Patents

Literature

179 results about "Fragrance extraction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fragrance extraction refers to the separation process of aromatic compounds from raw materials, using methods such as distillation, solvent extraction, expression, sieving, or enfleurage. The results of the extracts are either essential oils, absolutes, concretes, or butters, depending on the amount of waxes in the extracted product.

Method for extracting tobacco essence perfume

InactiveCN1899141AImprove qualityImprove inner qualityTobacco treatmentEssential-oils/perfumesFlavorReflux

The tobacco flavor extracting process includes the following steps: 1. crushing tobacco and setting in extracting tank; 2. adding solvent in 2-16 times the weight of tobacco to the extracting tank; 3. decompression reflux extracting at 20-60deg.c temperature and 0.020-0.098MPa vacuum degree for 1-8 hr; and 4. separating the liquid extract through filtering, and decompression concentrating the filtrate at vacuum degree of 0.020-0.098MPa to obtain the tobacco flavor of density 1.1-1.4g / ml. The extracting process is simple, safe, environment friendly, high in extracting efficiency and low in production cost, and the extracted tobacco flavor has the physical and chemical properties of natural tobacco components and may be added to cigarette to improve flavor, raise quality and lower tar.

Owner:宋光泉 +1

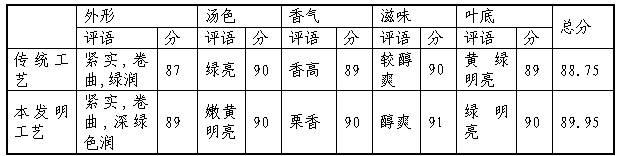

Processing method of bending and scented green tea

ActiveCN102160583AOvercome the disadvantages of heavy bitterness and astringency, and the aroma is easy to be oldIncrease aromaPre-extraction tea treatmentFragrance extractionGreen teas

The invention provides a processing method of a bending and scented green tea. The finished tea is obtained by the steps of: specific green spreading treatment of fresh leaves, roll / microwave combined green removing, humidifying and kneading, prebaking treatment, two times of frying in a small pan, one time of frying in a large pan, infrared drying, infrared fragrance extraction and the like. In the processing method, organic integration is carried out on the existing processing equipment and the process technique and the like, a special temperature-control and humidity-control device is arranged during green spreading of the fresh leaves, the defects of heavy bitter of tea soup and easily entrained slow fire of fragrance and the like in the existing processing technology are overcome by sectional and fine processing, and the purpose of improving the internal flavors such as fragrance and taste and the like of the bending and scented green tea is achieved. As for the processed product, the appearance is compact, the color is green, the fragrance is lasting, and the taste is thick, fresh and cool.

Owner:ZHEJIANG YUN CUI TEA IND DEV

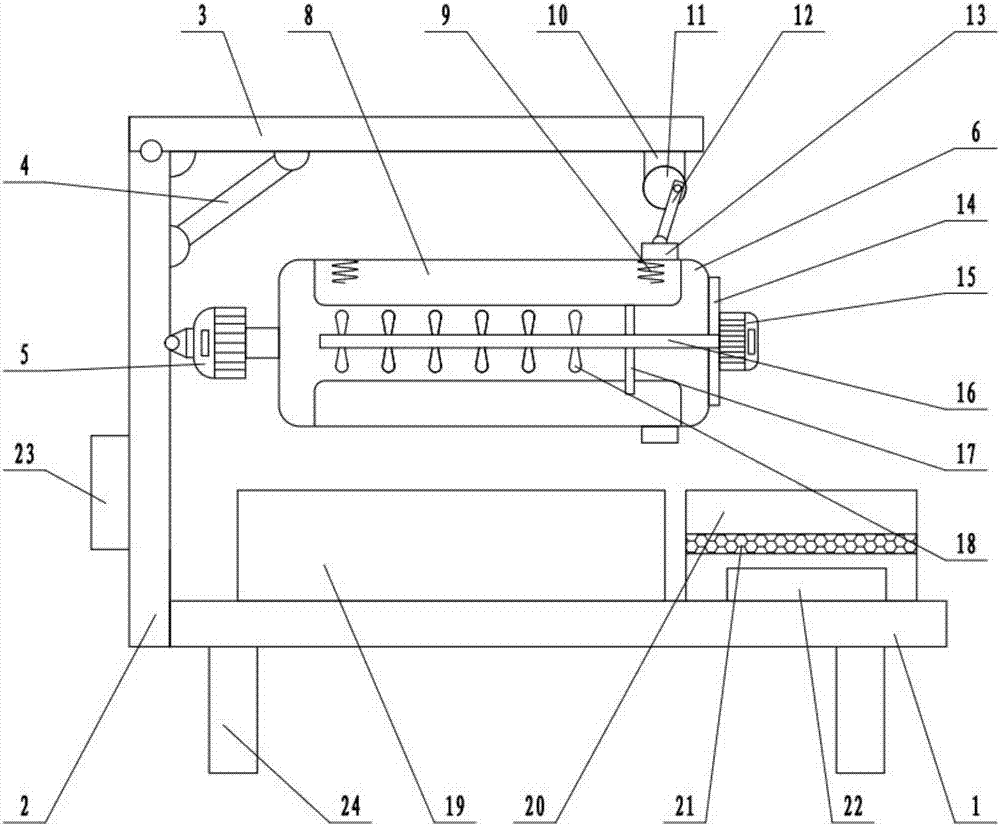

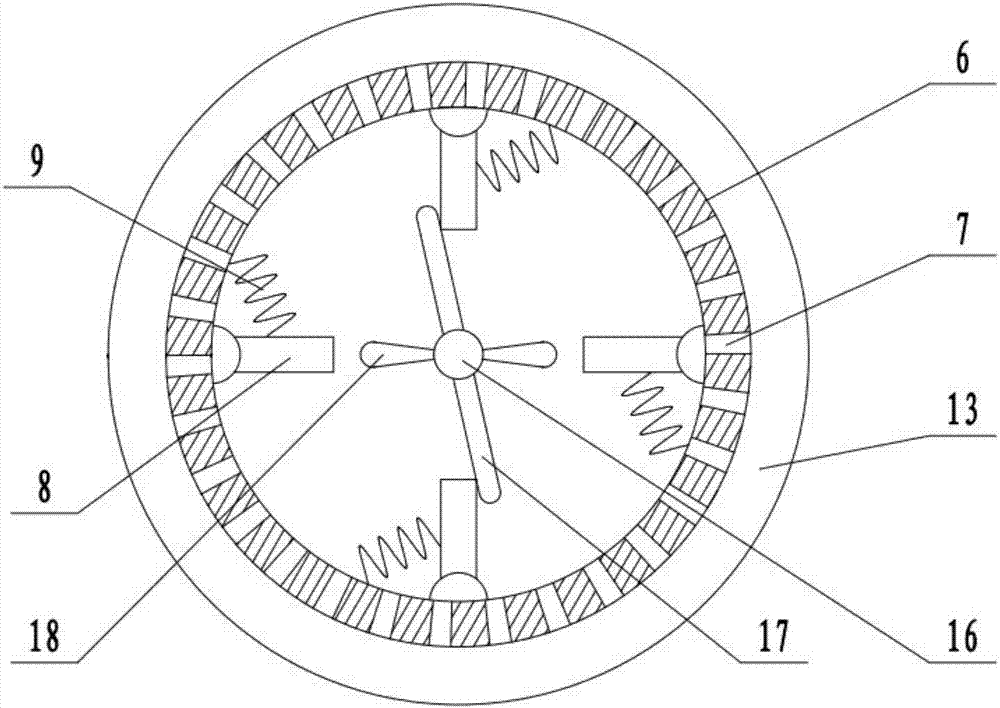

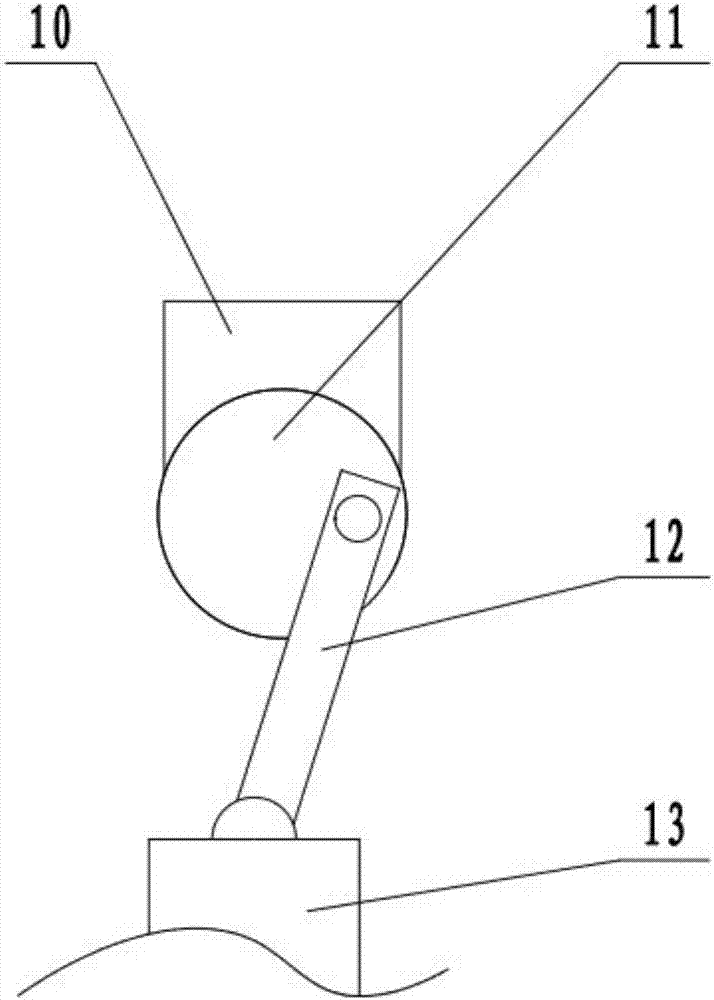

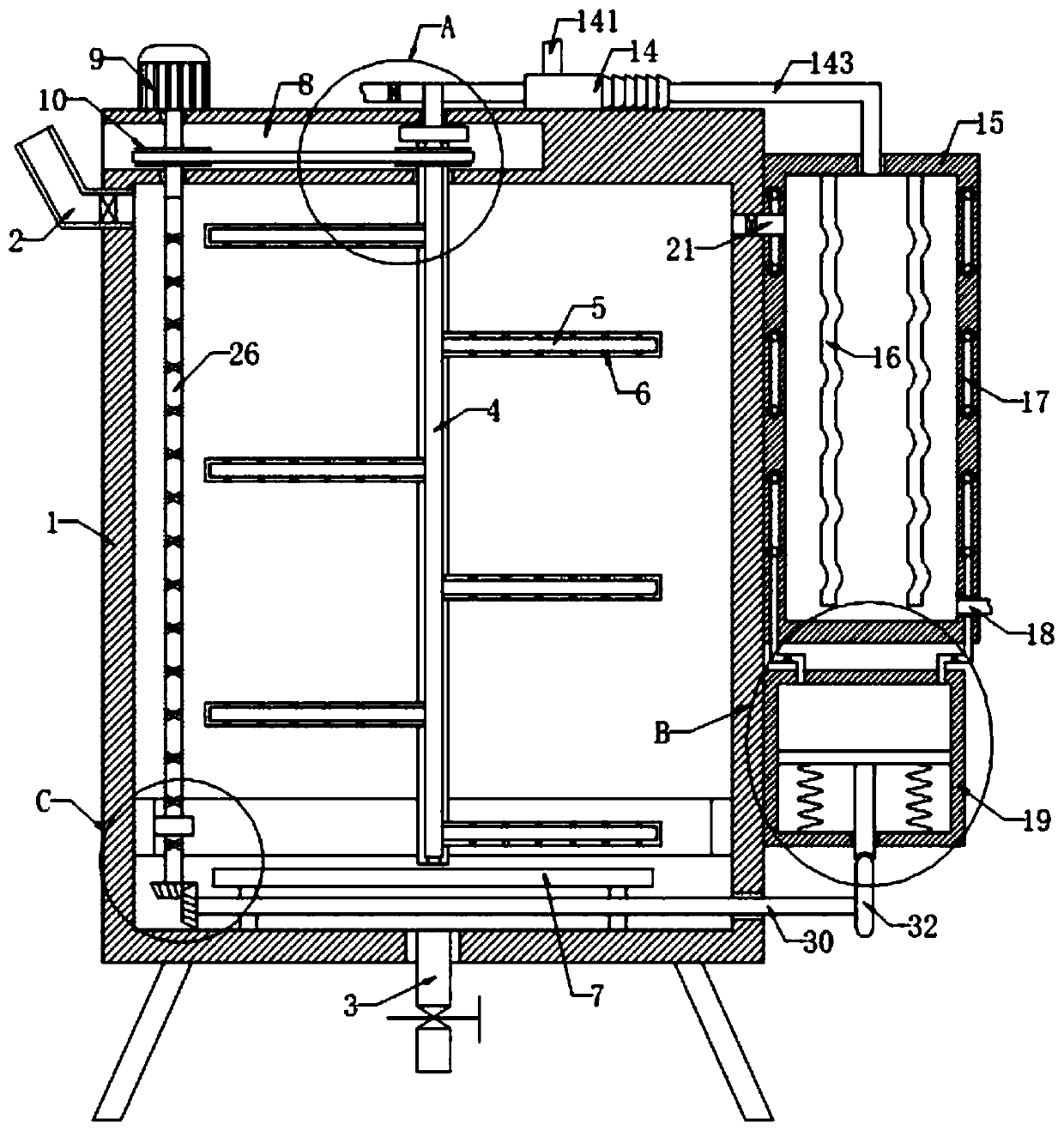

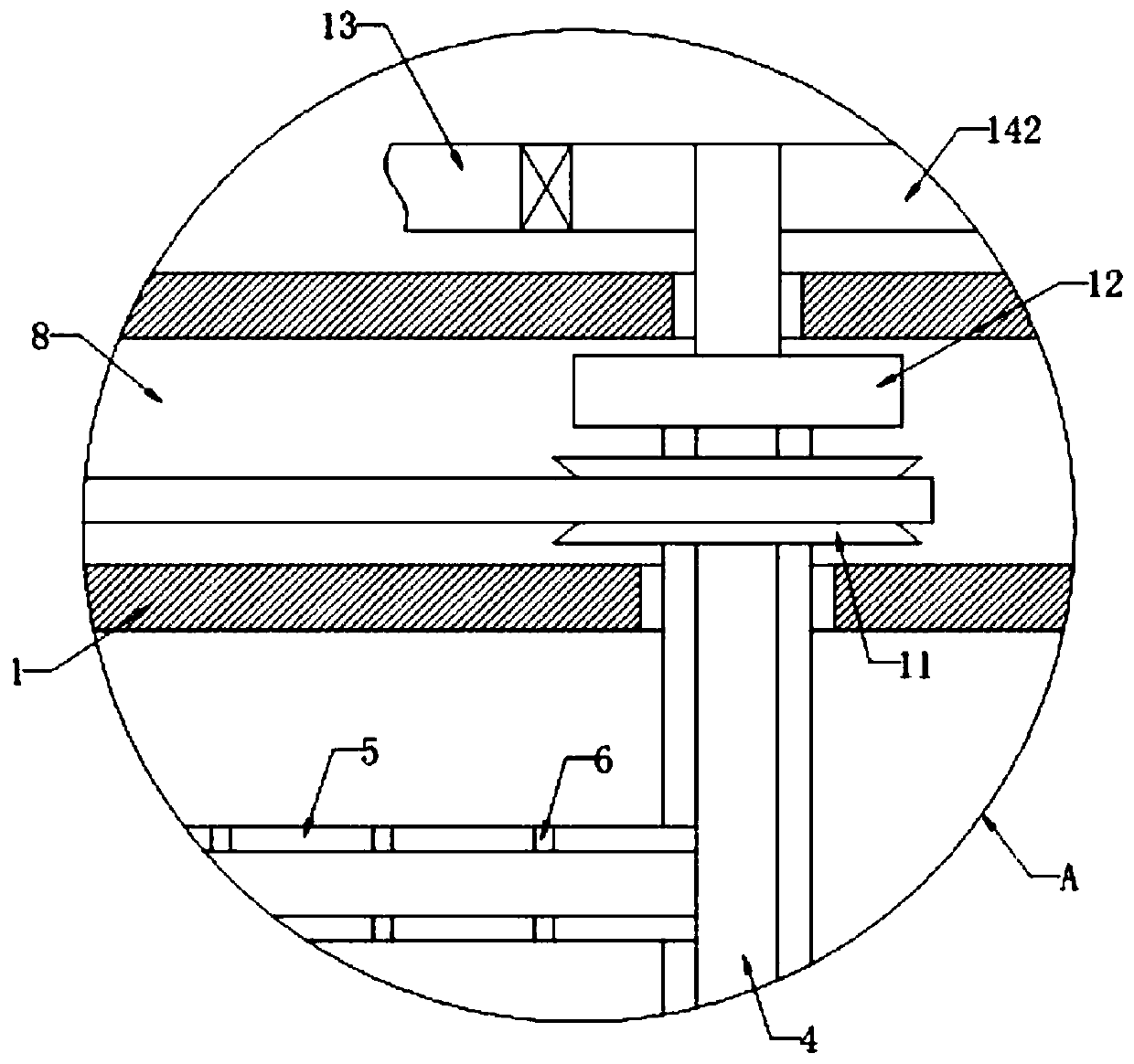

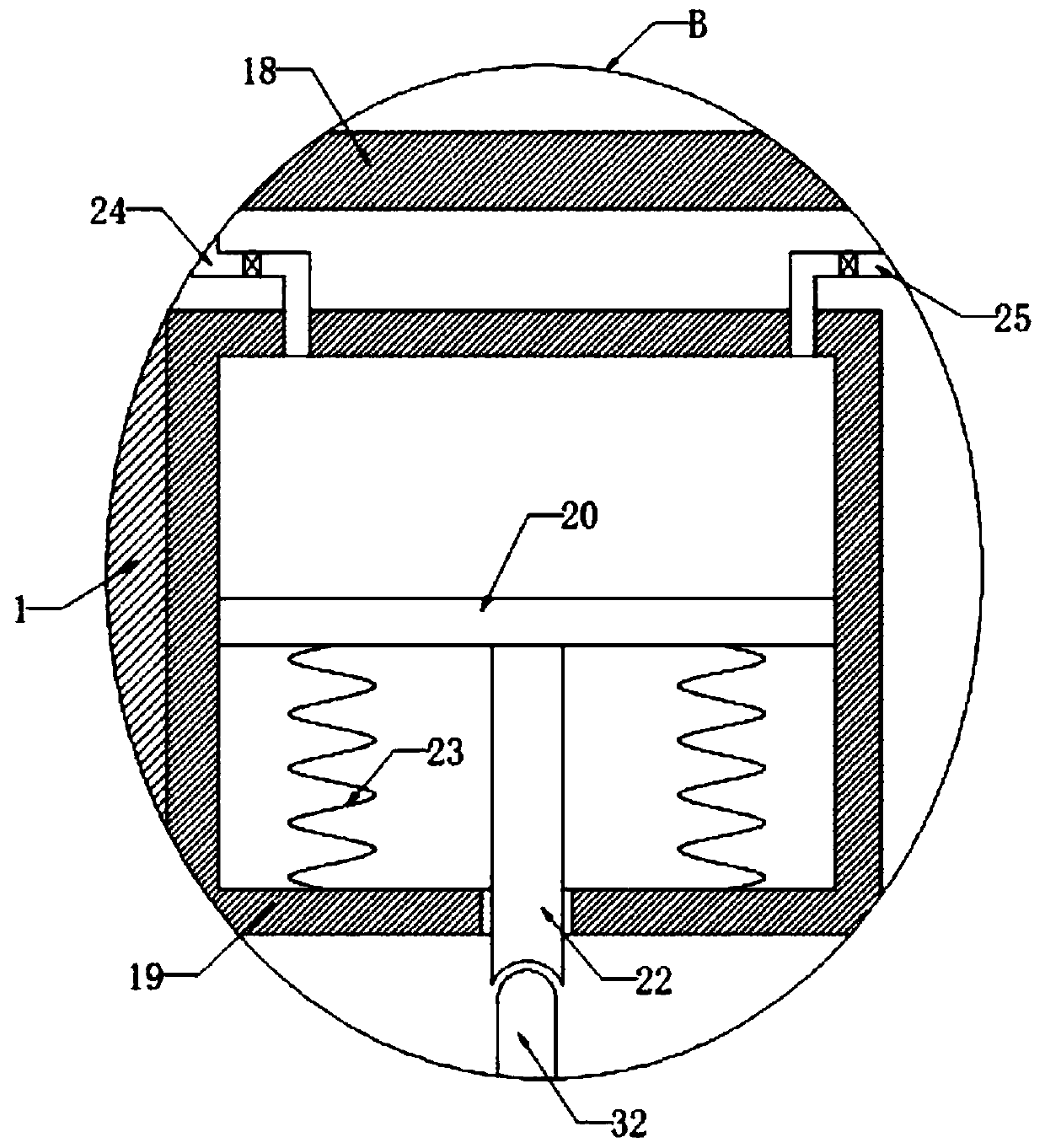

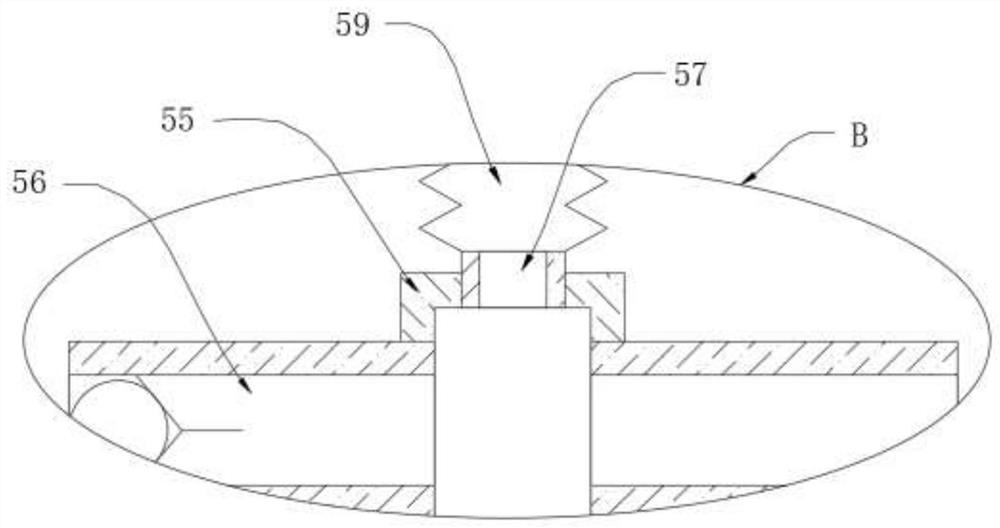

Vibrating type tea fragrance extraction screening machine

InactiveCN107116021AEasy feedingEasy dischargeSievingPre-extraction tea treatmentVertical vibrationFragrance extraction

The invention discloses a vibrating type tea fragrance extraction screening machine. The vibrating type tea fragrance extraction screening machine comprises a base, a supporting plate, a top plate, a roller, a cover plate, a first collecting box and a second collecting box; the supporting plate is fixedly connected to the left side of the base, the top plate is hinged to the top of the supporting plate, and a telescopic mechanism is hinged to the low surface of the top plate; a rotary motor is hinged to the right side wall of the supporting plate, the roller is fixedly connected to the shaft extending end of the rotary motor, and an electric heating plate is hinged to the inner wall of the roller; a vibrating motor is fixedly connected to the lower surface of the top plate, a rotary disc is fixedly connected to the shaft extending end of the vibrating motor, and a fixing bar is fixedly connected to the position, close to the edge of the rotary disc, of the surface of the rotary disc; and a connecting rod is rotatably connected to the fixing bar, and the lower end of the connecting rod is in hinged connection with the side wall of a bearing. In the tea fragrance extraction process, the roller rotates to enable tea to roll over in the roller, and heating of the tea is more uniform, and the fragrance extraction effect is promoted; and when rotating, the roller vertically vibrates to enable the tea to be more sufficiently mixed, and heating is more uniform, and the fragrance extraction effect is further promoted.

Owner:吴蕴仪

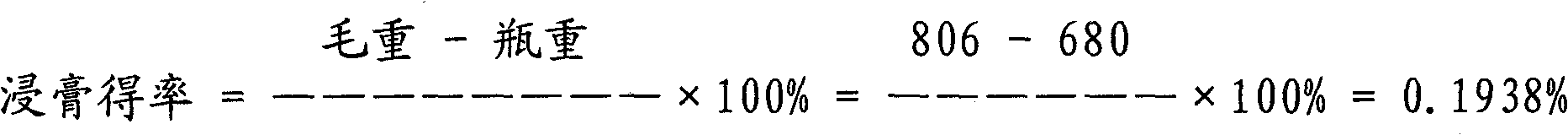

Method for extracting rose essential oil from fresh rose flowers

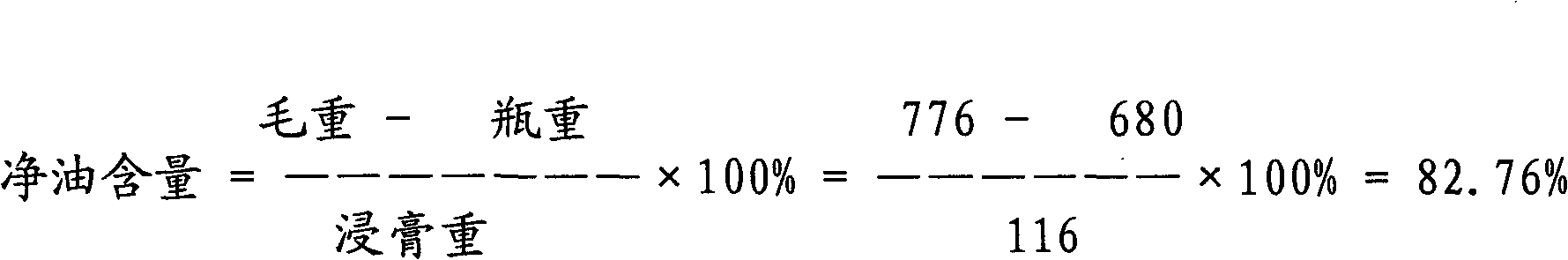

The invention discloses a method for extracting rose essential oil from fresh rose flowers, which relates to a method for spice extraction, in particular to a method for extracting rose essential oil from fresh rose flowers by using the organic solvent extraction and molecular distillation technology. The method comprises the following steps: carrying out lixiviation on fresh floribunda rose flowers by petroleum ethers, then sequentially carrying out filtration, dewaxing and concentration on the obtained product so as to obtain a first concentrated solution; carrying out lixiviation on the rose flower residues subjected to four times of lixiviation by an equivalent petroleum ether / dichloromethane mixed solvent, then sequentially carrying out filtration, dewaxing and concentration on the obtained product so as to obtain a second concentrated solution; mixing the first concentrated solution with the second concentrated solution, then adding the obtained mixture into a molecular distillation device so as to distill the mixture, thereby removing residual solvents, vegetable waxes, pigments and the like in absolute rose oil, and finally, obtaining the rose essential oil. The prepared rose essential oil is pure in aroma and clear in color and luster, the oil yield of the fresh rose flower reaches 0.1 percent, which is 3.3 times of the oil yield of the fresh rose flower through steam distillation.

Owner:平阴县玫瑰研究所

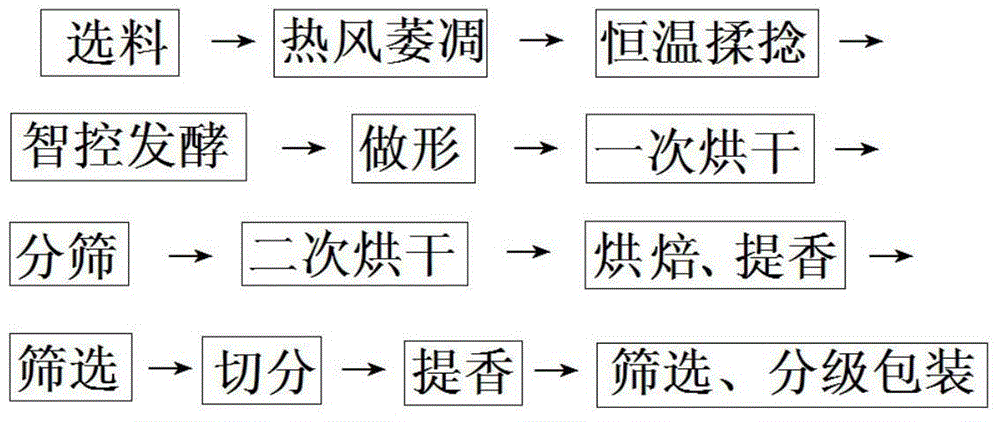

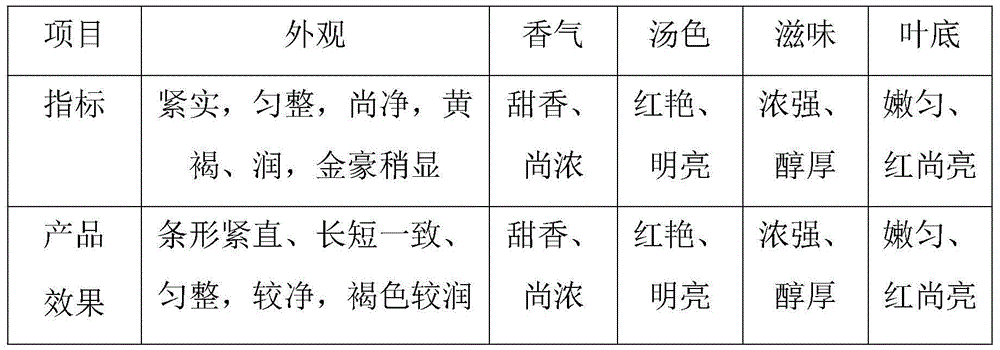

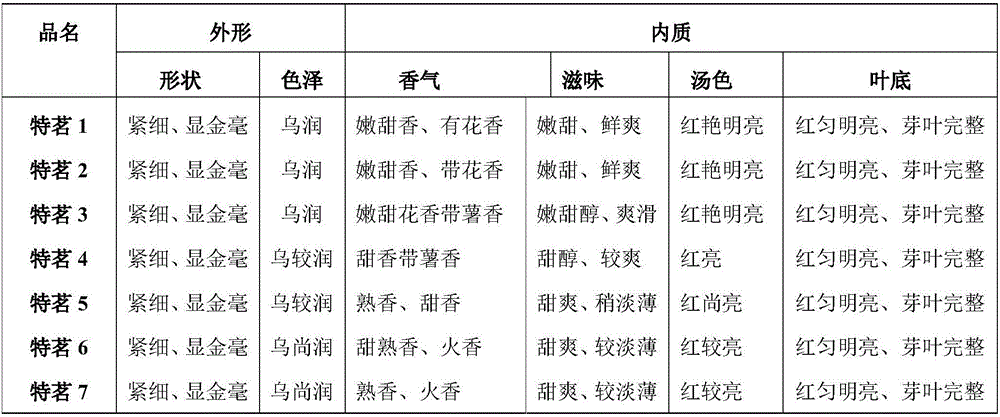

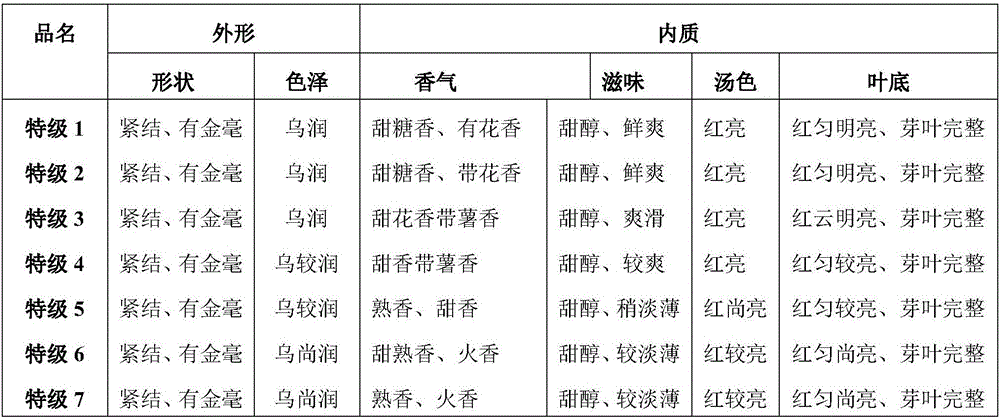

Processing method of congou black tea

ActiveCN103815066AStraight appearanceSame lengthPre-extraction tea treatmentFragrance extractionCooking & baking

The invention provides a processing method of congou black tea. The method comprises the steps of material selection, hot air withering, constant temperature rolling, intelligent controlled fermentation, shaping, primary drying, screening, secondary drying, baking, fragrance extraction, screening, cutting, fragrance extraction, screening, classification and packaging. The method adopts late spring and early summer one-sprout and two or three-leaf green, a constant temperature rolling, intelligent control fermentation, baking, fragrance extraction, optimization, striping and fragrance extraction technique and a standardized precise classification technique, so that 40-50% of energy consumption can be reduced effectively; the yield is increased; the prepared congou black tea is striped, tight and straight in appearance, consistent, even and orderly in length, sweet and thick in fragrance, red and bright in soup, thick and mellow in taste, tender, uniform, red and bright in leaf base, excellent in interior quality, and relatively clear; a safety control index reaches an export standard; the quality reaches the standard; and the method has a good economic benefit.

Owner:贵州省湄潭县芸香茶业有限公司

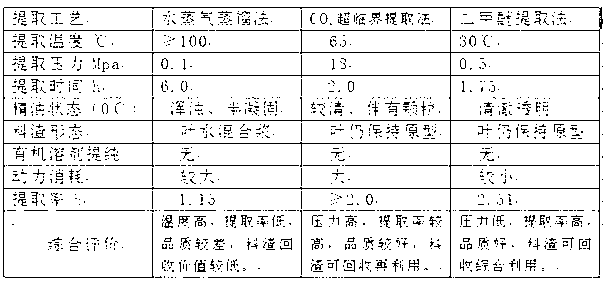

Method for extracting natural flavor with dimethyl ether

The invention relates to a method for extracting a natural flavor with dimethyl ether, which comprises the following steps: making leaves, fruits, flowers and seeds of aromatic plants into a pulp and freeze-drying the pulp, or cleaning and drying stems, barks and roots of aromatic plants, and pulverizing and granulating; sending the freeze-dried material or pulverized and granulated material into an extraction tank, extracting to obtain an extracting solution by using dimethyl ether as a flavor extracting agent, filtering the extracting solution to remove granular impurities, pumping to an evaporation tank, and separating the extracting solution under reduced pressure with a compressor; and carrying out rough separation on the residues after the separation under reduced pressure, carrying out fine separation with a molecular distillation instrument, and distilling by 2-5 stages to obtain the aromatic essential oil. The invention overcomes the defect of low efficiency in the traditional method and the defect of high cost in the supercritical method; the used dimethyl ether extracting agent is odorless and smellless, so the invention has the advantages of no environment pollution, low price and high extraction efficiency; and the obtained plant essential oil is clear and transparent, contains little wax, and overcomes the defects of high water content, high wax content and high oxidative deterioration tendency in the traditional plant essential oil.

Owner:LANZHOU UNIVERSITY

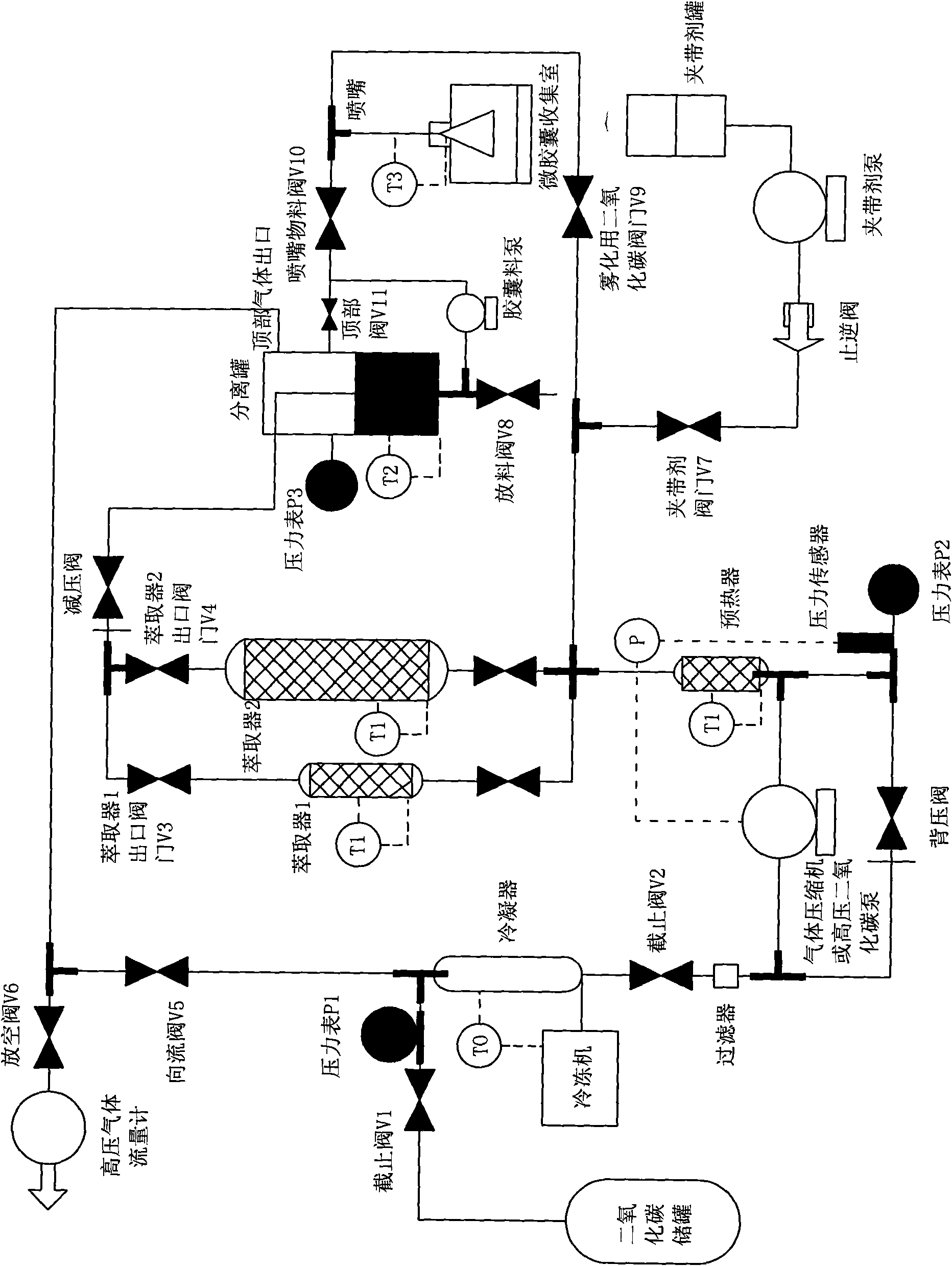

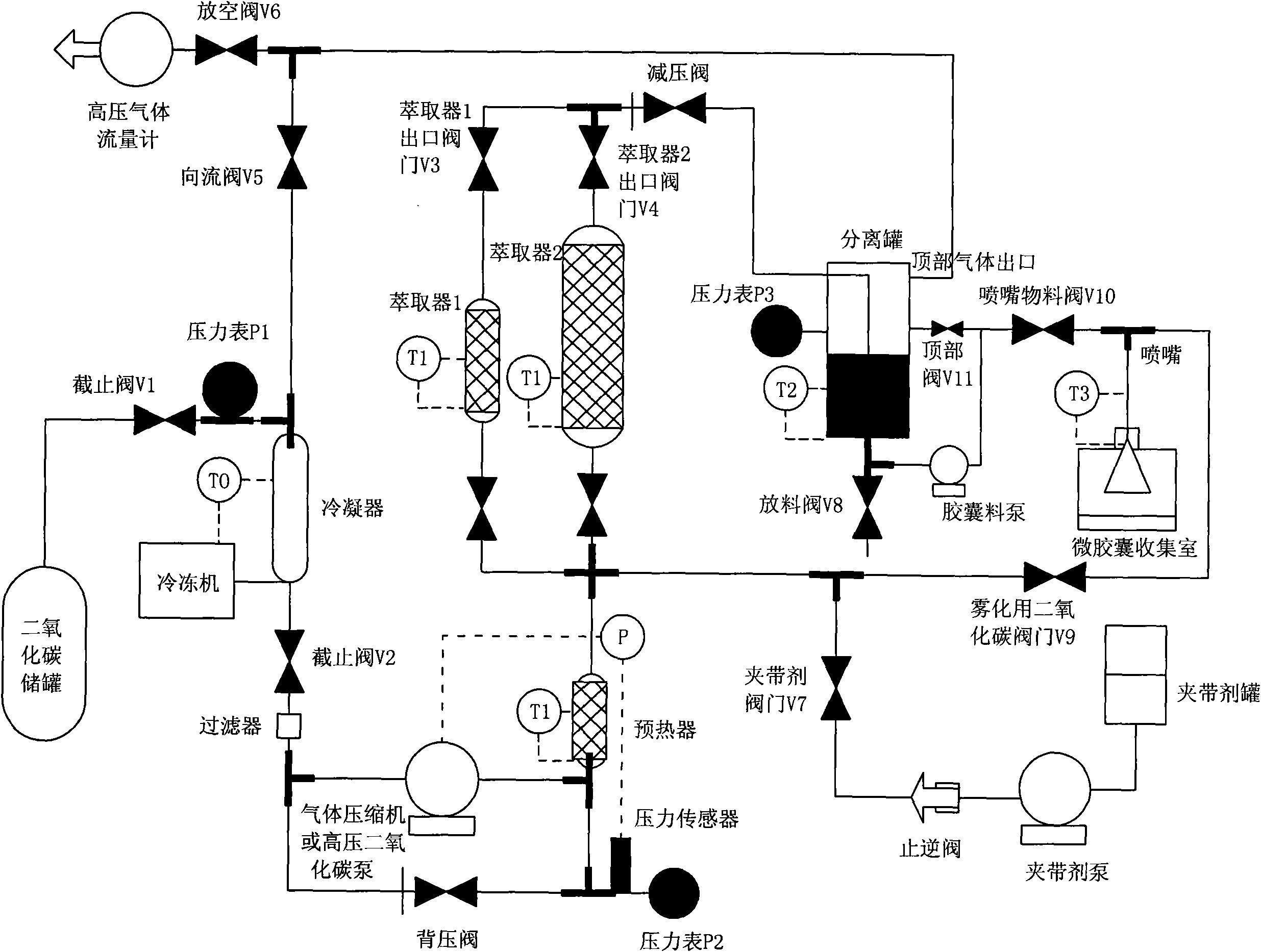

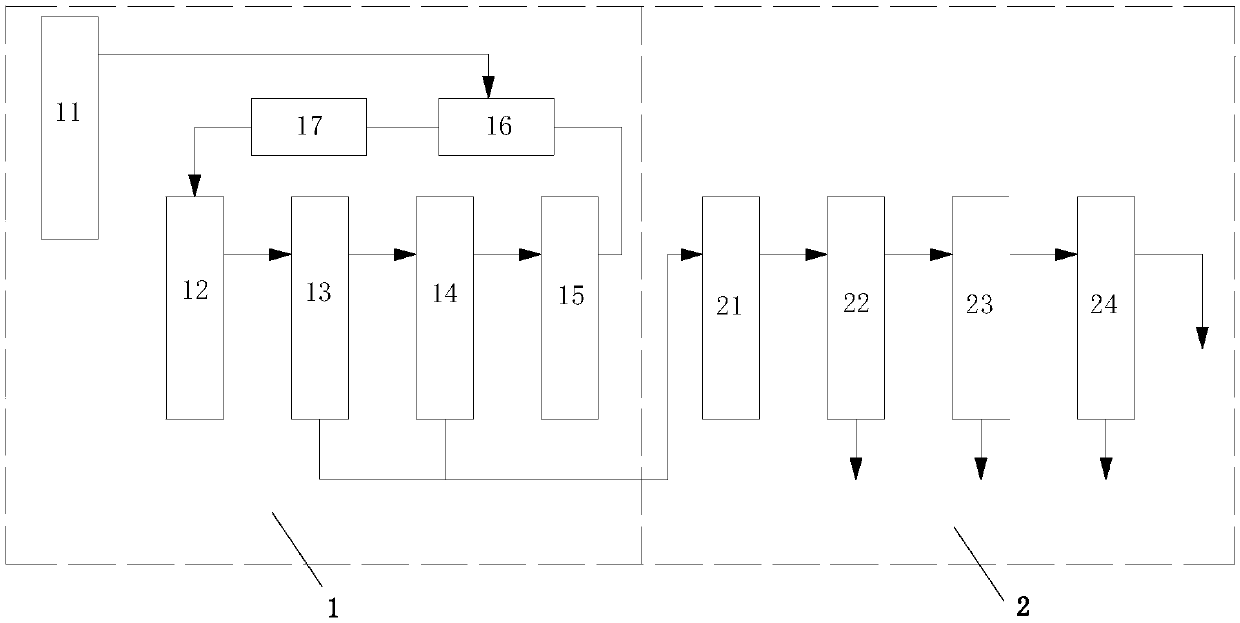

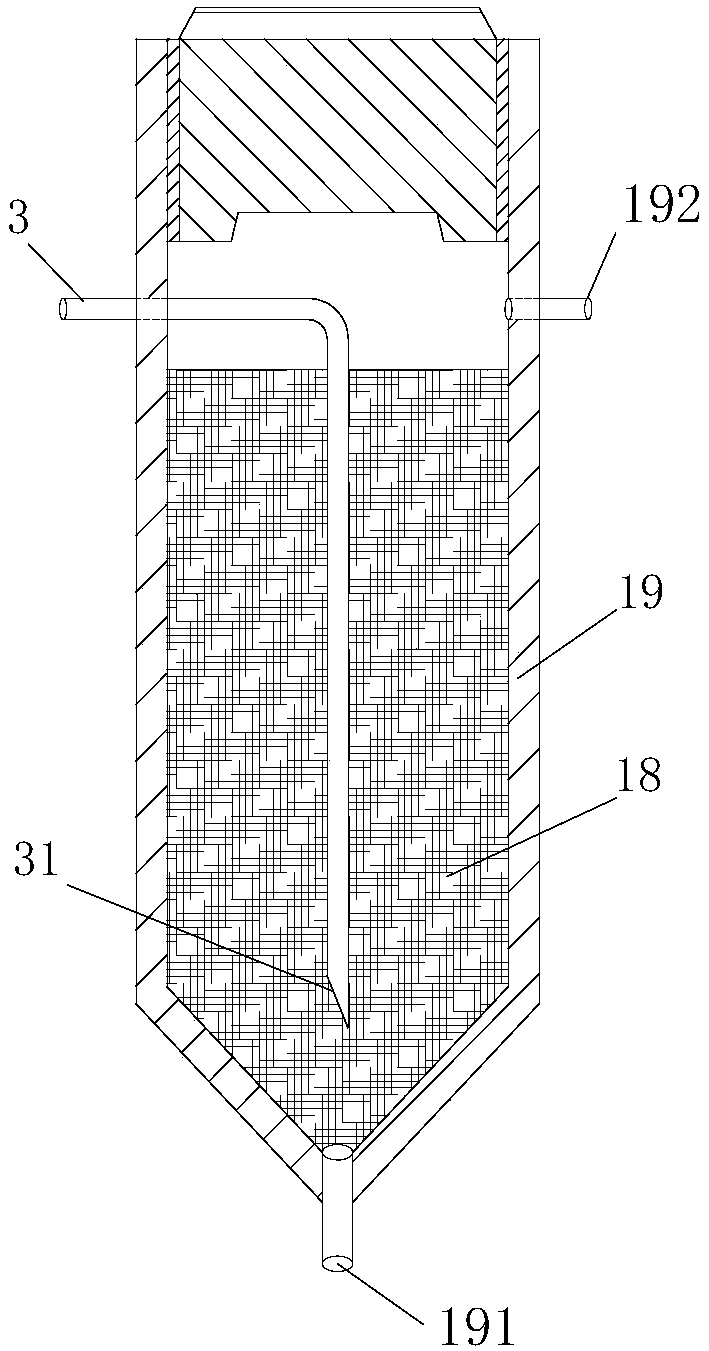

Technology and equipment for integrating essence and spice extraction and micro-capsule preparation

ActiveCN102041170AEasy to achieve low temperature extractionGood conditionEssential-oils/perfumesSolid solvent extractionFlavorNatural state

The invention relates to a technology and equipment for integrating essence and spice extraction and micro-capsule preparation. The technology comprises the steps that the material containing essence and spice is placed into an extractor; the wall material of a micro-capsule is placed into a separator; the extractor and the separator are sealed; carbon dioxide is pumped into the extractor througha compressor or a high-pressure pump from the storage tank of the carbon dioxide; the essence and the spice are extracted from the carbon dioxide material and placed into the separator; the extractedessence and the spice are fully mixed with the wall material or absorbed with the wall material; the mixture is transferred to a nozzle through the pump; the wall material in the nozzle, the essence and the spice are atomized through high-pressure gas and enter a micro-particle collecting room to form an essence and spice micro-capsule; and the carbon dioxide is circulated back to the storage tank of the carbon dioxide. The invention has the advantages that the technical scheme is coupled with the method for preparing the micro-particle by utilizing supercritical CO2 extraction and improved supercritical fluid preparation so that the low-temperature extraction of the essence and the spice and the microencapsulation at the atmosphere of the carbon dioxide for atomization can be easily realized; and the optimum natural state and the application effect of the essence and the spice are maintained.

Owner:CHINA TOBACCO FUJIAN IND

Method for manufacturing high-quality jasmine tea

ActiveCN103704385ALixiang is rich and freshThe taste is mellow and sweetPre-extraction tea treatmentFragrance extractionBud

The invention discloses a method for manufacturing high-quality jasmine tea. The method comprises the steps of (1) tea base manufacturing, (2) scenting and (3) flower frying. Compared with an existing flower frying method, the method has the advantages that a product is manufactured by scenting a high-quality tea base which is obtained by performing cooling, withering, green-removing, arranging, reshaping, rod flattening, drying and fragrance extraction on Mengshan locally-optimized tea variety 131 early-spring tail buds for three times, and frying Qianwei jasmine fresh flowers which are picked between July 20th and September 20th at one time; the manufactured product is flat, level, uniform and straight; pekoe and Zang gold tea are rich and fresh in jasmine fragrance; the high-quality jasmine tea is durable in fragrance and freshness, and mellow and sweet in taste, has a bright yellow-green liquor color, and has a tender leaf bottom.

Owner:四川省大川茶业有限公司

Black tea autofermentation machine

ActiveCN103250819AIncrease speedCompact structurePre-extraction tea treatmentInsulation layerBlack tea

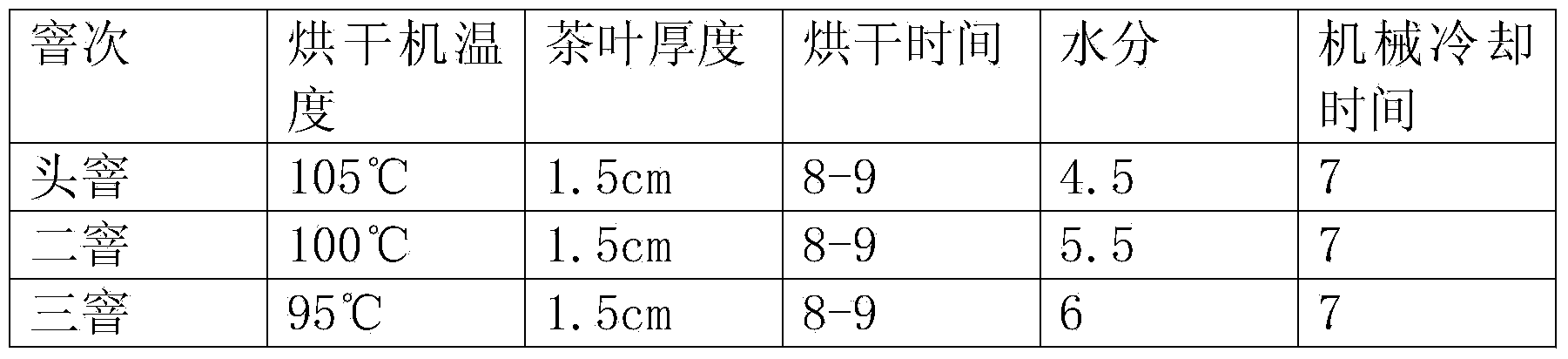

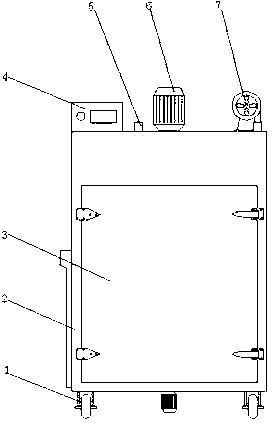

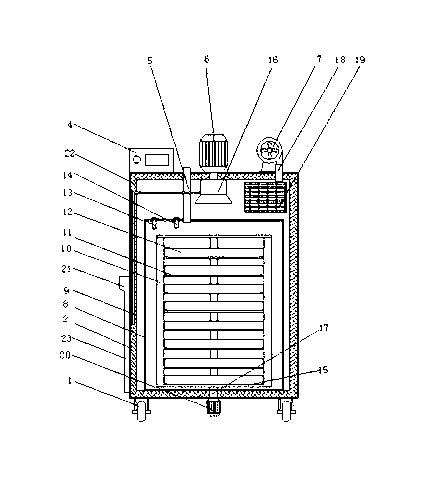

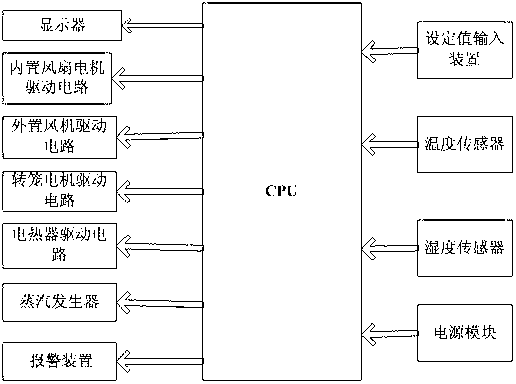

A black tea autofermentation machine relates to the technical field of tea processing equipment and especially belongs to an autofermentation machine applied in black tea processing and production. The black tea autofermentation machine comprises a machine body and a control device (4). A rotation cage is arranged inside the machine body. A casing is a composite-layer structure and comprises an outer shell, a heat-insulation layer (22) and an inner shell (8) which are arranged from outside to inside. A cavity is formed between the heat-insulation layer and the inner shell. A fermentation auxiliary device and a fragrance extraction auxiliary device are disposed inside the machine body. A CPU input end of the control device is connected with a power supply module, a temperature sensor (13), a humidity sensor (14) and a set value input device. A CPU output end is connected with a display, a built-in fan motor-drive circuit, an external blower fan drive circuit, a rotation cage motor-drive circuit, an electric heater drive circuit and a steam generator. The black tea autofermentation machine operates under the conditions of fixed temperature value, humidity value and time value, has a compact structure, has high automation degree, is convenient and efficient, and has positive effects of reasonable design and strong controllability.

Owner:LINYI JIHONG MACHINERY MFR

Orchid-shaped black tea making process

InactiveCN102715295ANice appearanceSoup color bright red and yellowPre-extraction tea treatmentFragrance extractionCarding

The invention relates to an orchid-shaped black tea making process, which comprises the steps of picking, spreading and airing, sunning, fixation, withering, carding, fermentation, first drying, fragrance extraction and the like. Black tea which is processed through the process is flat, straight, graceful and orchid-shaped, the appearance is attractive, the tea soup is reddish yellow and bright, the fragrance is pleasing and the internal quality of excellent.

Owner:句容市张庙茶场有限公司

Low-caffeine black tea with flower fragrance and production method of low-caffeine black tea

InactiveCN102986962AReduce manufacturing costIncrease productivityPre-extraction tea treatmentTea extractionFragrance extractionBlack tea

The invention discloses a low-caffeine black tea with flower fragrance and a production method of the low-caffeine black tea, belongs to the technical field of tea processing and aims to provide a production method of the low-caffeine black tea. The production method of the low-caffeine black tea, provided by the invention, comprises the steps of fresh tea leaf rocking, rolling, fermenting, arranging-drying and fragrance extracting, wherein the rocked fresh tea leaves are rolled, fermented, arranged and dried and subjected to fragrance extraction after being subjected to high temperature desiccation.

Owner:中国测试技术研究院生物研究所

Straight-strip-type Maofeng and preparation method thereof

PendingCN107439717AEasy to loseDissipate evenlyPre-extraction tea treatmentFragrance extractionGreen tea

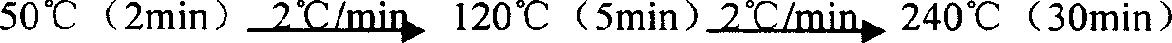

The invention relates to the technical field of process of tea leaves, and particularly relates to straight-strip-type Maofeng and a preparation method thereof. The preparation method comprises the following steps: picking fresh leaves, spreading, carrying out fixation, carrying out cooling resurgence, rolling for the first time, carrying out dynamic water loss, rolling for the second time, deblocking, tidying tea strips, tedding, drying for the first time, tedding, drying for the second time, tedding, drying for the third time, sieving and carrying out infrared fragrance extraction. The straight-strip-type Maofeng adopts the processes of multi-time molding, multi-section drying, quick cooling and the like, the produced tea strips are tight, straight and green, the inside fragrance is lasting and shows chestnut fragrance, the soup is yellowish green and bright, the taste is mellow and sweet after drinking, and leaf bottom is uniform; furthermore, the preparation method is simple, has the advantages that the quality of Maofeng type green tea is improved, the optimization of large-scale green tea is realized, and also has important significance on industry transformation and upgrading.

Owner:四川省农业科学院茶叶研究所 +1

Lentinus edodes-flavored water soluble seasoning powder and preparation method thereof

InactiveCN104187538ATake full advantage of the antibacterial effectExtended shelf lifeFood preparationFragrance extractionFlavor

The invention relates to lentinus edodes-flavored water soluble seasoning powder and a preparation method thereof. The water soluble seasoning powder is prepared from the following raw materials by weight parts: 10-20 parts of a lentinus edodes extract, 5-10 parts of a composite spice extract, 3-5 parts of edible salt, 15-20 parts of maltodextrin, 5-10 parts of sugar ester and 45-55 parts of purified water and is prepared by the steps of uniformly mixing the raw materials, performing centrifugal spraying and drying. The prepared lentinus edodes-flavored water soluble seasoning powder has the advantages of being capable of possessing the characteristic flavors and tastes of spice and lentinus edodes, high in concentration of effective components, relatively long in expiration date as the bacteriostatic function of the spice is fully utilized, convenient for industrial production, and wide in application prospect in flavors and fragrances as well as various compound seasoning products.

Owner:TIANJIN CHUNFA BIO TECH GRP

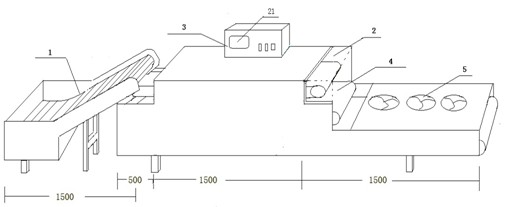

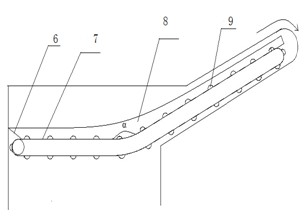

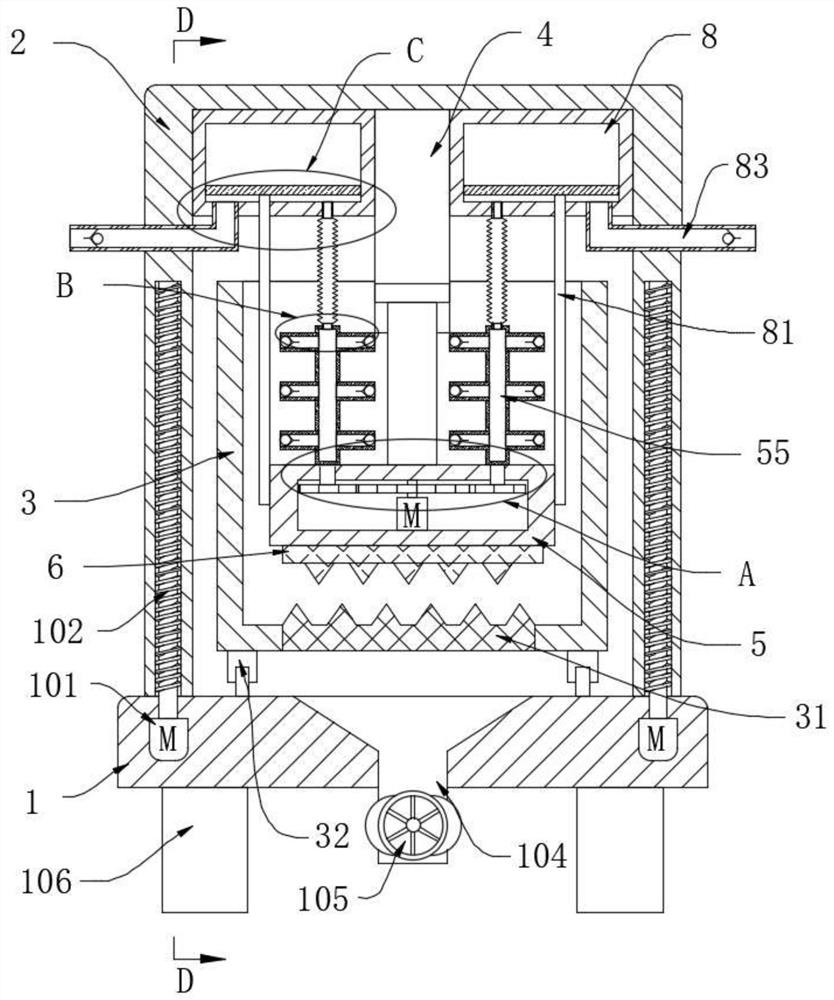

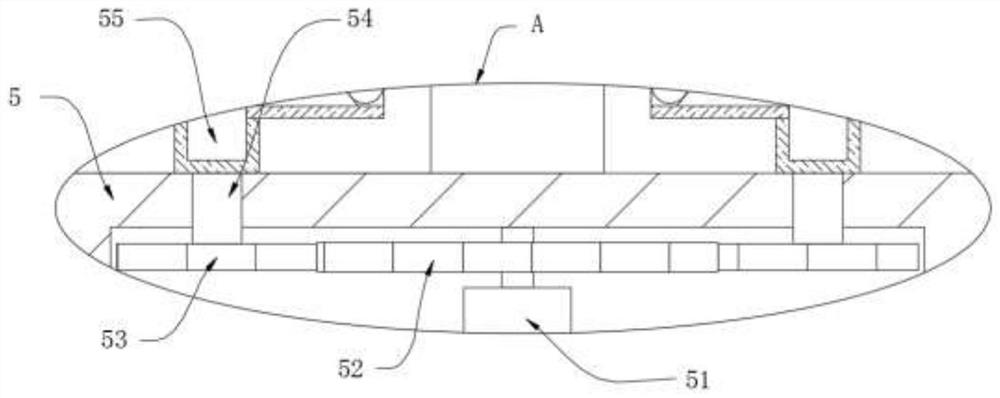

Multi-layered tunnel type tea infrared fragrance extracting machine

ActiveCN102160585APrecisely control the time of aromaImprove qualityPre-extraction tea treatmentTea flavoringFragrance extractionTemperature control

The invention provides a multi-layered tunnel type tea infrared fragrance extracting machine, consisting of an automatic no-breaking uniform feeding system, an infrared transmitting system, an uninterrupted infrared radiation accurate temperature control system, a stepless speed adjusting multi-layered tea conveying system and a tea cooling system, wherein the infrared transmitting system and thestepless speed adjusting multi-layered tea conveying system are positioned in a tunnel box body; and the uninterrupted infrared radiation accurate temperature control system is arranged above the tunnel box body. In the multi-layered tunnel type tea infrared fragrance extracting machine provided by the invention, automatic no-breaking uniform feeding, uniform heating of the tea, uninterrupted infrared radiation and automatic cooling can be achieved, the temperature control accuracy is less than or equal to + / -2 DEG C, the fragrance extraction time can be controlled accurately, the multi-layered tunnel type tea infrared fragrance extracting machine is mainly used for after treatment of dried tea, the tea enters the fragrance extracting machine by automatic no-breaking uniform feeding, and the infrared ray with a specific wavelength is utilized to carry out treatment on the dried tea under certain time and temperature so as to lead the fragrant ingredients of the tea to generate good transformation, therefore, the quality of the tea is improved and the economic value of the tea is improved.

Owner:TEA RES INST CHINESE ACAD OF AGRI SCI

Preparation method of strip-type Keemun black tea

InactiveCN106359697ABar Tight KnotDark colorPre-extraction tea treatmentTea flavoringFragrance extractionBlack tea

The invention discloses a preparation method of strip-type Keemun black tea, which includes the steps of: 1) picking; 2) withering; 3) rolling; 4) fermentation; 5) drying; and 6) fragrance extraction, wherein the dried tea bud leaves are subjected to fragrance extraction at about 80 DEG C for 2.5 h. The method effectively solves the problems that complete shape and internal quality of the Keemun black tea cannot be achieved both in the prior art.

Owner:ANHUI QIMEN COUNTY QIHONG TEA

Trichosantheskirilowiimaxim seed processing method

InactiveCN101889698AComminuted rupture does not occurImprove performanceFood preparationFragrance extractionAdditive ingredient

The invention discloses a trichosantheskirilowiimaxim seed processing method, which comprises the following steps of selecting, washing, soaking, digesting, baking, inspecting and packing. The conventional pan-frying process is replaced by the soaking process, the digesting process and the baking process, wherein the soaking process is favorable for taste absorption of ingredients, and can change the original structure of a hull by using the ingredients under a hull softening state so as to solve the processing problem caused by the fact that the trichosantheskirilowiimaxim seed has a thicker and harder hull and a crisper and tender seed meal compared with common seeds; the digesting process is favorable for improving the achievement of the soaking process; on the basis, three stages of the baking process at different temperatures are adopted, wherein the temperature is from low to high and the time is from long to short, which are consistent with the three technical characteristics of drying, baking and fragrance extraction. The method solves the problem that the hull is cracked in a smashing mode when the product is bit by teeth for removing the hull, and effectively improves the quality of the product.

Owner:衢州市衢天食品有限公司

Tobacco source spice extraction method and application thereof

ActiveCN111991838AStrong extraction and solubilityImprove extraction efficiencyTobacco preparationTobacco treatmentBiotechnologyFragrance extraction

The invention discloses a tobacco source spice extraction method and application thereof. The method comprises the steps of extracting nonpolar, medium-weak polar, medium polar and strongly polar components. Low-order and waste tobacco source materials are closely related to corresponding cigarette raw materials, homology and homogeneity of tobacco source flavor and cigarette products are achieved, and the method is suitable for actual requirements of perfuming and charging of the cigarette products. Fragrance components in the tobacco source material are extracted by stages, natural flavor which is homologous and homogeneous with cigarettes is provided, the original fragrance of the tobaccos can be increased, the fragrance amount is increased, irritation is relieved, and the quality of the cigarettes is improved. The compound flavor blending of the section flavor raw materials is suitable for blending of all-component tobacco source essence and also suitable for blending of all-component essence of other natural plants. According to the method, tobacco leaf resources are efficiently utilized, the characteristic that the boiling point of a CO2 critical fluid is low is utilized, thepurpose of selectively extracting and separating the tobacco flavor is achieved, waste is reduced, the process is simple and safe, the extraction efficiency is high, aroma substances are comprehensively extracted, the quality is stable, loss of the aroma substances can be avoided, and large-scale production can be achieved.

Owner:CHINA TOBACCO HEBEI INDUSTRIAL CO LTD

Black tea processing technique

InactiveCN103918812AImprove qualityBeautiful shapePre-extraction tea treatmentBiotechnologyFragrance extraction

The invention relates to the technical field of tea production and making, in particular to a black tea processing technique. The black tea processing technique comprises the steps of withering, low-temperature rolling, temperature-controlled fermentation, primary drying, spreading and airing A, shaping A, spreading and airing B, screening, drying of tea on the bottom of a sieve, shaping B of tea on the surface of the sieve, drying and fragrance extraction. According to the black tea processing technique, due to the comprehensive utilization of the low-temperature withering, the low-temperature rolling, the temperature-controlled fermentation, the temperature-controlled drying and the like, the quality of black tea is greatly improved; dried black tea is full of golden tips, attractive in appearance, the fragrance of the tea can last for a long time, tea water is red and bright, and the degrees of the red colors of leaf bottoms are even. Due to the fact that the temperature control technique is adopted, the degree of the bitter taste is effectively reduced, the tea can be more suitable for the vast tea drinking population, and the black tea processing technique is quite suitable for being popularized and drunk.

Owner:LONGYANG DISTRICT FENGXI TEA

Aquilariae lignum resinatum grease extraction and separation method and equipment

PendingCN107828512AHigh yieldNo pollution in the processEssential-oils/perfumesFragrance extractionSolvent

The invention discloses an aquilariae lignum resinatum grease extraction and separation method and aquilariae lignum resinatum fragrance extraction and separation equipment. The method is characterized in that supercritical carbon dioxide extraction equipment and molecular distillation equipment are combined to extract and obtain aquilariae lignum resinatum grease-containing mixed extract by virtue of a specific extraction and separation process, and then to separate and obtain aquilariae lignum resinatum essential oil and aquilariae lignum resinatum grease cream through a molecular distillation process. According to the method and the equipment, the yield of the aquilariae lignum essential oil and the aquilariae lignum resinatum grease cream is at least doubled compared with that achievedby another distillation method, the original fragrance of aquilariae lignum resinatum grease is maximally maintained in terms of quality, solvent pollution is avoided, the development requirement ofpure natural chemical essence for daily use can be met, and broader market prospect is achieved.

Owner:广州市浩立生物科技有限公司

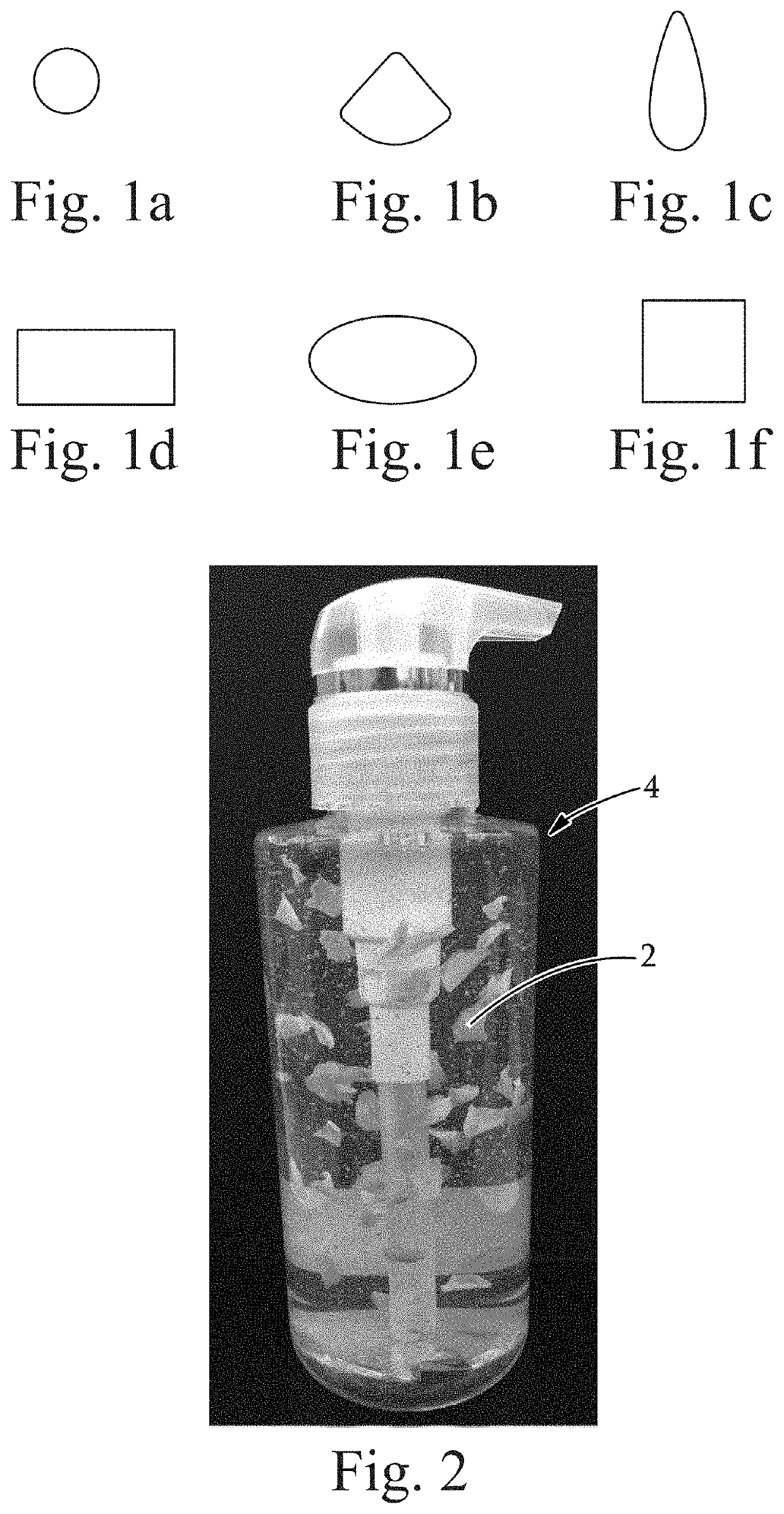

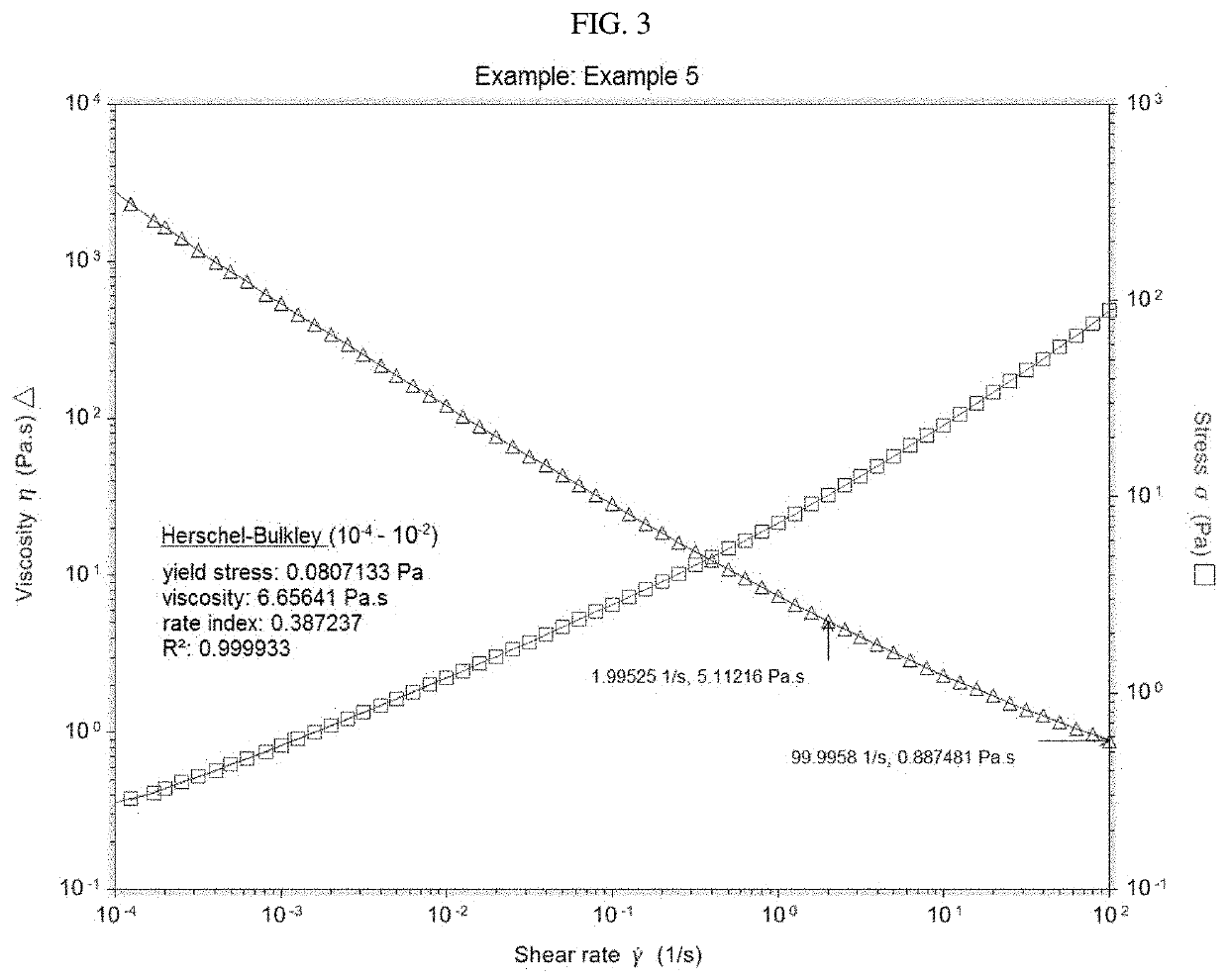

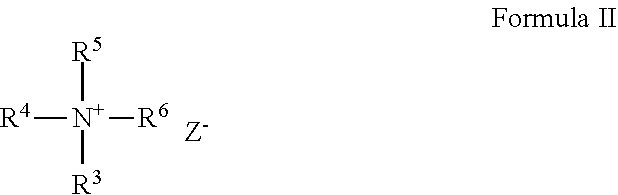

Shampoo composition comprising sheet-like microcapsules

Shampoo compositions having an anionic surfactant, cationic deposition polymer, sheet-like microcapsules and an aqueous carrier. The shampoo composition delivers both good in use benefits, while maintaining a consumer desirable appearance. The sheet-like microcapsules can also contain perfumes, extracts, dyes, colorants, and / or benefit agents.

Owner:THE PROCTER & GAMBLE COMPANY

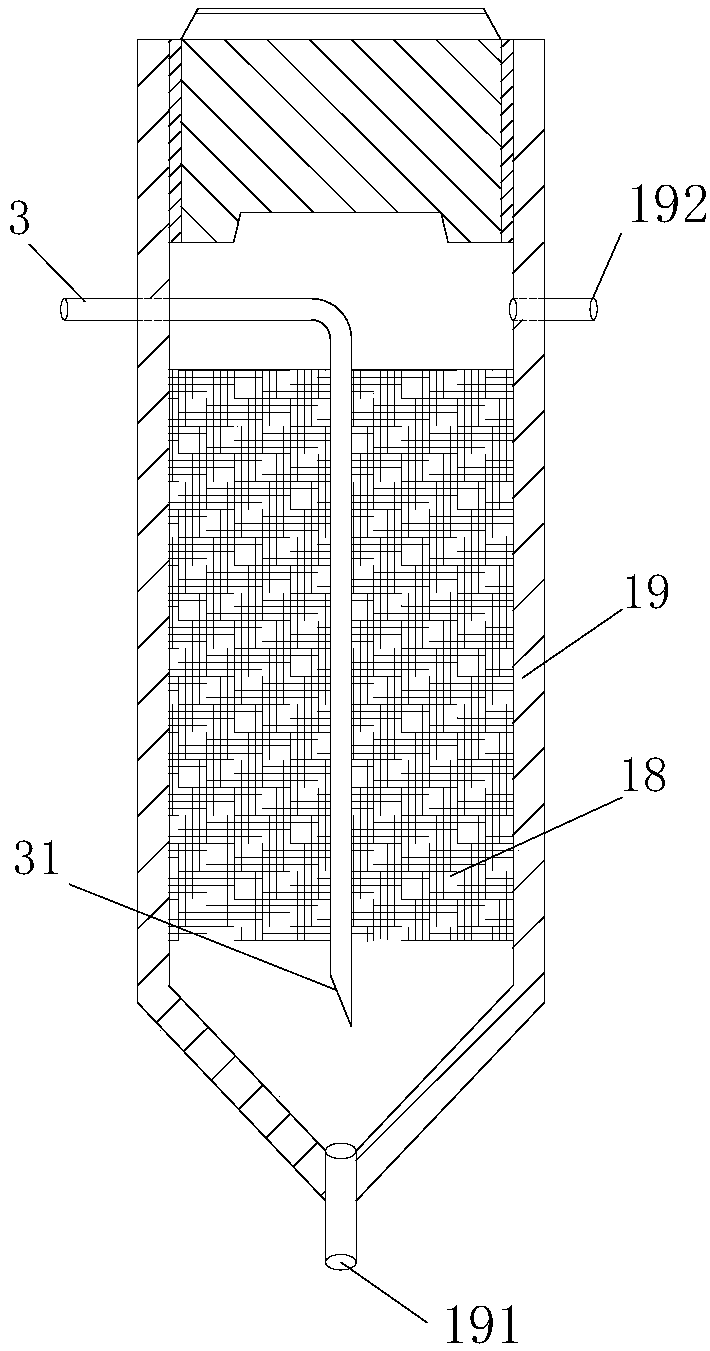

Rapid condensing device for extracting flavors and fragrances

ActiveCN111481957AFast heatingReduce power consumptionVapor condensationEssential-oils/perfumesFlavorFragrance extraction

The invention discloses a rapid condensing device for extracting flavors and fragrances. The device comprises a stirring box, a hollow rotating shaft is rotatably connected to the top in the stirringbox, hollow plates are uniformly distributed on the side wall of the hollow rotating shaft in the axial direction of the hollow rotating shaft in a communicating mode, a plurality of air outlet holesare uniformly formed in the side walls of the hollow plates, a groove is formed in the upper end of the stirring box, and a first driving mechanism for driving the hollow rotating shaft to rotate is installed on the stirring box. The hot gas generated after high-pressure gas is introduced into a vortex tube enters the hollow rotating shaft through the hot gas tube; in the rotating process of the hollow rotating shaft; the hot gas is continuously sprayed out from the air outlet holes; an essence and flavor stock solution is heated, so that the heating speed of the essence and flavor is increased, the power consumption is reduced, a screw nut drives a scraping ring to continuously slide up and down on the inner wall of the stirring box through the rotation of a reciprocating screw, the residual essence and flavor on the inner wall of a stirring box are cleaned, and the working intensity of staff is reduced.

Owner:江西依思特香料有限公司

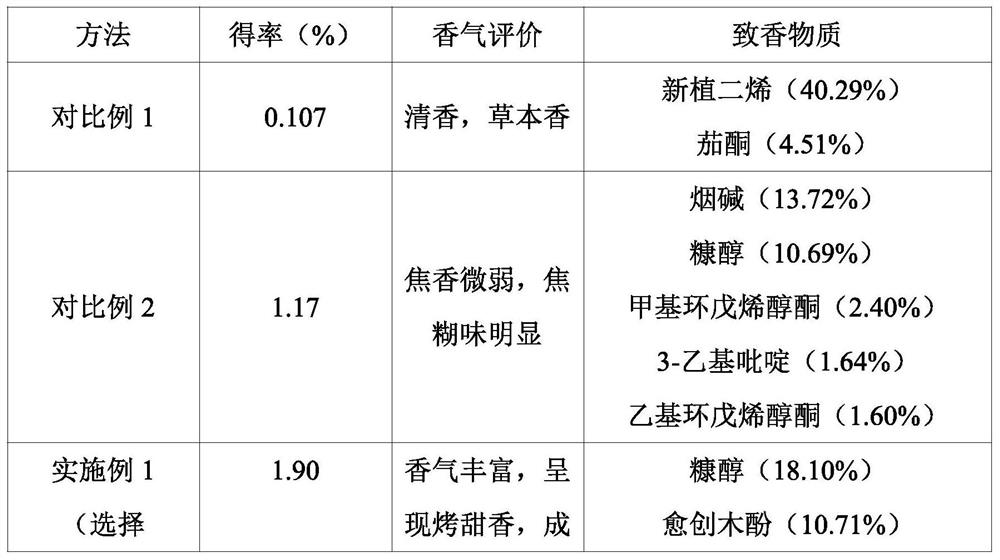

Tobacco flavor extraction method

ActiveCN114504119AImprove qualityGuaranteed qualityTobacco treatmentExtractive distillationFragrance extractionSteam distillation

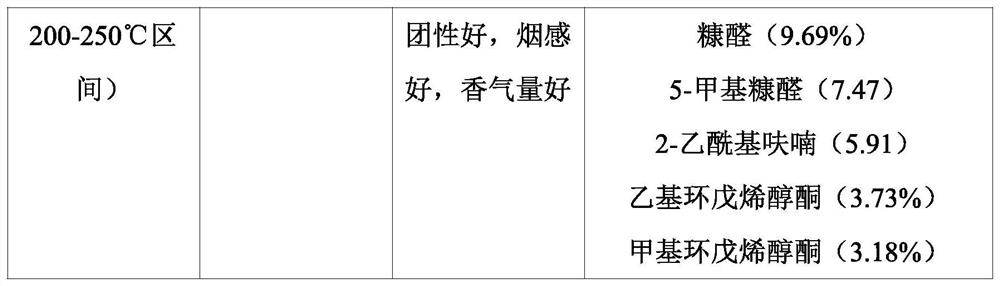

The invention discloses a tobacco flavor extraction method which comprises the following steps: preheating multifunctional steam distillation-dry distillation integrated equipment, and adding a tobacco raw material into a steam distillation-dry distillation device after the temperature is stable; the method comprises the following steps: introducing superheated steam and nitrogen into a steam distillation-dry distillation device together, and heating to increase the steam distillation-dry distillation temperature; collecting distillate of each temperature section according to the temperature; extracting the distillate of each section by using a solvent to obtain extract liquor; and dehydrating the extract liquor, and carrying out rotary evaporation to recover the solvent, thereby obtaining the tobacco flavor for enhancing the aroma of the novel tobacco product. Compared with the conventional common extraction method, the method has the advantages that the original aromatic substances of the tobacco can be extracted, the tobacco flavor with stronger roast fragrance and scorched sweet fragrance can be obtained, the condition is more mild, the product is more easily steamed out along with water vapor, the yield is improved, the problem of scorched smell caused by uneven heating easily occurring in a dry distillation method is avoided, and the method is suitable for industrial production. The method is especially suitable for aroma enhancement of novel tobacco products.

Owner:NANJING FORESTRY UNIV

Preparation method of high-quality tea leaves

PendingCN110915951AQuality improvementIncrease the fragrancePre-extraction tea treatmentFragrance extractionTea leaf

The invention discloses a preparation method of high-quality tea leaves. The preparation method comprises the following steps: S1, picking fresh tea leaves: picking fresh tea leaves which are uniformin size and have one bud and one leaf or one bud and two leaves; S2, fresh tea leaf spreading: the picked fresh tea leaves are placed on a bamboo sieve or a bamboo curtain to be aired; S3, withering the tea leaves: spreading the tea leaves on a withering trough, and performing withering for 8-13h so as to obtain fresh leaves with the water content of 50-60%; S4, performing fixation on the tea leaves: putting the fresh leaves obtained in the step S3 into a roller fixation machine, and performing fixation for three times in a low-temperature, high-temperature and low-temperature manner; S5, rolling the tea leaves: putting the tea leaves subjected to fixation into a rolling machine for rolling to obtain rolled leaves; S6, drying the tea leaves, wherein the drying comprises three steps of primary drying, sufficient drying and secondary drying; S7, fragrance extraction of the tea leaves: the dried tea leaves are put into a pot-type roasting machine to be roasted to be fragrant; and S8, screening the tea leaves: spreading the tea leaves obtained in the step S7 for airing and screening, removing damaged leaves and yellow leaves, and screening out fragments, so as to obtain finished tea.

Owner:天方茶业股份有限公司

Processing technology of green tea

InactiveCN104397216AAvoid the disadvantages of uneven heatingMake up for the shortcomingsPre-extraction tea treatmentFragrance extractionFree form

The present invention discloses a processing technology of green tea. The processing technology comprises the following steps: tea leave collection, tedding of fresh leaves, enzyme deactivation, shaping, drying, sterilization, fragrance extraction, screening, packaging and storage, and other steps. The processing technology is characterized in that: the step of enzyme deactivation includes a steam enzyme-deactivation and a roller enzyme-deactivation, after the steam enzyme-deactivation and the roller enzyme-deactivation are finished, rapid cooling is carried out by a rapid cooling technology;'phenol ammonia ratio'of the tea contents is reduced; the proportion of tea polyphenol which exhibits astringent taste is declined; the proportion of free form amino acid compound which can reflects fresh and refreshing characteristics is increased; the volatilization of volatile tea aromatic substances such as cis-3-hexen-1-ol, benzyl alcohol and others is reduced; three factors of color, smell and taste of the finished tea can be improved to achieve a higher level.

Owner:DUYUN YUNCHENGCHUN TEA

Method for preparing fresh green tea cold drink from Liuan Guapian tea

The invention discloses a method for preparing a fresh green tea cold drink from Liuan Guapian tea. The method comprises the steps of treating fresh Liuan Guapian green tea subjected to fixation by low-temperature fresh leaf extraction, carrying out freeze concentration, than adding a fragrance extracting agent to realize natural fragrance extraction of a tea drink, then adding tannase and beta-cyclodextrin to carry out clarification and control sedimentation treatment, and carrying out ultrafiltration, high-temperature instant sterilization, vacuum filling and sealing to obtain the Liuan Guapian green tea drink. The prepared tea drink is rich in nutrition, has high health value, tastes delicate and fresh, is rich in fragrance, is limpid and bright in liquor color, does not have sediments after standing for a long time, is low in preparation cost, simple and easy to prepare and suitable for industrial production, has wide application prospect and has important significance of promoting the deep-processing level of Liuan Guapian green tea, prolonging a processing industrial chain and increasing economic and social benefits of the Liuan Guapian tea industry.

Owner:安徽迎驾山泉股份有限公司

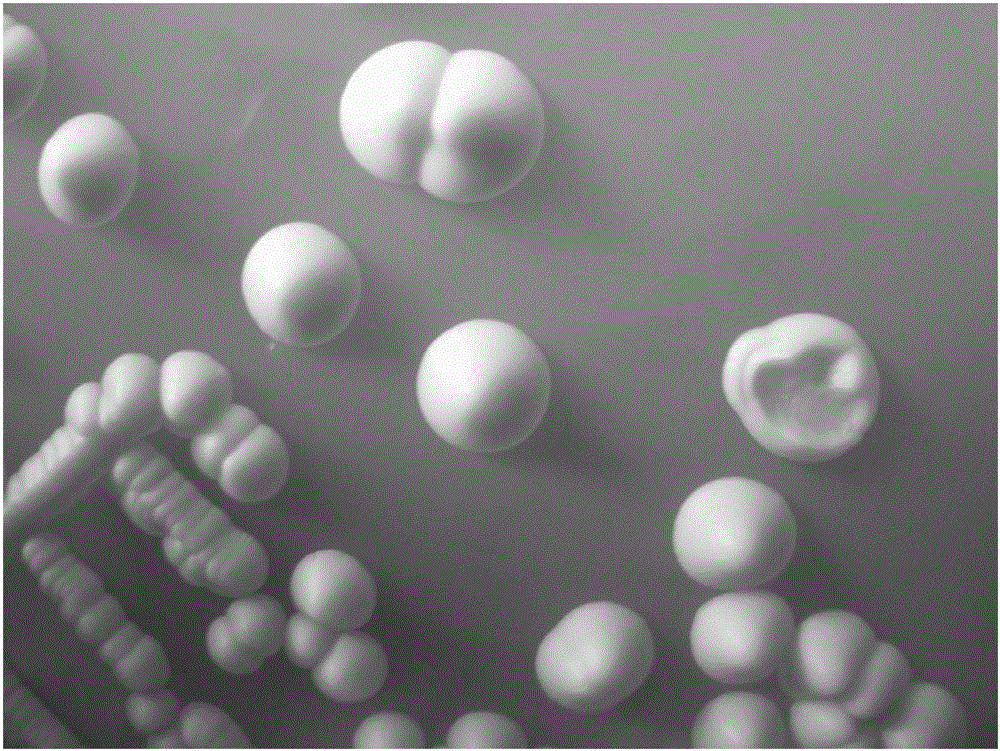

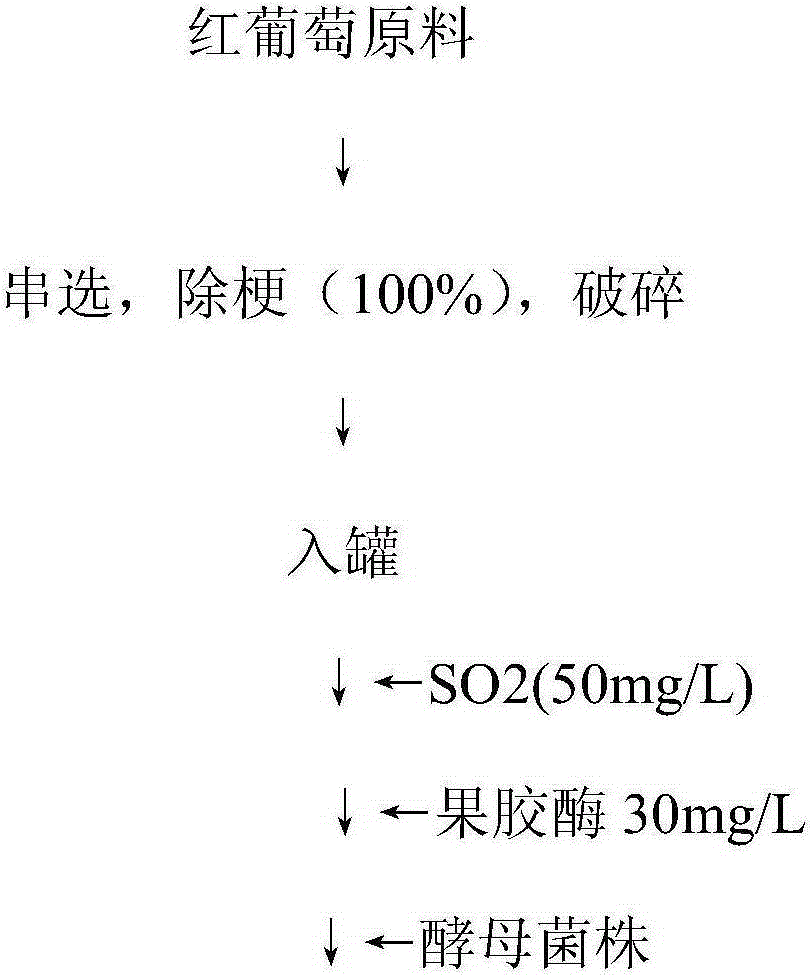

Ageing-type saccharomyces cerevisiae and its use in wine making

InactiveCN105296369AClear aging potentialGood colorFungiMicroorganism based processesMicroorganismVitis vinifera

The invention relates to the technical field of microbes and concretely relates to ageing-type saccharomyces cerevisiae and its use in wine making. The ageing-type saccharomyces cerevisiae and its use in wine making gradually change the passive situation of long-term import of wine saccharomyces cerevisiae in China and solve the problem of domestic wine quality homogenization. The saccharomyces cerevisiae NX11424 is preserved in the China general microbiological culture collection center (CGMCC), has a preservation number of CGMCC NO. 10050, has an excellent color and fragrance extraction capability, fully performs typical characteristics of grapes, provides a perfect skeleton feel and a structure feel for wine, and provides unique baking, barbecue and coffee ageing characteristics for new wine after alcoholic fermentation. Dry red wine prepared by the saccharomyces cerevisiae NX11424 is very suitable for ageing in an oak barrel and has obvious ageing potential and thus the saccharomyces cerevisiae NX11424 is an excellent ageing-type saccharomyces cerevisiae of dry red wine.

Owner:NORTHWEST A & F UNIV

Small yellow tea production process

InactiveCN107183242ASweet and mellow tasteLong lastingPre-extraction tea treatmentFragrance extractionDiuresis

The invention discloses a small yellow tea production process, and belongs to the field of tea production. The production process particularly includes the steps of fresh leaf picking, airing, nutrient solution preparation, steaming, initial drying, primary heaping for yellowing, re-drying, secondary heaping for yellowing, fragrance extraction and the like. Small yellow tea produced by the production process is durable, resistant to infusing, sweet, tasty, refreshing and mellow in taste, durably sweet after taste and rich in fragrance, the liquor color of the tea is yellowish and orange to reach sunset yellow, nutrient solution permeates into the small yellow tea in the preparation process, so that nutrient components are effectively mixed with the small yellow tea, the taste of original small yellow tea is kept, healthcare functions are increased, and the small yellow tea has the functions of warming stomach, tonifying spleen, reducing blood pressure and blood lipid, achieving diuresis, clearing heat, removing waste in bodies, resisting bacteria, diminishing inflammation, enhancing human immunity and the like.

Owner:安徽省抱儿钟秀茶业股份有限公司

Making method of raw tea for pure tea beverages

InactiveCN102599276AIncrease dissolution rateImprove stabilityPre-extraction tea treatmentTea leafFragrance extraction

The invention provides a making method of raw tea for pure tea beverages, which includes: selecting fresh leaves of specific varieties and tenderness as material, and subjecting the leaves to fixation, special curing, cell breaking, drying and fragrance extraction to obtain raw tea special for pure tea beverages. The traditional processes such as fixation, shaping, drying and the like are improved and optimized, the special processes are merged to the tea-leaf processing flow, the traditional processes and the special processes are organically combined, integrated and perfected, and accordingly the tea material special for pure tea beverages is provided for tea beverages production enterprises, dissolution rate of components of the tea leaves in soaking is increased, and the period of stable flavor quality of tea extract is prolonged.

Owner:TEA RES INST CHINESE ACAD OF AGRI SCI

Essence and flavor extracting equipment convenient to clean

PendingCN111634049ASqueeze fullyAvoid wastingTransportation and packagingMixersHydraulic cylinderFragrance extraction

The invention discloses essence and flavor extracting equipment convenient to clean. The essence and flavor extracting equipment comprises a base where a through hole is formed; a plurality of first motors are arranged in the base in an embedded mode, threaded rods are welded to output shafts of the first motors, the threaded rods and the base are rotationally connected in a penetrating mode through bearings, and the threaded rods are in threaded connection with a mounting cover jointly; the upper surface of the base is slidably connected with a squeezing box, and a filter net is inlaid in thebottom wall of the squeezing box; the section of the mounting cover is in a U shaped with a downward opening, and the inner top wall of the mounting cover is fixedly connected with a hydraulic cylinder; and a mounting block is welded to the output end of the hydraulic cylinder, the mounting block is of a hollow structure, and the lower surface of the mounting block is bonded with a squeezing hammer. The essence and flavor extracting equipment has the advantages that a better stirring effect is provided during squeezing to ensure that raw materials on the upper layer can also be squeezed to avoid raw material waste, after squeezing is completed, the squeezing box is more conveniently cleaned, the labor intensity is greatly relieved, and the working efficiency is improved.

Owner:江西依思特香料有限公司

Method capable of improving flavor of edible fungi precooking fluid and processing edible fungi precooking fluid into sauce

The invention relates to a method capable of improving flavor of edible fungi precooking fluid and processing into sauce. The method comprises the steps of stewing edible fungi precooking fluid, adjusting a pH value of the upper clear solution, adding 0.5-1% of flavourzyme; carrying out enzymolysis for 2 hours at 50-60 DEG C to improve bad flavor of the precooking liquid; adding spice extract solution, which is prepared from pepper, black pepper, anise, cinnamon and old ginger, salt, sugar, I+G, chicken flavor, rice wine and caramel pigment, and agitating; screening by a 200-mesh sieve; and adding CMC-Na to enhance the stability. The method is comprehensive utilization of waste precooking liquid processed by edible fungi. Firstly, 0.5-1% of flavourzyme is added to carry out enzymolysis by an enzymatic hydrolysis technology; bad flavor of the precooking liquid is improved; and then the spice extract solution is prepared and seasoned, and finally packaged and sterilized. According to the method, the edible fungi precooking liquid is pretreated by an enzymolysis approach and then a blending technology is utilized to process the sauce, which recycles the processing waste of edible fungi. The produced product is mellow in taste, and excellent in flavor, and is well received by consumers.

Owner:FARM PROD PROCESSING & NUCLEAR AGRI TECH INST HUBEI ACAD OF AGRI SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com