Printing machine

A technology for printing presses and printing rollers, applied in printing presses, rotary printing presses, printing, etc., can solve the problems of inability to shorten the length of the film, waste, and long materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

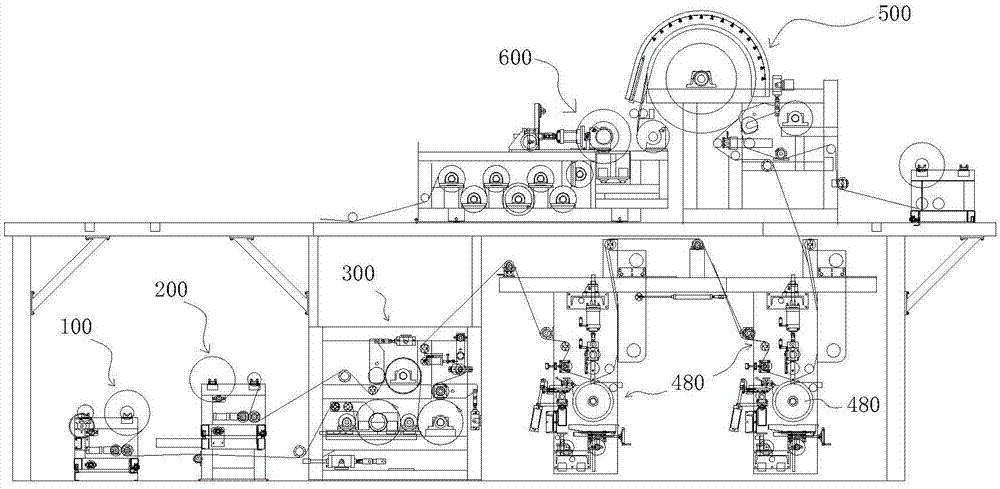

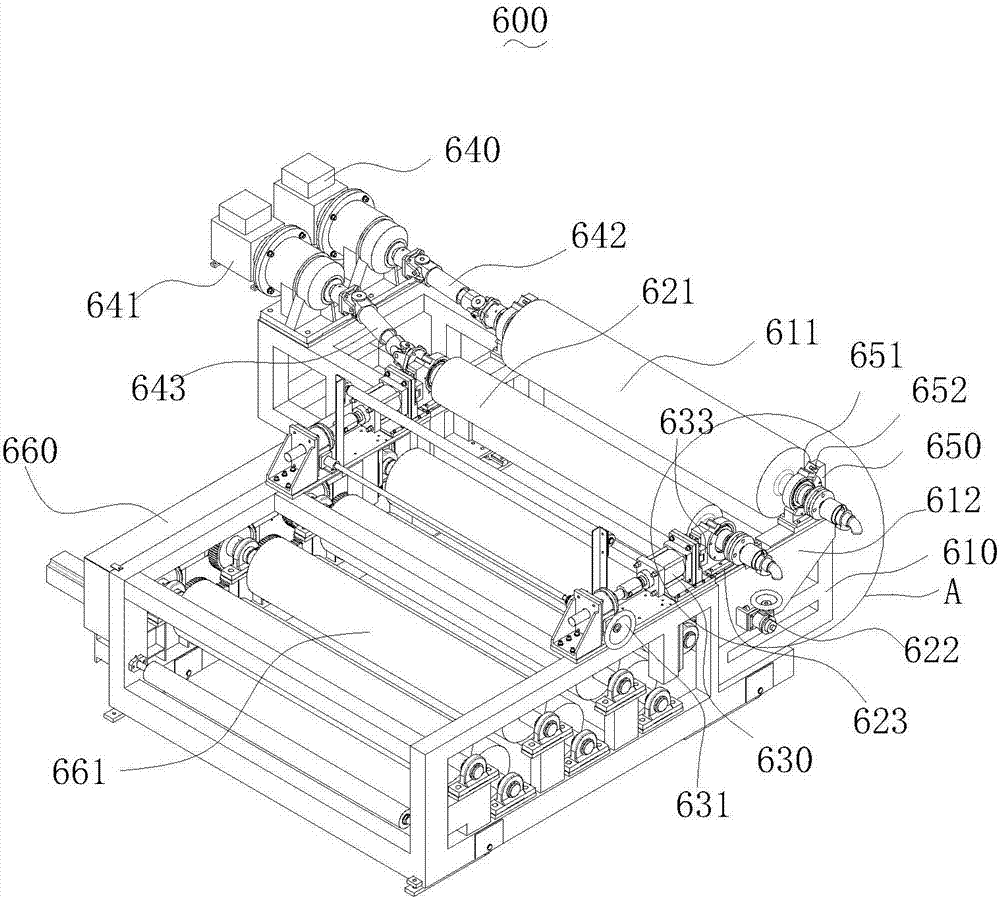

[0037] Such as Figure 1-5 As shown, a printing machine in this embodiment includes a printing assembly 400 and an embossing assembly 600. The printing assembly 400 includes several printing rollers 480, and the film enters the embossing assembly 600 after printing on the printing rollers 480. The embossing assembly 600 is arranged above the printing assembly 400, and the length of the film between the last printing cylinder 480 and the embossing assembly 600 is less than or equal to twice the length of the film between two adjacent printing cylinders 480; The embossing assembly 600 described above includes a first support 610, a rubber roller 611 arranged on the first support 610, a second support 620, and an embossing roller 621 arranged on the second support 620. The surface of the embossing roller 621 is It is provided with the same uneven texture as the film pattern, the rubber roller 611 and the embossing roller 621 are respectively connected to the first motor 640 and t...

Embodiment 2

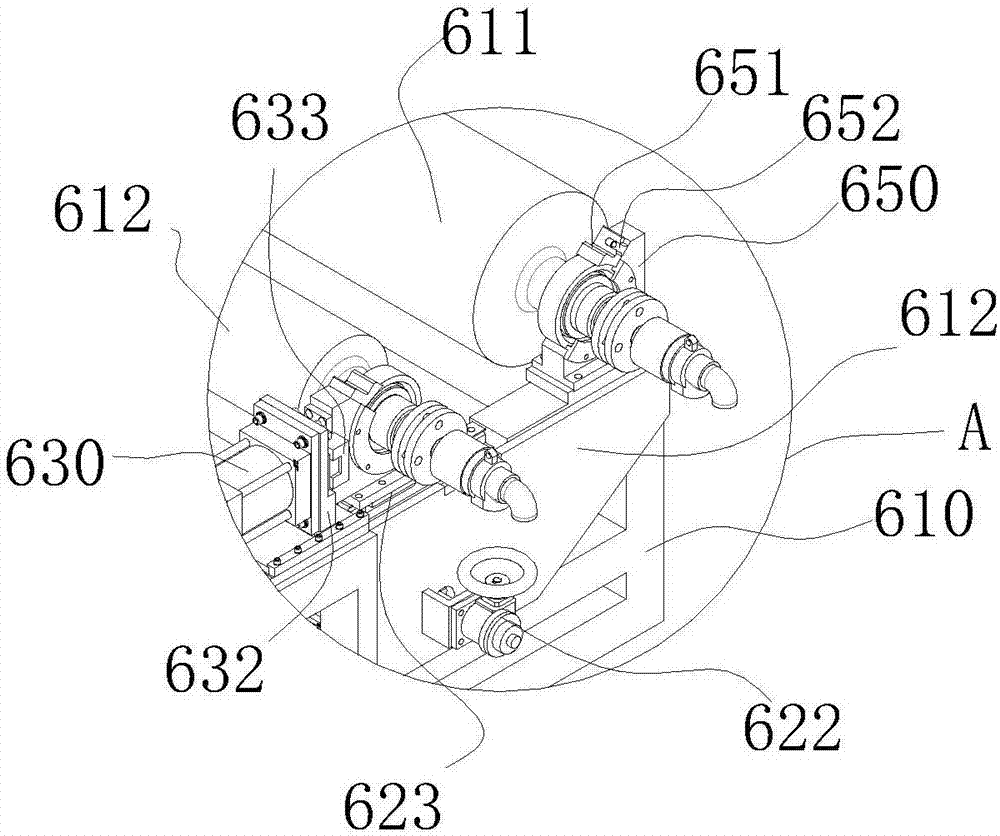

[0039] Such as Figure 1-5 As shown, the rubber roller 611 is connected to the first motor 640 through the first universal coupling 642, and the embossing roller 621 is connected to the second motor 641 through the second universal coupling 643. The rubber roller 611 is fixed on the first bracket 610 through the fixed seat 650, the embossing roller 621 is arranged on the second bracket 620, and the first bracket 610 is provided with a left and right moving slide rail 613, and the described The second bracket 620 is connected to the first bracket 610 through the left and right moving slide rails 613 , and the first bracket 610 can slide on the left and right moving slide rails 613 to adjust the left and right relative positions of the embossing roller 621 and the rubber roller 611 . The first bracket 610 is provided with a support plate 612, the support plate 612 is provided with a left and right position regulator 622, and the left and right position regulator 622 is connected...

Embodiment 3

[0041] Such as figure 1 , 6 , 7, 8, 9, and 10, the printing assembly includes a fixed frame 410, a printing cylinder 480 arranged on the fixed frame 410, a scraper 472 is also arranged on the fixed frame 410, and the scraper 472 is arranged on On the movable plate 470 , the scraper 472 contacts or separates from the printing cylinder 480 under the action of the movable plate 470 . The fixed frame 410 is also provided with an adjustment plate 411, a support member 420 and a longitudinal movement plate 440, the movable plate 470 is arranged on the longitudinal movement plate 440, the support member 420 is provided with a longitudinal movement slide rail 421, and the adjustment plate 411 An adjuster 430 is provided, and the adjuster 430 is connected with the longitudinally moving plate 440 and controls the longitudinally moving plate 440 to move longitudinally on the longitudinally moving slide rail 421, and a support frame 450 is also provided, and the movable plate 470 is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com