Wire sealing device and layout method for concrete shield/TBM segment embedding monitoring instrument

A monitoring instrument and wire sealing technology, which is used in measuring devices, instruments, earth-moving drilling and mining, etc., can solve the problems affecting the force of the segment and the shaking of the wires, and achieves the improvement of the connection rate, the close monitoring results, and the convenience of positioning and searching. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

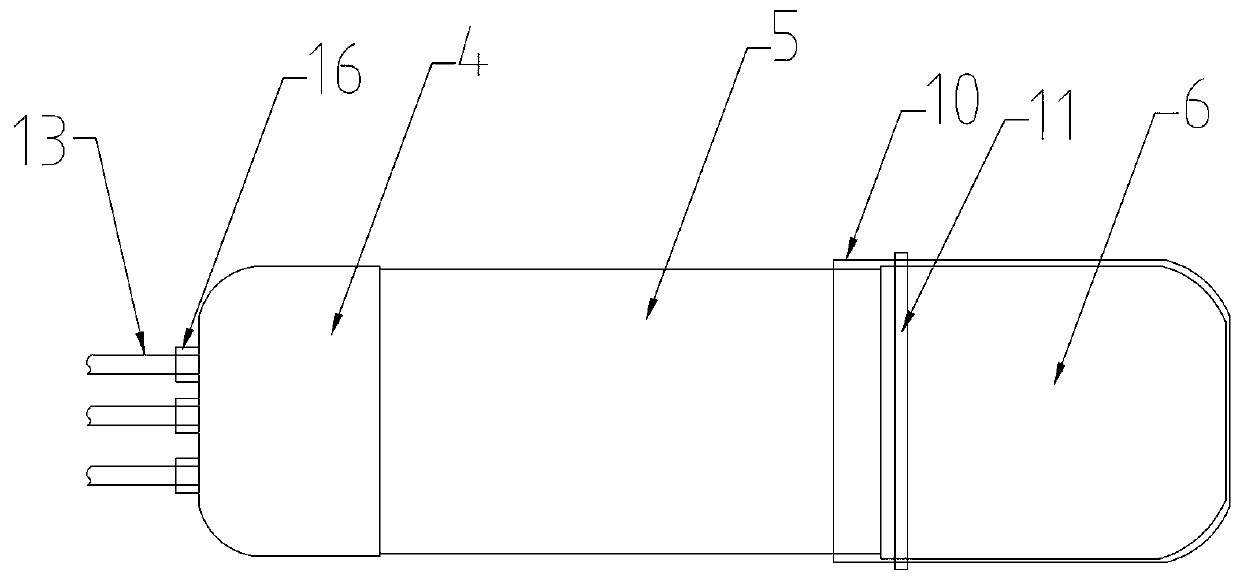

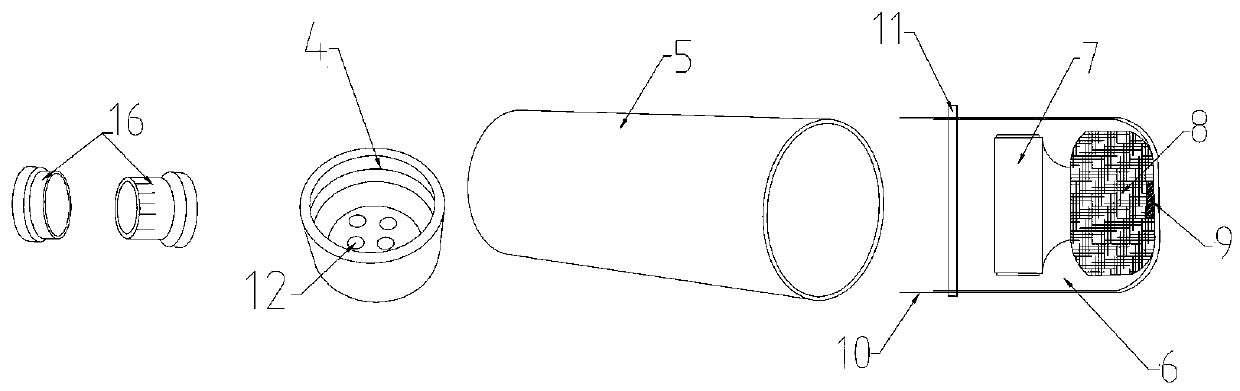

[0038] Example 1: A wire sealing device of a concrete shield / TBM segment embedded monitoring instrument, see figure 1 , figure 2 , Including a sealed cavity 5, the sealed cavity 5 is a hollow inside, open at both ends of the cylindrical structure, at one end of the sealed cavity 5 is installed with a screw-tight seal end 4, on the end surface of the sealed end 4 drilled with a wire insert Hole 12.

[0039] A sealing cover 6 is installed at the other end of the sealing cavity 5. The sealing cover 6 includes a cover body, an elastic positioning block 8 arranged at the bottom end of the cover body, and a plug-in connecting with the elastic positioning block 8 arranged inside the cover body. The plug-in type sealing block 9 is inserted and installed at the open end of the sealed cavity 5.

[0040] The wire end of the embedded monitoring instrument passes through the wire socket 12, the free length of the wire is enclosed in the sealed cavity 5, and the wire and the sealed end 4 are re...

Embodiment 2

[0043] Embodiment 2: A wire sealing device of a concrete shield / TBM segment embedded monitoring instrument. The difference from Embodiment 1 is that a positioning magnet block is provided at the end of the elastic positioning block. It is suitable for the use of a magnet block for more accurate positioning when the tube sheet making template is a steel mold.

Embodiment 3

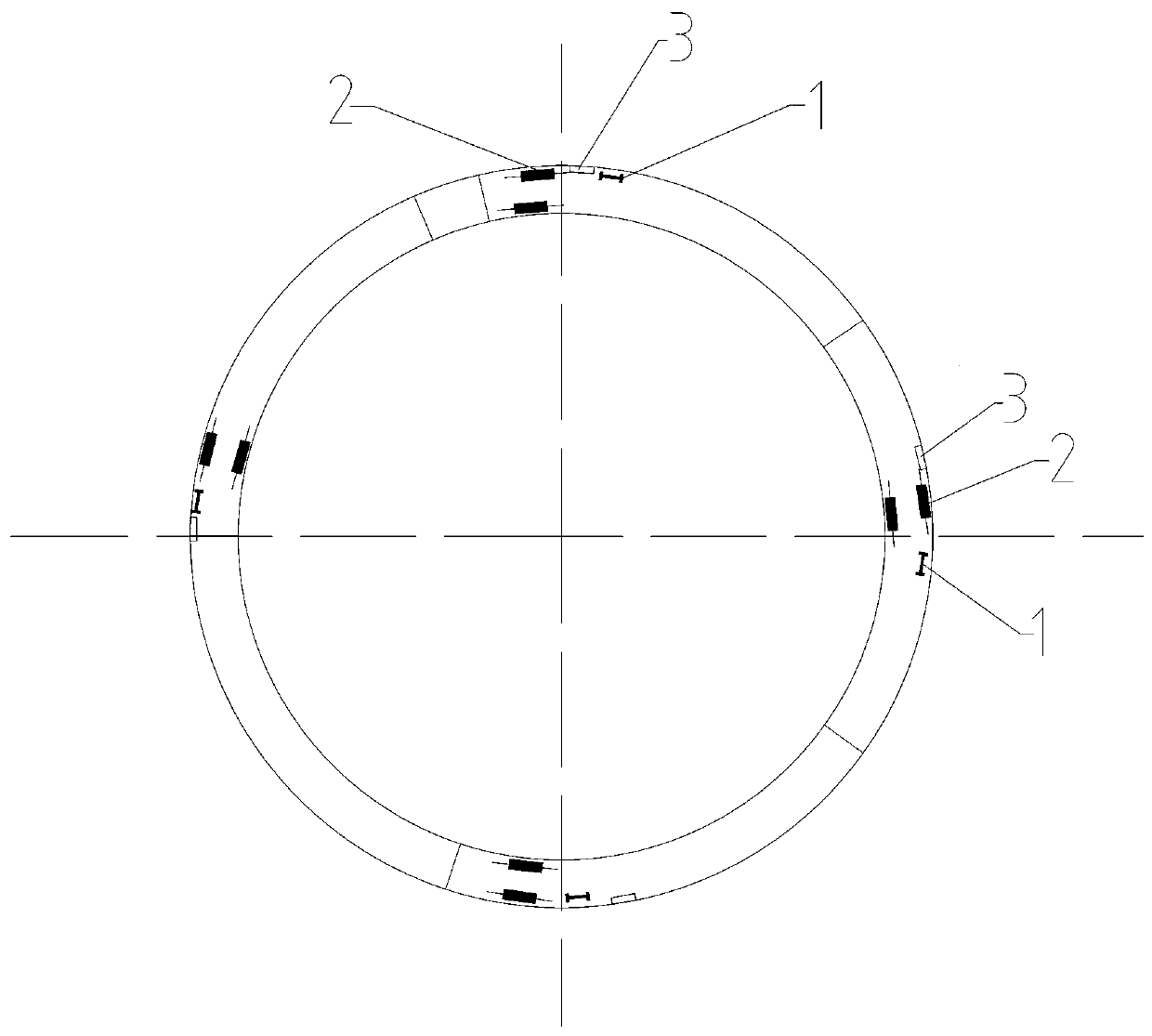

[0044] Example 3: A method for laying out monitoring instruments for embedded concrete shields / TBM segments, see Figure 3-Figure 7 , Including the following steps:

[0045] (1) There are multiple groups of monitoring instruments, which are respectively embedded in the positions to be monitored on the TBM segments. Each group of monitoring instruments includes a steel bar strain gauge 2, a concrete strain gauge 1 and an earth pressure gauge 3; each group of monitoring instruments is equipped with a wire sealing device .

[0046] (2) The steel bar strain gauge 2 is welded in parallel to the area where the stress position of the segment steel bar 15 is the largest; the high-strength steel wire 14 is used for spatial suspension positioning to fix the concrete strain gauge 1 inside the steel frame through wire binding; A steel-reinforced welded skeleton is used to fix the earth pressure gauge 3 on the skeleton of the segment reinforcement 15 and make one side of the earth pressure gau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com