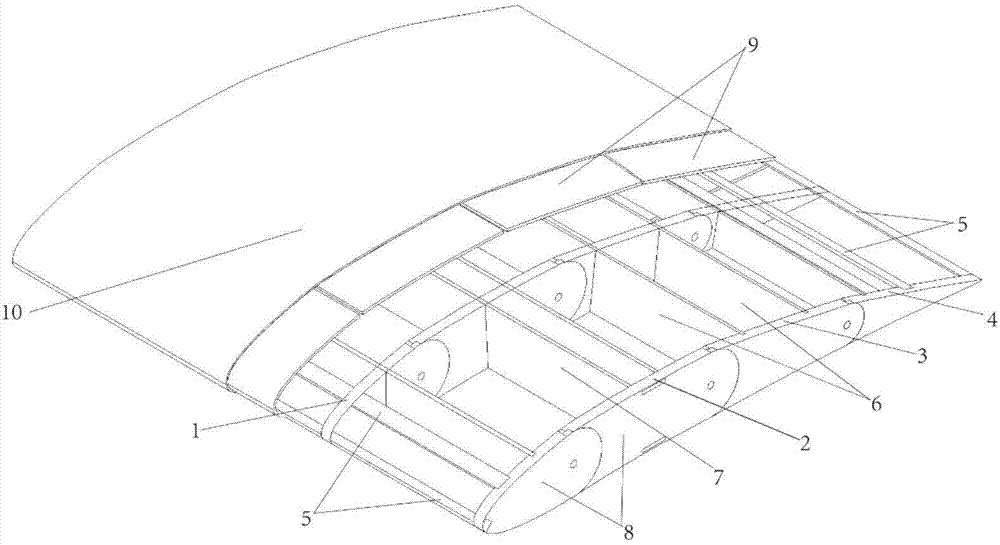

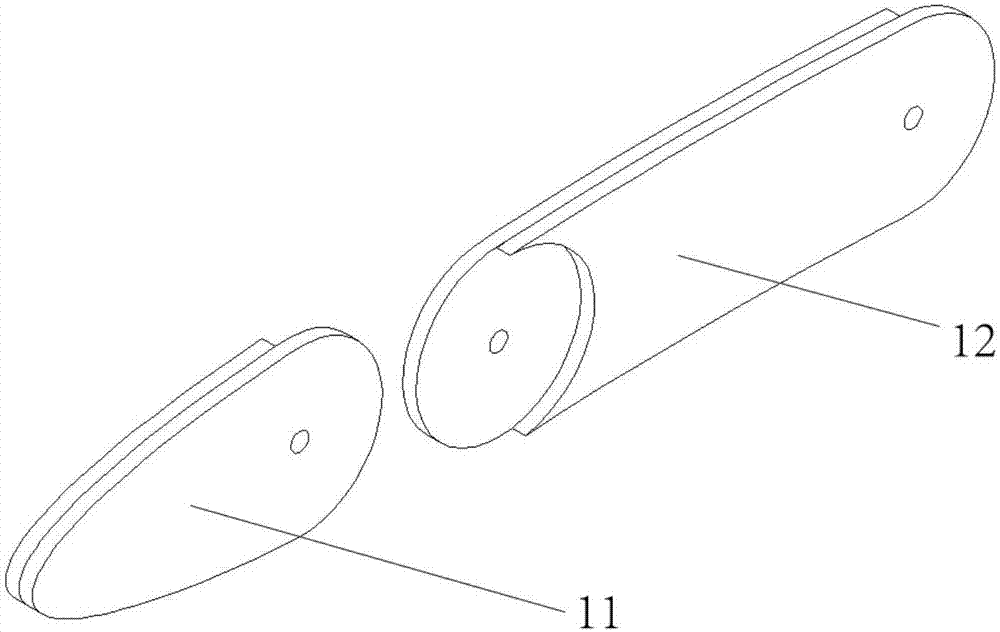

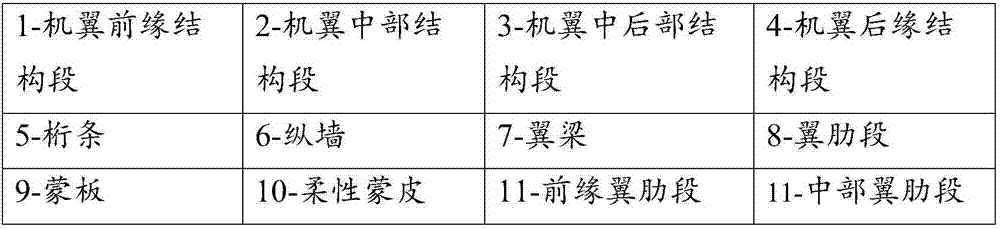

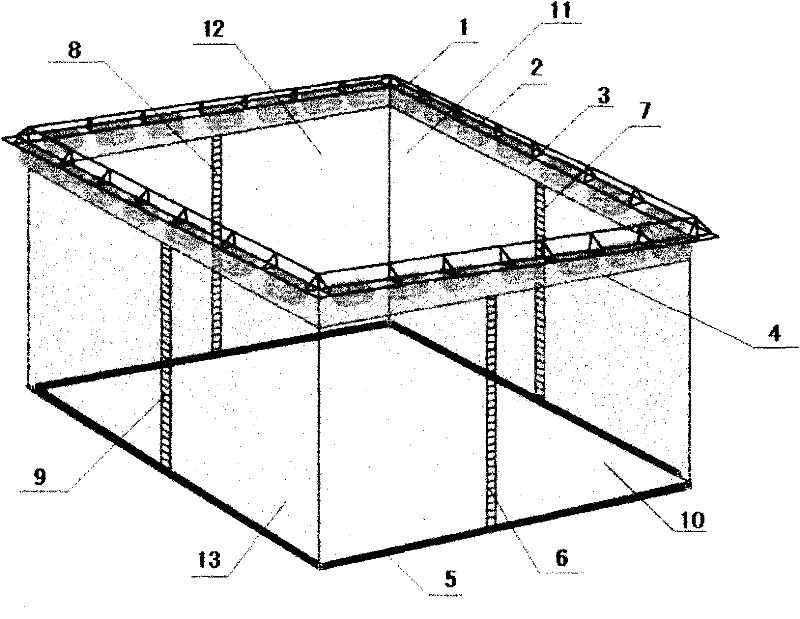

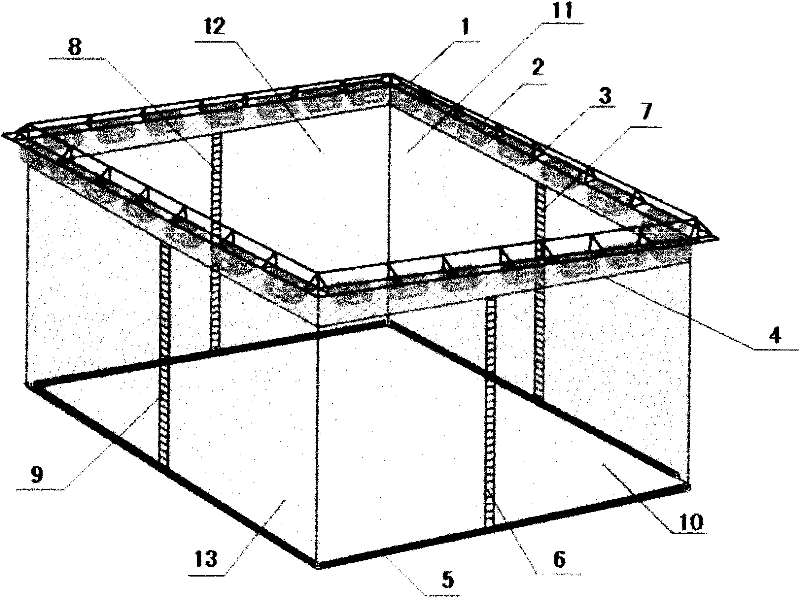

Self-adaptive wing structure with changeable bending

InactiveCN107444617AIncreased complexityReduce stress concentrationSpars/stringersWing adjustmentsLeading edgeControl system

The invention provides a variable camber self-adaptive wing structure, the whole wing is divided into wing leading edge section, wing trailing edge section and each spanwise fixed wing structure section therebetween, wherein the The wing structure segment connected to the edge structure segment is fixed to the fuselage through the spar, and these structural segments are connected to each other by a double-fin structure. This double-fin structure allows the force between the wing structure segments to pass through the ribs. The transmission of the contact surface avoids the influence of the hinge gap of the wing deformation mechanism on the deformation, and improves the structural weight and complexity increased to meet the structural strength requirements of the wing. Use the control system of the aircraft to control and change the camber of the wing, so that the aircraft can obtain the optimal aerodynamic efficiency at different speeds and angles of attack. This adaptive wing with variable camber can greatly improve the lift. Enhancing the maneuverability of the aircraft and improving the stall characteristics can greatly improve the endurance time of the aircraft and the stability of the aircraft itself.

Owner:BEIHANG UNIV

Combined fishnet square net cage used for mariculture

InactiveCN102239817AReduce deformation and volume lossImprove volume retentionClimate change adaptationPisciculture and aquariaDouble rowSeawater

The invention discloses a combined fishnet square net cage used for mariculture, relating to a mariculture net cage. In the combined fishnet square net cage, a cupronickel B10 stretching net, a brass HA177-2 stretching net, a high-strenght single-fast-knot polyethylene fibre net, a high-strength nylon warp knitting net, a fishing high-strength polyethylene monofilament rope, a galvanized iron pipe and a cylindrical foam buoy are adopted. The combined fishnet square net cage is characterized in that a frame system used for the net cage is of a square double-row galvanized iron pipe frame structure. In a fishnet system used for the net cage, a double-layer synthetic fibre fishnet serves as a first fishnet, a combined copper alloy stretching net serves as a second fishnet, and the first fishnet and the second fishnet are in longitudinal semi-soft connection; a square synthetic fibre fishnet is in a combined fishnet form of the fishnets used for the net bottom of the net cage; the combined fishnet used for the net bottom of the net cage is hung on the square double-row galvanized iron pipe frame; and the square double-row galvanized iron pipe frame of the net cage is connected with a float line frame of a mooring system by a mooring rope.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Clay board curtain wall

The invention discloses a clay board curtain wall. The curtain wall comprises a plurality of vertically arranged main keels and horizontally arranged angle steel connecting pieces; and clay boards are arranged among the main keels and are mounted on the angle steel connecting pieces. In the clay board curtain wall, the horizontal keels of the clay board curtain wall are adjusted to be the angle steel connecting pieces, the angle steel connecting pieces are connected with the main keels by stainless steel bolts without welding, and only bolt holes need to be arranged at corresponding positions on the main keels, so that the linearity of the keels is not influenced and the influence on physical properties of the keels is reduced. The angle steel connecting pieces is used instead of the horizontal keels in this assembly mode, so that large quantities of materials are saved while installation of the curtain wall is not influenced, thereby reducing manufacturing cost of the curtain wall. And, the way of connecting the angle steels with the connecting pieces is changed from welding to bolt connection, so that the influence on deformation of the main keels caused by welding is avoided and the process of adjusting steel linearity is removed.

Owner:无锡金城幕墙装饰工程有限公司

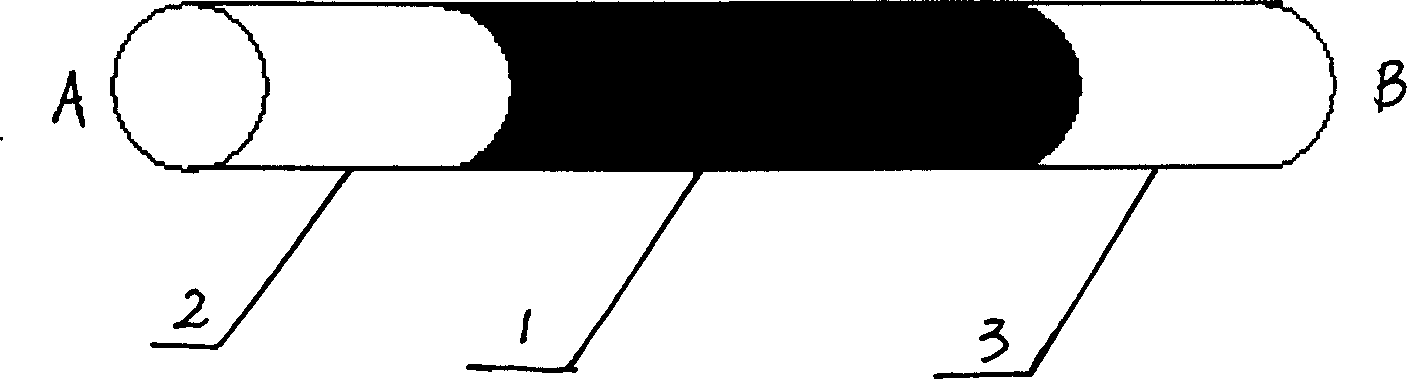

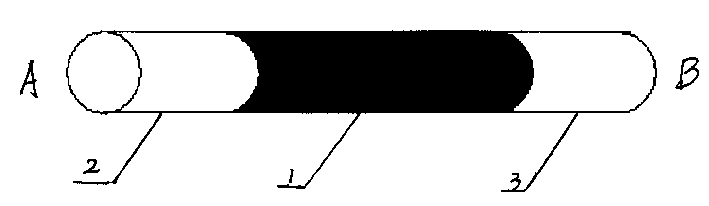

Machining method for stator of all-metal screw pump for thickened-oil thermal exploitation

The invention relates to a machining method for a stator of an all-metal screw pump; the adopted machining method is as follows: firstly, a central hole is machined on a metal bar, and then spiral grooves are machined by an electric spark machining method. A plurality of electrode tips, the intervals of which are equal to screw pitches of the spiral grooves, are arranged on a thinner steel tube; the steel tube with the electrode trips penetrates into a machined inner hole; and both ends of the steel tube are tightly clamped by insulation clamping heads and stretch toward one side or two sidesso as to ensure the straightness of the steel tube, thereby ensuring the interval between each the electrode tip and a workpiece to be equal in the overall length range. A workbench of an electric spark machine tool does a linear motion; the stator workpiece of the metal screw pump does a helical motion; the strict transmission ratio is ensured between the workbench and the stator workpiece of the metal screw pump, namely, the workpiece rotates for a circle, and the workbench walks for a screw pitch; as the number of the electrode tips is determined according to the number of the screw pitches, all electrodes simultaneously work and respectively finish the machining for one screw pitch so as to simultaneously finish the overall machining for internal spiral grooves of the stator. Electricsparks are used for machining the stator of the metal screw pump; as the electrodes do not contact the workpiece, a larger cutting force and the deformation of a cutter can be prevented when the cutter directly contacts the workpiece, thereby ensuring the machining precision. The machining difficulty can be greatly reduced; and the machining precision is improved.

Owner:新疆华易石油工程技术有限公司

Laser bar and cavity integrating method and structure

InactiveCN1466251AChange optical propertiesMeet the design requirementsActive medium materialResonant cavityIon laser

This invention discloses an integral method and its structure for a laser rod cavity including bonding common host crystals of unmixed laser active ion on one or two ends of mixed laser active ion laser crystal by heat to form two end caps to be filmed after optical process. The common host crystal of mixed laser rod crystal and unmixed laser active ions can be: Nd: YAG and unmixed YAG, Yb: YAG and unmixed YAG, Nd, GdVO4 and unmixed GdVO4, Yb:GdVO4 a and unmixed GdVO4, Lateral pump rod-cavity integral laser elements and end face pump rod-cavity integral laser elements can be processed according to different needs by filming, realizing the integral of resonant cavity and its working subjects.

Owner:ANHUI INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Method for joining conner parts of plastic steel doors and windows

InactiveCN1445430AImprove connection strengthOvercome poor deformation resistanceDoors/windowsAdhesiveEngineering

A connecting method for the corner parts of plastic-steel door or window includes such steps as making L-shaped reinforcing parts, inserting at least one said reinforcing part into the cavities of adjacent plastic-steel sections, and filling adhesive in the space between them for adhering them together. Its advantages are high connection strength, rigidity and resistance to deformation, and easy operation.

Owner:BEI JING NEW BUILDING MATERIALGRP

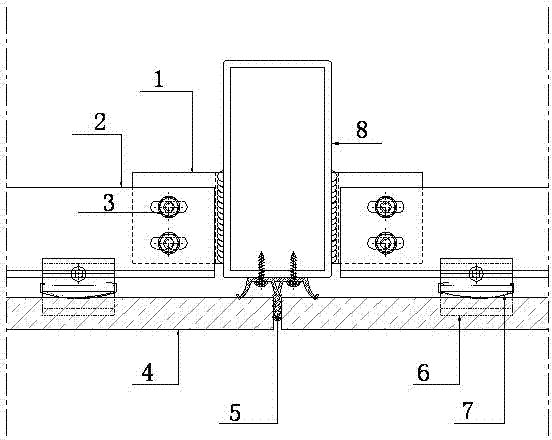

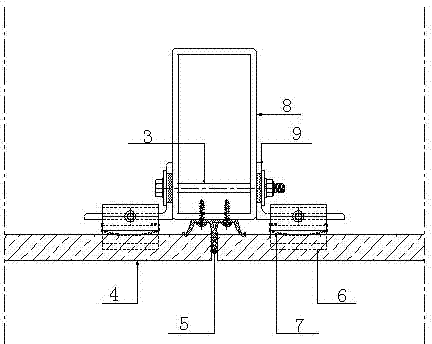

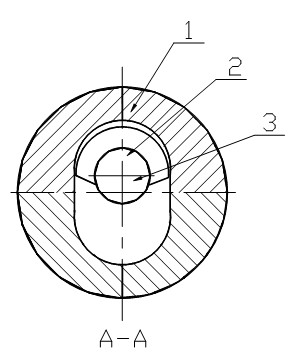

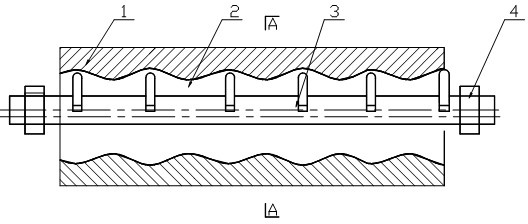

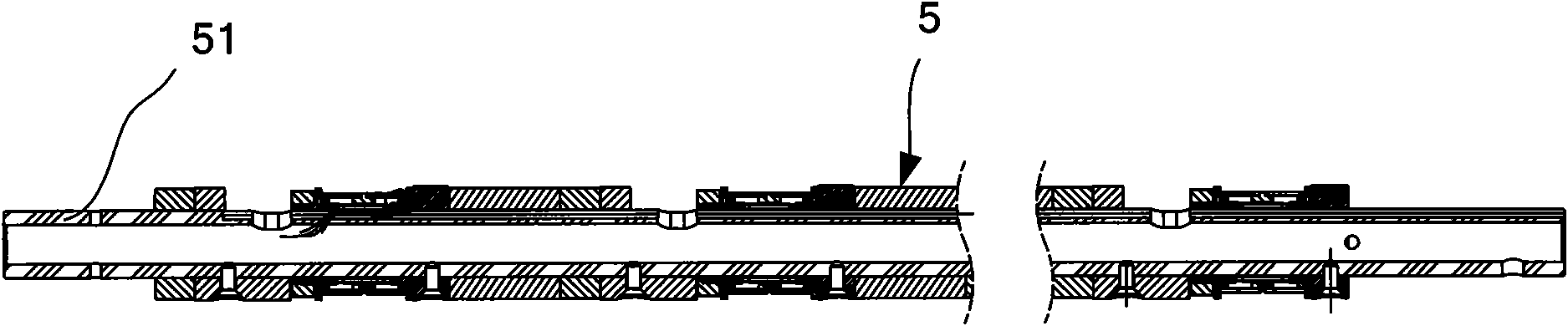

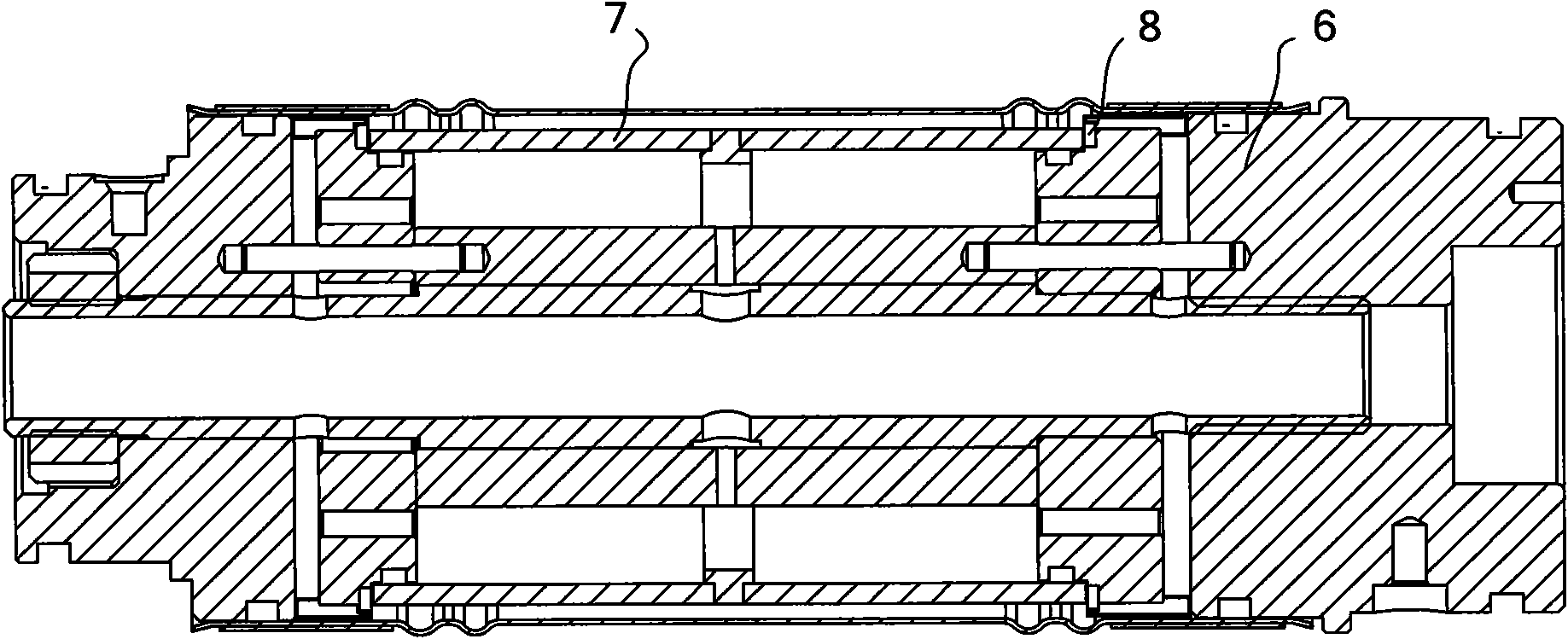

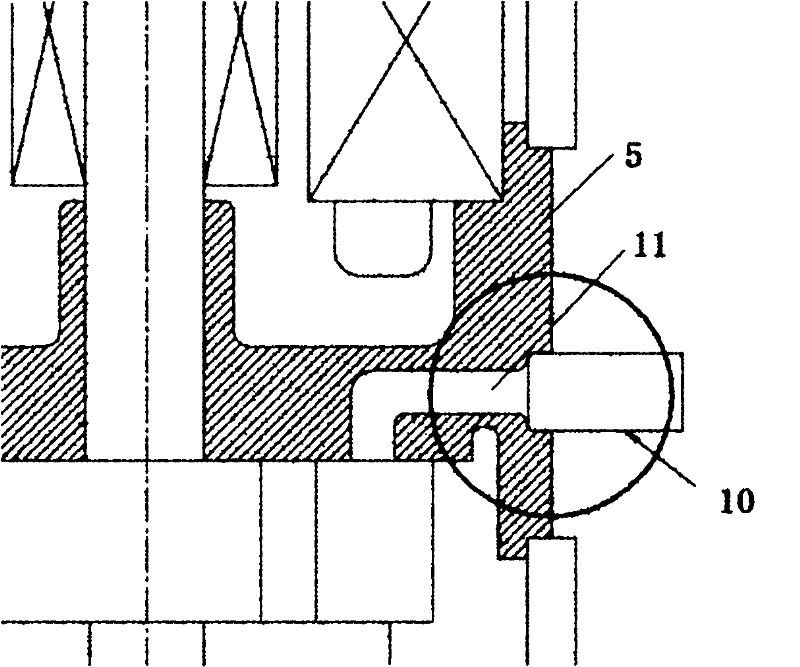

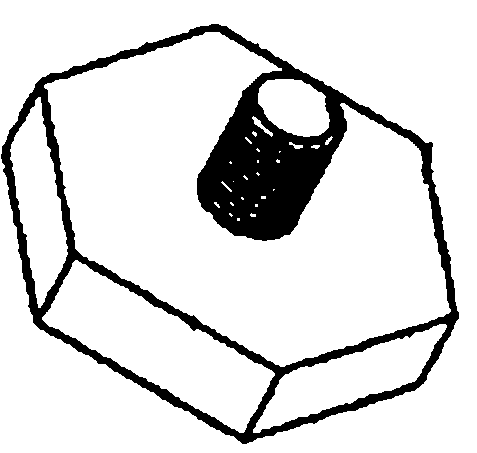

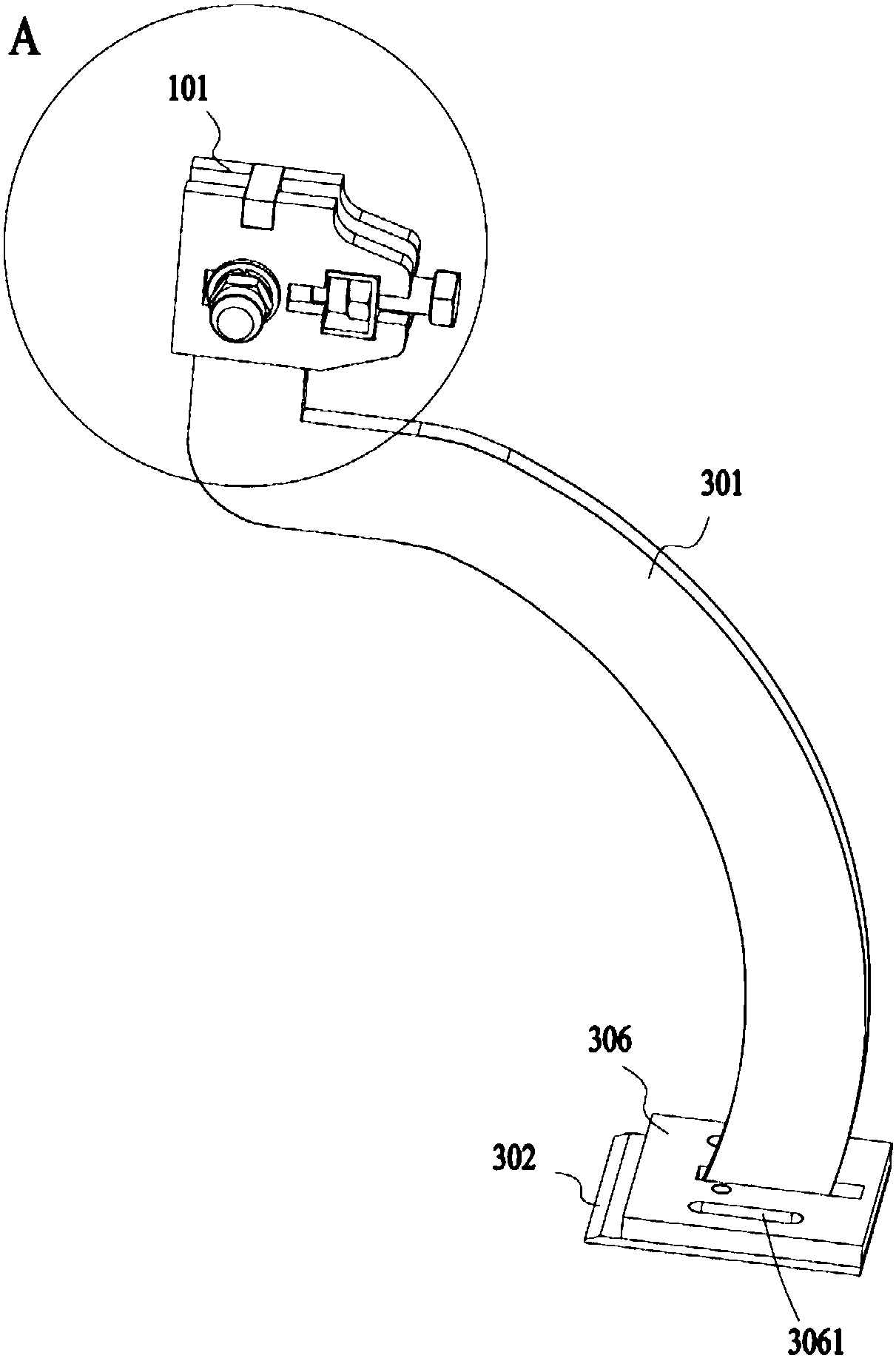

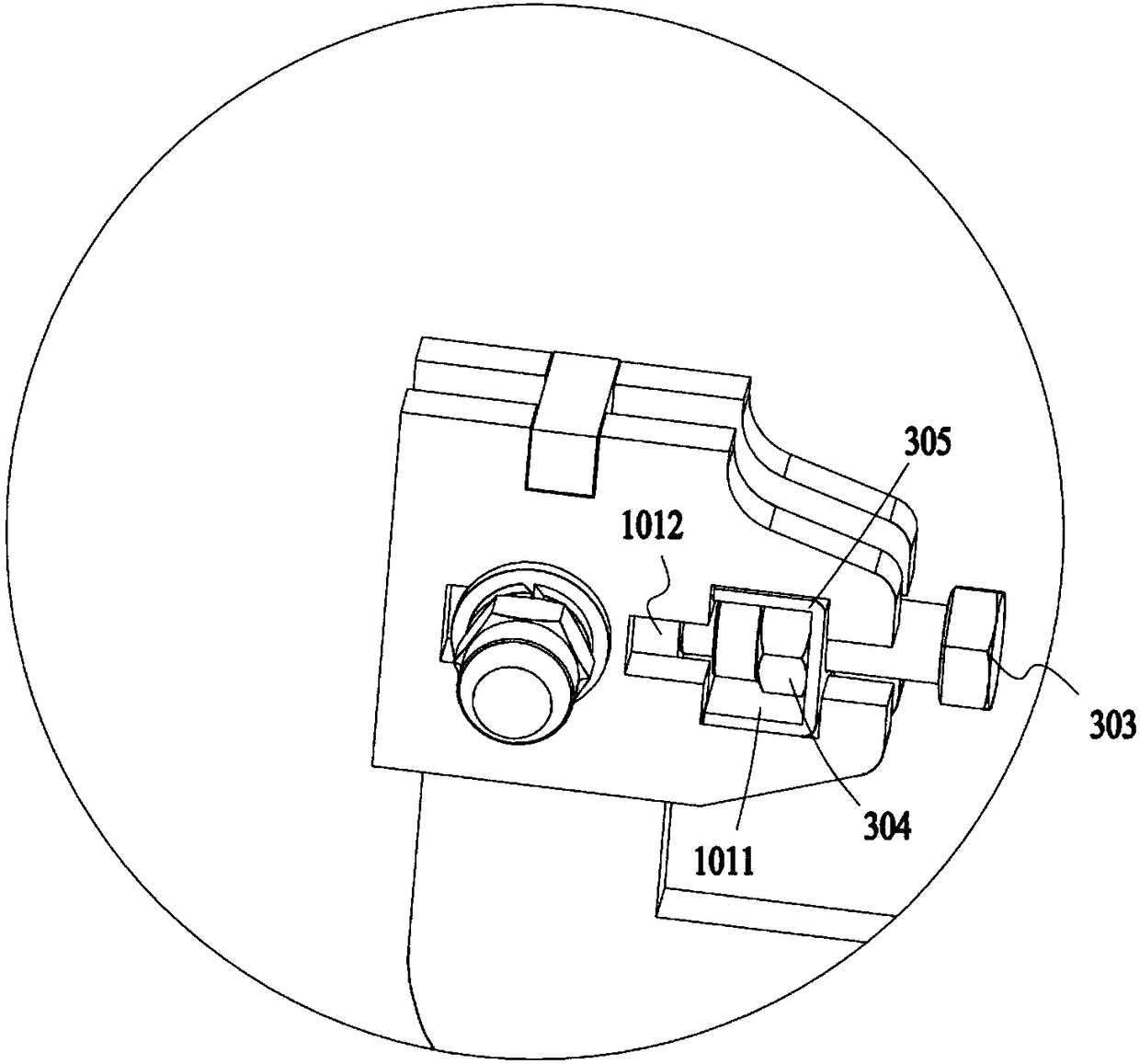

Acoustic wave transducer

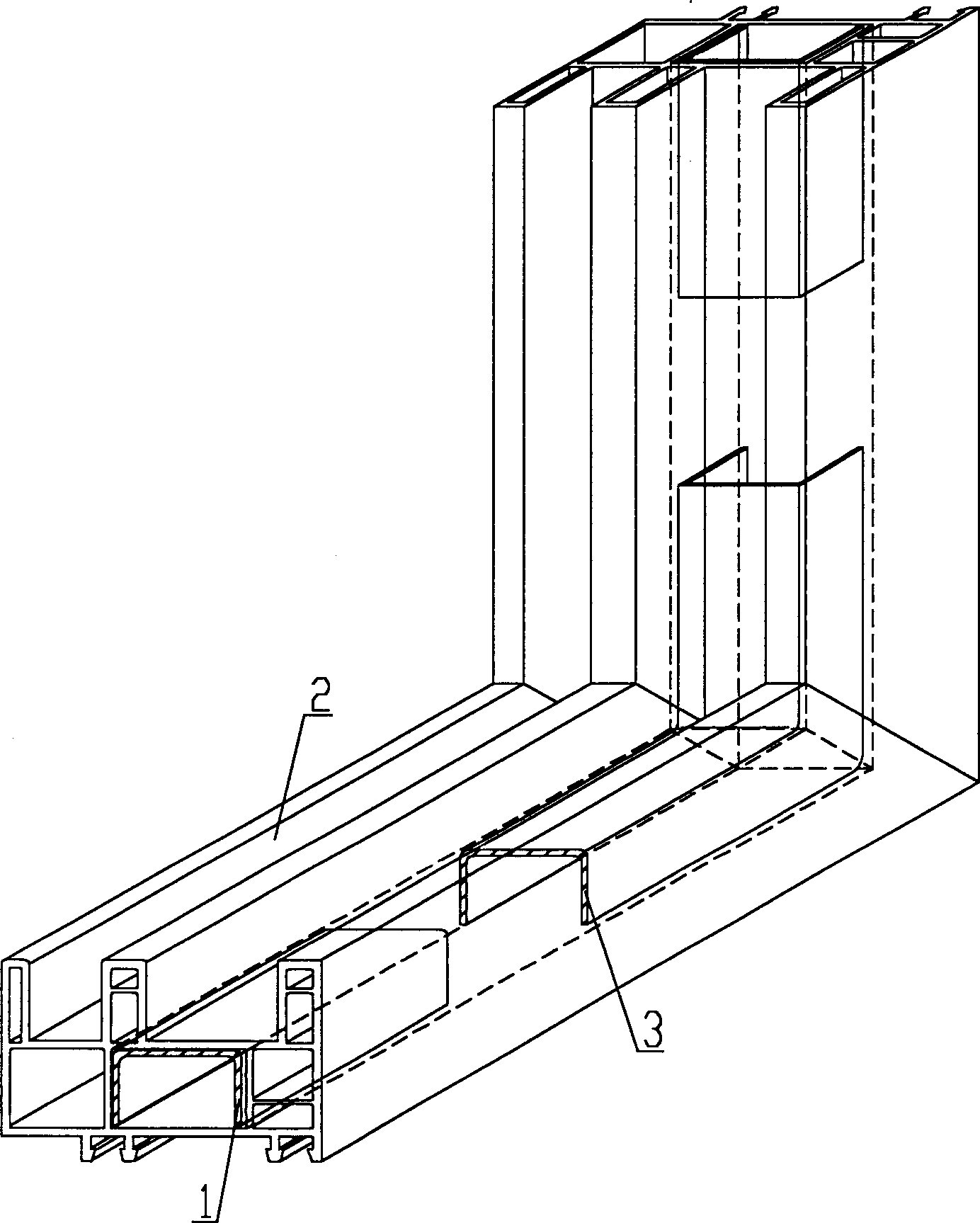

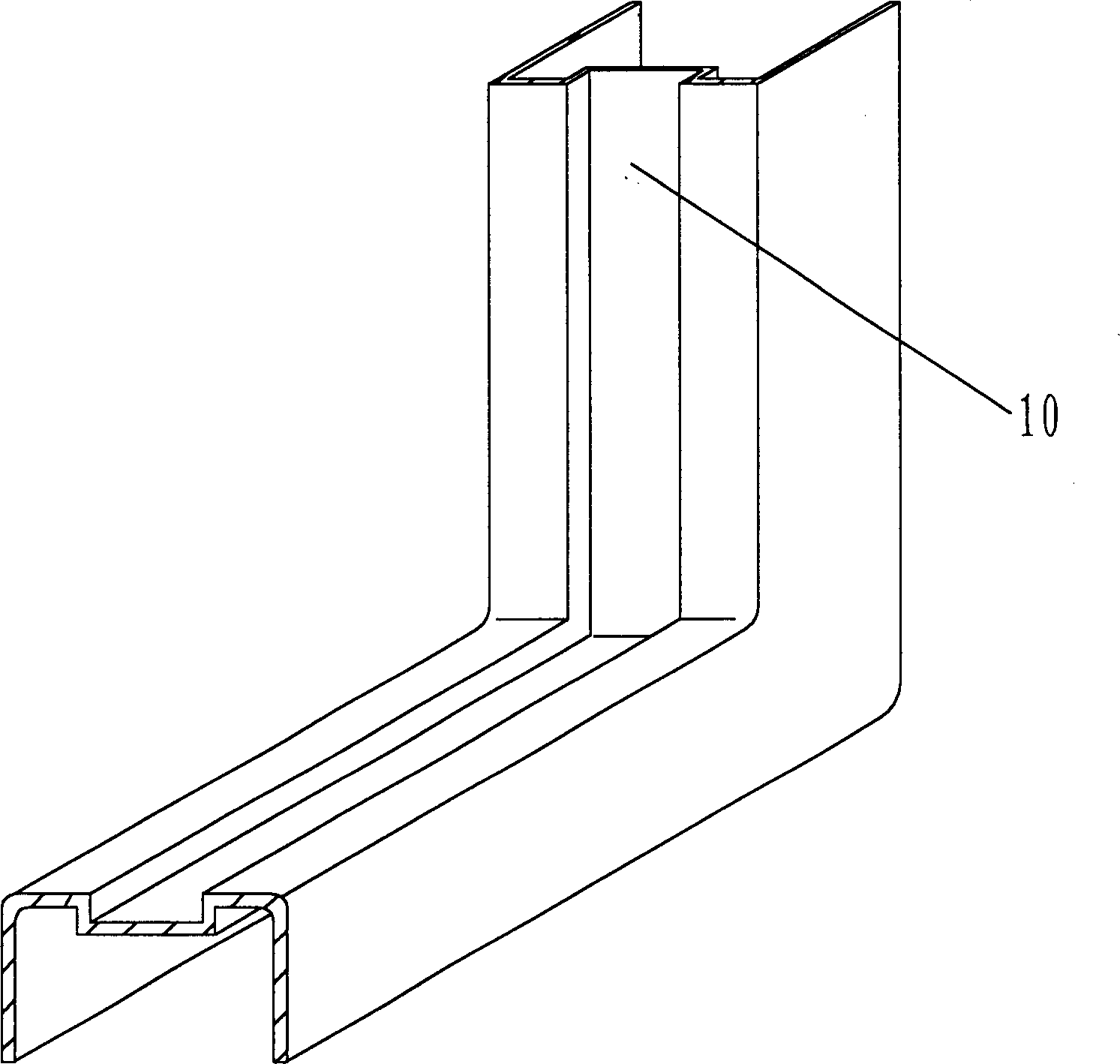

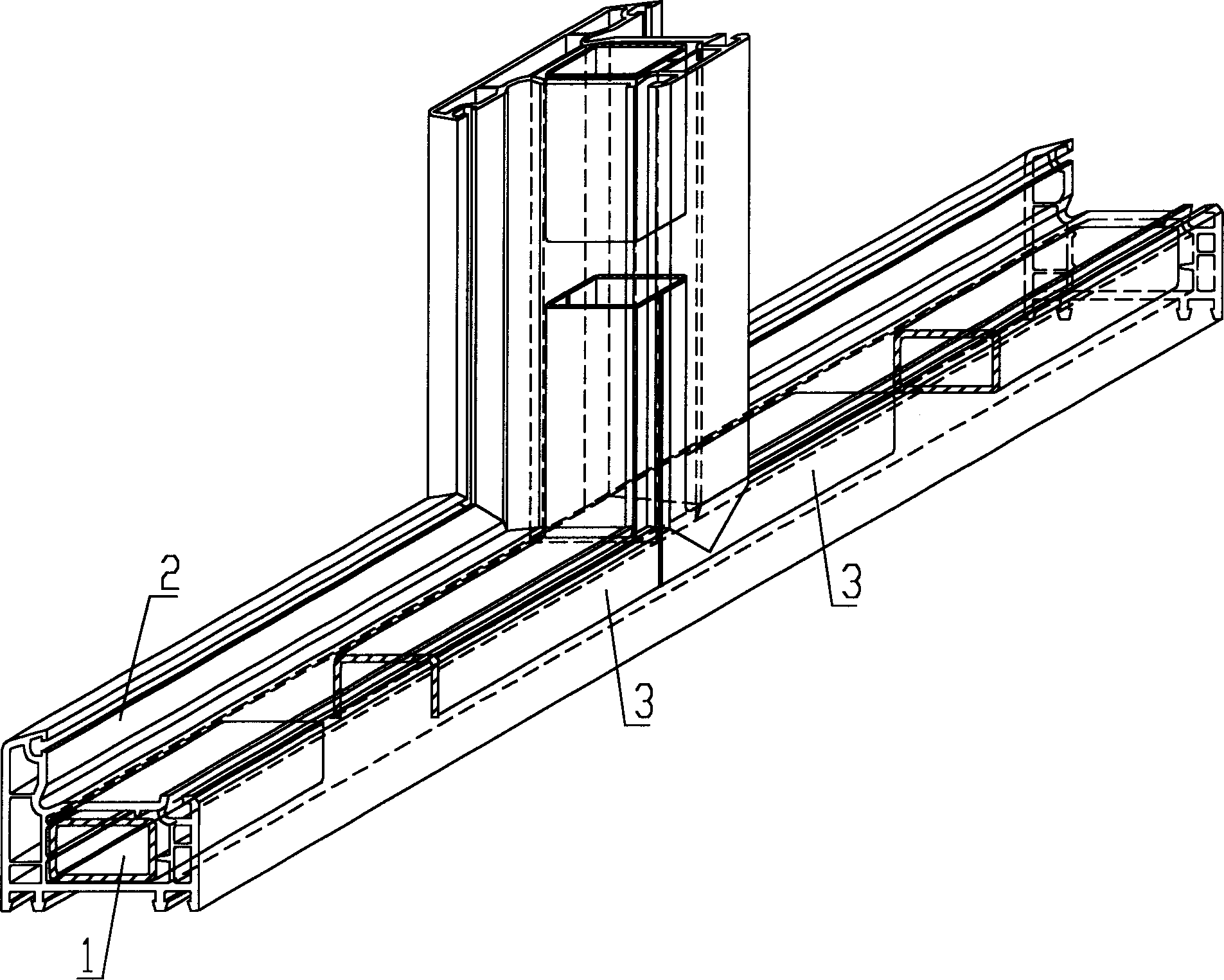

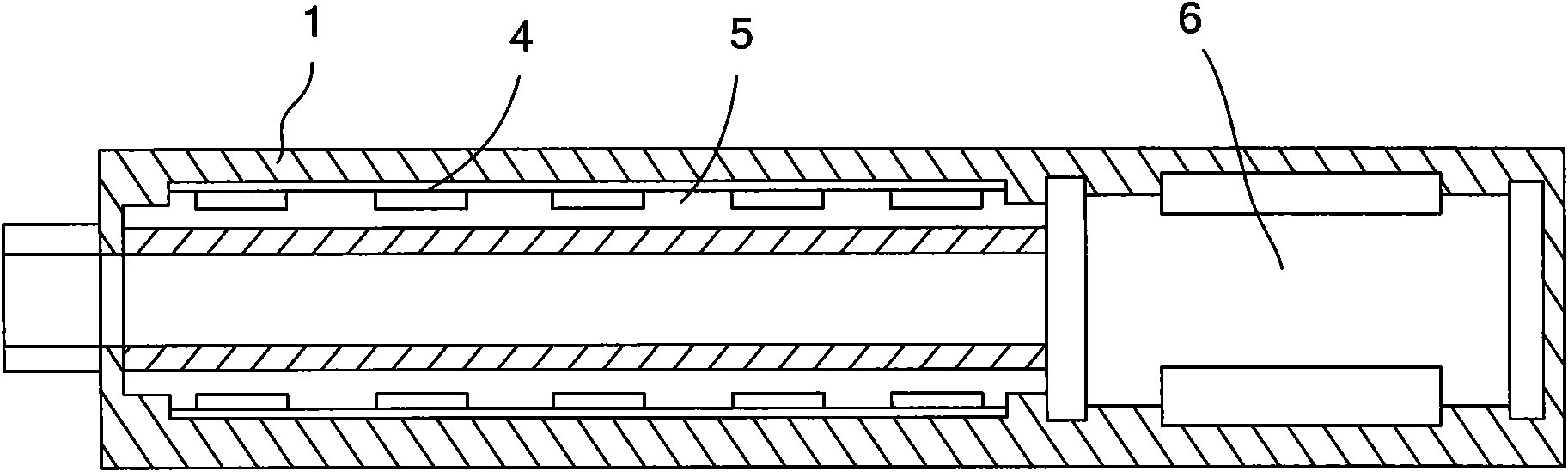

InactiveCN101833114ASmall amount of deformationAvoid deformation effectsSeismology for water-loggingTransducerAcoustic wave

The invention provides an acoustic wave transducer. The transducer comprises a notched shell, a receiving transducer module, a transmitting transducer and a bag, wherein the notched shell is provided with slotted holes for improving the acoustical insulation effect of the notched shell; the receiving transducer module is sleeved in the notched shell and comprises more than two receiving transducers sequentially connected together in series through screw threads; the transmitting transducer of which one end is fixedly connected to the interior of the notched shell is sleeved in the notched shell and arranged on one side of the receiving transducer module; the bag is a flexible part, and is sleeved in the notched shell and wrapped around the receiving transducer module; and oil is filled in the bag. In the transducer, as the receiving transducer module comprises more than two receiving transducers sequentially connected in series through the screw threads, each transducer can be assembled singly and conveniently; the deformation of each transducer is not accumulated during the deformation of the notched shell, so the overall deformation of the receiving transducer module is reduced; in addition, only one end of the transmitting transducer is fixedly connected with the notched shell, so the influence of the deformation of the notched shell on the transmitting transducer can be effectively avoided.

Owner:CHINA NAT OFFSHORE OIL CORP +1

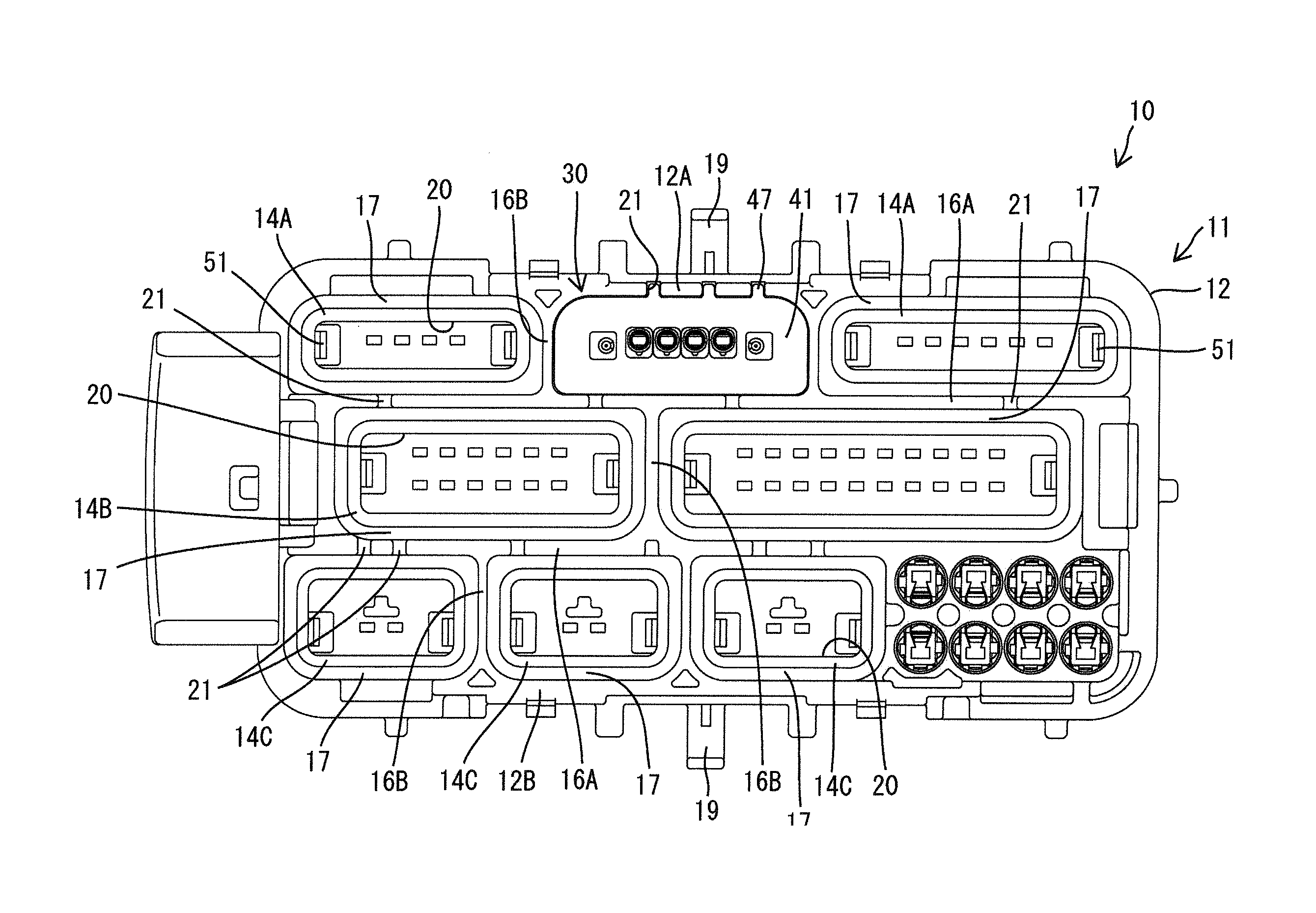

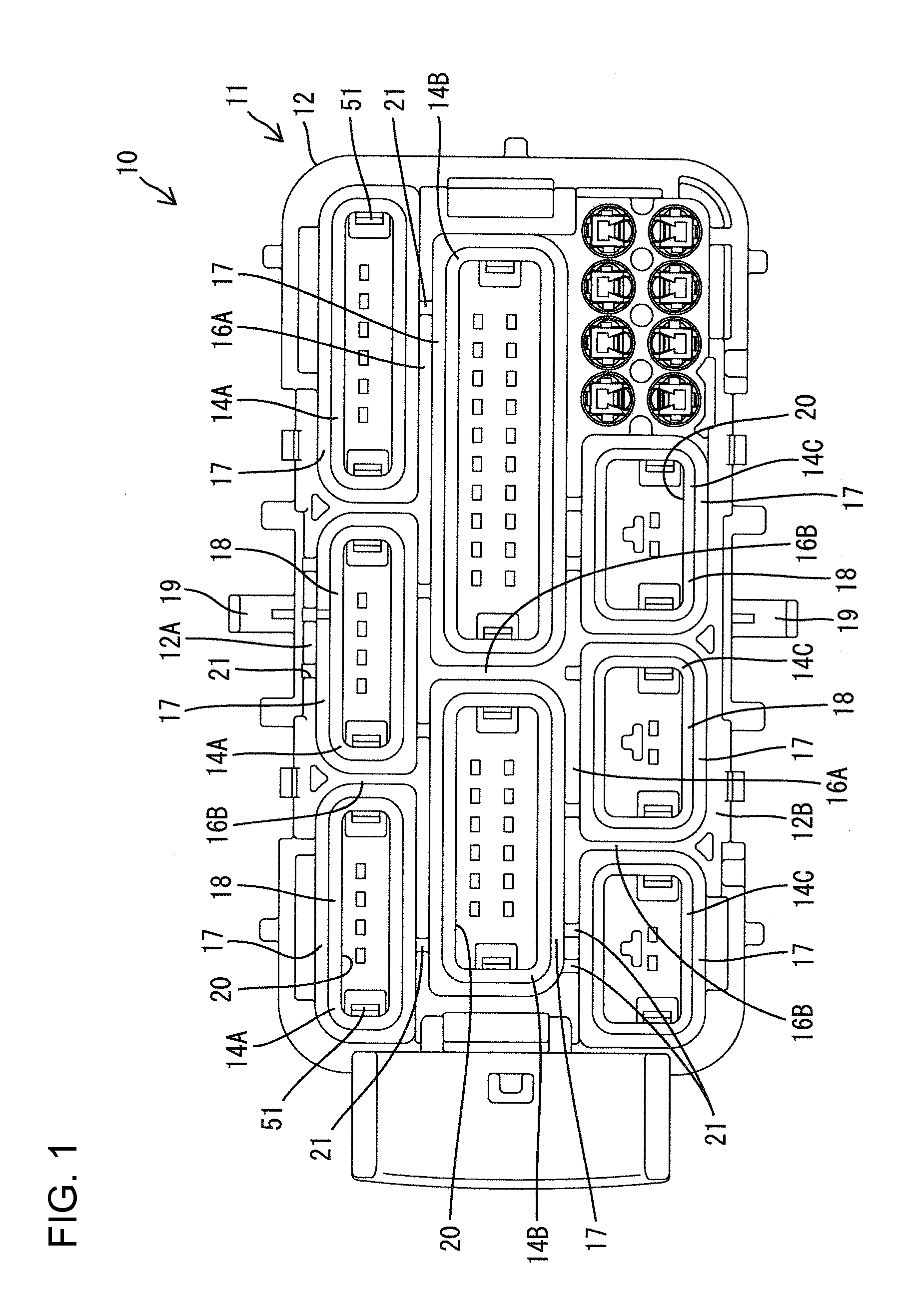

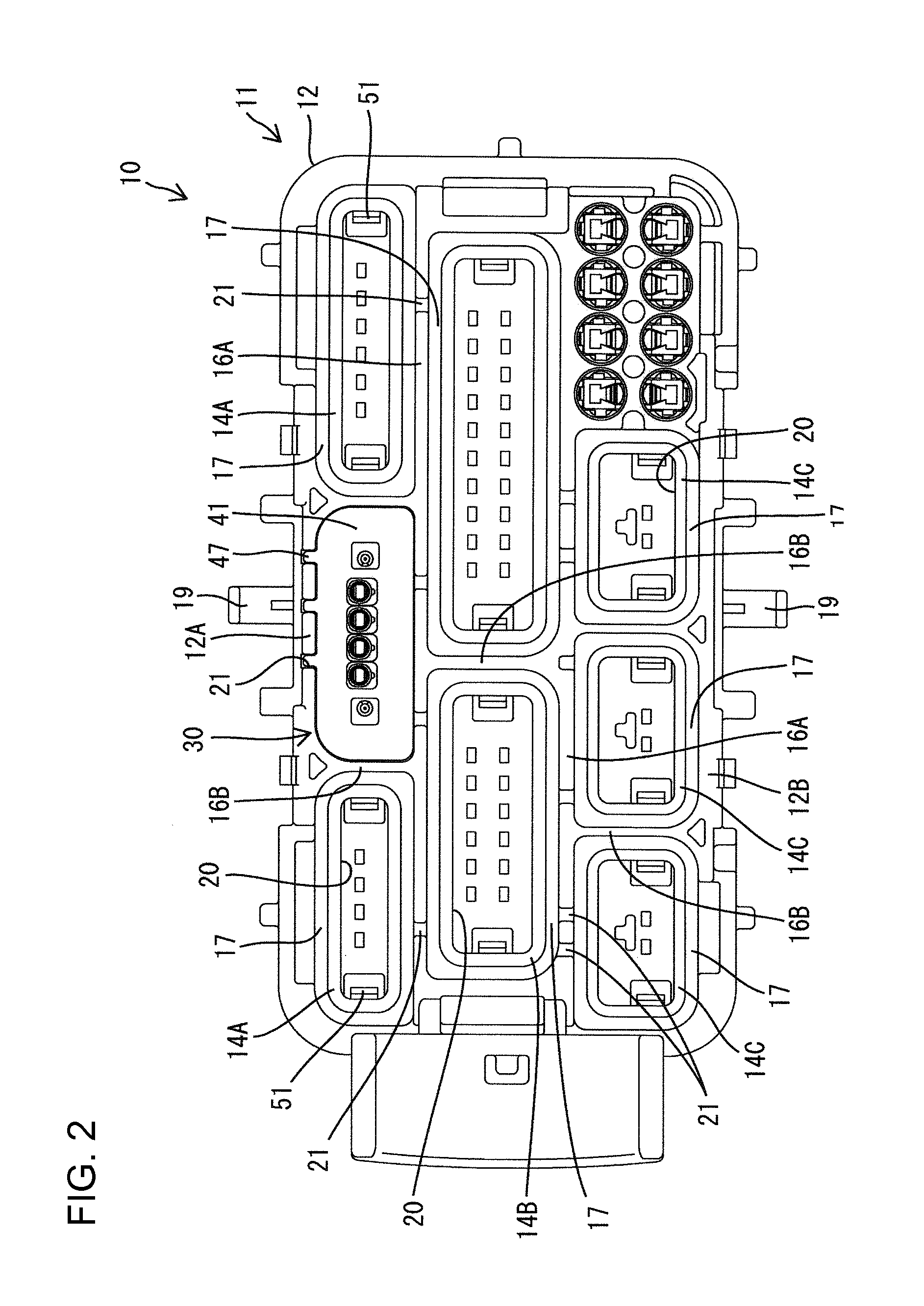

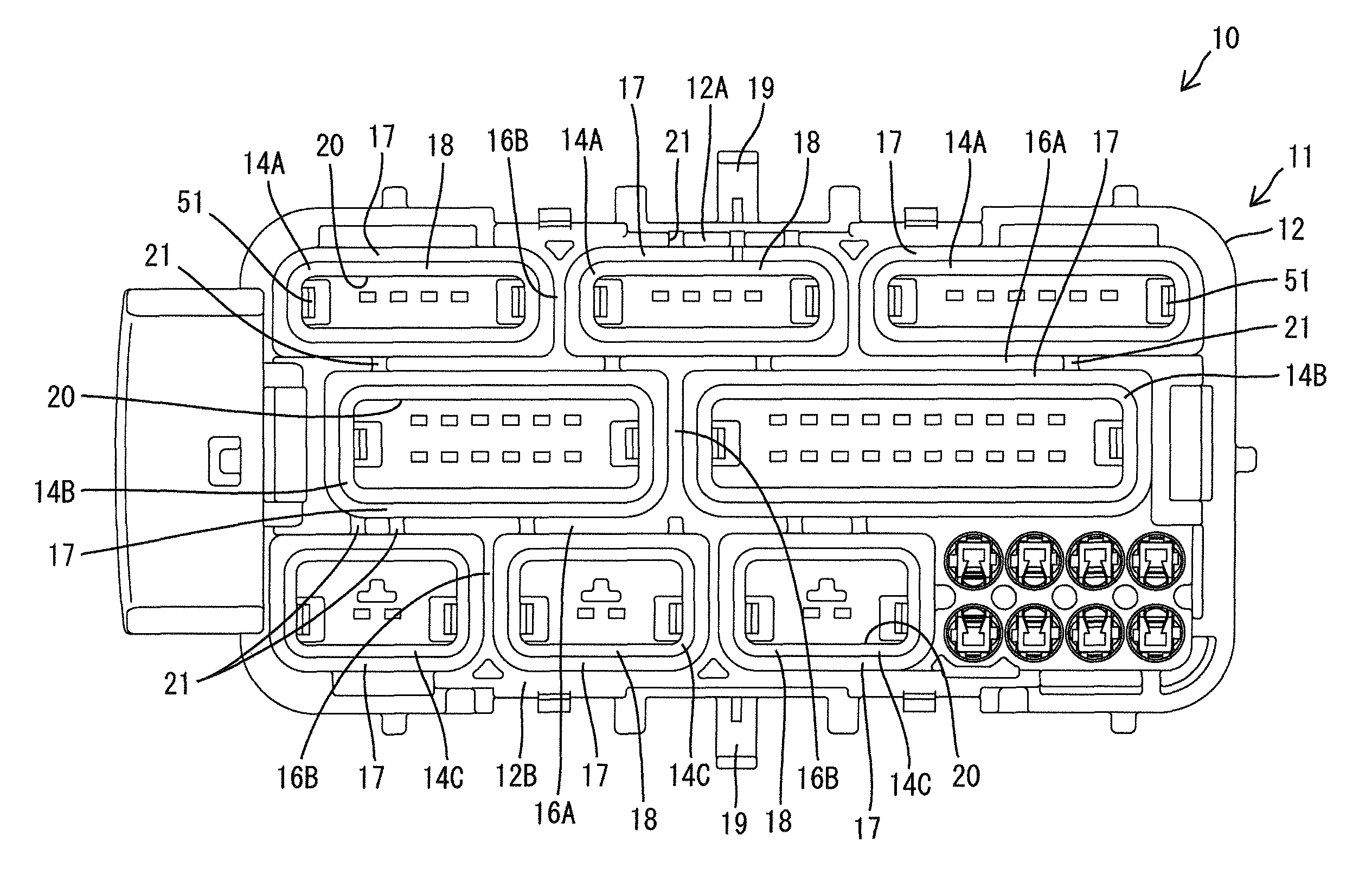

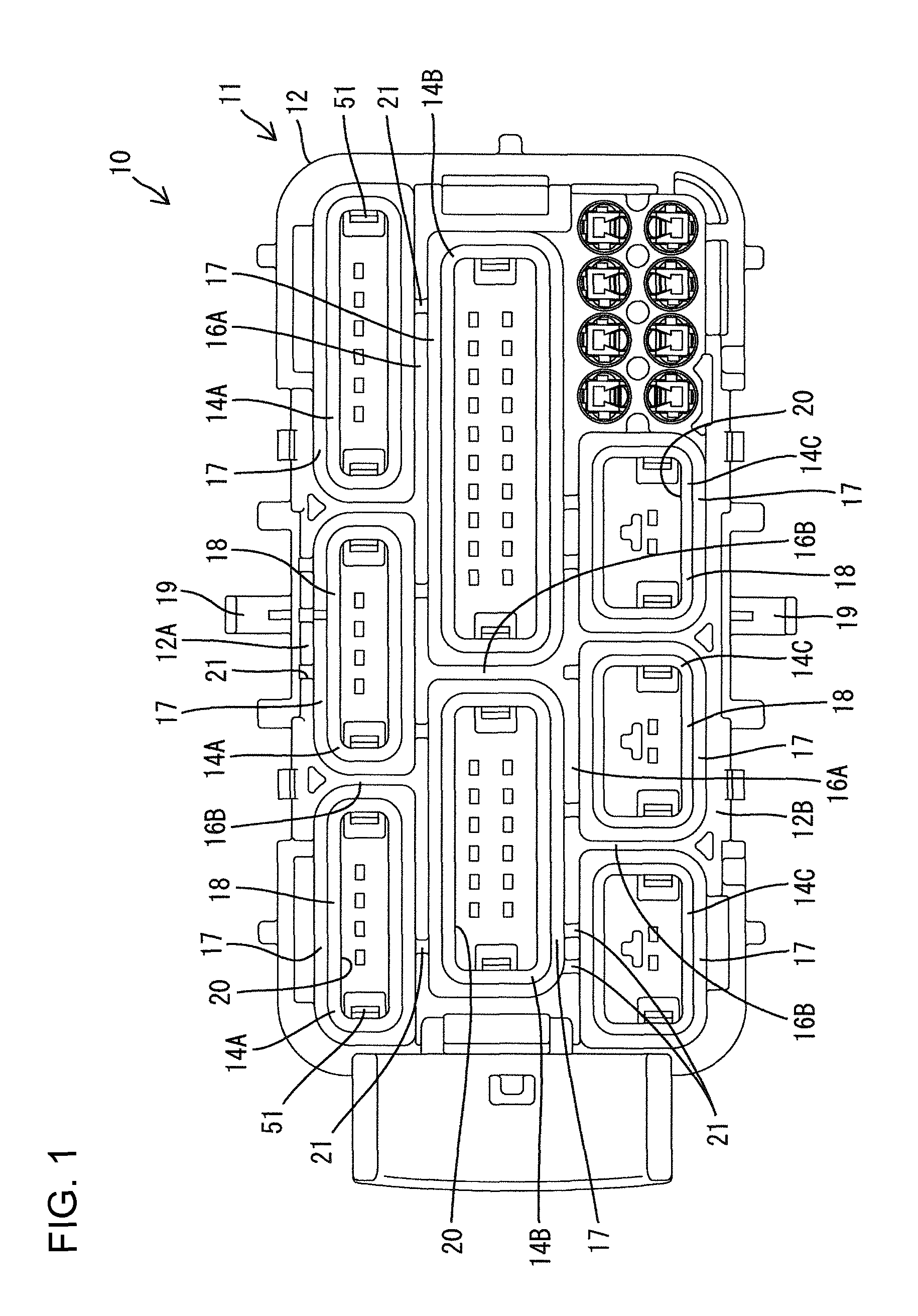

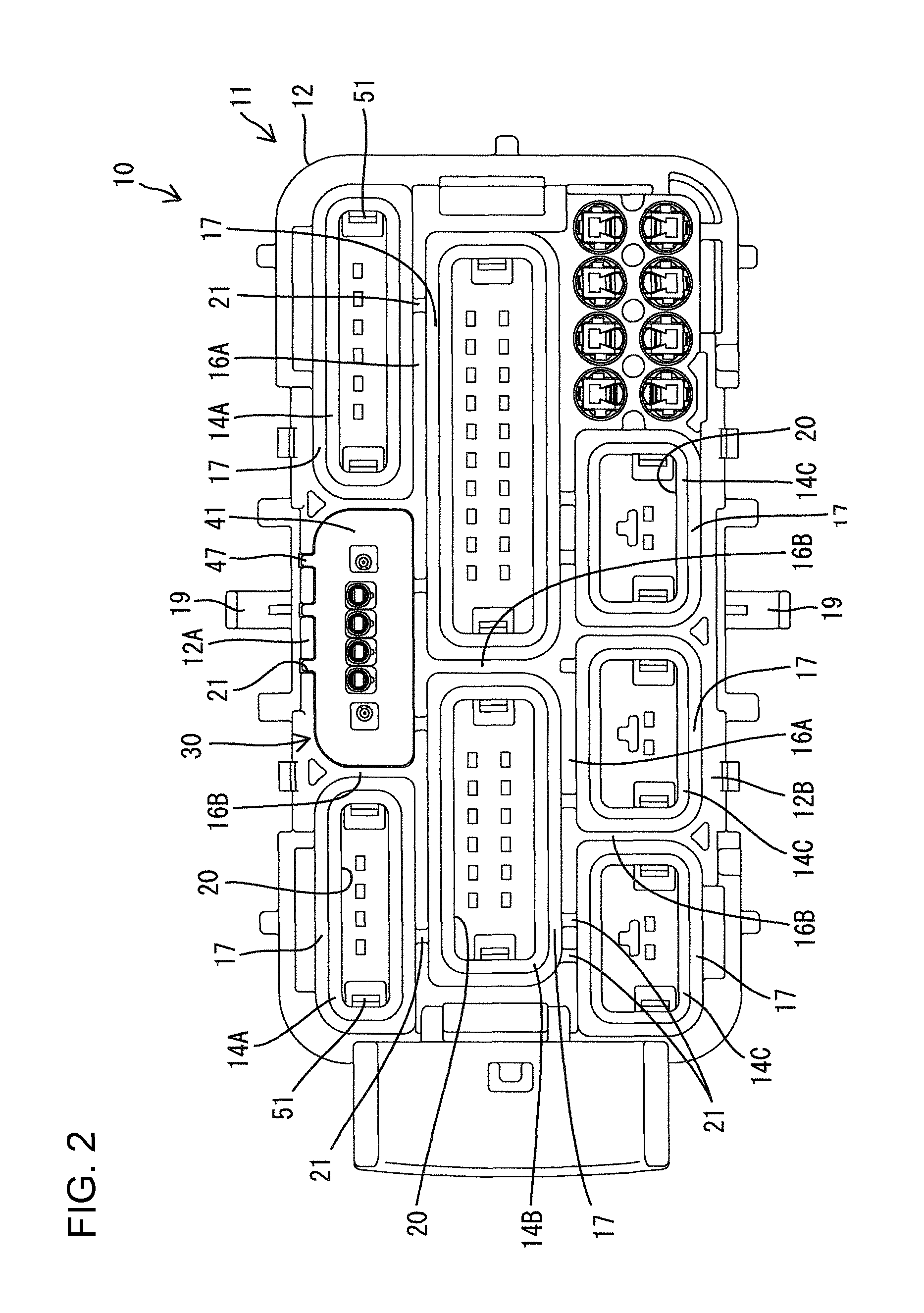

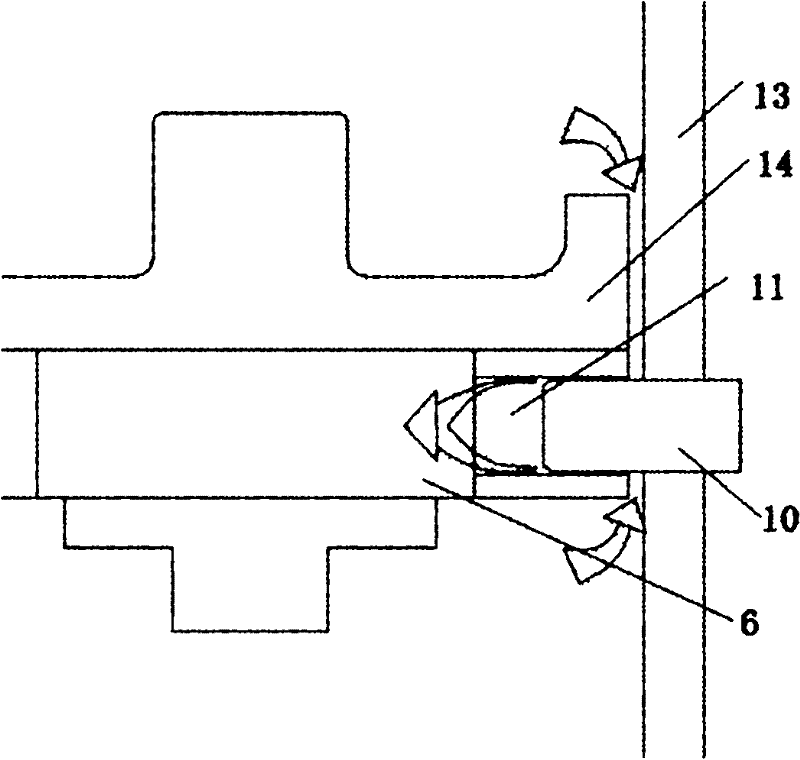

Connector

ActiveUS20120009809A1Avoid loss of tightnessEfficient use ofCouplings bases/casesEngineeringCam follower

A first housing (10) has a frame (11) with concave accommodation portions (20). A sub-connector (31) with female terminal fittings (33) is accommodated in the concave accommodation portions (20). A collective rubber stopper (36) is accommodated inside the concave accommodation portions (20) to seal a gap between a peripheral surface of an electric wire (34) pulled out of the sub-connector (31) and an inner peripheral surface of each concave accommodation portion (20). A first cam follower (19) is formed on an outer surface of the frame (11) and can engage an operation member (80). The frame (11) has an outer wall (12) defining an outer surface thereof where the first cam follower (19) is formed and an inner wall (18) separated from the outer wall part (12) via separated spaces (17) and constructing the inner peripheral surface of each concave accommodation portions (20).

Owner:SUMITOMO WIRING SYST LTD

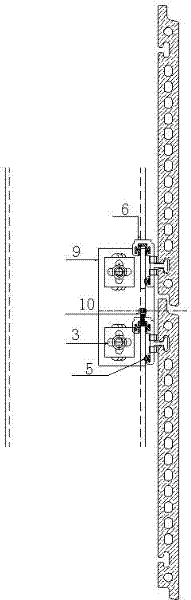

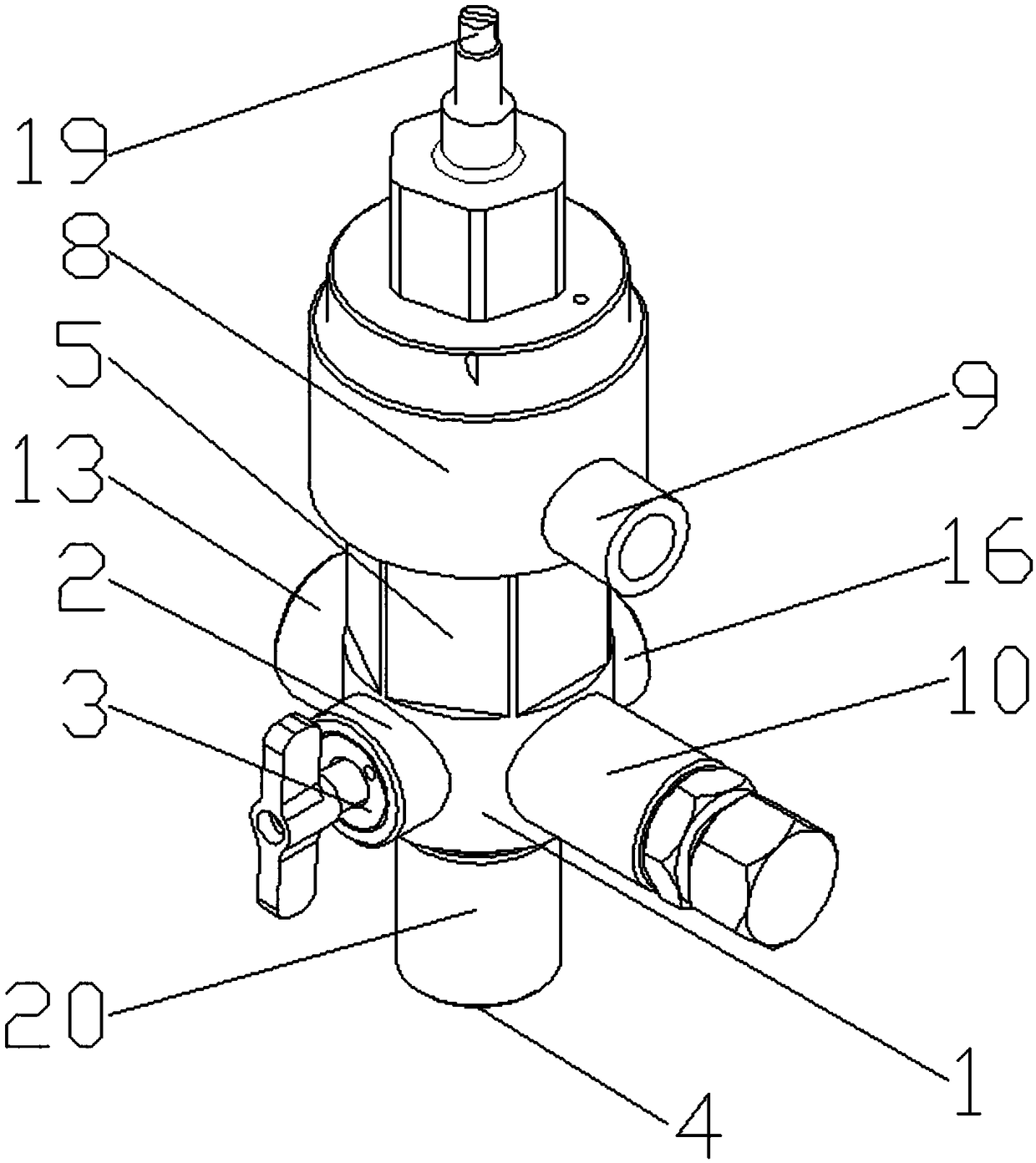

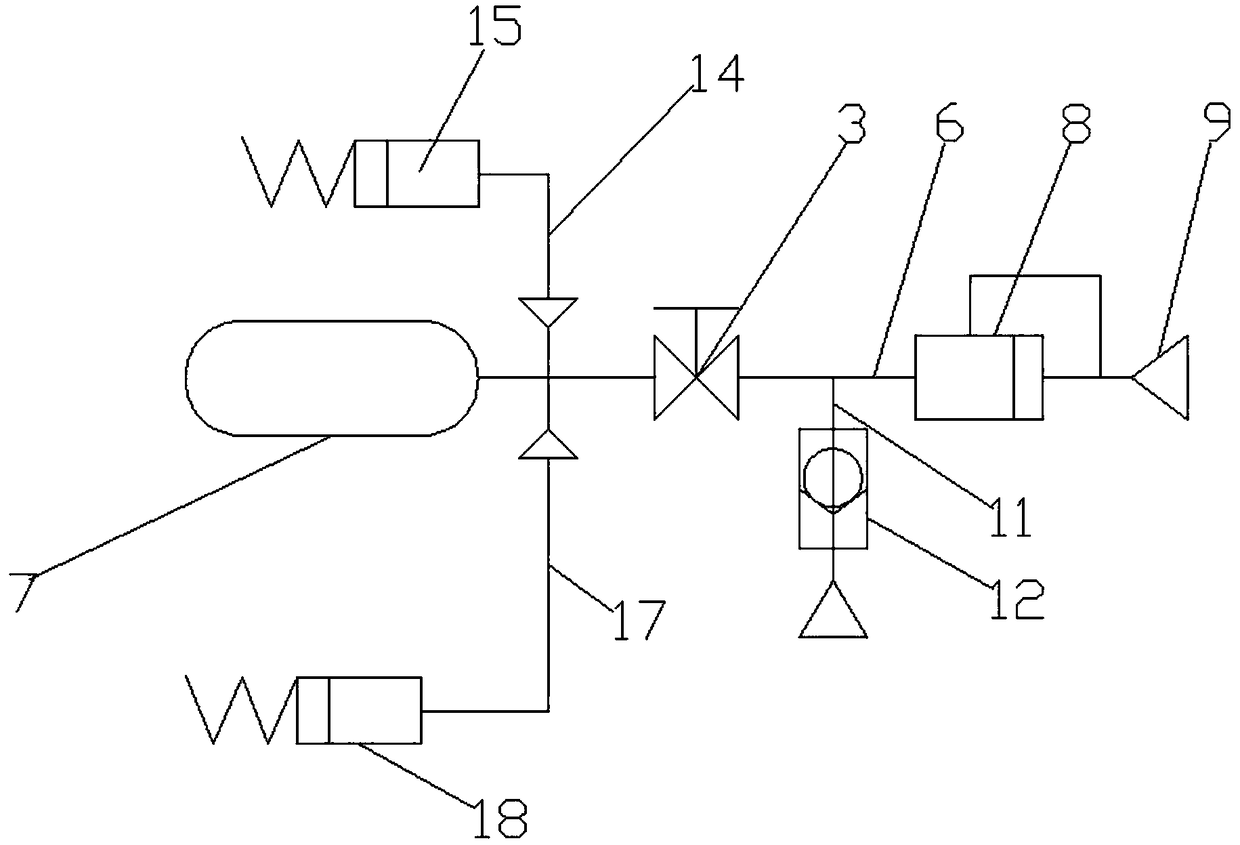

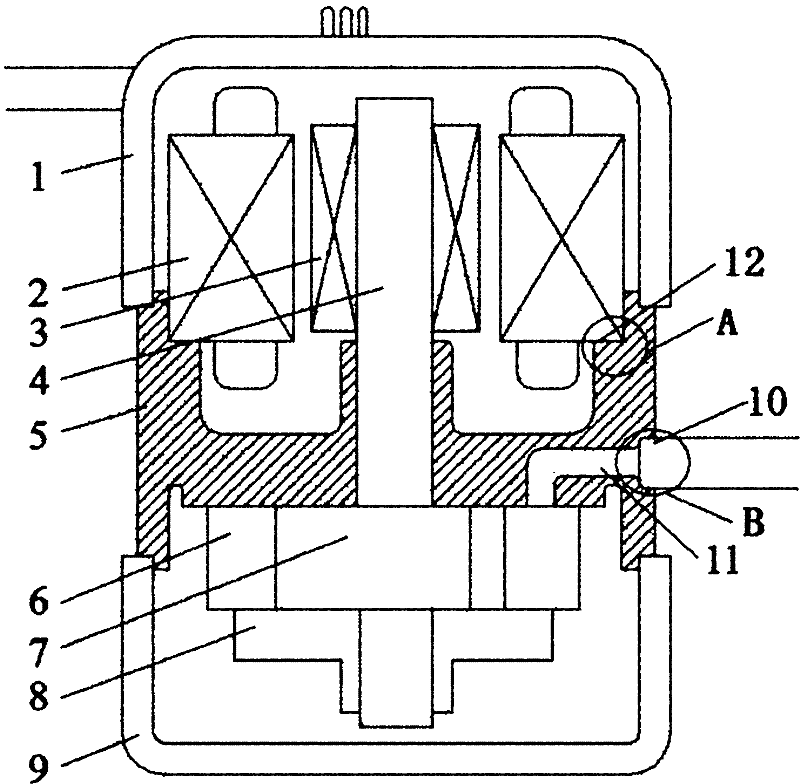

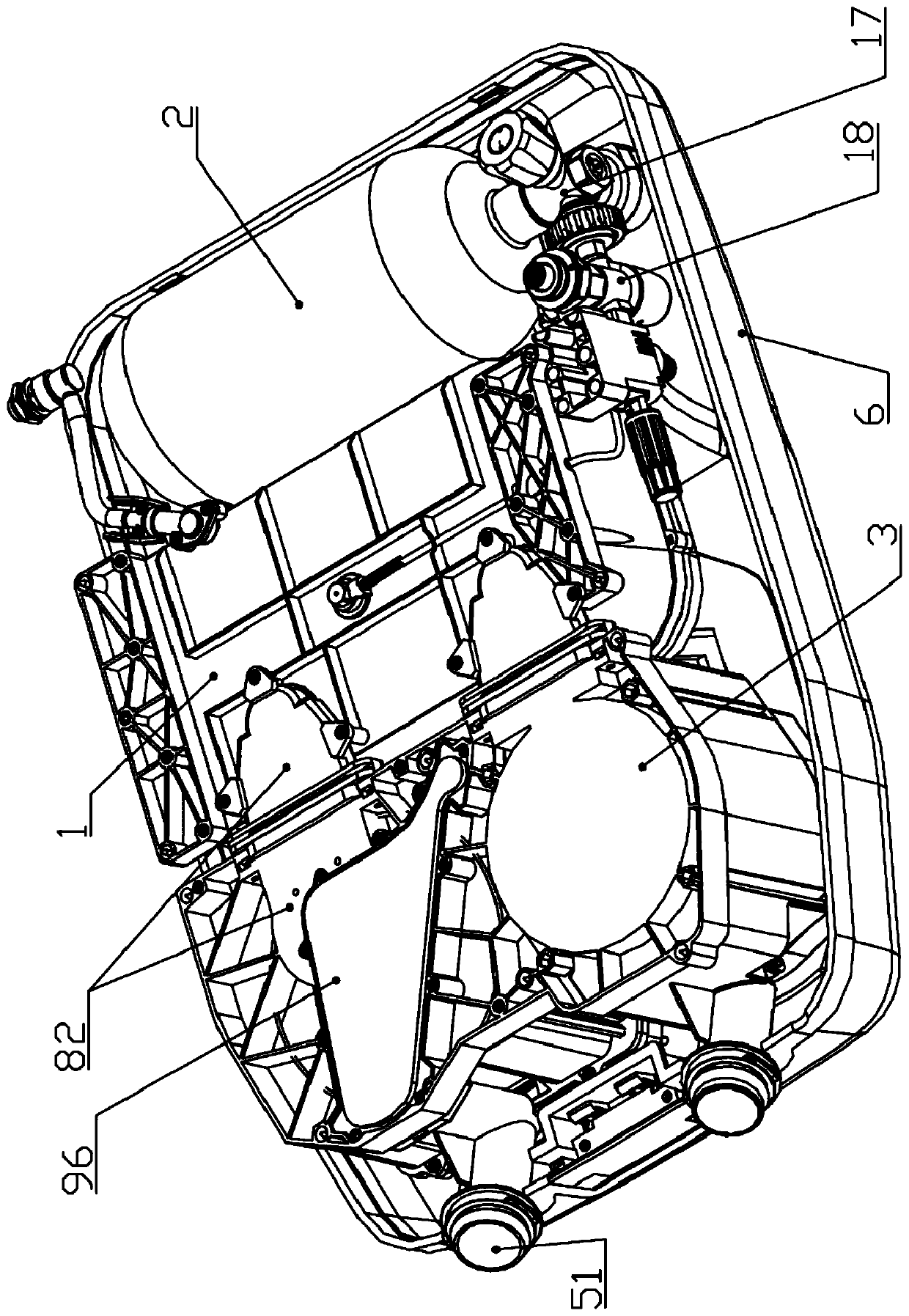

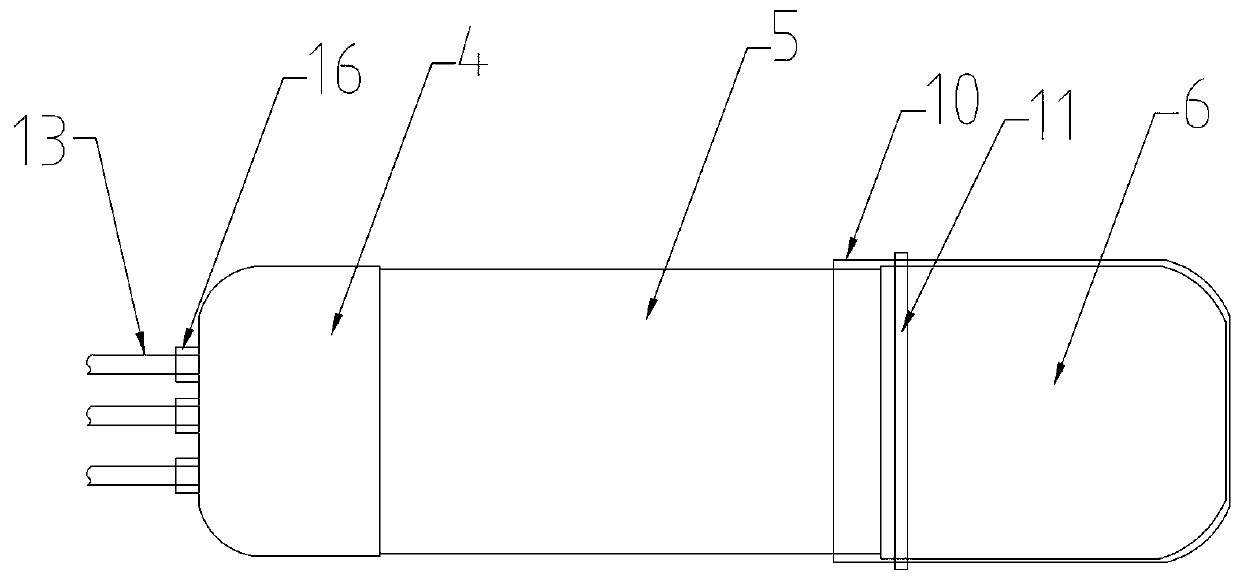

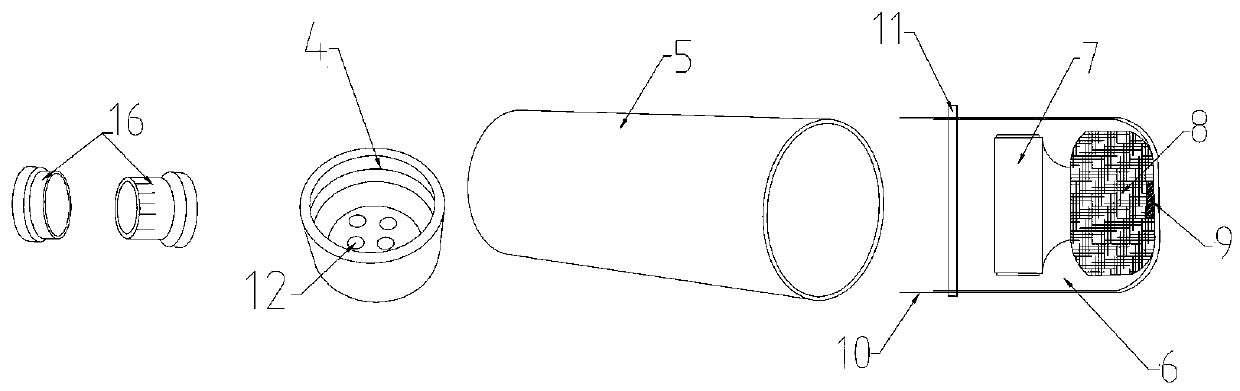

Hydrogen fuel cell unmanned aerial vehicle high-pressure gas cylinder valve

PendingCN108953994AMeet the best needsBest Demand GuaranteeAircraft componentsVessel mounting detailsGas cylinderHydrogen fuel cell

The invention relates to the technical field of unmanned aerial vehicle equipment, and particularly discloses a hydrogen fuel cell unmanned aerial vehicle high-pressure gas cylinder valve. The hydrogen fuel cell unmanned aerial vehicle high-pressure gas cylinder valve comprises a valve body base (1); a first mounting cavity (2) communicating with the interior of the valve body base is arranged inthe side wall of the valve body base and is internally provided with a high-pressure stop valve (3); one end of the high-pressure stop valve is located outside the valve body base; the other end of the high-pressure stop valve is located inside the valve body base; the two ends of the valve body base are provided with a first connector (4) and a second mounting cavity (5) separately; the second mounting cavity and the first mounting cavity communicate with each other through a first channel (6) arranged in the valve body base; the first connector is connected with a high-pressure gas cylinder(7); and a reducing valve (8) is arranged inside the second mounting cavity and provided with a gas outlet connector (9). The hydrogen fuel cell unmanned aerial vehicle high-pressure gas cylinder valve has the characteristics of being small in size, good in stability, high in control efficiency and good in safety.

Owner:德清天旭力精密机械制造有限公司

Lever-type connector with collective rubber stopper

A first housing (10) has a frame (11) with concave accommodation portions (20). A sub-connector (31) with female terminal fittings (33) is accommodated in the concave accommodation portions (20). A collective rubber stopper (36) is accommodated inside the concave accommodation portions (20) to seal a gap between a peripheral surface of an electric wire (34) pulled out of the sub-connector (31) and an inner peripheral surface of each concave accommodation portion (20). A first cam follower (19) is formed on an outer surface of the frame (11) and can engage an operation member (80). The frame (11) has an outer wall (12) defining an outer surface thereof where the first cam follower (19) is formed and an inner wall (18) separated from the outer wall part (12) via separated spaces (17) and constructing the inner peripheral surface of each concave accommodation portions (20).

Owner:SUMITOMO WIRING SYST LTD

Rotor type compressor

ActiveCN102477986APrevent thermal deformationFew partsRotary/oscillating piston pump componentsLiquid fuel engine componentsInterference fitEngineering

The invention relates to a rotor type compressor, which comprises: an upper shell cover, stators, rotors, a crankshaft, a shell, an upper cylinder cover, a cylinder, a piston, blades, a lower cylinder cover, a lower shell cover, and an air inlet connecting pipe. The upper cylinder cover and the shell are integrated together and molded into a one-piece frame in one step. The top of the one-piece frame is provided with a concave platform that is equipped with a concave platform plane, on which the lower ends of the stators are fixed. The one-piece frame is provided with an air suction port, one end of which is disposed on a side of the one-piece frame and the other end of which is disposed on a contact surface between the one-piece frame and the cylinder. The air inlet connecting pipe is introduced into the air suction port under static pressure so as to be in interference fit with the air suction port. Compared with prior art, the compressor of the invention has the advantages of coaxiality, uniform gap between the stators and rotors, no influence on the eccentric gap of a pump body during installing the air inlet connecting pipe, and no hidden trouble of internal leakage, etc.

Owner:SHANGHAI HITACHI ELECTRICAL APPLIANCES CO LTD

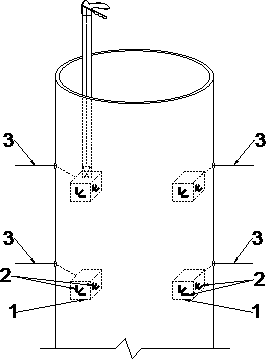

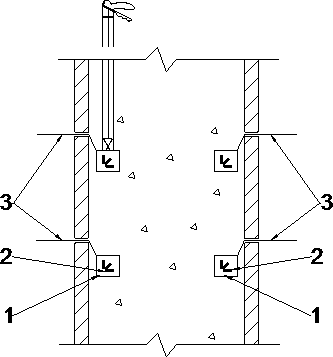

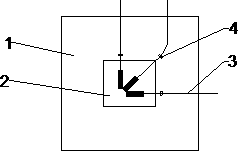

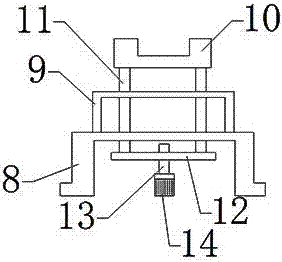

Internal strain monitoring device and method for steel pipe concrete

InactiveCN109115170ATrue reflection of strainEliminate disturbanceMeasurement devicesData acquisitionEngineering

The invention discloses an internal strain monitoring device and method for steel pipe concrete. The device is composed of a strain sensing module, a positioning module and a data collection module; the strain sensing module is composed of a test base body, a strain rosette, a lead and a binding post; the positioning module is composed of a positioning pipe, a fixed handle, a movable handle, a torsion spring, a line ranger, an extended positioning rod, a wire rope, a rotating shaft, a spring and a calibrated scale; and the data collection module is composed of a data collector and a computer.The test base body is fixed in a predetermined position by the positioning module, the fixed handle is rotated to adjust the angle of the test base body, and concrete is placed and maintained; and thestrain of the test base body is monitored, and further strain in the predetermined position in the steel pipe concrete is monitored. The test base body is positioned accurately via the positioning module, disturbance of concrete placement to the position of the strain sensing module is eliminated, the problem that a present strain test component tends to offset in a sample is solved, and the device and method can be widely applied to the field of internal strain monitoring and test of concrete.

Owner:SHANDONG UNIV OF SCI & TECH

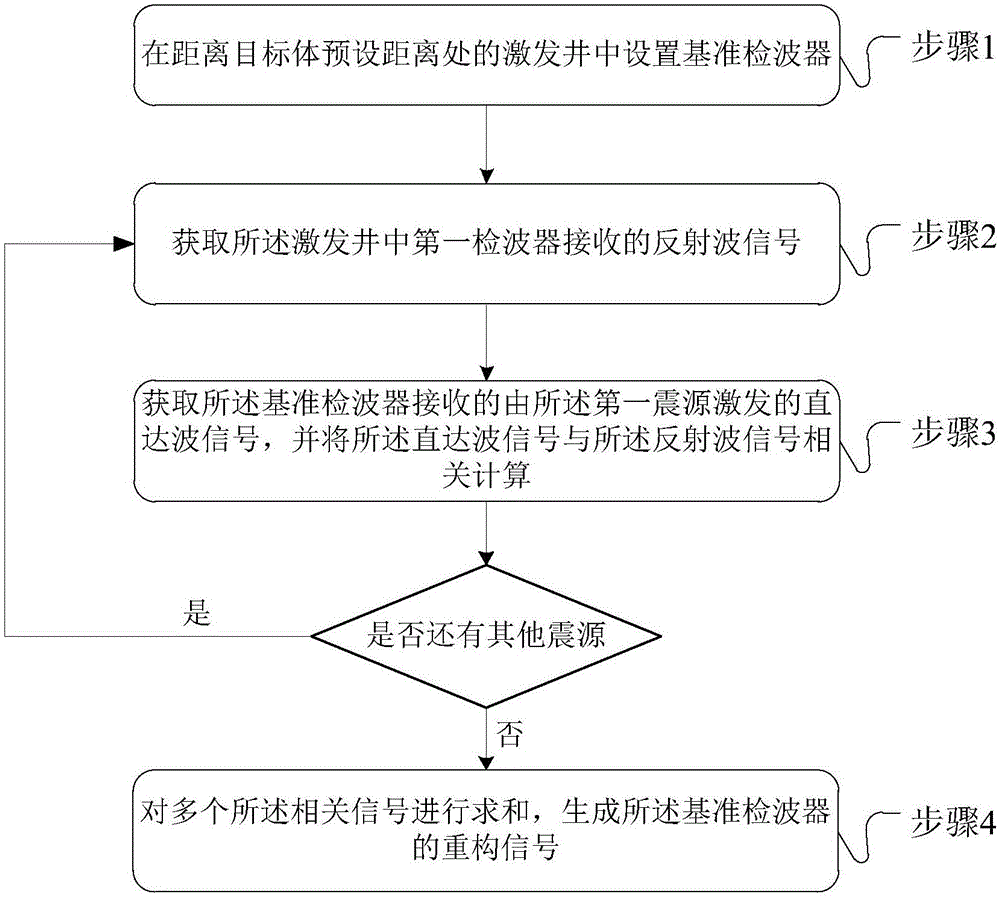

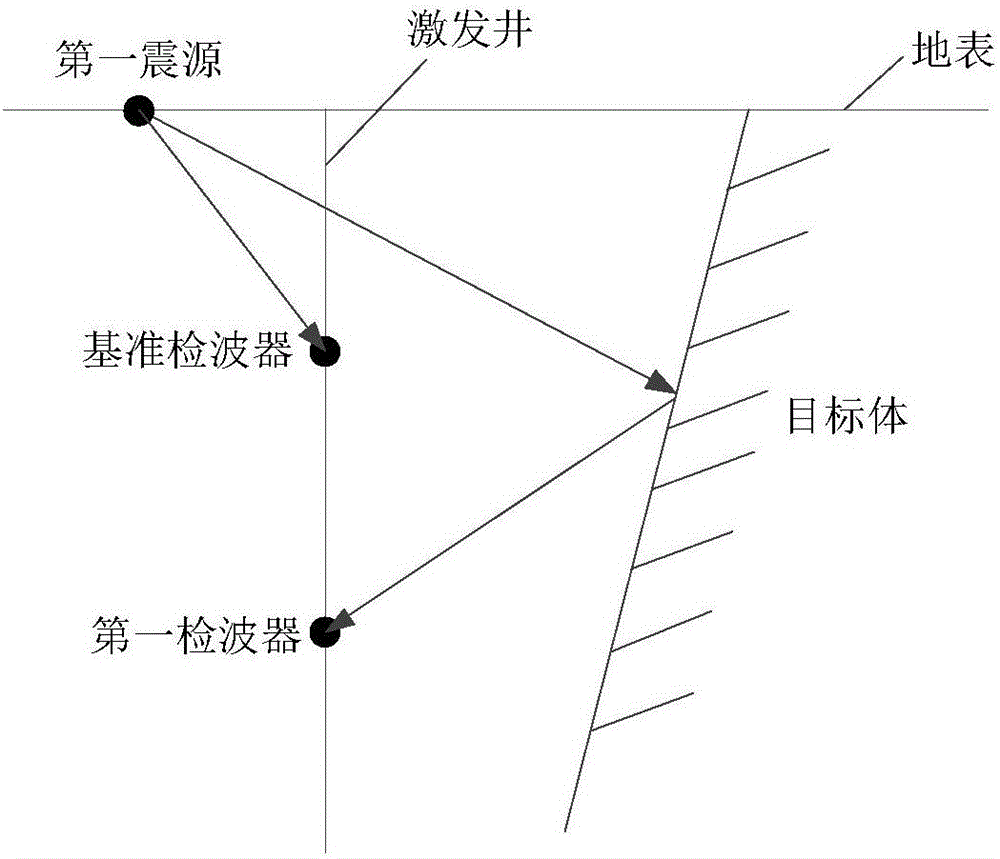

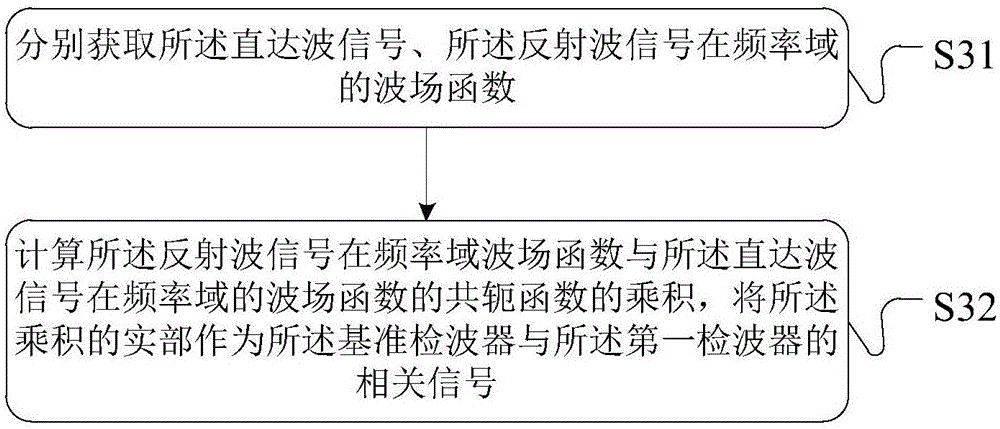

Processing method and device of seismic imaging

InactiveCN106597536AHigh resolutionAvoid deformation effectsSeismic signal processingReflected wavesReference wave

The invention provides a processing method and device of seismic imaging. The method comprises that 1) a reference wave detector is arranged in an excitation well in a preset distance to an object; 2) a reflection wave signal received by a first wave detector in the excitation well is obtained; 3) a direct wave signal excited by a first seismic center and received by the reference wave detector is obtained, and correlation between the direct wave signal and the reflection wave signal is calculated; and 4) reflection wave signals excited by other seismic centers are received from the first wave detector are obtained one by one, the steps 2) and 3) are repeated, correlation signals between the direct waves received by the reference wave detector and the reflection wave signals are calculated, a sum of the correlation signals is calculated, and a reconstruction signal of the reference wave detector is generated. The method and device can reduce the sensitivity of static correction and a near-land-surface speed model, and improve the imaging precision of a high steep structure.

Owner:PETROCHINA CO LTD

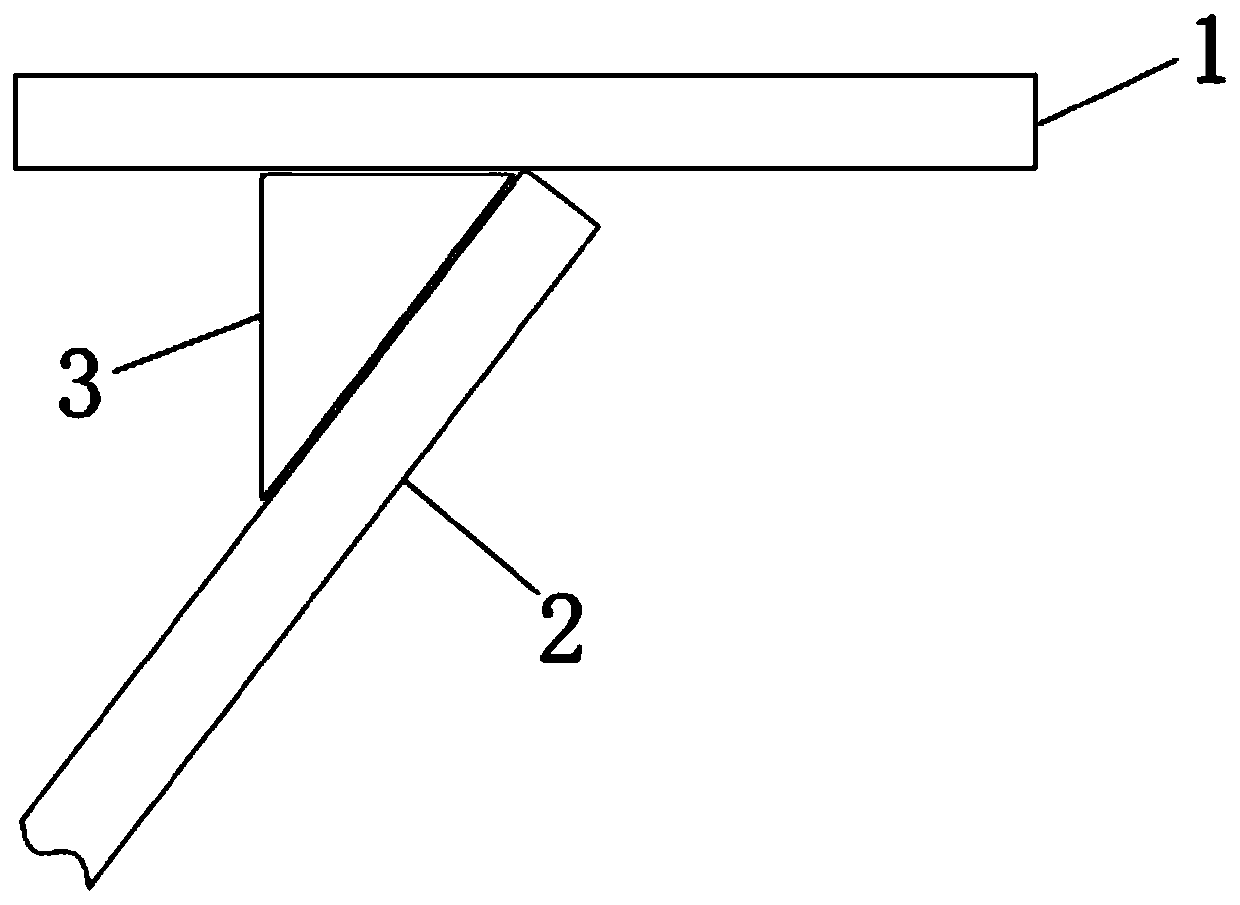

Light guide rail component with elastic adapting function

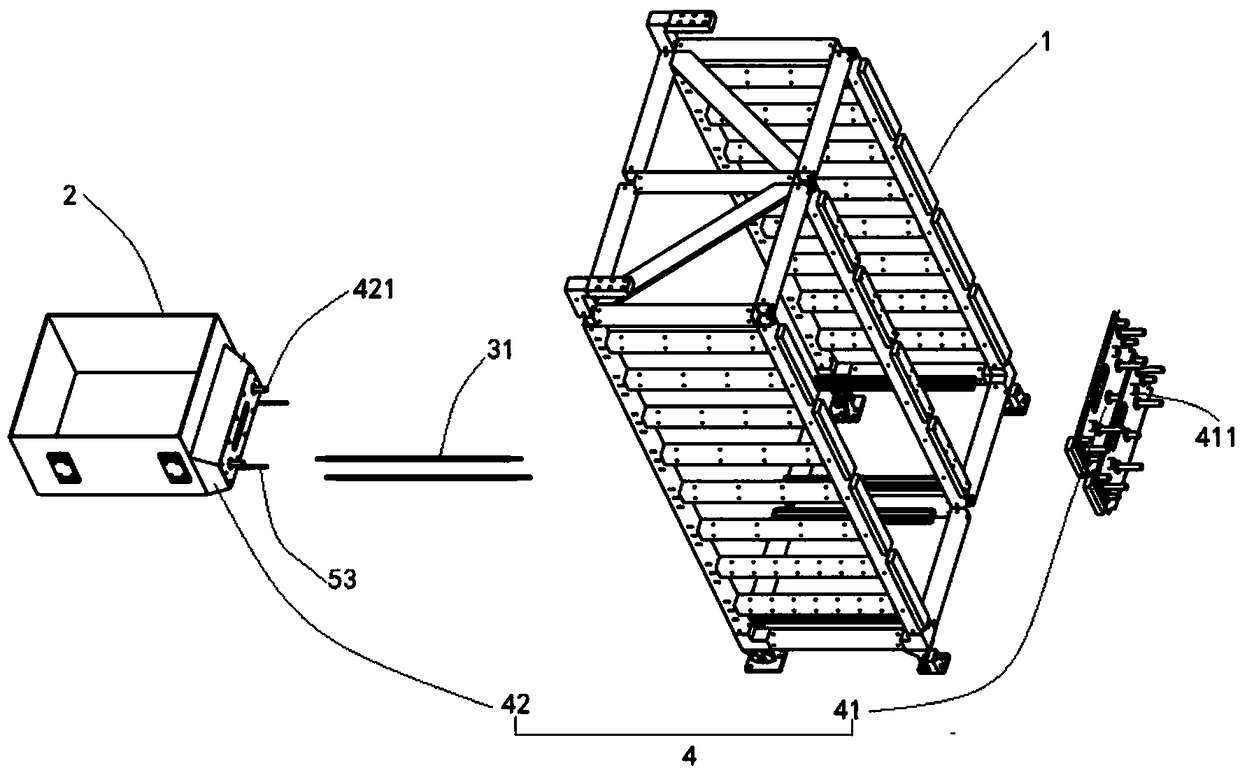

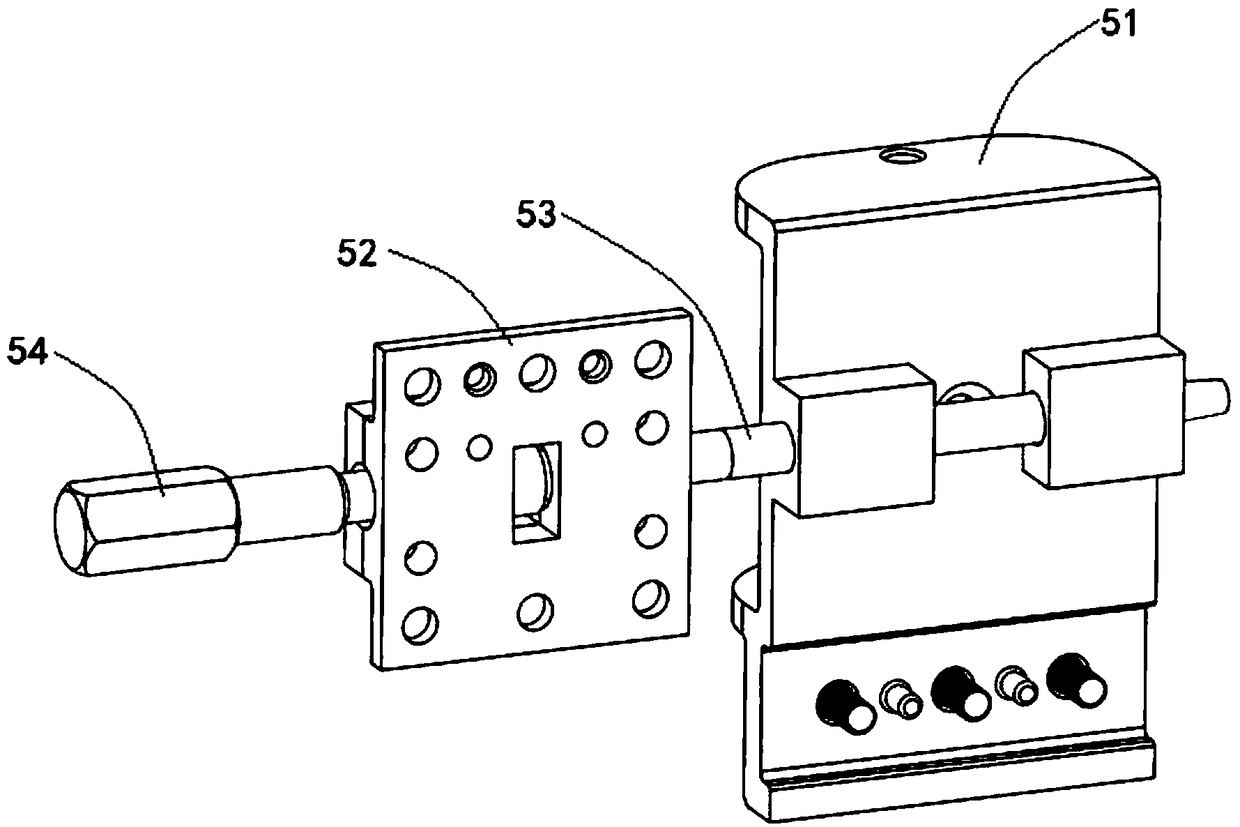

PendingCN108100309AAchieve installationSatisfy on-orbit operation requirementsCosmonautic partsArtificial satellitesElectricityFull life cycle

The invention relates to a light guide rail component for realizing cabinet and load installation. The guide rail component comprises a guide component, a back insertion component and a power assisting component. The inner wall of a cabinet and the side wall of a load are in slide connection through the guide component, the back of the cabinet and the back of the load are connected through the back insertion component, one end of the power assisting component is connected with the front end of the load, and the other end of the power assisting component is connected with the back of the cabinet. The light guide rail component has advantages that an independent mechanical system is formed by the guide component, the back insertion component and the power boosting component, mounting of thecabinet and the load can be well realized, and a series of effective loads in different standards can be provided with corresponding mechanical and electrical interfaces; besides meeting of upward mechanical conditions, corresponding man-machine ergonomic design is carried out so as to meet the requirement on on-orbit operation of astronauts; in addition, the guide rail component is available foron-orbit reconstruction and supportive to on-orbit mounting, experiments, replacement, repair and maintenance of different effective load units in a full life cycle.

Owner:北京天宫空间应用技术有限公司

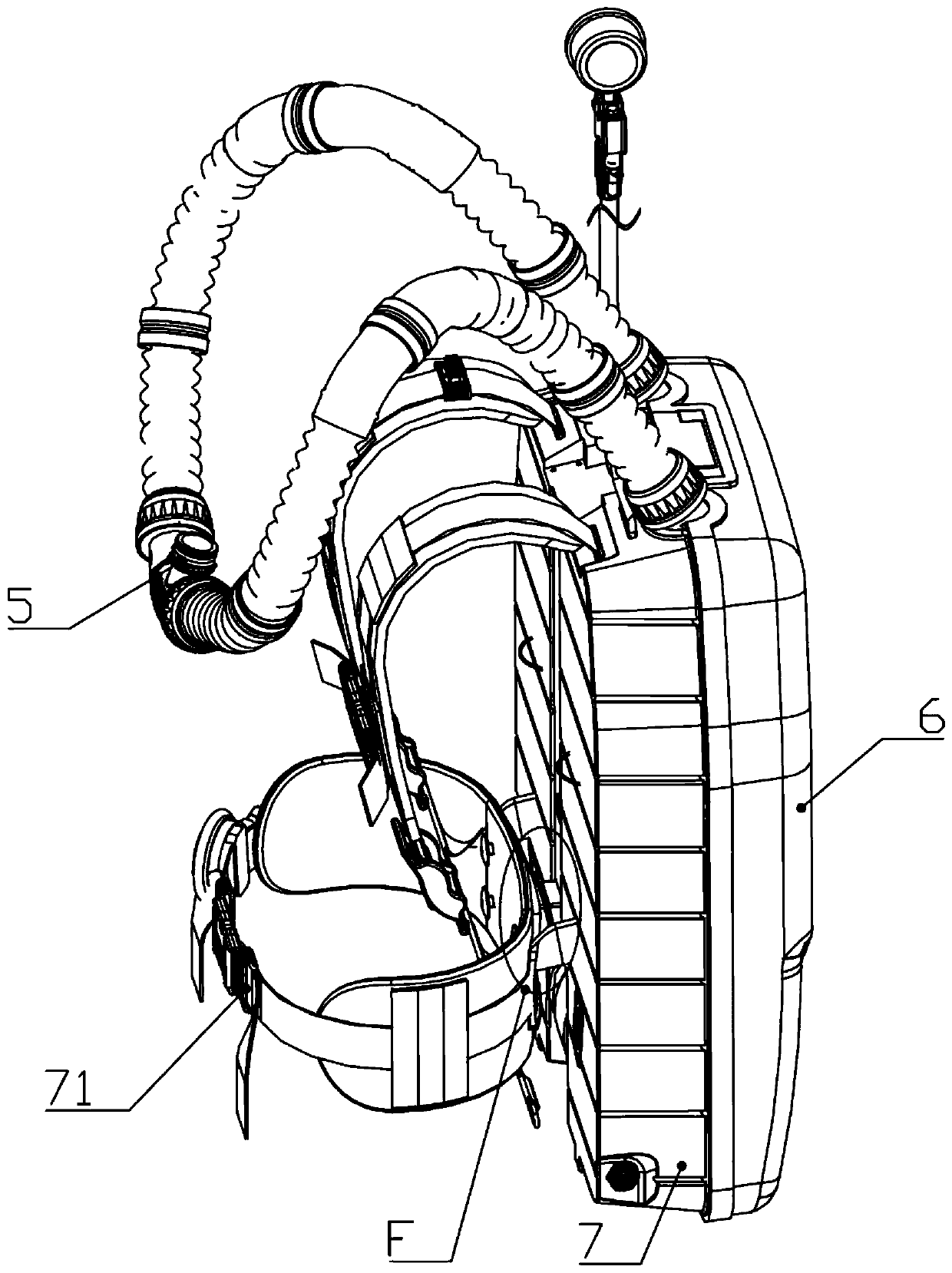

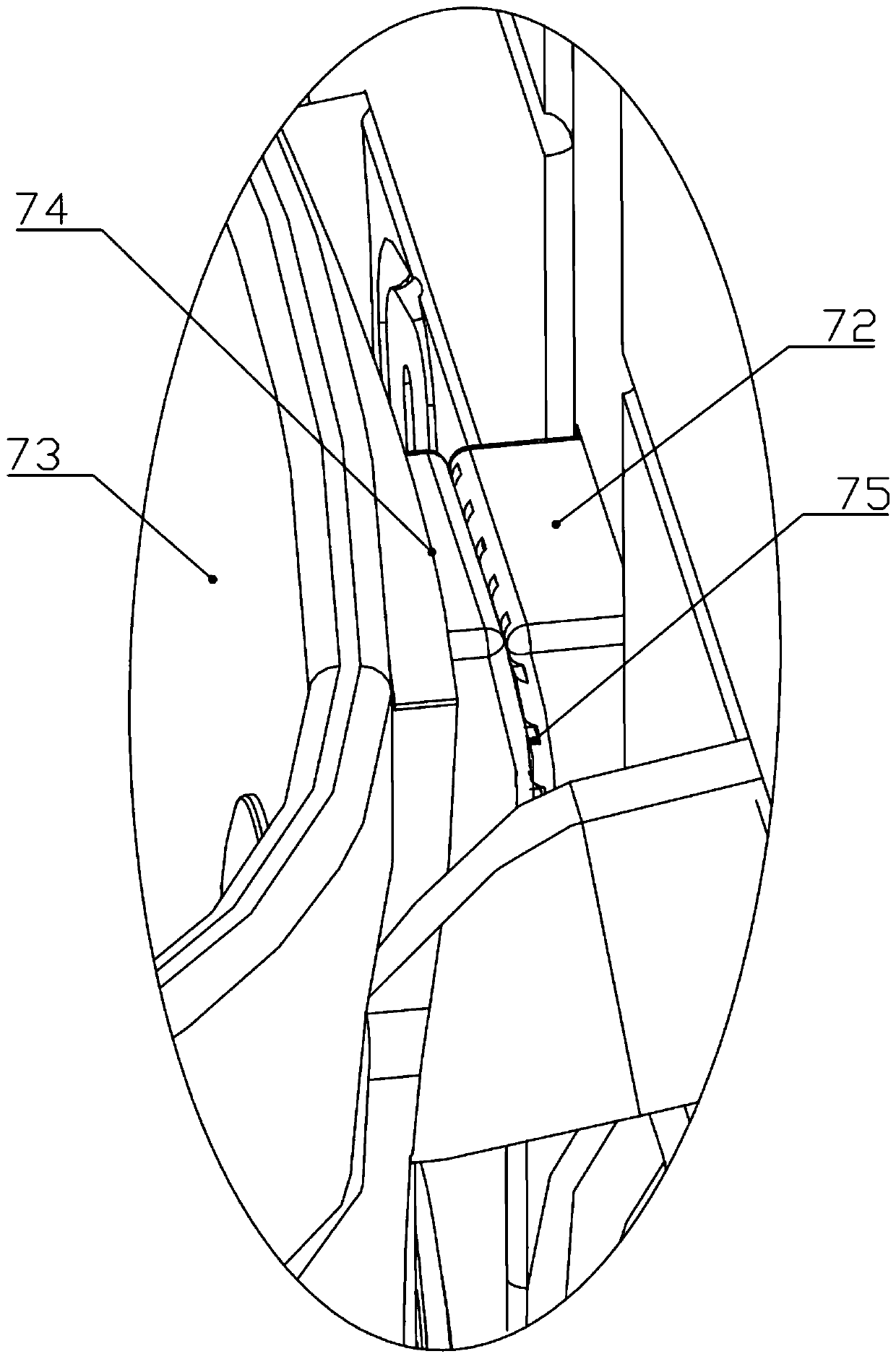

Oxygen respirator with novel ventilation structure

ActiveCN110420404AAvoid deformation effectsProtection against impactFire rescueRespiratory apparatusEmergency rescueRespirator

The invention discloses an oxygen respirator with a novel ventilation structure, and belongs to the technical field of emergency rescue equipment. The oxygen respirator with the novel ventilation structure comprises a respirator main body, wherein the respirator main body at least comprises an air bag assembly, an oxygen tank, a cooling tank and a cleaning tank; the outer end of the air bag assembly is provided with an air bag body; a plurality of air vents are formed in the lower end of the air bag body; and the lower end of the cooling tank and / or the cleaning tank communicates with the airvents. According to the technical scheme, a structural design that the ventilation structure is arranged at the lower portions of the tank bodies, such as the oxygen tank, the cooling tank, the cleaning tank, is specifically disclosed. Through the structure design, the influence caused by the impact can be avoided, besides, the traditional way by connecting pipelines for ventilation is abandoned,and ventilation is directly carried out by the air vents formed in the lower end of the air bag body, so that the deformation influence of the impact on the pipelines is further avoided, the influenceof temperature on the ventilation structure is reduced, and the whole equipment is more stable and assembly is simpler and more convenient.

Owner:ZHEJIANG HENGTAI SAFETY EQUIP

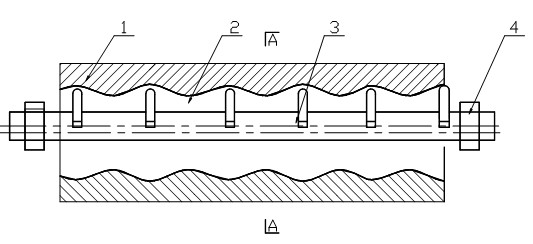

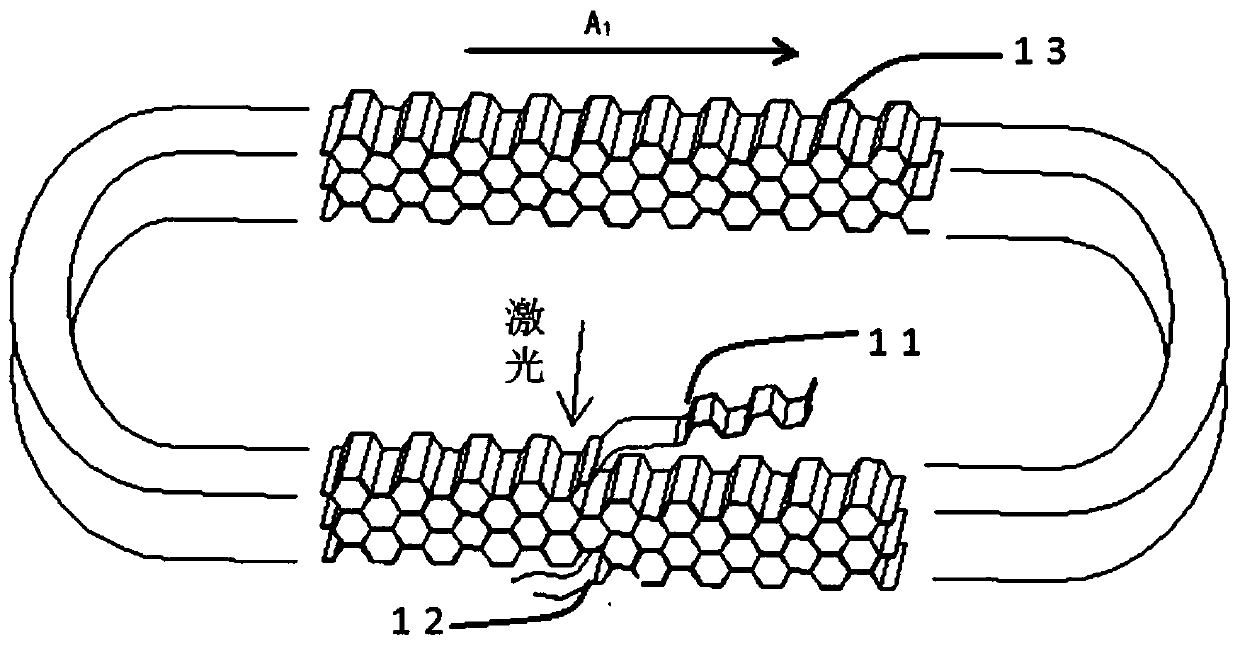

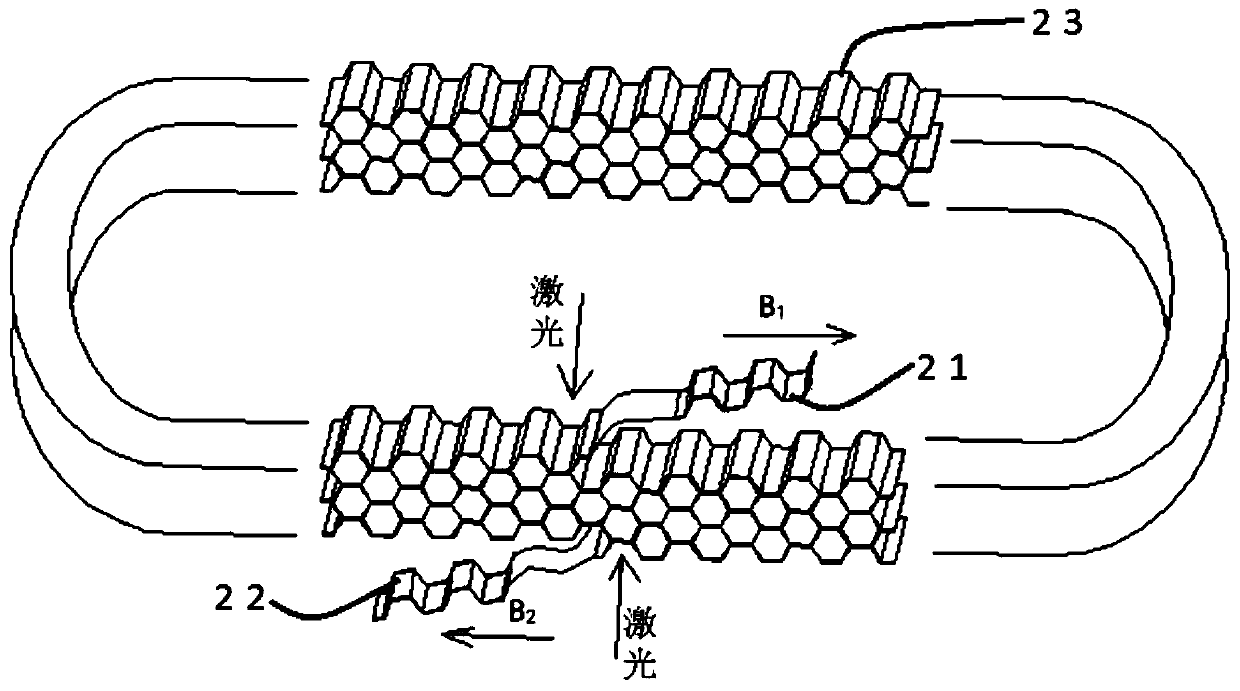

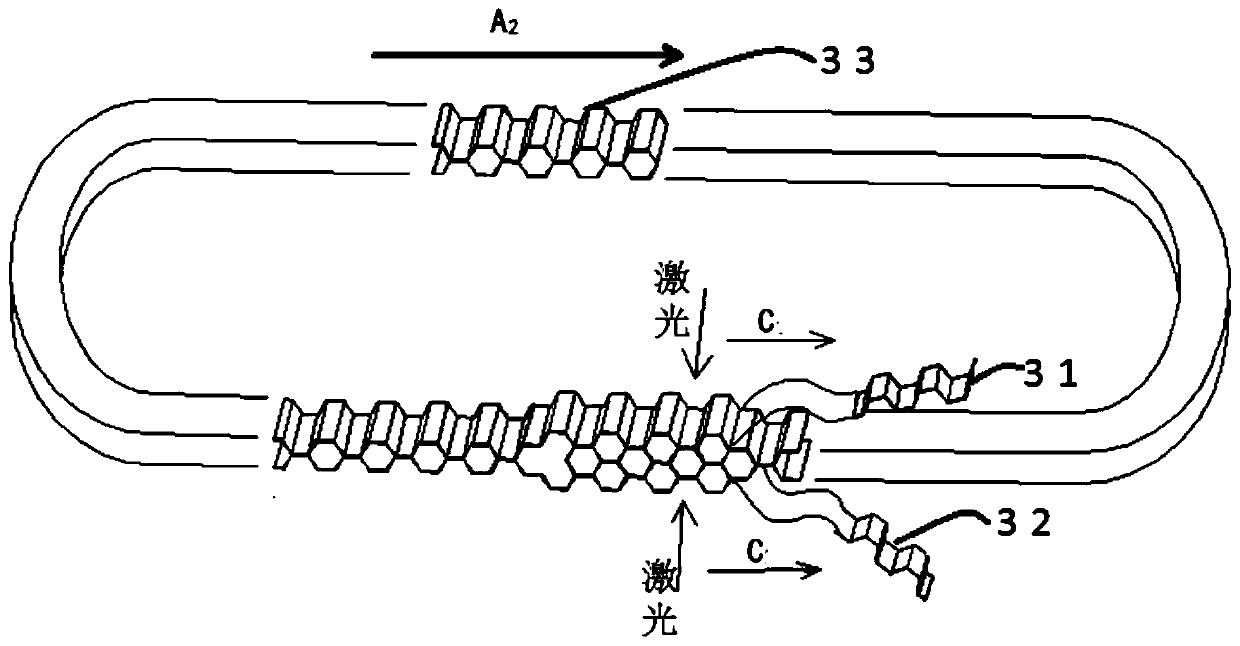

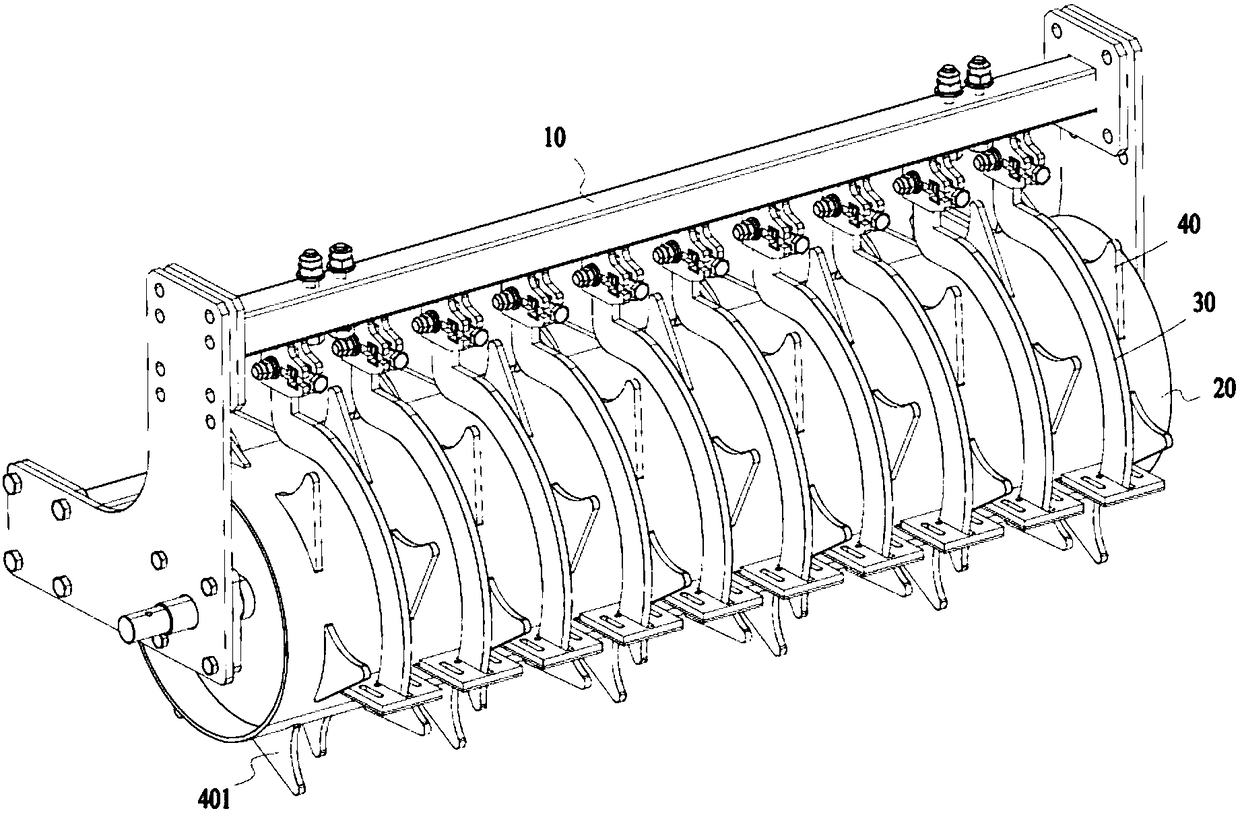

Manufacturing method for honeycomb structure

ActiveCN109848558AAvoid deformation effectsContinuityWelding/soldering/cutting articlesMetal working apparatusClosed loopHoneycomb structure

The invention provides a manufacturing method for a honeycomb structure. The manufacturing method comprises the steps that a corrugated ribbon is provided, wherein the corrugated ribbon is constitutedthrough alternative connection of concave surface sections and convex surface sections, and any one of the concave surface sections and any one of the convex surface sections in the corrugated ribbonare used to form a honeycomb core grid after closed loop connection; the corrugated ribbon is annularly coiled axially with an axis as the center, so the convex surface sections and the concave surface sections can overlay to constitute a plurality of honeycomb core grids, and then the sealed loop is constituted by the honeycomb core grids; and overlaid positions between the sections of the corrugated ribbon are fixedly connected, so the honeycomb structure constituted through successive connection of the honeycomb core grids is obtained. The manufacturing method provided by the invention isdifferent from traditional honeycomb processing in that overall cutting is carried out after processing of the honeycomb structure, so a process for single sheet cutting is omitted during production,production efficiency is greatly increased and manpower cost is reduced; the cutting process and influences of cutting on belt deformation are avoided, so product quality is greatly improved; and themanufactured honeycomb cores are continuous and circulative as a whole.

Owner:BEIJING ANDER TECH

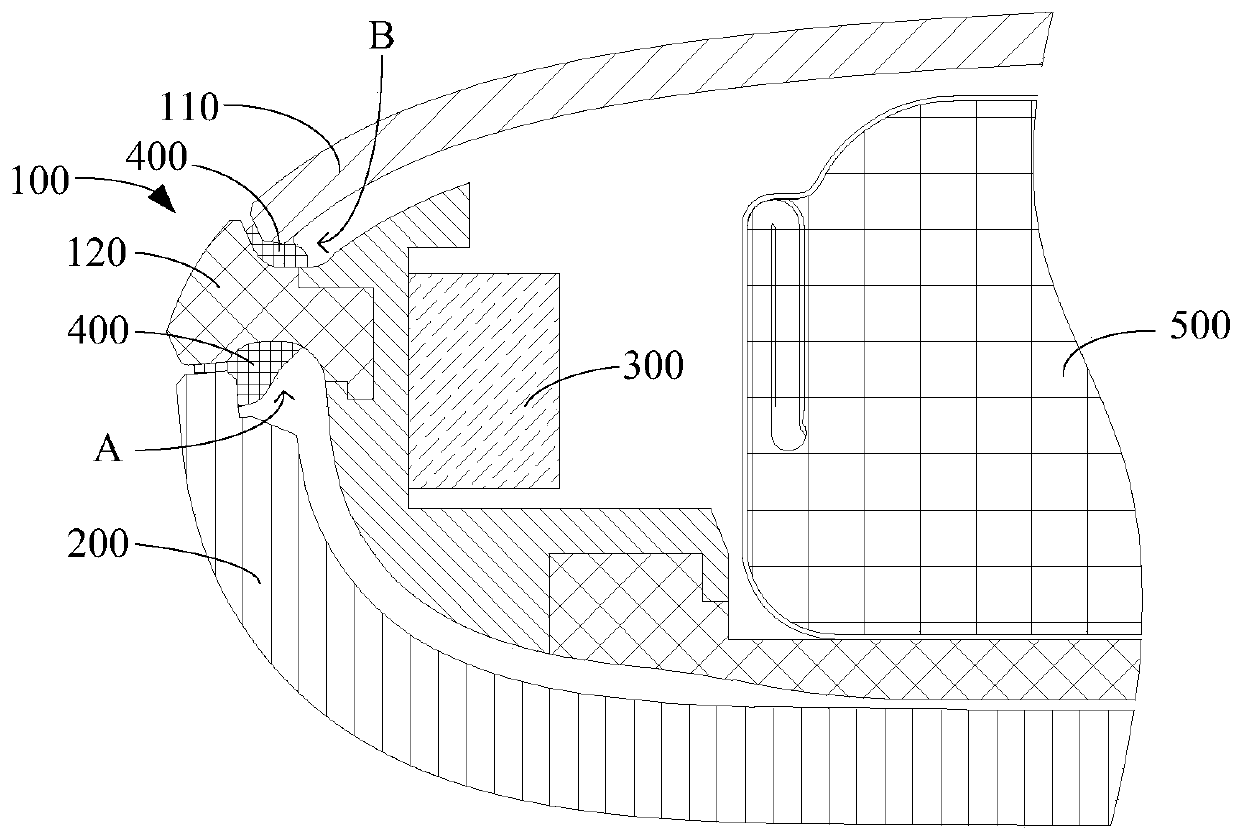

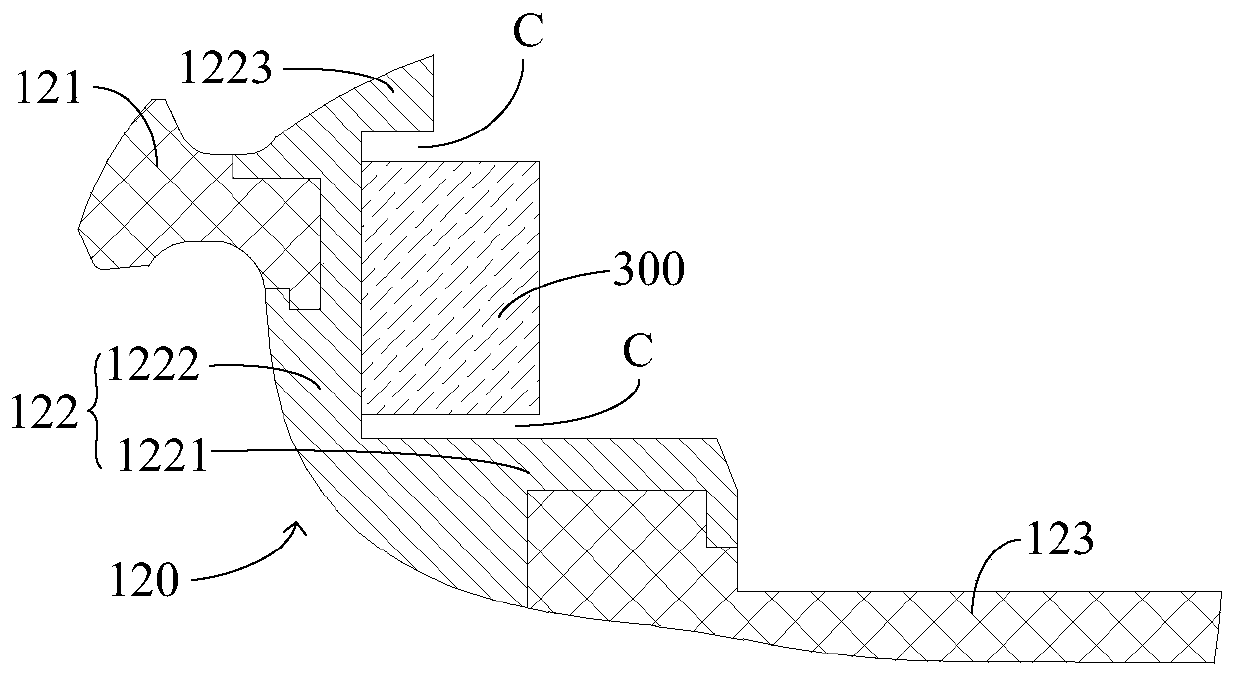

Electronic equipment

ActiveCN110673757AAvoid deformation effectsAvoid influenceInput/output processes for data processingEngineeringMechanical engineering

The invention discloses electronic equipment. The electronic equipment comprises a shell (100) and a display module (200) arranged on the shell (100), wherein a first assembly gap is formed between the shell (100) and the display module (200); the shell (100) or the display module (200) comprises a pressure key area; the shell (100) is provided with an inner cavity; a pressure sensor (300) is arranged in the inner cavity; the pressure sensor (300) is connected with the surface of the inner side of the pressure key area; the pressure sensor (300) senses deformation of the pressure key area to form a key trigger signal; and the first assembly gap is filled with an elastic piece (400). According to the scheme, the problem that an existing pressure key is unstable in work can be solved.

Owner:VIVO MOBILE COMM CO LTD

Blast furnace roof flange installing method

InactiveCN109759734AImprove accuracy and qualityUniform deformationWelding/cutting auxillary devicesAuxillary welding devicesWelding deformationSpot welding

The invention relates to a blast furnace roof flange installing method. Preheating is conducted to 190-210 DEG C before welding; rib plates are adopted for strengthening a flange for restraining deformation, and the rib plates are arranged along the periphery of a furnace roof at equal intervals; preliminary leveling is conducted on the flange, and after leveling, welding lines between the rib plates and a furnace body are leveled; accurate leveling is conducted on the flange, four-point leveling is conducted on the flange along the flange center according to cross symmetry, vertical welding lines between the corresponding rib plates in the four-point direction and the flange are subjected to spot welding, and after accurate flange leveling and spot welding of the vertical welding lines between all the rib plates and the flange are gradually finished according to the above manner, the vertical welding lines between all the rib plates and the flange are welded through a skip reverse welding method; and during flange welding, welding is synchronously conducted along the flange center according to the four-point positions of the cross center line, a segmented reverse welding method isadopted in welding, and synchronous reversing is conducted in the welding process. In the flange welding process, a balance level and an invar ruler are adopted for welding deformation monitoring. Bymeans of the blast furnace roof flange installing method, the flange installing quality can be improved, the construction period is shortened, and the construction cost can be better reduced.

Owner:SHANGHAI ERSHIYE CONSTR CO LTD +1

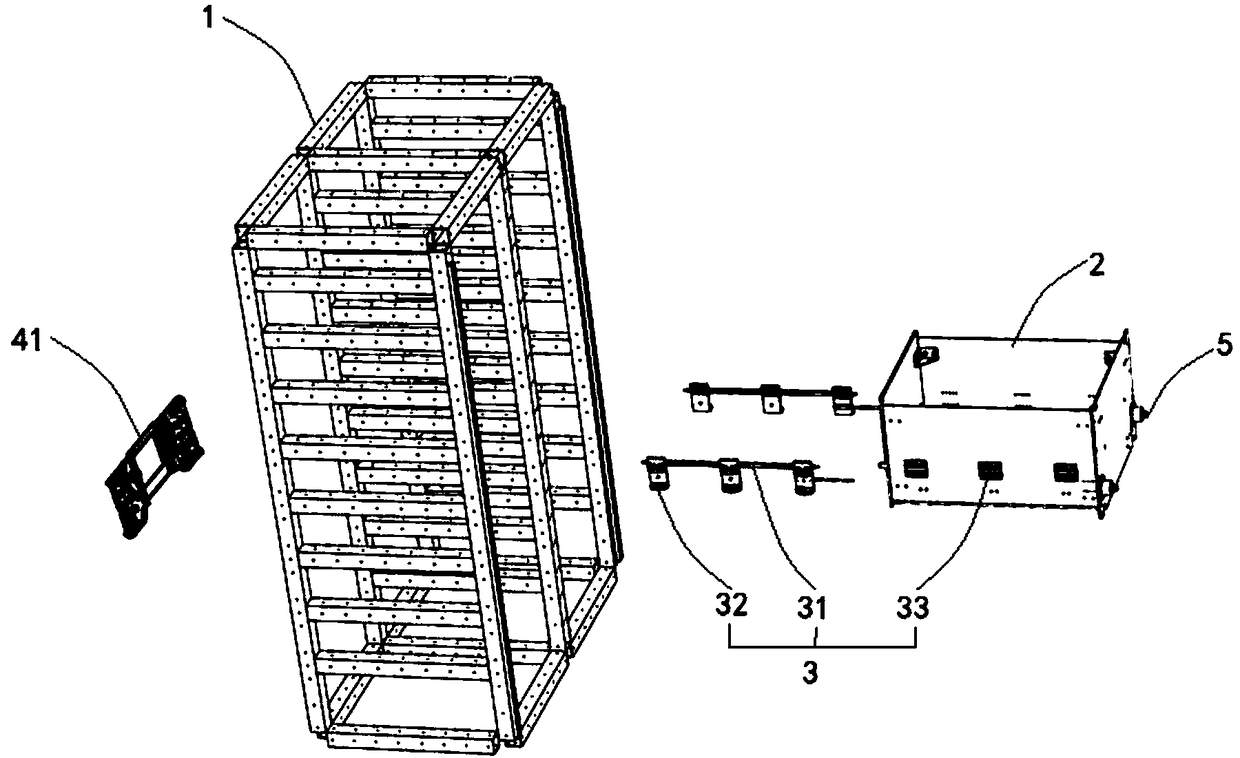

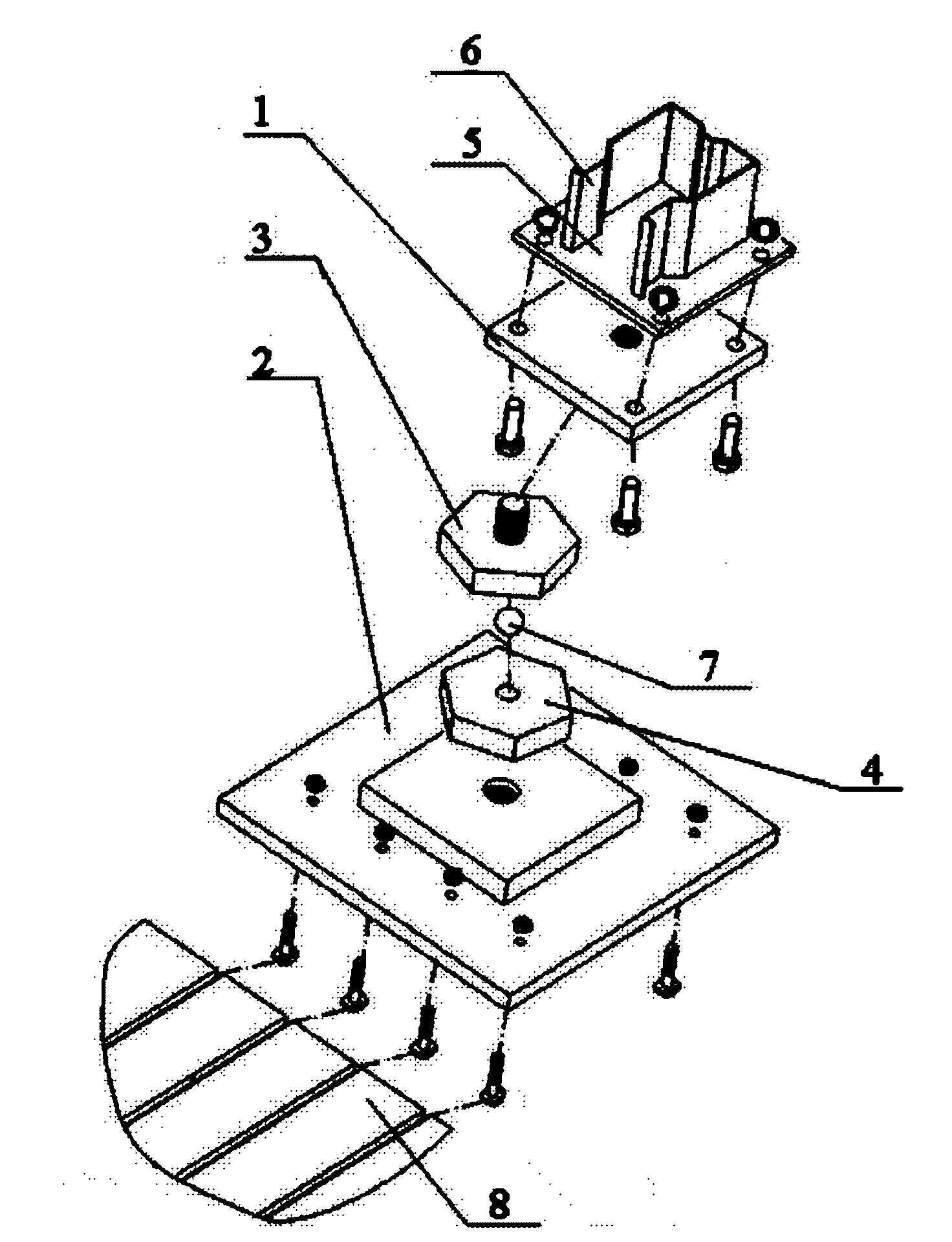

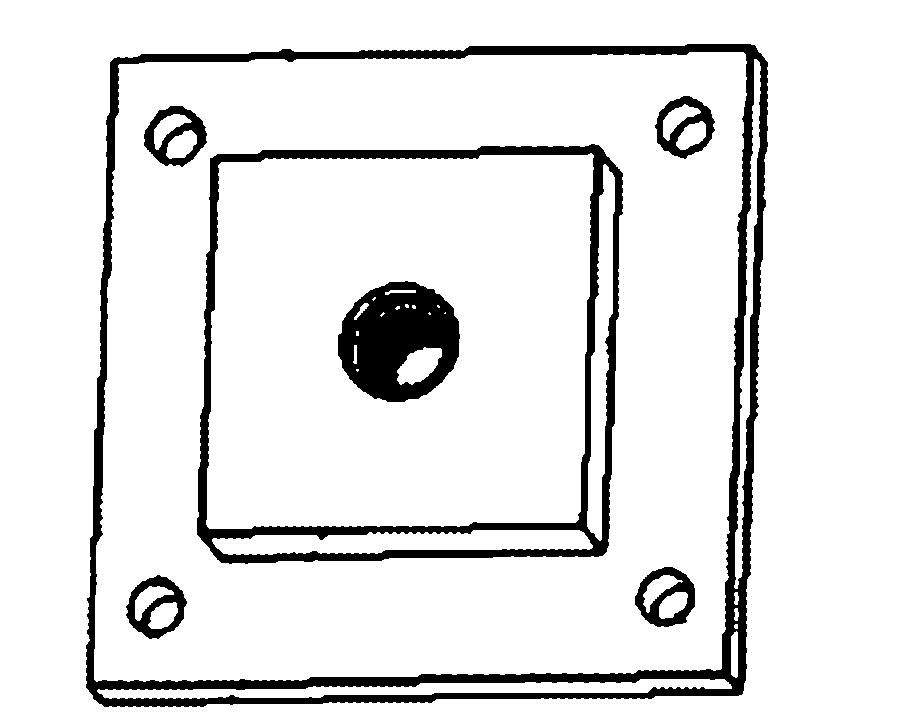

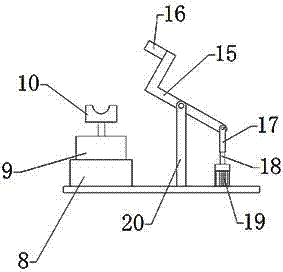

Combined clamp for rack upright post pressure test

InactiveCN102156068AAvoid deformation effectsGuaranteed matchStrength propertiesArchitectural engineeringSteel ball

The invention relates to a combined clamp for a rack upright post pressure test. The combined clamp comprises an upright post fixing plate, a worktable fixing plate, an upper steel ball clamping block and a lower steel ball clamping block, wherein an upright post bottom plate is fixed on the upper surface of the upright post fixing plate; an upright post is welded on the upright post bottom plate; the lower surface of the upright post fixing plate is connected with the upper steel ball clamping block; a T-shaped groove worktable is fixed on two sides of the worktable fixing plate respectively; the upper surface of the worktable fixing plate is connected with the lower steel ball clamping block; and the same groove for clamping steel balls is formed between opposite surfaces of the upper steel ball clamping block and the lower steel ball clamping block. The combined clamp can guarantee that two ends of a test piece are always hinged with a press worktable in the test, and the test result is more accurate.

Owner:DONGHUA UNIV

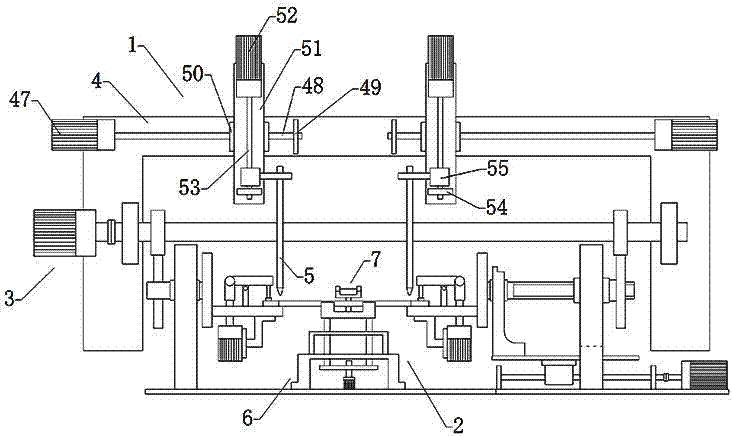

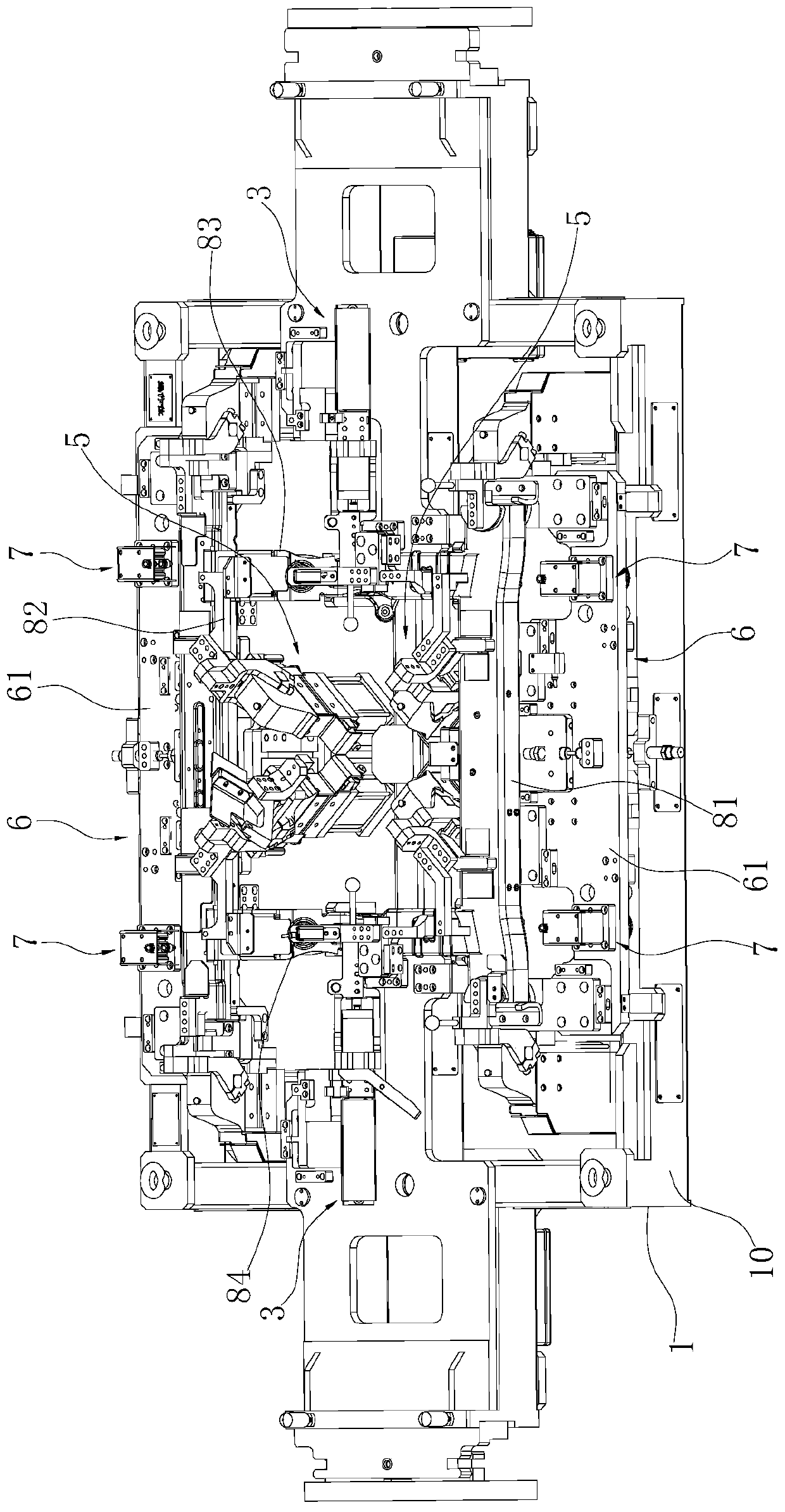

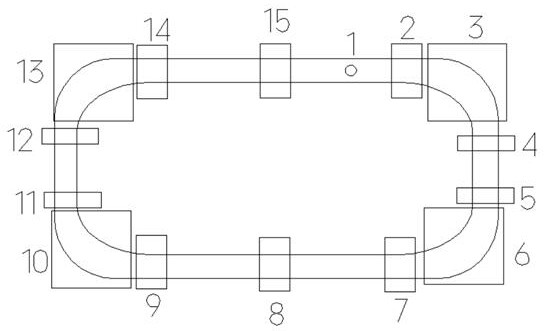

Device applicable to rotational welding of three parts

InactiveCN106862848AHigh degree of automationGood welding performanceWelding/cutting auxillary devicesAuxillary welding devicesWeldingEngineering

The invention relates to a device suitable for three-piece rotary welding, which includes a device suitable for three-piece rotary welding, which includes a gantry welding mechanism, a positioning mechanism and a synchronous rotation mechanism; the gantry welding mechanism includes a gantry frame and a welding head, the welding head is set at the beam position of the gantry frame, a synchronous rotation mechanism is fixed on the column of the gantry frame, and a positioning mechanism is arranged at the middle position of the synchronous rotation mechanism, and the positioning mechanism includes a supporting mechanism and a pressing mechanism. The support mechanism includes a door-shaped support frame A and a door-shaped support frame B, the door-shaped support frame B is fixed on the upper surface of the door-shaped support frame A, a bracket is arranged above the door-shaped support frame B, and the upper surface of the bracket is provided with an edge There is a groove in the horizontal direction, and a pressing mechanism is arranged at the rear of the supporting mechanism. The invention has the advantages of high welding efficiency, precise welding and good welding effect.

Owner:成都联润科技有限公司

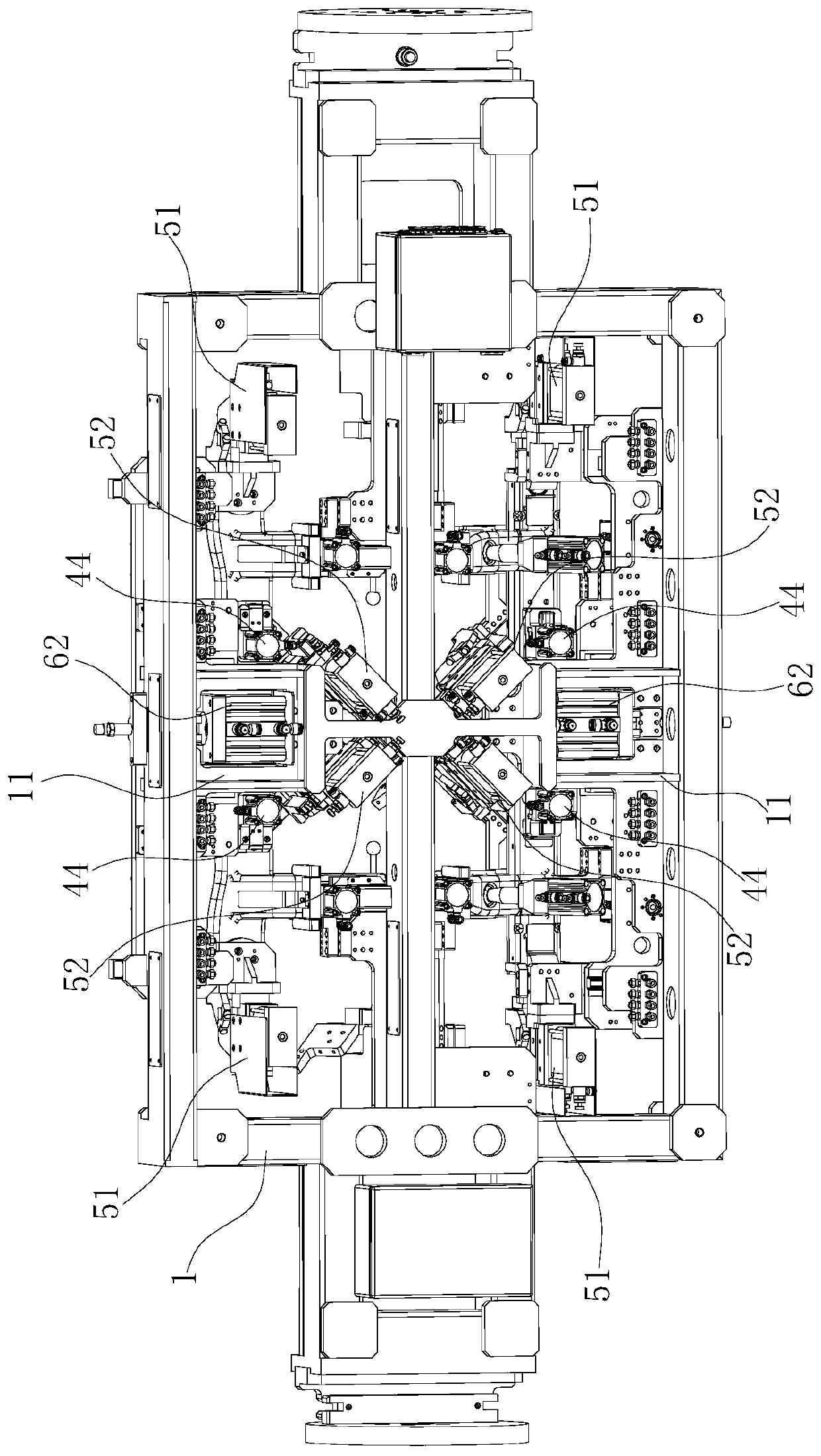

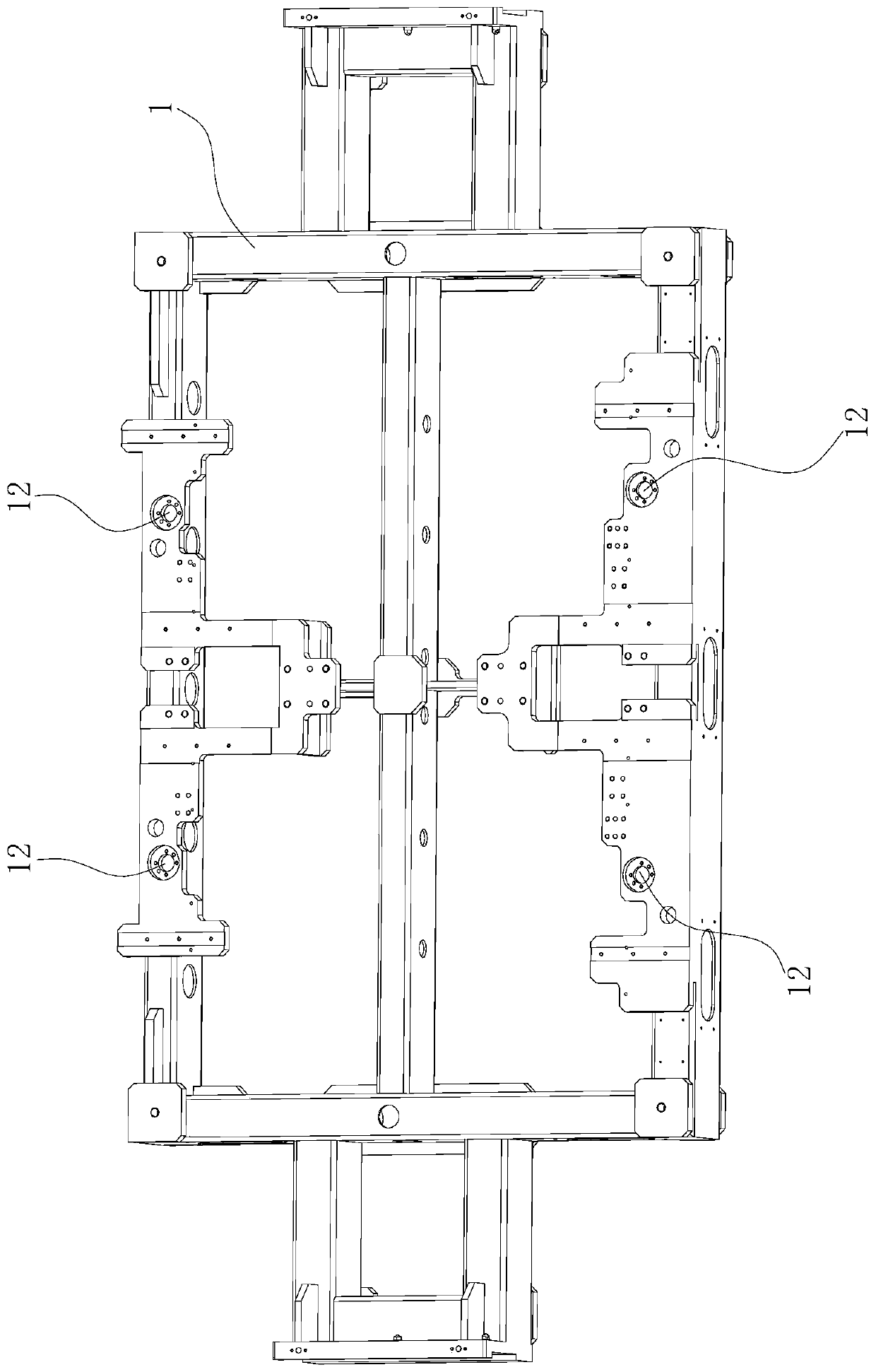

Auxiliary frame positioning and assembling tool

PendingCN110961809AAvoid PullbackAvoid deformationWelding/cutting auxillary devicesAuxillary welding devicesPhysicsVehicle frame

The invention relates to an auxiliary frame positioning and assembling tool which comprises a fixed assembling position, a first positioning assembly, a movable assembling position, a second positioning assembly, a slide-in structure and a self-locking structure, wherein each slide-in cylinder can drive a corresponding slide-in platform in order that each cross beam slides to a splicing position of a corresponding longitudinal beam; and the self-locking structure is used for locking the corresponding slide-in platform and a workbench. Compared with the prior art, the auxiliary frame positioning and assembling tool can stably load and position each cross beam and each longitudinal beam of the auxiliary frame, facilitates the assembly of each cross beam and the corresponding longitudinal beam through the slide-in structure, and locks the corresponding slide-in platform and the workbench through the self-locking structure, so as to avoid the influence of tension springback generated by welding heat on the slide-in cylinders, avoid the influence of deformation on parts due to heat concentration in the welding process. The auxiliary frame positioning and assembling tool is improved in repeatability precision and stability, and has a long service life.

Owner:NINGBO JIANXIN CHASSIS SYST

Modification method for leukocyte filtering membrane

InactiveCN106117590AAvoid deformation effectsAchieve filteringSemi-permeable membranesFilter effectChemistry

Owner:广州新克力生物科技有限公司

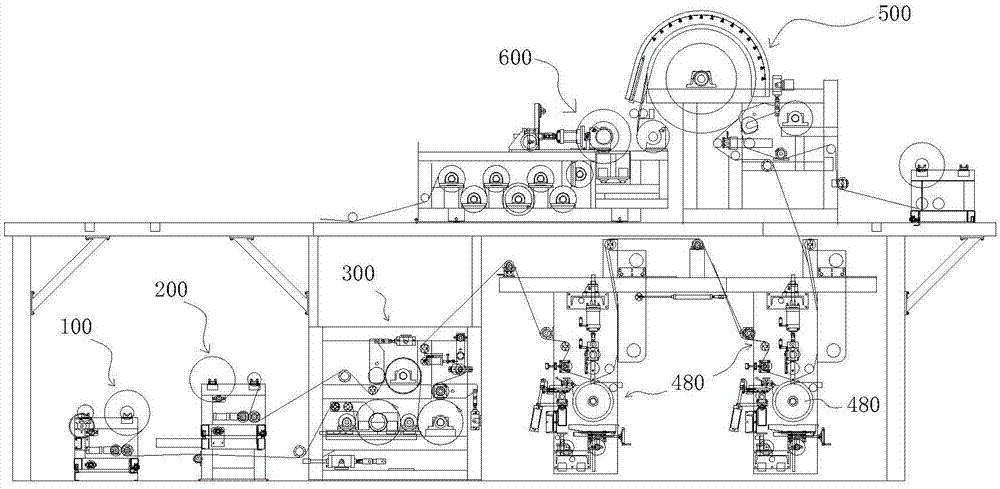

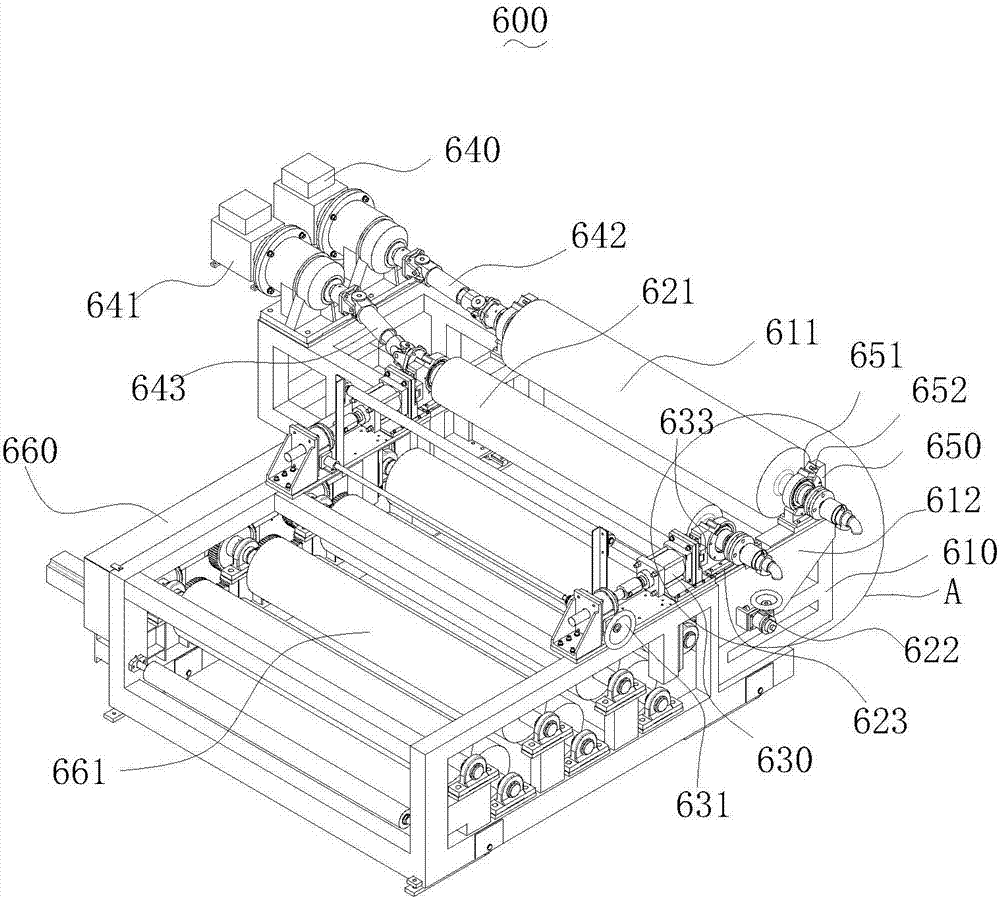

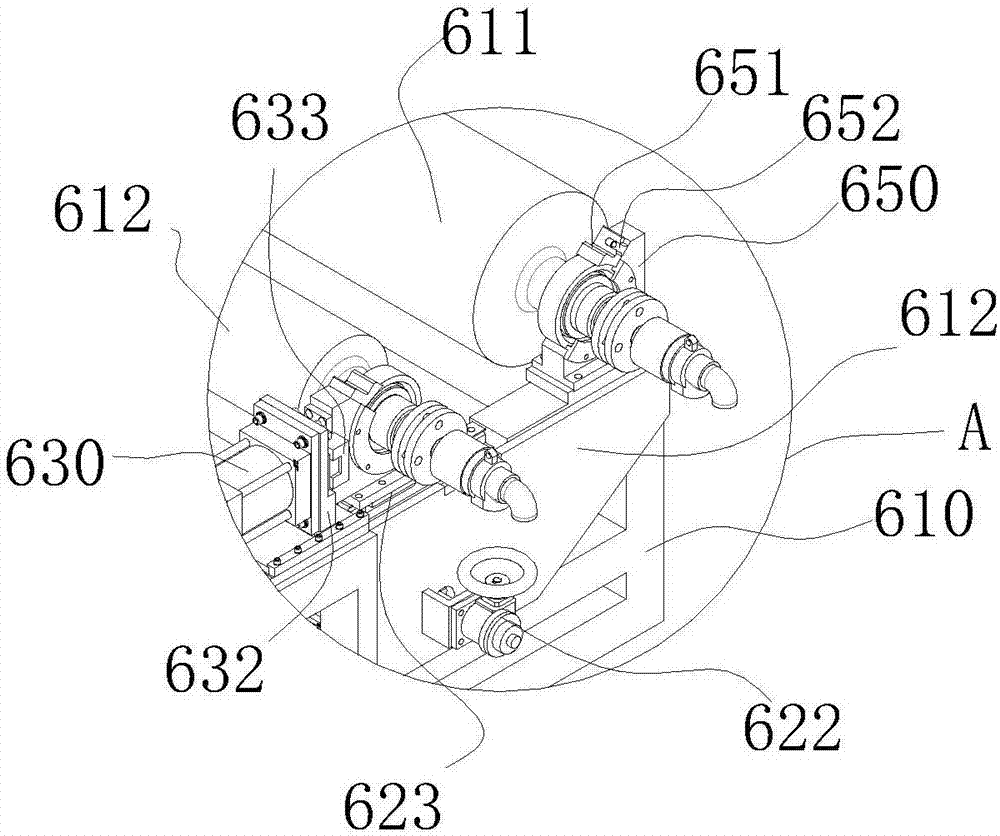

Printing machine

ActiveCN107415455AShorten the lengthAvoid deformationRotary pressesPrinting pressMechanical engineering

The invention relates to a printing machine. The printing machine comprises a printing assembly and an embossing assembly. The printing assembly comprises a plurality of printing rollers, and a film enters the embossing assembly after being printed by the printing rollers. The embossing assembly is arranged above the printing assembly. According to the printing machine, the embossing assembly is arranged over the printing rollers or above the printing rollers, so that the traditional mode of placing the embossing assembly and the printing rollers in parallel is changed, he length of the portion, between the embossing assembly and the printing rollers, of the film is shortened, the influence that the film is deformed due to tension action is reduced, a printing pattern can be accurately aligned to an embossing pattern, and the product quality is improved.

Owner:FOSHAN PUYING MACHINERY EQUIP

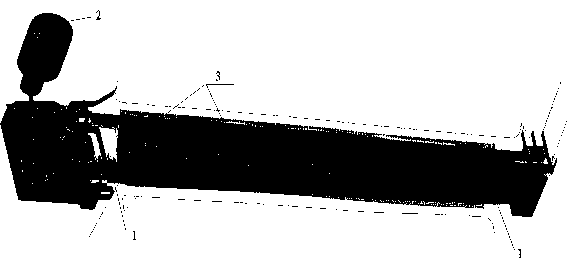

Cleaner bar device and seeder for soil preparation roller

The invention discloses a cleaner bar device for a soil preparation roller. The cleaner bar device comprises a connecting arm which is connected with a machine frame and capable of swinging relative to the machine frame, a cleaner bar which is installed on the connecting arm and capable of getting close to or away from the surface of the roller through the swinging of the connecting arm, a limiting member which is acted on the connecting arm to adjust the maximum displacement between the cleaner bar and the surface of the roller. The invention further discloses a soil preparation roller deviceand a seeder. According to the cleaner bar device, the limiting member can be acted on the connecting arm to drive the cleaner bar close to or away from the surface of the roller, when the loss of the cleaner bar occurs (the distance between the edge of the cleaner bar and the surface of the roller is increased), the utilization rate of the cleaner bar is effectively increased by reducing the distance between the cleaner bar and the surface of the roller through the adjusting member, and the influence of connecting arm deformation can be effectively prevented.

Owner:武汉甘太喜科技有限公司

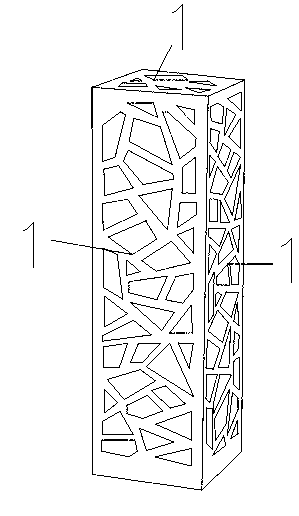

Lampshade with lamp panels having grids

InactiveCN102829424AGuaranteed StrengthAvoid deformation effectsLighting heating/cooling arrangementsProtective devices for lightingEngineeringThermal radiation

The invention relates to a lampshade with lamp panels having grids. The lampshade comprises a lampshade body, wherein the lampshade is in a rectangular structure. The lampshade is characterized in that fix sides of the lampshade are all hollow lamp panels (1) with grids. As for the lampshade with the lamp panels having the grids, the six sides of the lampshade are all the hollow lamp panels (1) with the grids, so that the lampshade strength is kept, and material is saved. Meanwhile, the heat in the lampshade is conveniently dispersed, so that the lampshade is prevented from being affected by the heat radiation to deform, and the service life is prolonged.

Owner:沈卫军

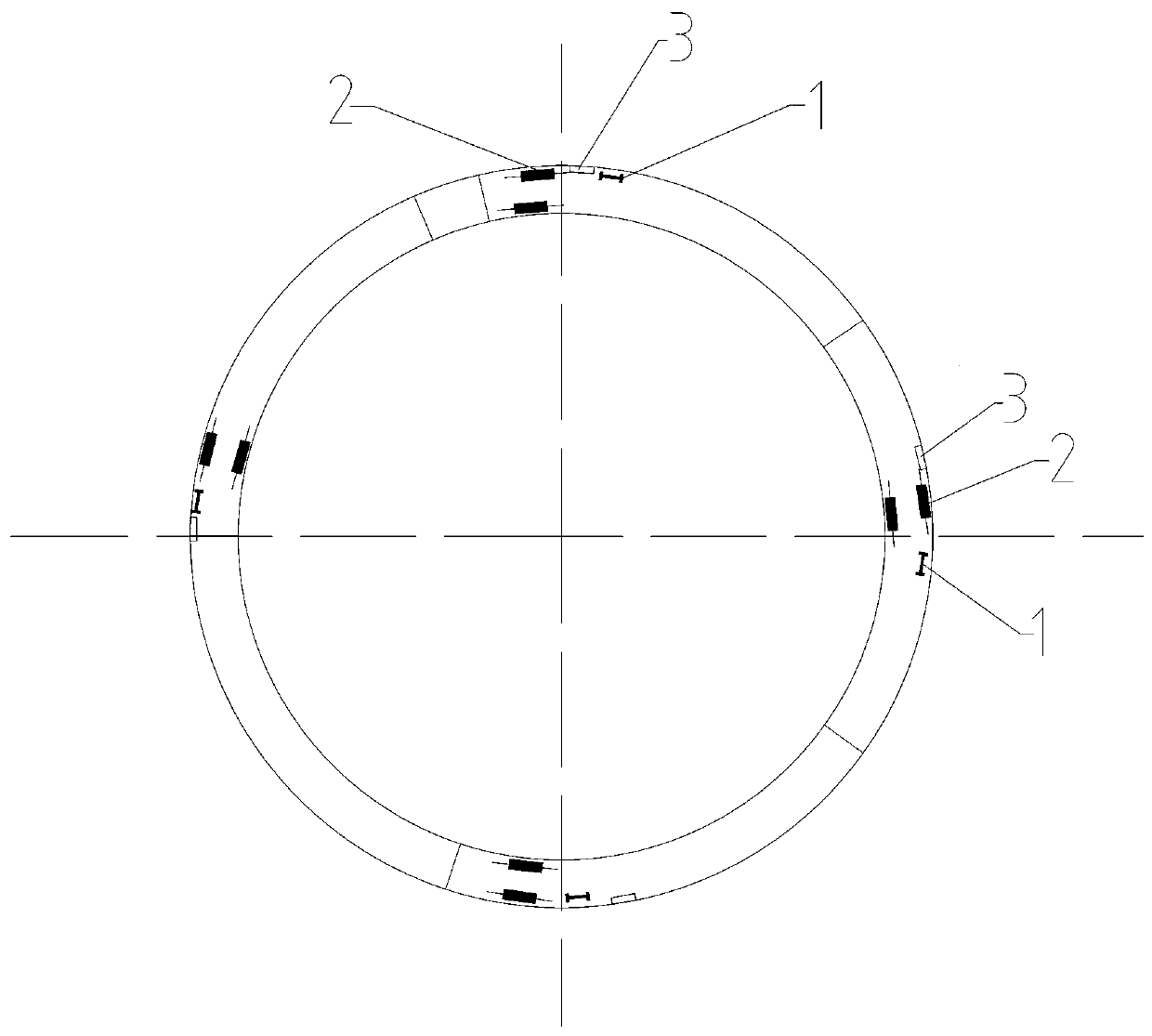

Wire sealing device and layout method for concrete shield/TBM segment embedding monitoring instrument

InactiveCN110514328AGuaranteed independenceGuaranteed interferenceUnderground chambersForce measurementEngineeringInstrumentation

The invention discloses a wire sealing device and a layout method for a concrete shield / TBM segment embedding monitoring instrument. The wire sealing device comprises a sealing cavity, wherein a screw-tight sealing end is installed at one end of the sealing cavity, and a wire jack is drilled on the end surface of the sealing end; a sealing cover is installed at the other end of the sealing cavity,and the sealing cover comprises a cover body, an elastic positioning block provided at the bottom end inside the cover body, and a plug-in sealing block provided inside the cover body and connected together with the elastic positioning block; the wire end of the embedded monitoring instrument passes through the wire jack, and the free-length wire is encapsulated in the sealing cavity. The wire sealing device and layout method for the concrete shield / TBM segment embedding monitoring instrument provided by the invention can bring together the wires of the monitoring instruments embedded in theTBM segments to facilitate positioning and searching, and can also ensure that the sensors installed on the segments respond to the stress and strain of the segments to the maximum to improve the connection rate of the monitoring instruments and the accuracy of the monitoring results.

Owner:STATE KEY LAB OF SHIELD & TUNNELING TECH +1

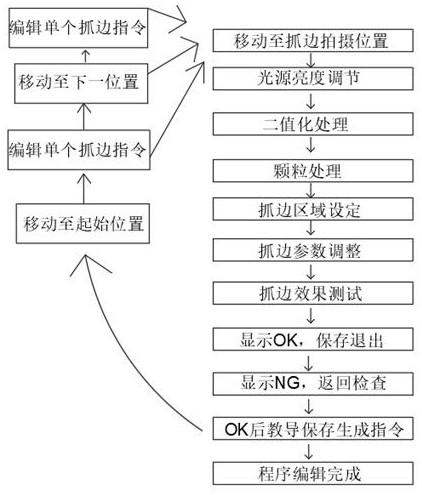

Processing system for edge grabbing and dispensing functions

InactiveCN112705421AAvoid deformation effectsImprove yieldLiquid surface applicatorsCoatingsLight sourceComputer graphics (images)

The invention discloses a processing system for edge grabbing and dispensing functions. The process comprises the following steps of A1, moving to an edge grabbing shooting position; A2, adjusting the brightness of a light source; A3, carrying out binarization processing; A4, conducting particle treatment; A5, setting an edge grabbing area; A6, adjusting edge grabbing parameters; A7, testing the edge grabbing effect, displaying OK, saving the parameters, quitting a program, displaying NG and returning to check the parameters; A8, moving to an initial position, editing a single edge grabbing instruction, moving to a next position, editing a single edge grabbing instruction, and repeating the actions to an end position; A9, after OK is displayed, the instructions are taught and saved; and A10, accomplishing program editing. The dispensing precision is high, the edge grabbing operation is correct and complete, the reject ratio is low, the cost is low, and the good market application value is achieved.

Owner:SHENZHEN AXXON AUTOMATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com