Optical Sensor For Extreme Environments

a technology of optical sensors and hazardous environments, applied in the field of optical sensors, can solve the problems of limited life-time, huge engineering challenge in realizing a sensor for such hazardous environments, and the production of chemically hazardous environments in coal and gas fired power systems, and achieves low cost, low loss, and high sensing resolution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

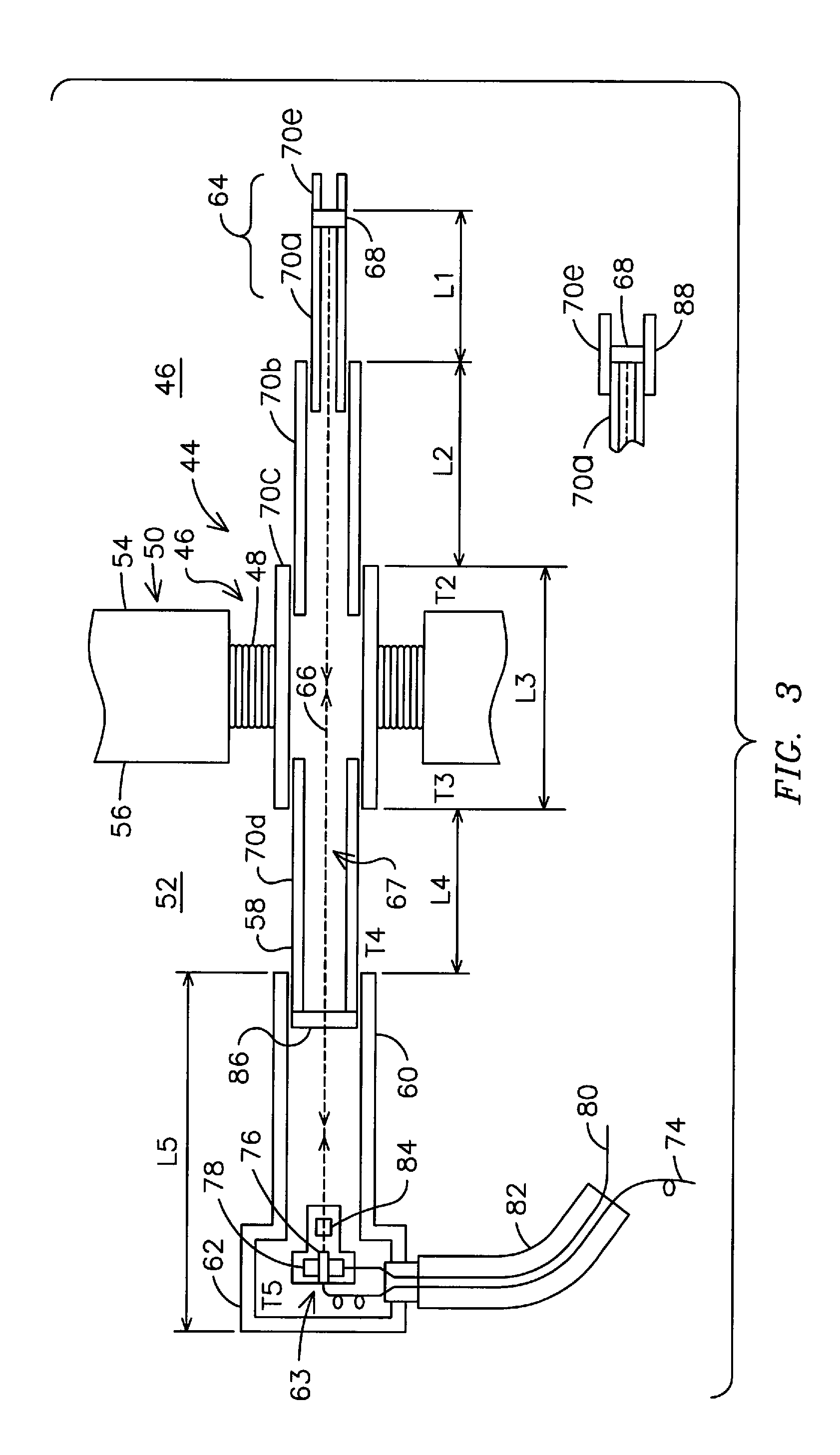

[0032]Knowing the exact thickness of optical components is a critical need when designing high quality large, miniature, and super small optics for numerous platforms such as integrated-waveguide optics, bulk-optics, and fiber-optics. Over the years, many methods have been described to measure thickness from the thin-film level (i.e., smaller than the optical wavelength) to thick plates (i.e., hundreds of wavelengths). Perhaps the most tried method is based on the classic Michelson optical interferometry using a broadband optical source such as white light [see P. A. Flourney, R. W. McClure, G. Wyntjes, “White light interferometric thickness gauge,” Appl. Opt., 11, 1907 (1972); L. M. Smith and C. C. Dobson, “Absolute displacement measurements using modulation of the spectrum of white light in a Michelson interferometer,” Appl. Opt., 28, 3339 (1989)]. Here, the short coherence length of the broadband source is used to produce interferometer arms path-length difference-based output de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com