Processing system for edge grabbing and dispensing functions

A processing system and function technology, which is applied to devices and coatings that apply liquid to the surface, can solve the problems that the compensation accuracy cannot meet the requirements of the dispensing process, the dispensing is inaccurate, and the shape is strange, and achieves good market application. Value, avoid shell deformation, improve yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

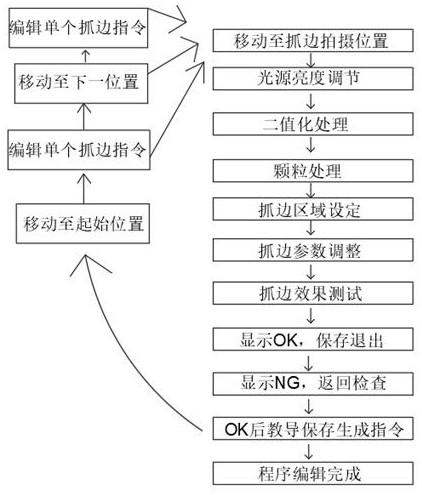

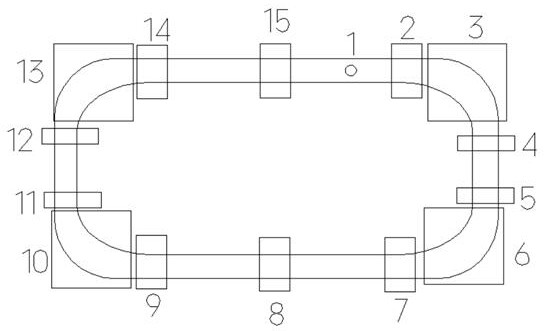

[0038] like Figure 1-Figure 2 One embodiment described above: a processing system for edge-grabbing and dispensing functions, comprising the following steps:

[0039] Step A1: Move to the edge-grabbing shooting position;

[0040] Step A2: Light source brightness adjustment;

[0041] Step A3: binarization processing;

[0042] Step A4: particle treatment;

[0043] Step A5: Setting the edge grabbing area;

[0044] Step A6: Adjustment of edge grabbing parameters;

[0045] Step A7: Test the edge grabbing effect, display OK, save and exit, display NG, return to check;

[0046] Step A8: Move to the starting position, edit a single edge grab command, move to the next position, edit a single edge grab command, repeat the above actions to the end position;

[0047] Step A9: After OK, teach the save command;

[0048] Step A10: Program editing is completed.

[0049] Preferably, in step A1, enter the teaching instruction, move the three axes, use the camera to focus on the edge de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com