Laser bar and cavity integrating method and structure

A technology of lasers and laser crystals, which is applied to lasers, laser components, phonon exciters, etc., can solve the problems of wide application limitations of lasers, poor ability to resist mechanical structure deformation and mechanical vibration, and affect the working characteristics of lasers. Strong resistance to thermal change of mechanical structure, strong resistance to air disturbance, and small temperature rise at both ends

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

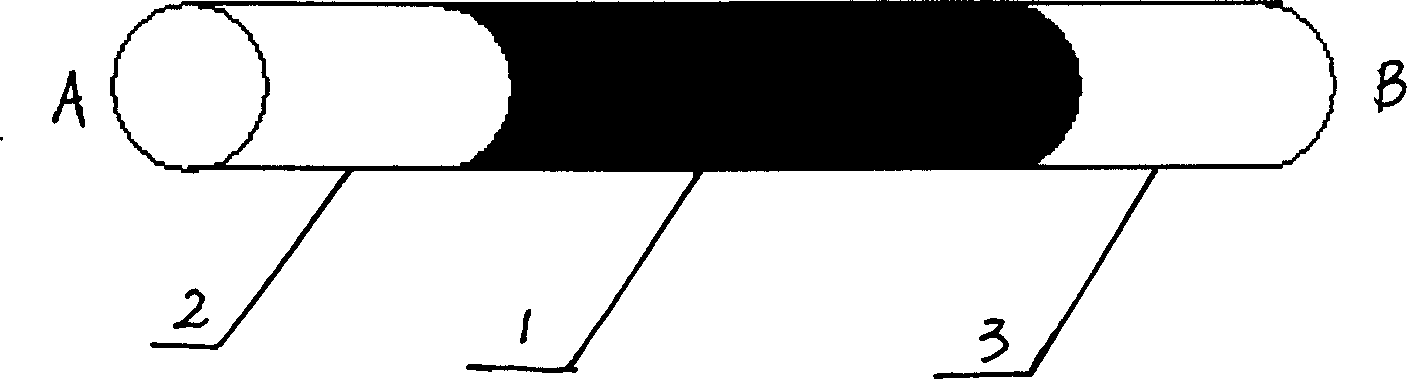

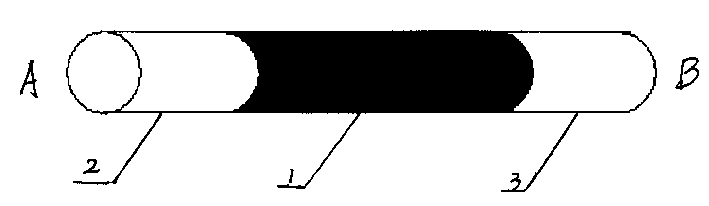

[0026] See Figure 1. The present invention includes a laser rod 1 doped with laser-activated ions, the crystal of which is Nd:YAG or Yb:YAG, and the two ends of the laser rod 1 are respectively bonded at high temperature with the same matrix crystal YAG rods 2 and 3 that are not doped with laser-activated ions. , forming two end caps that are optically machined and then coated. The end face of the A end cap is coated with a total reflection film for emitting laser light L to the laser itself, and an anti-reflection film for the pump light P is coated on the end face of the B end cap. Rear endoscopy and anterior endoscopy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com