Method for joining conner parts of plastic steel doors and windows

A technology for plastic-steel doors and windows and connection methods, applied in the direction of windows/doors, building components, buildings, etc., can solve the problems of complicated and time-consuming reinforcement methods, easy to damage the inner cavity of profiles, and easy deformation of plastic door and window frames or fan angle couples. And the effect of improving the resistance to deformation, solving easy deformation, and overcoming poor deformation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

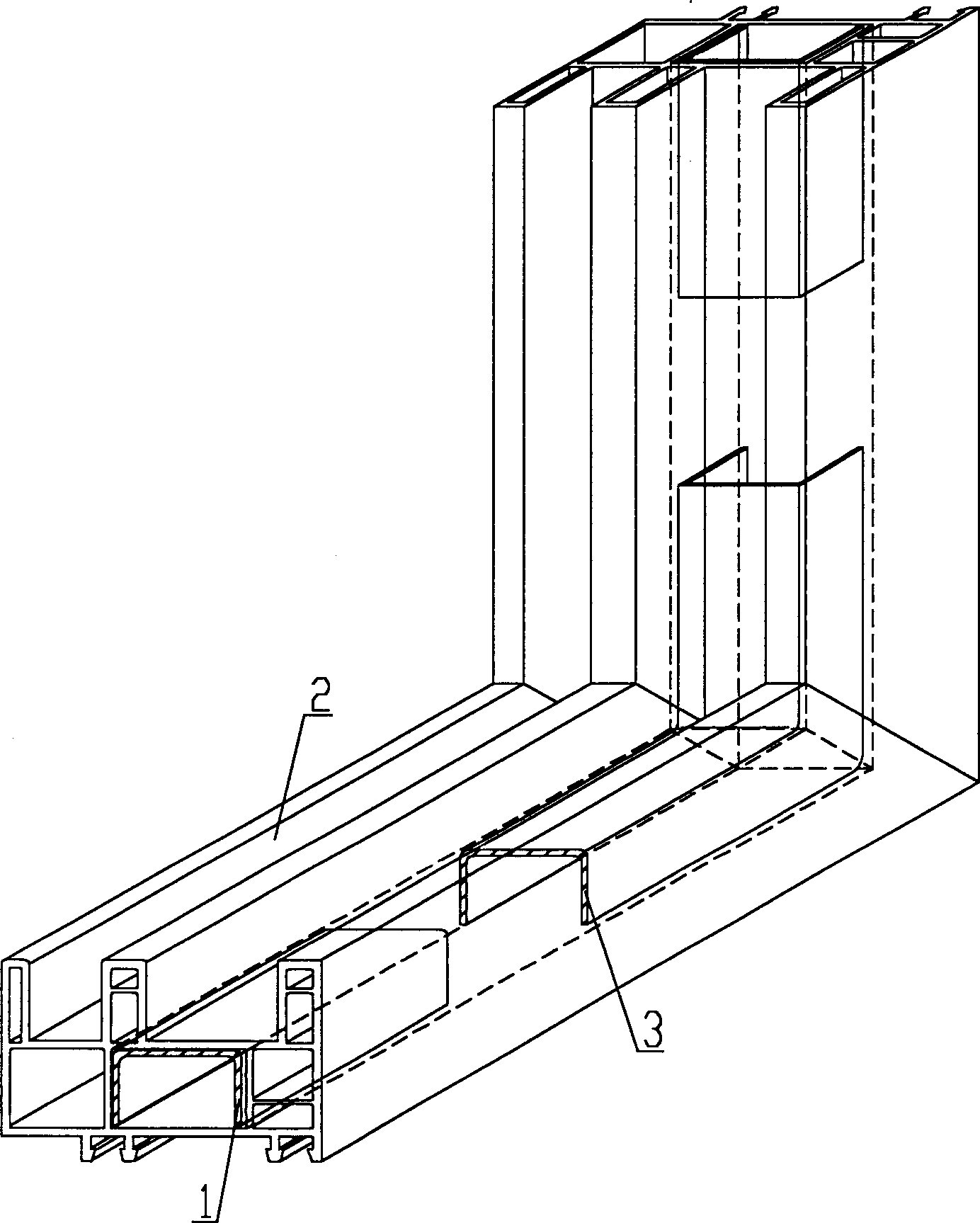

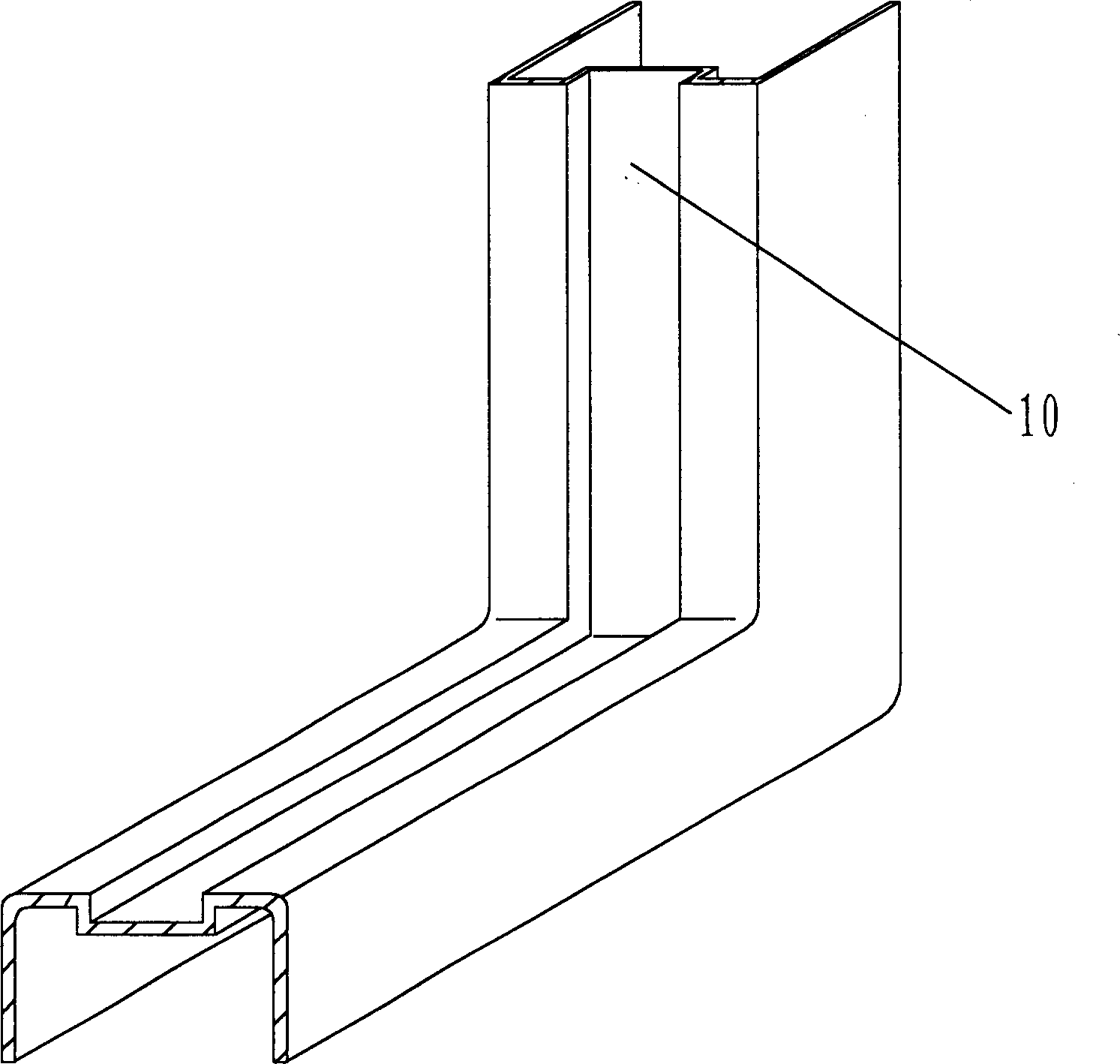

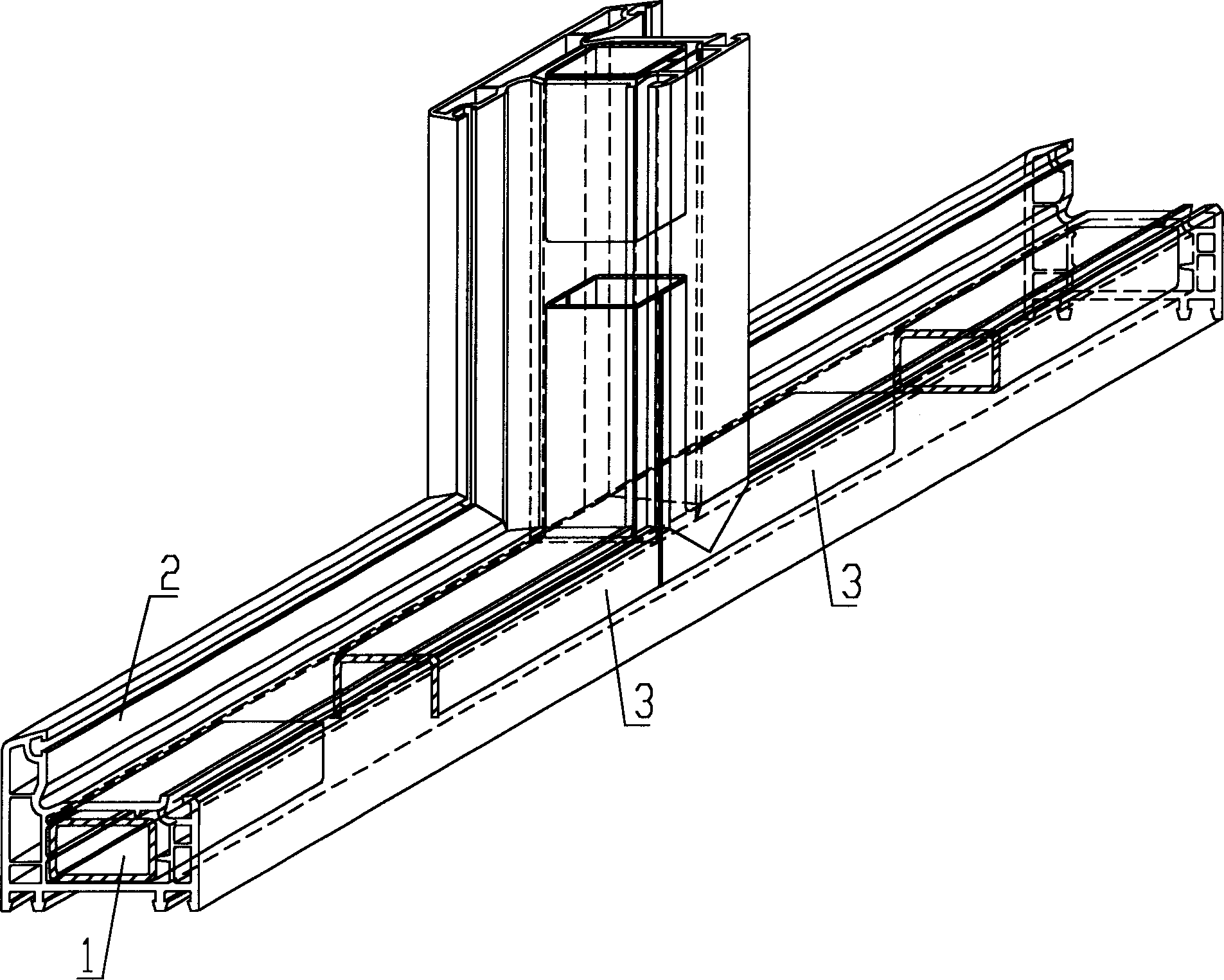

[0011] Such as figure 1 , figure 2 and image 3 As shown, the connection method of the plastic-steel door and window corner coupler part of the present invention is: firstly, a reinforcing member 3 matching the inner cavity of the plastic profile is made; After steel liner 1 is inserted into the cavity of plastic profile 2, the distance from one end to the coupling end of plastic profile 2 is greater than the length of the right-angled side of reinforcement 3 by 1-5 mm, so as to overcome steel liner 1, reinforcement 3 and plastic profile 2 Deformation effects due to different shrinkage and expansion rates. Then, insert the pre-prepared L-shaped reinforcement 3 into the cavities of two adjacent plastic profiles 2. Fill with adhesive, push two adjacent plastic profiles to couple. The adhesive will gradually solidify with the passage of time, so that the reinforcement 3 and the plastic profile 2 are closely combined to form a tightly connected coupling of two adjacent plasti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com