Tea cooling and roasting technique and tea cooling and roasting machine

The technology of a hot pot machine and tea, which is applied in the field of tea processing technology and tea processing machinery, can solve the problems of high labor intensity, low production efficiency, tea surface explosion point and old fire point, etc., and achieves low labor intensity and high production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

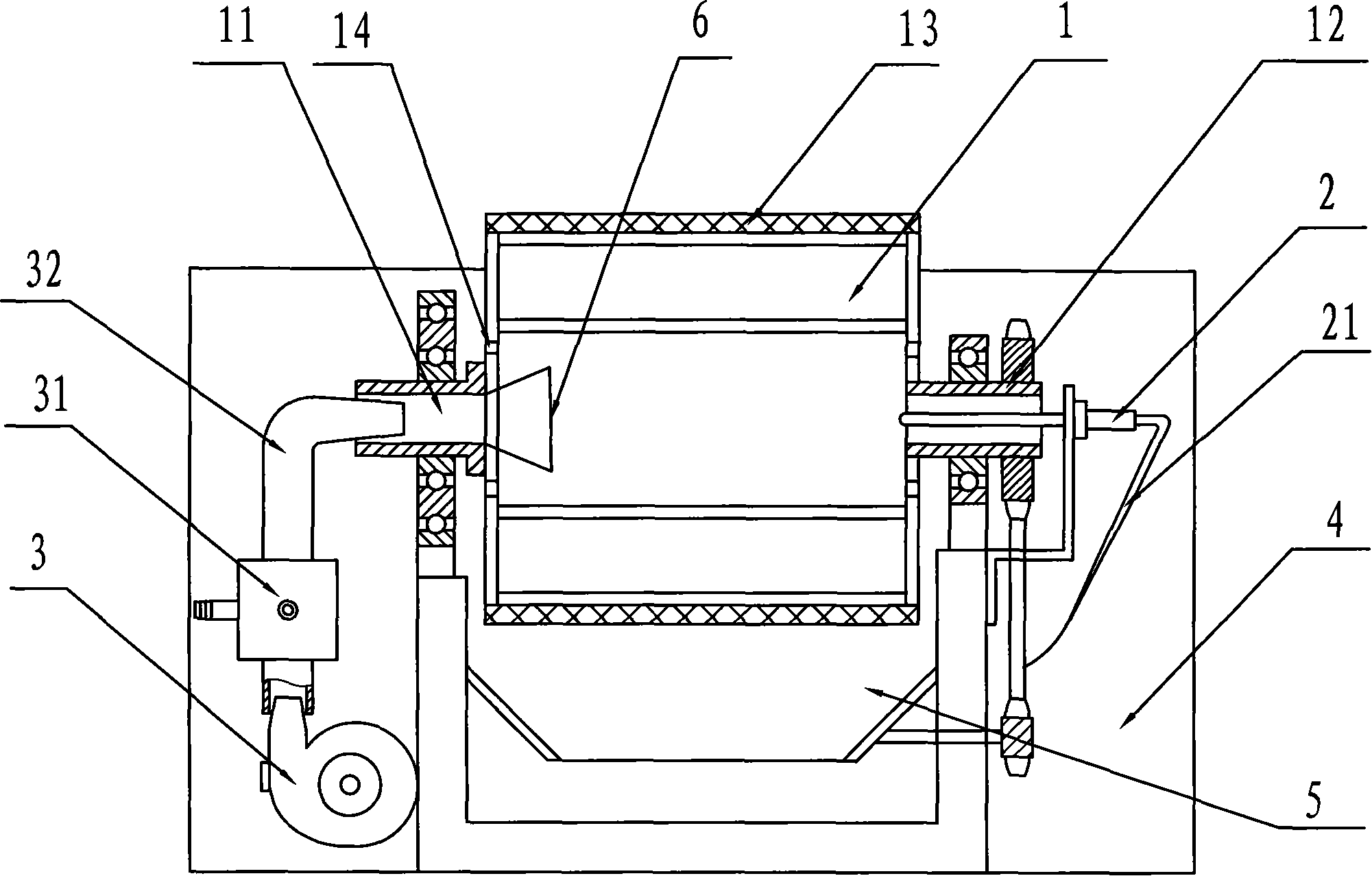

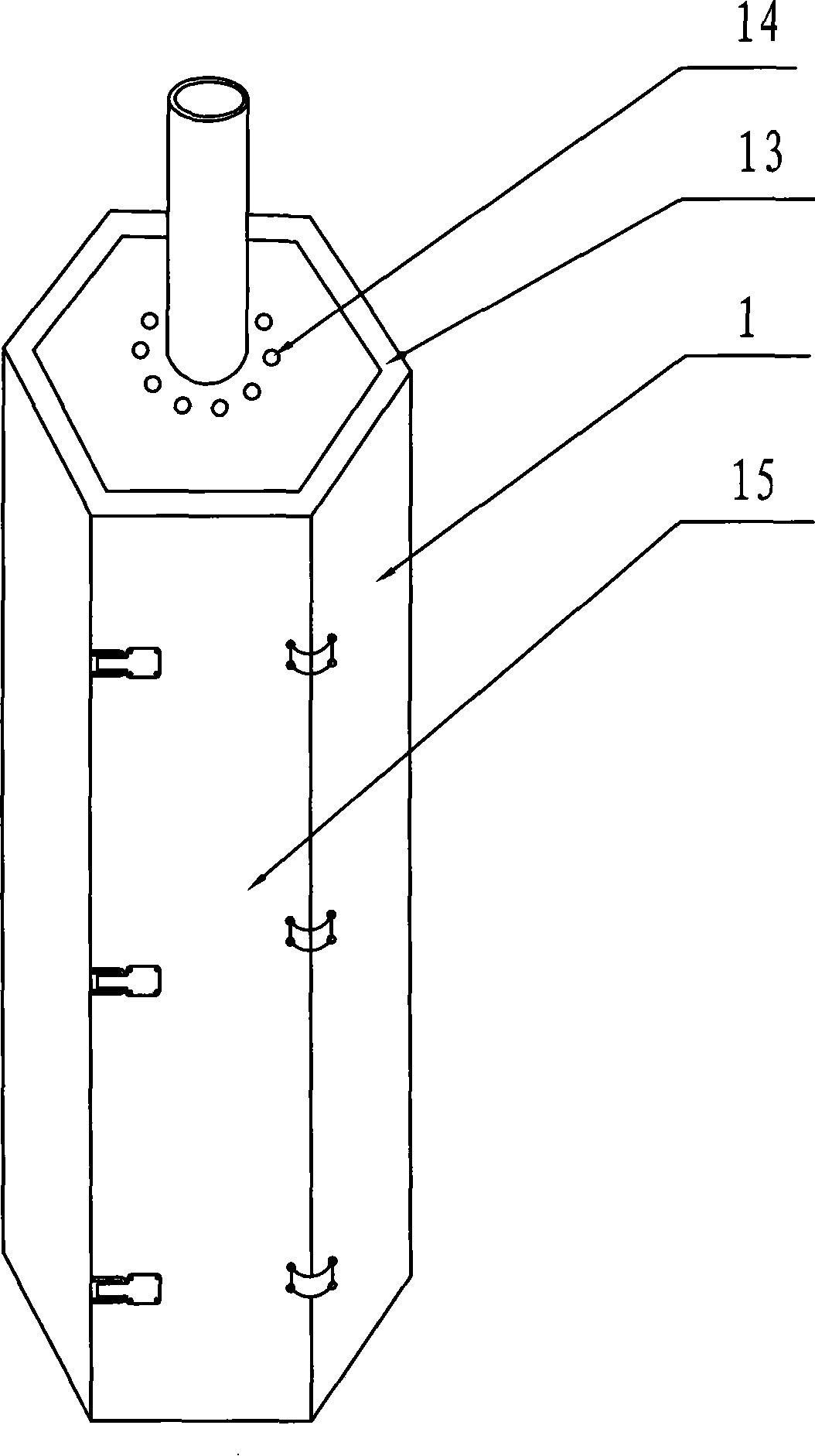

[0026] Embodiment 1: as figure 1 As shown, the present invention includes a frame 4, a cylinder body 1 installed on the frame 4, a heating air source and a motor. The holes 11, 12, the shaft center hole 11 and the shaft center hole 12 are distributed symmetrically. Moreover, the shaft center hole 11 is matched with a heating air source, and a temperature sensor 2 is provided in the cylinder body 1 at the same time. The diameter of the shaft center hole 11 is 58 mm, and the diameter of the shaft center hole 12 is 12 mm.

[0027] The above-mentioned heated air source includes a blower 3 , a heat generator 31 and a hot air pipe 32 . One end of the heat generator 31 is connected with the blower 3 , while the other end is connected with the hot air pipe 32 . The heat generator 31 can adopt various forms, such as a gas combustion type, a liquid combustion type, or an electric heating type. The other end of the hot air pipe 32 passes into the center hole 11 of the shaft, and is b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com