Processing method of bending and scented green tea

A processing method and technology of green tea, which is applied in the field of tea processing and quhao-shaped green tea processing, can solve problems such as the aroma is easy to be overheated, and the tea soup is bitter and astringent, so as to achieve the effect of enhancing the aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The fresh leaf raw material used for the processing of a kind of curly green tea is: 50 kilograms of tea fresh leaves based on one bud and one leaf and one bud and two leaves.

[0022] The specific implementation is as follows:

[0023] (1) Spread the fresh leaves on the three-dimensional green stand of stainless steel wire mesh, and then place the stand in a green stand with controllable temperature and humidity until the moisture content of the fresh leaves is about 70%; see figure 1 , the stainless steel wire mesh three-dimensional stall stand is made of stainless steel wire mesh 1 and stainless steel frame 2;

[0024] (2) Put the green leaves treated in step (1) first on the roller fixing machine for fixing treatment. The roller fixing machine adopts the 6CST-40 roller fixing machine produced by Zhejiang Shangyang Machinery Co., Ltd., and the setting temperature for fixing is 300 °C, the temperature of the inner wall of the drum is 180-200 °C, and the amount of lea...

Embodiment 2

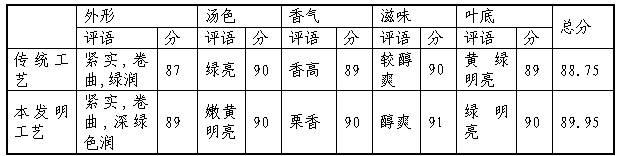

[0032] Comparison of sensory evaluation of Quhao-shaped green tea processed by different processes

[0033] The present invention compares the sensory evaluation of Quhao-shaped green tea processed by different processes. It can be seen that the total score of the product processed by the process of the present invention is quite different from that of the traditional process. The new process is obviously better in aroma and taste scores. The results are shown in Table 1.

[0034] Table 1 Comparison of sensory evaluation of Quhao-shaped green tea processed by different processes

[0035]

[0036] Note: 1. Traditional crafts: Spread bamboo plaques on the ground-cracking machine with rollers-kneading-baking-baking-frying in a small pot-frying in a large pot-baking until fully dry; 2. From the sensory evaluation results, it can be seen that the products processed by the new technology are significantly better than the traditional technology.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com