Tobacco source spice extraction method and application thereof

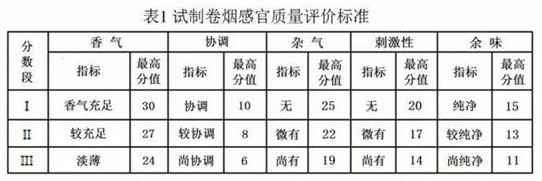

An extraction method and tobacco technology, which are applied in the directions of tobacco, tobacco preparation, tobacco processing, etc., can solve the problems that beginners are not suitable for grasping, the tobacco source material is not utilized, the aromatizing process is complicated, etc., and achieves good smoke satisfaction and stimulation. The effect of low sex and improving the quality of cigarettes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Example 1: Low-grade tobacco leaves, waste tobacco leaves, tobacco dust and tobacco stems are used as tobacco source materials, and the blending ratio of the mass parts is 2:4:3:1, and the tobacco-derived flavors produced are used for cigarette flavoring.

[0041] a. Extraction of non-polar components: Weigh 200Kg of dried low-grade tobacco leaves, 400Kg of discarded tobacco leaves, 300Kg of tobacco dust, and 100Kg of tobacco stems, crush them through an 80-mesh sieve, add them to the extraction kettle, cover and seal them, and evacuate to −0.085MPa Access to 5000LCO 2 Fluid, after extraction for 1.5h at 5.0MPa extraction pressure and 25°C extraction temperature, CO 2 The extract is poured into the separation kettle, and the separation kettle is desolvated at −0.1MPa and 60°C to obtain tobacco essential oil a 1 , and at the same time, the extraction kettle was desolvated under the conditions of −0.15MPa and 60°C to obtain the filter residue a 1 , CO after gasification...

Embodiment 2

[0047] Example 2: The difference between this example and Example 1 is that the tobacco source material used is only tobacco powder, and the spices produced are used for flavoring reconstituted tobacco leaves.

[0048] a. Extraction of non-polar components: Weigh 1000Kg of dry tobacco powder, pass through an 80-mesh sieve and add to the extraction kettle. When the extraction kettle is evacuated to −0.085MPa, 4000L CO 2 Fluid, after extracting at 3.5MPa extraction pressure and 30°C extraction temperature for 1.5h, CO 2 The extract is poured into the separation kettle, and the separation kettle is desolvated at −0.1MPa and 60°C to obtain tobacco essential oil a 2 , and at the same time, the extraction kettle was desolvated under the conditions of −0.15MPa and 60°C to obtain the filter residue a 2 , CO after gasification 2 Compressed, condensed, liquefied and circulated to the storage tank for use;

[0049] b. Extraction of weak polar components: to the above filter residue a ...

Embodiment 3

[0053] Example 3: The difference between this example and Example 1 is that the tobacco source materials used are low-grade tobacco leaves and waste tobacco leaves, the mass ratio is 3:7, and the produced spices are flavored and used for popping beads in cigarette filters or microcapsules.

[0054] a. Extraction of non-polar components: Weigh 300Kg of dried low-grade tobacco leaves and 700Kg of waste tobacco leaves, crush them through an 80-mesh sieve and add them to the extraction kettle. 2 Fluid, after extraction for 1.5h at 1.5MPa extraction pressure and 35°C extraction temperature, CO 2 The extract is poured into the separation kettle, and the separation kettle is desolvated at −0.1MPa and 60°C to obtain tobacco essential oil a 3 , and at the same time, the extraction kettle was desolvated under the conditions of −0.15MPa and 60°C to obtain the filter residue a 3 , CO after gasification 2 Compressed, condensed, liquefied and circulated to the storage tank for use;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com