Two-box type impact testing box

An impact test chamber, hatchback technology, applied in measuring devices, instruments, scientific instruments, etc., can solve problems such as frost sticking and frost sticking in the pre-cooling area, which can be easily restored to the test state, reduce the formation of frost, and reduce heat exposure. or the effect of being cooled evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is described in detail below in conjunction with accompanying drawing:

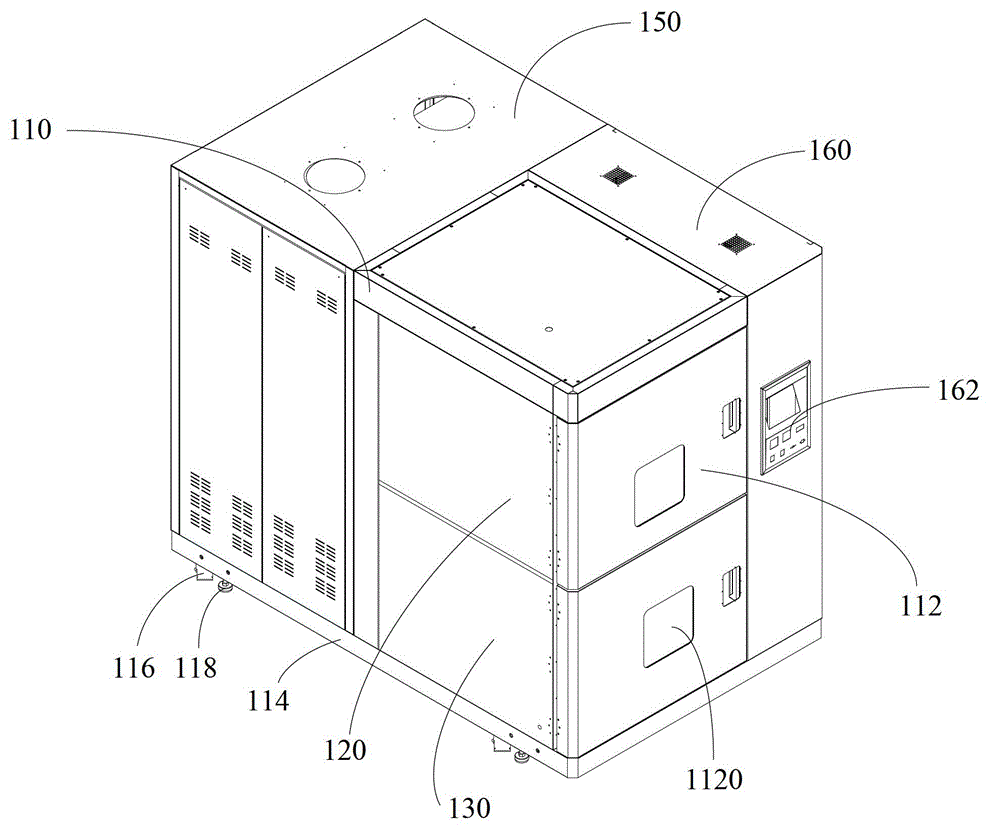

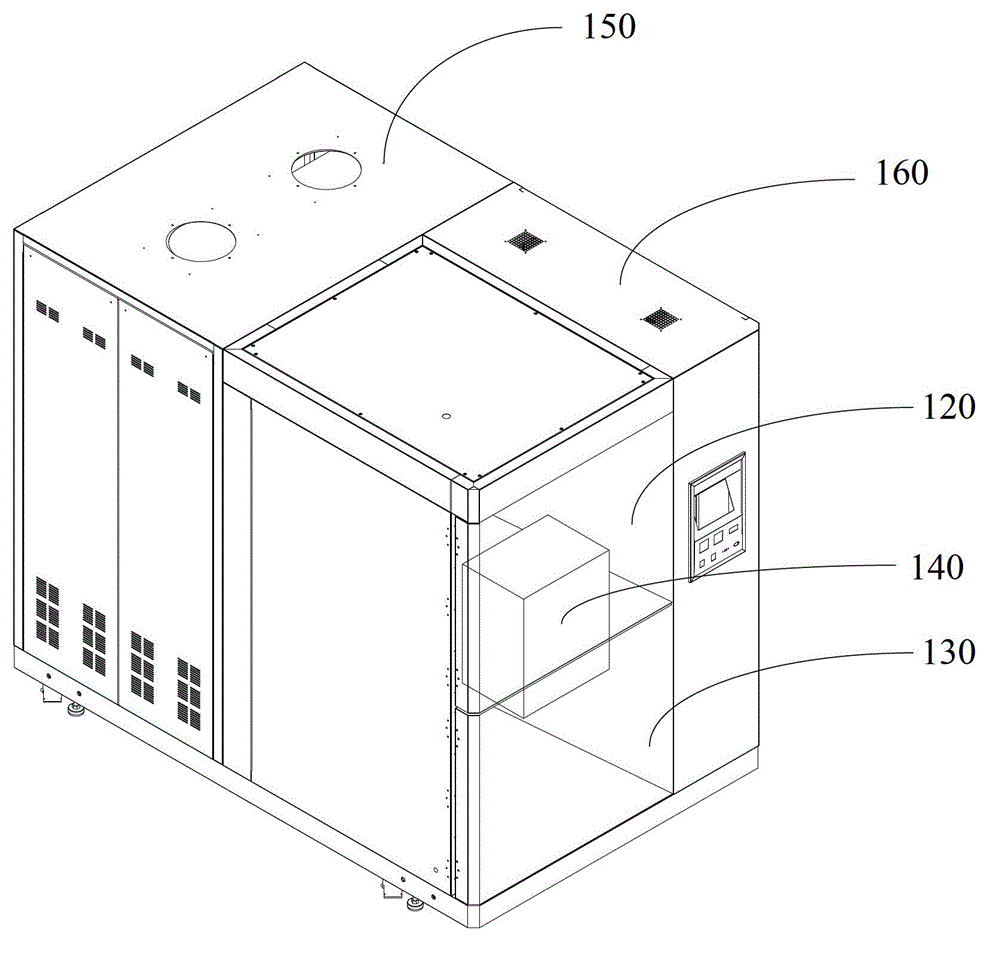

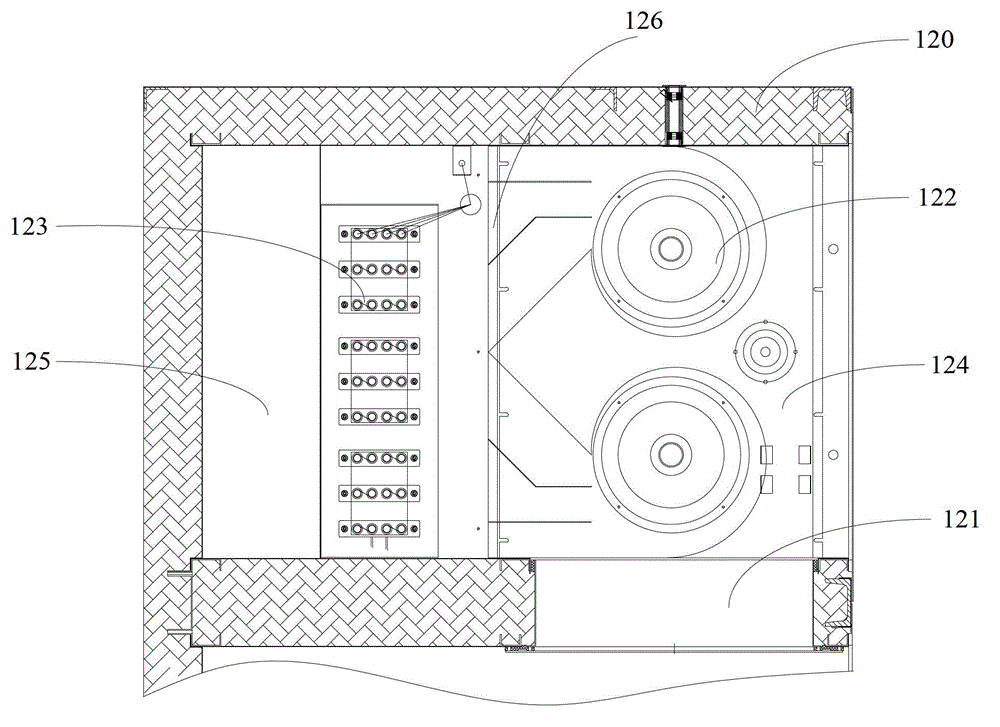

[0035] Such as figure 1 , figure 2 As shown, a two-compartment impact test box includes a box body 110 and a high temperature box 120, a low temperature box 130, a hanging basket 140, a cold cabinet 150 and a control system 160 arranged inside the box body 110; image 3 As shown, the high temperature box 120 is adjacent to the low temperature box 130, and the adjacent box wall is provided with a through hole 121 which is connected, and the hanging basket 140 can move axially in the through hole 121; the high temperature box 120 The side wall of the high temperature box 120 is provided with a first impeller 122, and the rear wall of the high temperature box 120 is provided with a first heating device 123, and the first impeller 122 drives the air circulation in the high temperature box 120; Figure 4 As shown, the side wall of the low temperature box 130 is provided with a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com