Patents

Literature

61 results about "Pan frying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pan frying or pan-frying is a form of frying food characterized by the use of minimal cooking oil or fat (compared to shallow frying or deep frying), typically using just enough to lubricate the pan. In the case of a greasy food such as bacon, no oil or fats may need to be added. As a form of frying, the technique relies on oil or fat as the heat transfer medium, and on correct temperature and time to not overcook or burn the food. Pan frying can serve to retain the moisture in foods such as meat and seafood. The food is typically flipped at least once to ensure that both sides are cooked properly.

Making process of tea with leaves of Aquilaria sinensis

A making process of tea with leaves of Aquilaria sinensis includes the steps: firstly, selecting fresh leaves; secondly, sun-drying the fresh leaves; thirdly, air-drying and cooling the leaves by moving the fresh leaves of Aquilaria sinensis and the fresh tea leaves subjected to sun-drying to a cooling rack; fourthly, moving the leaves of Aquilaria sinensis and the tea leaves which are air-dried and cooled into a green-making room, mixing the leaves of Aquilaria sinensis and the tea leaves according to the mass ratio of 5-40% to 60-95%, and performing green-making and fermentation; fifthly, performing rolling and pan-frying; sixthly, rolling for shaping tea; and seventhly, baking to extract fragrance. The leaves of Aquilaria sinensis and the tea leaves are put together on the cooling rackfor air-drying and cooling, flavor of the leaves of Aquilaria sinensis and flavor of the tea leaves are allowed to permeate into each other, the leaves of Aquilaria sinensis and the tea leaves are then mixed proportionally for green-making and fermentation, the leaves of Aquilaria sinensis and the tea leaves are subjected to fermentation and fragrance extraction together, and accordingly the leaves of Aquilaria sinensis and the tea leaves are mutually and fully permeated and merged, and the made tea with leaves of Aquilaria sinensis has the effects of digestion aiding without harming stomach,and has strong long-lasting scent.

Owner:陈鸿进

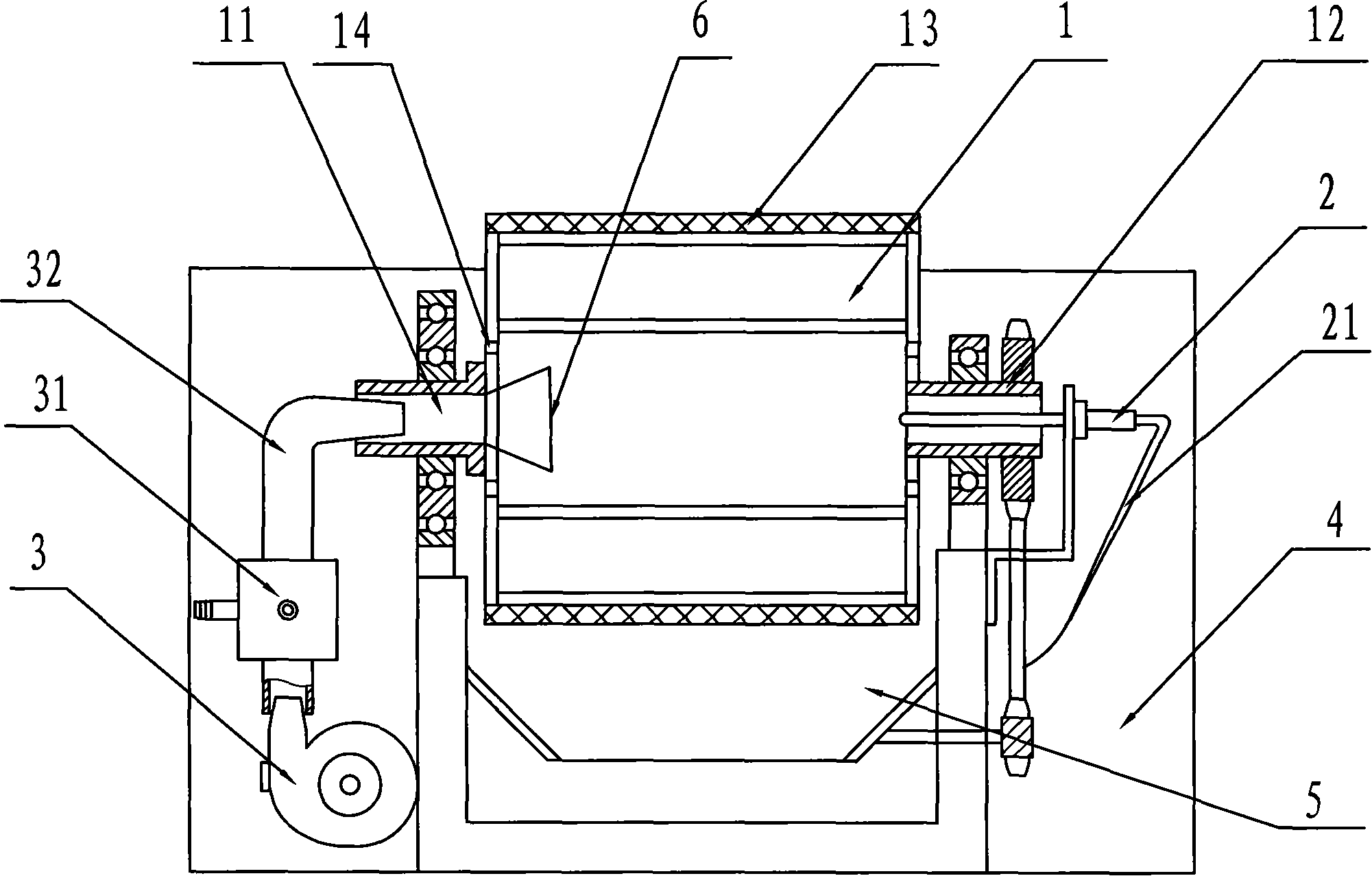

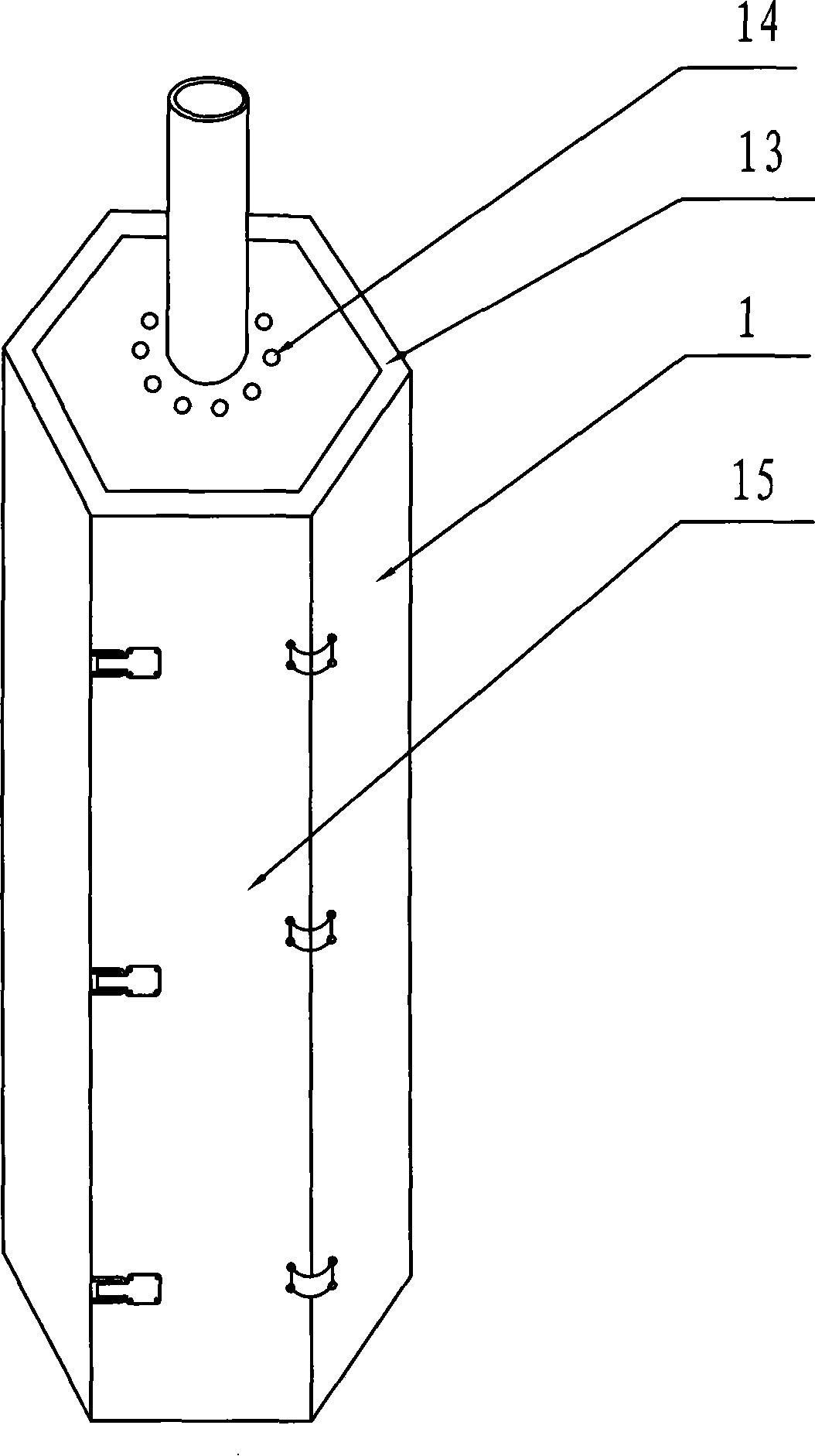

Tea cooling and roasting technique and tea cooling and roasting machine

InactiveCN101189993AReduce labor intensityIncrease productivityPre-extraction tea treatmentEngineeringHot blast

The invention relates to tea pan-frying technique and a tea pan-frying apparatus, which comprises a frame, a cylinder installed on the frame, a motor and a heating air source. The whole of the cylinder is in enclosed shape. Two sides of the cylinder are provided with at least an axle middle hole which is matched with the heating air source, and a temperature sensor is installed in the cylinder. The heating air source comprises a fan, a thermal generator and a hot blast pipe. The cylinder is wrapped with an insulating layer; meanwhile, two side surfaces of the cylinder are opened with a plurality of moisture discharging vents. The invention has the advantages of low labor intensity, high production efficiency, evenly drying inner-outer tea, discharging moisture, removing tea fannings, brightening tea and producing tea with good color, fragrance, taste and shape.

Owner:苏和生

Compression production process for fresh aromatic Tie Guanyin tea and product thereof

InactiveCN101978842AEasy to makeReduce productionPre-extraction tea treatmentClimate change adaptationMoistureChemistry

The invention discloses a compression production process for fresh aromatic Tie Guanyin tea and a product thereof. The process comprises the picking of fresh tea leaves, sun drying, fine manipulation, pan frying, kneading, picking and choosing, compression forming, packaging, drying and the like. The process comprises the following steps of: performing the fine manipulation at the temperature of between 18 and 21 DEG C and the humidity of between 75 and 85 percent, and performing rotating and spreading for 2 to 4 times respectively and alternately; after the pan frying is performed, kneading the tea leaves in a tea kneading machine; picking the leaves of which the quality meets the standard out after the kneading; compressing the picked tea leaves to form baled Tie Guanyin tea of which the thickness or the diameter is not more than 0.8 centimeter, and packaging the baled Tie Guanyin tea for forming; performing the kneading, the picking and choosing, the compression forming and the packaging at the temperature of between 16 and 22 DEG C and the humidity of between 30 and 50 percent; and drying immediately after the packaging, namely baking for the first time until the moisture content is between 10 and 14 percent, and baking for the second time until the tea leaves are dried completely to form a finished product. The process is reasonable and unique, has high feasibility, so that the product has the unique fresh aromatic taste, is mellow, delicious and fresh, has high and lasting fragrance and attractive appearance, and improves the integral quality of the tea leaves.

Owner:陈荣发

Manufacture method of carbon-flavor tikuanyin tea

ActiveCN102860370ADark colorSand rate is obviousPre-extraction tea treatmentCooking & bakingEngineering

The invention discloses a manufacture method of carbon-flavor tikuanyin tea. The method comprises the following steps of: picking up Tikuanyin fresh leaves; airing; sunning; shaking; wrapping and twisting; making primary tea; inspecting; bunching; distributing to uniform piles; launching; manually sorting stalks; feeding and baking; inspecting; and packing finished product into bins. The step of shaking is as follows: cooling, standing, and repeatedly shaking and airing; a step of pan frying and red side removal is performed between shaking and wrapping-twisting; and the step of feeding and baking is as follows: performing at least six times of slow baking in a baking oven, and correspondingly performing slow baking and airing. In the processing process, a light-fermentation and low-temperature conventional method is selected, and a multi-channel temperature baking process of the baking oven is combined, so that the prepared finished product tikuanyin tea is complete, round, heavy, black bloom and rich, and tastes hot, and has remarkably 'hot chestnut flavor', 'fried rice flavor' or 'sweet flower flavor'.

Owner:FUJIAN KOHKIANHUATS TEA

Preparation method of peony bud tea

The invention discloses a preparation method of a peony bud tea. The preparation method comprises the steps of airing, inactivating, pan-frying and sterilizing initially-bloomed peony buds to obtain the peony bud tea. According to the method, the drying speed is high, the time is short, the control is easy, the color and the shape of a peony bud can be kept to the great extent, the aroma enhancement effect is good, the sensory quality is excellent and phenomena such as charring, bud breaking and the like do not exist. Particularly, the initially-bloomed peony buds are picked, so that nutritional ingredient loss caused by ripen flower abscission can not be caused.

Owner:菏泽市牡丹区牡丹研究所

Preparation method for organic dried sweet-scented osmanthus and product

The invention provides a preparation method for organic dried sweet-scented osmanthus, which comprises: (2) a picking step of manually picking fresh sweet-scented osmanthus in a way of keeping the rate of fineness of the fresh sweet-scented osmanthus over 95 percent; (4) a high-temperature fixing step of placing the fresh sweet-scented osmanthus in batches into a high-power electric frying pan or fixing equipment, heating and turning the fresh sweet-scented osmanthus up and down, and performing fast temperature reduction; (5) a low-temperature pan-frying step of placing in batches the sweet-scented osmanthus into a low-power electric frying pan, setting the temperature to be 60 to 70 DEG C, heating and turning the sweet-scented osmanthus up and down and stopping the frying when the water content of the sweet-scented osmanthus is less than 30 percent; and (6) an intermediate-temperature oven-drying step of placing the sweet-scented osmanthus into oven-drying equipment, heating and turning the sweet-scented osmanthus up and down, and stopping the oven-drying when the water content is less than 5 percent to prepare the dried sweet-scented osmanthus. Compared with the prior art, the method has the advantages that: the selection of the material is rarefied, namely, the fresh sweet-scented osmanthus adopts osmanthus fragrans var aurantiaoug and is planted in an environment meeting the planting standard of organic products; a process is simple; the natural color, luster and fragrance of the sweet-scented osmanthus are kept; and the dried sweet-scented osmanthus has natural color and luster, full-bodied, natural and lasting fragrance, pure flavor, storage stability and secure and reliable quality.

Owner:吕焱

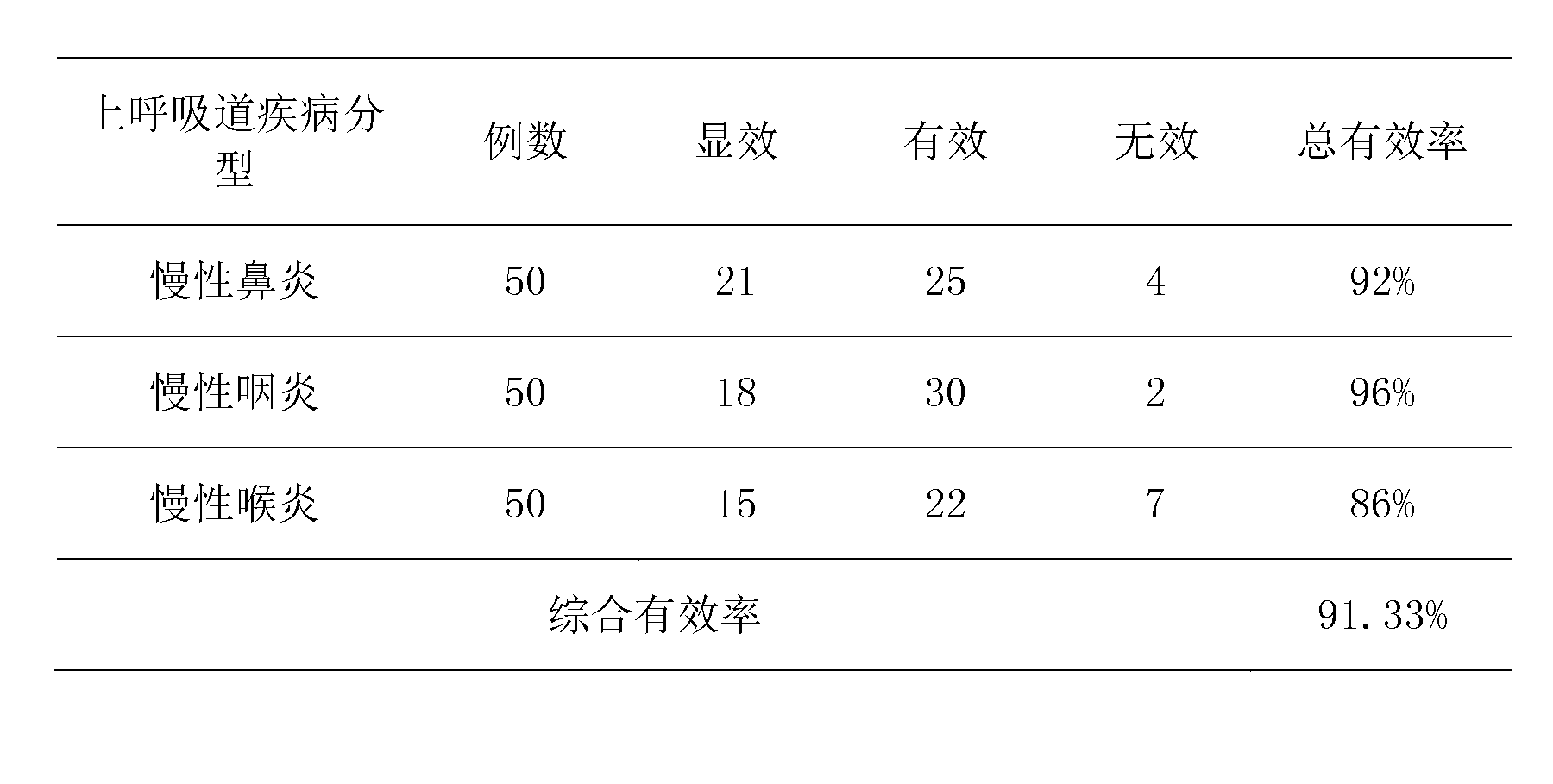

Preparation method of ampelopsis grossedentata tea

The invention relates to a preparation method of ampelopsis grossedentata tea. The preparation method comprises the steps of: selecting tender branches and leaves of ampelopsis grossedentata, putting the branches and the leaves into a pot, carrying out hand-grabbing and stir-frying, quickly raising the temperature to 70-80 DEG C for 3-4min, wherein the tender branches and leaves are hot in hand feel and scald hands; reducing the temperature to 45-55 DEG C, carrying out pan-frying by using a tea drag until stuffy droplet crackles occur, frying to be semi-dried and discharging; lightly pressing and then airing for cooling, placing in a twisting machine, sizing and dissolving block masses; placing in an automatic chain plate type dryer for drying, primarily drying for 0.5-1h, and controlling the temperature to be 120-130 DEG C; in order to prevent the condition that the ampelopsis grossedentata is externally dried and internally wet, spreading for cooling the ampelopsis grossedentata for 0.5-1h after primary drying, and then sufficiently drying, controlling the temperature to be 115-120 DEG C until the water content of the ampelopsis grossedentata reaches 6-7 percent; and spreading for cooling, sterilizing and packaging. The ampelopsis grossedentata is pan-fried by using the hot pot, then twisted by using the twisting machine, and dried by using the automatic chain plate type dryer, thereby ensuring pure color and taste; the ampelopsis grossedentata tea is few in nutrient loss, and can be directly taken; and the ampelopsis grossedentata tea has remarkable effect on treatment of chronic rhinitis, chronic pharyngitis and chronic laryngitis.

Owner:武汉代代木生物科技有限公司

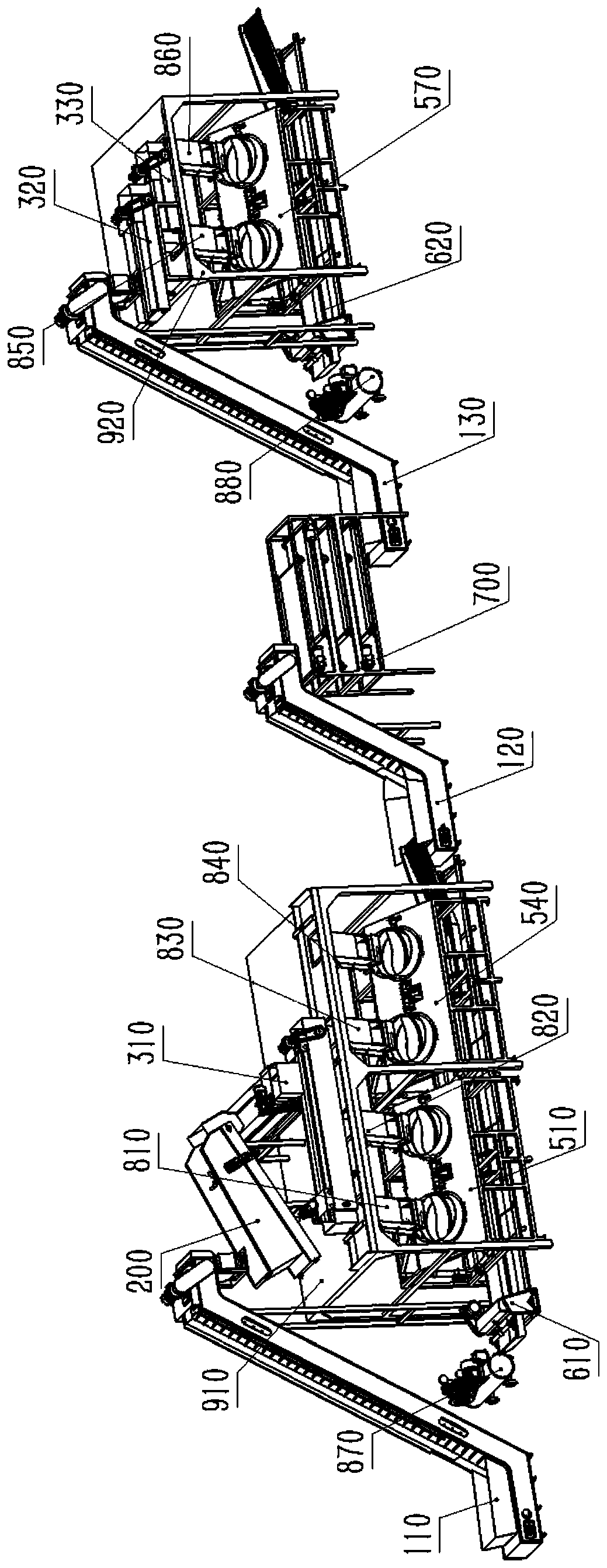

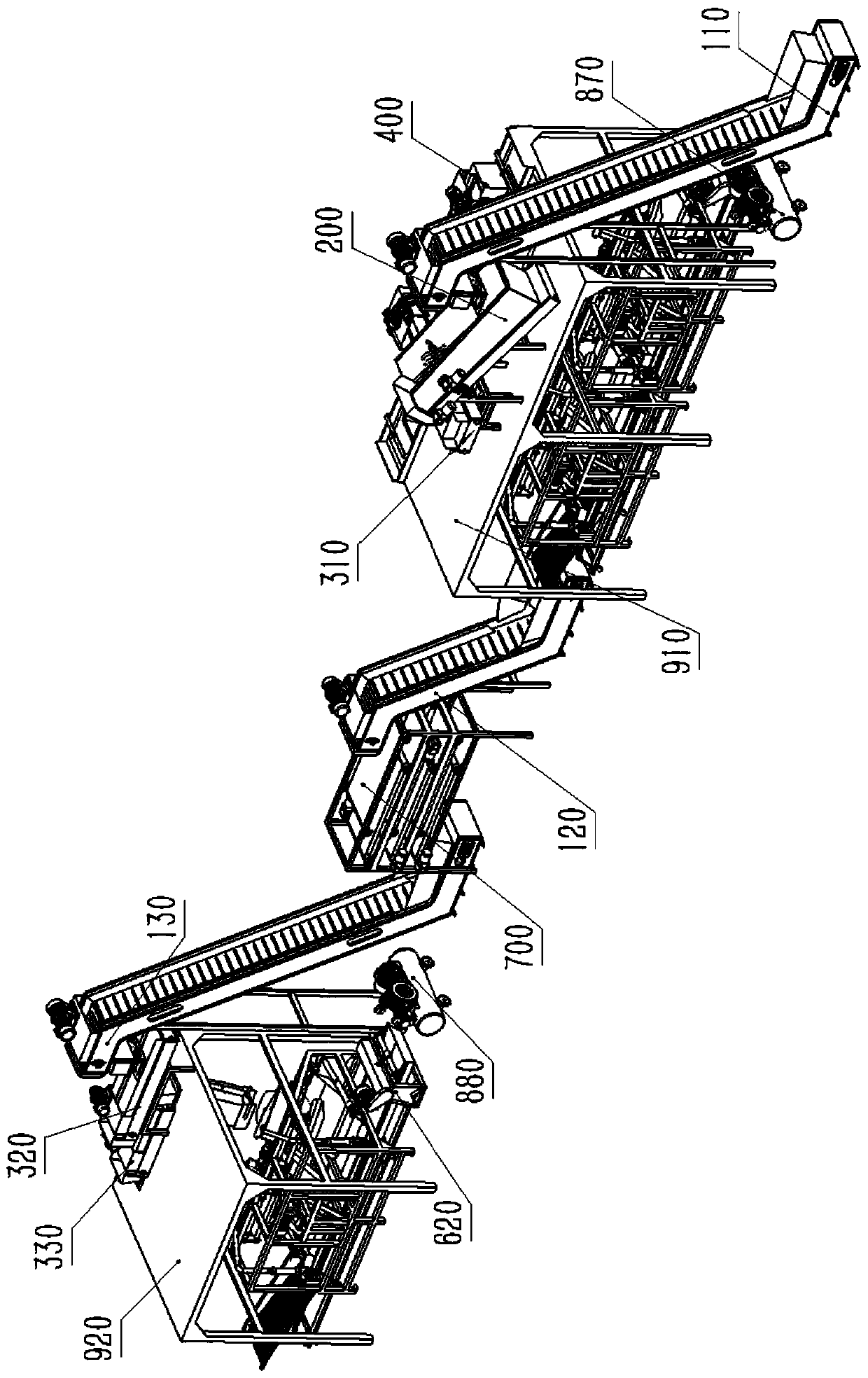

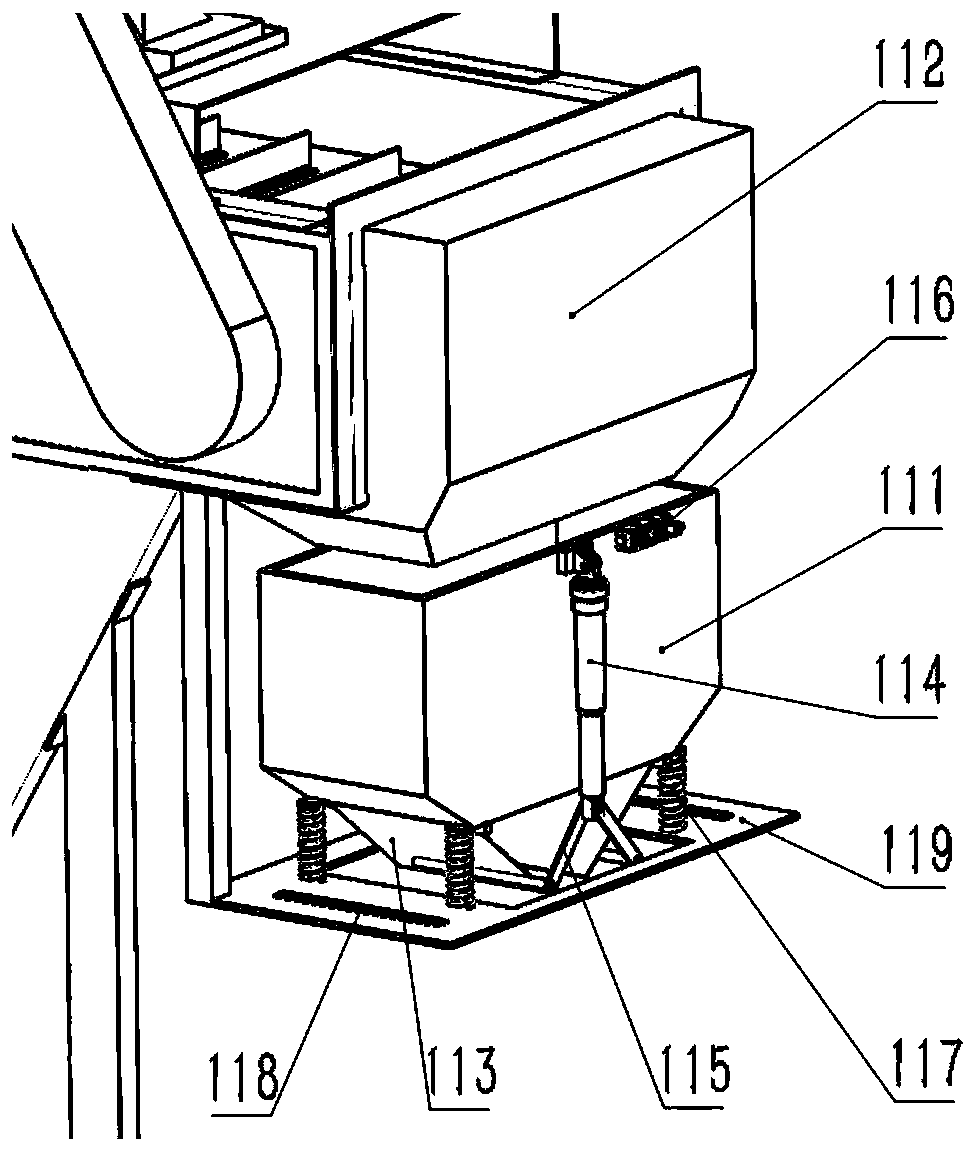

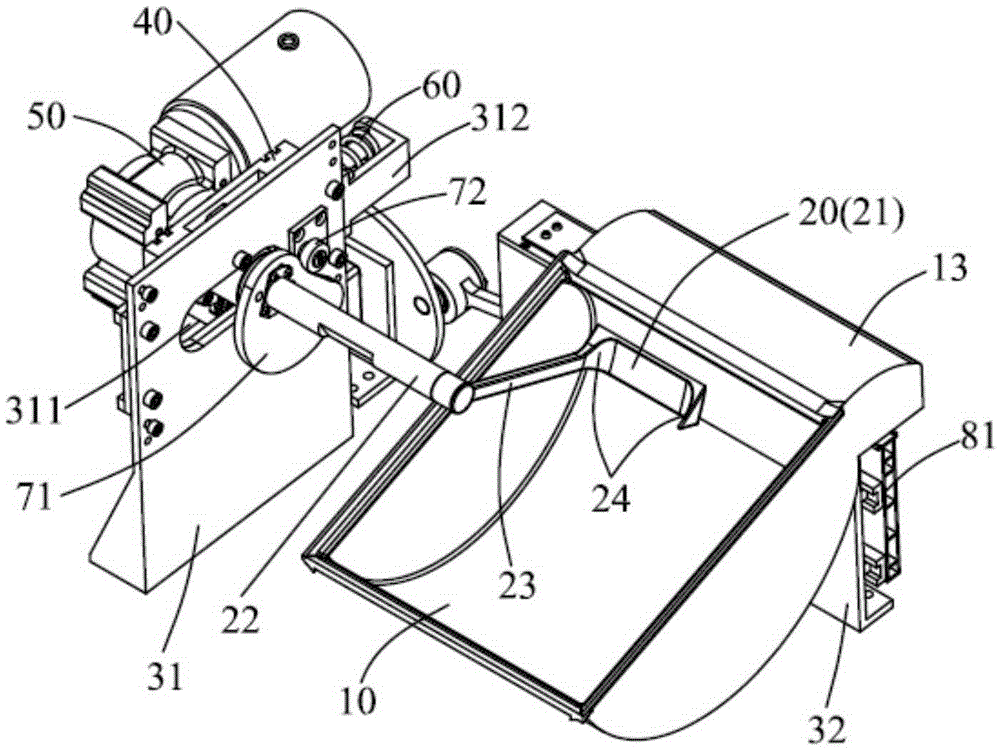

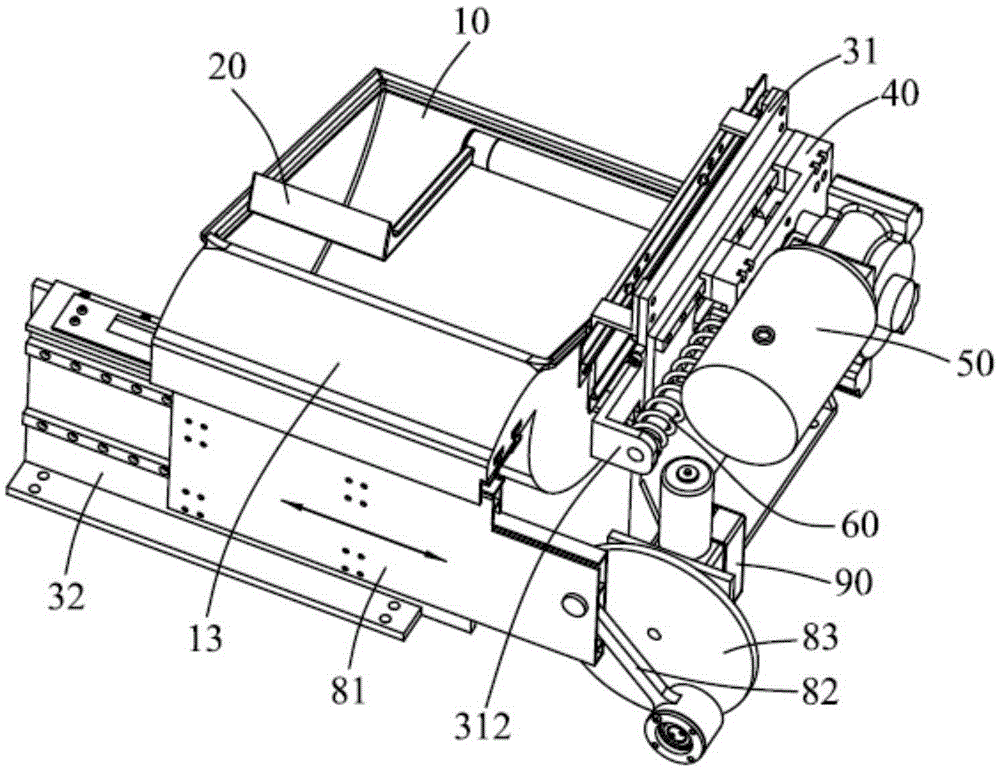

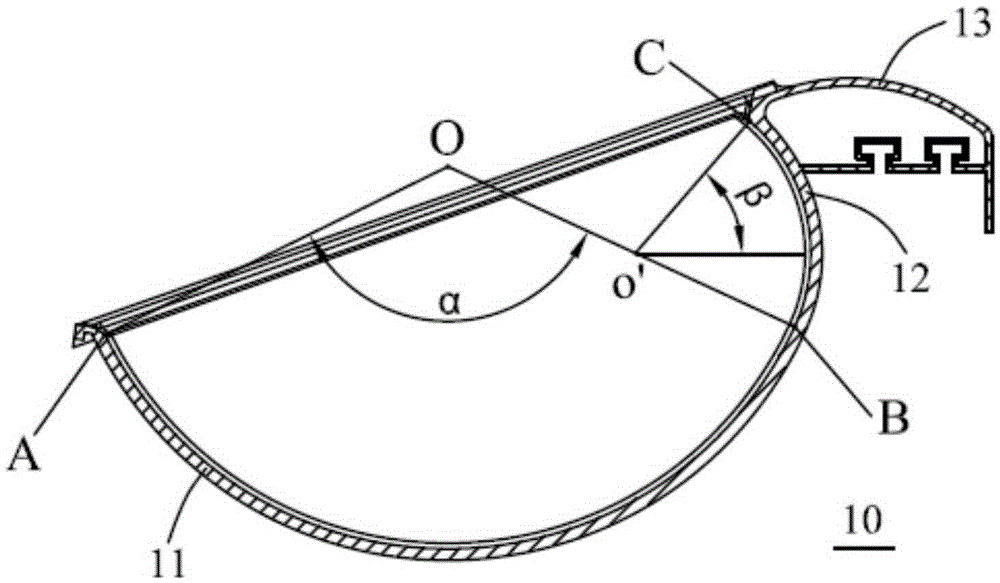

Bead tea continuous forming system based on automatic feeding and control method thereof

ActiveCN109733903AImprove qualityGuaranteed qualityWeighing apparatus using elastically-deformable membersWeighing apparatus with automatic feed/dischargeEngineeringMaterial distribution

The invention relates to a bead tea continuous forming system based on automatic feeding and a control method thereof. The system comprises a PLC control unit, an initial frying unit, a spreading andcooling unit and a refrying unit, a vertical lifting machine, a weighing mechanism, a material distribution mechanism and a vibration type conveyor are arranged on the initial frying unit and the refrying unit, so that automatic feedingg, automatic pan-frying are realized, the continuous making of the pearl tea production is realized, and the production efficiency and the quality of the pearl teaare greatly improved. The control method comprises a primary frying feeding link, a primary frying link, a spreading and cooling link, a refrying and feeding link and a re-frying link control process.According to the control method, the automation degree of the forming system is higher.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Taro pancake and method for making same

The invention discloses a taro pancake and a method for making the taro pancake. The taro pancake contains the raw materials in following proportions: one medium-sized taro, 15 to 18% of cream, 15 to 18% of powdered sugar, 20 to 25% of kaoliang, 20 to 25% of millet flour, 3 to 4% of salt, 1 to 2% of alkali, and 7 to 8% of dried ginger. The method comprises the following steps that: the taro is peeled and cleaned and then cut into small pieces, these pieces are steamed for 30 minutes to obtain quite soft mashed taro, the resultant mashed taro is taken out and added with 20g cream and 20g powdered sugar while the mashed taro is hot, the mixture is pounded up by a spoon to obtain mashed mixture for future use; the resultant is mixed with kaoliang and millet flour to obtain fine powder, the fine powder is mashed and put in a pancake making machine for pan-frying, and finally, the taro pancake can be eaten after being dried. Compared with the current pancakes, the taro pancake disclosed by the invention has sweet and delicious taro taste, has the efficacies of dispersing accumulation, regulating Qi flow, detoxifying, tonifying spleen, clearing away pathogenic heat and relieving cough, enhances human immunity and disease resistance, and can achieve the purposes of detoxifying and nourishing body in the case of long-term use.

Owner:万华

Ganoderma lucidum feedstuff for edible pigeon, preparing method and uses thereof

The invention provides a ganoderma feed for edible pigeons. By adding with ganoderma, the pigeon feed is prepared. The ganoderma feed for edible pigeons can be made into liquid-like or granular shape. The edible pigeon feed can be used for feeding ganoderma pigeons, can cause pigeons to contain not only the nutrient component of common pigeon for table purpose, but also to contain rich essence of ganoderma. While in pan-frying, stewing, burning, the substances of ganoderma are not required to be added, the pigeon meat and soup can achieve the ideal effect of containing rich essence of ganoderma and special flavor of ganoderma.

Owner:梁国强

Preparation method of health-care mulberry leaf tea

The invention provides a preparation method of health-care mulberry leaf tea. The preparation method comprises the following steps of picking high-quality fresh mulberry leaves, cleaning the picked mulberry leaves with distilled water, performing sunning, and performing spreading; performing steam fixation treatment, and performing pan-frying treatment so as to obtain mulberry leaf tea primary semifinished products; compounding a mixture containing Chinese junipers, argy wormwood, aloe and licorice roots, performing crushing, adding an ethanol solution, performing leaching treatment, performing filtration so as to obtain extract, and performing heating and concentrating until the mass is 1 / 2 of original mass; uniformly spraying the concentrated extract onto the mulberry leaf tea primary semifinished products, and performing turning over while spraying; and rolling processed mulberry leaf tea at the temperature of 50-60 DEG C for 20-40min, performing freeze drying at the temperature being minus 20-minus 10 DEG C for 20-30min, and performing crushing so as to obtain the health-care mulberry leaf tea.

Owner:苏州先蚕丝绸有限公司

Trichosantheskirilowiimaxim seed processing method

InactiveCN101889698AComminuted rupture does not occurImprove performanceFood preparationFragrance extractionAdditive ingredient

The invention discloses a trichosantheskirilowiimaxim seed processing method, which comprises the following steps of selecting, washing, soaking, digesting, baking, inspecting and packing. The conventional pan-frying process is replaced by the soaking process, the digesting process and the baking process, wherein the soaking process is favorable for taste absorption of ingredients, and can change the original structure of a hull by using the ingredients under a hull softening state so as to solve the processing problem caused by the fact that the trichosantheskirilowiimaxim seed has a thicker and harder hull and a crisper and tender seed meal compared with common seeds; the digesting process is favorable for improving the achievement of the soaking process; on the basis, three stages of the baking process at different temperatures are adopted, wherein the temperature is from low to high and the time is from long to short, which are consistent with the three technical characteristics of drying, baking and fragrance extraction. The method solves the problem that the hull is cracked in a smashing mode when the product is bit by teeth for removing the hull, and effectively improves the quality of the product.

Owner:衢州市衢天食品有限公司

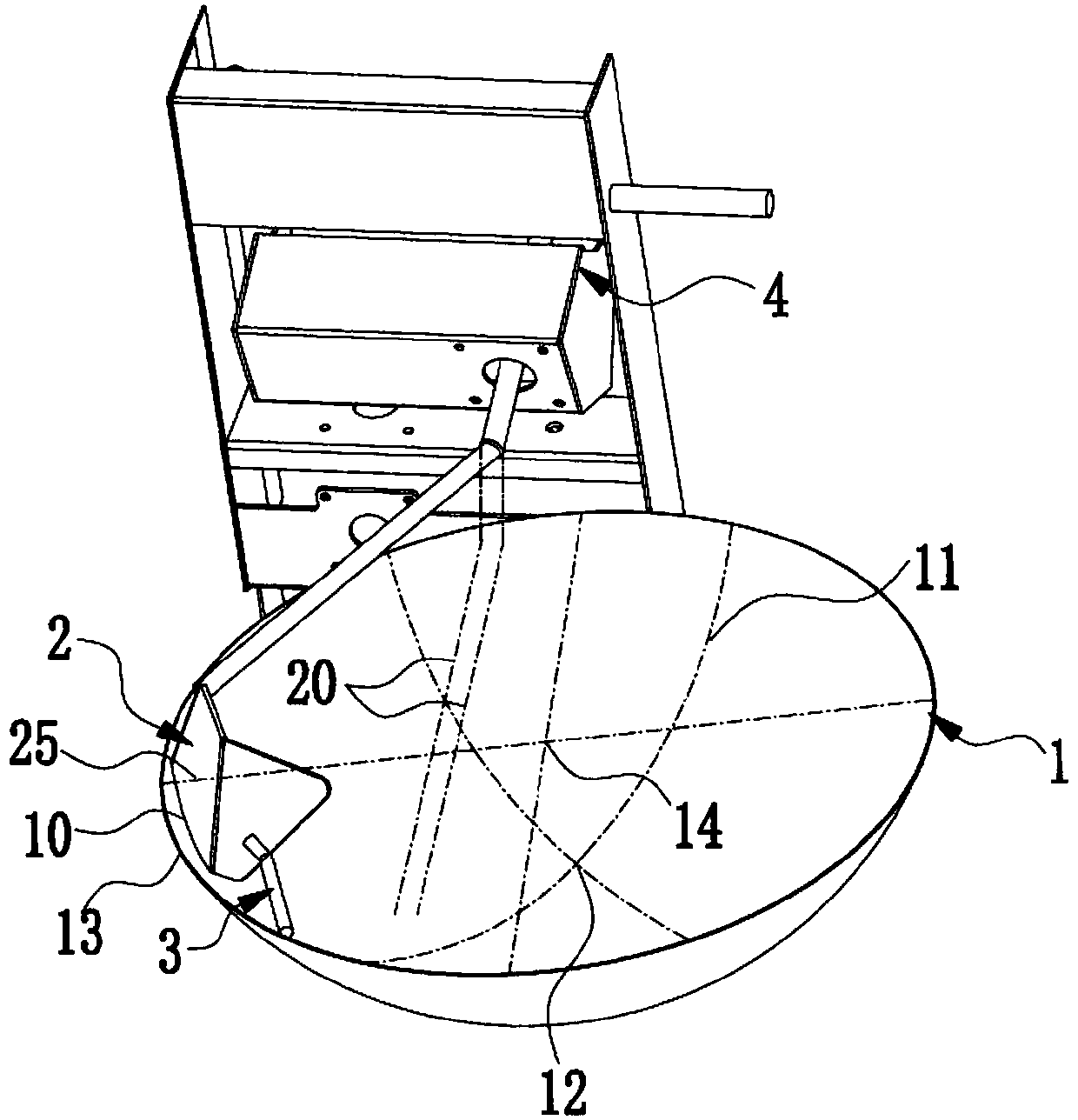

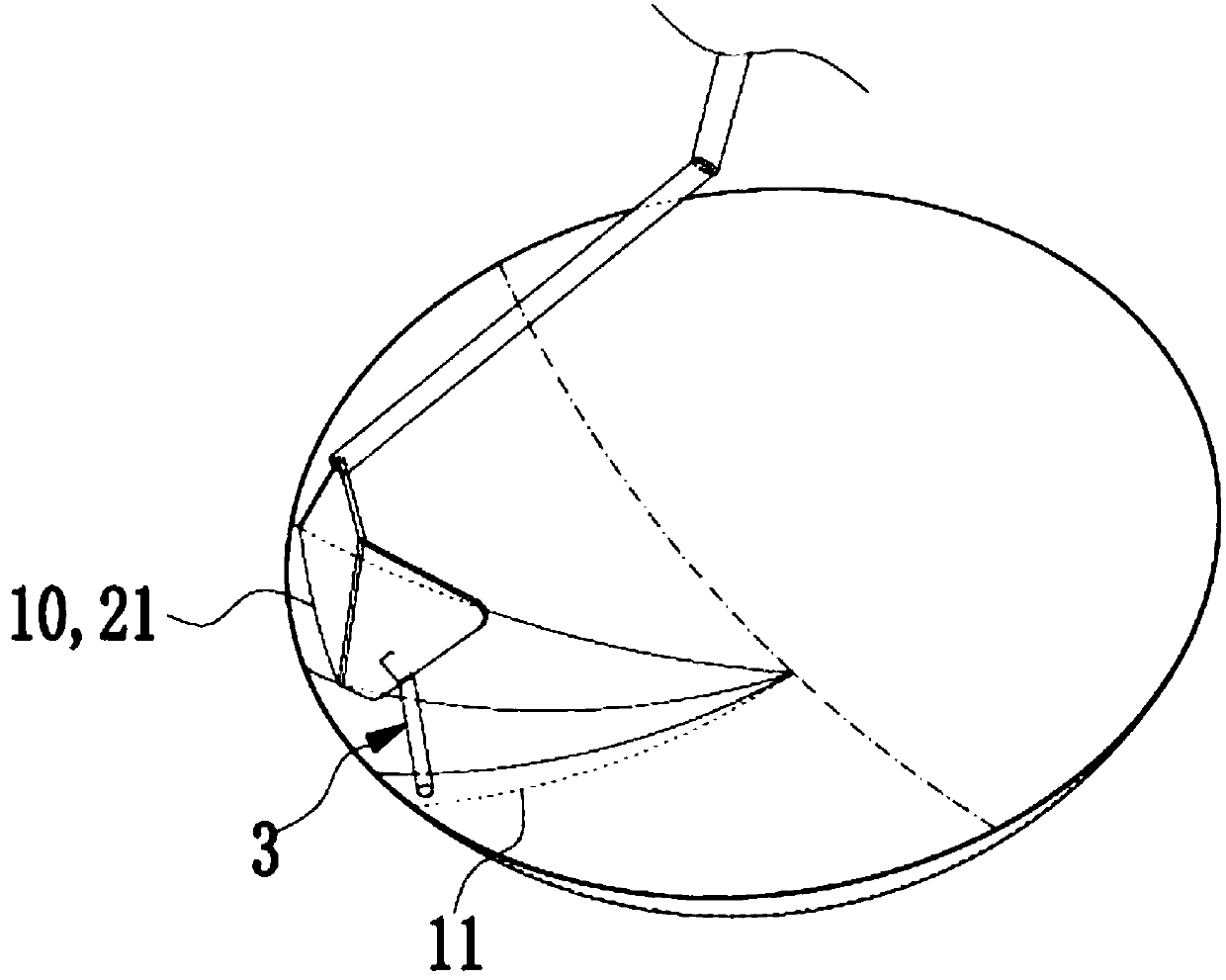

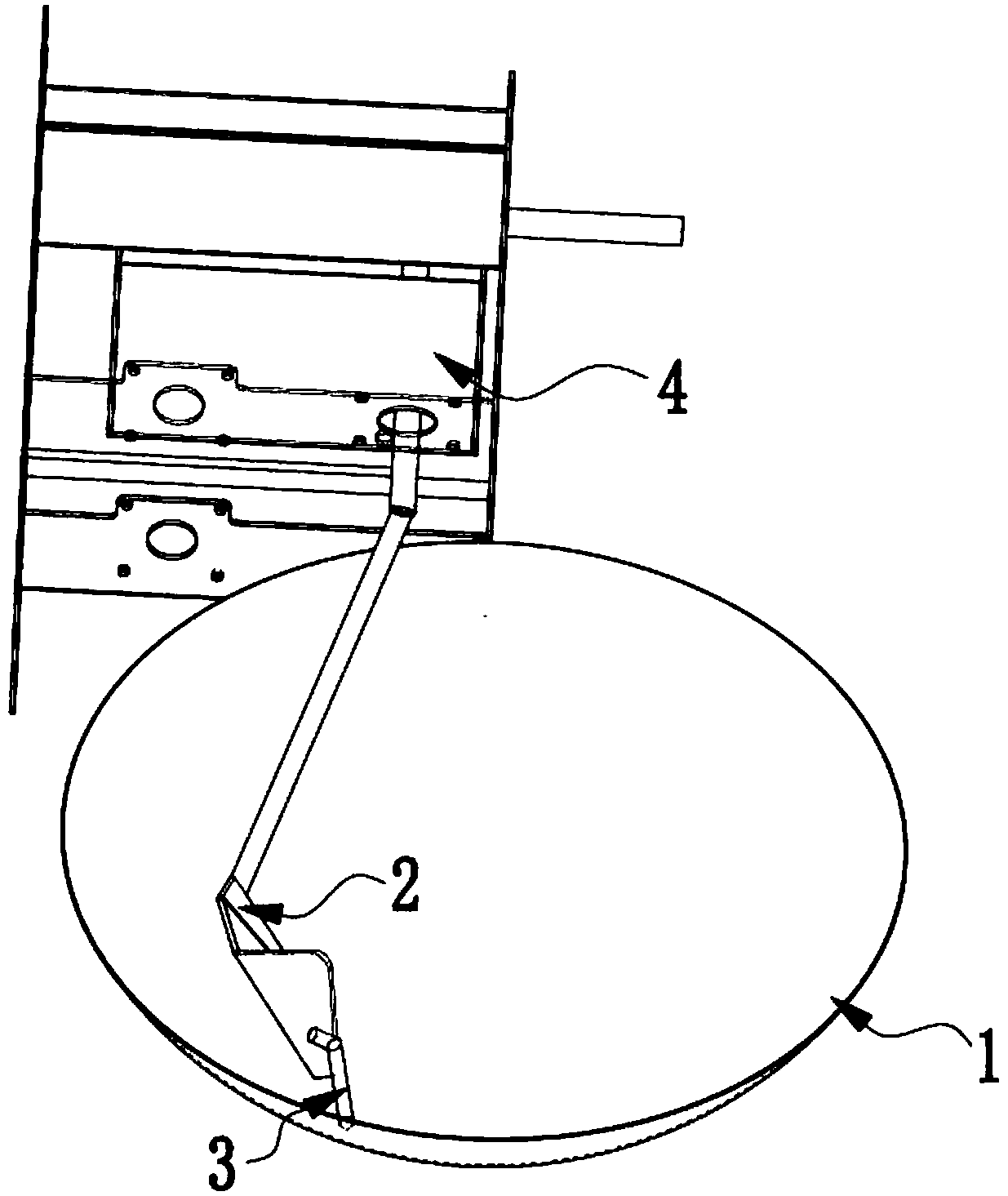

Artificial frying simulation cooking robot and cooking method thereof

The invention discloses an artificial frying simulation cooking robot and a cooking method thereof. The artificial frying simulation cooking robot comprises a pot body, a special spatula, an abuttingrod and a drive device. The abutting rod and the drive device are respectively connected to the special spatula and are matched with the special spatula for switching between a first frying process and a second frying process. In the first frying process, the edge of the special spatula is kept in contact with an inner wall of a pan, the special spatula slides from a tangent point position of thespecial spatula with the inner wall to a pan bottom position of a pan body, and the angle between the spatula surface of the special spatula and the pan mouth of the pan body gradually decreases; in the second pan frying process, the special spatula does not contact with the inner wall, and the special spatula flips from the pan bottom position to the tangent point position. According to the artificial frying simulation cooking robot and the cooking method thereof, the structure is simple, and the problems of sticking, scrap and sticking easily occur when there is a gap between the edge of thespecial spatula and the inner wall of the pan are avoided; besides, after materials are scooped up, the frying of the materials is achieved through the turnover of the special spatula, which effectively simulates the action during the manual frying and helps to make the materials be heated and mixed more evenly.

Owner:方正明

Low carbohydrate fried food

A method for preparing a low-carbohydrate food product that is pleasing in appearance, and tasty, providing both the look and feel of conventional fried food. The method uses a liquid coating to cause a powdered hard cheese with specific properties to adhere to the surface of a foodstuff. The hard cheese coated foodstuff is then cooked, by pan frying, or deep frying. Foodstuffs including meat, freshwater fish, seafood, poultry, cheese, low-carbohydrate vegetables, as well as soy-based and synthetic protein foods. Other low-carbohydrate foodstuffs may be used in this invention. A variety of hard cheeses, and other cheeses, as well as cheese products including imitation cheese may be used to coat the foodstuff before preparation. The resulting food product has a crunchy, golden brown exterior, and is very tasty, providing a delicious food with small or negligible amounts of carbohydrate.

Owner:LONG JAMES I +1

Preparation process of salt tea

The invention discloses a preparation process of salt tea which has the functions of reducing phlegm and clearing away heat and detoxifying and relieving sore-throat and is convenient for drinkers to make and carry. The preparation process is realized by the following steps: (1) weighing 500-600g of tea essence and 250-350g of salt; (2) spreading out the tea essence under the sun to be dried to remove moisture and naturally fermenting to obtain sunned tea with the water content of 95-97%; (3) rocking the sunned tea to obtain rocked tea; (4) spreading out the rocked tea at normal temperature and standing for 10-24 hours to obtain aired tea with the leaf thickness of 2-4cm and the water content of 90-94%; (5) pan-frying and cooling the aired tea, and after cooling, spraying salt into the cooled aired tea to obtain a semi-product; and (6) pouring the semi-product into a kneading machine to be kneaded, after kneading, pouring into a setting machine to set spherically, and after setting, pouring into a non-toxic container and standing for a week; and finally obtaining the salt tea with the water content of 10-20%.

Owner:NANAN ZHONGDU CULTIVATION CO LTD

Compound tea and preparation method thereof

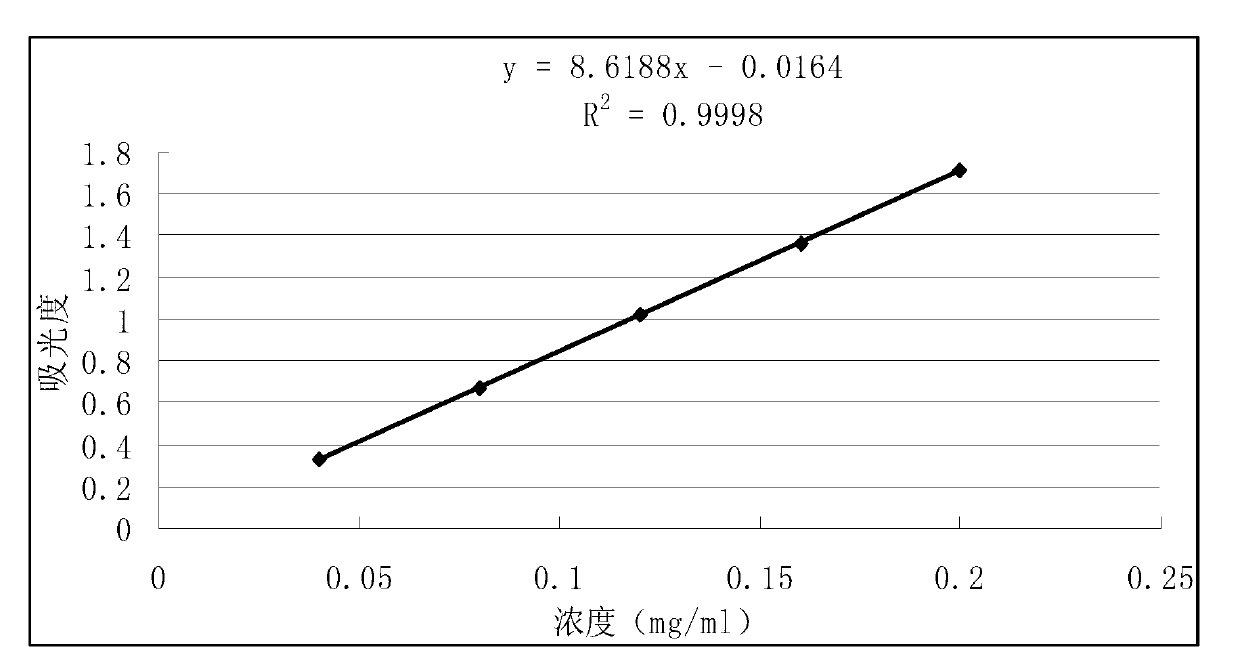

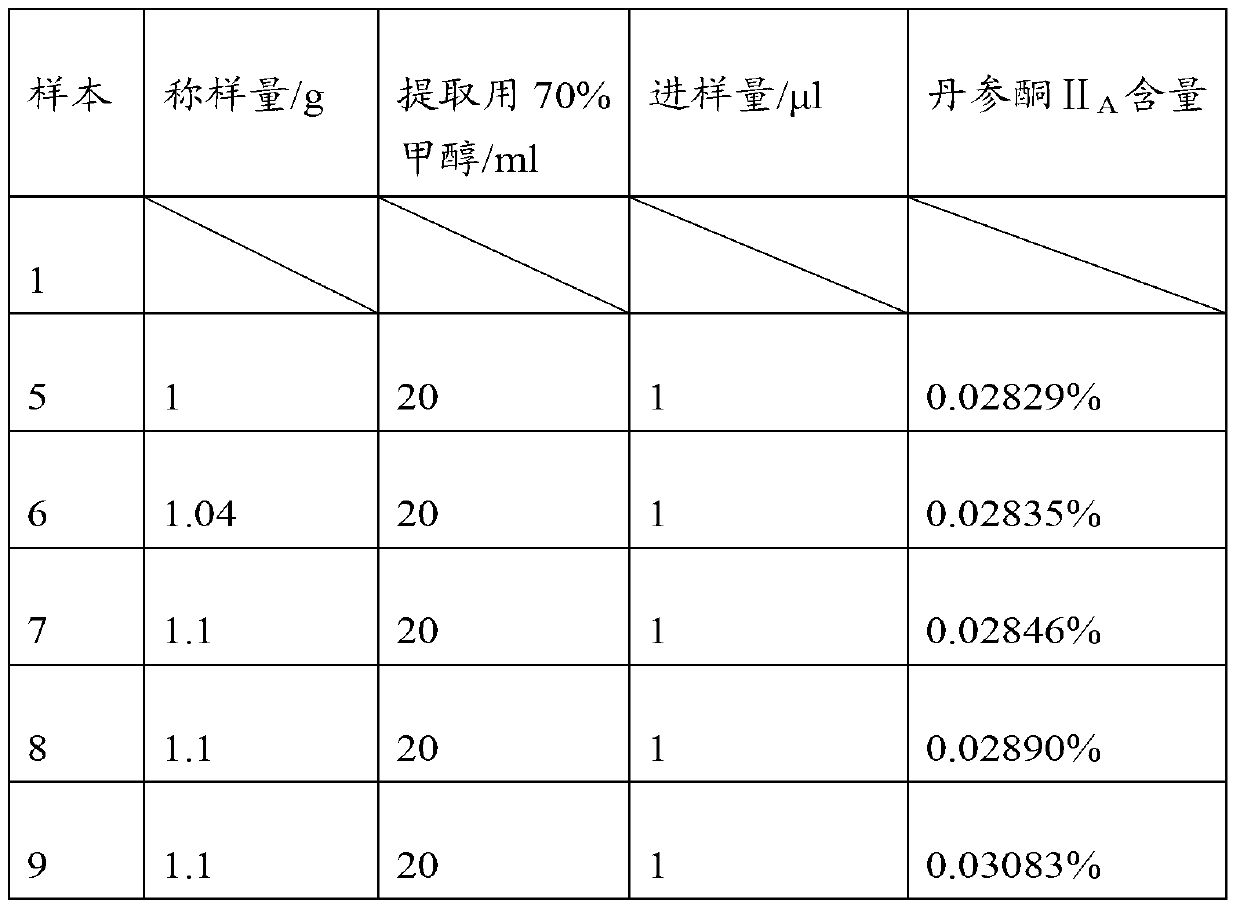

InactiveCN103340256AKeep active ingredientsPreserve appearancePre-extraction tea treatmentSalvia miltiorrhizaBlack tea

The invention relates to the technical field of beverages and in particular relates to compound tea and a preparation method thereof. The preparation method comprises a step of adding a salvia miltiorrhiza extract and a medlar extract in a black tea fermentation step and / or a drying step, wherein the preparation of black tea comprises the sub-steps of withering, pan-frying, rolling, fermentation and drying. According to the preparation method of the compound tea, the salvia miltiorrhiza extract and the medlar extract are added in the black tea fermentation or drying step, so that the effective components, the appearance and the taste of black tea are retained to the maximum extent, and the effects of salvia miltiorrhiza, medlar and black tea are organically integrated; therefore, the novel compound tea with the effects of the salvia miltiorrhiza, the medlar and the black tea is obtained.

Owner:王学勇 +1

Manufacturing technology of organic dendrobium officinale flower tea

InactiveCN106173065AGuaranteed qualityImprove qualityTea substituesCooking & bakingManufacturing technology

The invention discloses a manufacturing technology of an organic dendrobium officinale flower tea. The manufacturing technology comprises the following steps: (1) picking: watering organic dendrobium officinale one day before blossoming to wash off dusts and impurities on the flowers, and picking the flowers on the first day of blossoming; (2) screening; (3) drying; (4) washing a boiler: pouring prepared spring tea stalks into a tea frying machine, heating to a temperature of 120 to 128 DEG C, and pouring out the tea stalks; (5) pan frying: adjusting the heating temperature to make the temperature stay in a range of 120 to 128 DEG C, pouring the dried flowers, frying the flowers until the color of the flowers becomes golden-yellow and bright, closing the fire, keeping on frying the flowers by using the waste heat of the boiler, when the temperature reaches 60-80 DEG C, closing the tea frying machine, and pouring out the flowers; and (6) baking: evenly paving the fried flowers on a sieve, baking the flowers in a baking machine for 90 to 110 minutes at a temperature of 90 to 100 DEG C so as to obtain the organic dendrobium officinale flower tea. The provided manufacturing technology is simple and innovative; after picking, the flowers do not need to be washed, the obtained flower tea is clean, the quality is high, and the functions are excellent.

Owner:FUJIAN LIANTIANFU BIOLOGICAL SCI & TECH CO LTD

Cooking device

ActiveCN106618142ARealize the effect of flipping the potReduce cooking energy consumptionCooking vesselsEngineeringCooking process

The invention provides a cooking device, which comprises a cooker, comprising a pot body and a back turning part extending from the cooker body; a frying mechanism, comprising a stir fry power device and a stir frying component. Wherein, the working end of the stir frying component is matched with the inner wall of the cooker body, and the inner part of the cooker is moved from the main body of the cooker to the turning part along with the inner wall of the cooker. The cooking device realizes the effect of pan frying through the matching of the frying component and the cooker. There is no need to control the complex movement of the cooker as a simulated cook and manually turn the pan, which can effectively reduce the cooking energy consumption. In addition, because the material in the cooking process acts under the guidance of the turning back part, the inner movement of the pan is carried out, so that the material does not fall outside the pot.

Owner:AIC ROBOTICS TECH

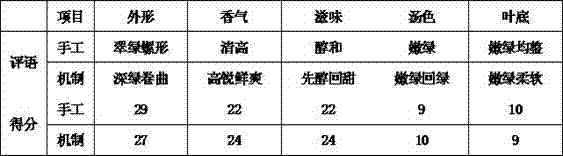

Fabrication method of machine-made Biluochun tea

The invention discloses a fabrication method of machine-made Biluochun tea. The method comprises the following steps: (1) enzyme deactivation, wherein a 6CSW-65 minitype enzyme deactivation machine is adopted, the enzyme deactivation temperature is 165-175 DEG C, the leaves input quantity is 2.8-3.3 kilograms; (2) twisting, wherein a 6CRW-25 minitype twisting machine is adopted for once twisting of a pan of enzyme deactivated leaves obtained in step (1), and the pressure is controlled to be light, heavy and then light; }(3) pan frying, wherein an electric pan with a frying handle is used, the leaves input quantity is 3 kilograms of twisted leaves, the pan temperature is controlled to be 85-105 DEG C, and the temperature is controlled to be from high to low; and (4) drying, wherein a minitype automatic dryer is adopted, the dryer temperature is controlled to be 110-130 DEG C, the leaves feeding quantity is regulated, the tea is dried until the tea becomes powder after being twisted by hands, drying is stopped when the moisture content of leaves reaches 5-10% of the moisture content of fully dry leaves, and after the tea is spread for cooling, the tea fabrication is completed. The method for fabricating tea is high in efficiency, fast in speed, and the tea fabricating cost can be greatly reduced.

Owner:梁昌连

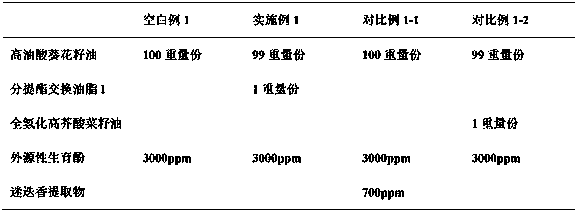

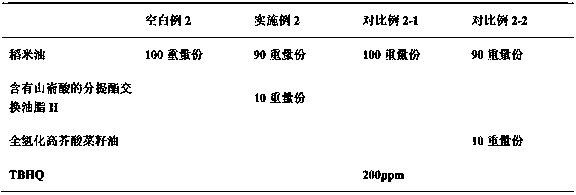

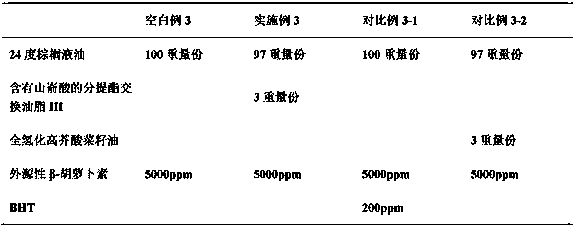

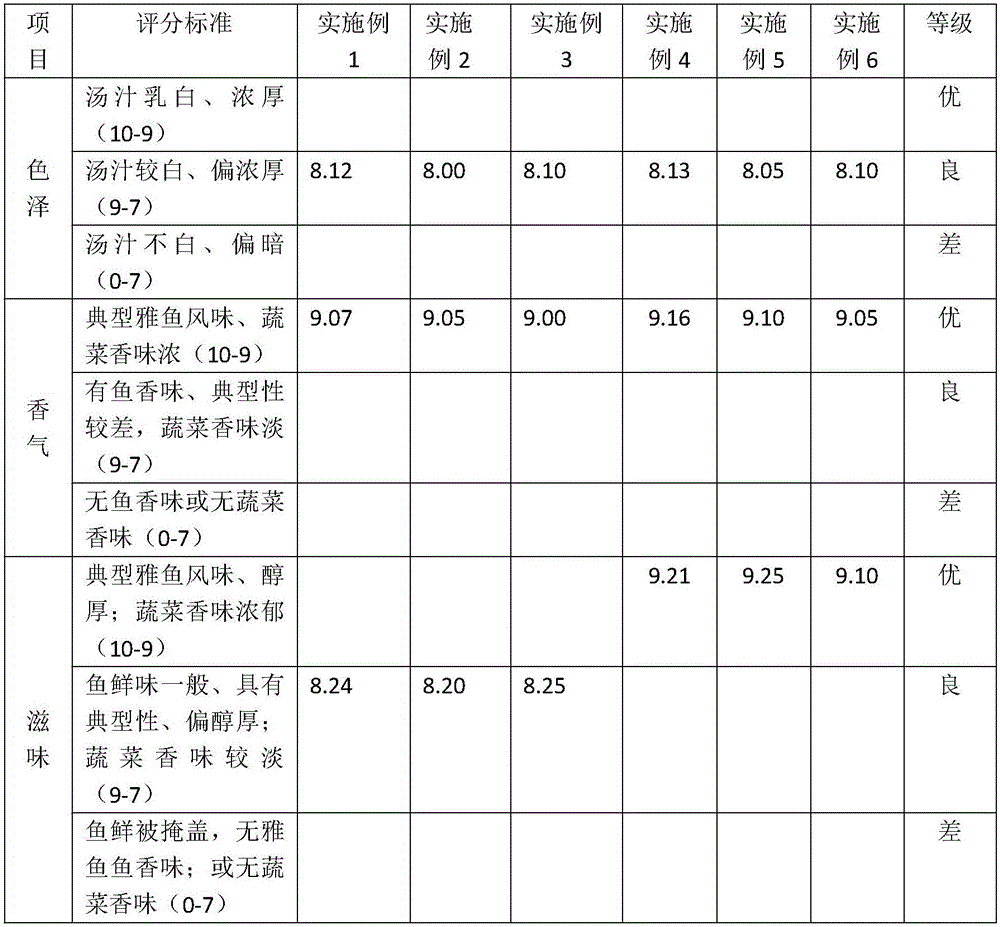

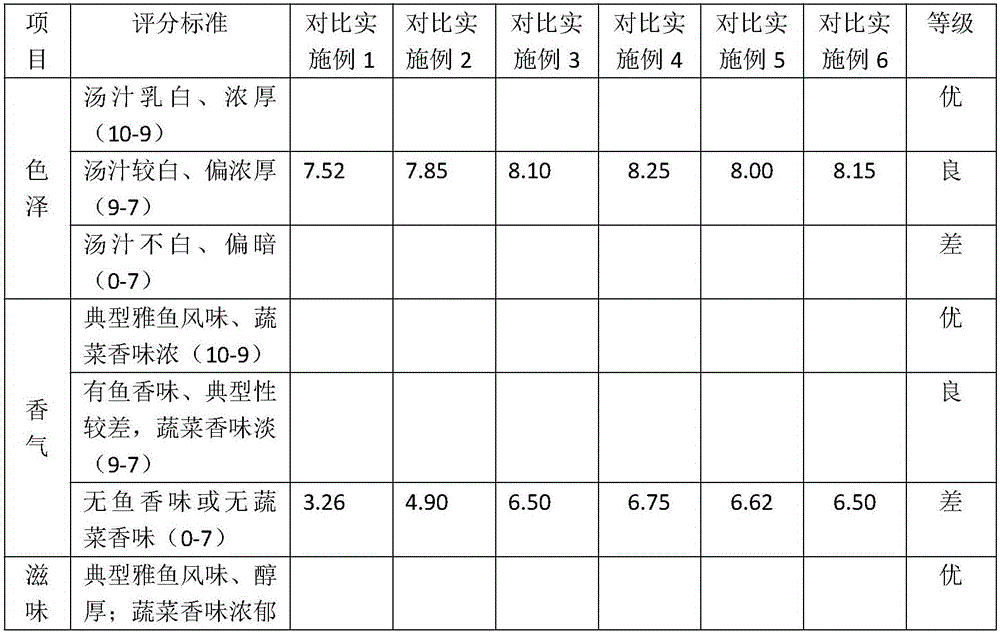

Fat composition and preparation method thereof

ActiveCN108260676AReduce oxidation lossImprove qualityEdible oils/fatsCooking & bakingFat composition

The invention relates to a fat composition and a preparation method thereof. The fat composition contains fractionated and transesterified fat containing docosanoic acid. The fat composition providedby the invention can enable endogenous and exogenous biological active substances to maintain good stability under high-temperature conditions such as pan-frying, baking and cooking.

Owner:WILMAR SHANGHAI BIOTECH RES & DEV CENT

Production process of nettle tea

PendingCN107549409AThe process steps are simplePreserve natural nutrientsTea substituesConvulsionProstate cancer cell

The invention discloses a production process of nettle tea. The production process comprises the following steps: A, picking; B, washing; C, water boiling and de-enzying; D, airing; E, rolling; F, drying; G, pan frying; H, extracting aroma; I, packaging. According to the production process of the nettle tea, disclosed by the invention, nettle tender leaves are prepared into tea, and the process issimple in steps and is suitable for popularization; by optimizing process steps and parameters, in particular to water boiling and de-enzyming, burrs on the nettle leaves are softened and natural nutritional components of the nettle are retained; in addition, the nettle tea has the efficacy of dispelling wind and relieving constipation, promoting digesting and relaxing the bowels; besides, the nettle tea has good effects of treating rheumatoid arthritis, postpartum ventilation, infantile convulsion, polio sequelae, hypertension and dyspepsia, especially inhibiting the proliferation of prostate cancer cells, mediating immune functions of T lymphocyte, preventing differentiation and spread of epithelial tissue cancer cells and the like. The nettle tea produced by the process has the advantages of removing pungent odor and bitterness of the nettle leaves, elegant color luster, strong aroma and comfortable mouth feel.

Owner:青海千紫缘农业科技博览园

Ganoderma lucidum feedstuff for edible pigeon, preparing method and uses thereof

The invention provides a ganoderma feed for edible pigeons. By adding with ganoderma, the pigeon feed is prepared. The ganoderma feed for edible pigeons can be made into liquid-like or granular shape. The edible pigeon feed can be used for feeding ganoderma pigeons, can cause pigeons to contain not only the nutrient component of common pigeon for table purpose, but also to contain rich essence ofganoderma. While in pan-frying, stewing, burning, the substances of ganoderma are not required to be added, the pigeon meat and soup can achieve the ideal effect of containing rich essence of ganoderma and special flavor of ganoderma.

Owner:梁国强

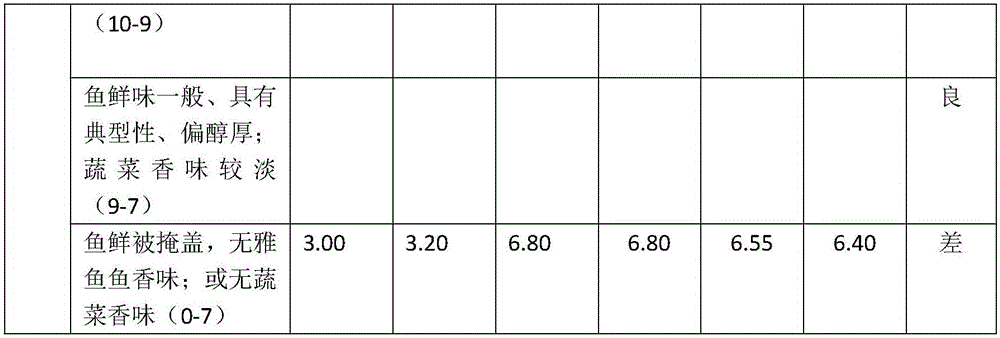

Instant compounded-taste Schizothorax fish soup and preparation method thereof

The invention provides an instant compounded-taste Schizothorax fish soup and a preparation method thereof. The method comprises the following steps of: (1) soaking fresh Schizothorax fish with 1wt% yeast powder solution for 1-3 hours, then pan-frying the soaked fresh Schizothorax fish in hot oil until the Schizothorax fish becomes light yellow; (2) boiling the substance obtained in the step (1) in water until the water is boiled, further boiling with low fire for 0.5-1.5 hours, then adding vegetable granules at a vegetable granule and Schizothorax fish mass ratio of 1 to (9-11), further boiling out with low fire for 2-3 hours, and adding a proper amount of salt and monosodium glutamate, wherein the vegetable granules are lentinus edodes granules or endive sprout granules; and (3) filtering the substance obtained in the step (2), reserving cooking liquor for later use, removing bony spurs in filter residues, then grinding the filter residues, boiling out the ground filter residues in water, and filtering the boiled filter residues to obtain cooking liquor; and (4) mixing the obtained cooking liquors, and performing vacuum concentration on the obtained cooking liquor, thereby obtaining the instant compounded-taste Schizothorax fish soup. The preparation method is simple; the instant compounded-taste Schizothorax fish soup is easy to carry, not only reserves the unique flavor of Schizothorax, but also has the fragrance of endive sprout and lentinus edodes.

Owner:SICHUAN AGRI UNIV

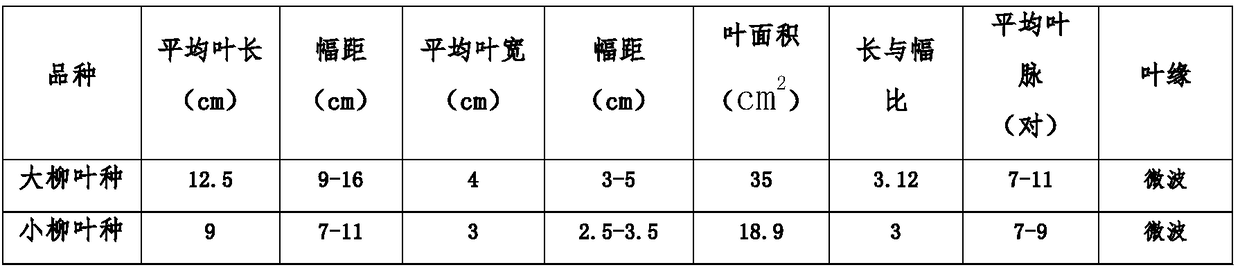

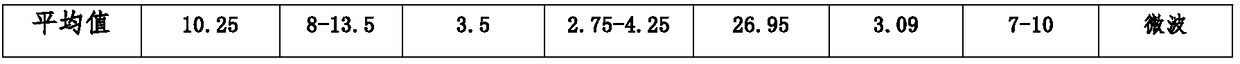

Manual making method of willow leaf species Yongxi houqing tea

InactiveCN108812971ADark green colorBright colorPre-extraction tea treatmentCell buddingAgroforestry

The invention belongs to the field of tea making technologies and specifically relates to a manual making method of willow leaf species Yongxi houqing tea. The method comprises the following steps: tea picking, fresh leaf pretreatment, de-enzyme, shaking-rolling-spreading, stir-frying of tea base, pan frying, screening and storage. The picking standard of two true leaves and one terminal bud is adopted, and tea leaves are picked eight centimeters from the tip of tea; the stir-frying of tea base comprises stir-frying of first tea base and stir-frying of second tea base; the preparatory work before pan frying is pan washing, tea juice and tea ash on the inner wall of the pan are removed to keep the pan wall smooth and bright and the tea soup pure and clear; and pan frying is a process of shaping and drying, the frying method is changed in the process, and smokeless charcoal fire is adopted for long-time low-temperature drying. By manual manufacture of Yongxi houqing tea, the original natural features of Yongxi houqing tea are maintained, and color of the obtained tea is blackish green and apparent and gloss is obvious; fragrance is rich and long-lasting. As the formed tea is dried atlow temperature, fragrance of the tea is more refreshing, fresh and lasting, and the taste is mellow and thick.

Owner:吴建华

Preparation method of tea containing wild sweet potato leaves and mulberry leaves

The invention discloses a preparation method of tea containing wild sweet potato leaves and mulberry leaves. According to the method, the ratio of the used wild sweet potato leaves to the used mulberry leaves is equal to (2 to 5) : (6 to 8); the preparation process comprises the steps of picking, water-removing, mixing, rolling, baking and posttreatment, wherein the water-removing comprises the steps of pan-frying the wild sweet potato leaves, and steaming the mulberry leaves; mixing comprises the step of stir-frying the pan-fried wild sweet potato leaves and the steamed mulberry leaves in a mixed way at the temperature of 100-150 DEG C; the posttreatment comprises the steps of heating the baked tea for 6-12 hours at the temperature of 30-50 DEG C, and then cooling to the room temperature. The method is simple and convenient; the prepared tea containing the wild sweet potato leaves and the mulberry leaves has good effects of relieving cough and reducing sputum, reducing blood pressure, reducing swelling and the like, thus being suitable for daily drinking.

Owner:SICHUAN EBIAN XUESHAN YUZHI FOOD CO LTD

Edible fungus pancake making method

InactiveCN103004913AUnique tasteFull of nutritionDough treatmentBakery productsBiotechnologyNutritive values

The invention discloses an edible fungus pancake making method, which comprises the following steps of: 1) raw material mixing; 2) paste preparation; and 3) pan-frying. The edible fungus pancake made by adopting the method has a unique taste and rich nutrition; by adding fresh edible fungus into the pancake, the nutrition of the pancake is increased, the nutritional value is greater and the appetite is promoted; the edible fungus has the healthcare efficacies of reducing blood sugar, delaying aging, preventing and curing cancers and improving immunity; the taste can be changed according to different people and catering demands of people in multiple aspects can be met; and the edible fungus pancake making method is simple and convenient and the edible fungus pancake is easy to prepare.

Owner:张永和

Making process of tea with leaves of Aquilaria sinensis

A making process of tea with leaves of Aquilaria sinensis includes the steps: firstly, selecting fresh leaves; secondly, sun-drying the fresh leaves; thirdly, air-drying and cooling the leaves by moving the fresh leaves of Aquilaria sinensis and the fresh tea leaves subjected to sun-drying to a cooling rack; fourthly, moving the leaves of Aquilaria sinensis and the tea leaves which are air-dried and cooled into a green-making room, mixing the leaves of Aquilaria sinensis and the tea leaves according to the mass ratio of 5-40% to 60-95%, and performing green-making and fermentation; fifthly, performing rolling and pan-frying; sixthly, rolling for shaping tea; and seventhly, baking to extract fragrance. The leaves of Aquilaria sinensis and the tea leaves are put together on the cooling rackfor air-drying and cooling, flavor of the leaves of Aquilaria sinensis and flavor of the tea leaves are allowed to permeate into each other, the leaves of Aquilaria sinensis and the tea leaves are then mixed proportionally for green-making and fermentation, the leaves of Aquilaria sinensis and the tea leaves are subjected to fermentation and fragrance extraction together, and accordingly the leaves of Aquilaria sinensis and the tea leaves are mutually and fully permeated and merged, and the made tea with leaves of Aquilaria sinensis has the effects of digestion aiding without harming stomach,and has strong long-lasting scent.

Owner:陈鸿进

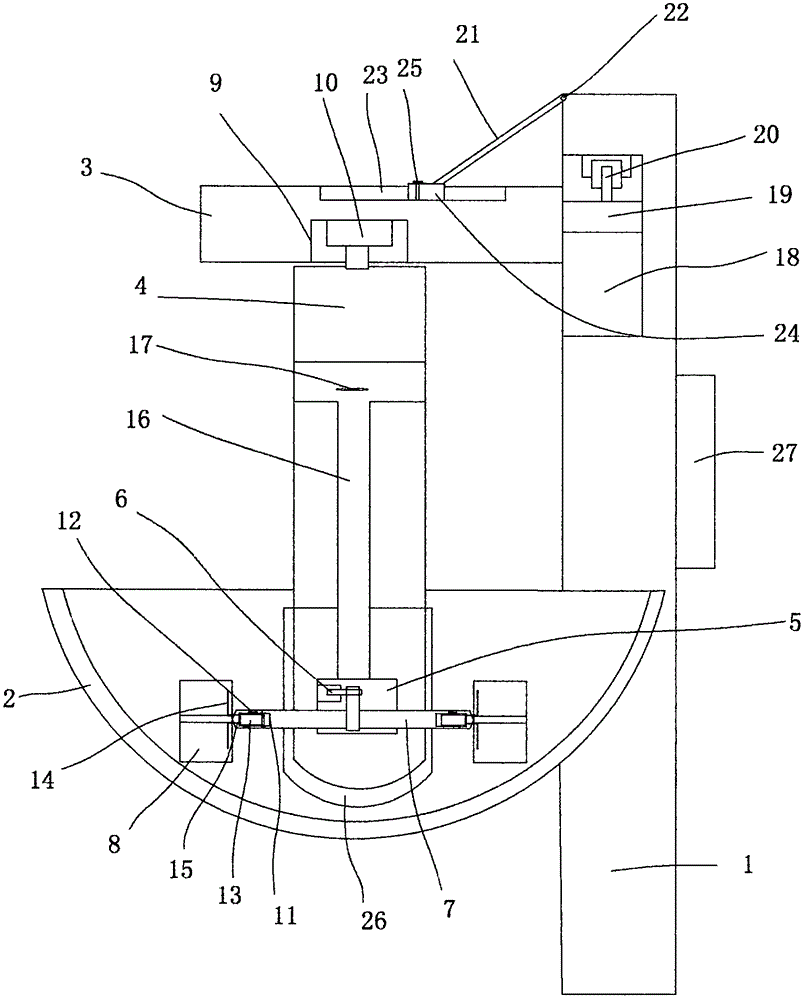

Tea pan-frying device

InactiveCN106172941ASimple structureEasy to operatePre-extraction tea treatmentEngineeringFrying-pans

Owner:王恒标

Making method of loquat fruit tea

InactiveCN108419877AHigh nutritional valueImprove economyTea substituesFreeze-dryingAdditive ingredient

The invention provides a making method of loquat fruit tea. Fresh loquats are used as raw materials of loquat leaf fruit tea, and the making method comprises the following processing procedures of performing rolling and pan frying, performing micro-freeze drying, performing circular soaking, performing ultrasonic extraction, treating loquat fruits, performing reflowing and leaching, performing blending, performing homogenizing, performing sterilization and the like, so that nutrient components contained in the raw materials are reserved, the finished products of the fruit tea are rich in nutrients, and fine and smooth in mouth feel, and have the health-care efficacy of nourishing the lung, relieving a cough and the like. The nutrient value and the economic value of the loquats are increased, and besides, a new way is provided for development and utilization of the loquats.

Owner:芜湖市三山区绿色食品产业协会

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com