Method for producing a glass ceramic element with patterned coating

A glass-ceramic, structured technology applied in the direction of manufacturing tools, reproduction/marking methods, chemical instruments and methods, etc., to achieve the effect of solving visibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

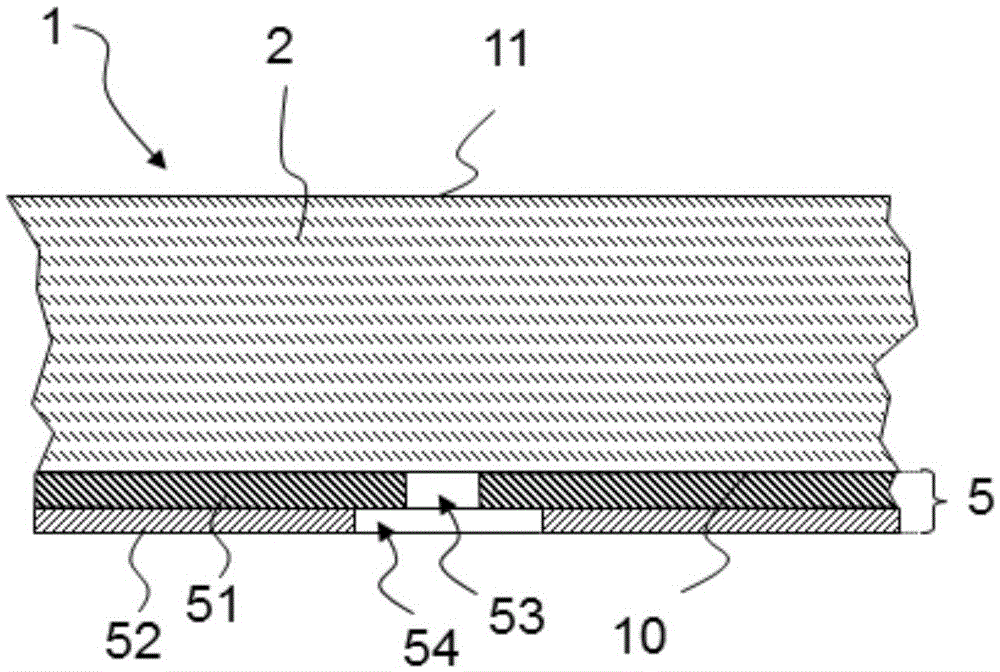

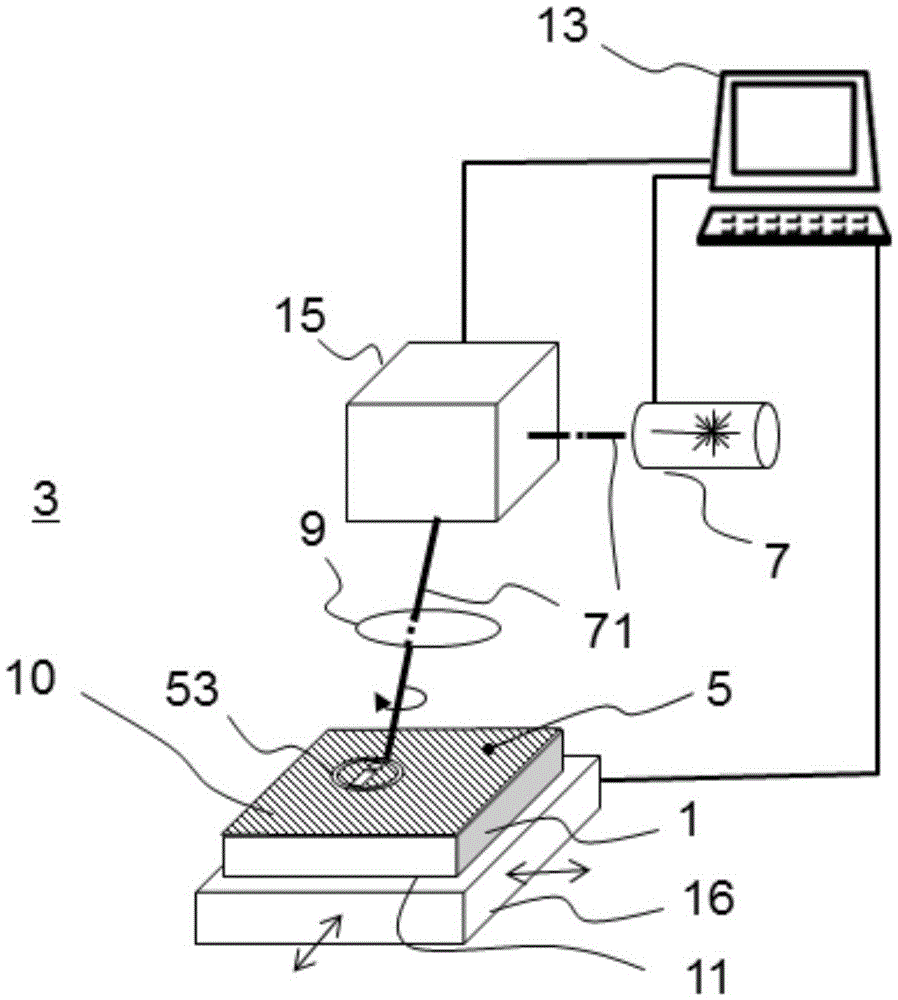

[0024] For a detailed description of the glass-ceramic part 1 provided with a structured coating, see first figure 1 , which includes a coating 5 fabricated in conventional screen printing. The plate-shaped glass ceramic part 1 has two opposite sides 10 , 11 . In the case of a glass-ceramic part in the form of a glass-ceramic cooking plate, one of the sides 10 , 11 forms the use surface.

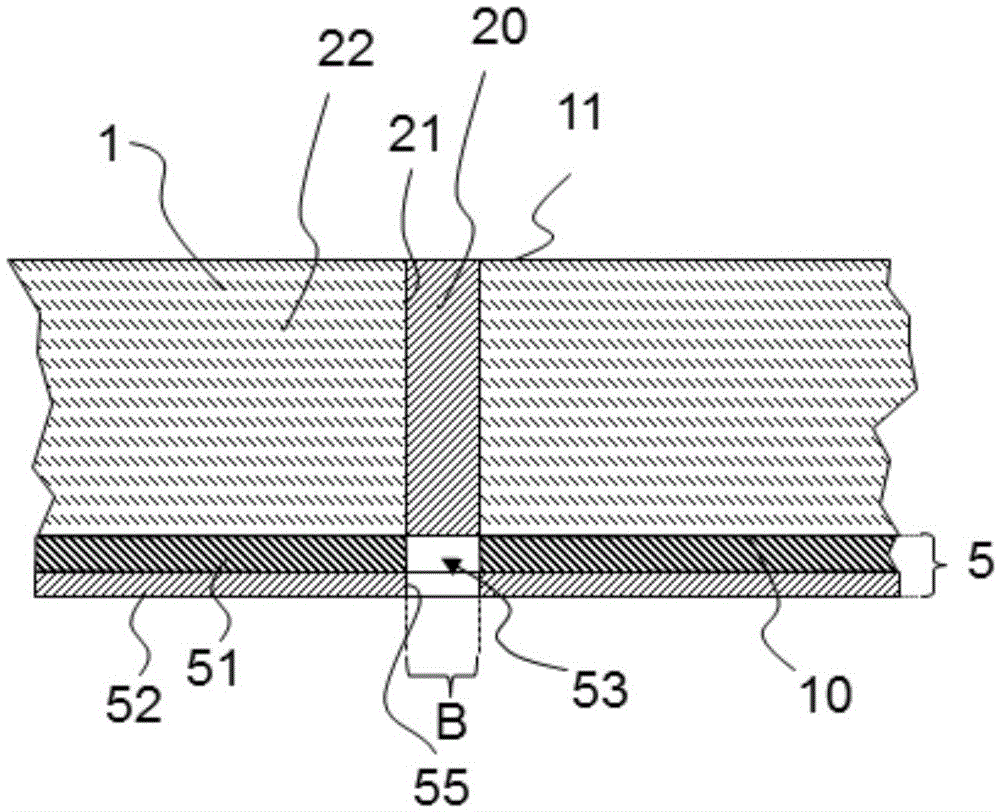

[0025] The coating 5 on at least one side 10 , 11 is multilayered and consists of a first colored layer 51 on the glass ceramic 2 and a second colored layer 52 applied on the first colored layer 51 . Structural components 53 are present in the first color layer 51 . The structural component is formed by a region in which the glass ceramic 2 is exposed and in which there is also no coating. The outline of the structural component can have the shape of a logo, a character or a logo, for example. This structured interruption by the color layer enables light to pass through the glass-ceramic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com