Oxygen respirator with novel ventilation structure

A ventilation structure and respirator technology, applied in the direction of respiratory protection devices, fire rescue, life-saving equipment, etc., can solve the problems of being easily affected by environmental factors such as temperature and collision, and insufficient work stability, so as to avoid the influence of deformation and equipment Stabilizing, reducing impact effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

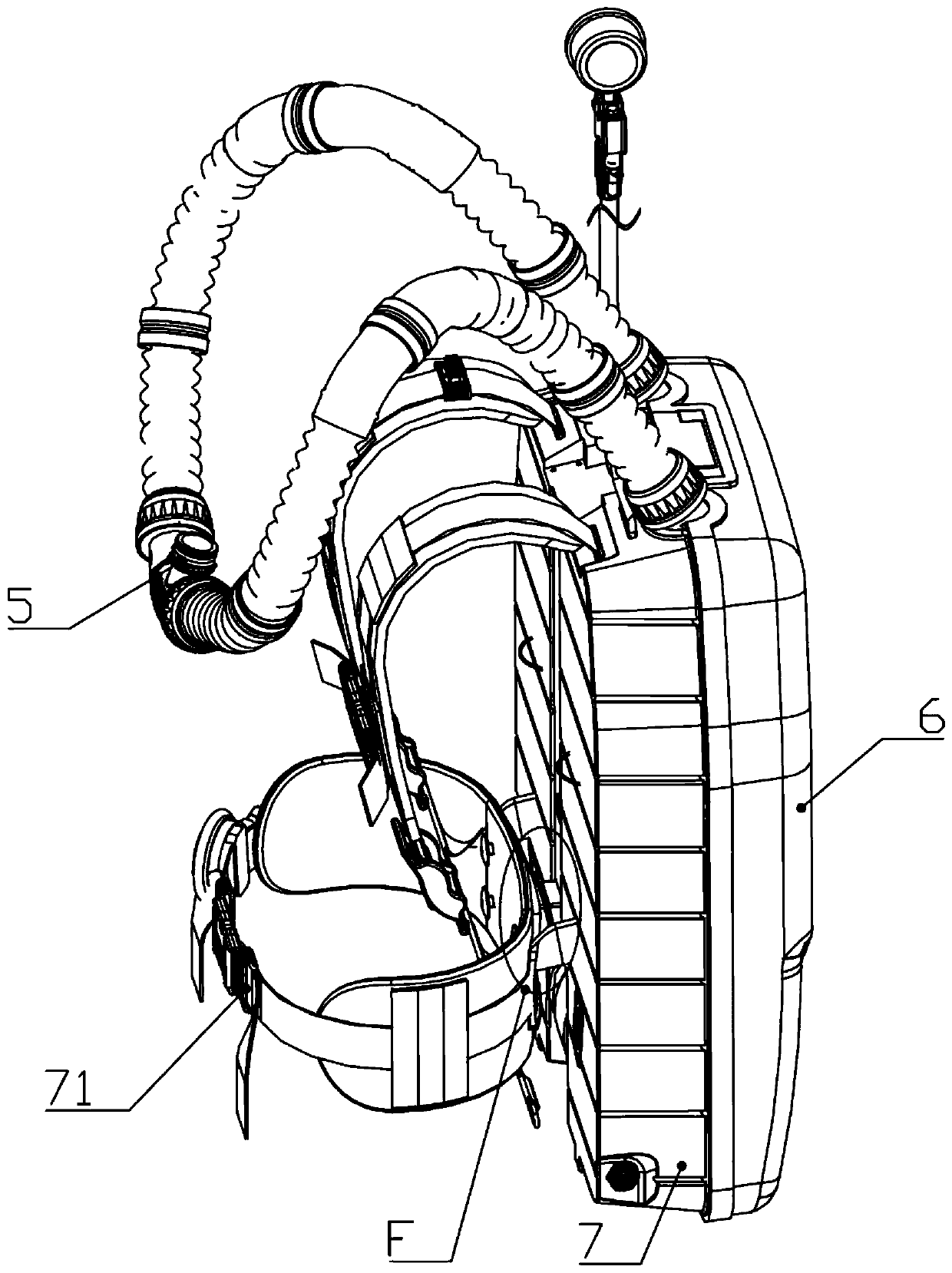

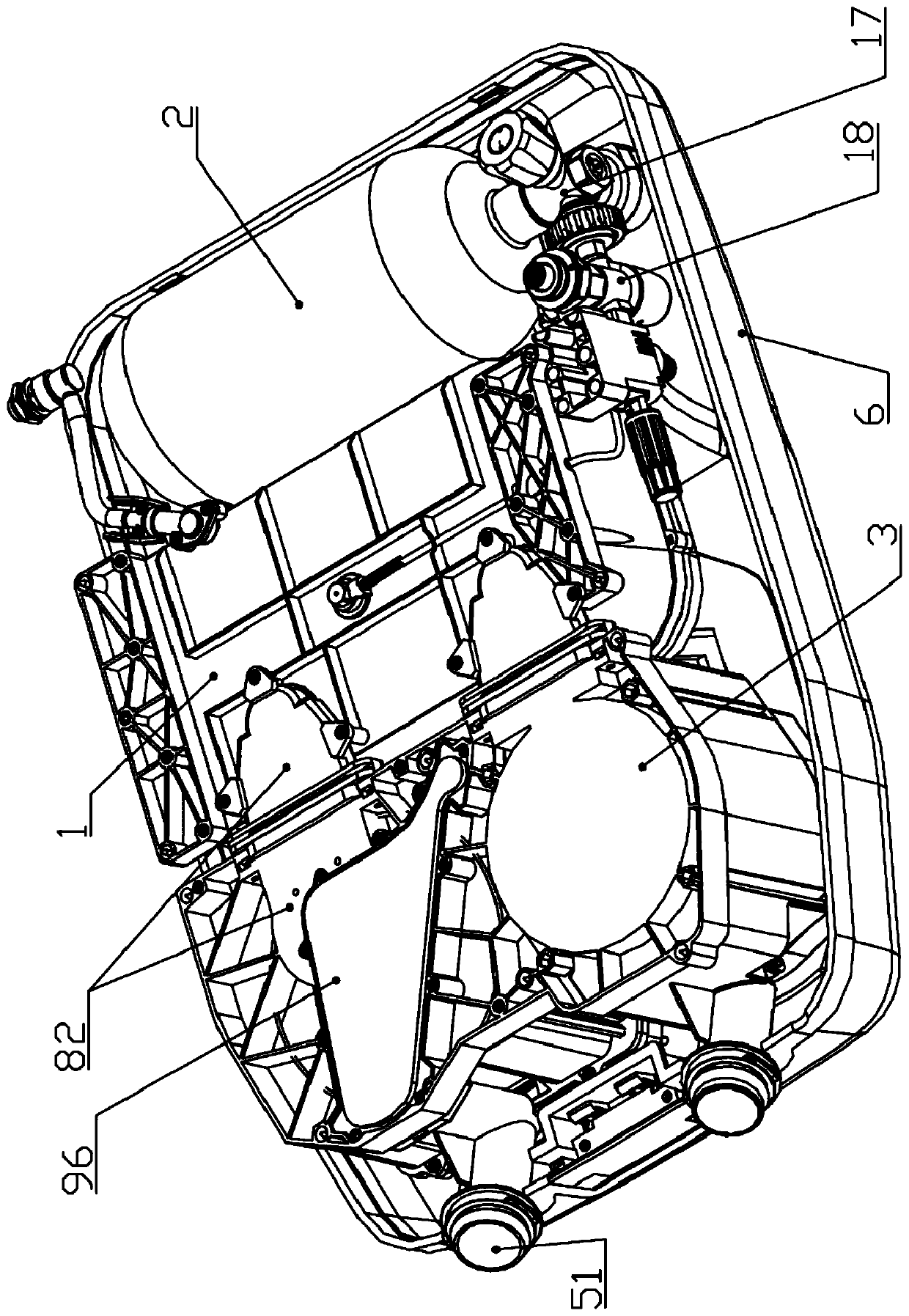

[0044] Embodiment one: if Figure 1-15 As shown, an oxygen respirator includes a respirator main body; The technical solution specifically discloses a structural form of an oxygen respirator.

[0045] 2 Preferably, a clean tank storage area is formed in the main body of the respirator, and the clean tank 4 is detachably arranged in the clean tank storage area; the main body of the respirator also includes a breathing valve assembly 5, and the breathing valve assembly 5 and The cooling tank 3 and / or the cleaning tank 4 are set independently.

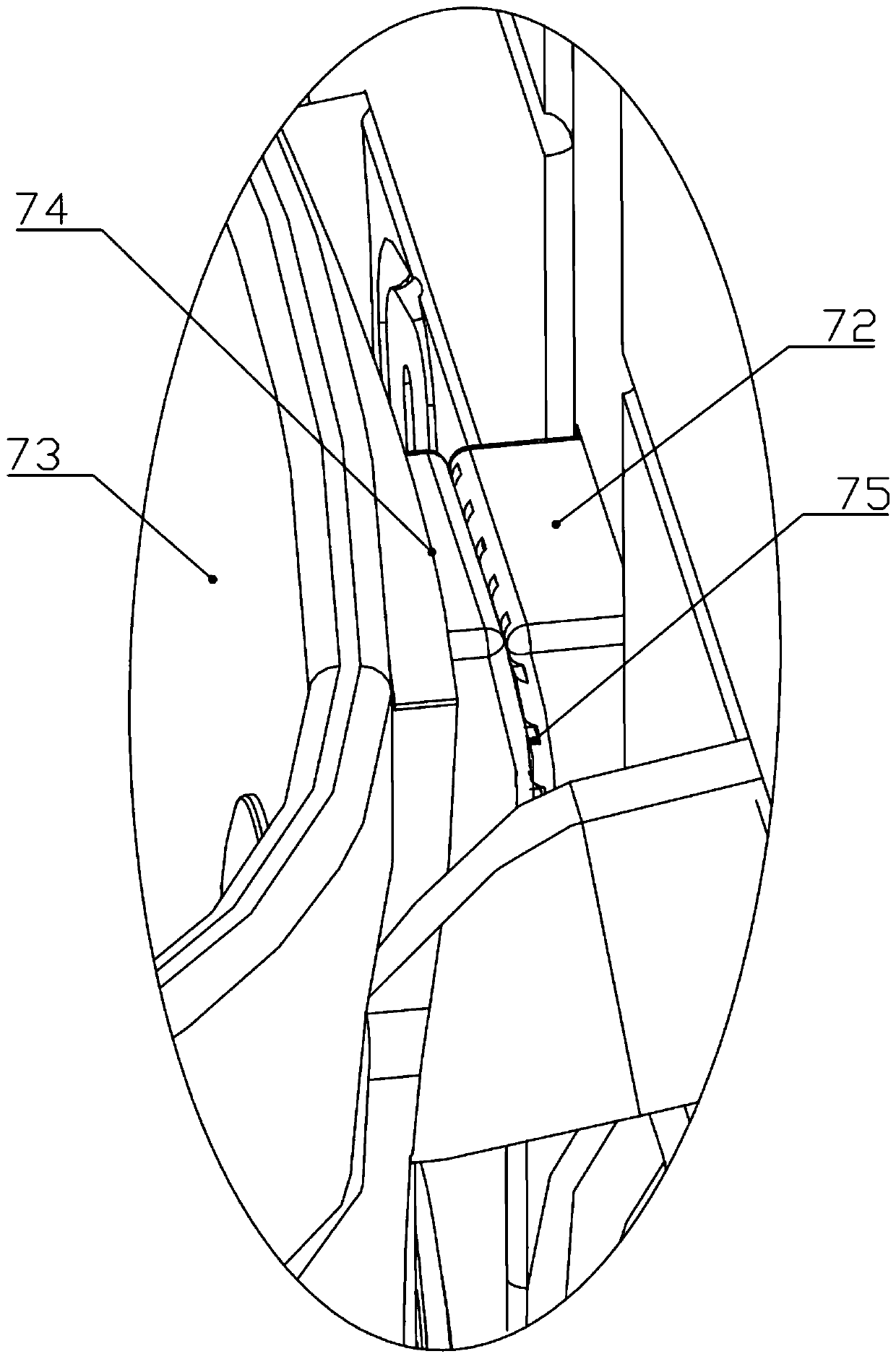

[0046]The technical solution specifically discloses an installation method of the cleaning tank 4 . By independently designing the clean tank 4 in the clean tank storage area, such a design can be quickly disassembled when the clean tank 4 needs to be actually replaced. The main body of the respirator described in this technical solution includes a three-way respirator connected with an air inlet joint 51, and the air inlet joint 51 ne...

Embodiment 2

[0077] Embodiment 2: This technical solution is basically the same as Embodiment 1, the difference is that the connection modes of the air inlet joint 51, the gas flow channel and the clean tank 4 are different. Previously, the gas flow channel was placed on the lower side of the clean tank 4, and the connection with the gas flow channel was realized by opening a hole at the lower end of the clean tank 4. In the present embodiment, the gas flow path can be connected and sealed with the clean tank 4 and can be realized by connecting the middle nut, that is, there is a threaded section at one end of the gas flow path, and the clean tank 4 also has a threaded section, and the two threads are connected by the nut. Changes in position between segments implement connections. Of course, there are many ways to realize the connection between the gas flow channel and the clean tank 4, and only two of them are specifically described here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com