Fabrication method of machine-made Biluochun tea

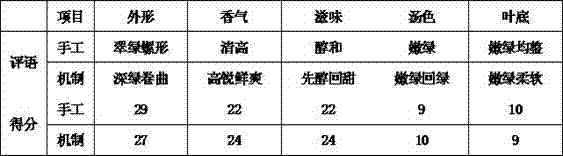

A production method, the technology of Biluochun, is applied in the production field of mechanism Biluochun tea, which can solve the problems of low work efficiency, large quality difference, and uneven mastery, and achieve the effect of reducing tea production cost, high accuracy and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] The preparation method of machine-made Biluochun tea comprises the following steps:

[0014] (1) For greening, use 6CSW-65 miniature greening machine, the temperature for curing is 170 degrees, and the amount of leaves is 3 kg. After suffocating for 3 minutes, blow the steam to exhaust, and then exhaust the steam every 2 minutes, and fry until the leaves are soft. , dark green leaves, green gas disappears, no red stalks, no red leaves, no smoke burnt leaves;

[0015] (2) Kneading, using 6CRW-25 micro-twisting machine, kneading the green leaves in a pot of step (1) once, the pressure is "light-heavy-light", first lightly press to make the leaves curl, and then press heavily to make the tea sticks Make it tighter, and finally loosen the pressure to take back the tea juice, dissolve the lumps, knead until the tea juice overflows, and the ropes are tightly knotted, the time is 15 minutes;

[0016] (3) Stir-fry in a pan, use an electric pan with frying hands, throw 3 kg of ...

Embodiment 2

[0019] The preparation method of machine-made Biluochun tea comprises the following steps:

[0020] (1) For greening, use 6CSW-65 miniature greening machine, the temperature of greening is 165 degrees, the amount of leaves thrown is 3.3 kg, first smothered for 3 minutes, then blow the steam to exhaust, and then exhaust the steam every 2 minutes, fry until the leaves are soft , dark green leaves, green gas disappears, no red stalks, no red leaves, no smoke burnt leaves;

[0021] (2) Kneading, using 6CRW-25 micro-twisting machine, kneading the green leaves in a pot of step (1) once, the pressure is "light-heavy-light", first lightly press to make the leaves curl, and then press heavily to make the tea sticks Make it tighter, and finally loosen the pressure to take back the tea juice, dissolve the lumps, knead until the tea juice overflows, and the ropes are tightly knotted, the time is 20 minutes;

[0022] (3) Stir-fry in a pan, use an electric pan with frying hands, throw 3 kg...

Embodiment 3

[0025] The preparation method of machine-made Biluochun tea comprises the following steps:

[0026] (1) For greening, use 6CSW-65 miniature greening machine, the temperature of greening is 175 degrees, the amount of leaves thrown is 2.8 kg, first smothered for 3 minutes, then blow the steam to exhaust, and then exhaust the steam every 2 minutes, fry until the leaves are soft , dark green leaves, green gas disappears, no red stalks, no red leaves, no smoke burnt leaves;

[0027] (2) Kneading, using 6CRW-25 micro-twisting machine, kneading the green leaves in a pot of step (1) once, the pressure is "light-heavy-light", first lightly press to make the leaves curl, and then press heavily to make the tea sticks Make it tighter, and finally loosen the pressure to take back the tea juice, dissolve the lumps, knead until the tea juice overflows, and the ropes are tightly knotted, the time is 18 minutes;

[0028] (3) Stir-fry in a pan, use an electric pan with frying hands, throw 3 kg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com