Patents

Literature

42results about How to "Increase scrolling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

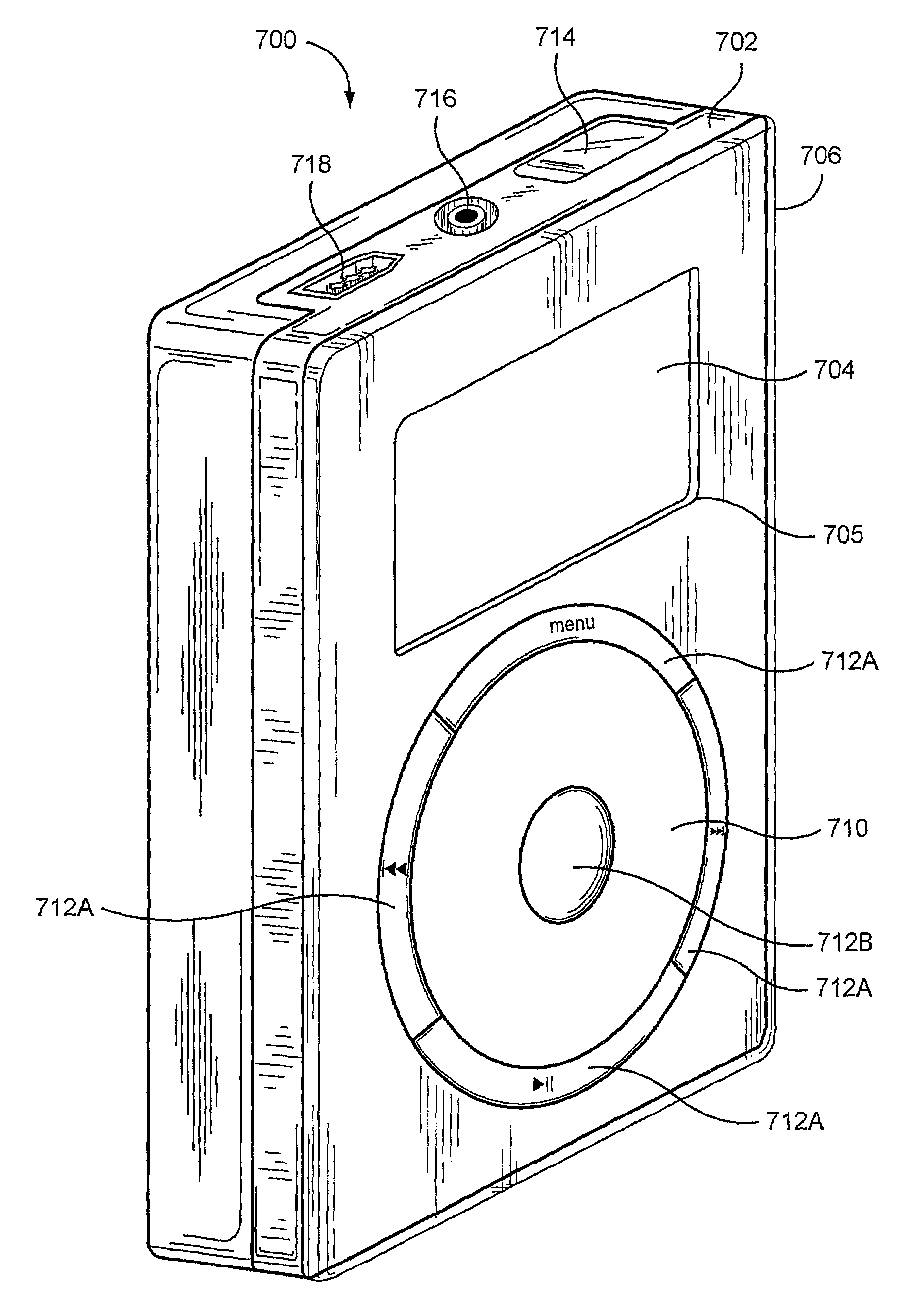

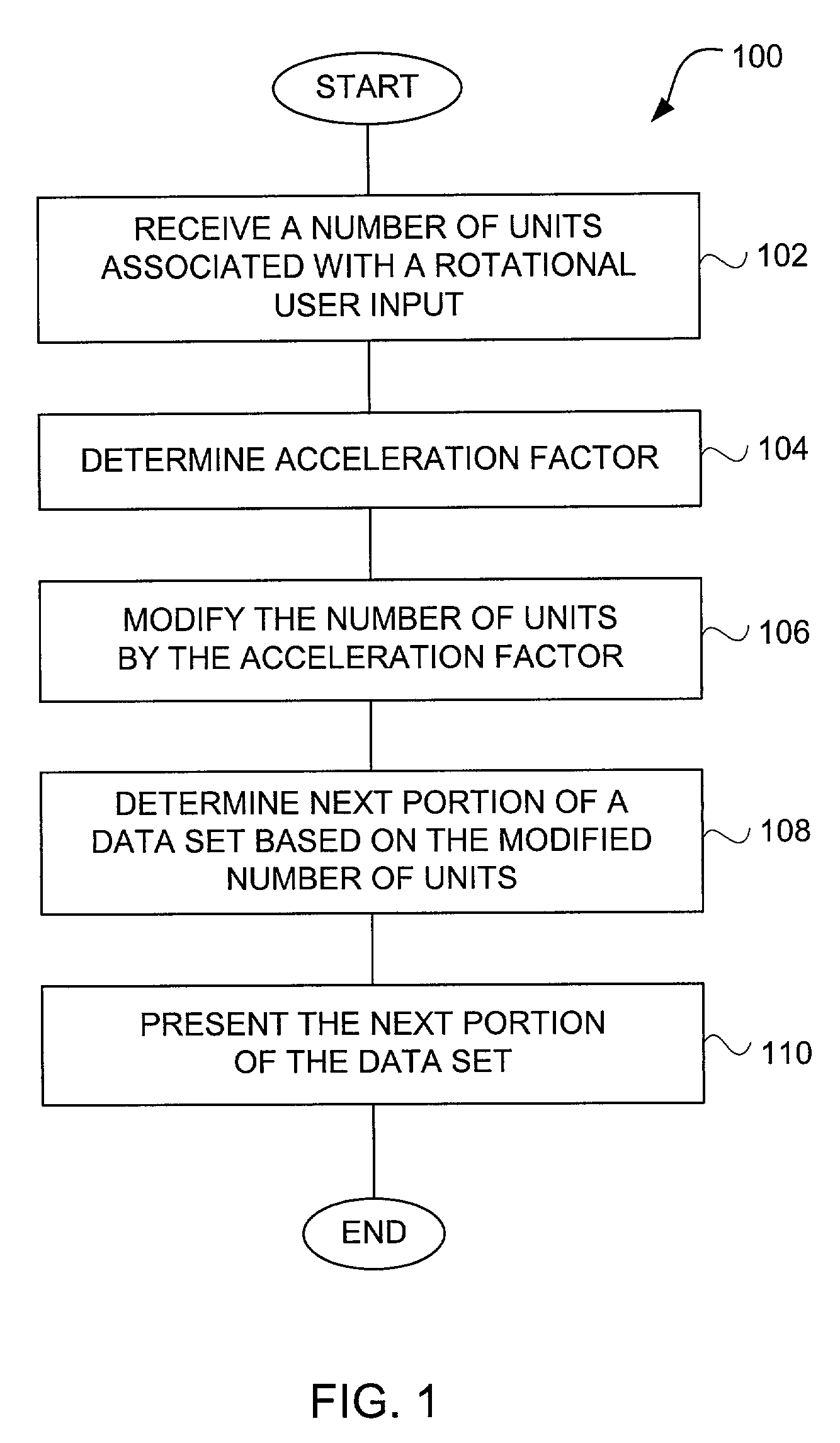

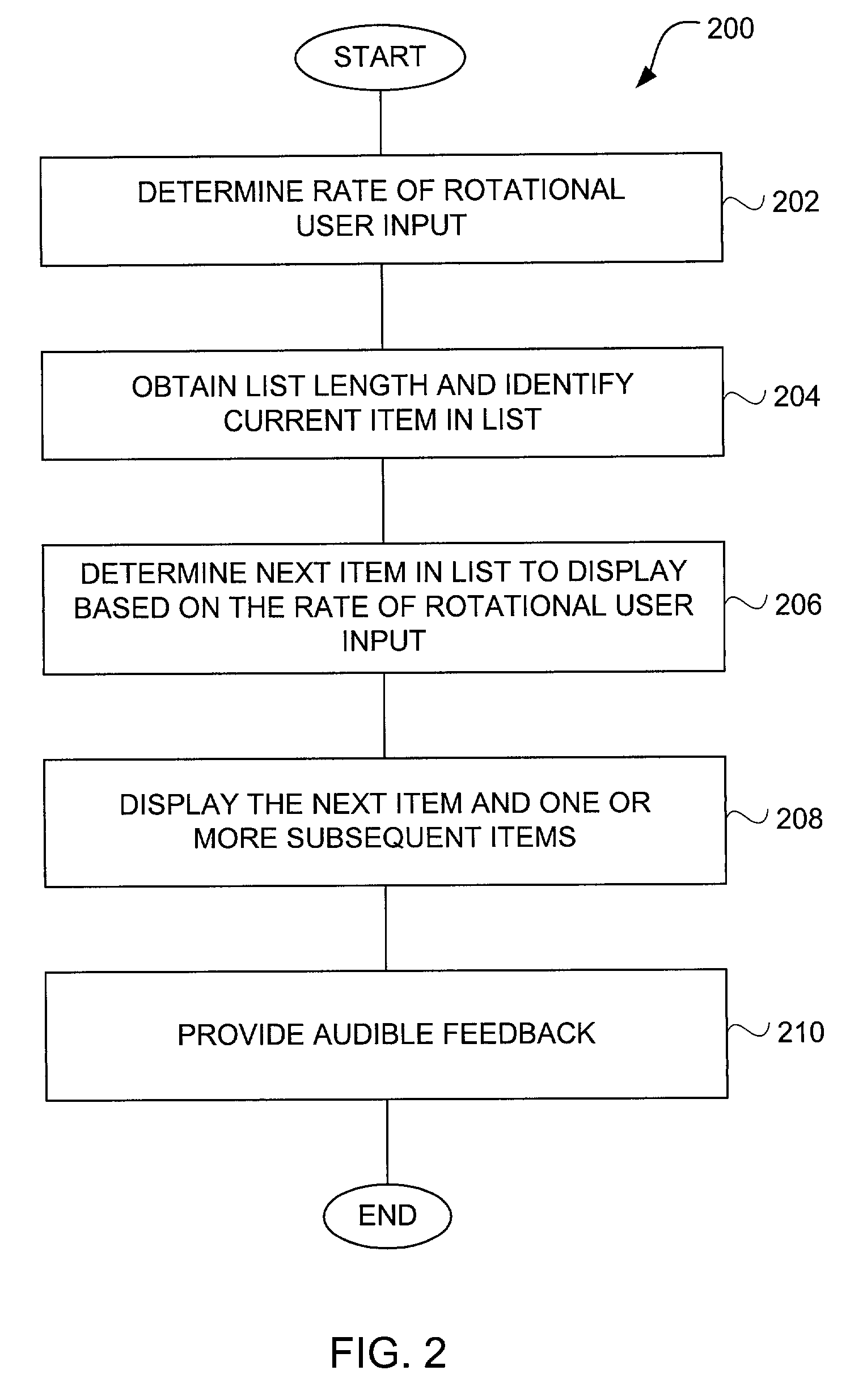

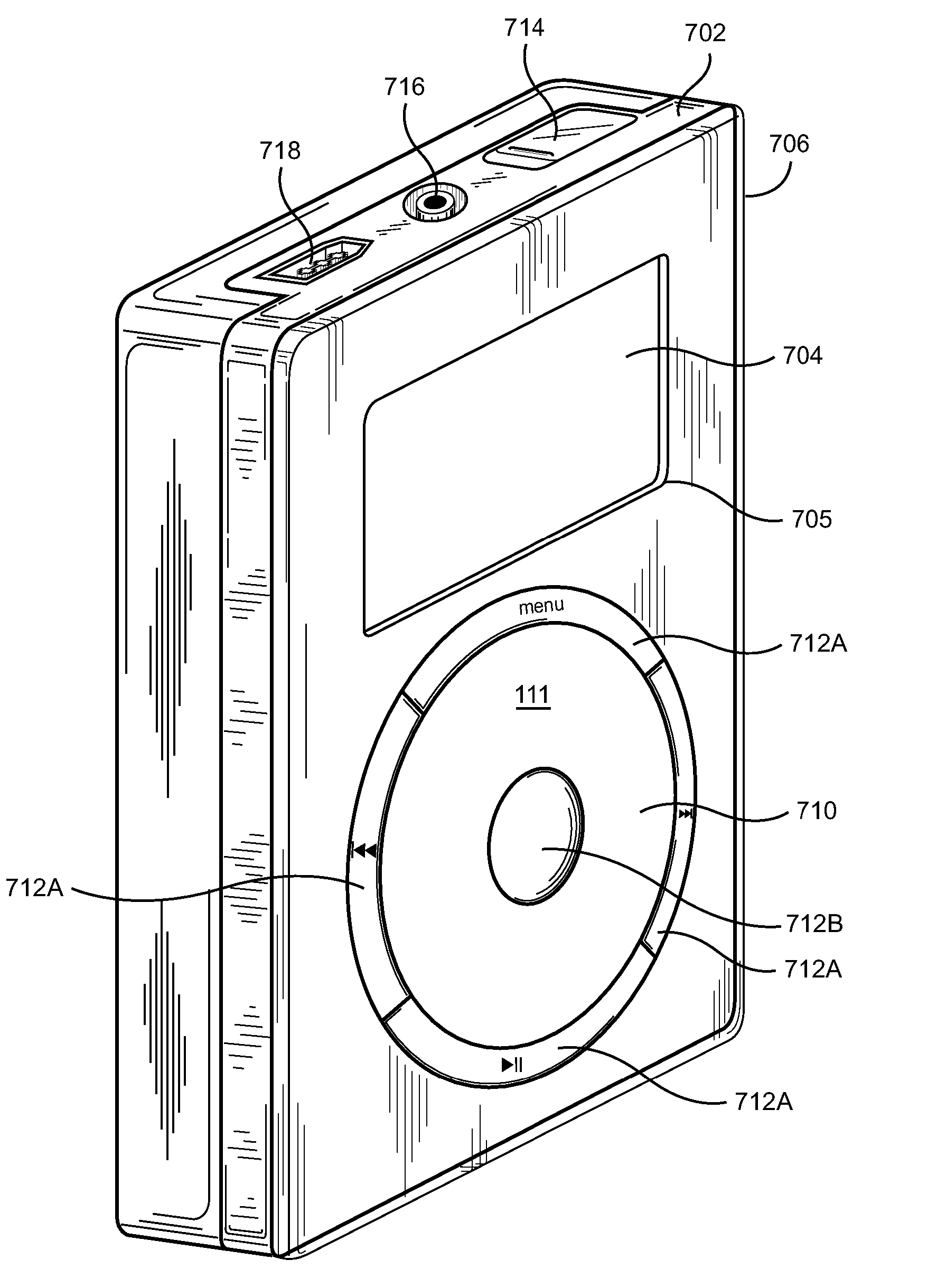

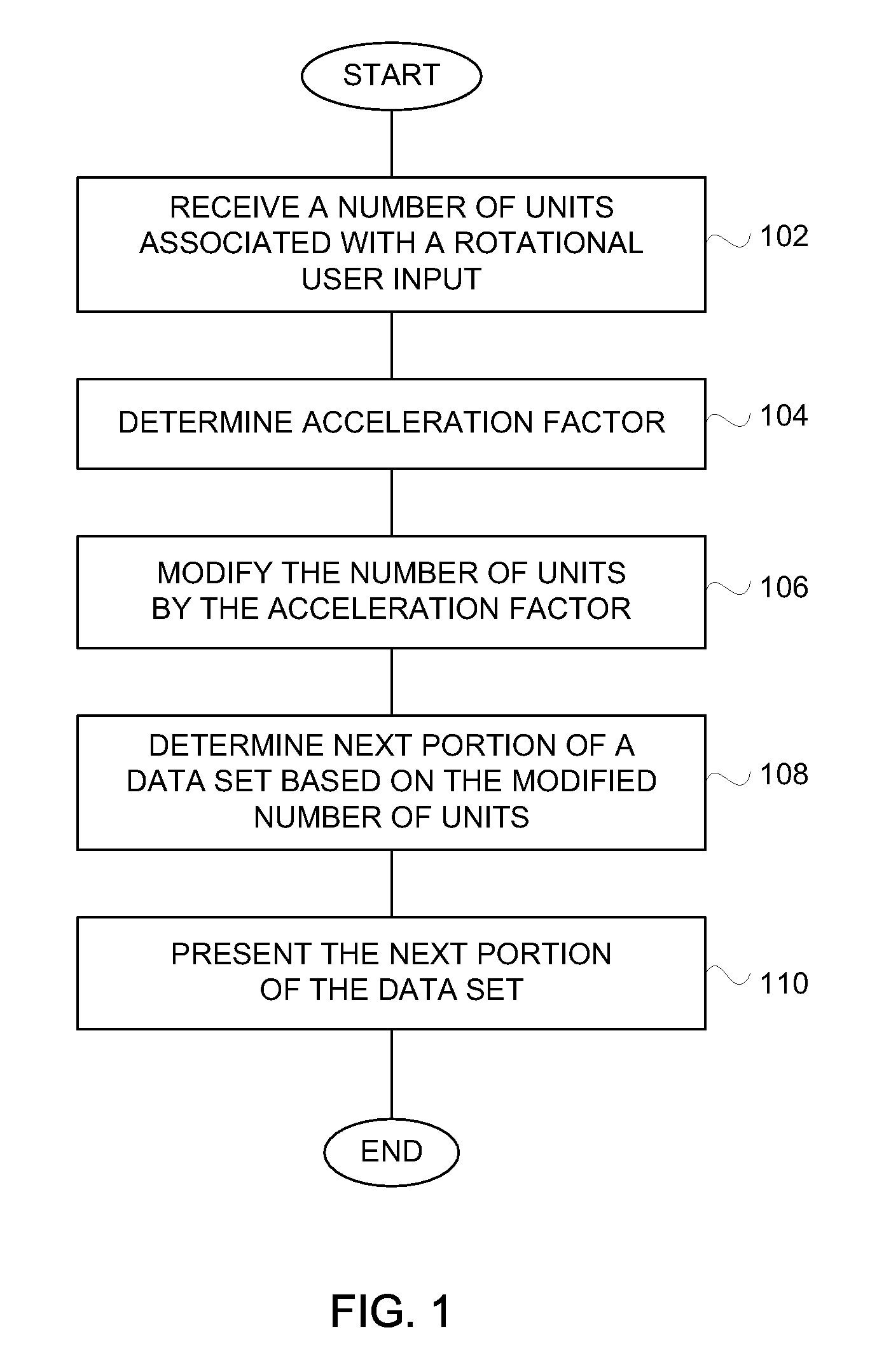

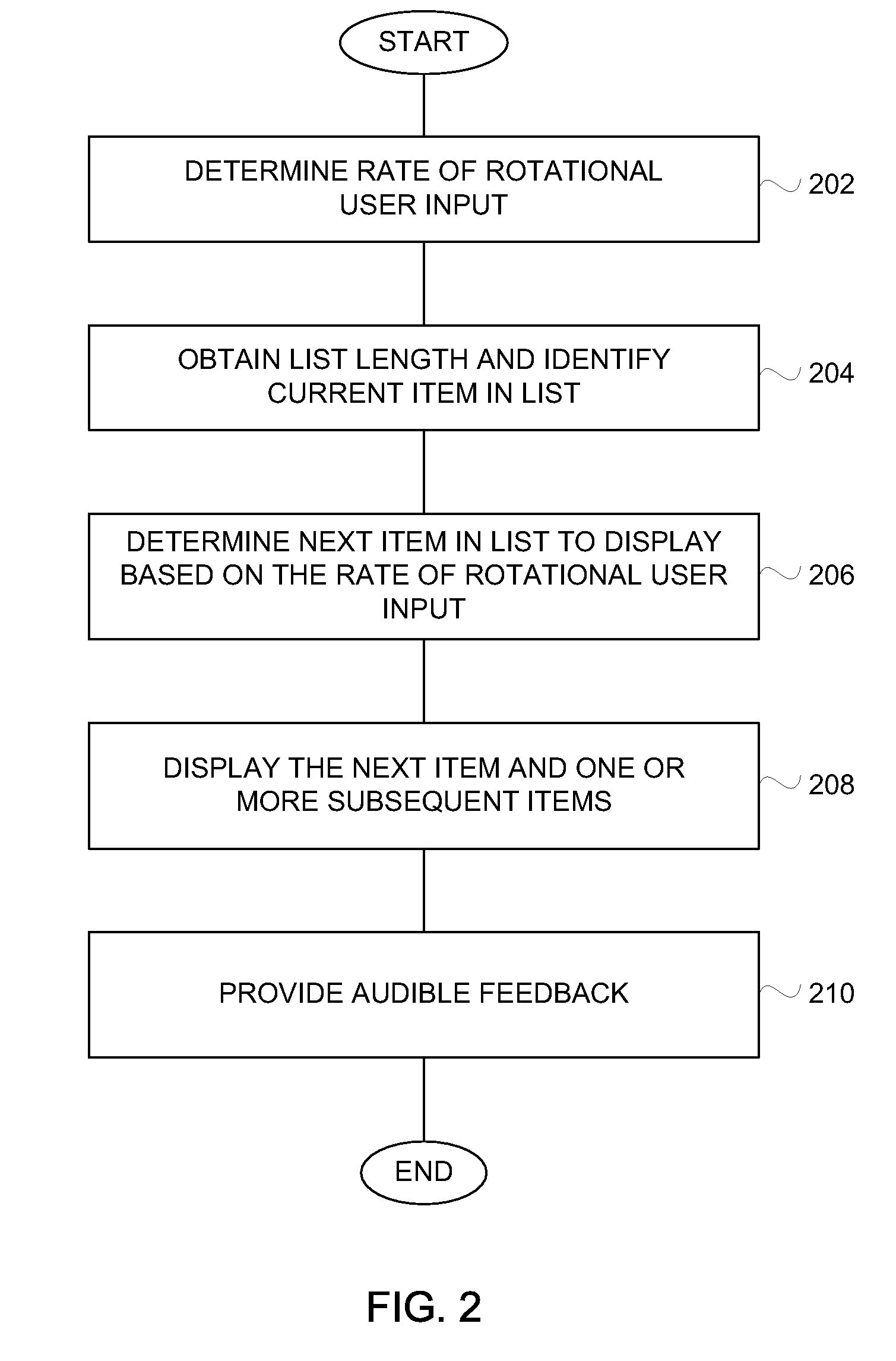

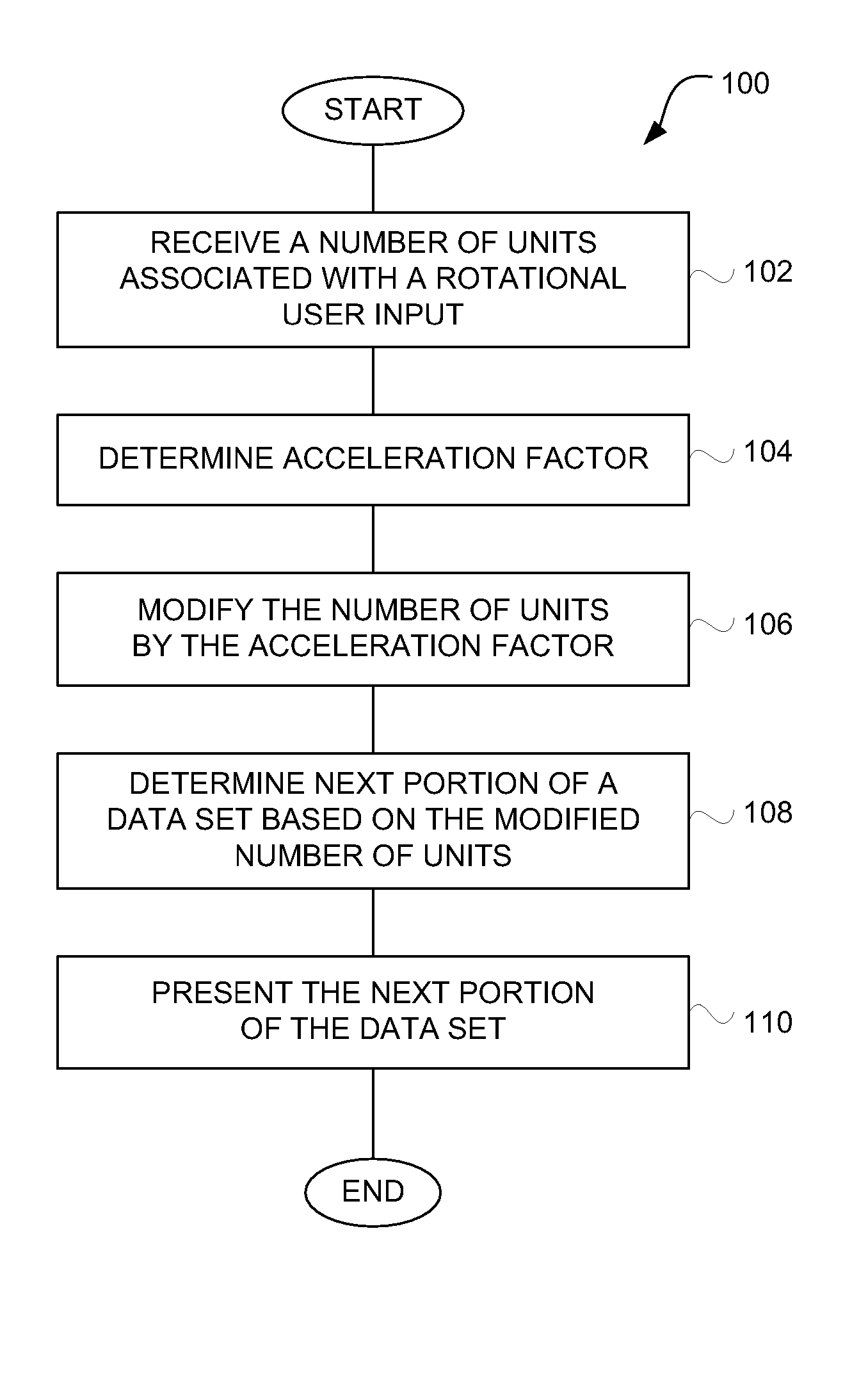

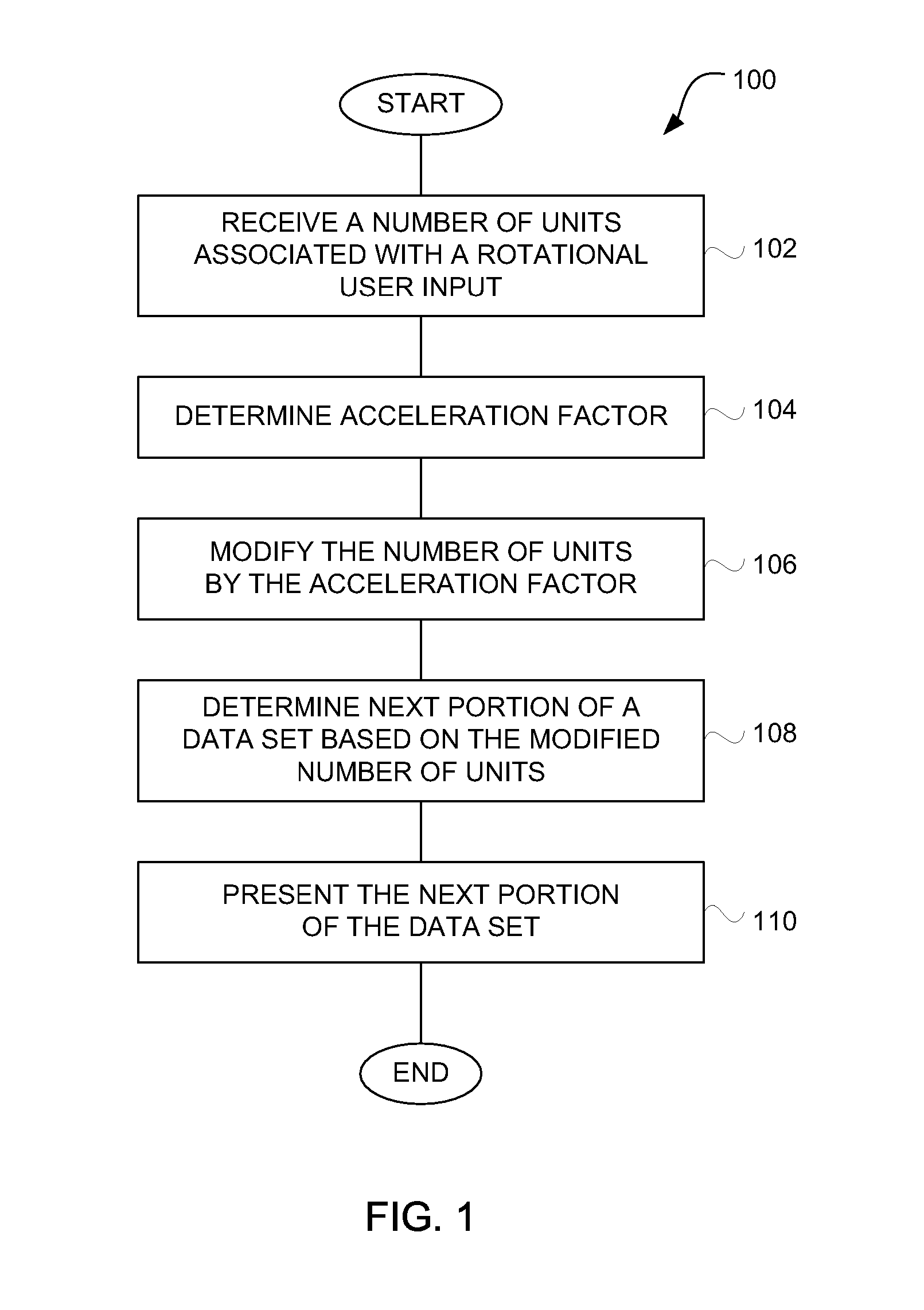

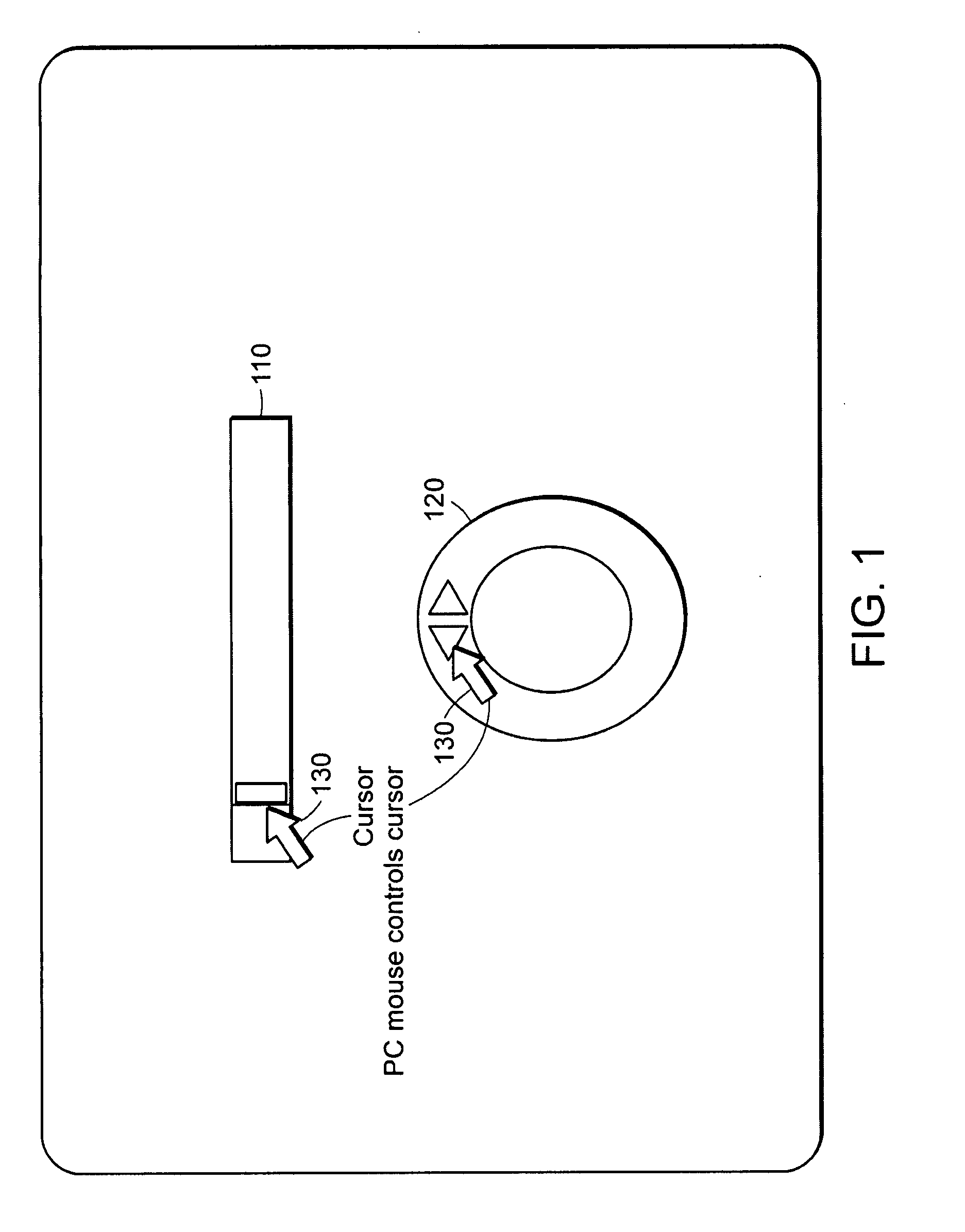

Method and apparatus for accelerated scrolling

InactiveUS7312785B2Increase scrollingFaster and with great easeInput/output for user-computer interactionCathode-ray tube indicatorsGraphicsData set

Improved approaches for users to with graphical user interfaces of computing devices are disclosed. A rotational user action supplied by a user via a user input device can provide accelerated scrolling. The accelerated nature of the scrolling enables users to scroll or traverse a lengthy data set (e.g., list of items) faster and with greater ease. The amount of acceleration provided can be performed in successive stages, and / or performed based on the speed of the rotational user action. In one embodiment, the rotational user action is transformed into linear action with respect to a graphical user interface. The resulting acceleration effect causes the linear action to be enhanced such that a lengthy data set is able to be rapidly traversed.

Owner:APPLE INC

Method and apparatus for accelerated scrolling

InactiveUS20070080936A1Increase scrollingFaster and with great easeCathode-ray tube indicatorsDetails for portable computersGraphicsData set

Improved approaches for users to with graphical user interfaces of computing devices are disclosed. A rotational user action supplied by a user via a user input device can provide accelerated scrolling. The accelerated nature of the scrolling enables users to scroll or traverse a lengthy data set (e.g., list of items) faster and with greater ease. The amount of acceleration provided can be performed in successive stages, and / or performed based on the speed of the rotational user action. In one embodiment, the rotational user action is transformed into linear action with respect to a graphical user interface. The resulting acceleration effect causes the linear action to be enhanced such that a lengthy data set is able to be rapidly traversed.

Owner:APPLE INC

Method and apparatus for accelerated scrolling

InactiveUS20070085841A1Increase scrollingFaster and with great easeCathode-ray tube indicatorsInput/output processes for data processingGraphicsData set

Improved approaches for users to with graphical user interfaces of computing devices are disclosed. A rotational user action supplied by a user via a user input device can provide accelerated scrolling. The accelerated nature of the scrolling enables users to scroll or traverse a lengthy data set (e.g., list of items) faster and with greater ease. The amount of acceleration provided can be performed in successive stages, and / or performed based on the speed of the rotational user action. In one embodiment, the rotational user action is transformed into linear action with respect to a graphical user interface. The resulting acceleration effect causes the linear action to be enhanced such that a lengthy data set is able to be rapidly traversed.

Owner:APPLE INC

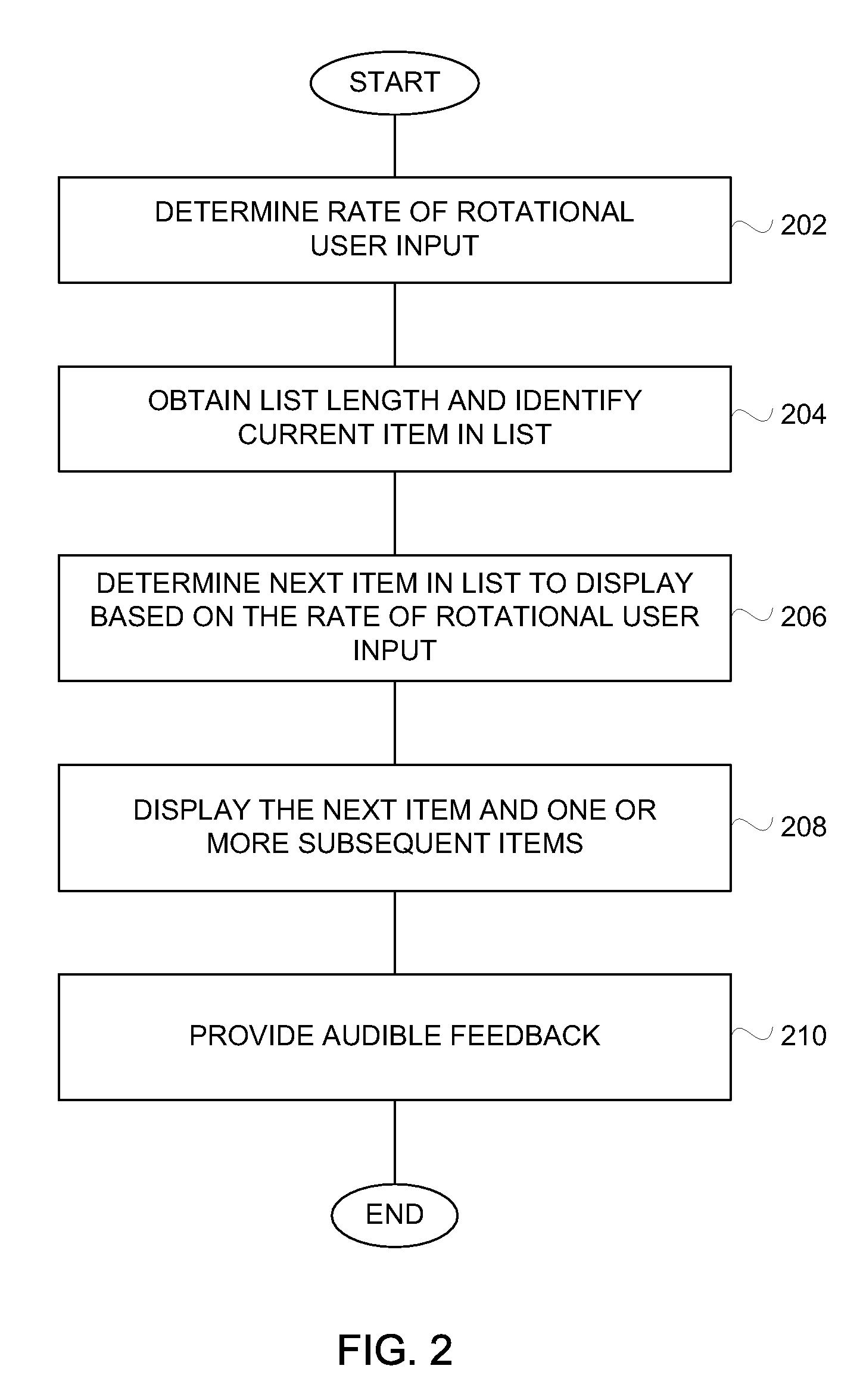

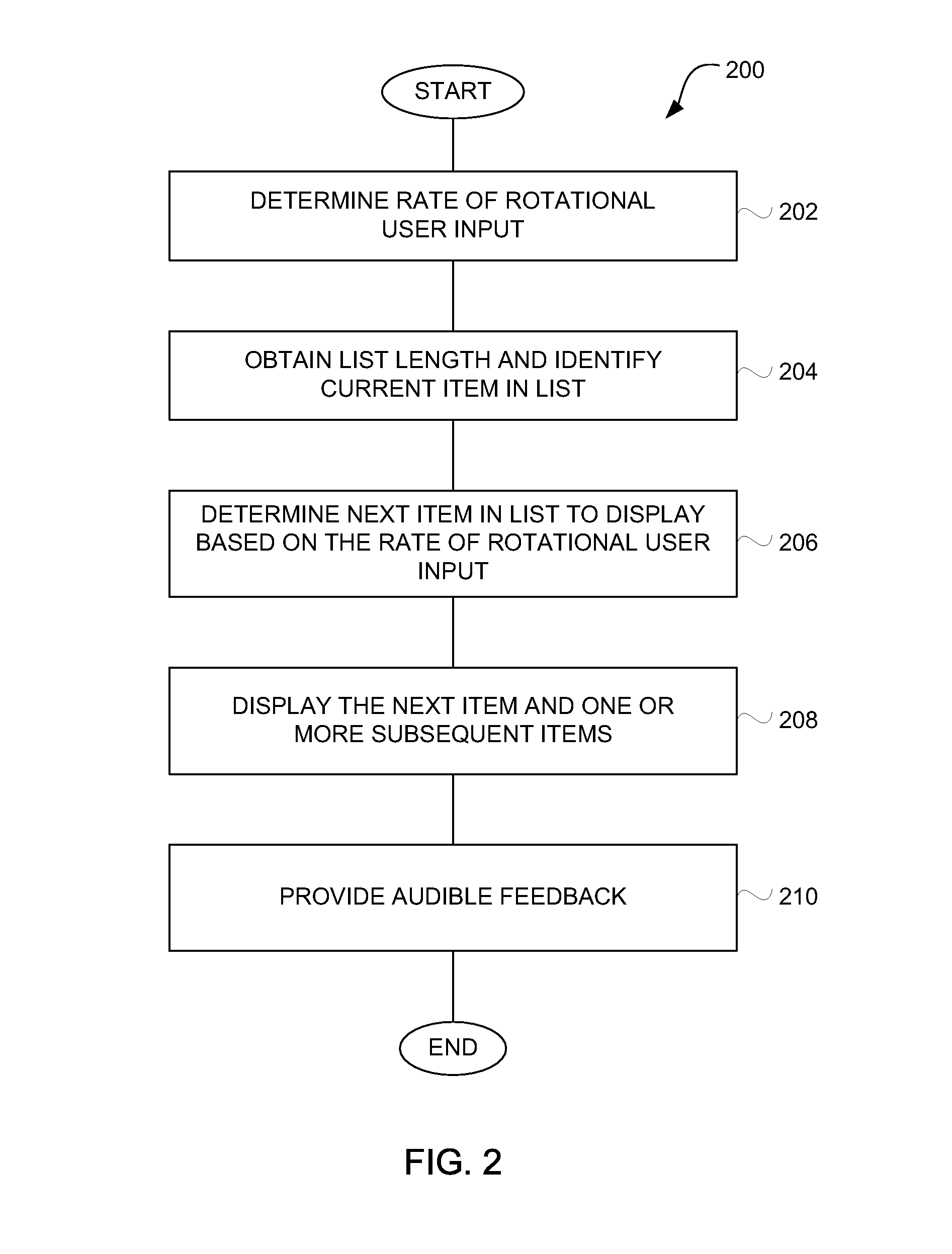

Method and Apparatus for Accelerated Scrolling

ActiveUS20080094352A1Increase scrollingFaster and with great easeCathode-ray tube indicatorsSubstation equipmentGraphicsData set

Improved approaches for users to with graphical user interfaces of computing devices are disclosed. A rotational user action supplied by a user via a user input device can provide accelerated scrolling. The accelerated nature of the scrolling enables users to scroll or traverse a lengthy data set (e.g., list of items) faster and with greater ease. The amount of acceleration provided can be performed in successive stages, and / or performed based on the speed of the rotational user action. In one embodiment, the rotational user action is transformed into linear action with respect to a graphical user interface. The resulting acceleration effect causes the linear action to be enhanced such that a lengthy data set is able to be rapidly traversed.

Owner:APPLE INC

Intuitive control of portable data displays

InactiveUSRE42336E1Increase scrollingInput/output for user-computer interactionCathode-ray tube indicatorsVisually impairedData display

Owner:META PLATFORMS INC

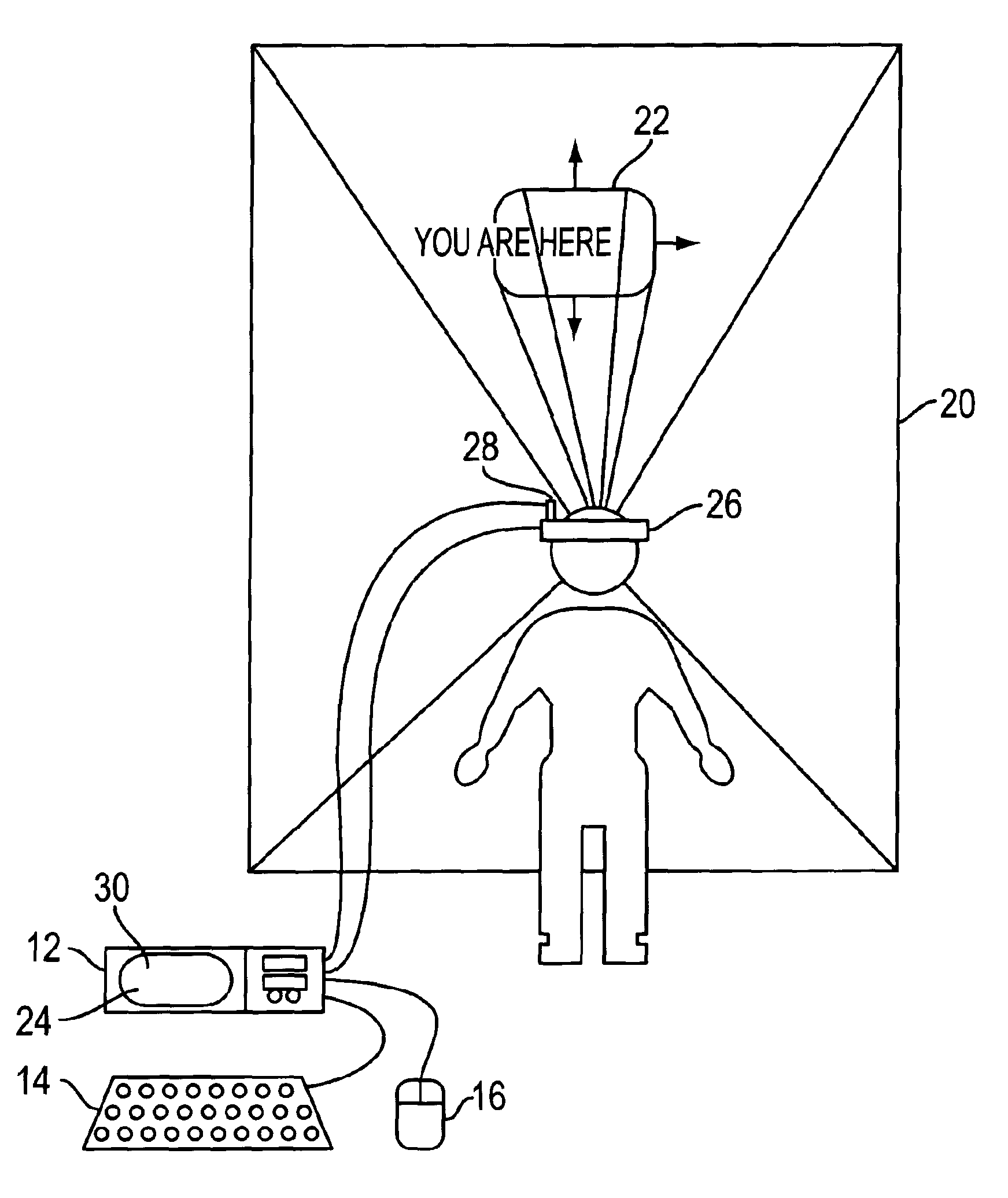

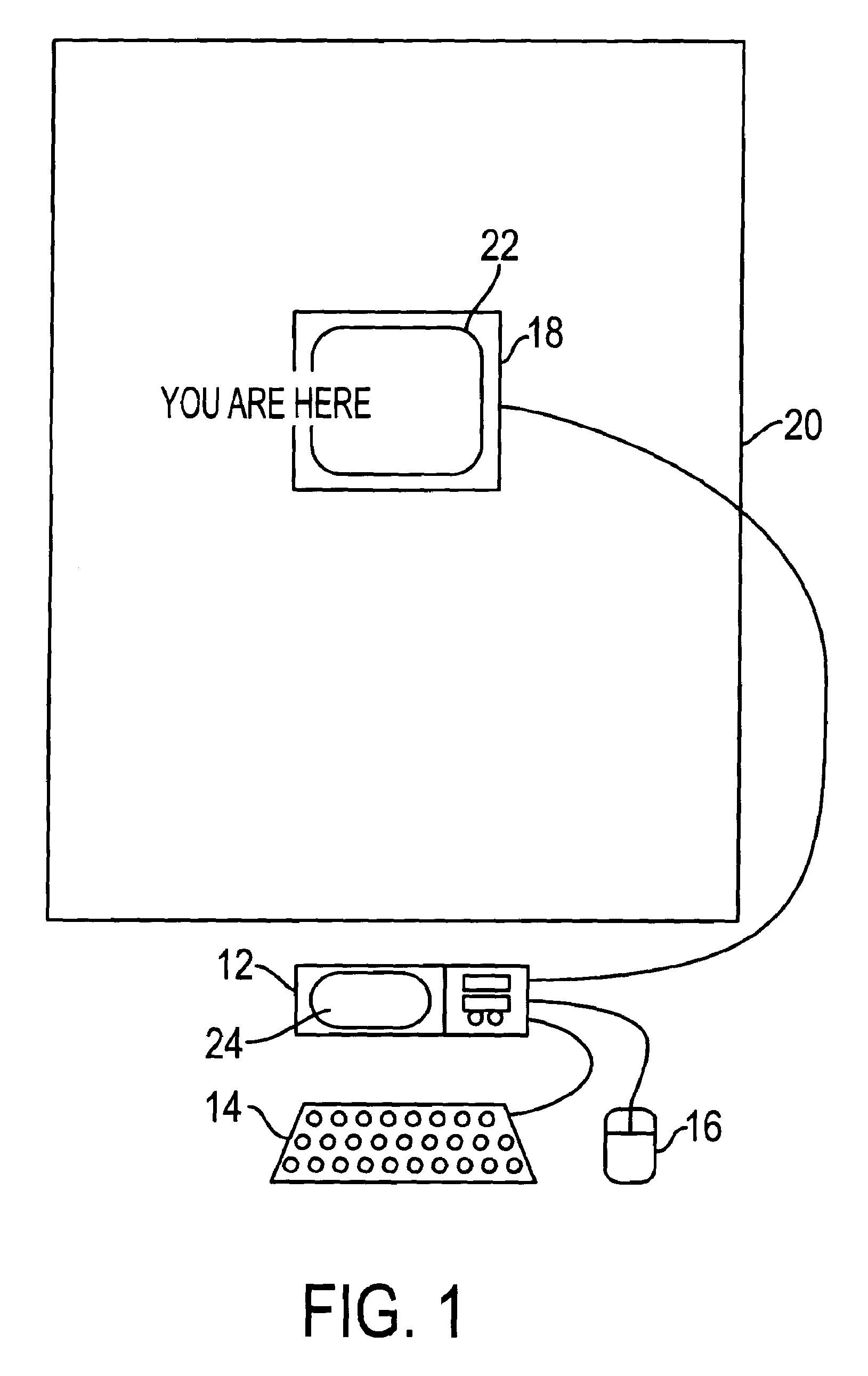

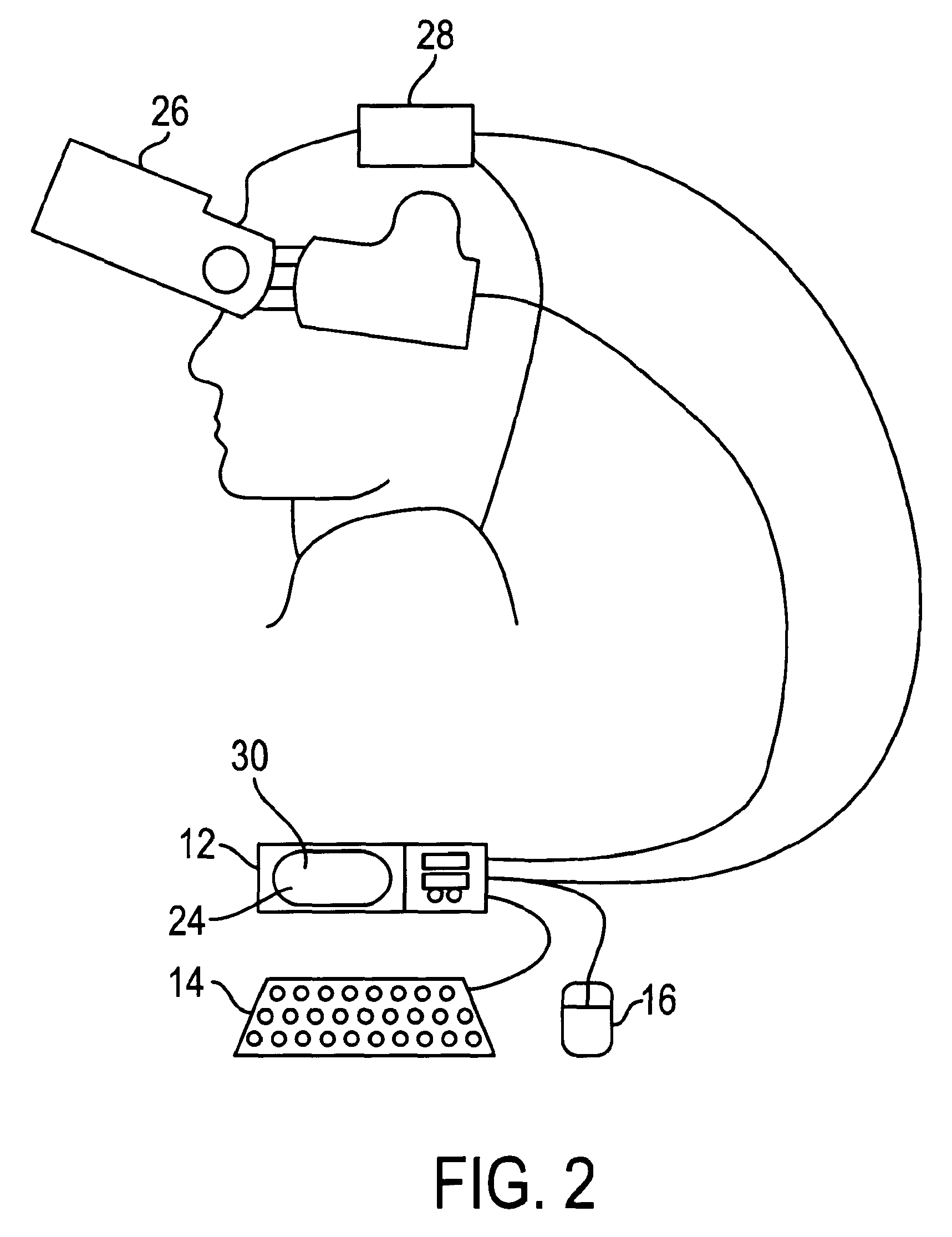

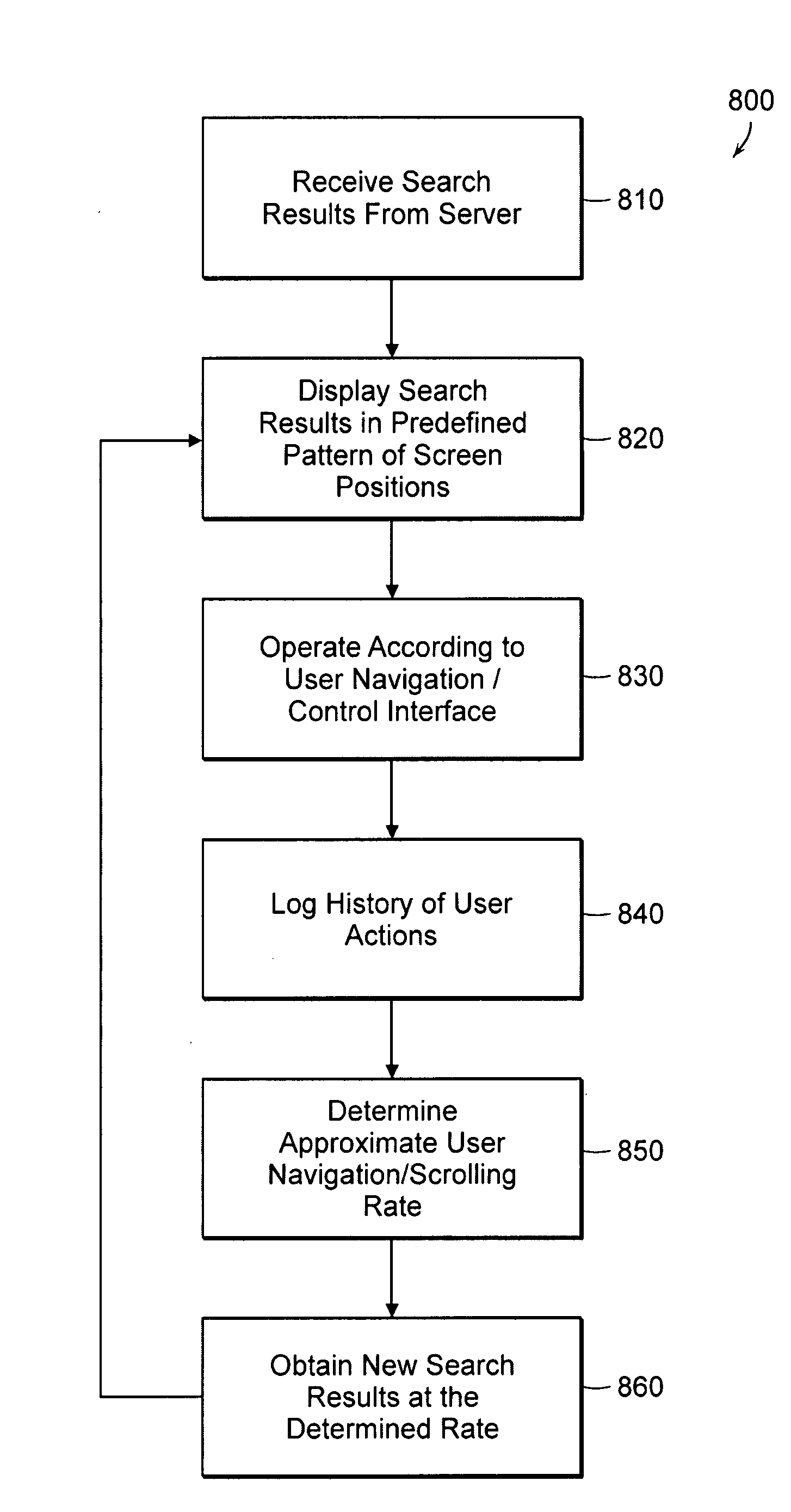

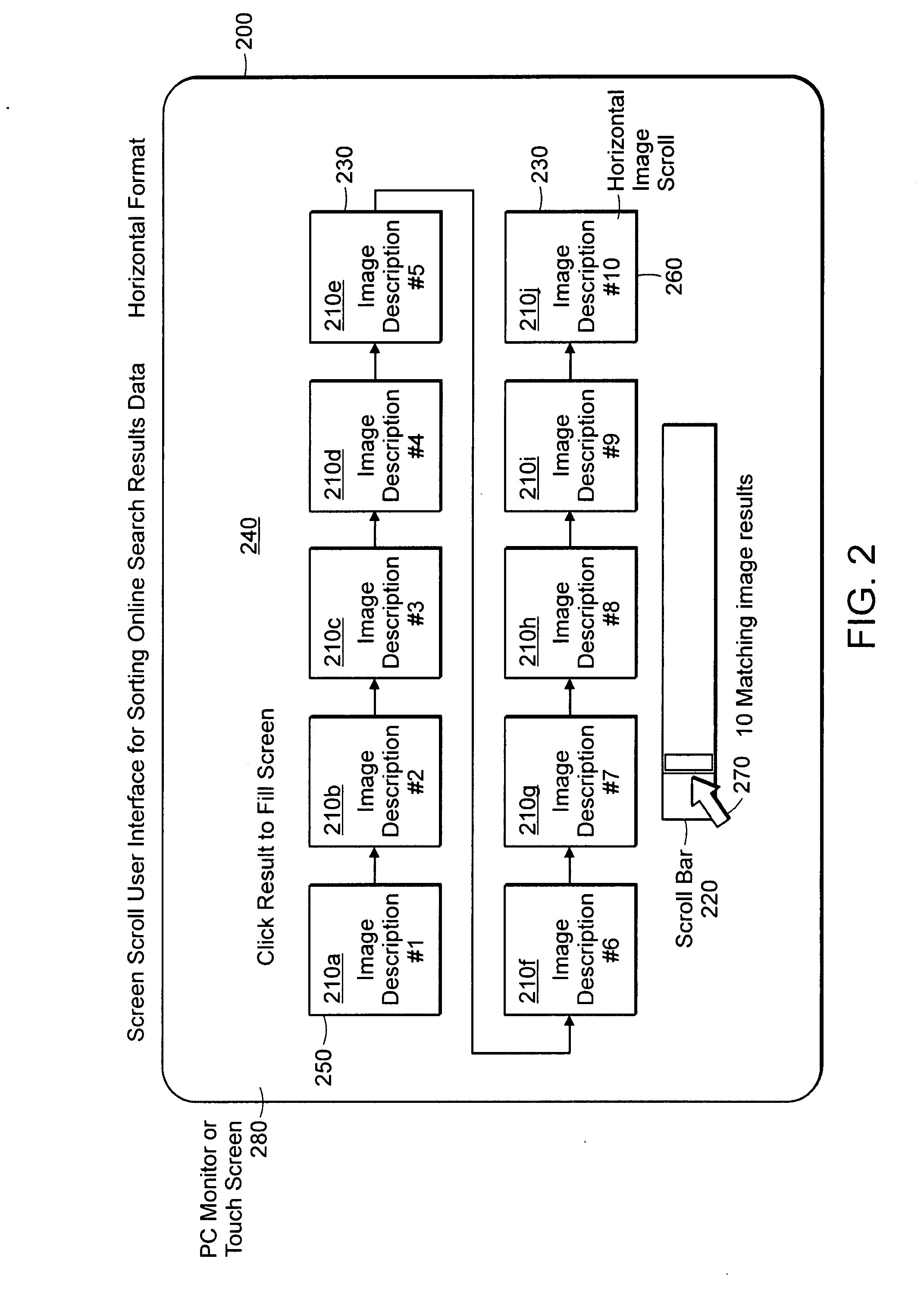

Database Search Results User Interface

InactiveUS20080235205A1Increase scrollingEnhanced content availabilityDigital data information retrievalDigital data processing detailsDisplay deviceUser interface

A system and method for retrieving and displaying search results by retrieving a user's search results from a database and providing an interface with which the user scrolls through the search results. The system and method approximate a rate at which the user scrolls through the search results based on at least one user action, and retrieves additional search results from the database based on the approximated rate. The system and method display the search results on a display device in predetermined patterns of screen positions in cooperation with the navigation / scroll control interface.

Owner:INTELLECTUAL VENTURES HLDG 32

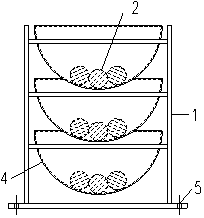

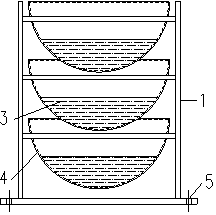

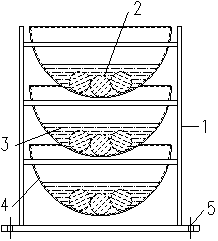

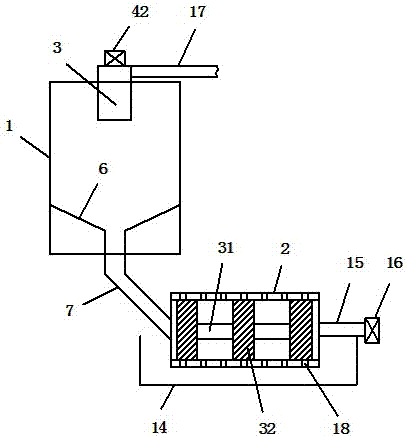

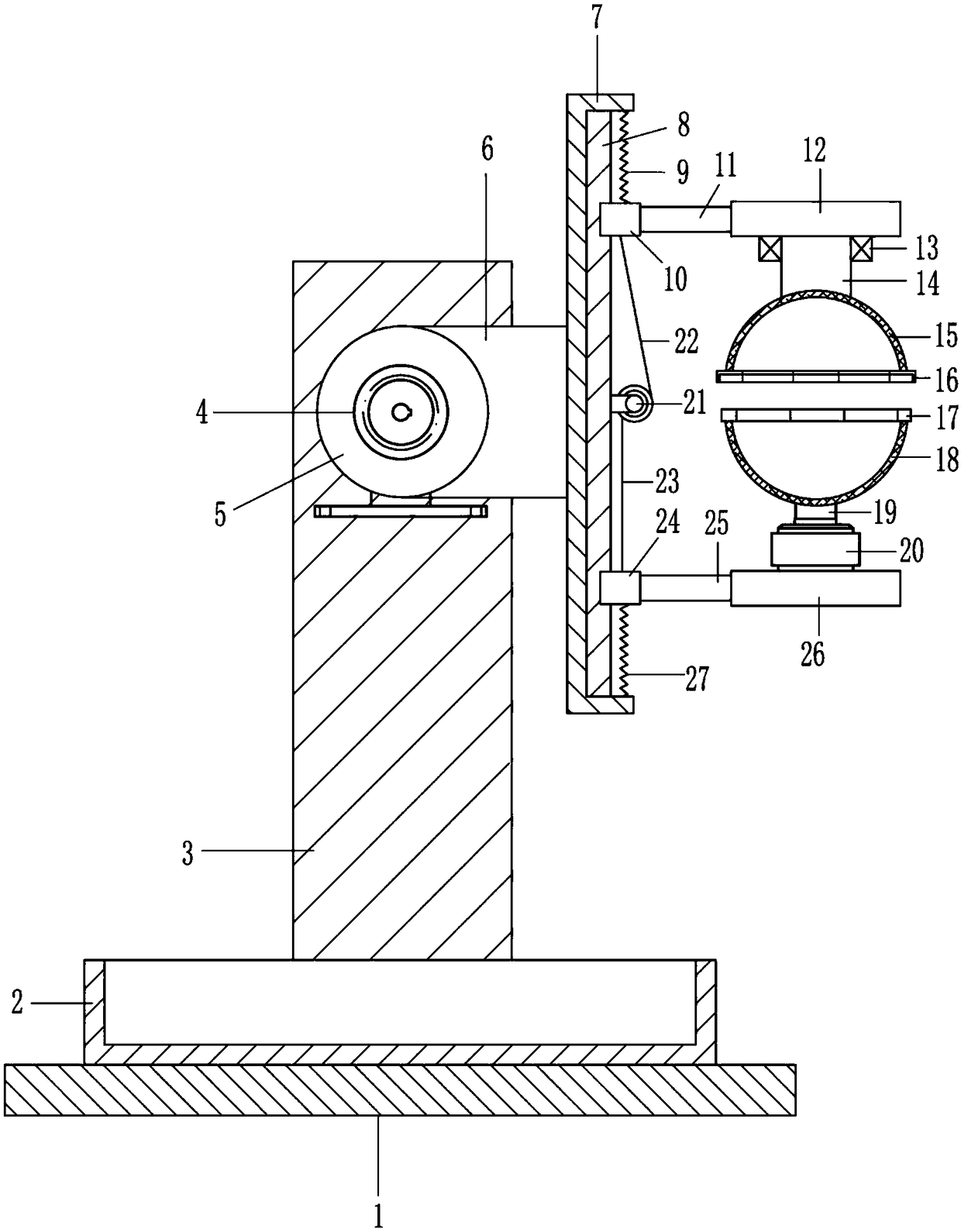

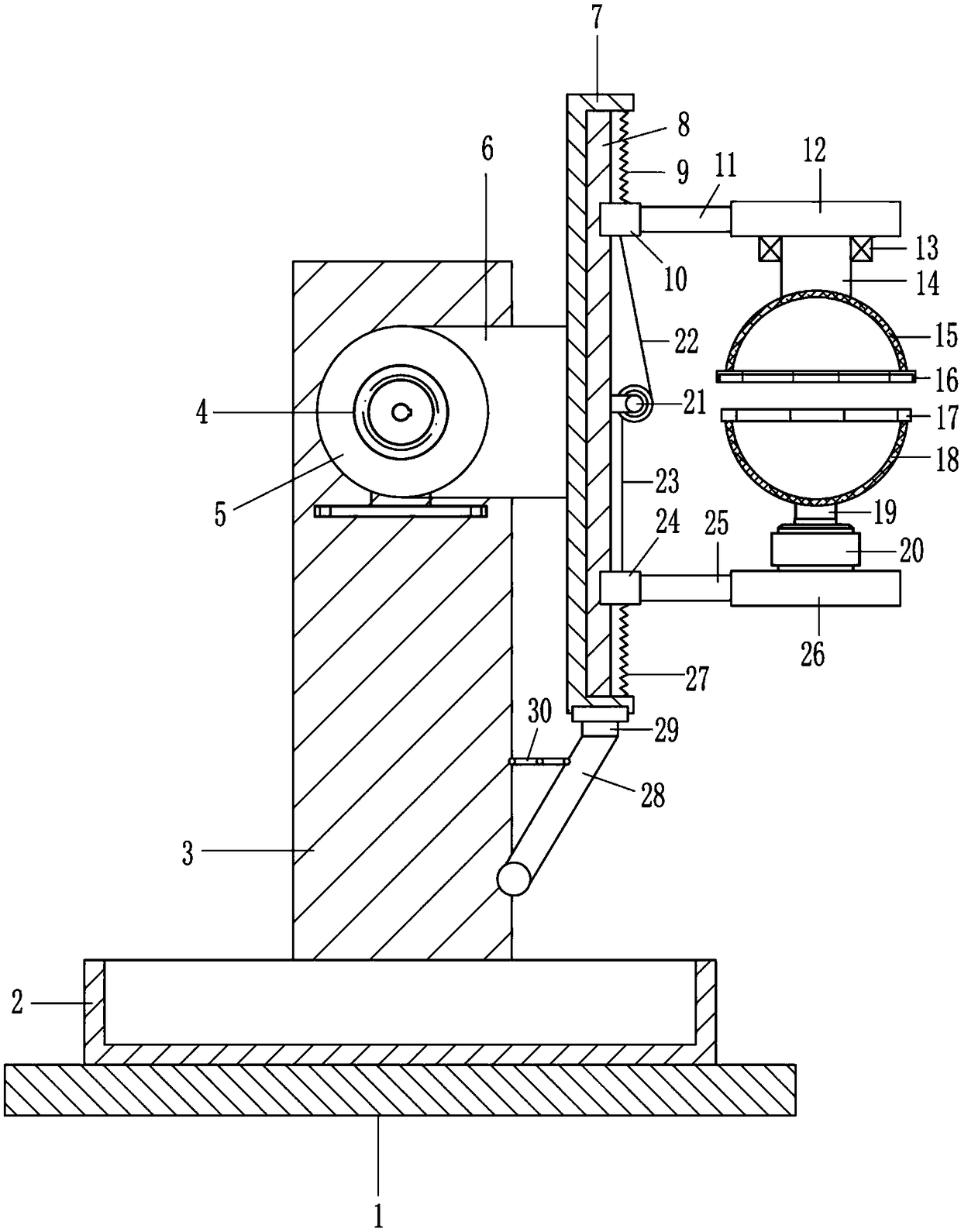

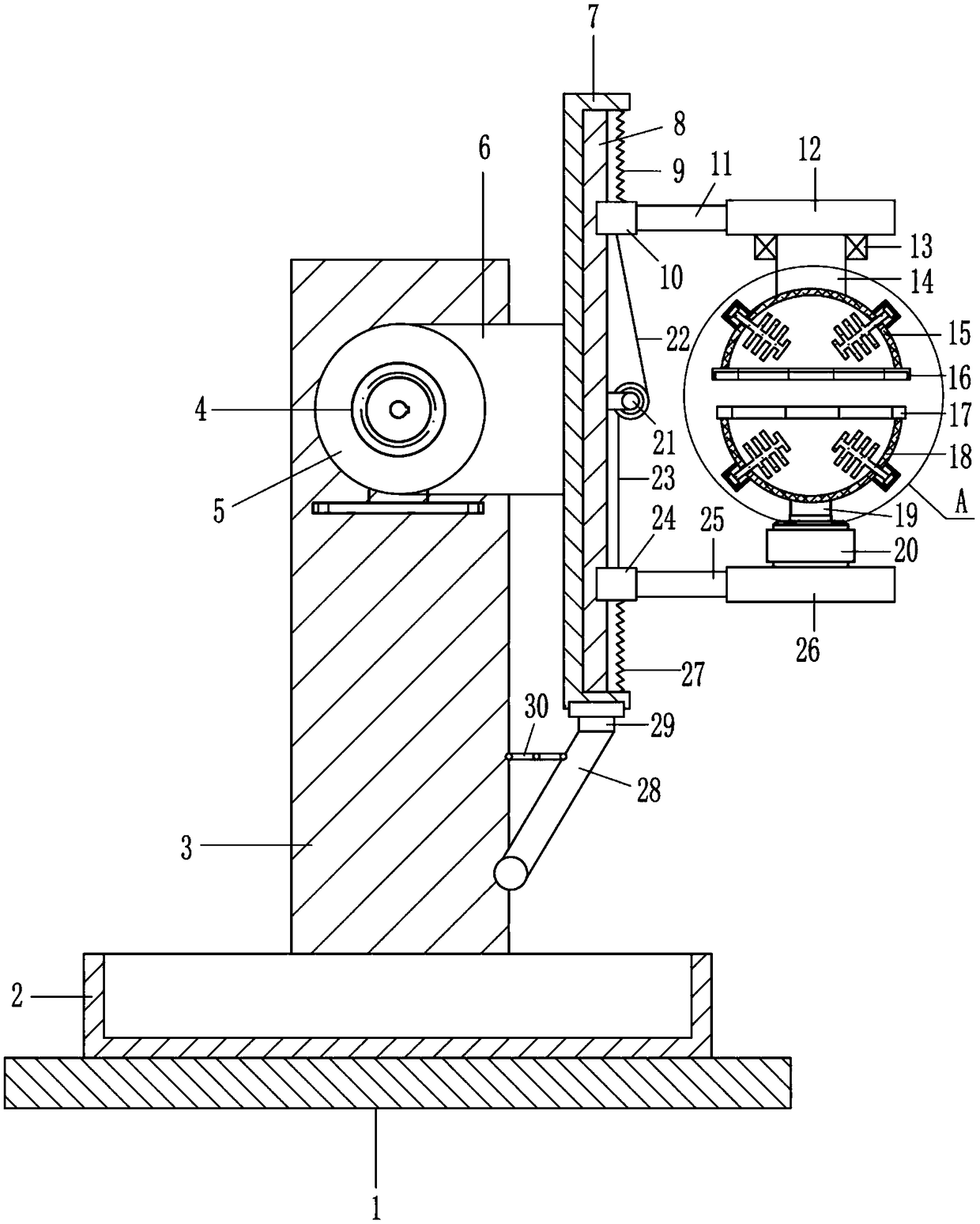

Multilayer spherical container damper

InactiveCN103557266AIncrease scrollingReduce coefficient of frictionNon-rotating vibration suppressionWind energy generationSteel ballTower

The invention relates to a multilayer spherical container damper which consists of a fixing support, steel balls, liquid, containers and bolts. The containers are spherical containers, a plurality of containers are sequentially placed on the fixing support from top to bottom, the containers contain any one or all of the steel balls or liquid, and the fixing support is fixed above the multilayer spherical container damper through the screws. The rolling frequency of the steel balls in the containers depends on the container radius and the steel ball radius, the oscillation frequency of the liquid in the containers depends on the liquid level height and the container radius, the masses of the steel balls and the liquid depend on the expected damping effect and are 1.5%-2.5% of first-order modal mass of a wind power generating tower. When the steel ball rolling frequency or the liquid oscillation frequency is almost completely consistent with the natural vibration frequency of the damper, the control effect is good, and therefore the spherical container radius, the steel ball radius and the liquid level height are determined. The multilayer spherical container damper is simple in structure and novel in concept.

Owner:TONGJI UNIV

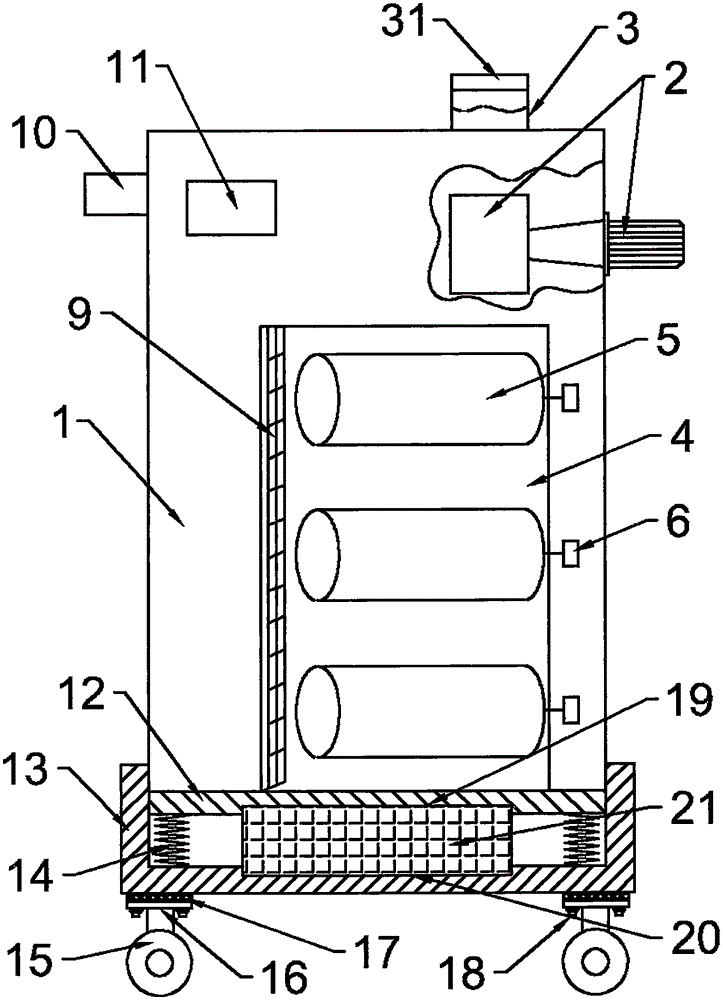

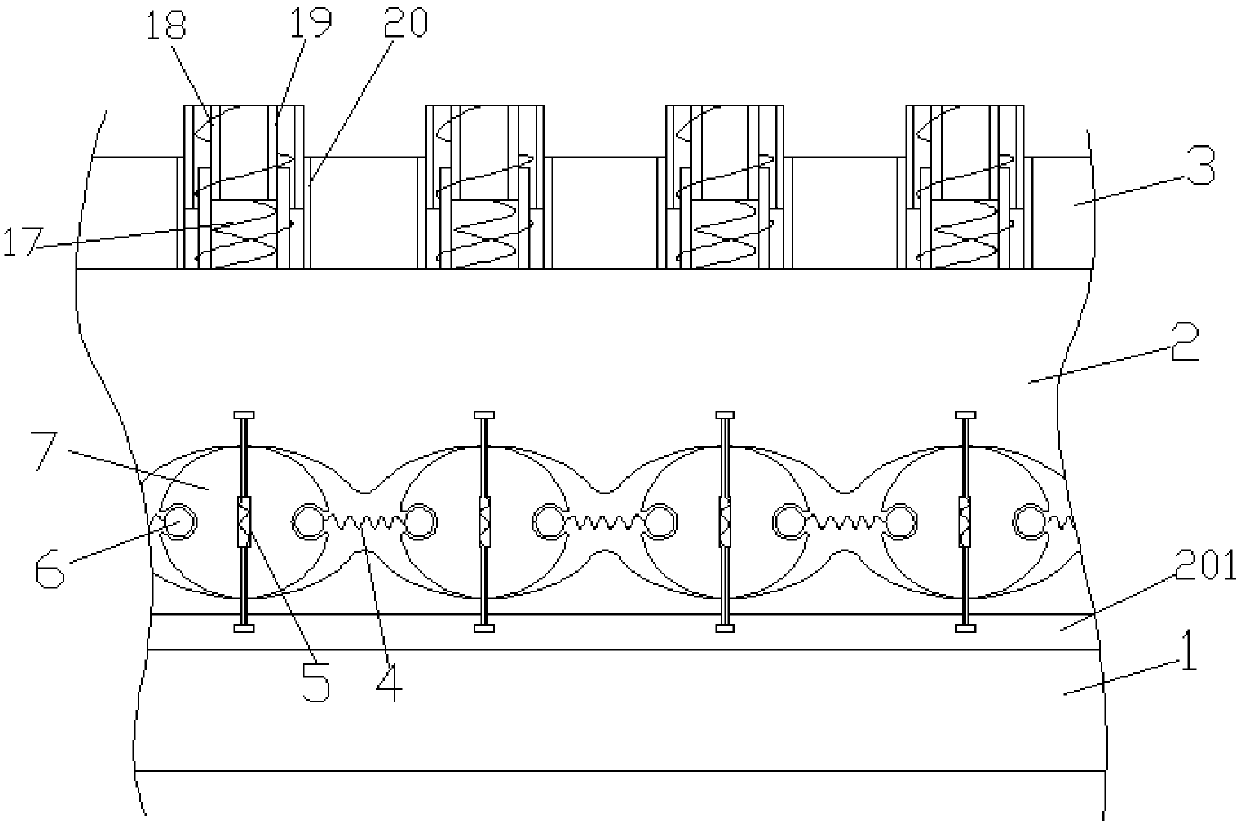

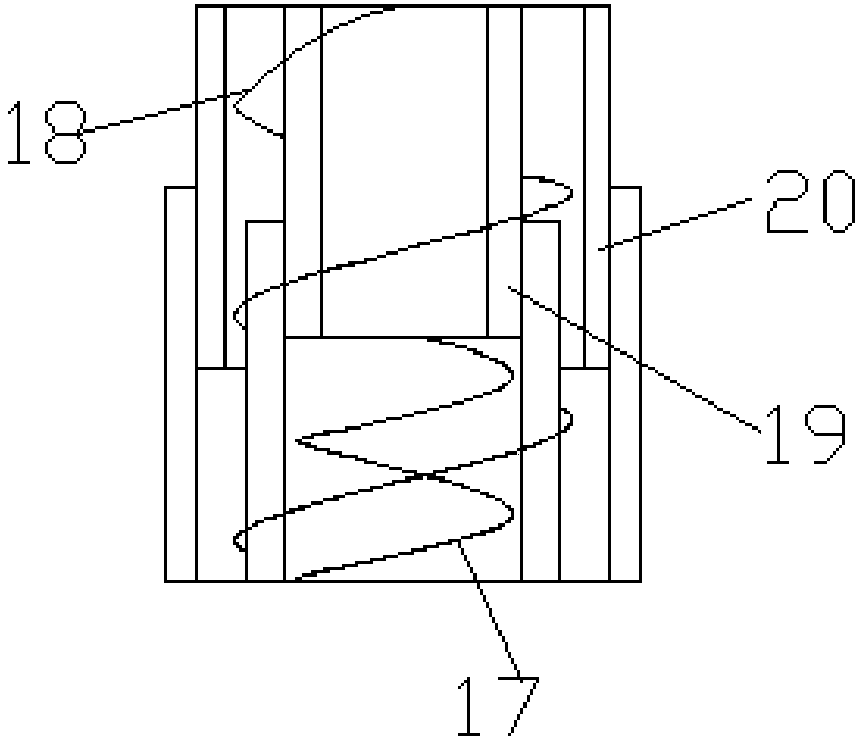

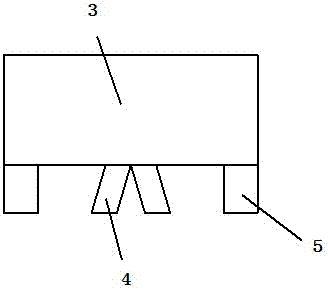

Drug drying box

InactiveCN105651022AImprove efficiencyHeating evenlyGranular material dryingDrying gas arrangementsDrugAgricultural engineering

The invention discloses a drug drying box. The drug drying box comprises a box body, wherein a fan is arranged on the box body, an exhaust hole is formed in the top of the box body, and an accommodating cavity is arranged in the middle of the box body; a roller is arranged in the accommodating cavity, the right end of the roller is connected with a rotor of a motor, and a winnowing plate is mounted on the inner wall of the roller; the winnowing plate comprises a bottom plate and a backwards tilting plate, vertical plates are arranged on the two sides of the bottom plate, and an arc-shaped plate is arranged at the upper end of the backwards tilting plate; a base is arranged on the lower side of the box body, a carrier plate is horizontally arranged in the base, and damping springs are arranged at the periphery of the lower side of the carrier plate; idler wheels are further arranged at the lower part of the base, a T-shaped frame is arranged at the upper ends of the idler wheels, and a damping block is arranged between the T-shaped frame and the base; a mounting groove is further formed in the lower surface of the carrier plate, a fixing groove is formed in the upper surface of the base, and a damping pad is mounted between the mounting groove and the fixing groove in a fit manner. Thermal efficiency is high, and heating is even, so that the drug drying work efficiency is improved. The rolling degree of drugs is increased by the winnowing plate, so that drying is thorough. Through multi-stage damping, the stability of the drying box is ensured.

Owner:姚莲琴

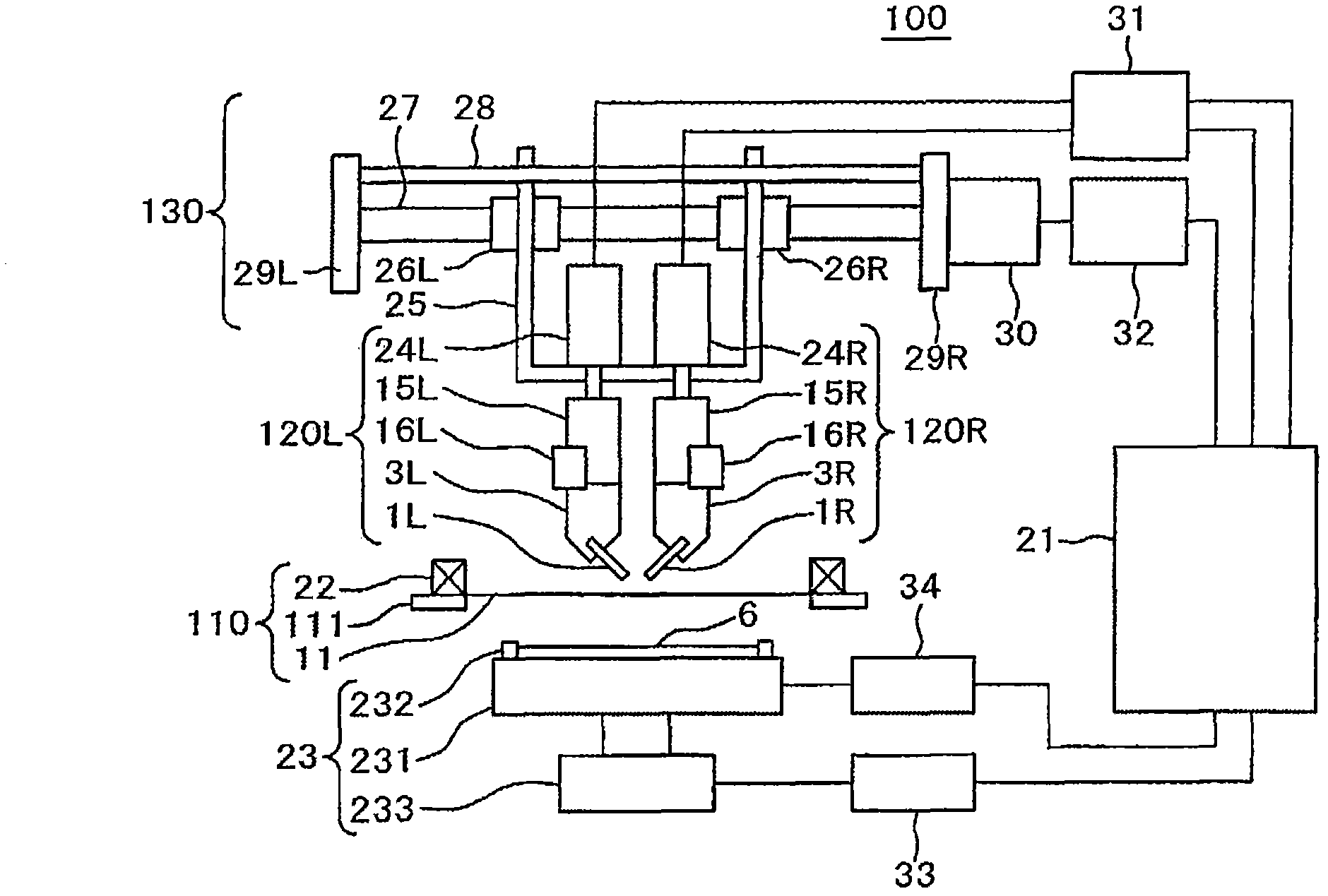

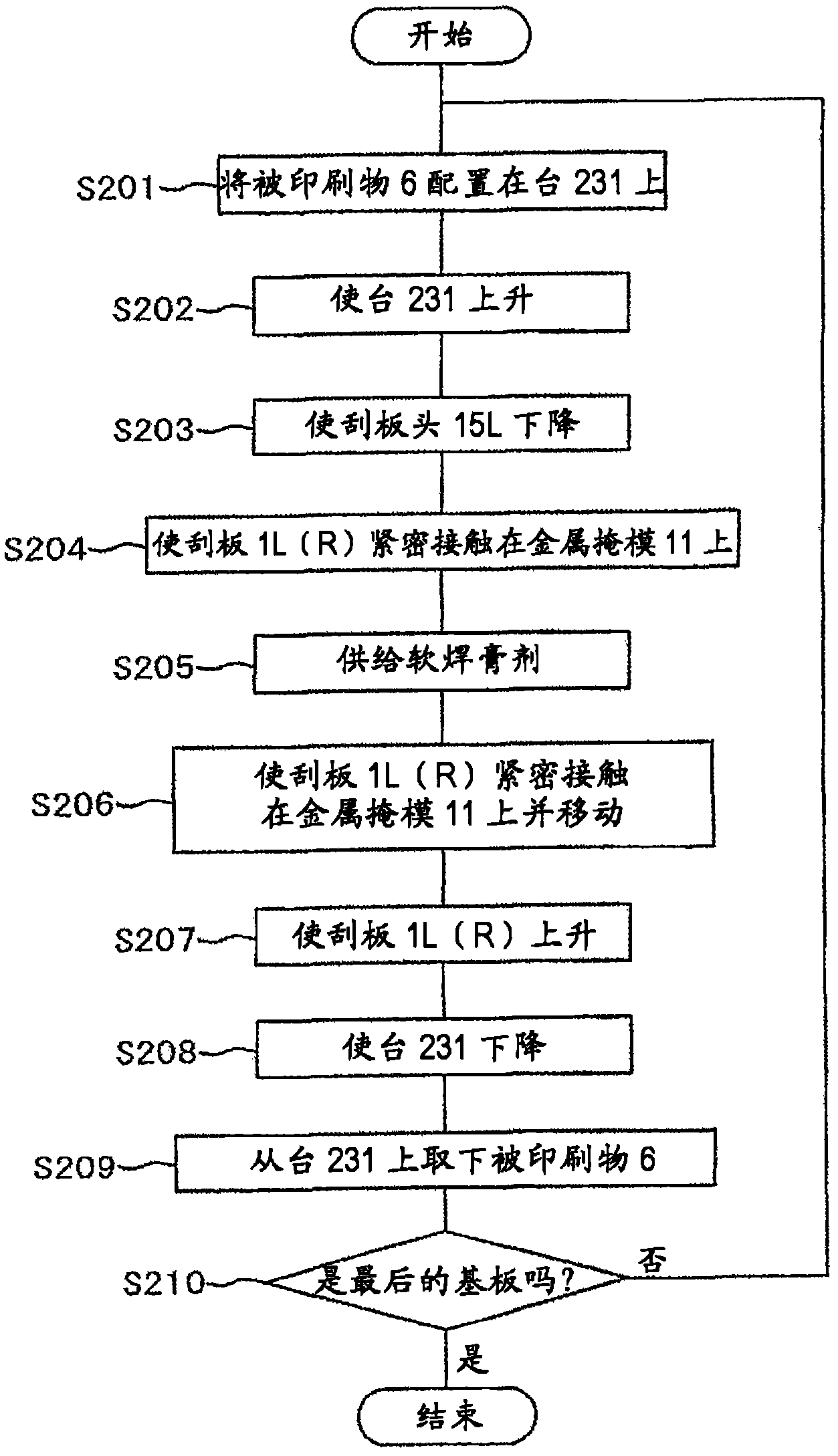

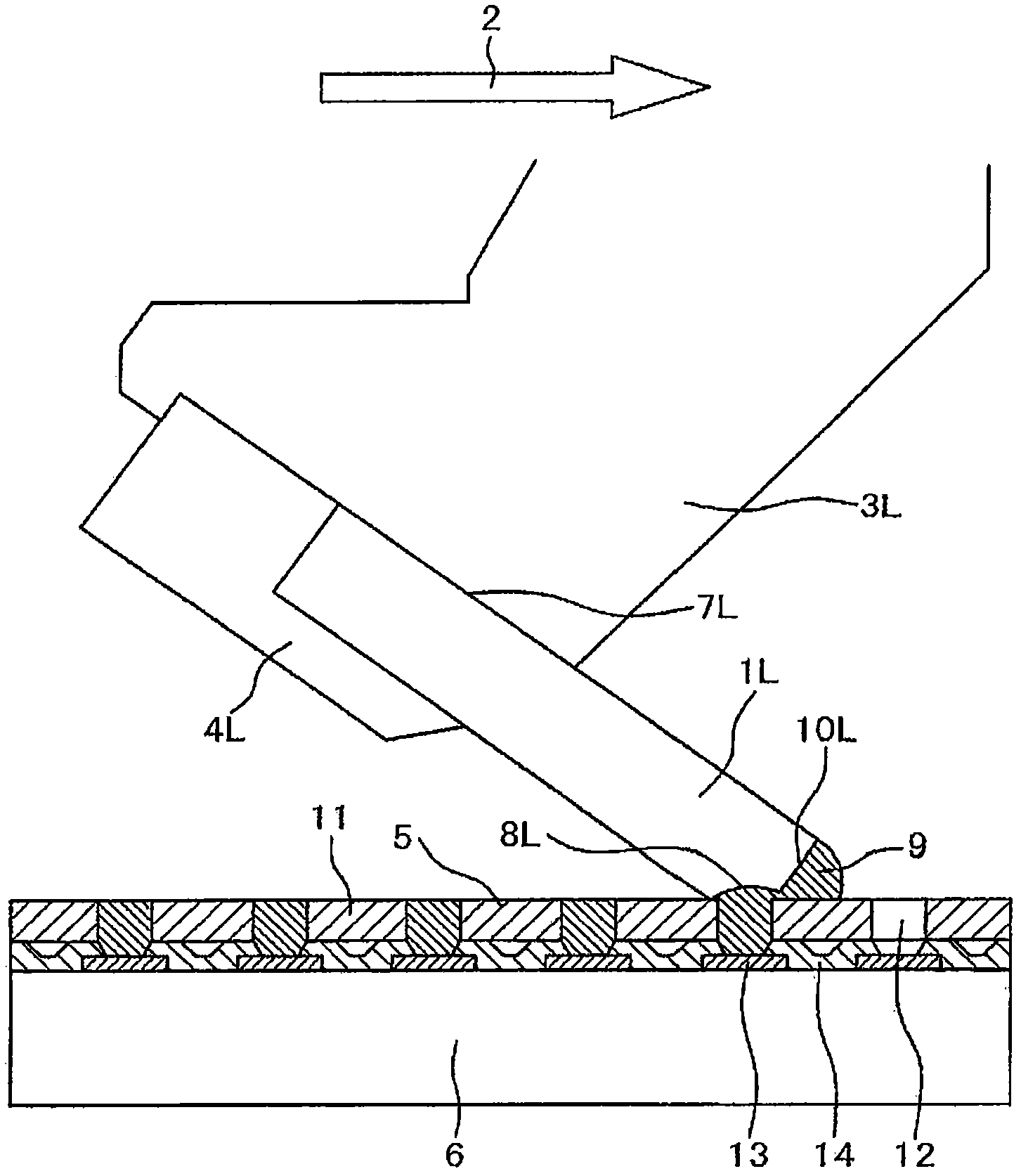

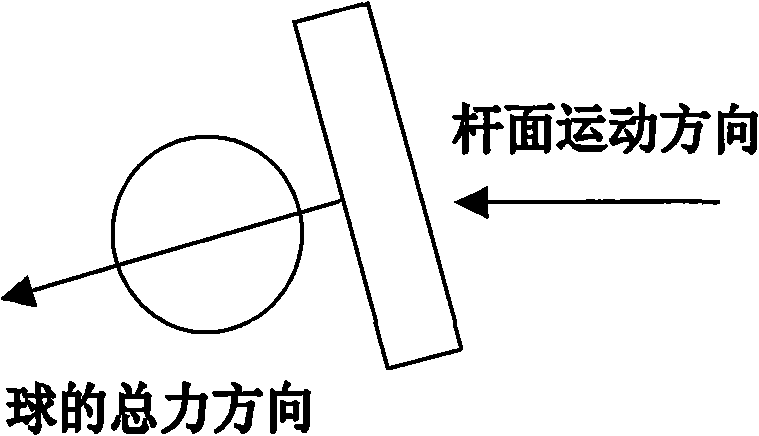

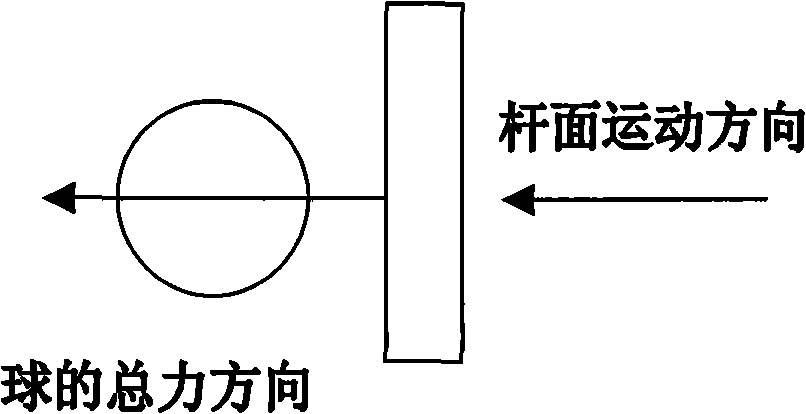

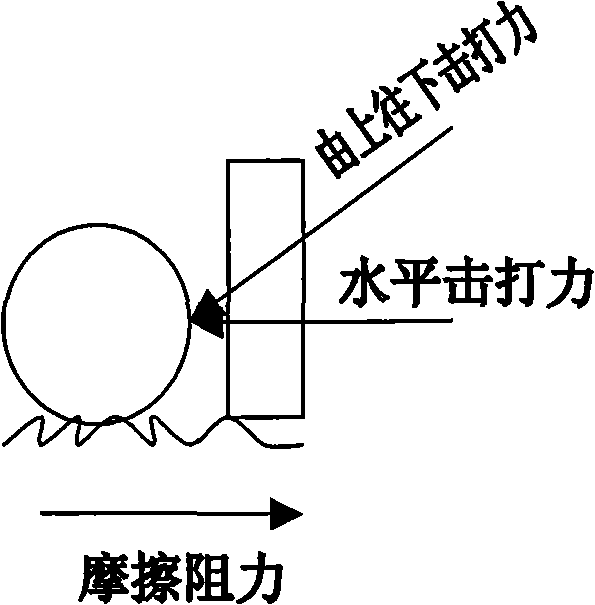

Screen printing method and device thereof

InactiveCN102267278APrinting is good and stableIncrease scrollingScreen printersScreen printingEngineering

PROBLEM TO BE SOLVED: To provide a printing method and an apparatus for the printing method, in which a squeegee can be mounted, wherein the squeegee is shaped such that regardless of the size of the opening area of the opening of a printing mask, the rolling of paste is accelerated when paste is filled and transferred to a printing mask with a required pattern opening and the filling property of the paste into the pattern opening of the printing mask is also accelerated in order to achieve accurate and stable printing, in addition, force is applied vertically to the paste with respect to the opening of the printing mask.SOLUTION: In the printing apparatus, by using the squeegee, paste is transferred to a predetermined part of an object to be printed, which is fixed on a table, from the printing mask that has an opening in a predetermined position. In the printing apparatus, the corner of one of squeegee ends has an arcuate and concave shape. An attack angle between the squeegee and the printed side of the object to be printed is made to be smaller than the mounting angle of the squeegee. Accordingly, satisfactory printing can be achieved in the printing method and the apparatus for the printing method.

Owner:HITACHI HIGH TECH INSTR CO LTD

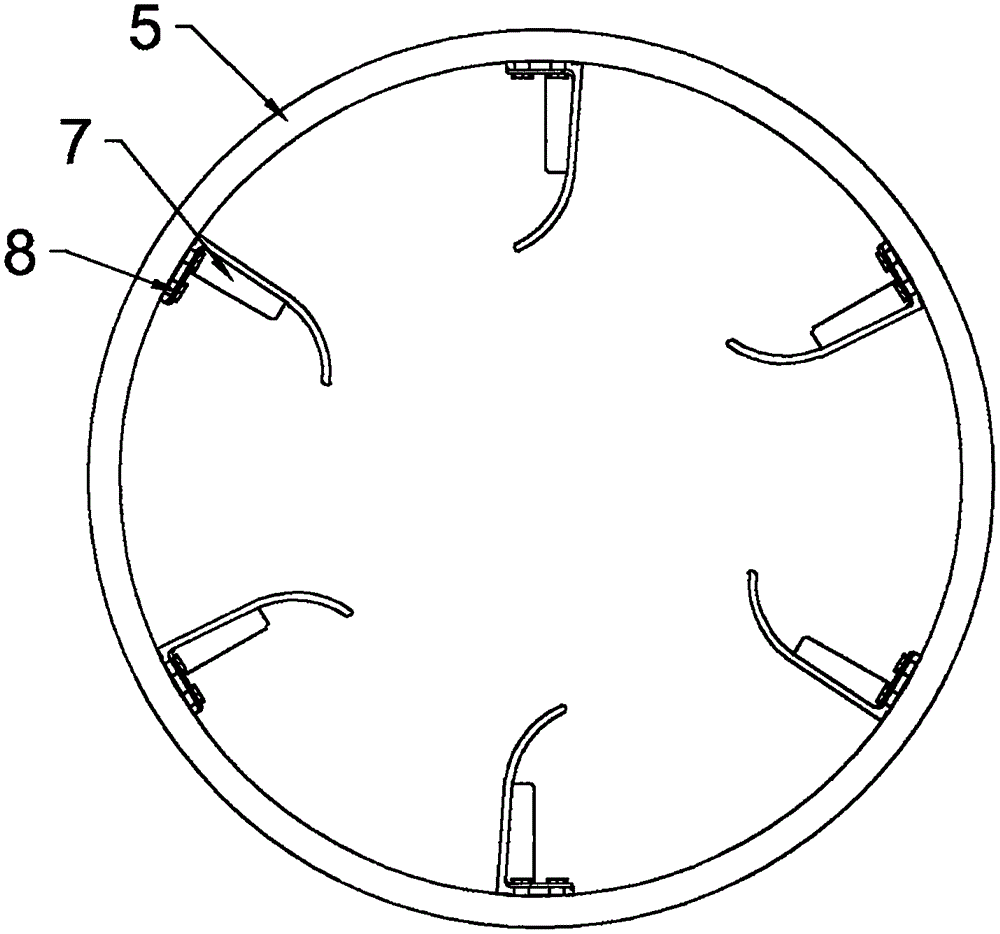

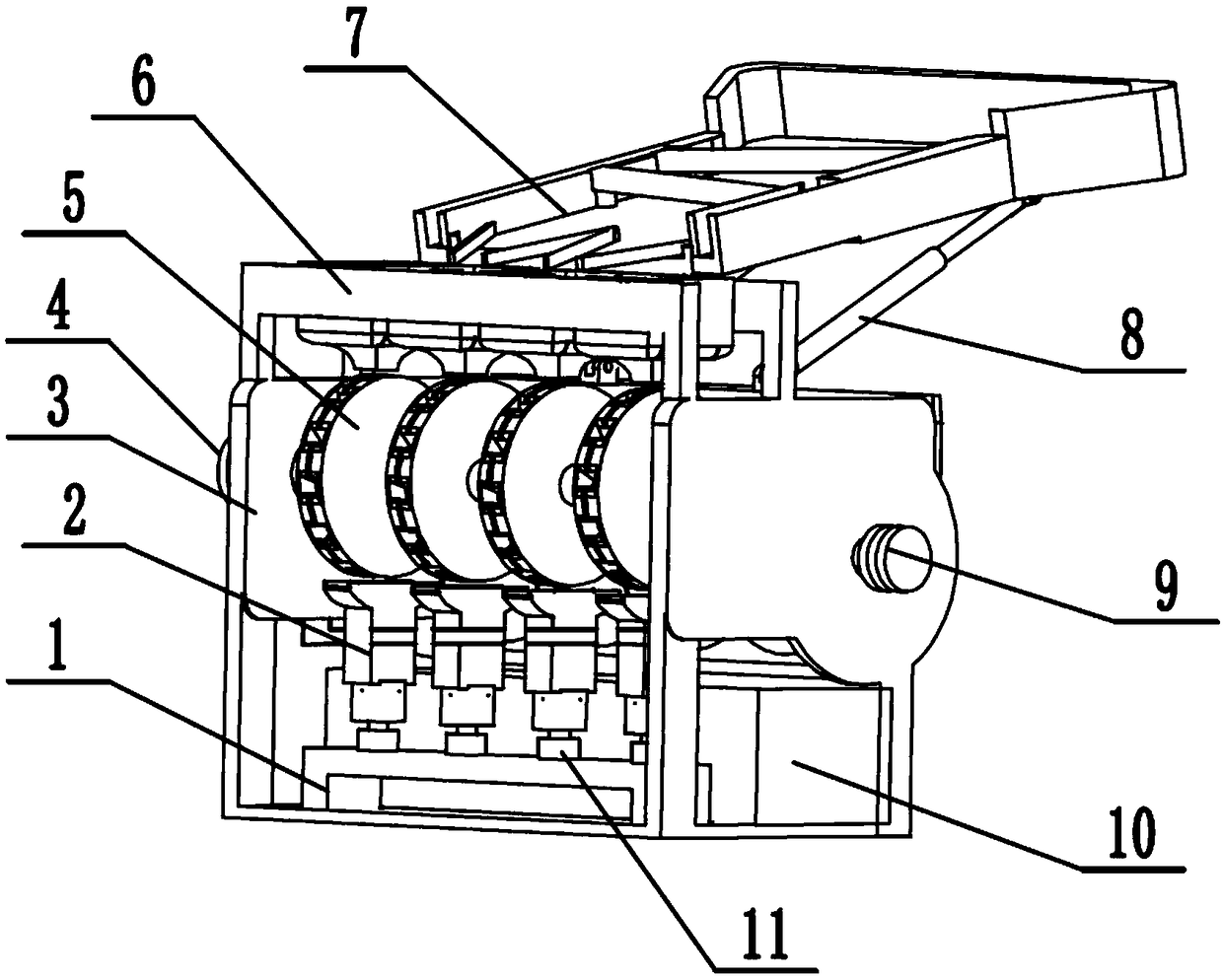

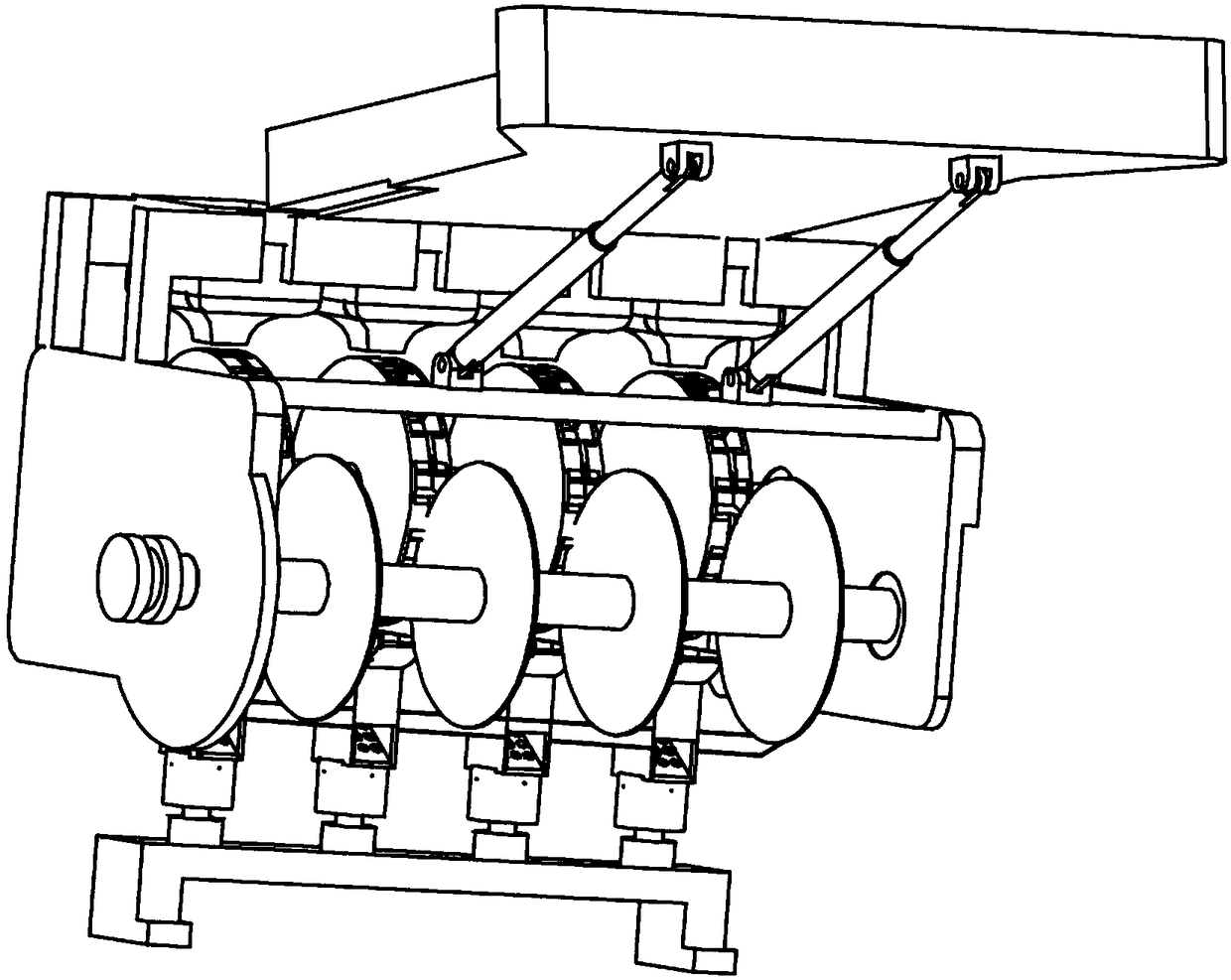

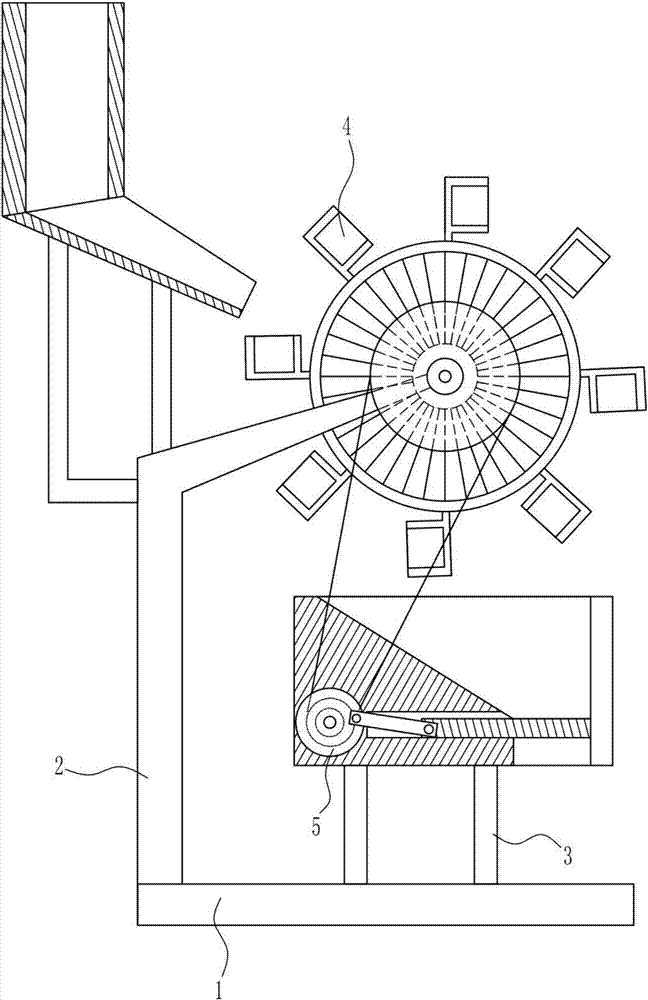

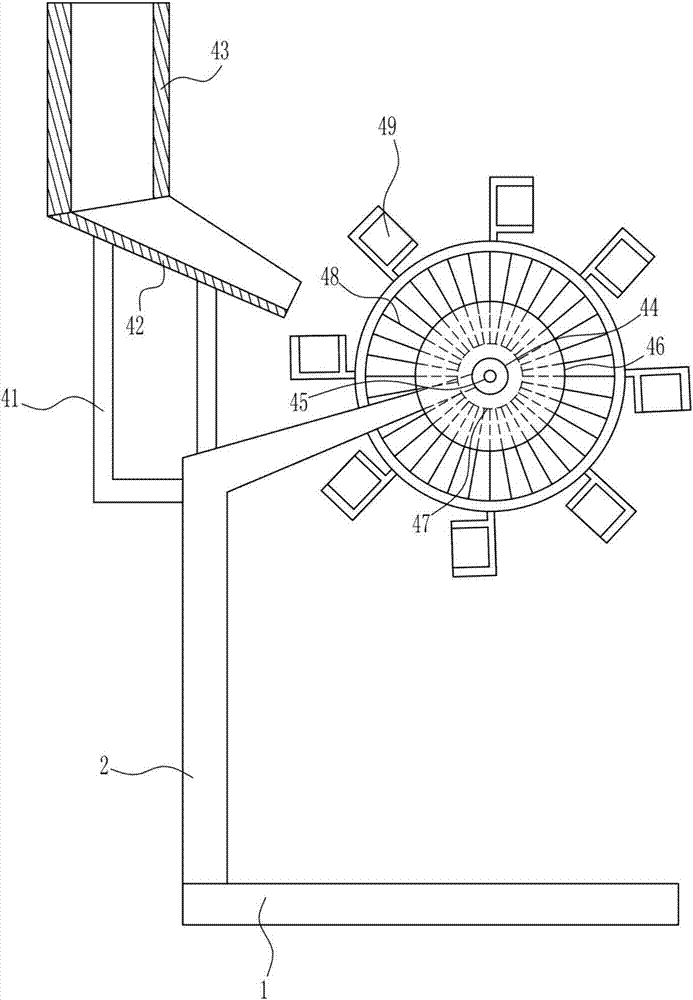

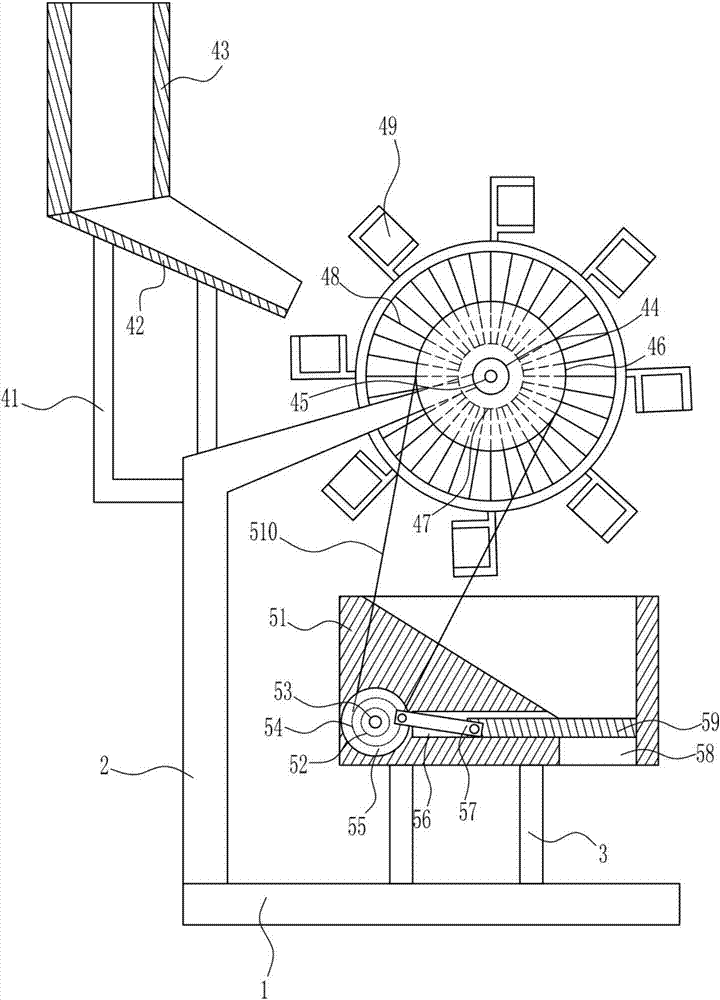

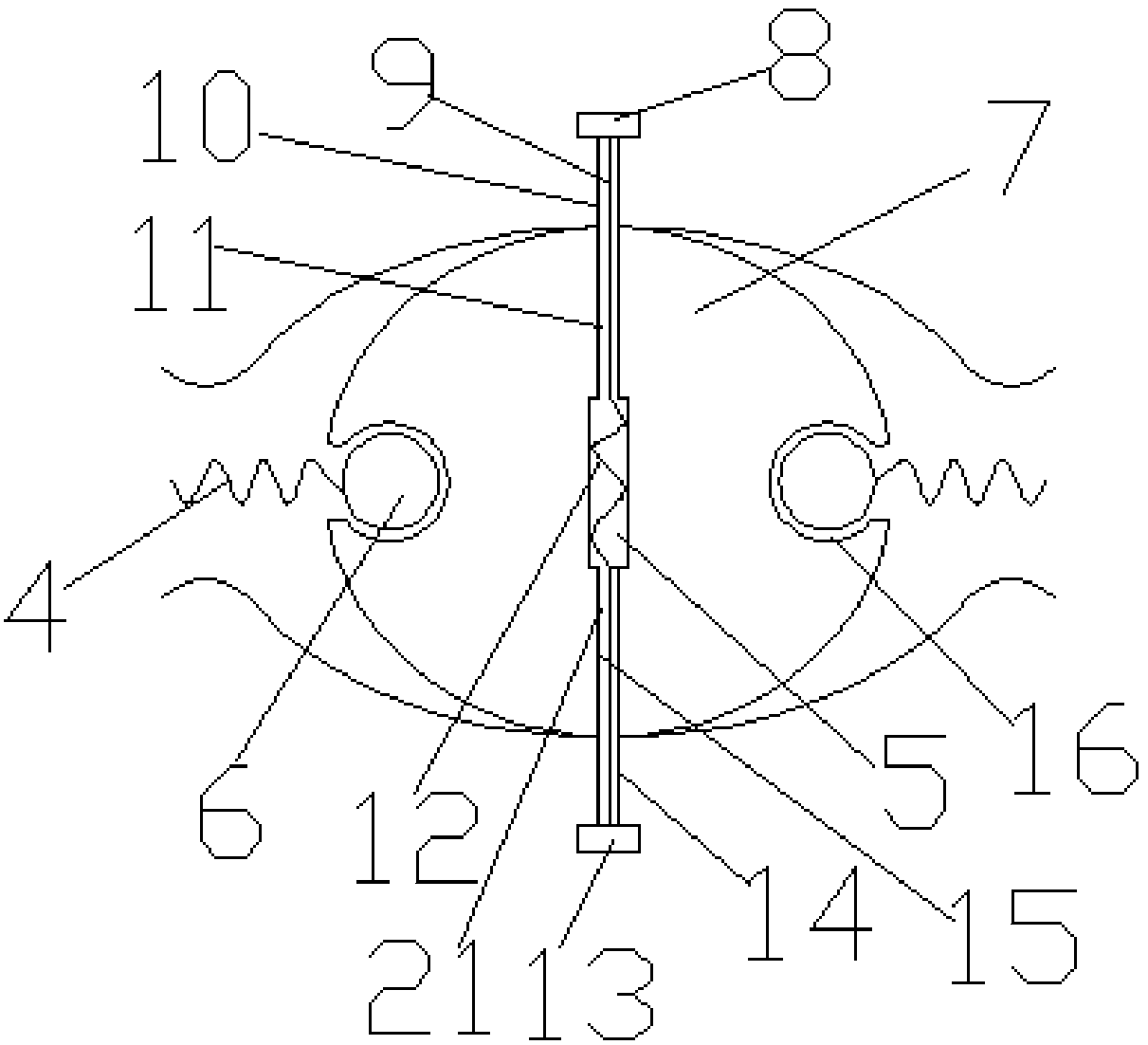

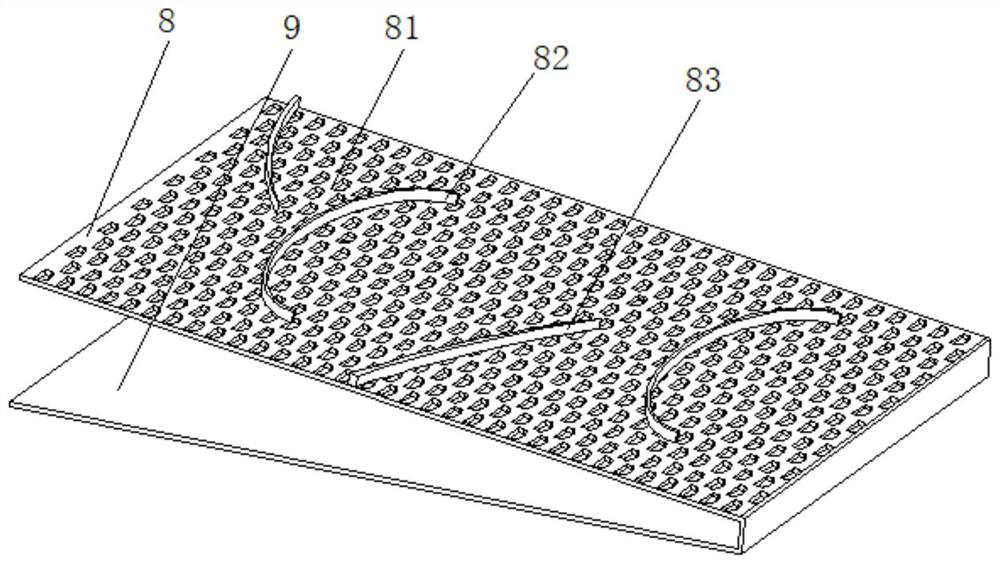

Opening device capable of automatically separating large macadamia nuts from small macadamia nuts

ActiveCN109329962AIncrease scrollingIncrease frictionHuskingHullingEngineeringMechanical engineering

The invention provides an opening device capable of automatically separating large macadamia nuts from small macadamia nuts, belongs to the field of nut processing equipment, and particularly relatesto a device which adopts rotating wheels having a special structure and a large and small macadamia nut separating device and cooperates with cutting knives to perform subpacking and cutting for opening the macadamia nuts. The opening device consists of a fan mounting frame, collectors, a mounting frame, a rotating wheel belt wheel, rotating wheels, a feeding box mounting frame, a macadamia nut separating machine, hydraulic pressure rods, a cutting knife belt wheel, a collecting box, fans, cutting knives, cutting knife shafts, a rotating wheel shaft and a feeding box. According to the openingdevice disclosed by the invention, macadamia nuts of different specifications are separated, and a manner of p opening the single macadamia nut is adopted, so that the opening efficiency of the macadamia nuts is greatly improved, and the cost is saved.

Owner:绍兴米苏机械设备有限公司

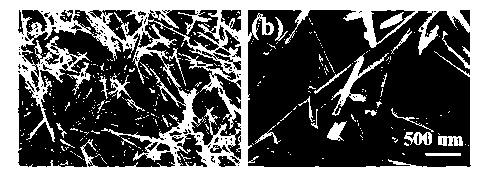

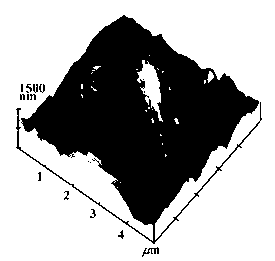

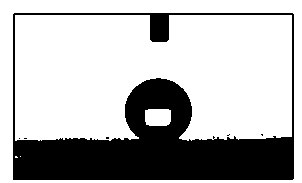

Preparation method of super-hydrophobic antimony sulfide coating

The invention discloses a preparation method of a super-hydrophobic antimony sulfide coating. The preparation method is characterized by comprising the following steps of: dissolving antimony trichloride and a sulfur precursor in a polyhydric alcohol solvent, reacting under a microwave condition, carrying out centrifugal washing on a product to remove a residual solvent, then carrying out ultrasonic dispersion in an absolute ethyl alcohol, carrying out spin-coating of dispersion liquid on a base material to obtain a uniform coating, finally steeping the coating in a stearic acid alcohol solution, taking and drying to obtain the super-hydrophobic antimony sulfide coating. The preparation method disclosed by the invention has the advantages of simple process, easiness in operation, good repeatability and suitability for mass production of super-hydrophobic coating.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Toy for rolling children toy glass balls

Owner:福建省德化县唯美玻璃有限公司

Multistage screening equipment for cherries

The invention discloses multistage screening equipment for cherries. The multistage screening equipment comprises a screening groove and a filtering plate, a discharging opening is formed in the innerwall of the screening groove, a first discharging port and a second discharging port are formed in the bottom of the screening groove, the bottom of the first discharging port and the bottom of the second discharging port are connected with a first collection pipeline and a second collection pipeline respectively, and a power assembly is arranged at the lower end of the screening groove. According to the multistage screening equipment, the problems that in the process of harvesting the cherries, workers manually screen the cherries through screens so that only the relatively few cherries canbe screened at a time through the method, the surfaces of the cherries cannot be damaged in the screening process, however, the efficiency is low, moreover, if secondary screening needs to be carriedout, the work also needs to be performed repeatedly, so that the collection time of the cherries is prolonged, and the workload of the workers is increased are solved.

Owner:王燕

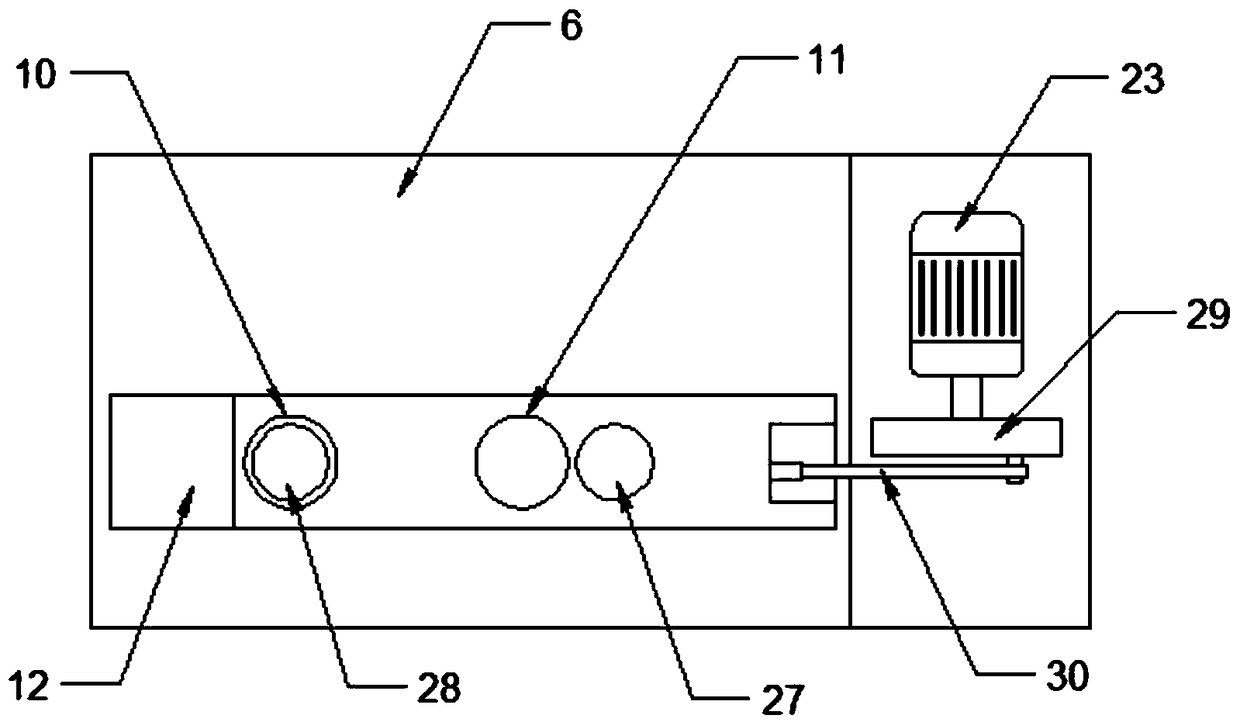

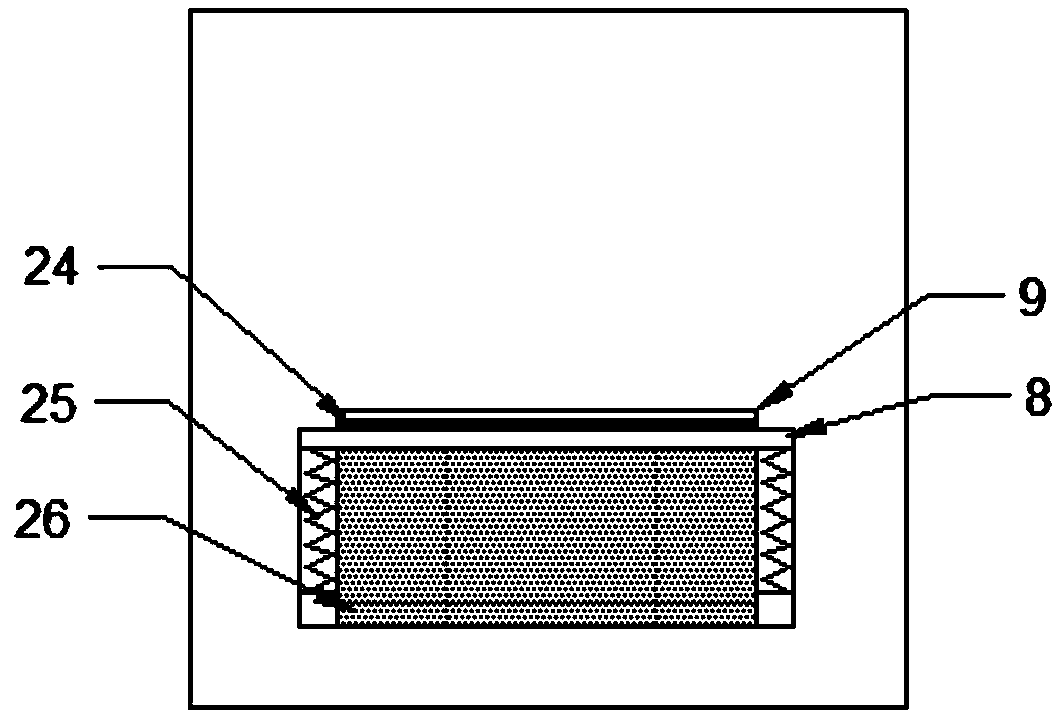

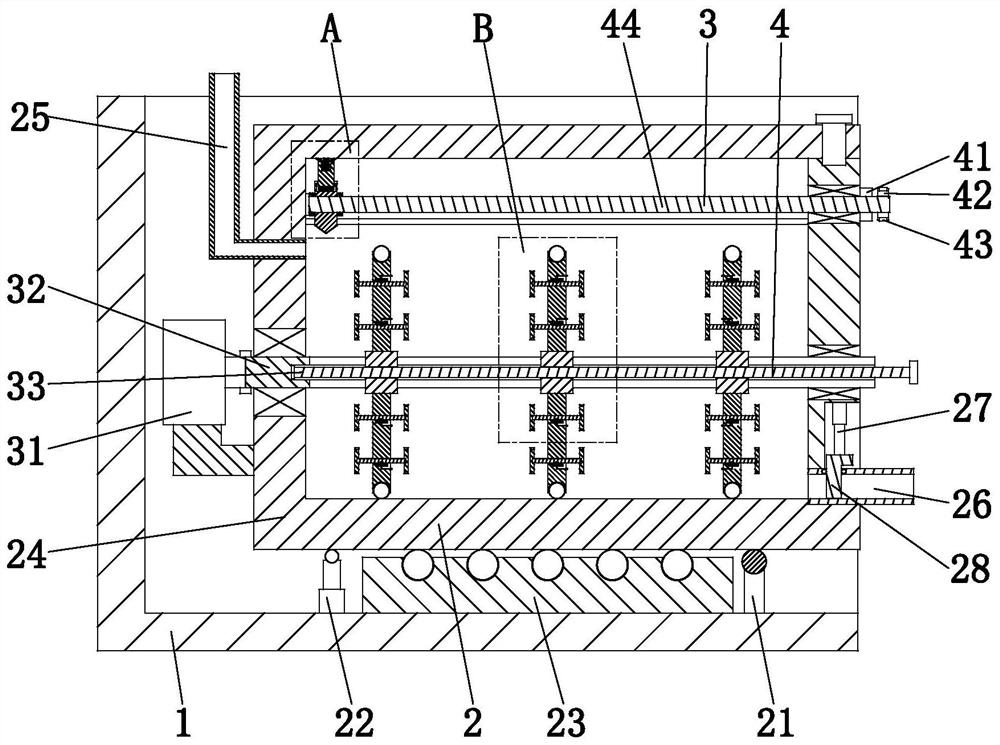

Polymer liquid glue preparation and processing technology

InactiveCN111672350AGuarantee the quality of useImprove cleanlinessRotary stirring mixersTransportation and packagingProcess engineeringPolymer

The invention provides a polymer liquid glue preparation and processing technology. A support, a box body module, a stirring module and a scraping module are matched to complete preparation and processing of polymer liquid glue. According to the invention, the problem that a large amount of raw materials need to be mixed and diluted in the manufacturing and processing process of the polymer liquidglue and then are fully stirred can be solved, however, in the mixing, diluting and stirring process of a large number of raw materials, due to the fact that the viscosity of the glue solution is increased along with prolonging of the stirring time, the viscosity of the glue solution is higher so that the glue solution is easily adhered to the inner wall of the upper end of the stirring box in the stirring process, the mixing property of the stirred glue solution in the stirring box is reduced, the glue solution adhered to the inner wall of the stirring box is more and more difficult to cleanalong with time extension, finally, the stirring box needs to be replaced, and the production cost of the glue solution is improved, and the thick glue solution is difficult to dump after being mixedand stirred in the stirring box, so that a large amount of the glue solution is left in a stirring box.

Owner:邹帅虎

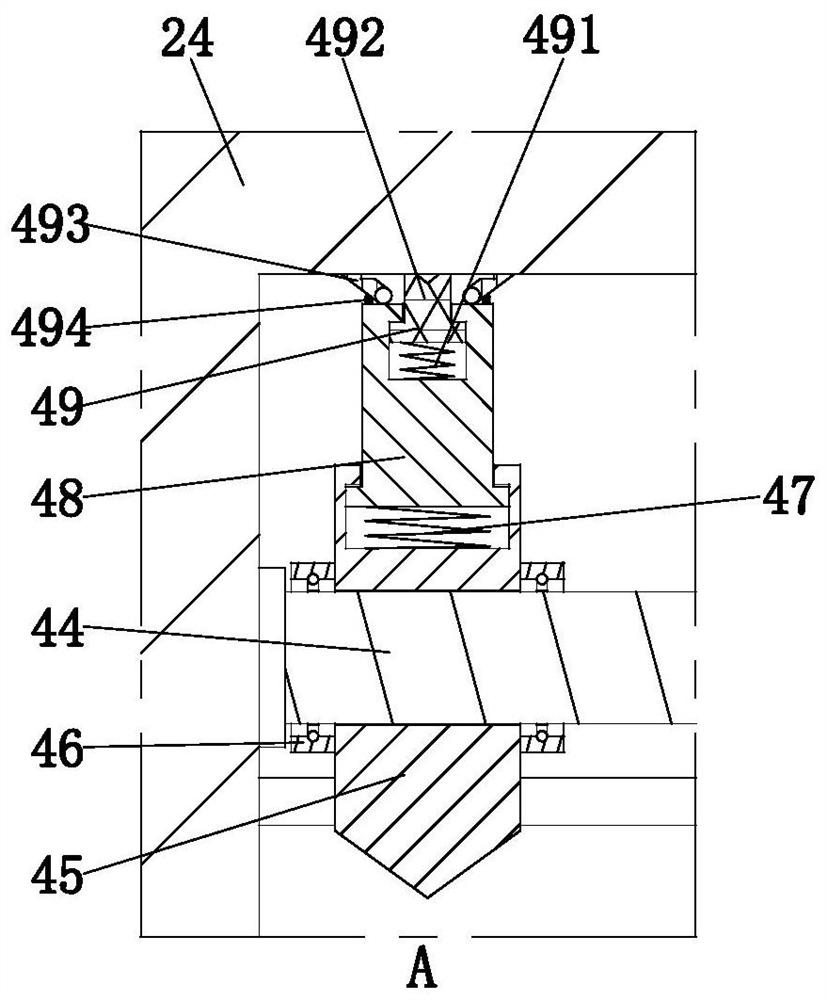

Anti-seismic quakeproof device for building

InactiveCN108018887AFree from twisting and collapsingNot easy to absorbProtective foundationEngineeringSeismic wave

The invention discloses an anti-seismic quakeproof device for a building. The anti-seismic quakeproof device for the building comprises a building foundation, an up-down separated upper base, a lowerbase arranged on the building foundation and an antitorque wave reducing device which is arranged between the lower base and the upper base and used for releasing seismic wave energy in the horizontaldirection. The upper surface of the upper base is fixedly provided with a buffer base. The antitorque wave reducing device is arranged between upper half oval arc faces and lower half oval arc faces.The antitorque wave reducing device comprises wave reducing oval bodies which can roll. The buffer base is provided with a plurality of storage grooves. The storage grooves are provided with buffer devices which release seismic wave energy in the vertical direction. By means of the arrangement of the antitorque wave reducing device and the buffer devices, the anti-seismic quakeproof device for the building can effectively absorb the energy of secondary waves and primary waves, the service life is long, the antitorque capacity is high, the building can be better prevented from seismic wave damage, and the upper building keeps more stable.

Owner:ANHUI POLYTECHNIC UNIV

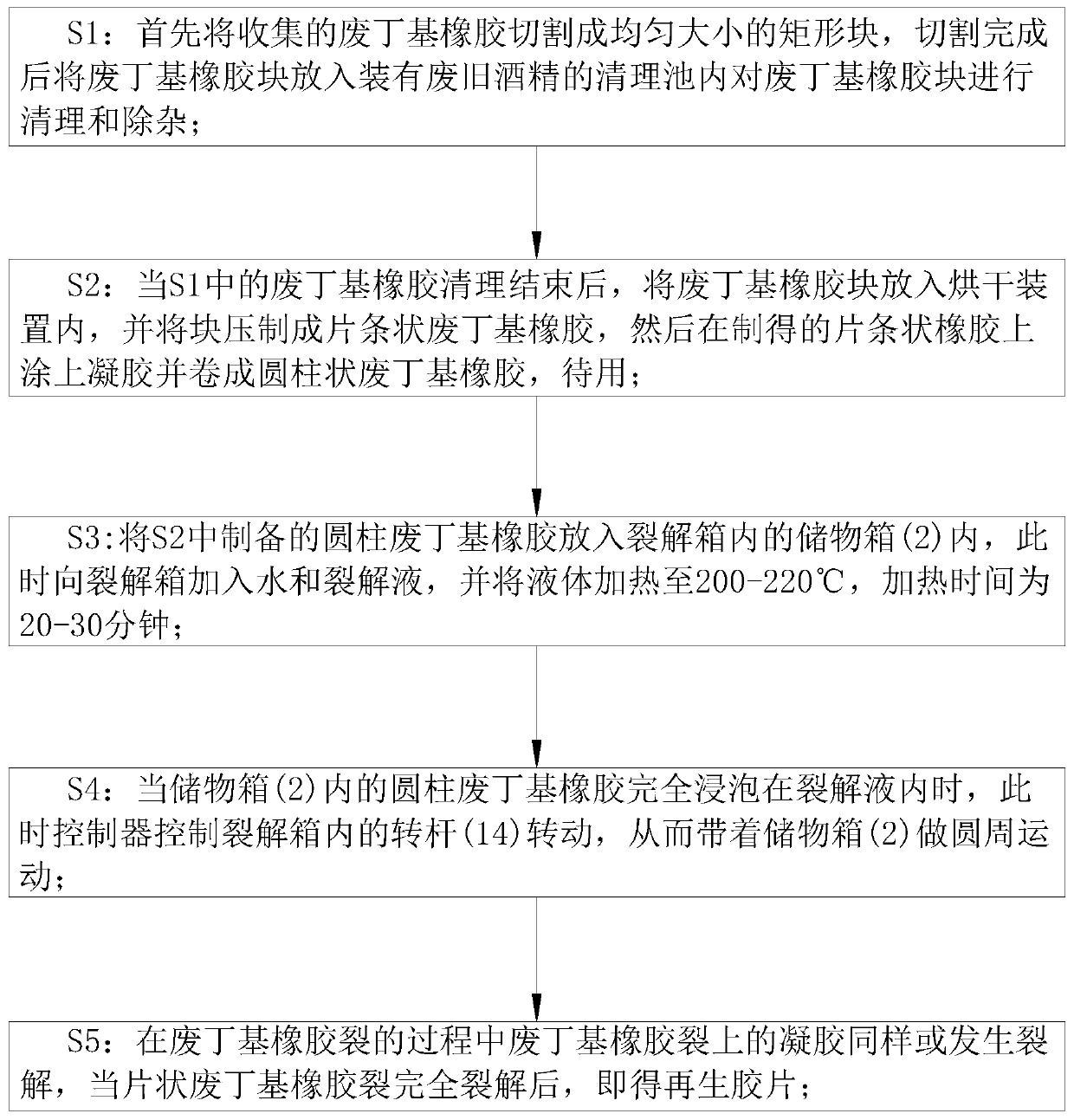

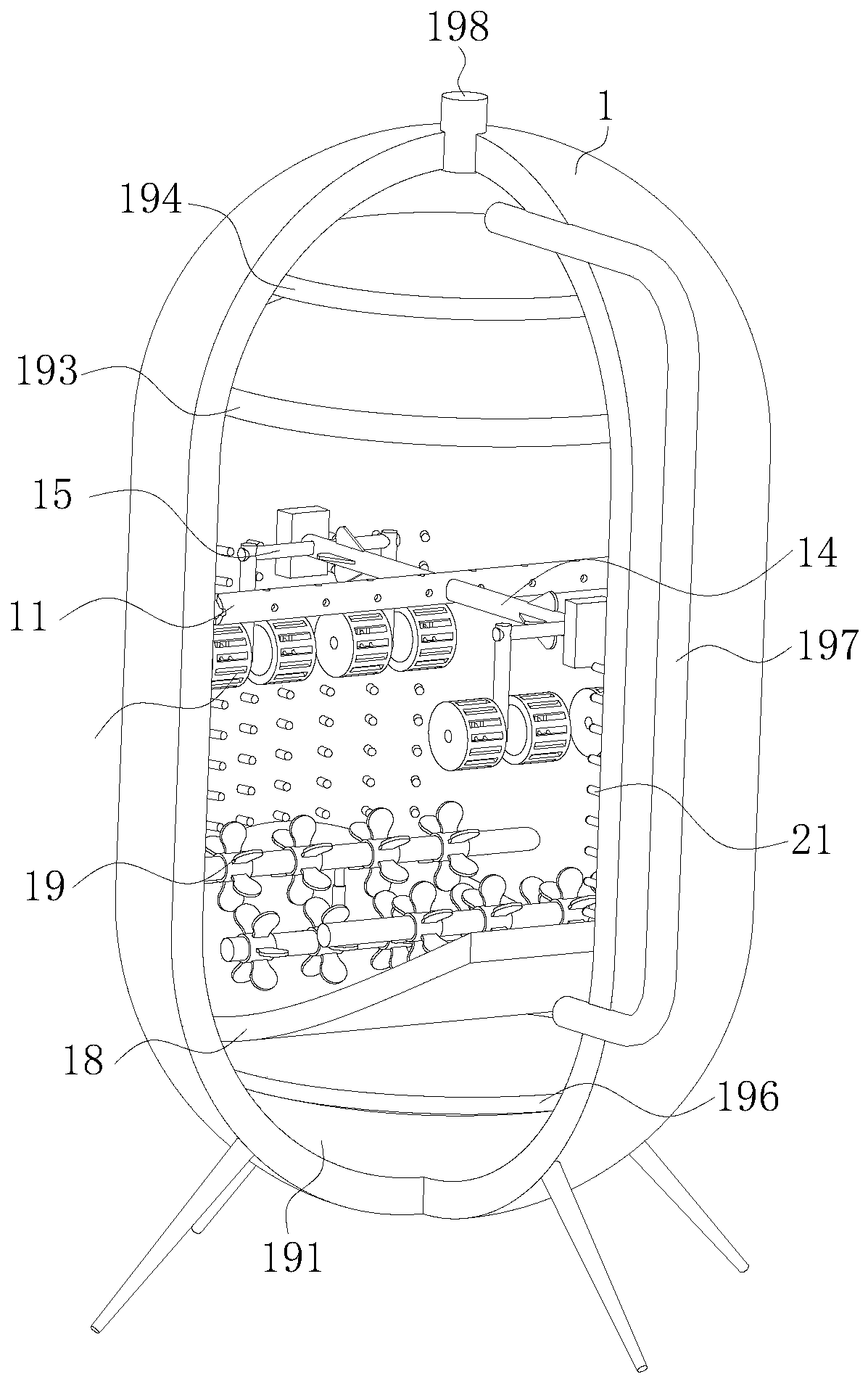

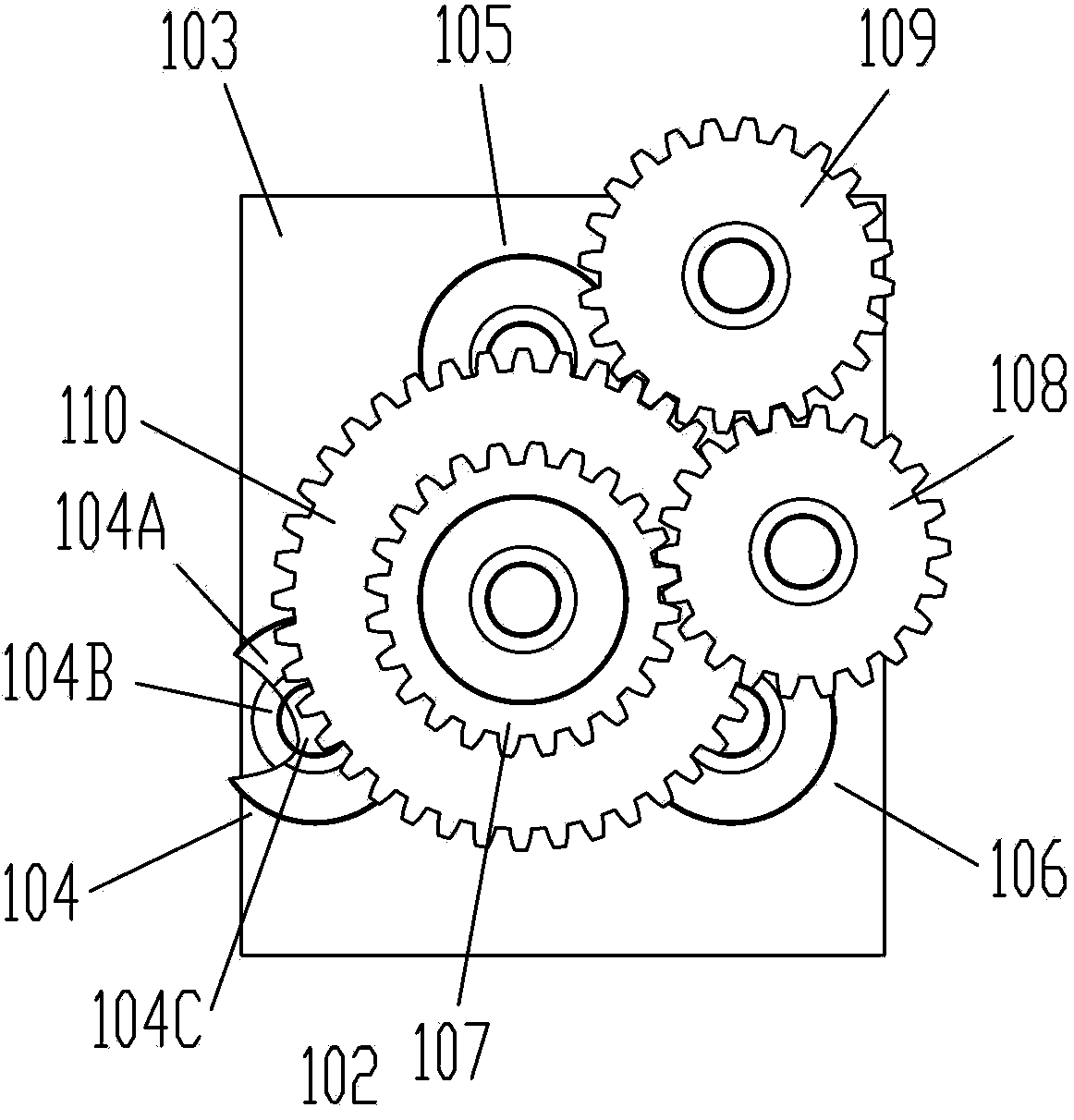

Cracking process of waste butyl rubber

InactiveCN111548530AAvoid accumulationDoesn't over crack the problemPlastic recyclingButyl rubberChemistry

The invention belongs to the technical field of cracking of waste butyl rubber, and particularly relates to a cracking process of waste butyl rubber. The cracking box comprises a box body; wherein a driving rod is rotationally connected into the inner wall of the box body through a motor; a circular groove is formed in the inner wall of the driving rod, and first through holes are uniformly formedin the inner wall of the circular groove; the outer surface of the driving rod is fixedly connected with rotating rods which are uniformly arranged, and the two rotating rods correspond to each other; the outer surface of each rotating rod is fixedly connected with a dorsal fin. According to the invention, the method is mainly used for solving the problems that during the pyrolysis process of waste butyl rubber in the prior art, the waste butyl rubber is usually directly put into a lysis solution, which may cause accumulation of the waste butyl rubber in the lysis solution, the cracking liquid can also precipitate and accumulate, so that the problems of partial excessive cracking and partial incomplete cracking of the waste butyl rubber are caused, and meanwhile, excessive cracking of thewaste butyl rubber can generate a large amount of harmful gas, so that the atmosphere and a water source can be polluted are solved.

Owner:陈一帆

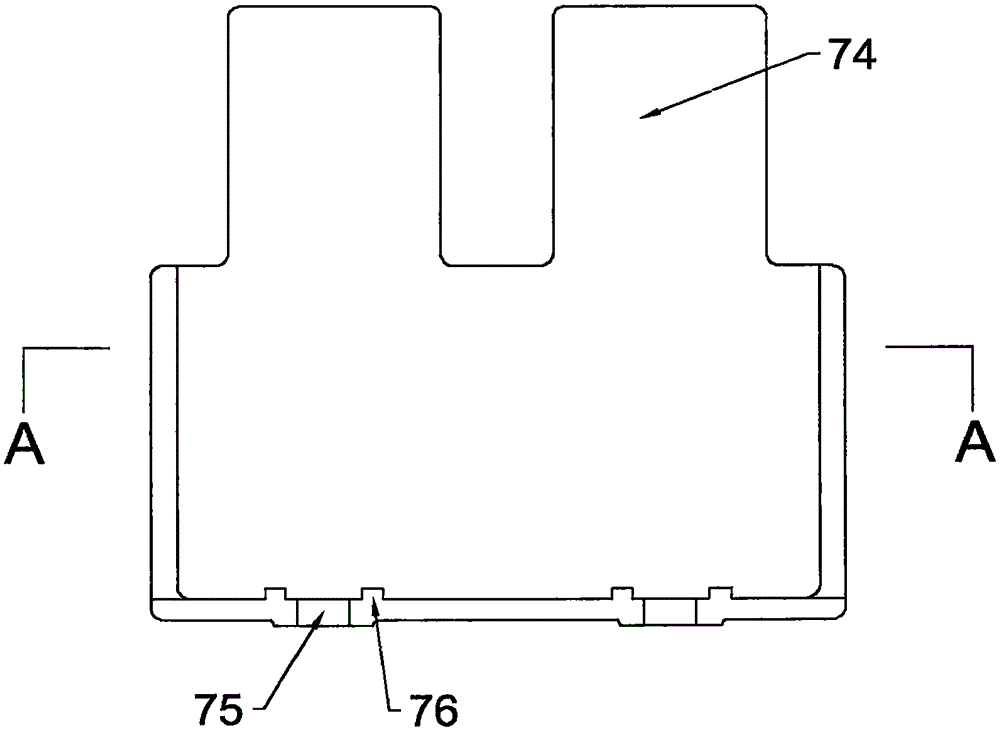

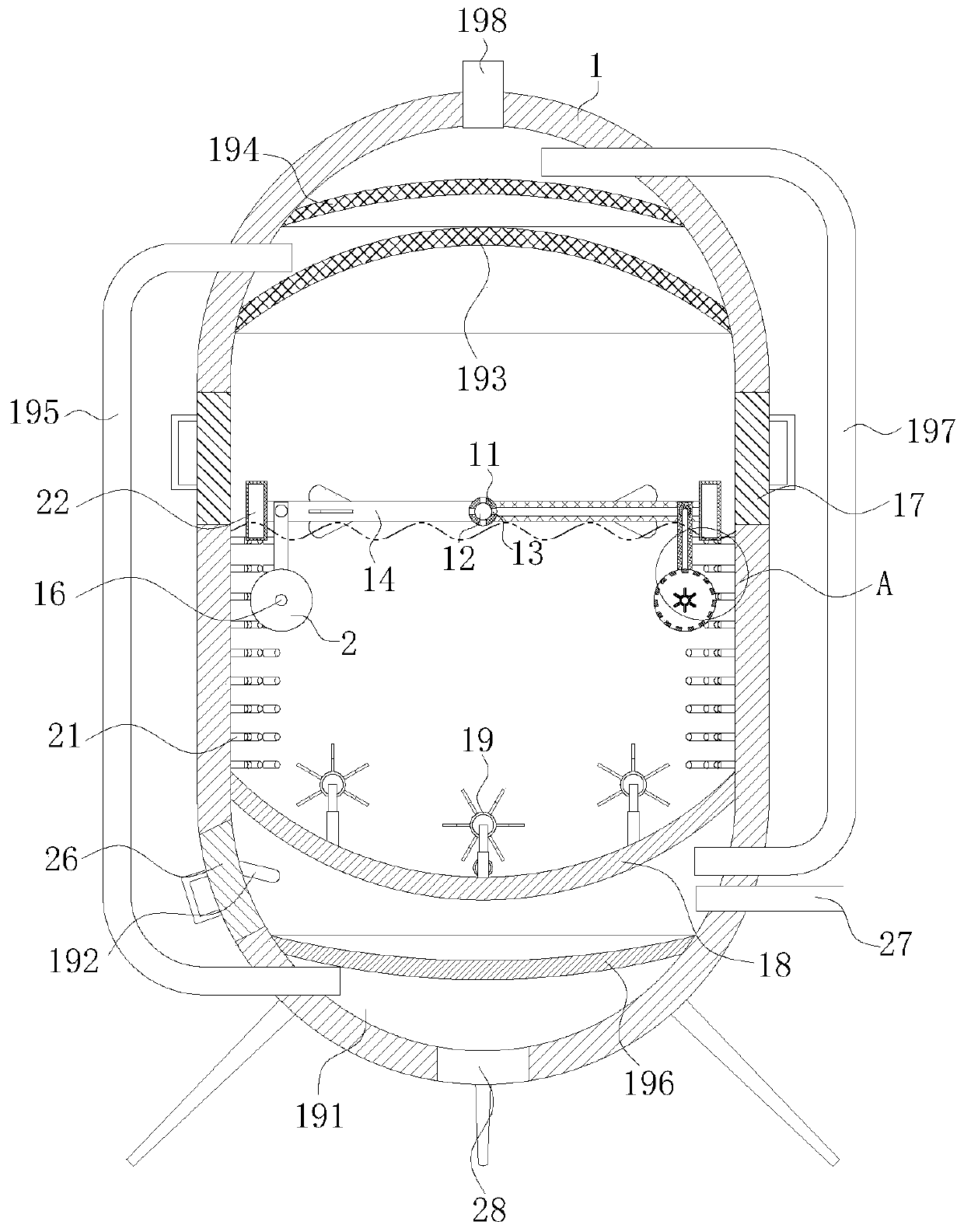

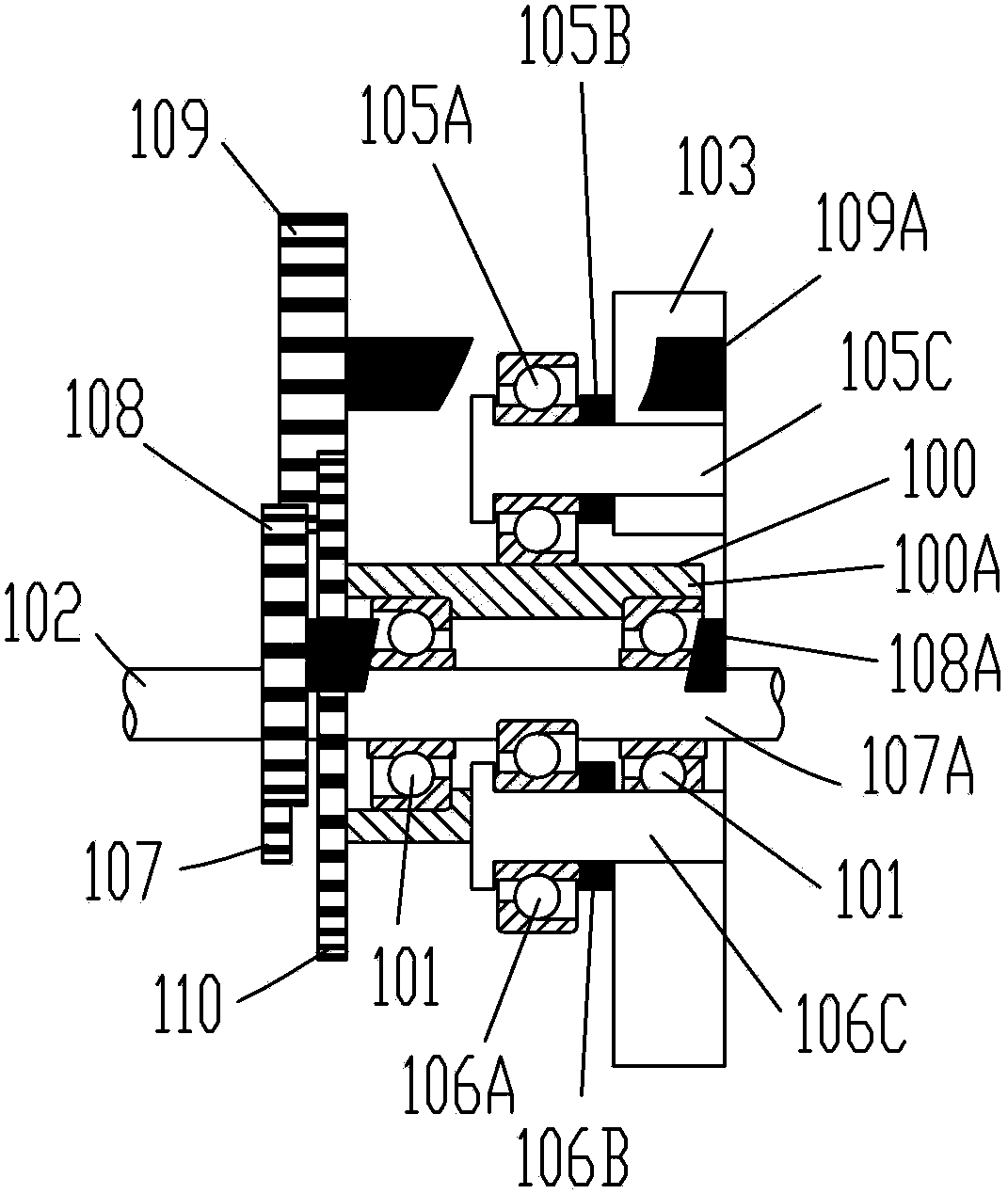

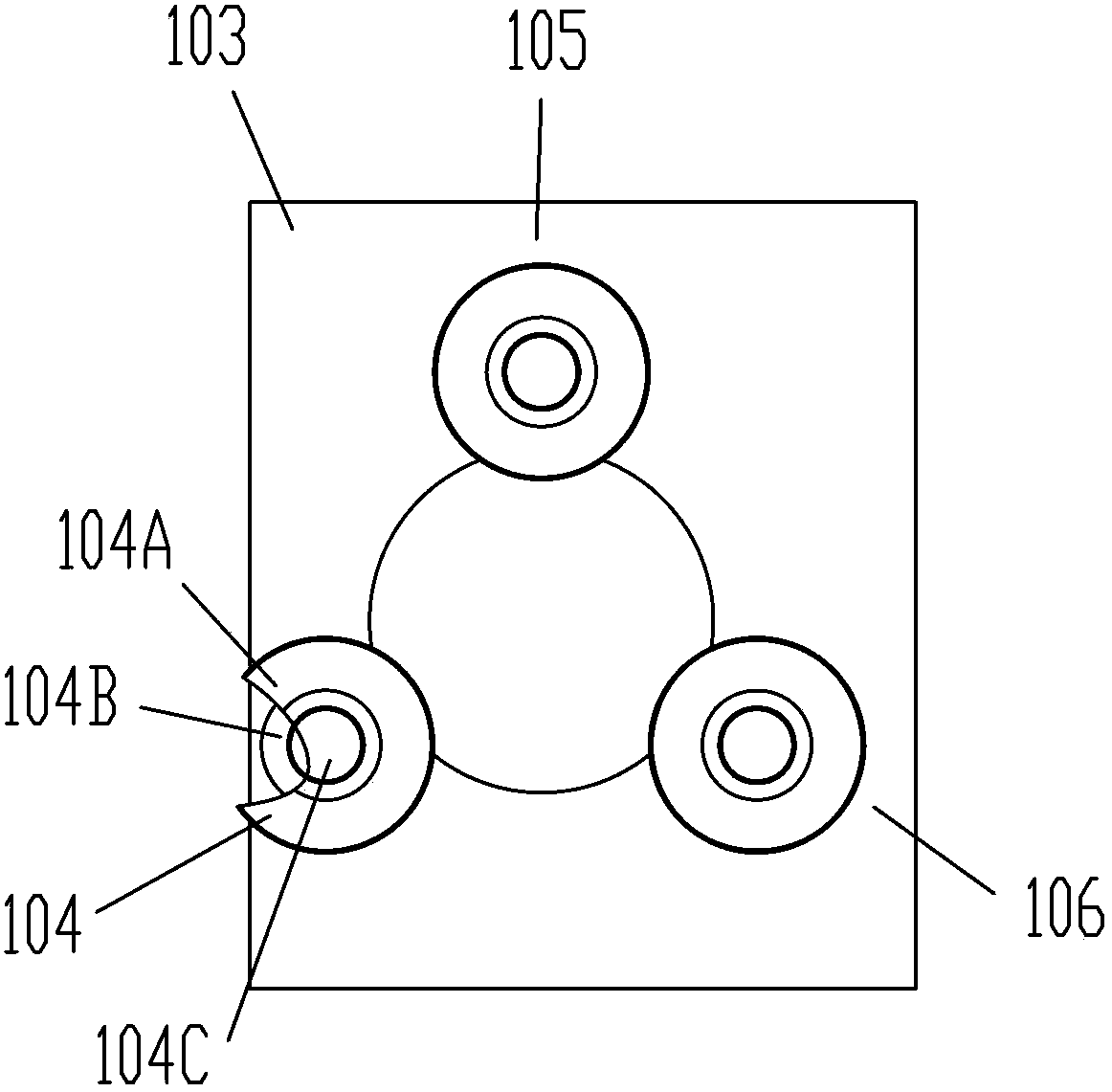

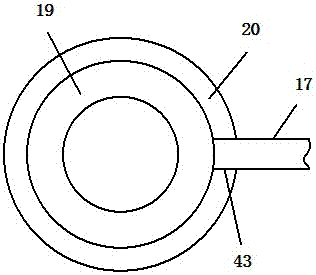

Mechanism for adjusting rotation directions and rotation speeds of inner ring and outer ring of rotation bearing

InactiveCN103511473AReduce slidingIncrease scrollingBearing assemblyBall bearingsMain bearingEngineering

The present invention relates to the field of transmission mechanisms, particularly to a mechanism capable of adjusting rotation directions and rotation speeds of an inner ring and an outer ring of a rotation bearing. The mechanism comprises a base (103), a main bearing set (100,130) penetrating through the base (103), a plurality of support rotation bearing (104,105,106) installed on the base (103) and positioned on the periphery of the main bearing set (100, 130), and a transmission mechanism, wherein the main bearing set (100, 130) comprises at least a main bearing (101,131), the main bearing (101, 131) comprises an inner ring (101E, 111) and an outer ring (101A, 112), the inner ring (101E or 111) and a shaft (102) are connected, the mechanism further comprises a plurality of rolling assemblies (101D) in an application of a contact type bearing, and the mechanism further comprises a fluid (115) in an application of a non-contact type bearing. According to the present invention, the transmission mechanism is additionally arranged in the rotation bearing, such that the inner ring and the outer ring of the bearing perform proper rotation.

Owner:刘复建

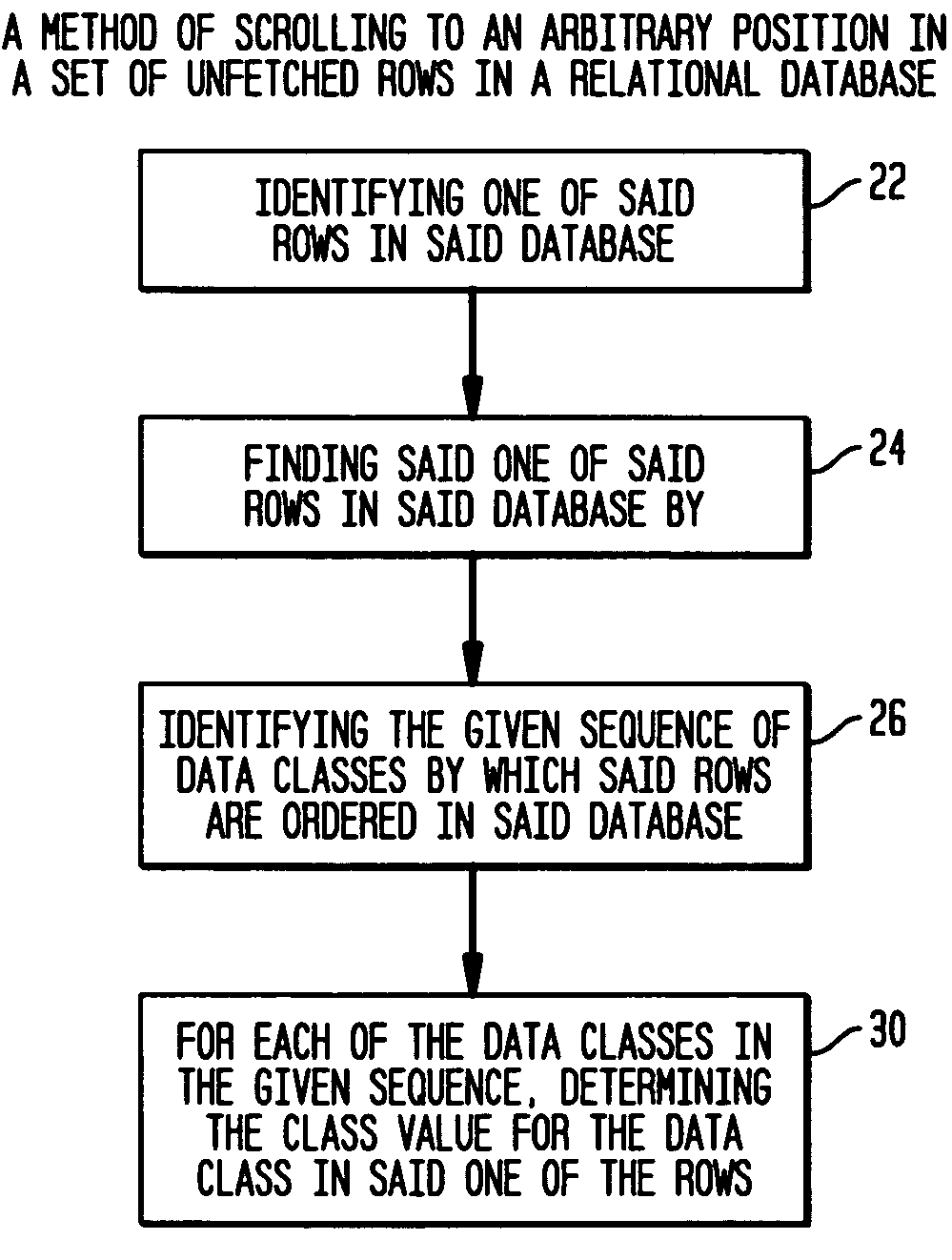

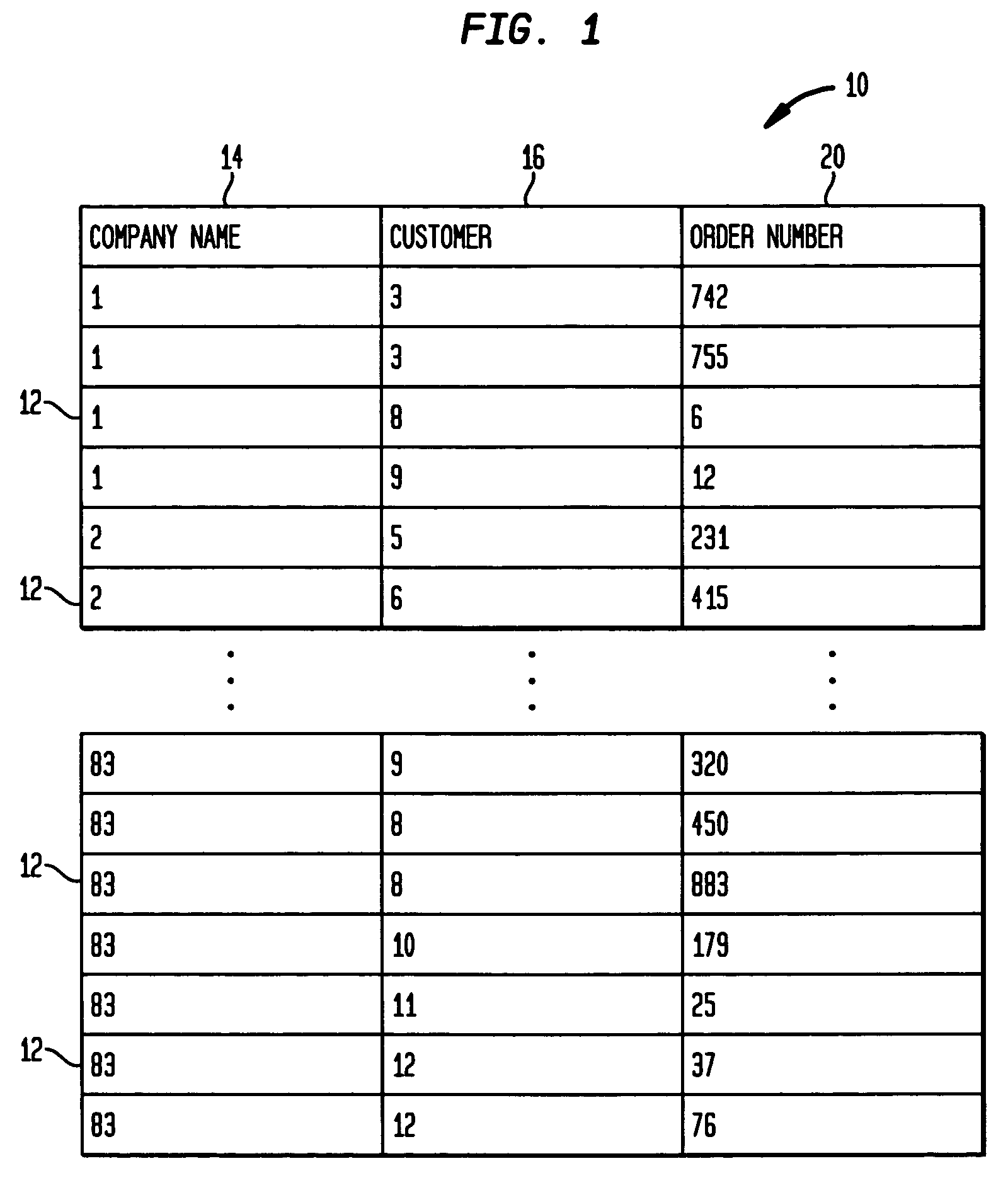

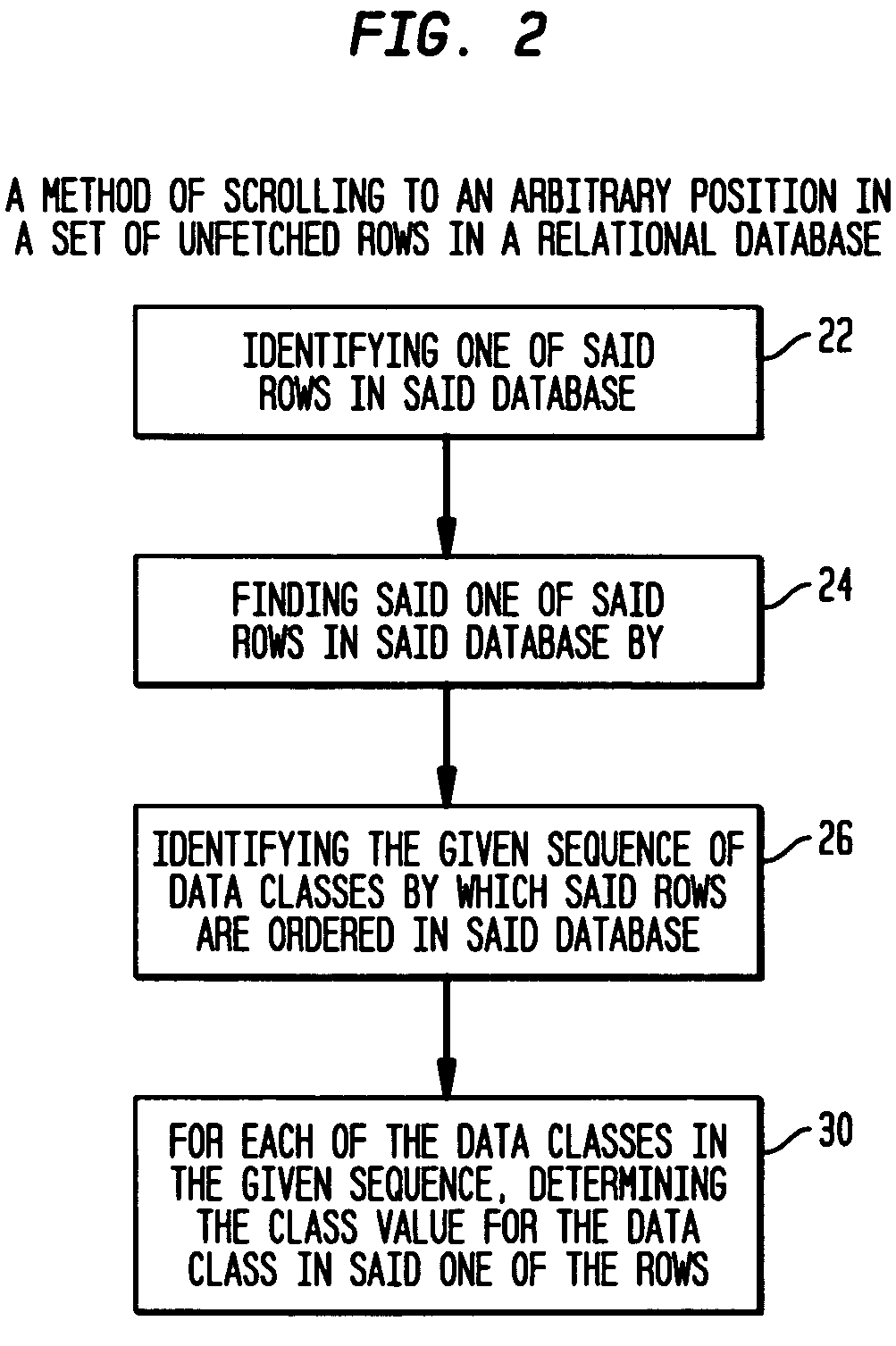

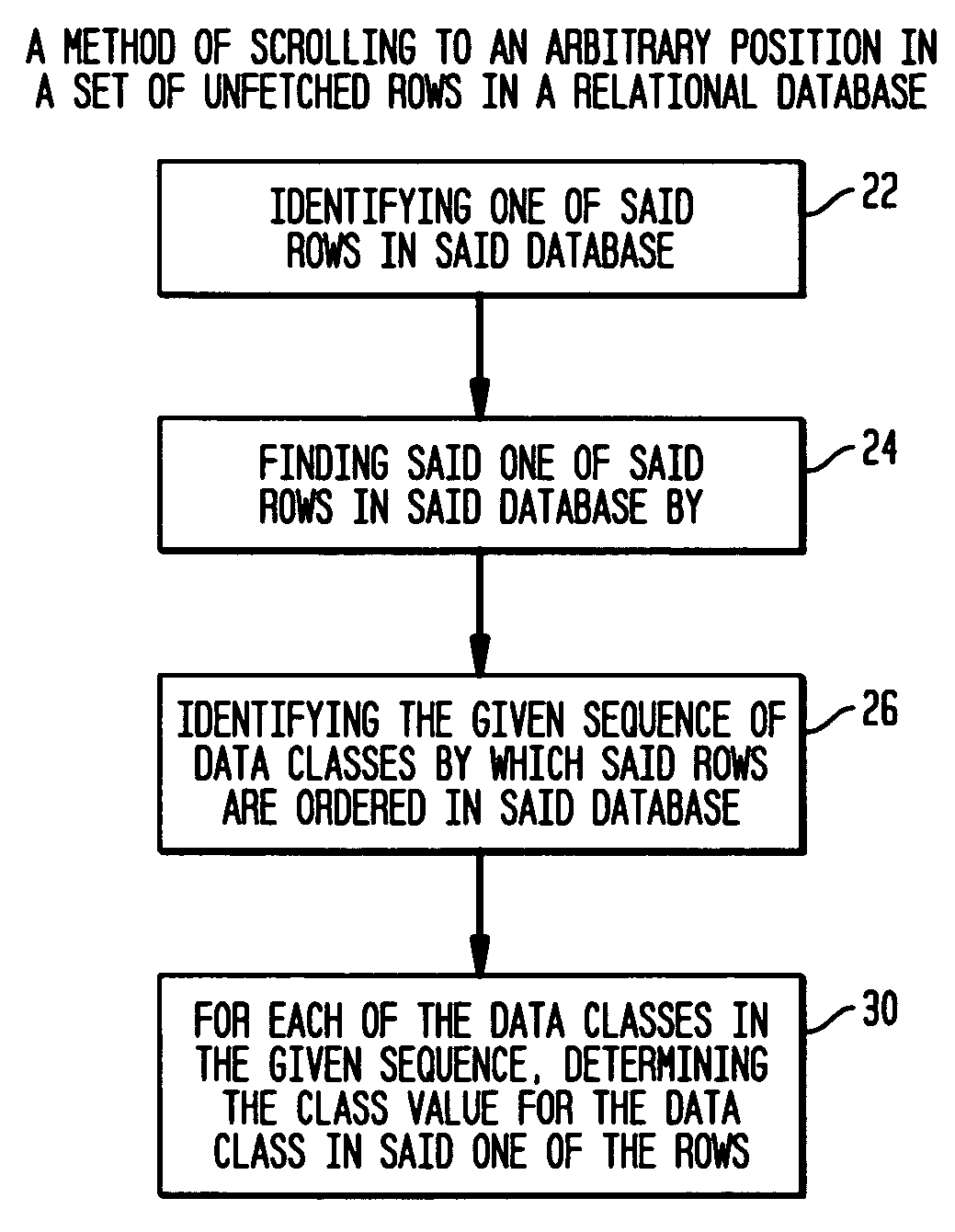

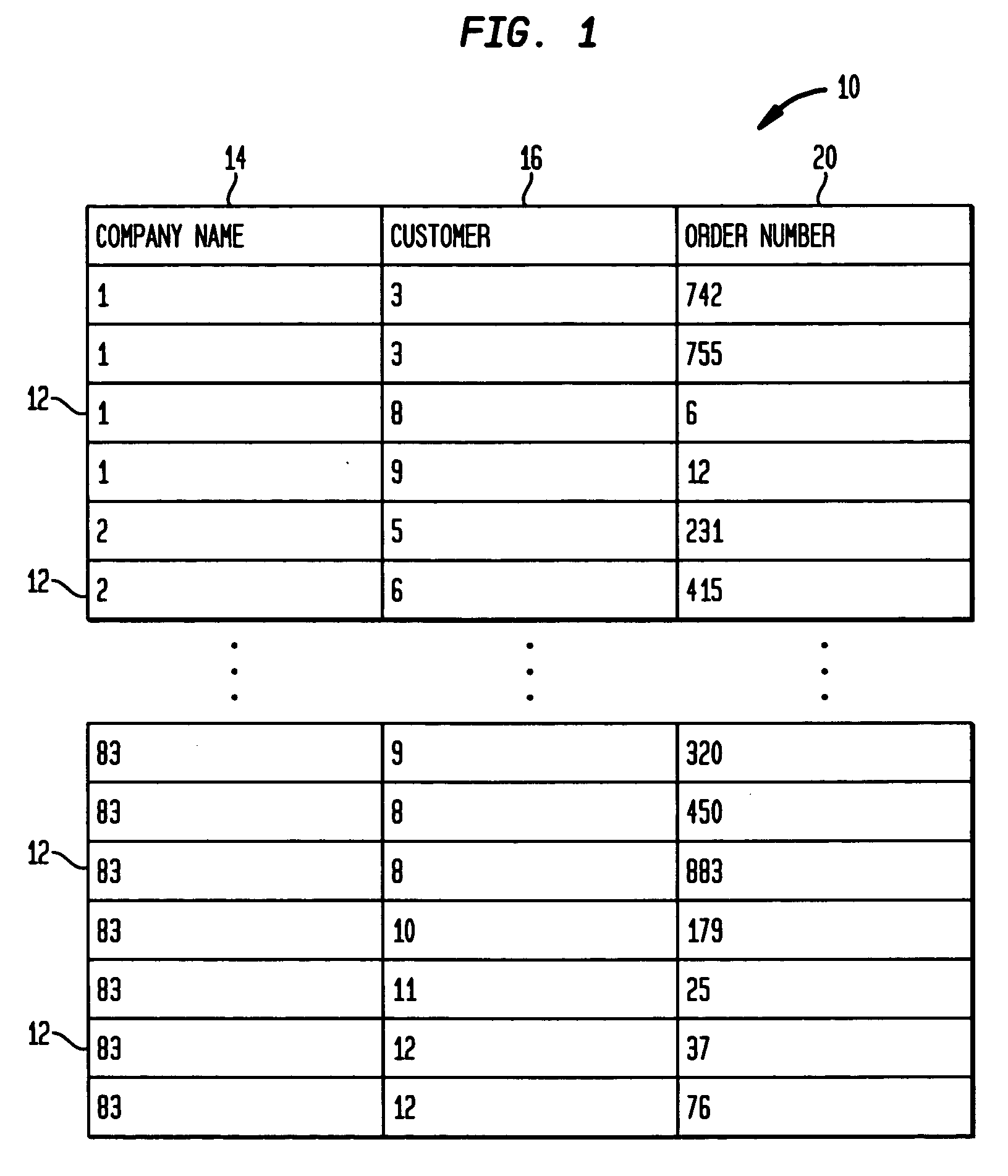

Advanced scrolling for relational database applications

InactiveUS7406463B2Increase scrollingReduce in quantityData processing applicationsDigital data information retrievalData classRelational database

Disclosed are a method, a system and a computer program for scrolling to an arbitrary position in a set of unfetched rows of data in a relational database. Each of the rows has a plurality of columns and a class value in each of the columns. Also, each column of the set of rows of data has class values for a specified data class, and the rows are ordered according to a given sequence of these classes. The method of this invention, preferably, comprises the steps of identifying one of the rows in the database, and finding that one of the rows by identifying the given sequence of data classes by which the rows are ordered, and for each of the data classes in the given sequence, determining the class value for the data class in the identified one of the rows.

Owner:INT BUSINESS MASCH CORP

Advanced scrolling for relational database applications

InactiveUS20060095409A1Increase scrollingReduce in quantityData processing applicationsDigital data information retrievalData classRelational database

Disclosed are a method, a system and a computer program for scrolling to an arbitrary position in a set of unfetched rows of data in a relational database. Each of the rows has a plurality of columns and a class value in each of the columns. Also, each column of the set of rows of data has class values for a specified data class, and the rows ore ordered in the set according to a given sequence of these classes. The method of this invention, preferably, comprises the steps of identifying one of the rows in the database, and finding that one of the rows by identifying the given sequence of data classes by which the rows are ordered in the database, and for each of the data classes in the given sequence, determining the class value for the data class in the identified one of the rows. These rows may be ordered for purposes of a query in the database. Preferably, values of the data classes in the identified one of the rows are themselves determined, one data class at a time, and in the order in which the data classes occur in the given sequence.

Owner:IBM CORP

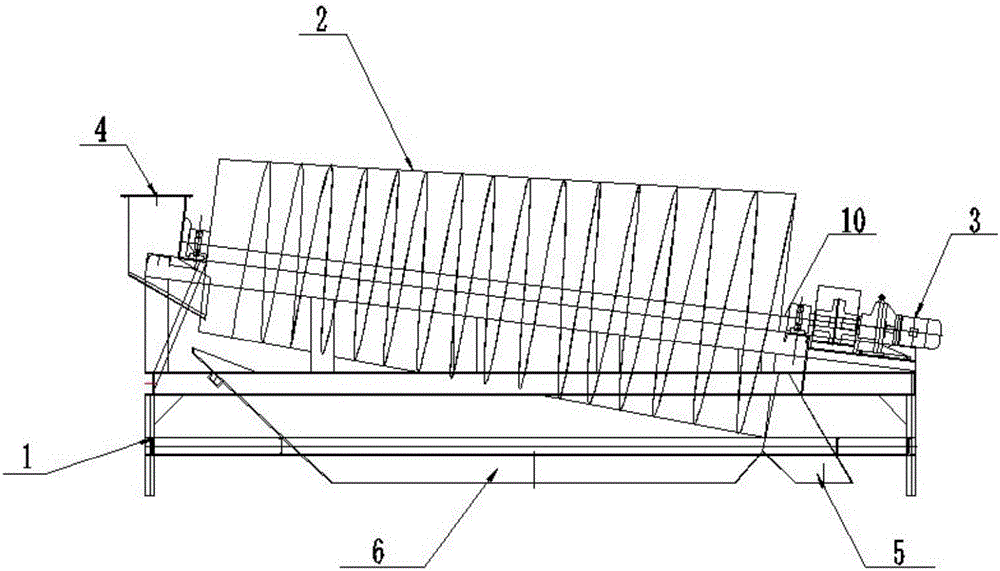

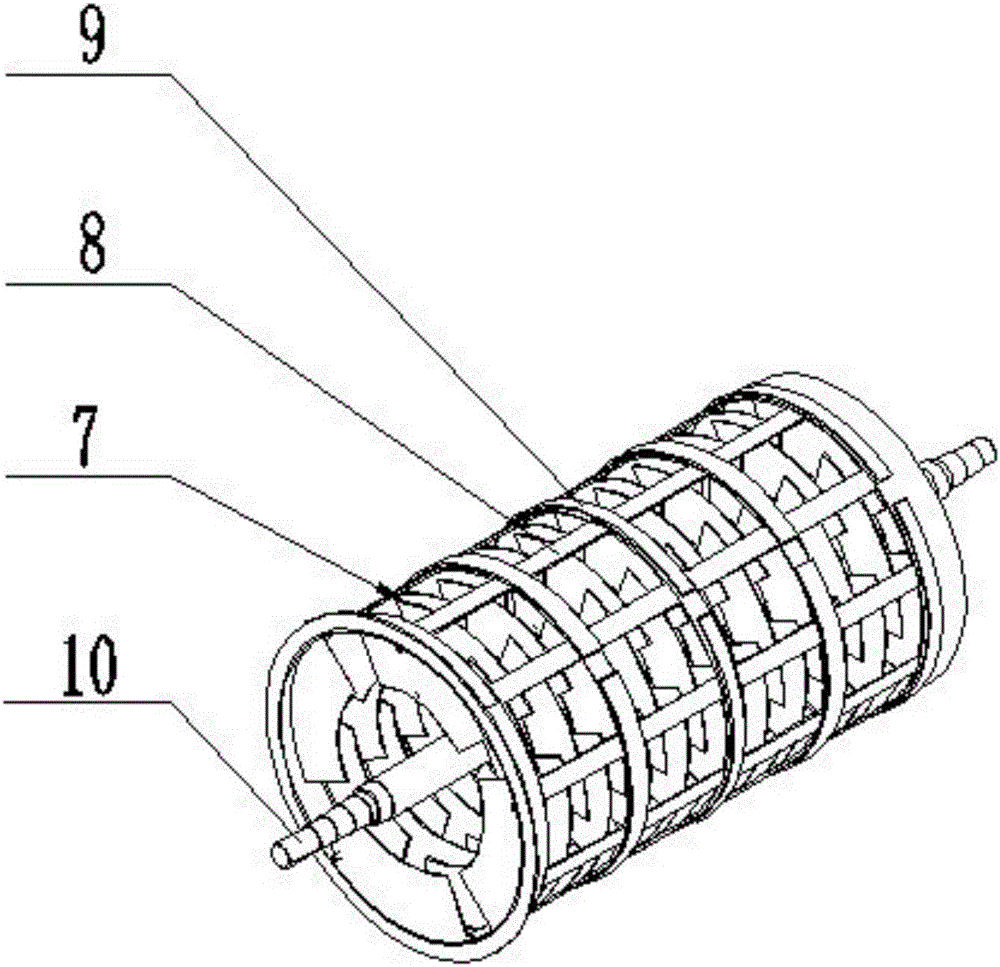

Novel solid wrapping slurry removing equipment

The invention relates to novel solid wrapping slurry removing equipment. The novel solid wrapping slurry removing equipment comprises a rack, a barrel, a rotary shaft, and a driving device arranged on the rack. The driving device is connected with the rotary shaft and used for driving the rotary shaft to rotate. The barrel is fixed to the rotary shaft to enable the barrel to rotate around the rotary shaft, the barrel and the horizontal plane are arranged obliquely, and the barrel is used for containing solids to be subjected to wrapping slurry removal; a feed port is formed in one end of the barrel, a first discharge port is formed in the other end of the barrel, and the position of the feed port is higher than that of the first discharge port. A second discharge port is formed in the side, close to the horizontal face, of the outer wall of the barrel. Wrapping slurry in the solids can be separated, the solids with the wrapping slurry removed are convenient to recycle, and the wrapping slurry is conveniently subjected to resource reuse.

Owner:HENAN WINNER VIBRATING EQUIP

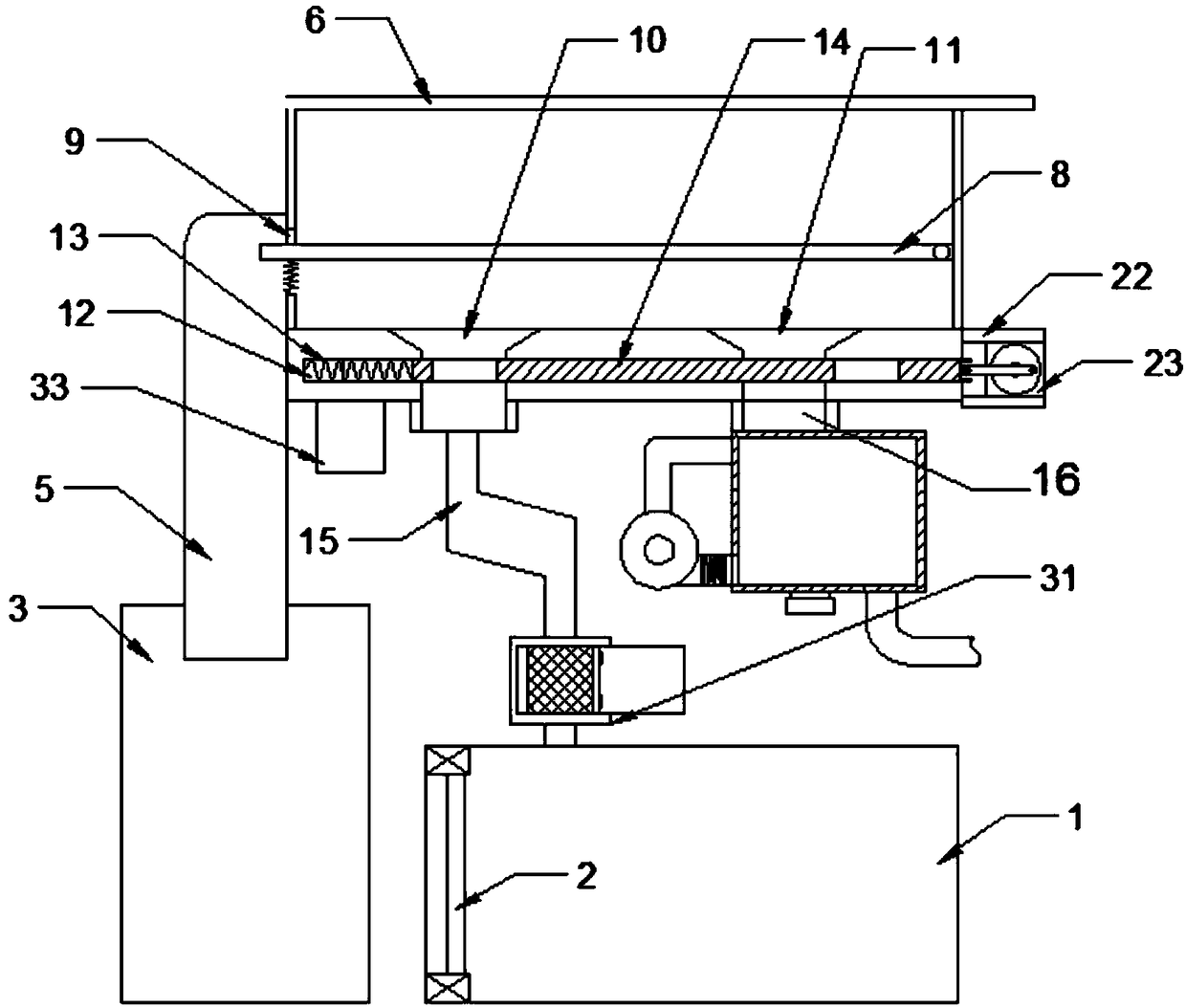

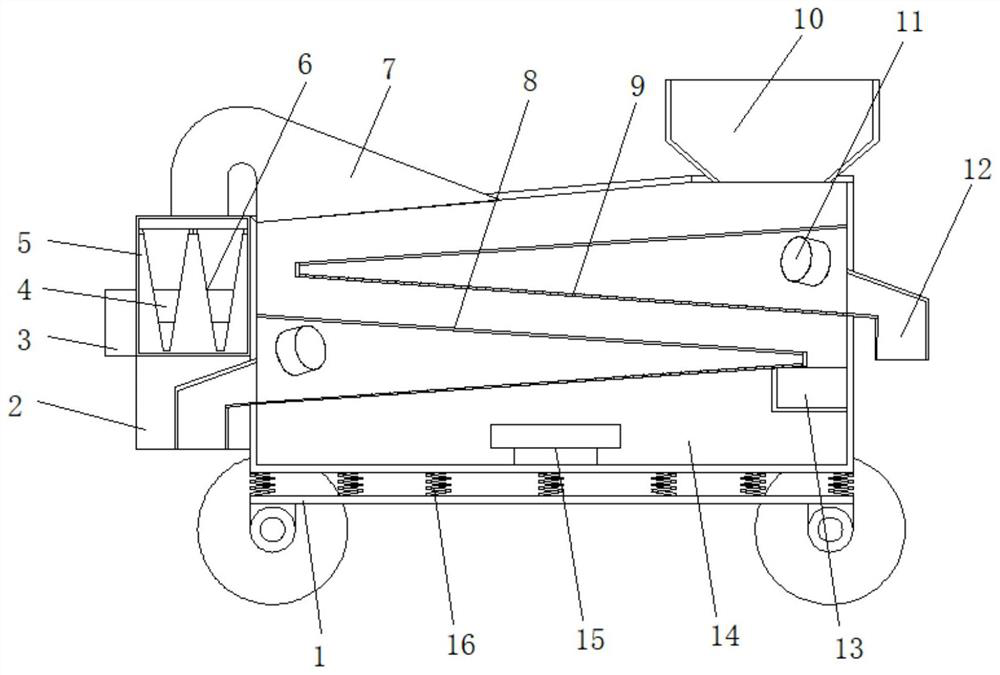

Wheat impurity removing device for agricultural machinery

InactiveCN112191524AImprove vibrationImprove screening efficiencySievingGas current separationAgricultural scienceAgricultural engineering

The invention discloses a wheat impurity removing device for agricultural machinery, and relates to the technical field of agriculture. The wheat impurity removing device for the agricultural machinery aims to solve the problems that harvested wheat contains wheat awn, gravel and other impurities, the wheat needs to be manually raised for impurity removal, and the labor intensity is high. The wheat impurity removing device for the agricultural machinery specifically comprises a base, wherein a plurality of springs are fixedly installed at the top of the base, a box body is fixedly installed among the top ends of the springs, a feeding box is fixedly installed at the top end of the box body, a discharging pipe is fixedly installed on the side face of the box body, and a plurality of screenplates and supporting plates are fixedly installed in the box body and are alternately arranged. Wind force is generated between the screen plates and the supporting plates in the box body, bran and dust among wheat can be removed by means of the wind force, the wind blows upwards from the lower sides of the screen plates, vibration of the wheat is accelerated while impurities are removed, so thatthe impurity removing efficiency is improved, the possible blocking phenomenon of meshes of the screen plates is avoided, and the impurity removal efficiency of the device is improved.

Owner:马建龙

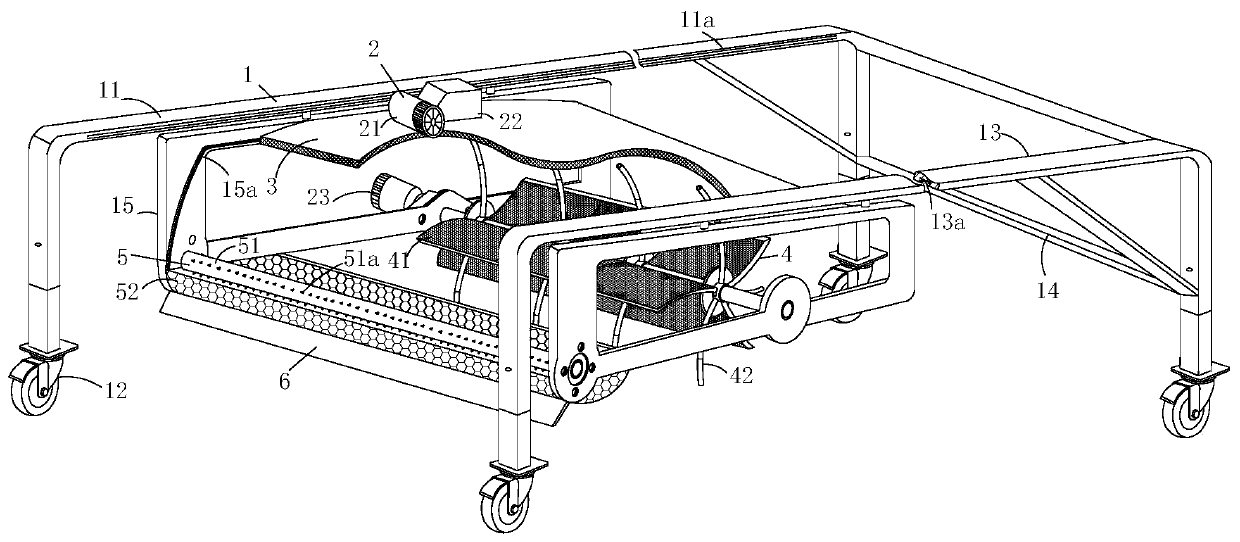

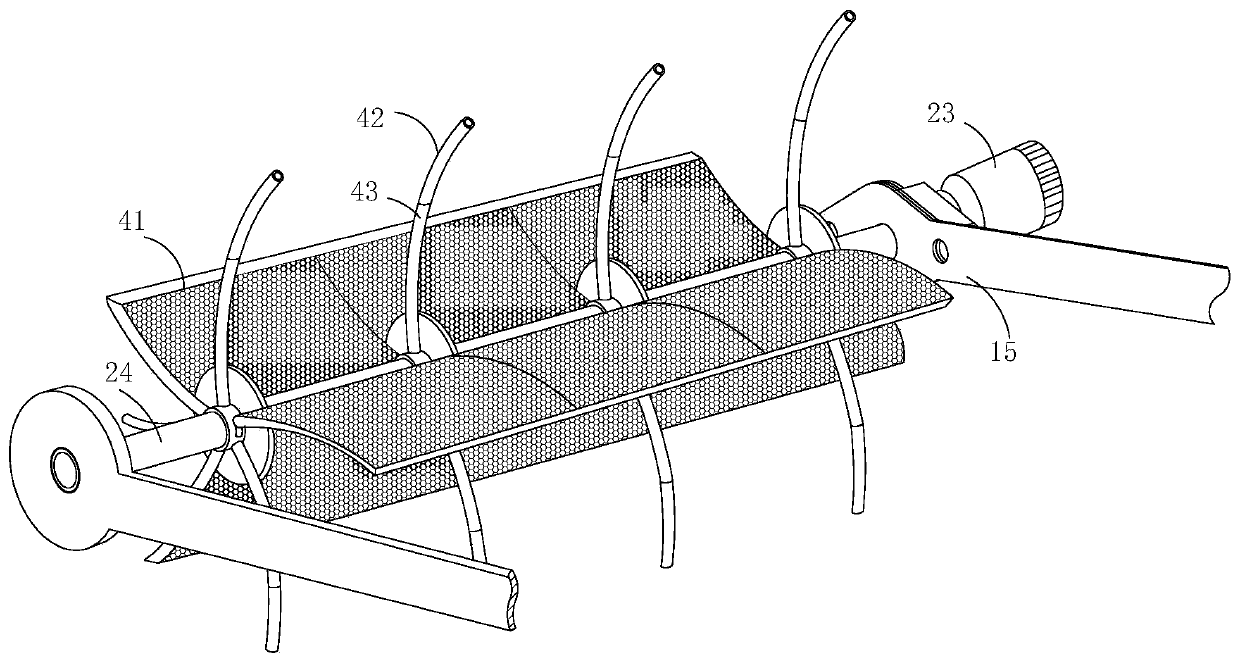

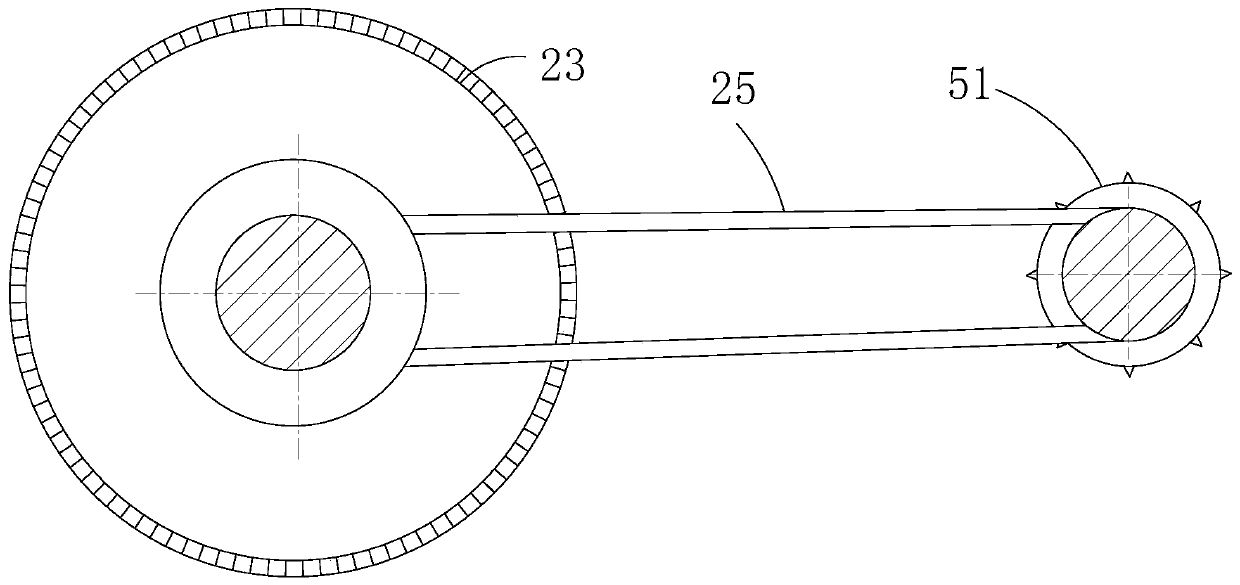

Leveling device for long jump sand pool

The invention relates to the field of sports equipment, in particular to a leveling device for a long jump sand pool. The leveling device comprises a support mechanism, a power mechanism for providingpower is installed on the support mechanism at the edge of the sand pool, and the power mechanism is connected with a screening mechanism for preliminarily cleaning sand in the sand pool; an arc-shaped baffle used for shielding the sand in the sand pool is installed on the outer side of the screening mechanism; a crushing mechanism for retreating the sand is arranged on one side of the screeningmechanism, and a sand flattening brush for flattening the cleaned sand is mounted at the bottom of the crushing mechanism; and the screening mechanism is connected with the power mechanism, and the screening mechanism and the crushing mechanism are driven by the power mechanism to rotate. The leveling device can crush and screen frozen or hardened sandy soil, the sand in the sand pool is cleaned,and the safety of the sand pool in use is guaranteed.

Owner:SHANGLUO UNIV

Improved feed granulation machine

The invention discloses improved fodder granulation machine. The machine comprises a granulation barrel, a churn barrel is connected with the lower side of the granulation barrel, a rotating sprinkle mechanism is arranged on the top of the granulation barrel, several sprinkling nozzles are arranged in the center of the rotating sprinkle mechanism, several mist sprinkling nozzles are arranged on the edge of the rotating sprinkler mechanism, a taper cant is arranged at the bottom of the granulation barrel, the center of the tapered cant is connected by a connection pipe with a churn barrel, a material sprinkle pipe is arrange on the internal of the connection pipe, vanes are arranged inside the material sprinkle pipe, a first through hole is formed on the lateral wall of the material sprinkle pipe, a filter net is arranged outside the first through hole, the first through hole is situated below the vanes, the lateral wall of the material sprinkle pipe is connected with a material feed pipe, the material feed pipe is located between the vanes and the first through hole, a feed trough is arranged on the external side of the churn barrel, a water feed pipe is connected with the rotating sprinkle mechanism. By the improved feed granulation machine, defects of the available machinery can be perfected, the produced feed is uniform in particle volume, and high in bulkiness.

Owner:文松

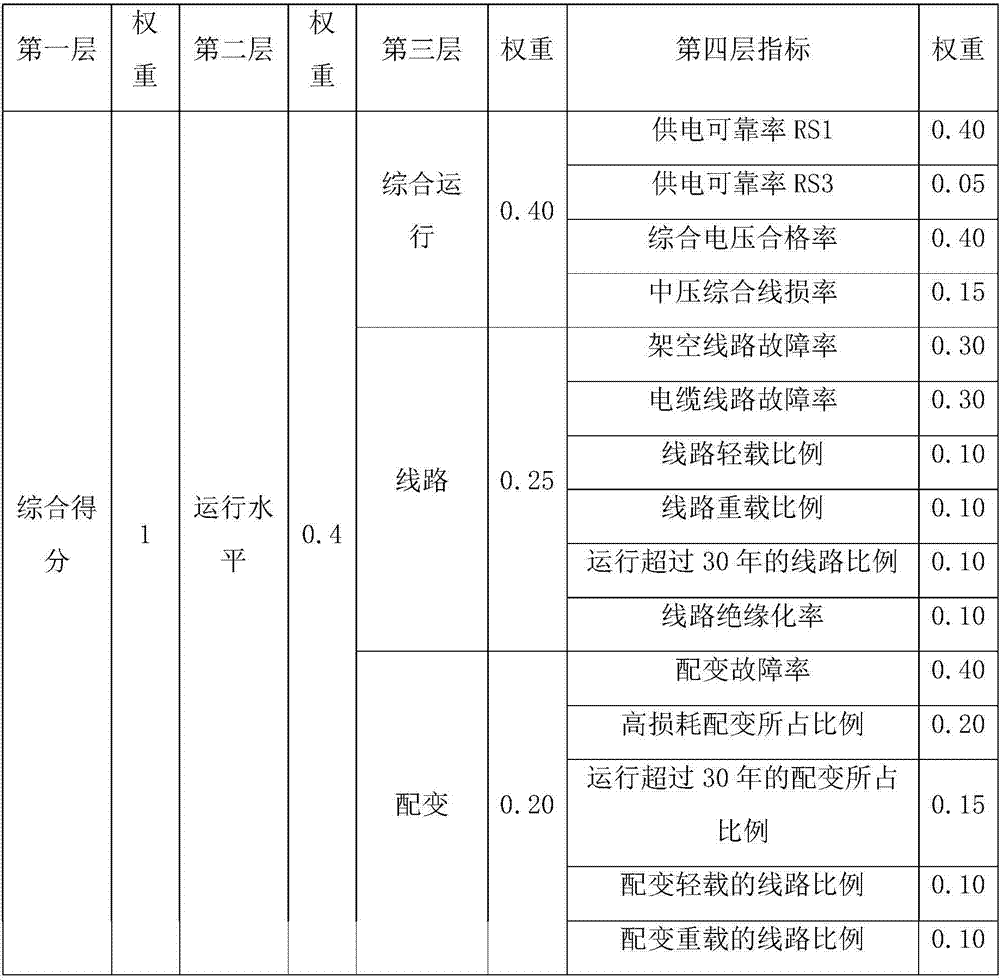

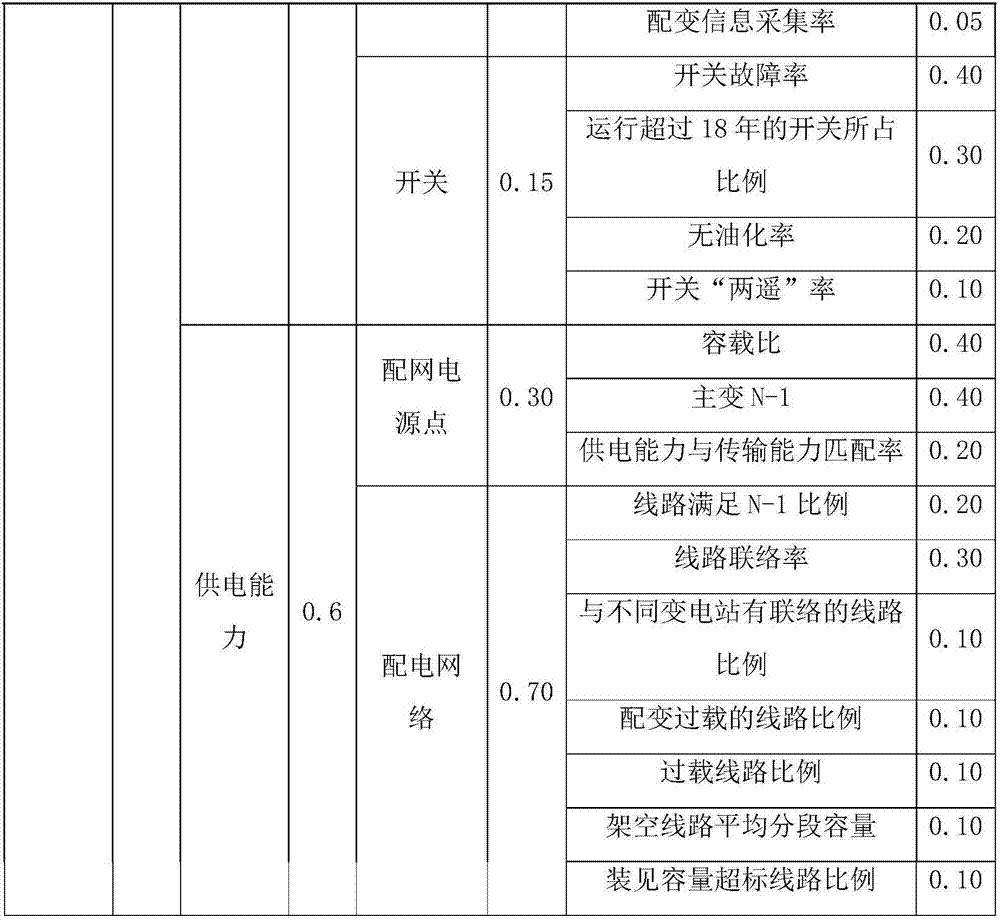

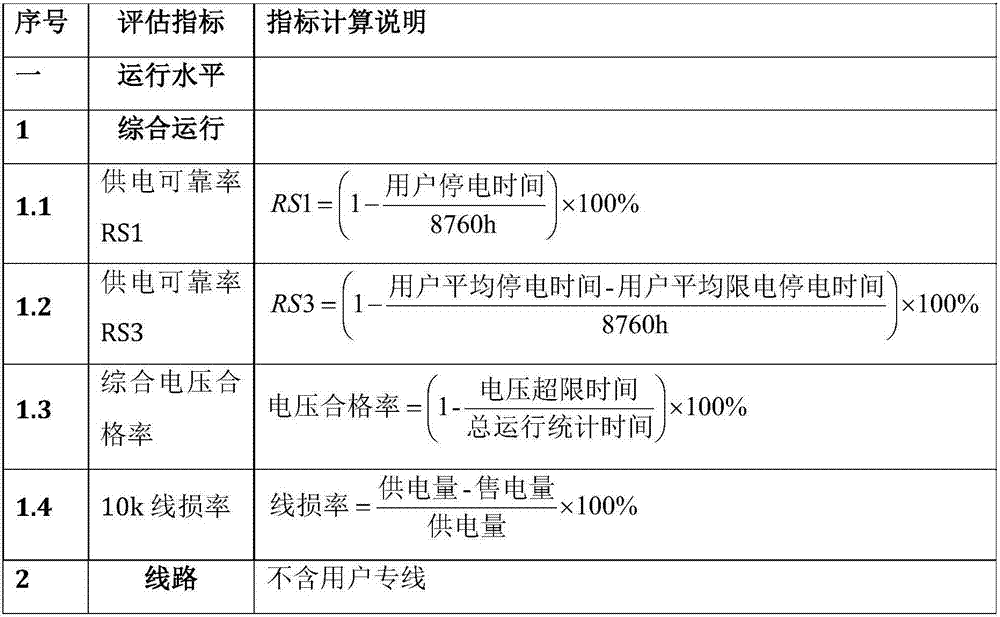

Visual power grid current situation diagnosis and analysis system

InactiveCN107292470AShorten calculation cycleImprove calculation accuracyResourcesInformation technology support systemDistribution transformerSimulation

The invention relates to the technical field of power grid planning, and specifically relates to a visual power grid current situation diagnosis and analysis system. The system is characterized in that four layers of evaluation indexes are set, wherein the first layer is a comprehensive score of the operation level and the power supply capability, the second layer is the operation level and the power supply capability, the third layer is comprehensive operations, lines, distribution transformers, switches, distribution network power supply points and a distribution network, the comprehensive operations, the lines, the distribution transformers and the switches belong to evaluation for the operation level, the distribution network power supply points and the distribution network belong to evaluation for the power supply capability, the fourth layer is specific evaluation indexes for each part; and a comprehensive score of each layer of indexes is acquired through performing summation after being weighted by a score of the lower layer, and a comprehensive score of the operation level and the power supply capability of an evaluated region is acquired finally by performing layer-by-layer weighting and summation on all indexes. Calculation formulas for each layer of evaluation indexes are preset in a processor and a result is calculated automatically after required data is obtained. The system performs visual and clear division on various indexes, shortens the calculation period and improves the calculation accuracy.

Owner:RES INST OF ECONOMICS & TECH STATE GRID SHANDONG ELECTRIC POWER +2

Handheld pen type edge oiling tool

InactiveCN106308020AIncrease scrollingWon't shakeBrush bodiesBristle carriersEngineeringMechanical engineering

Provided is a handheld pen type edge oiling tool. The handheld pen type edge oiling tool comprises a brush head and a handle. The brush head is detachably connected with the handle. A guide rod is arranged between the brush head and the handle. The guide rod is located in the handle and provided with a connection thread. The brush head is provided with a connection threaded rod which is inserted into the connection thread and used for fixedly connecting the brush head with the guide rod. The rolling brush head is arranged on the edge oiling tool so that paints can be directly coated on edges, thereby increasing working efficiency of edge coating. Due to the fact that the guide rod is connected with the brush head, rolling amplitude of the brush head is improved so that the brush head does not swing during coating.

Owner:江都区慕溪皮具工作室

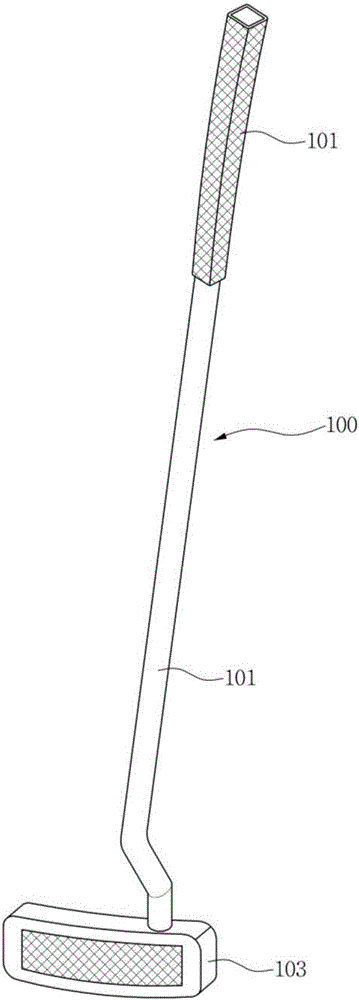

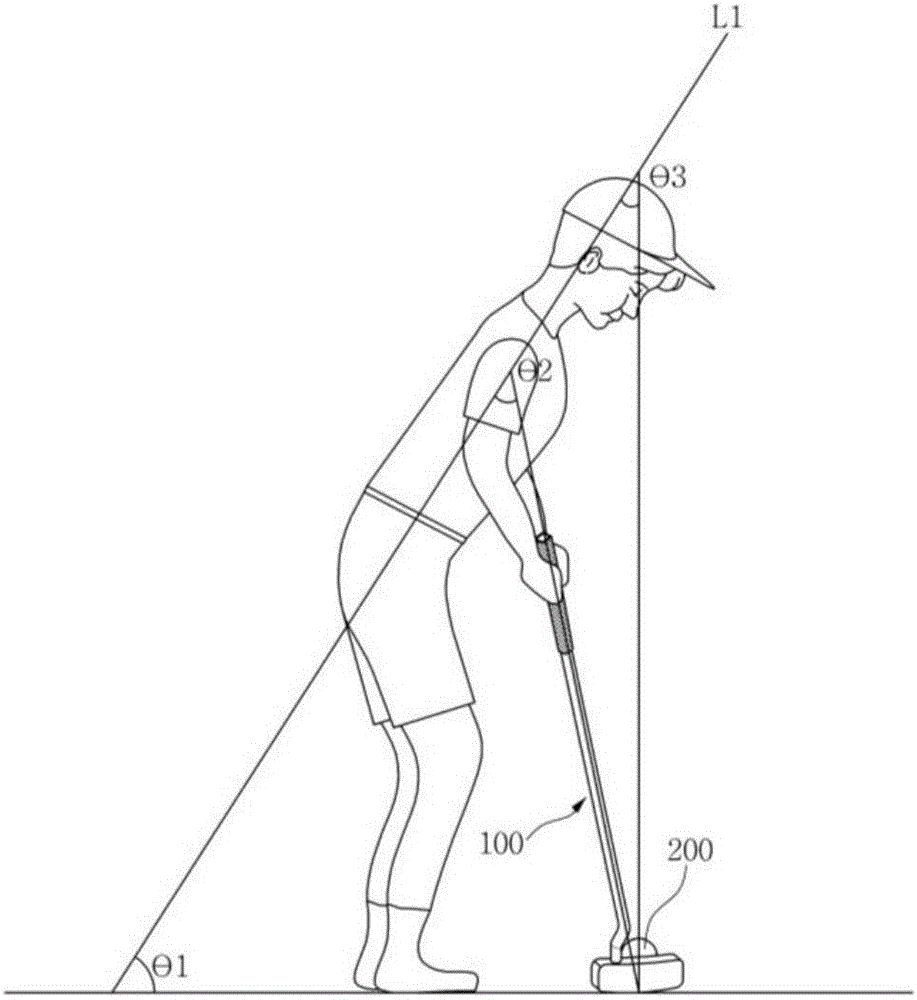

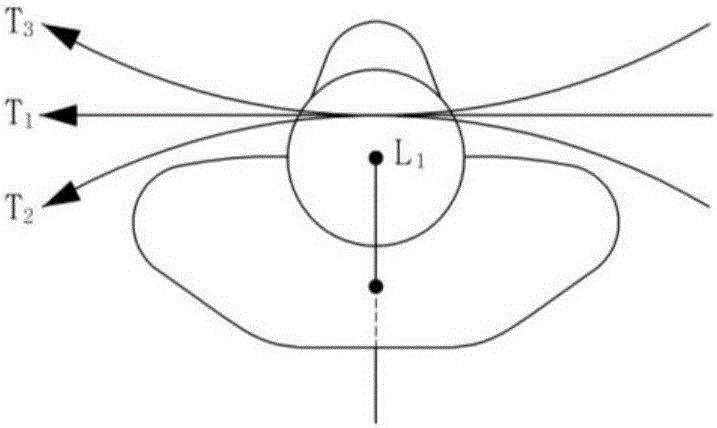

Golf push rod with novel grasp

InactiveCN101332352AMutual Parallel GuaranteeReduce exposureGolf clubsStringed racketsPalmar surfaceArticulation points

The invention relates to a golf pushing bar with a novel grip, which comprises a grip, a bar body, and a bar head. The grip is provided with a finger hole which is used for buckling fingers, a notch, and a supporting part which is used for supporting thumbs. The finger hole is horizontally arranged on the grip. The notch is arranged on the edge of the grip at the two sides of the finger hole. The supporting part is arranged on the left upper corner of the grip. When in use, finger roots are in the same plane with five articulation points which are connected with the centre of a palm, thus ensuring that palmar surfaces of two hands are parallel to the striking surface of the bar head. The angle and the direction which control the two palmar surfaces are equal to the angle and the direction which control the angle and the direction of the striking surface of the bar head, therefore, the control is simpler and easier, furthermore, the surfaces of a supporting plane arranged the two sides of the grip respectively deviate left and right, and the left plane is also provided with a raised line and a recess area, thus greatly reducing the mutual interference between a left hand and a right hand and ensuring that when players hold the grip, the players feel .more comfortable.

Owner:陈笠

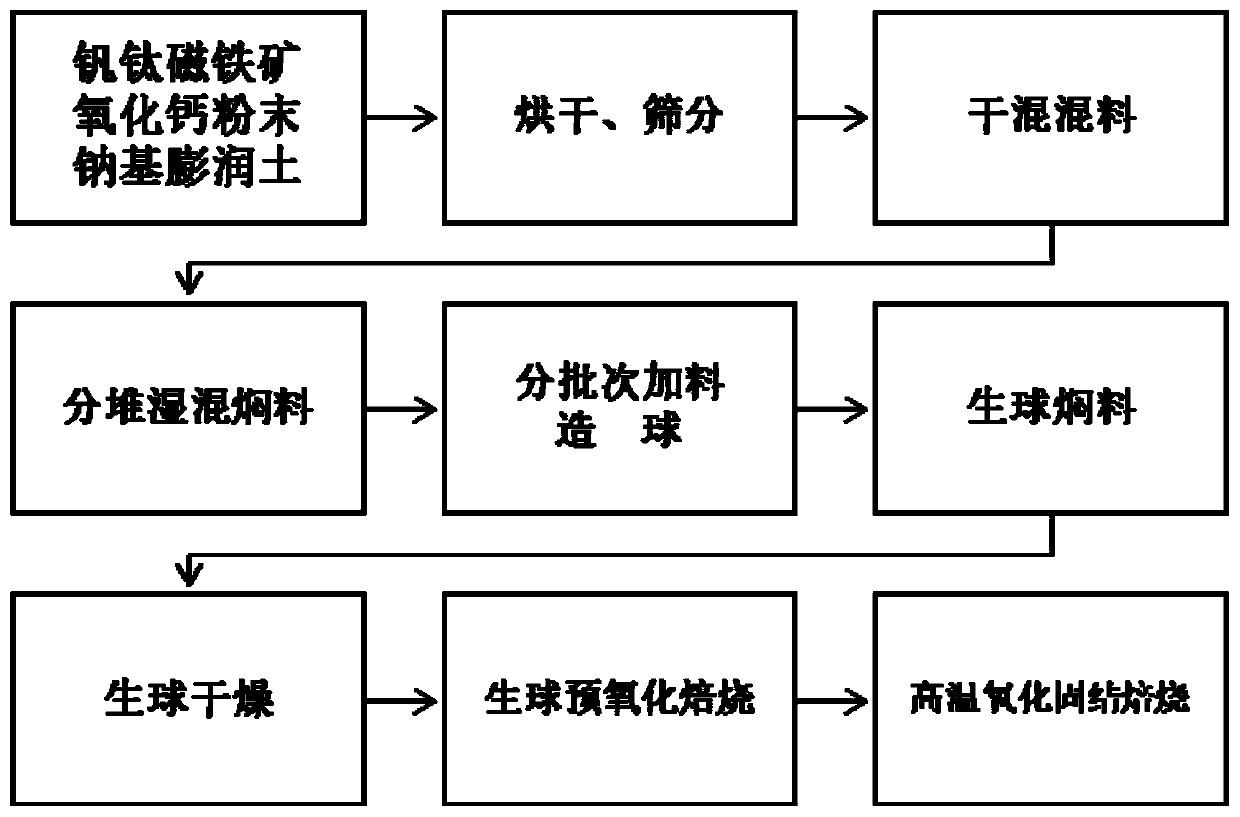

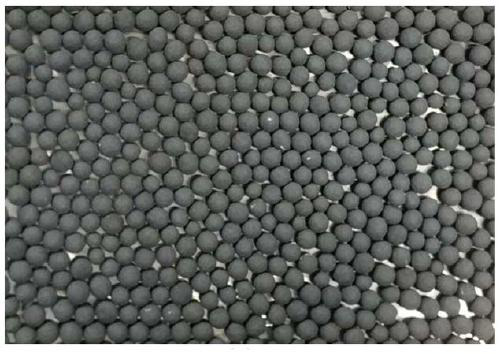

A method for preparing high-basic chromium-vanadium-titanium pellets by using calcium oxide

The invention relates to a method for preparing high-alkalinity chromium-containing vanadium-titanium pellets by using calcium oxide. The method is to batch raw materials including vanadium-titanium magnetite and additives calcium oxide powder and sodium bentonite so that the alkalinity is 1.8 ~2.1, dry and dry mix the materials respectively; divide the mixed mineral materials into two parts evenly, add 3~4% water of the total mass of raw materials to the first part, and add 6~4% of the total mass of raw materials to the second part 8% water, mix evenly, seal and let stand; when making balls, use the first part of the mineral powder during the cue ball forming period, and the second part of the mineral powder for the long term when the cue ball grows. Spray before the cue ball grows. The amount of water is controlled at 1ml / 10g mineral powder ~ 2ml / 10g mineral powder to prevent adhesion between the cue balls, and the interval between each water addition and feeding is 40 to 90 seconds, so that the diameter of the produced pellets is within 8mm ~ 12mm; Carry out green pellet stewing, drying, pre-oxidation roasting, and secondary high-temperature oxidation roasting to obtain high-alkalinity chromium-containing vanadium-titanium pellets.

Owner:NORTHEASTERN UNIV LIAONING

A kind of toy for children's toy glass ball rolling

Owner:福建省德化县唯美玻璃有限公司

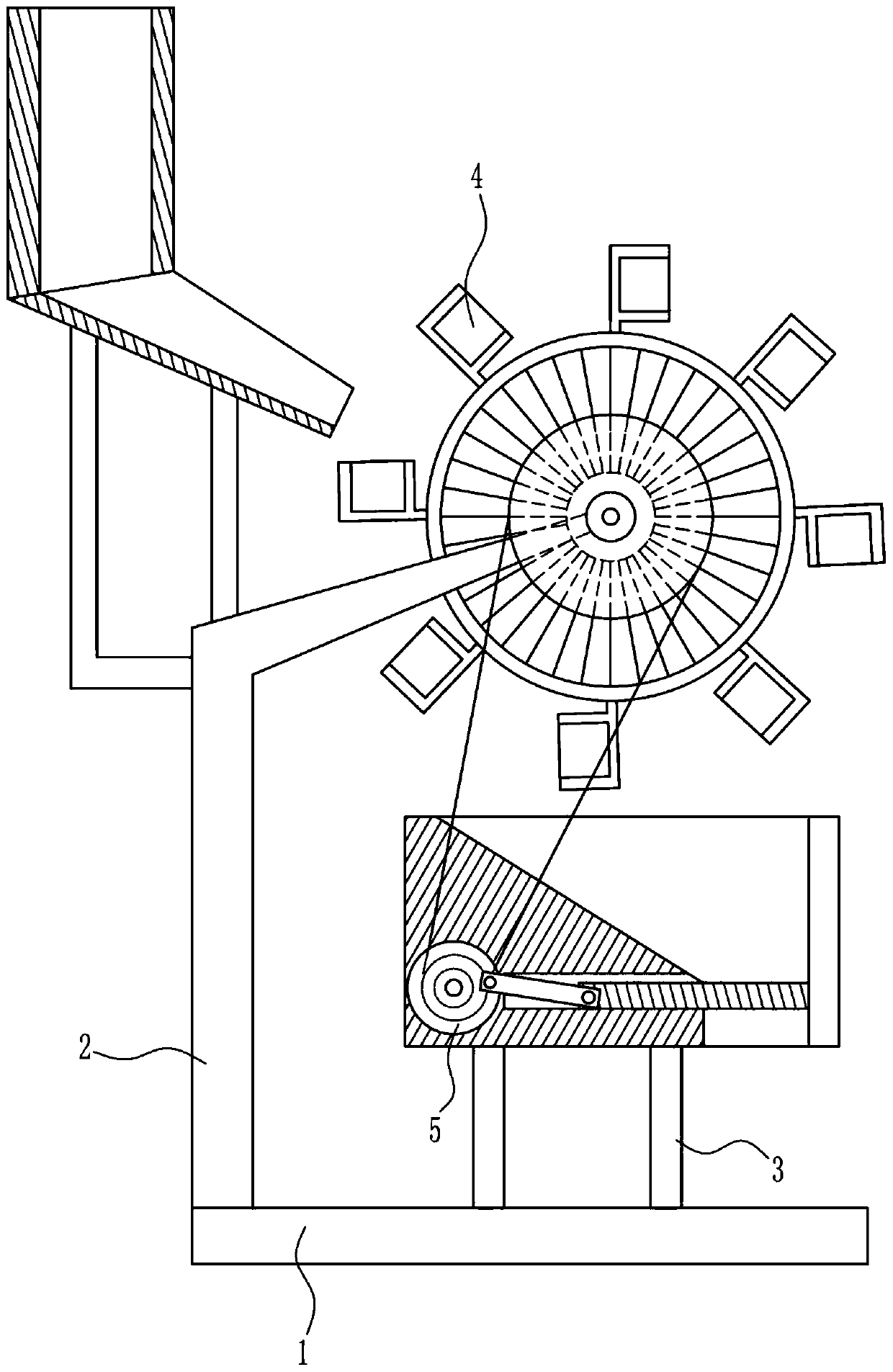

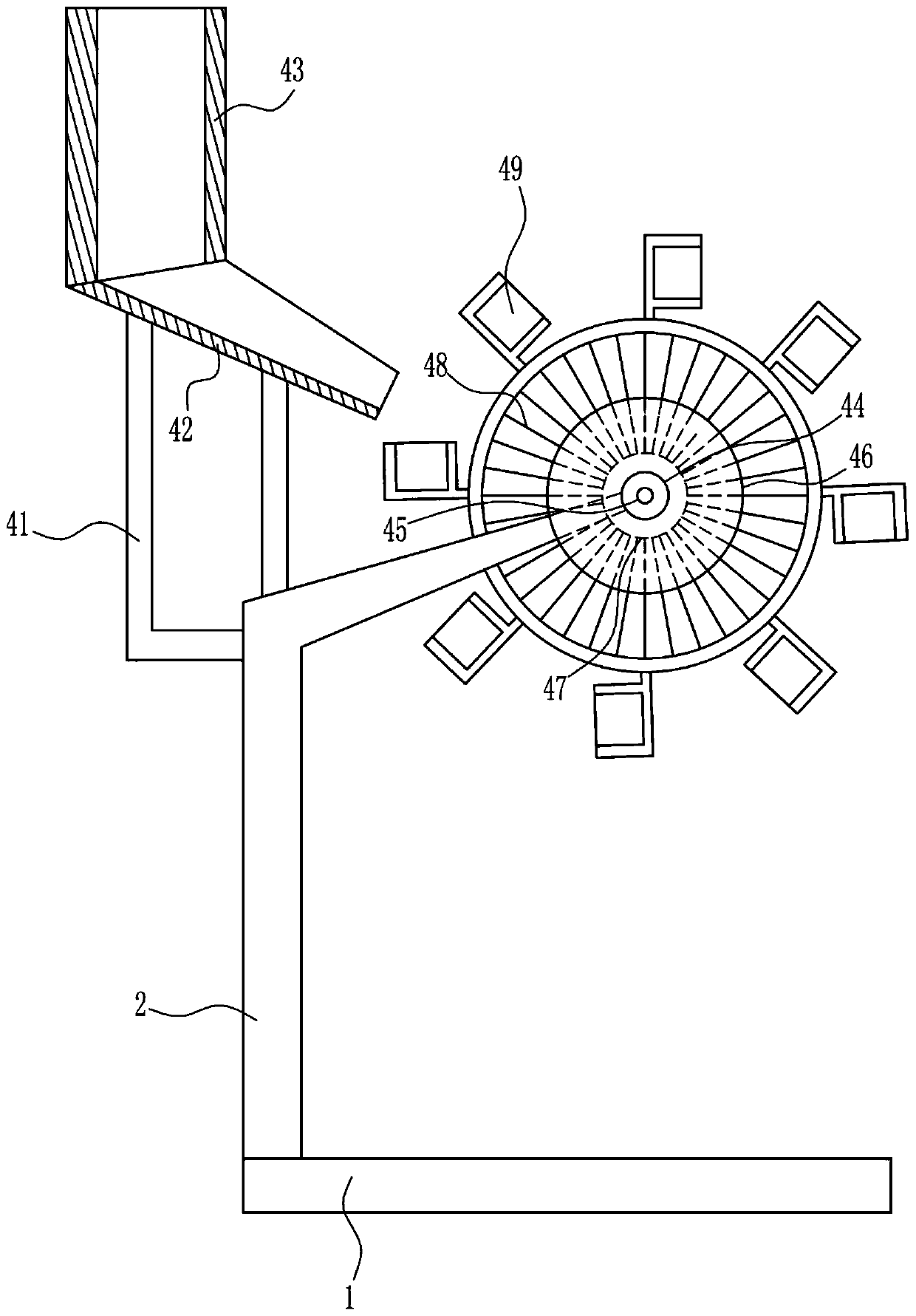

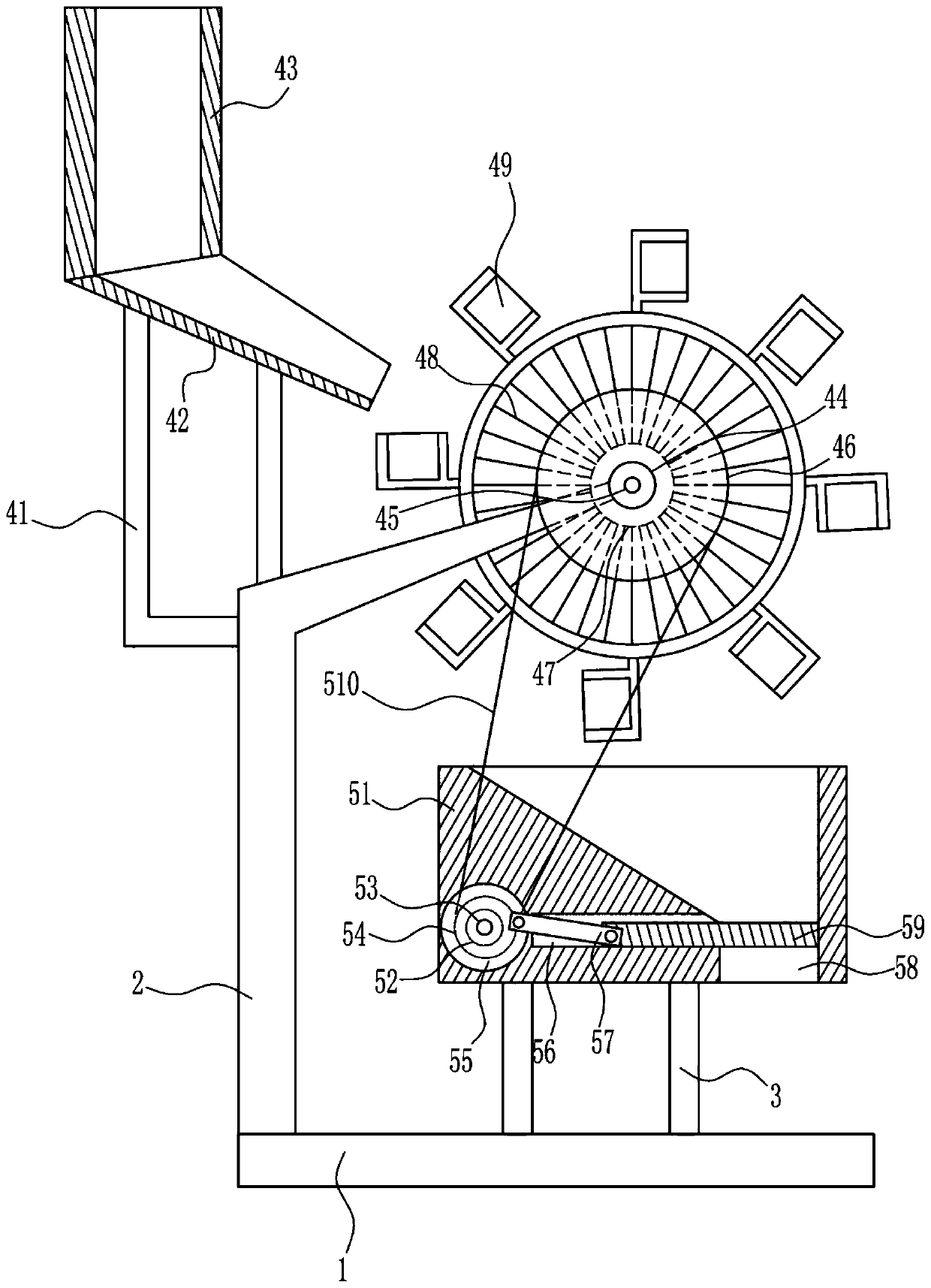

Camellia seed stoning machine for producing tea oil

InactiveCN108707506ATo achieve the effect of iron removalIncrease scrollingFatty-oils/fats productionOil productionOperations management

The invention relates to the tea oil production field and particularly relates to a camellia seed stoning machine for producing tea oil. According to the camellia seed stoning machine, broken stones in rapeseeds can be adequately removed, and iron can be removed. The camellia seed stoning machine comprises a mounting plate, a collection tank, a support frame, a first motor, a rotating disc, a rotating rod, a mounting frame, a sliding rail and the like, wherein the support frame is fixedly connected to the top surface of the mounting plate, and the collection tank is arranged at the mounting plate; the first motor is fixedly connected to the support frame, and the rotating disc is in transmission connection with the output end of the first motor; the rotating rod is fixedly connected to therotating disc; the mounting frame is fixedly connected to the rotating rod; the sliding rail is fixedly connected to the inner wall of the mounting frame; and a motor reel is fixedly connected to theslide rail and is located in the middle of the slide rail. According to the camellia seed stoning machine, broken stones in rapeseeds can be adequately removed, and iron can be removed.

Owner:李前彩

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com