Drug drying box

A technology for drying ovens and medicines, applied in the drying of solid materials, granular materials, drying gas layout, etc., can solve the problems of long drying time, low production efficiency, insufficient drying, etc., and achieve accurate and controllable heating temperature, installation and disassembly. Convenience and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

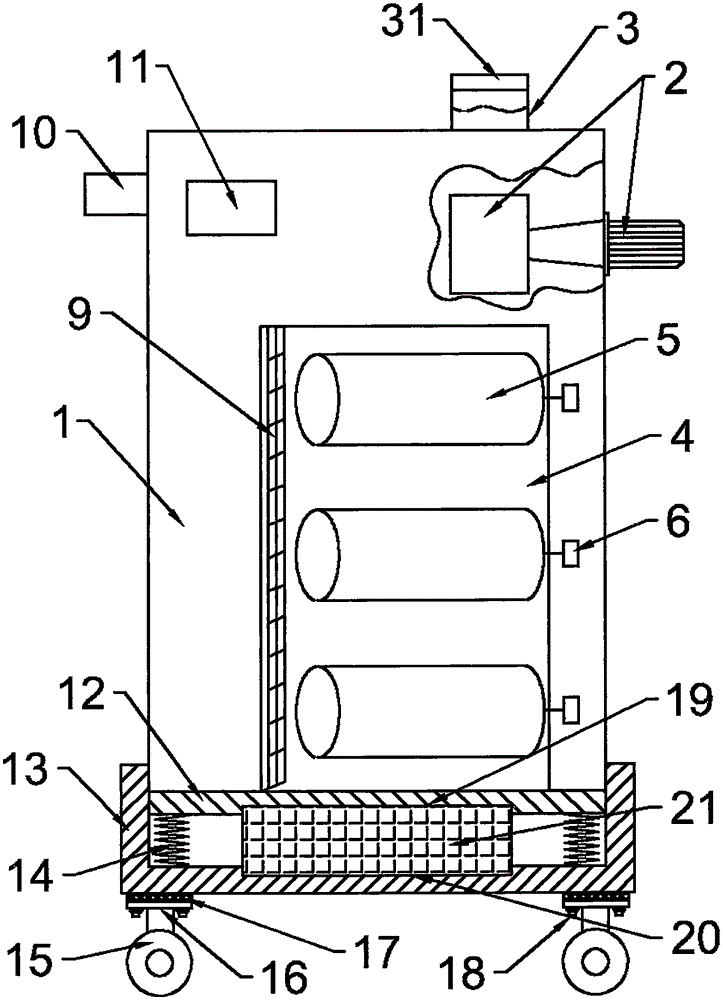

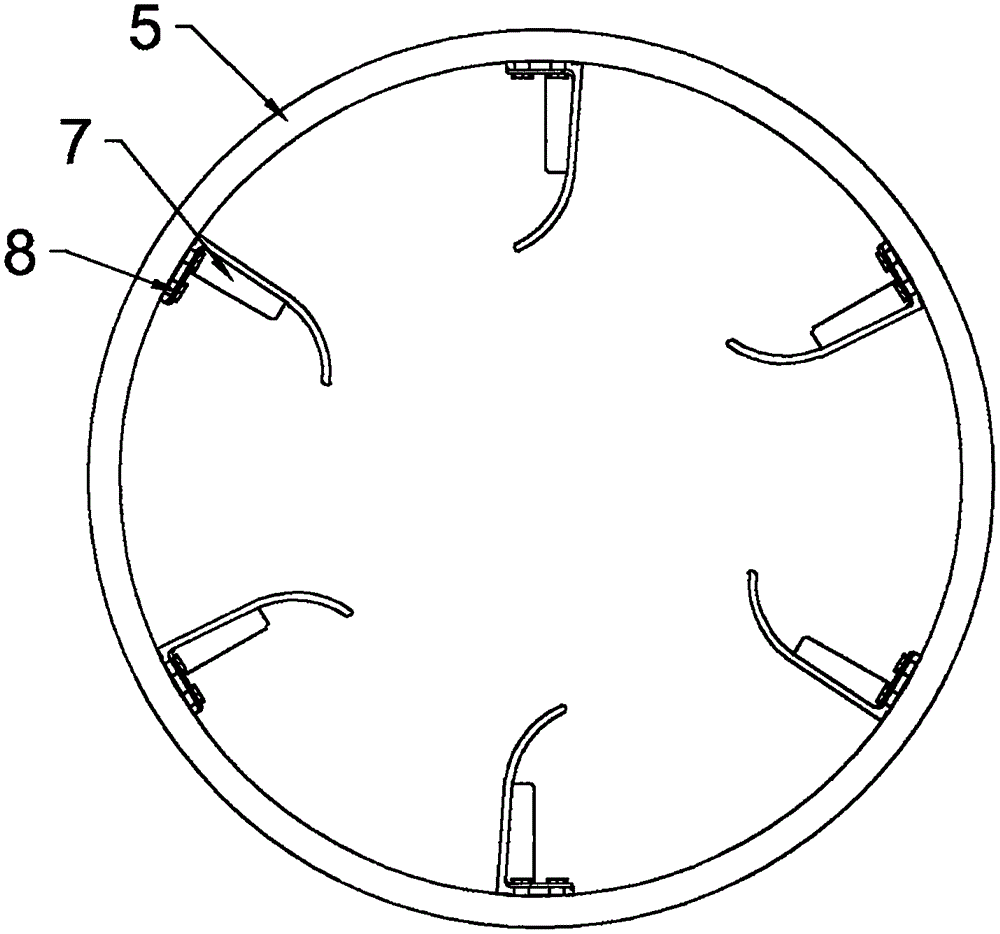

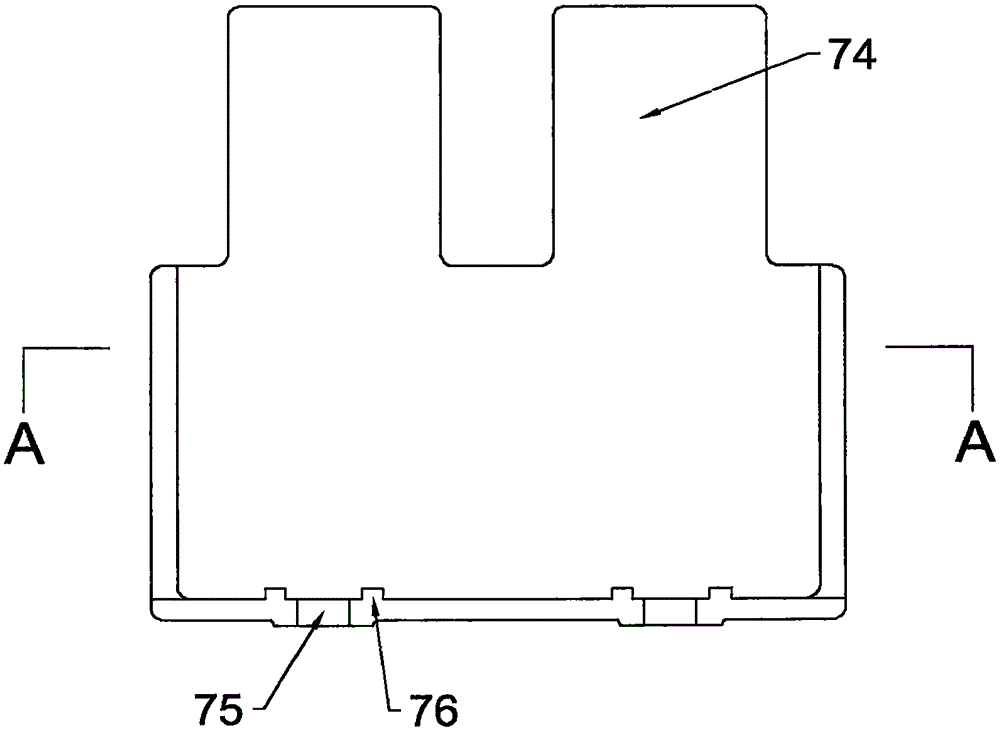

[0018] see Figure 1-5 , a medicine drying box, comprising a box body 1 and a fan 2 arranged on the box body 1, the top of the box body 1 is provided with an exhaust hole 3, and the middle part of the box body 1 is provided with an accommodating cavity 4, The accommodating cavity 4 is provided with a drum 5, the right end of the drum 5 is connected with the rotor of the motor 6, and the inner wall of the drum 5 is equipped with a lifting plate 7, and the lifting plate 7 includes a bottom plate 71 and a backward tilting plate 72, and the two sides of the bottom plate 71 are provided with The vertical plate 73, the front end of the bottom plate 71 is connected in an arc to the lower end of the reclining plate 72, the upper end of the reclining plate 72 has a pair of arc-shaped plates 74 arranged side by side and curved backwards, the lower end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com