Patents

Literature

51results about How to "Improve the quality of cigarettes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

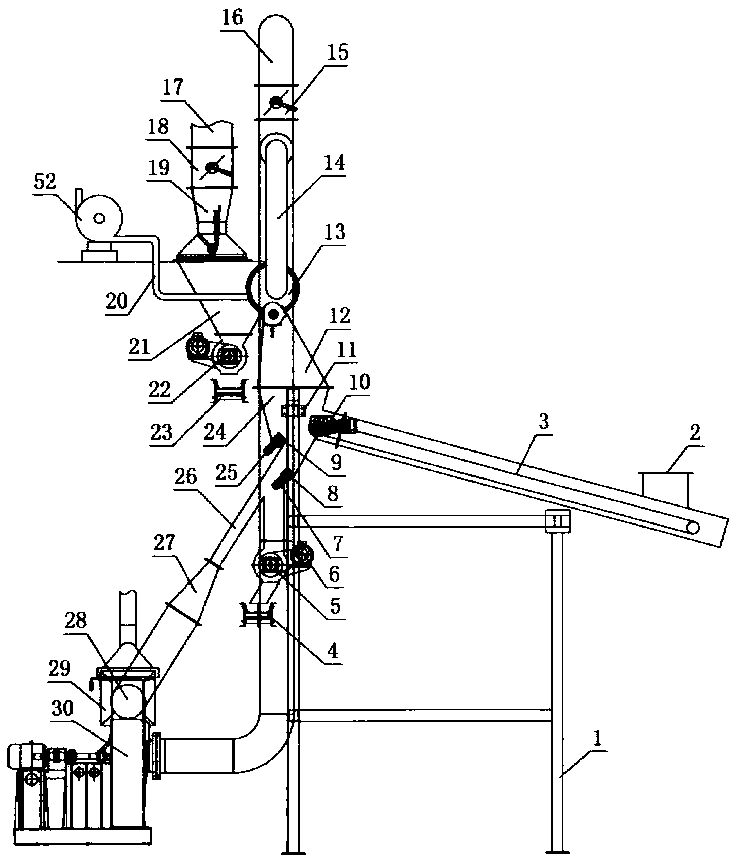

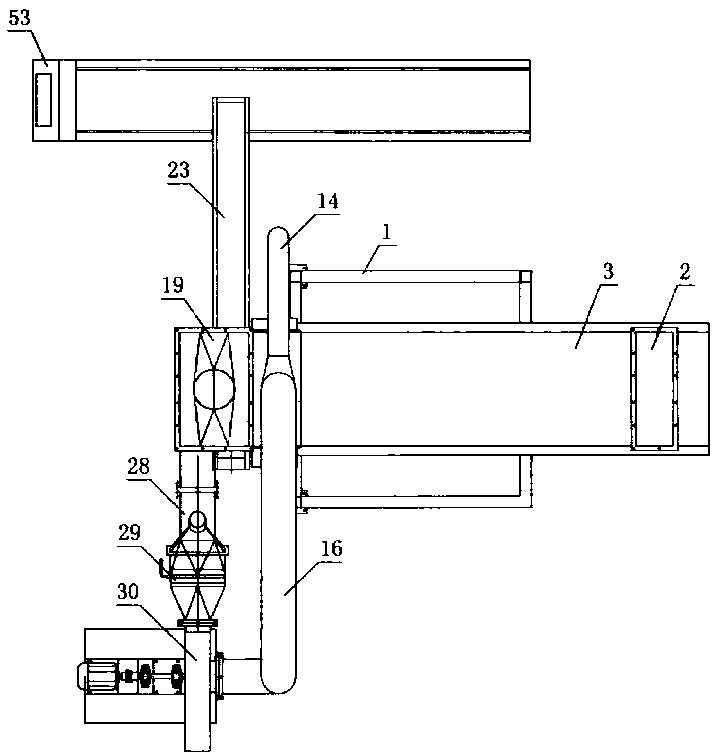

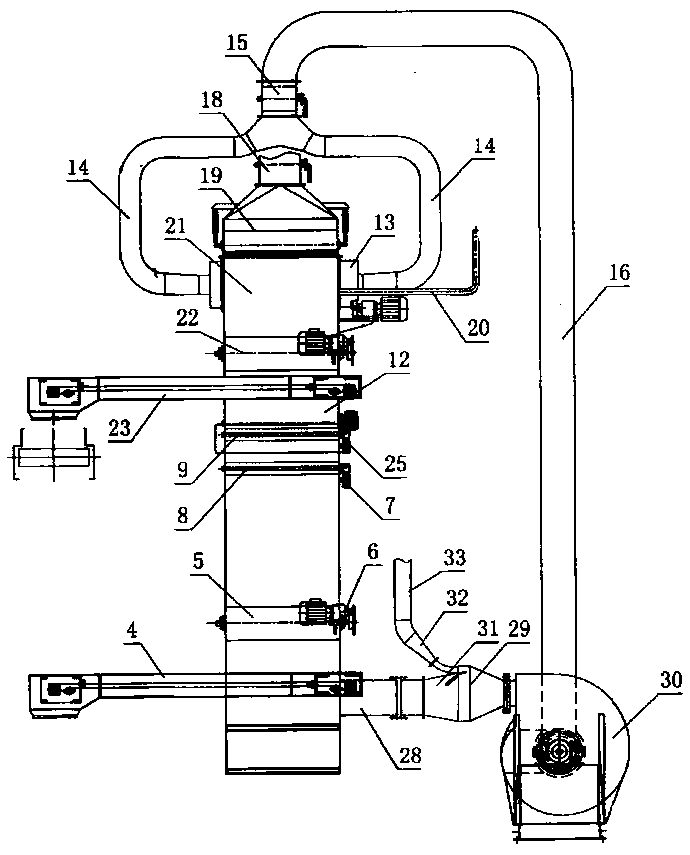

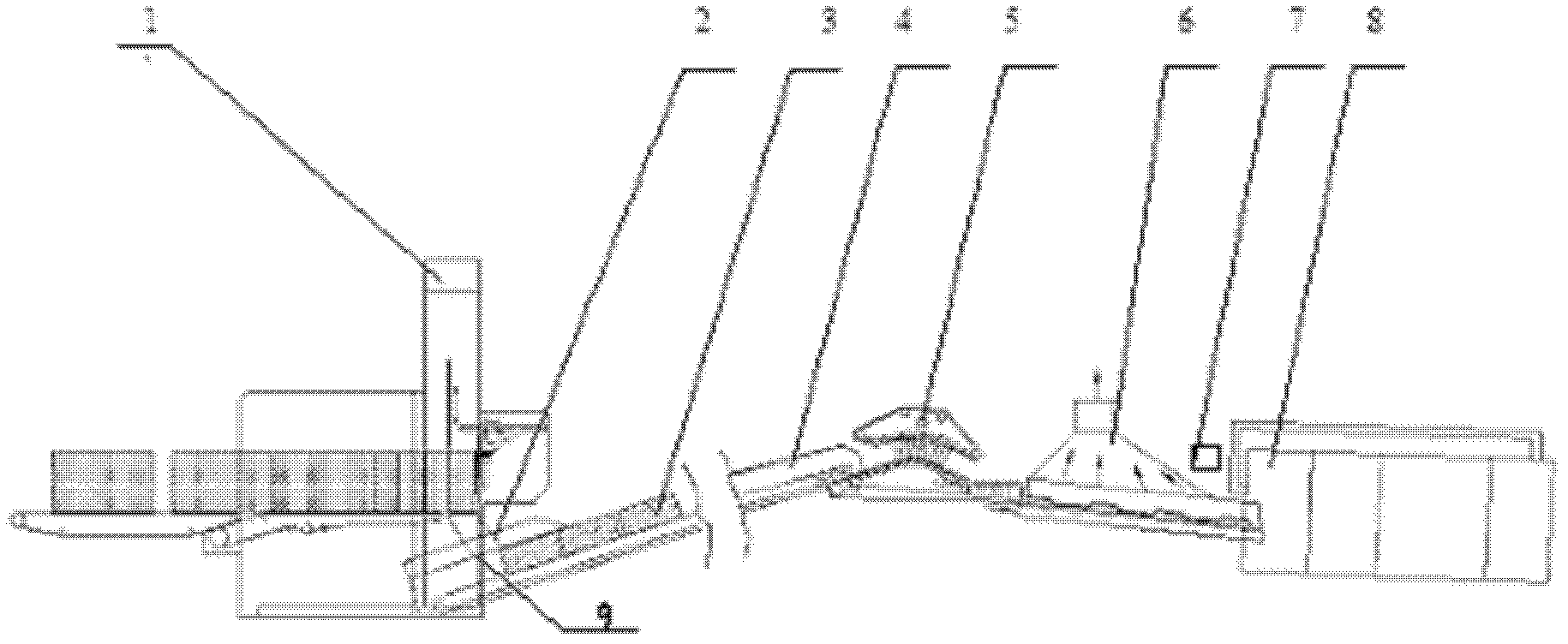

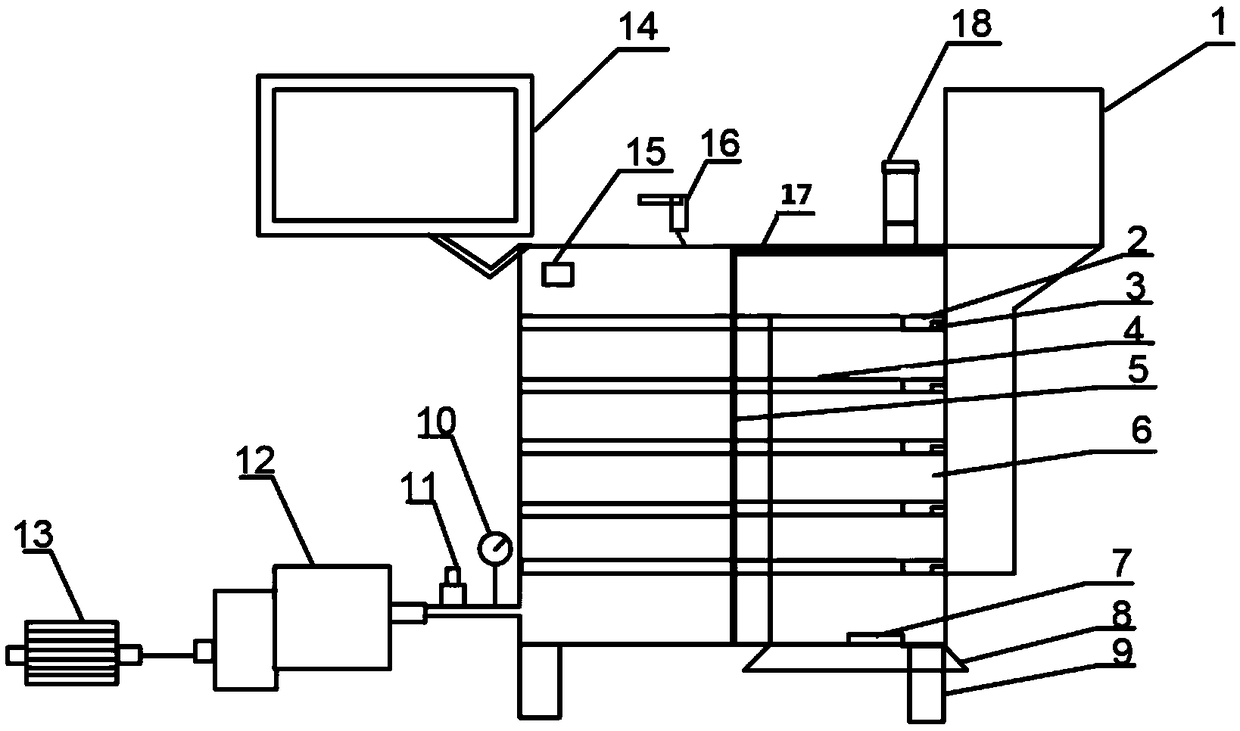

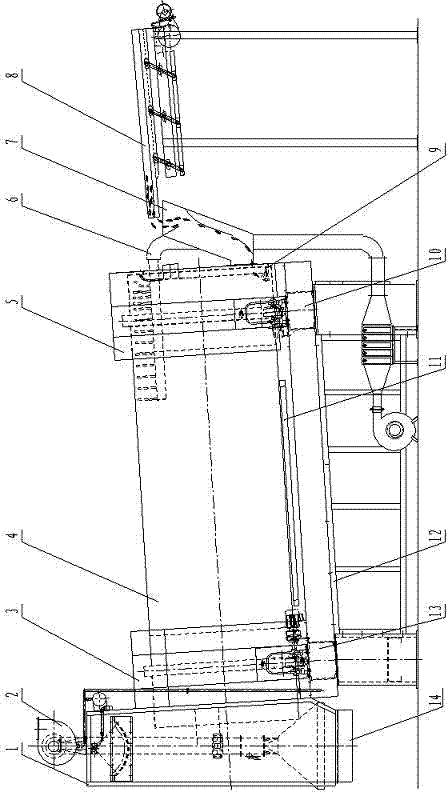

Device for sorting and recycling broken cigarette paper and tobacco powder in tobacco shreds

ActiveCN103624004AImprove qualityReduce contentSievingGas current separationBiotechnologyEngineering

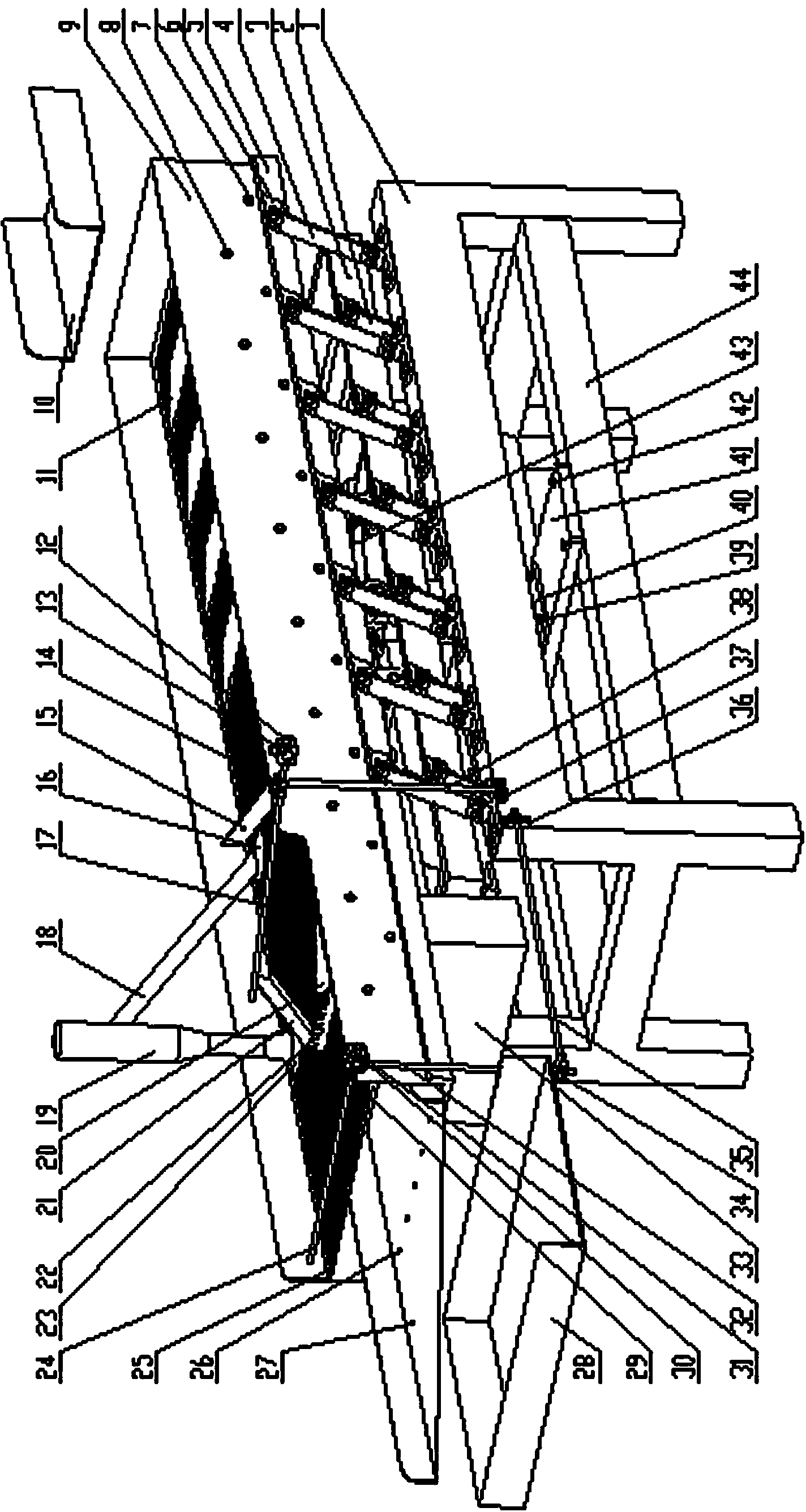

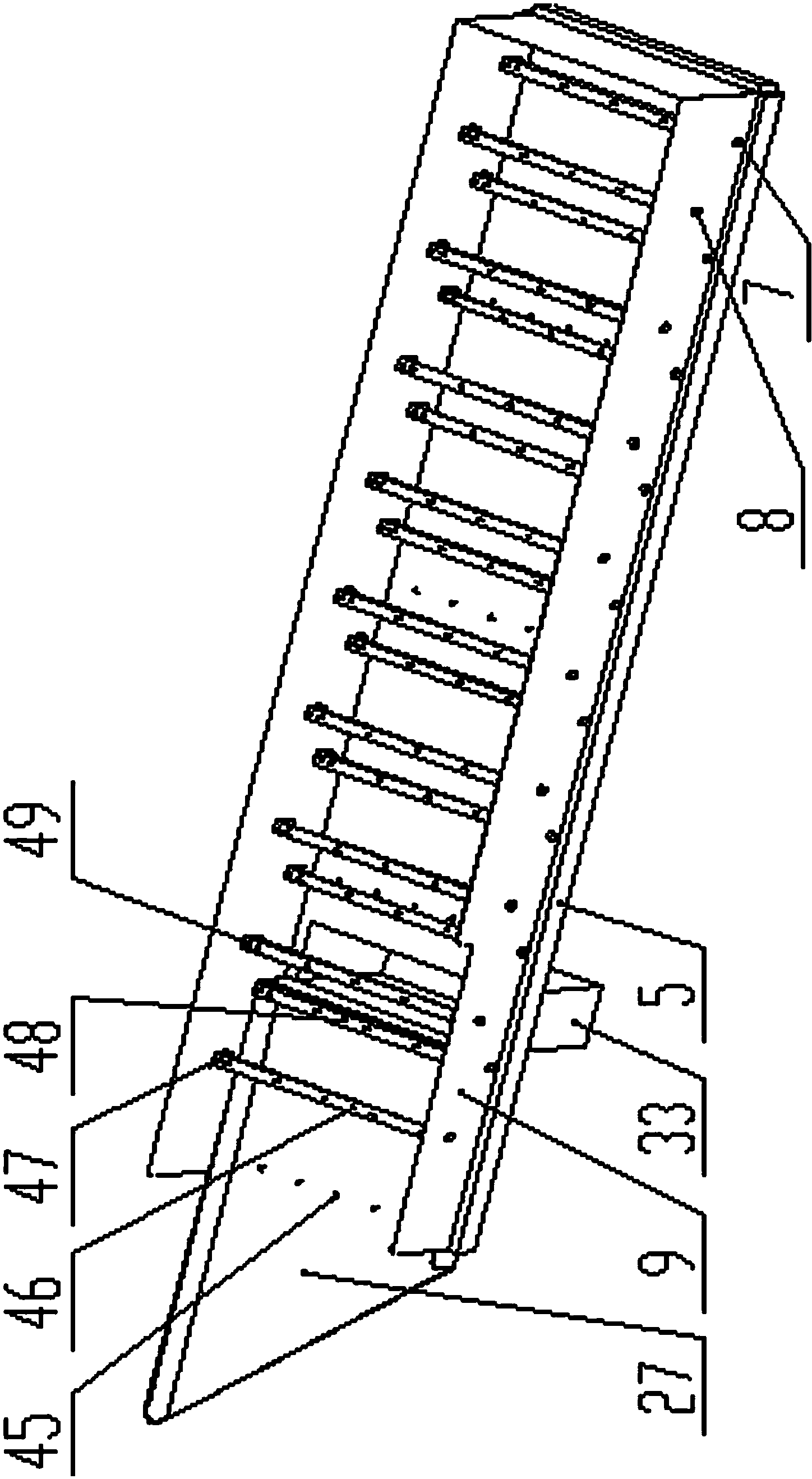

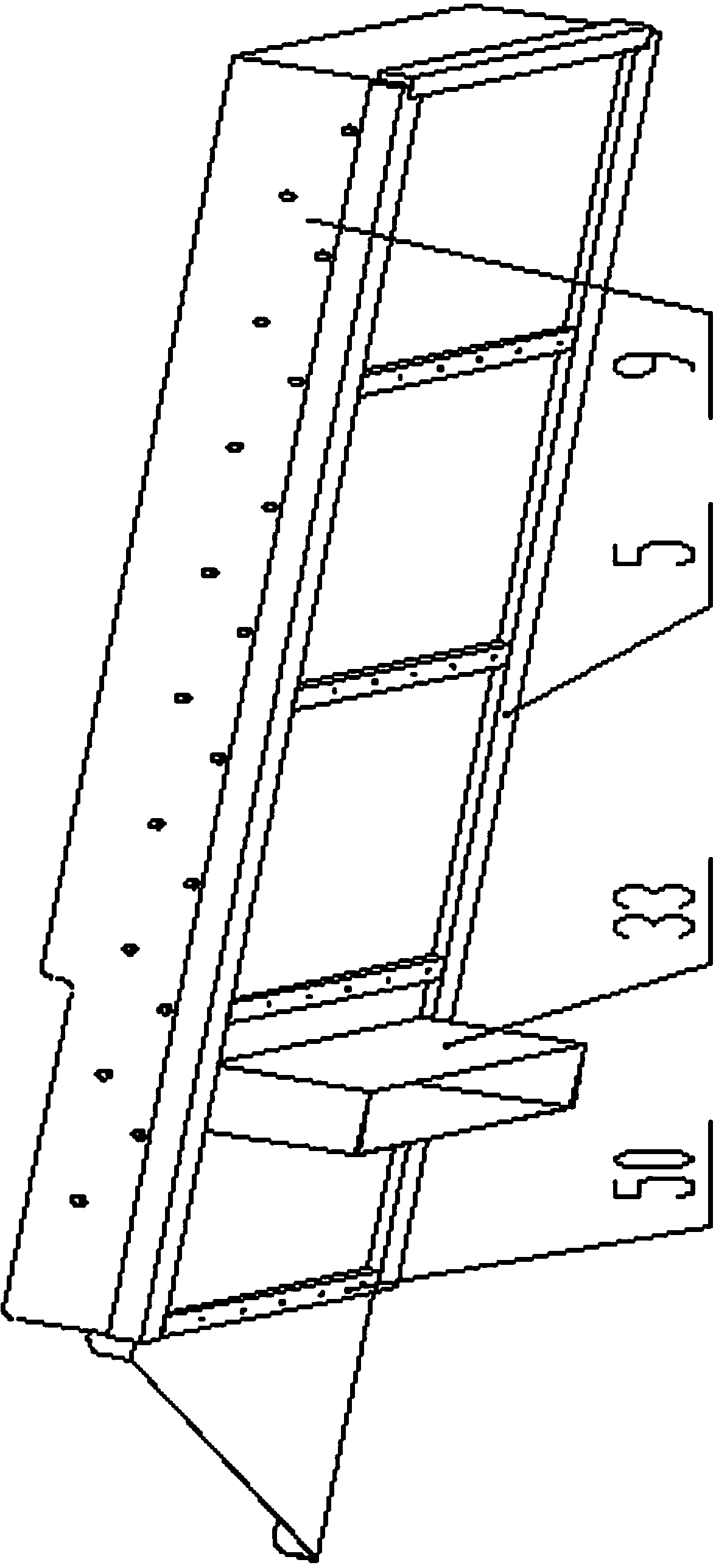

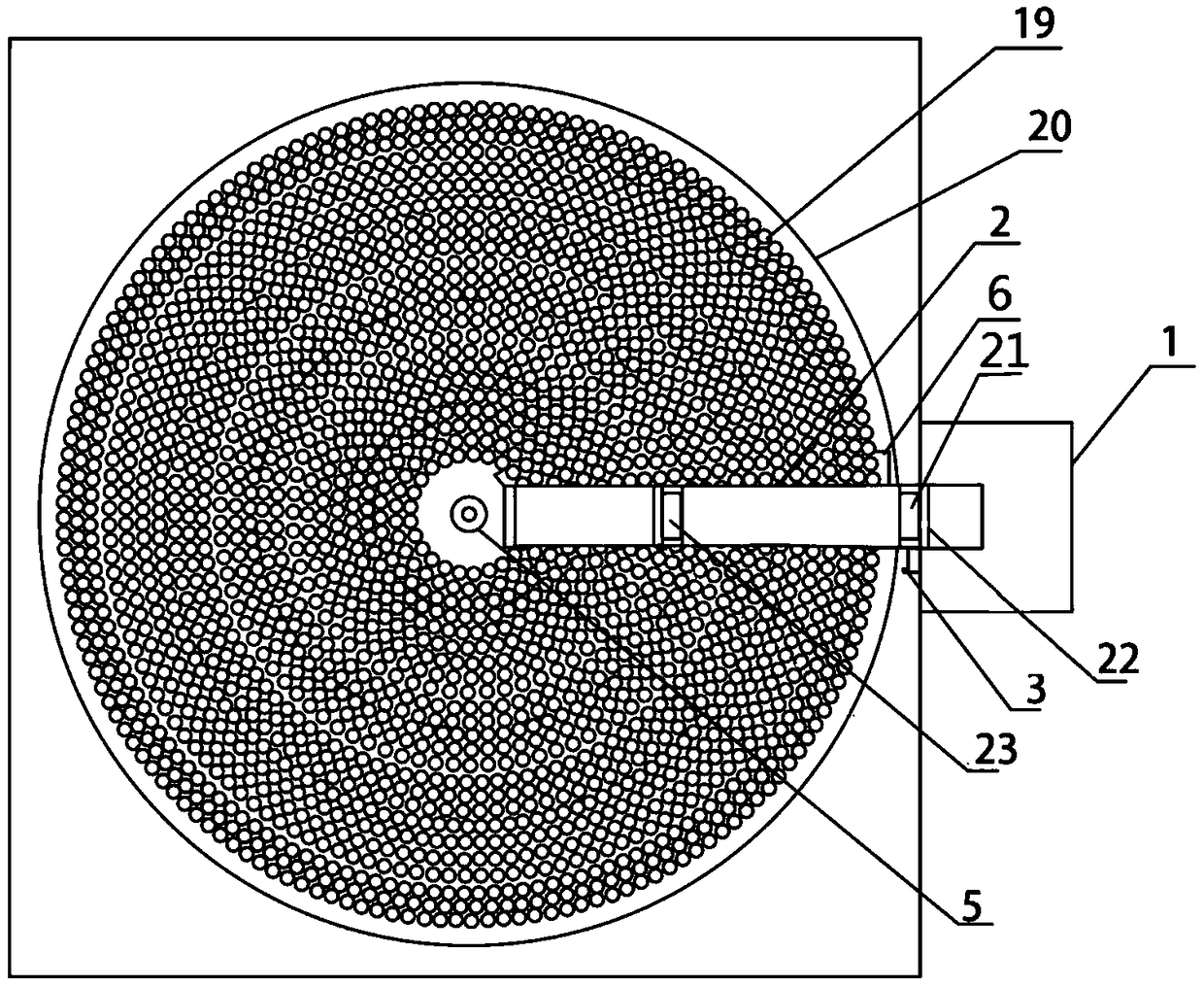

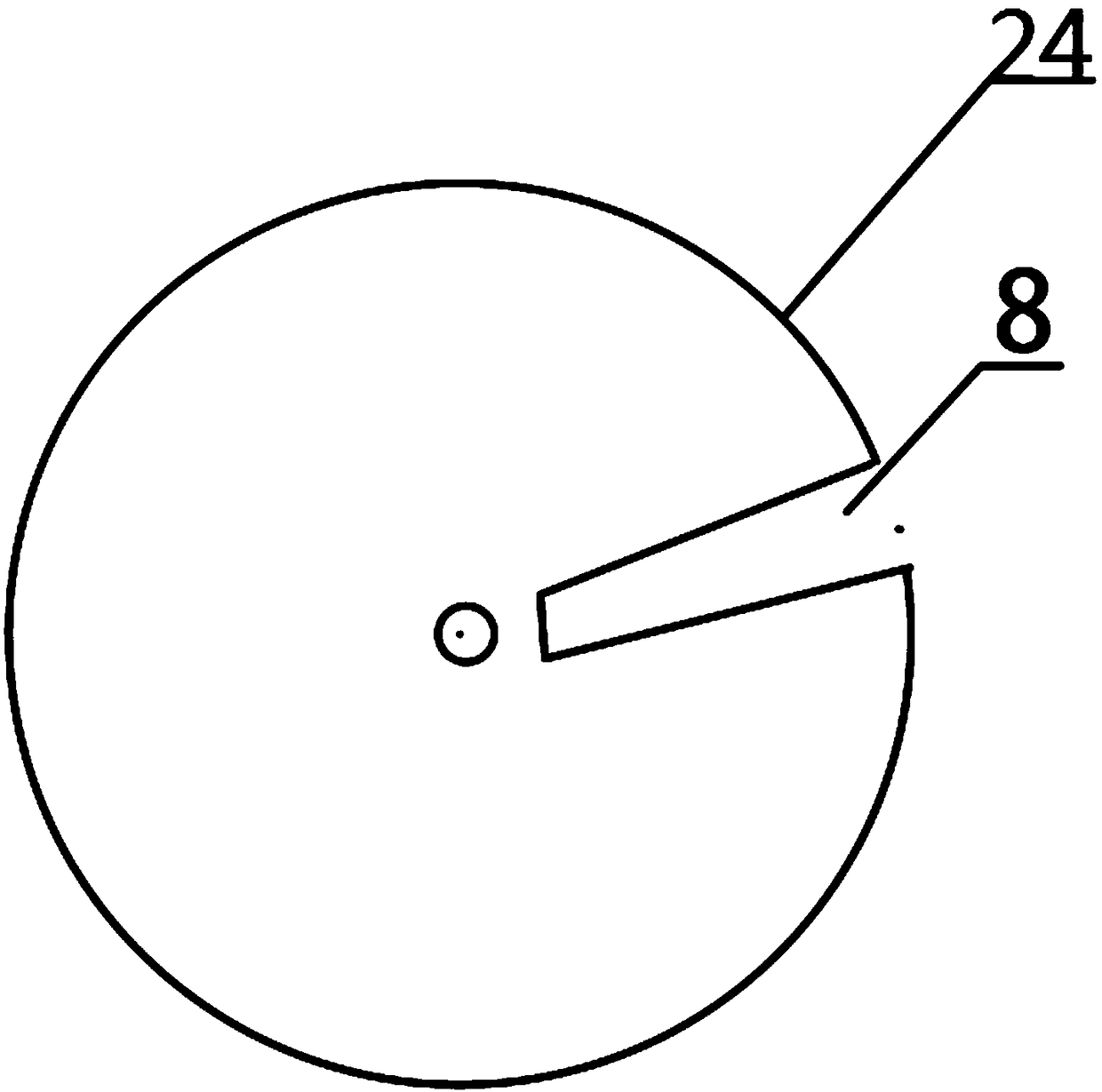

The invention relates to a device for sorting and recycling broken cigarette paper and tobacco powder in tobacco shreds. The device is installed on a recycling tobacco shred processing production line. A groove vibrating frame of the device achieves vibration transport of the tobacco shreds through an eccentric driving device, wherein the eccentric distance e of an eccentric wheel of the eccentric driving device is equal to 8-10mm, the material fling angle beta is equal to 8-12 degrees, and the rotating speed of the eccentric wheel is equal to 4-6rpm / s. Two layers of sieve plates are designed in the groove vibrating frame, sieve meshes of the first layer sieve plates are kidney-shaped meshes which are 3*25mm in diameter and used for filtering the tobacco shreds, the sieve meshes of the second layer sieve plates are round meshes which are 1.5mm in diameter and used for filtering the tobacco powder, and a tobacco powder outlet is designed in the bottom of the groove vibrating frame. Partition plates, splitter plates and the like are installed on the surfaces of the first layer sieve plates, air pipes and supports are designed and installed on a groove vibrating rack, and an air pressure adjusting valve is connected. A negative pressure adsorption tube is designed, when being sieved from the tobacco shreds, the broken cigarette paper is collected in a suspending mode and adsorbed under the effect of airflow, and tobacco shreds are transported to a next working procedure through a discharge groove.

Owner:HONGTA TOBACCO GRP

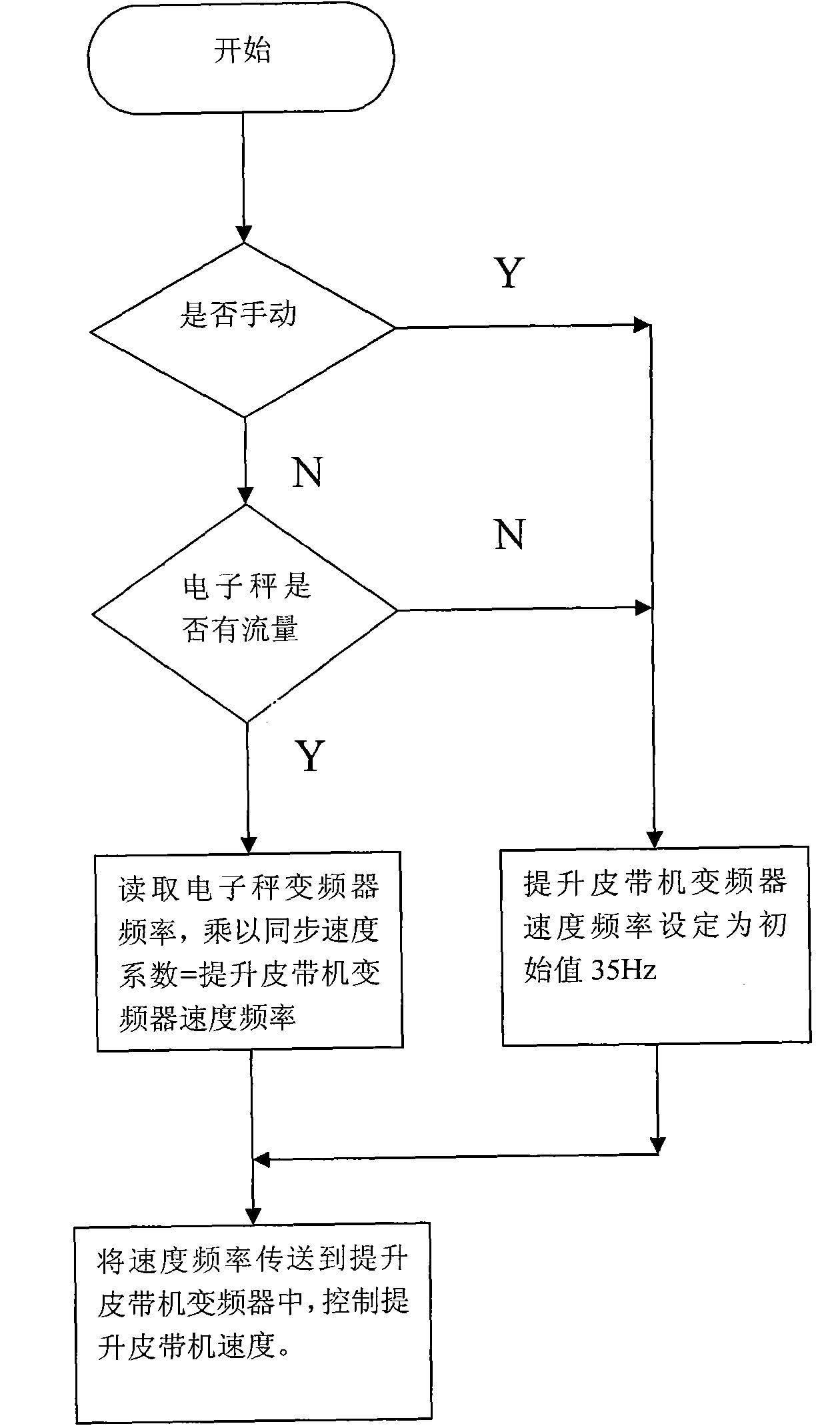

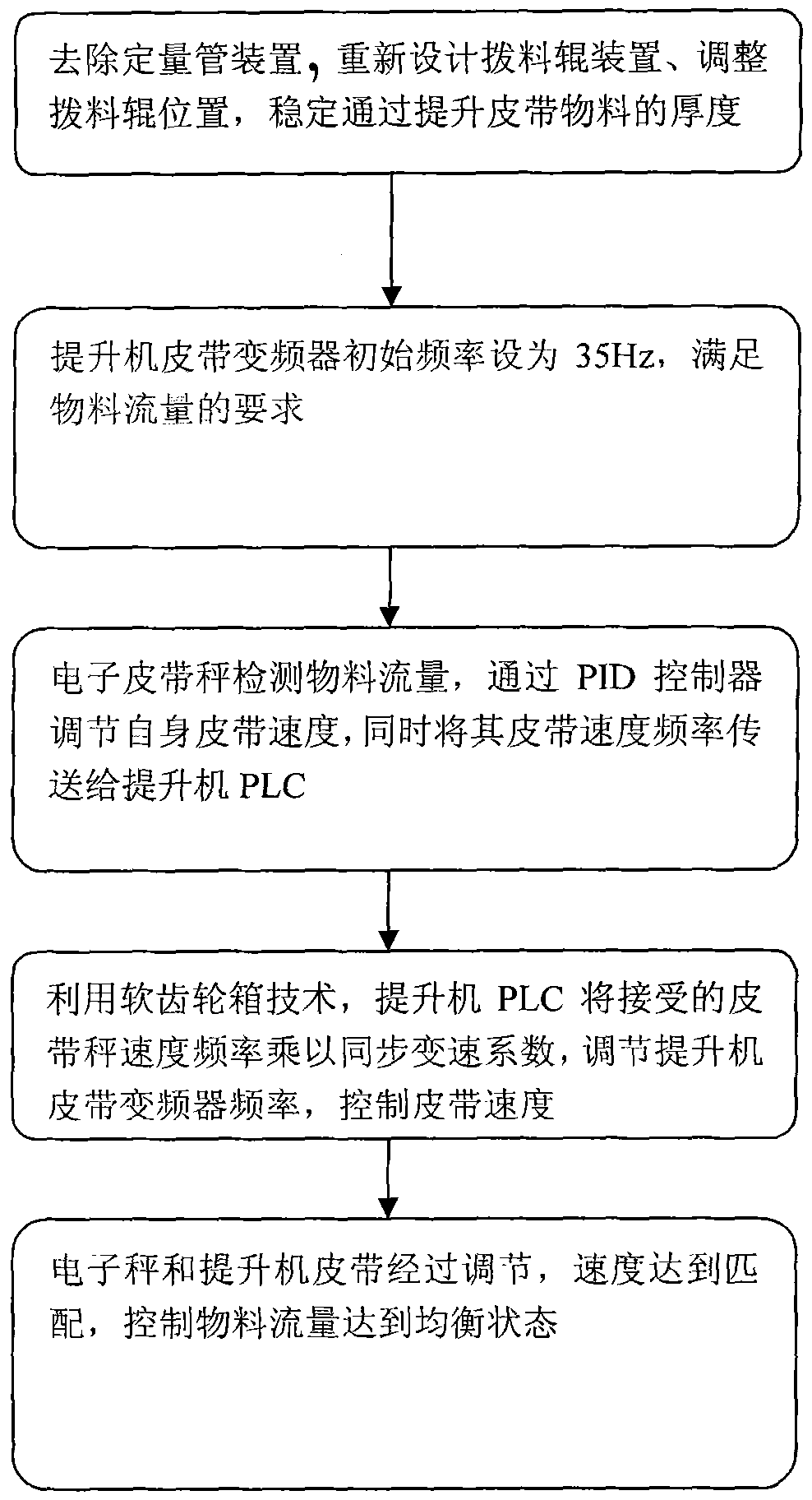

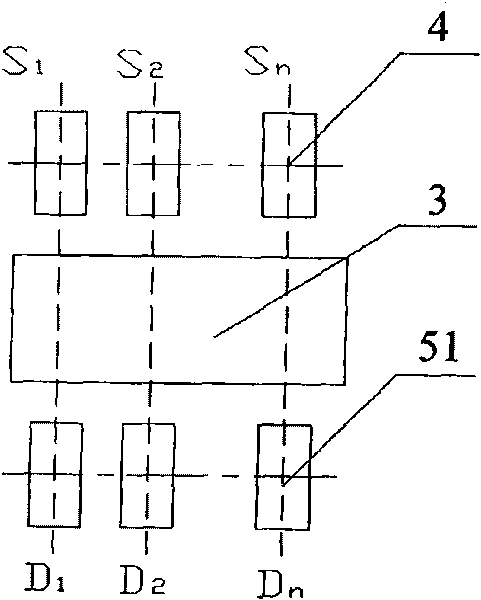

Method for controlling material flow balance without quantitative feed pipe

ActiveCN101934930AHigh precisionSmall fluctuationControl devices for conveyorsEngineeringElectric control

The invention discloses a material flow control method, particularly relates to a method for controlling material flow balance without a quantitative feed pipe, and belongs to the field of material flow control. The method is applied in computer programming technology, electronic gear box technology and frequency converter control technology, and improves the conventional material flow process in the following modes: removing a quantitative pipe device; redesigning a material dialing roller device, and adjusting the position of a material dialing roller; changing the control mode, and taking a hoister belt as an electric control point; determining a speed controller mode; and establishing a data communication mode between an electronic balance and a hoister PLC. The method applied in a process of controlling cigarette manufacturing shreds can balance the flow of high-moisture tobacco shreds, improve the conveying precision of the material, reduce the conveying fluctuation of the material, facilitate the processing of subsequent processes of the tobacco shreds, improve the quality of cigarettes and relieve the labor intensity of operators at the same time, and has good industrial application value and popularization and application prospects.

Owner:CHINA TOBACCO HENAN IND

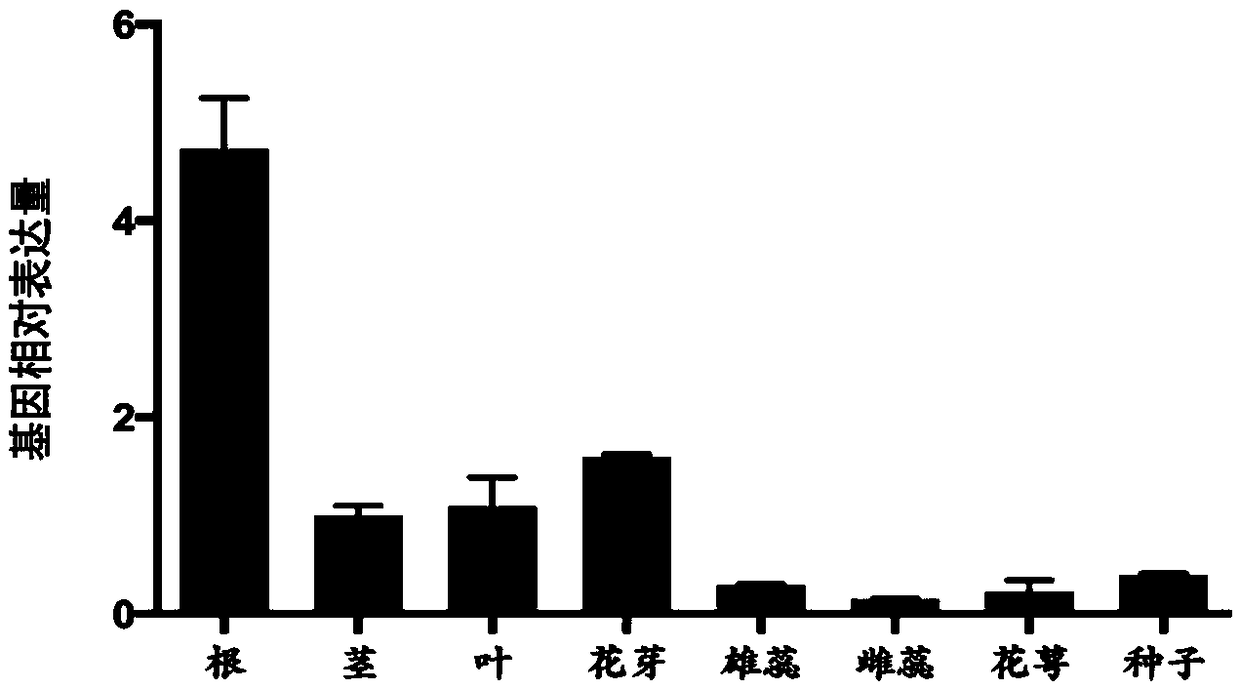

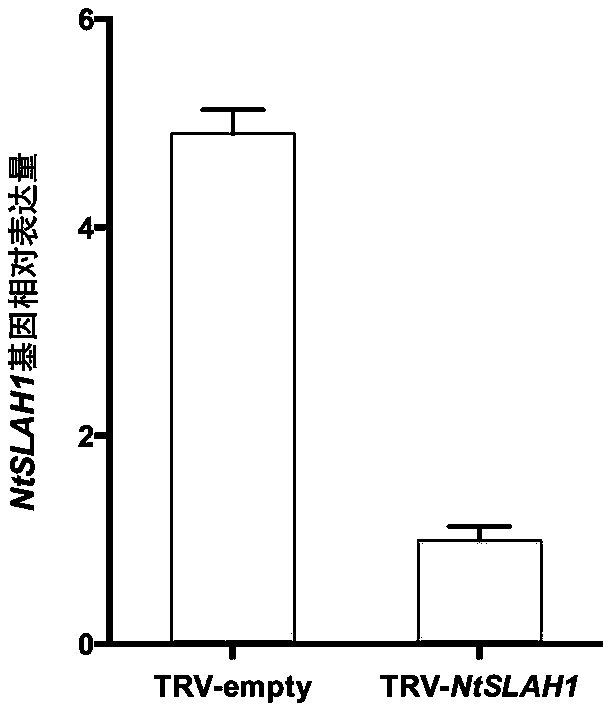

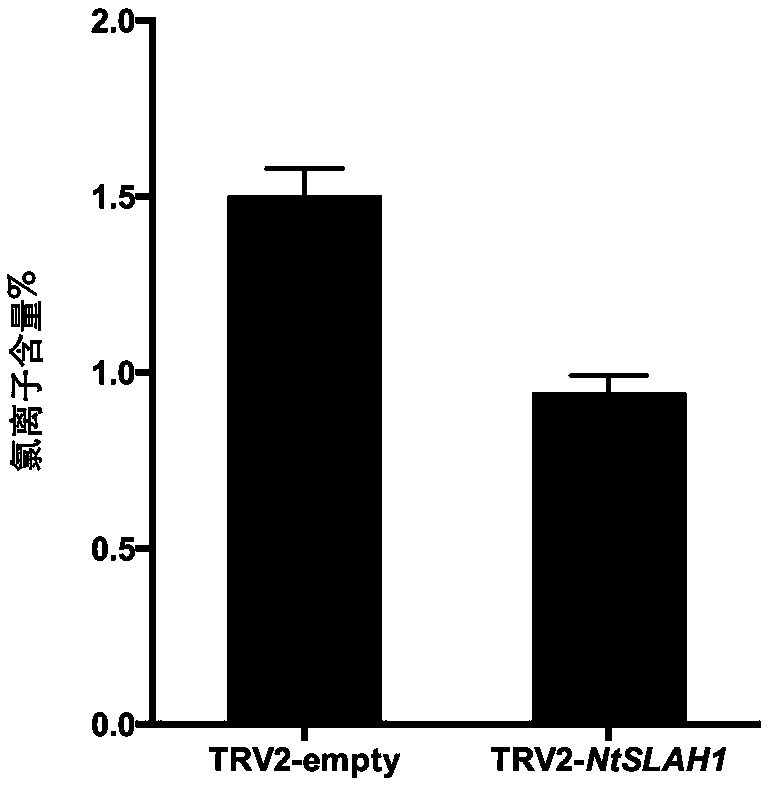

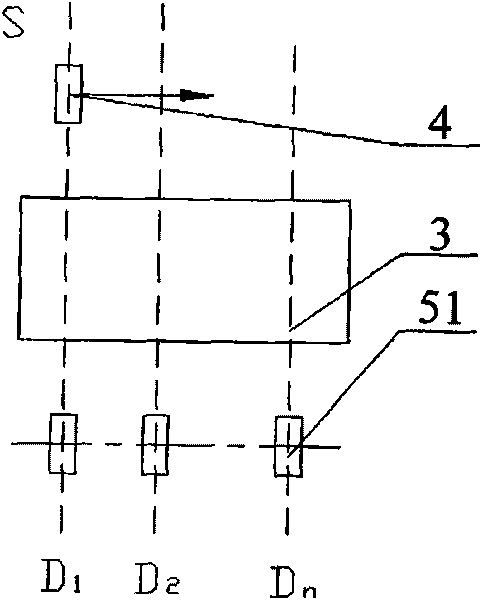

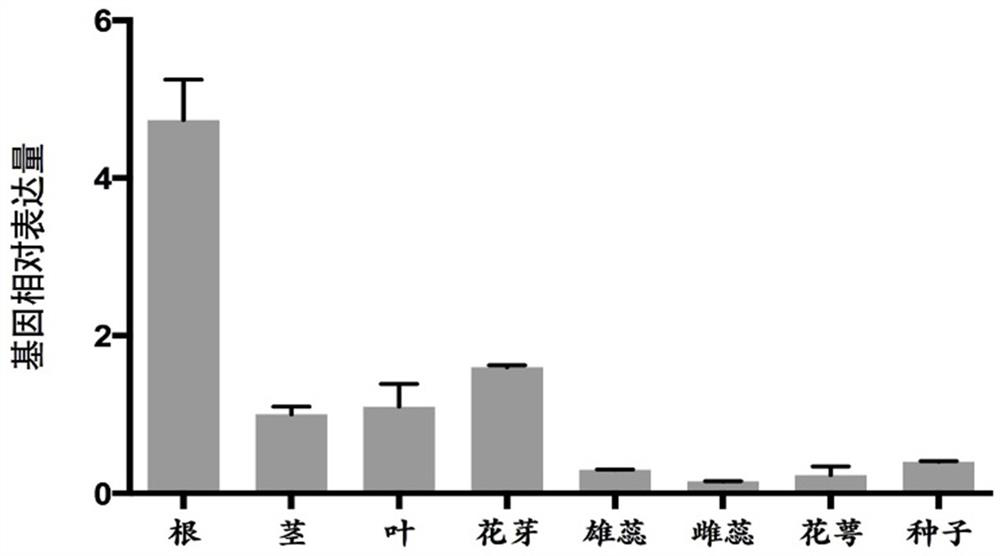

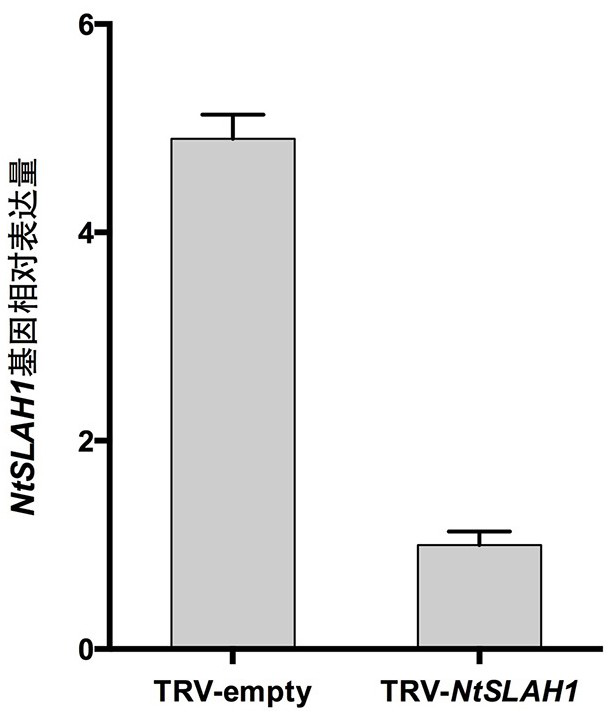

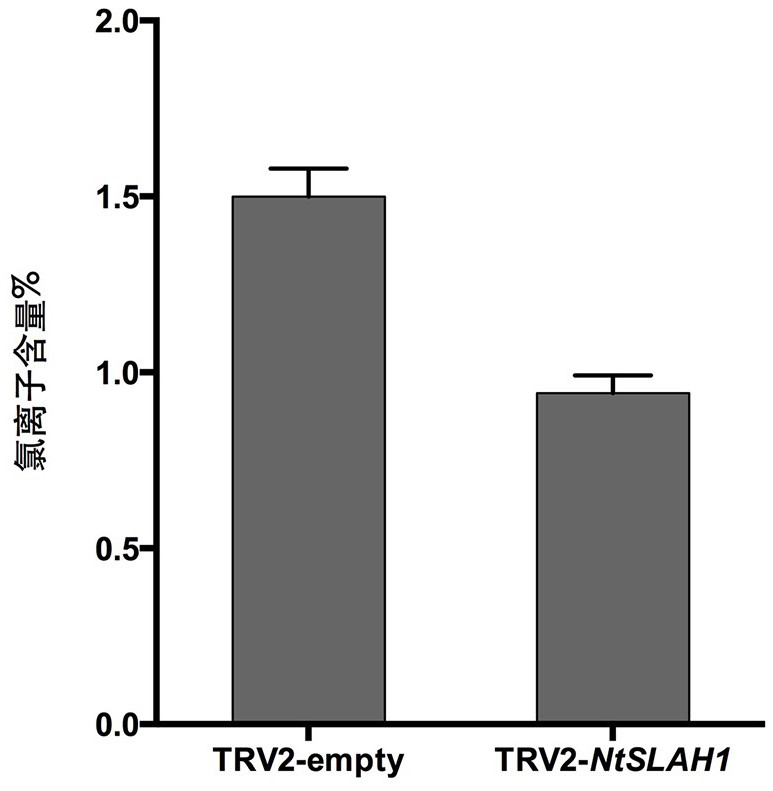

Nicotiana tabacum slowly activating anion channel homologue (NtSLAH1) and application thereof

ActiveCN108192896AReduce Chloride ContentQuality improvementPlant peptidesFermentationNicotiana tabacumNucleotide

The invention belongs to the technical field of tobacco genetic engineering, and in particular relates to a nicotiana tabacum slowly activating anion channel homologue (NtSLAH1) and application thereof. The CDS sequence of the gene comprises 1107 bp basic group, and the sequence of the basic group is shown in SEQ ID NO. 1, wherein the 270th-615th nucleotides are specific nucleic acid fragments. The NtSLAH1 is a key protein of tobacco chlorine ion metabolism; after the expression of the NtSLAH1 gene is inhibited by using a virus-induced gene silencing (VIGS) technology, the chloride ion contentin transgenic silencing plants is significantly reduced. Therefore, a good foundation is laid for cultivating new varieties of low-chlorine tobacco, and a fundamental technical support is also provided for the stability of tobacco quality and the improvement of cigarette quality.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

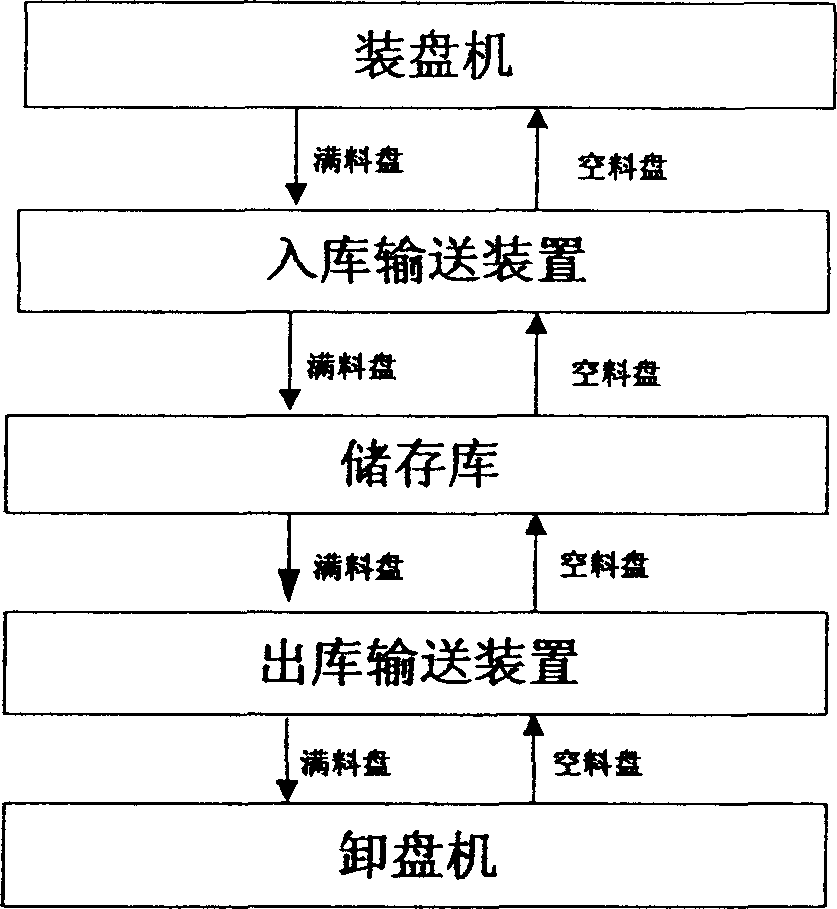

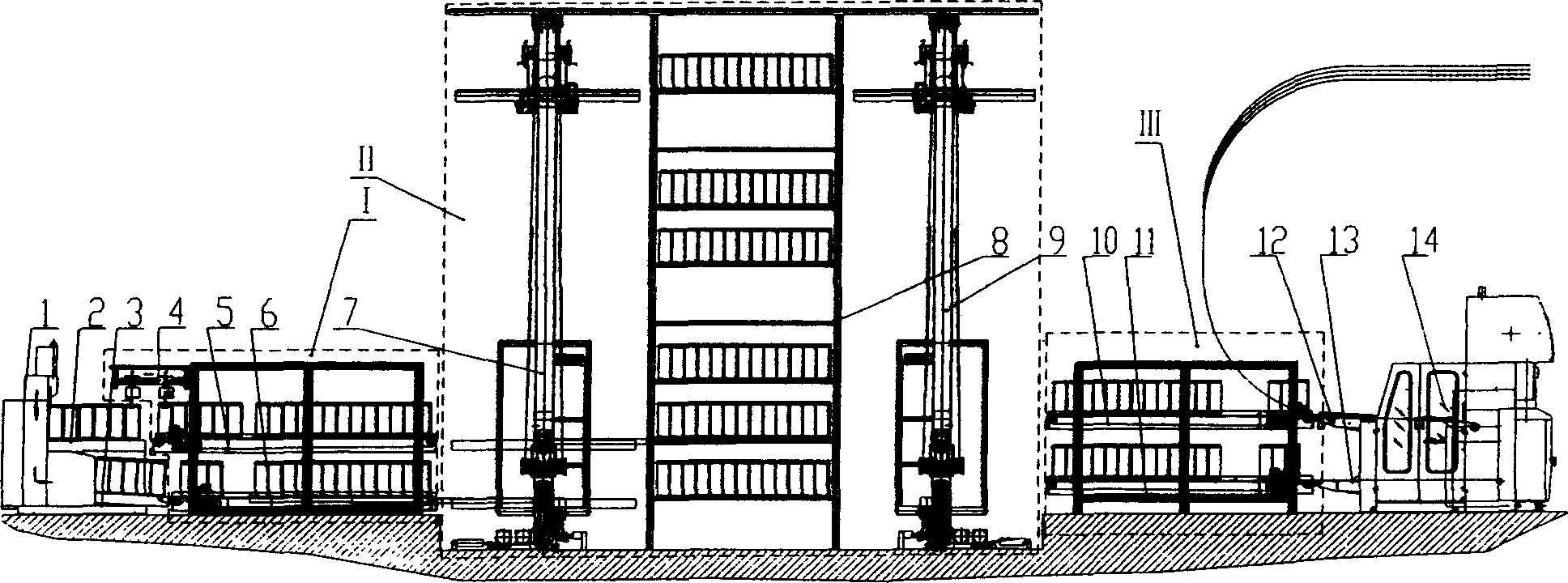

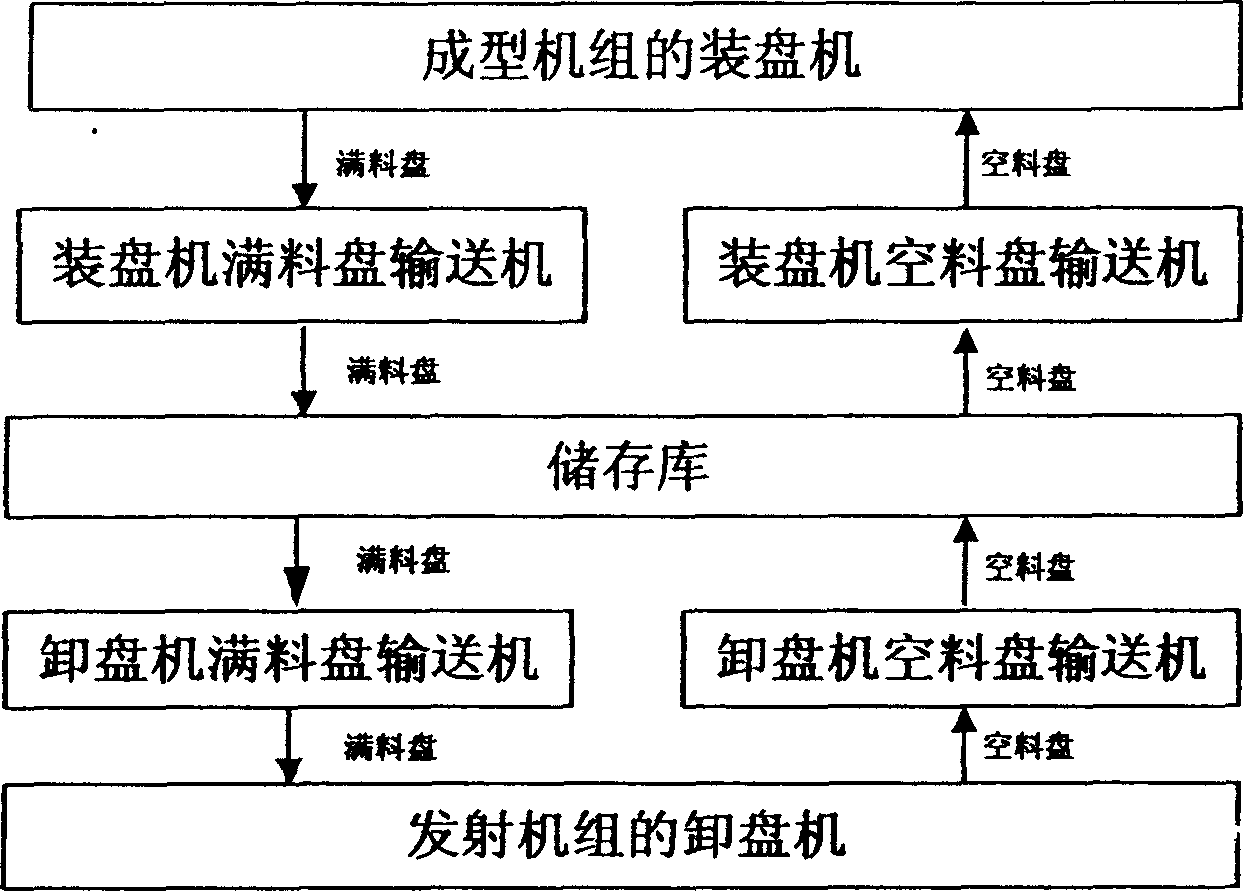

Automatic storage and transfer technology of cigarette stick shaped material

InactiveCN1686013AIncrease storage capacityExtend curing timeCigarette manufactureRod-shaped articlesAutomatic controlEngineering

An automatic storing-conveying technology for the rod material of cigarette includes taking empty tray from its storage, conveying it to rod material loader, loading the rod material in the tray, conveying the full-load tray in the storage for storing it, taking the full-load tray out of the storage, conveying it to unloader, unloading the rod material for further processing, and conveying the empty tray into its storage for further use.

Owner:YUNNAN KUNMING SHIPBUILDING DESIGN & RESEARCH INSTITUTE +1

Cigarette containing lentinan and preparation method thereof

InactiveCN101692933AImprove solubilityHazard reductionTobacco treatmentAdditive ingredientHuman health

The invention discloses a cigarette containing lentinan and a preparation method thereof, aiming at solving the technical problem of reducing the harmful ingredients in cigarettes. The cigarette containing the lentinan has the tobacco shred containing the lentinan with the mass of 0.001-10% of the tobacco shred. The preparation method of the cigarette containing the lentinan comprises the following steps: dissolving the lentinan in the water to be solution with the mass concentration of 1-10%; evenly spaying the lentinan solution onto the tobacco shred according to the proportion that the lentinan accounts for 0.001-10% of the tobacco shred; and finally, naturally drying and making into the cigarettes according to the conventional cigarette technology. Compared with the prior art, as the tobacco shred contains the extract of the ingredient of the lentinan which has good dissolubility, can enters the human body along with the main stream smoke and is absorbed by the human body through blood circulation, thus playing the role of resisting tumour, oxidation and aging; furthermore, the smoke of the cigarettes is mellow without impurity gas, so that the invention improves the quality of the cigarettes and reduces the hazard to the human health.

Owner:广东神农烟科技术有限公司

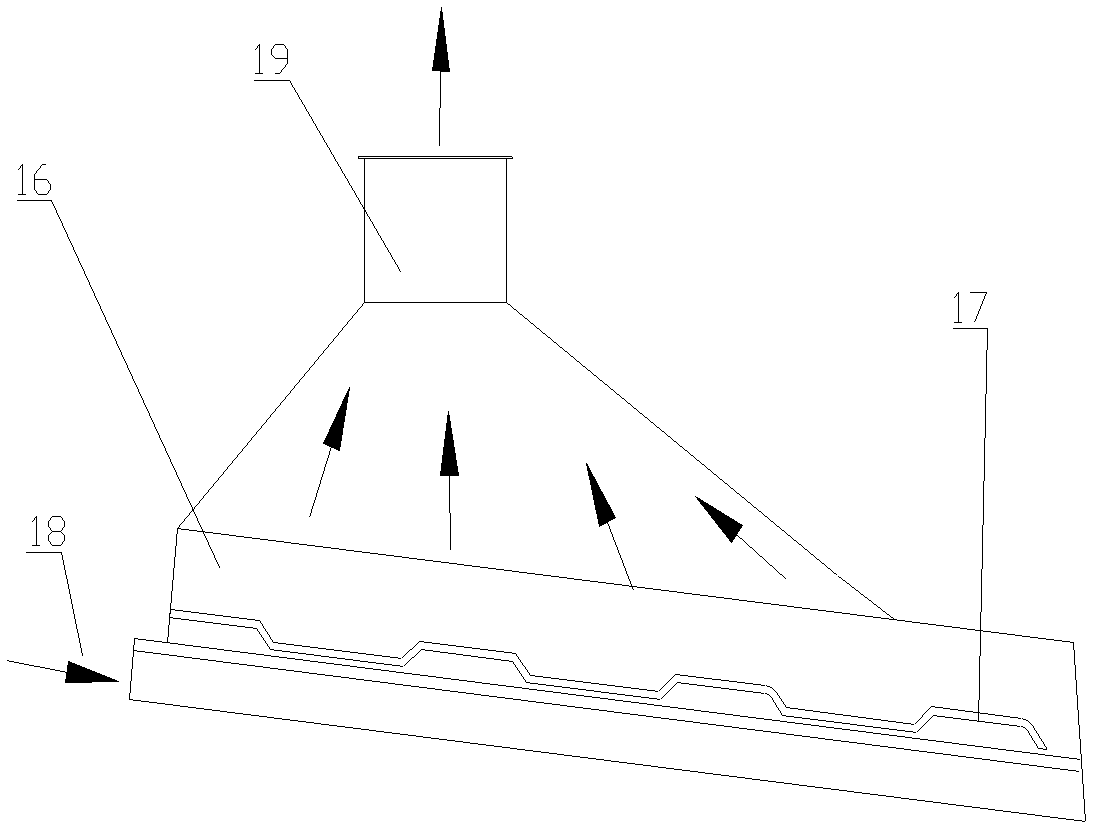

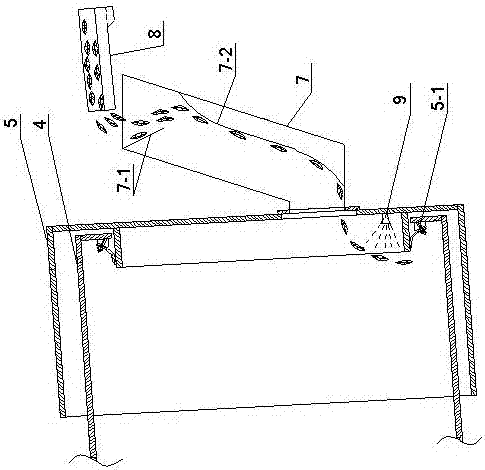

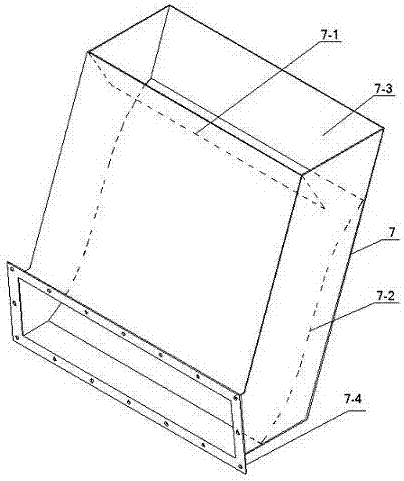

A tobacco shredding air distributor

PendingCN108889623ASolve the problem of mixing a large number of stemsHigh purityGas current separationAir volumeEngineering

The invention discloses a shredded tobacco scattering air distributor, the upper left end of the frame is provided with a cut tobacco separating and beating air separating cabin, An upper end of thatcut tobacco separate and scattered air separation bin is provide with a shred suction network transferring device, A tobacco settling chamber is arranged at the left end of the suction wire mesh rotating device, the lower end of the tobacco settling chamber is provided with a tobacco discharge valve, the lower end of the shredded tobacco discharge valve is provided with a shredded tobacco conveyorbelt, the rear end of the tobacco conveyor belt is provided with a tobacco conveyor main belt, the upper end of the tobacco shred settling chamber is provided with a filter screen device, the upper end of the filter screen device is provided with an air volume regulating valve, the upper end of the air volume regulating valve is provided with a blowing pipe, The upper end of the blowing pipe is arranged on the dust removing main pipe in the workshop. The invention separates the stem from the tobacco shreds, which is a processing step for improving the quality of the tobacco shreds after the drying step. The tobacco shreds and the stem shreds are separated step by step by beating and throwing materials, thus realizing the flexible and efficient separation of the tobacco shreds and the stemshreds, and solving the problem that a large number of the stem shreds are mixed in the existing tobacco shreds.

Owner:阜阳丰达机电设备有限公司

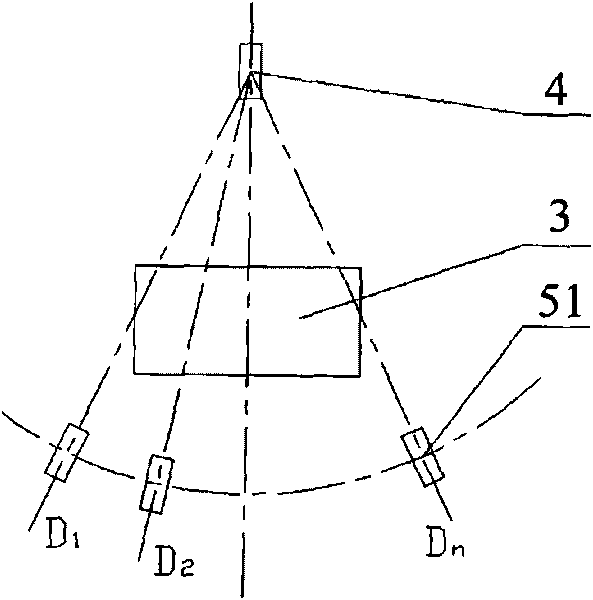

Device and method for detecting agglomeration of smoked sheets in smokebox

InactiveCN101750426AImprove product qualityAccurate measurementMaterial analysis using wave/particle radiationSpecific gravity measurementControl systemData acquisition

The invention discloses a device and a method for detecting the agglomeration of smoked sheets in a smokebox. The device comprises a bracket, a conveyer, a radiation source, a radiation detector, a synchronous movement mechanism and a data acquisition and control system, wherein the bracket is arranged in a shielding casing, the radiation source and the radiation detector are installed on the synchronous movement mechanism, and the synchronous movement mechanism is fixed on stands at both sides of the conveyer; and the radiation source and the radiation detector move synchronously on the synchronous movement mechanism and measure a smokebox which passes through the middle of the synchronous movement mechanism and is conveyed by the conveyer to be measured, the data acquisition and control system collects a signal output by the radiation detector, the signal is analyzed according to an agglomeration judgment standard, and the agglomeration condition of smoked sheets in the smokebox to be measured is obtained. The device can measure the density variation DVR value of the smoked sheets of the smokebox more accurately, judges whether an agglomerate exists in the smokebox or not, and gives out the size and the position of the agglomerate; and moreover, the device adopts nondestructive examination and has the characteristics of high detection accuracy, high stability and reliability and the like.

Owner:邸生才

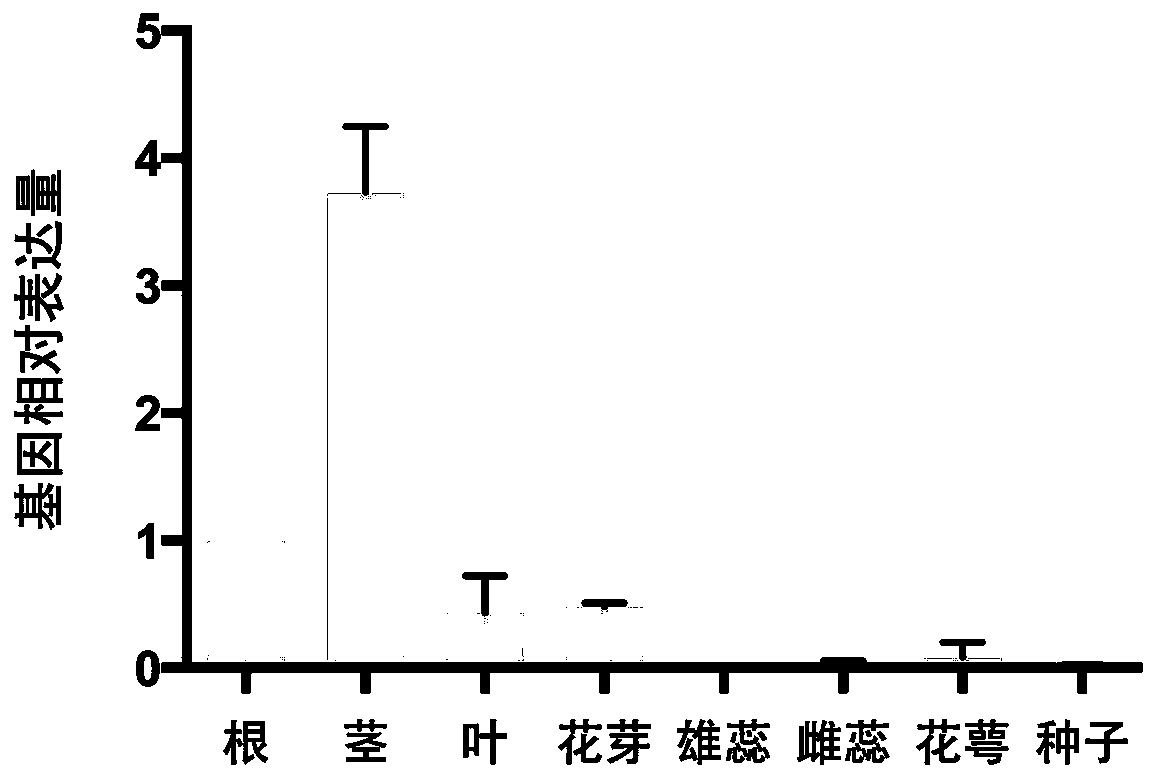

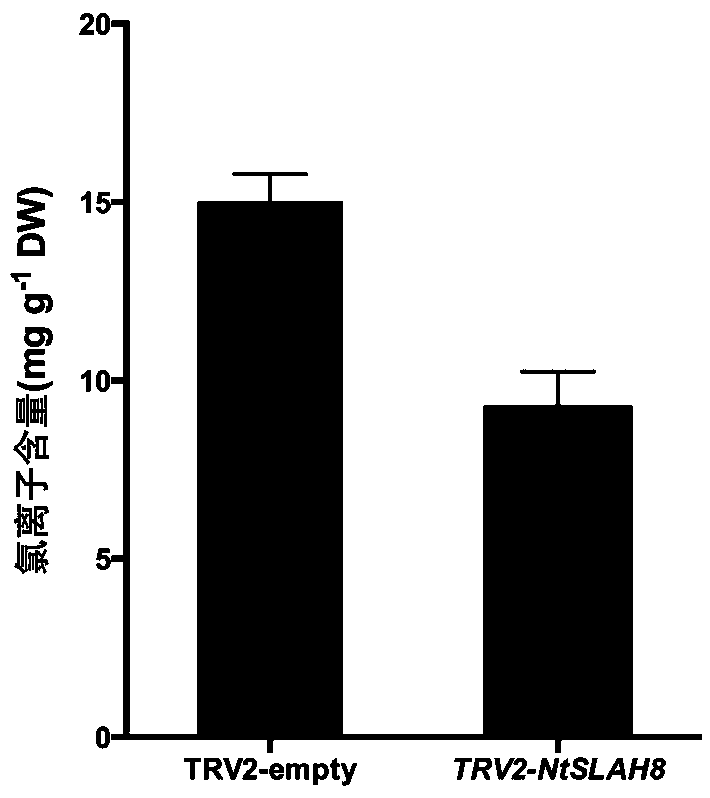

Tobacco slowly activating anion channel protein NtSLAH8 and application thereof

InactiveCN109337914AReduce Chloride ContentQuality improvementPlant peptidesFermentationIon contentNicotiana tabacum

The invention belongs to the technical field of tobacco genetic engineering, and particularly relates to tobacco slowly activating anion channel protein NtSLAH8 and application thereof. A gene CDS sequence comprises 579bp basic group, with the base sequence being as shown in SEQ ID NO.1; the first to 388th nucleotide for a specific nucleic acid fragment. The tobacco slowly activating anion channelprotein NtSLAH8 belongs to key protein for metabolism of tobacco chlorine ion, and the chlorine ion content in transgenic silencing plant is obviously reduced after NtSLAH8 gene expression is inhibited through a virus induced gene silencing (VIGS) technology, so that a good foundation can be laid for cultivation of low chlorine content novel varieties, and meanwhile a fundamental technical support for the stabilizing of tobacco leaf quality and improvement of cigarette quality.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

Tobacco piece scattering regionalization dampening system and process

ActiveCN103099301AAchieve low temperature regainKeep the smellTobacco preparationSpray nozzleFood flavor

The invention discloses a tobacco piece scattering regionalization dampening system and tobacco piece scattering regionalization dampening process. The tobacco piece scattering regionalization dampening system comprises a vertical splitting machine, a conveyor belt, a natural scattering splitting machine, a vibration type heating dampening scattering machine and a regionalization type polygon dampening drum which are arranged in sequence. The natural scattering splitting machine comprises an annular upper flexure belt, an annular lower flexure belt and rotary rollers arranged in the upper flexure belt and in the lower flexure belt. The vibration type heating dampening scattering machine comprises a vibration groove body, a cover body and a humid airflow device, wherein a grid plate is arranged in the vibration groove body. A drum body of the regionalization type polygon dampening drum is sequentially regionalized into a scattering region, a dispersed region, a humidification dampening region and a feeding region, and independent nozzles with different spraying angles are respectively installed on the regions. The tobacco piece scattering regionalization dampening system and the tobacco piece scattering regionalization dampening process achieve lower-temperature dampening of tobacco pieces, can keep tobacco smoking flavor, reduce smashing, improve the productivity of a tobacco factory and cigarette quality, reduce cigarette weight on the premise that preset cigarette quality standards are maintained, and thus reduce tobacco cost.

Owner:CHINA TOBACCO MACHINERY TECH CENT +1

Antrodia camphorata extract and cigarette containing antrodia camphorata extract

ActiveCN101744360AImprove solubilityHazard reductionTobacco treatmentAntinoxious agentsSolubilityAdditive ingredient

The present invention discloses an antrodia camphorata extract and a cigarette containing antrodia camphorata extract. The present invention aims to realize the techniques of increasing fragrance, keeping moisture and reducing harmful ingredients in cigarettes. The antrodia camphorata extract is prepared with the following method: hot water of which the mass is 3 to 10 times of that of antrodia camphorata coarse powder is added to antrodia camphorata dried and crushed, the antrodia camphorata coarse powder is digested at a temperature of 80 DEG C to 95 DEG C, filtrate filtered is concentrated at a temperature of 60 DEG C under the reduced pressure of 0.05 MPa for 2 hours, and the antrodia camphorata extract is obtained. The cigarette containing antrodia camphorata extract is made by adding antrodia camphorata extract of which the mass accounts for 0.001 to 10% of that of tobacco shreds to the tobacco shreds. Compared with the prior art, the plant extract containing antrodia camphorata active ingredients in the tobacco shreds has excellent solubility. The active ingredients can enter human bodies with the main smoke flow during the smoking and be absorbed by the human bodies through blood circulation. Consequently, the extract performs the functions for resisting tumours, viruses, ageing, etc. Cigarette smoke is pure and free of mixed gas. The quality of the cigarette can be improved, and the harm of the smoke to human bodies is accordingly reduced.

Owner:SHENZHEN DABAIHUI TECH

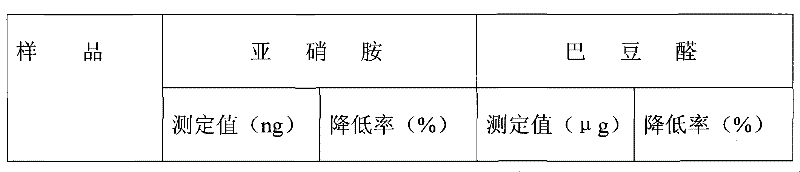

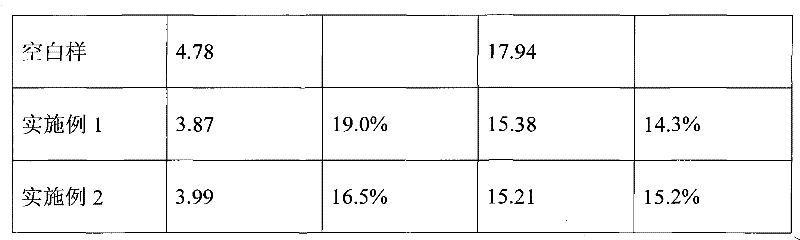

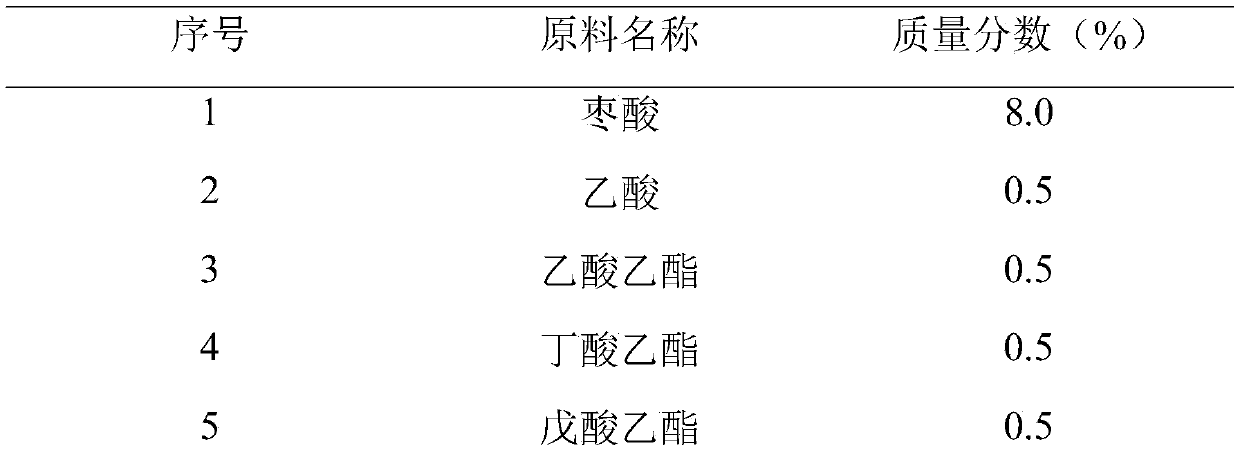

Fruity note base for cigarettes and application thereof

InactiveCN111269749AImprove temperamentIncrease the amount of aromaTobacco treatmentEssential-oils/perfumesBiotechnologyEthyl butyrate

The invention relates to a fruity note base for cigarettes, and belongs to the technical field of tobacco product blending. The fruity note base comprises the following components in percentage by weight: 0-12.0% of jujube acid; 0-12.0% of jujube tincture; 0-1.0% of acetic acid, 0-2.3% of ethyl acetate; 0-2.3% of ethyl butyrate, 0-2% of ethyl valerate, 0-2.0% of isoamyl isovalerate, 0-1.1% of cinnamon leaf oil, 0-1.9% of clove bud oil, 0-3% of sweet orange oil, 0-5.0% of lanamyl ether, 0-1.0% of Peru extract and the balance of a mixture of 95% ethanol and propylene glycol or 70% ethanol, wherein the weight percentage of the ethyl acetate, the ethyl butyrate, the ethyl valerate and the isoamyl isovalerate is not 0. When the fruity note base is added into cigarettes, the fruity aroma of thecigarettes can be increased, the aroma quality and the aroma quantity are improved, the aftertaste is clean, the comfort degree is improved, and the purpose of meeting diversified requirements of consumers on cigarette tastes is achieved.

Owner:CHINA TOBACCO SICHUAN IND CO LTD

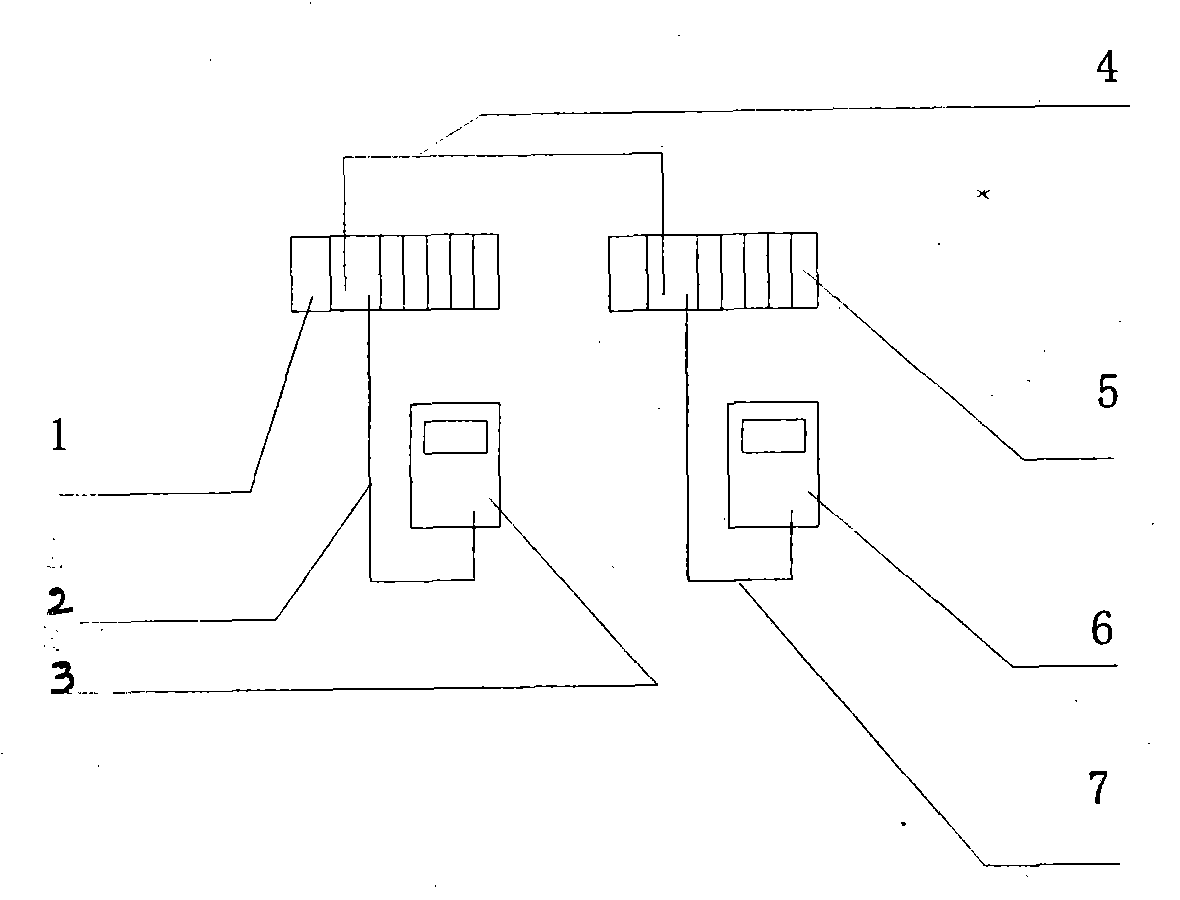

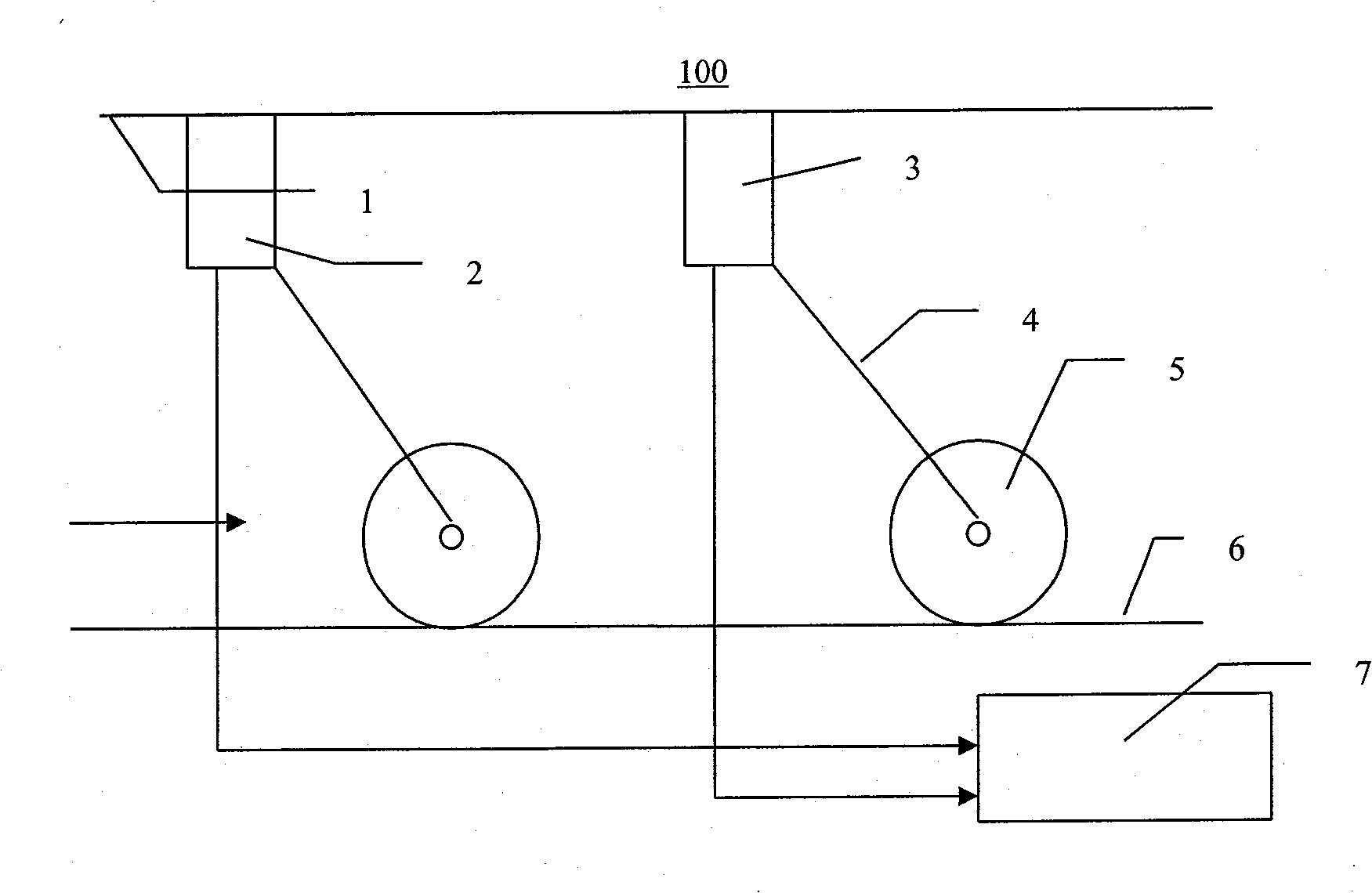

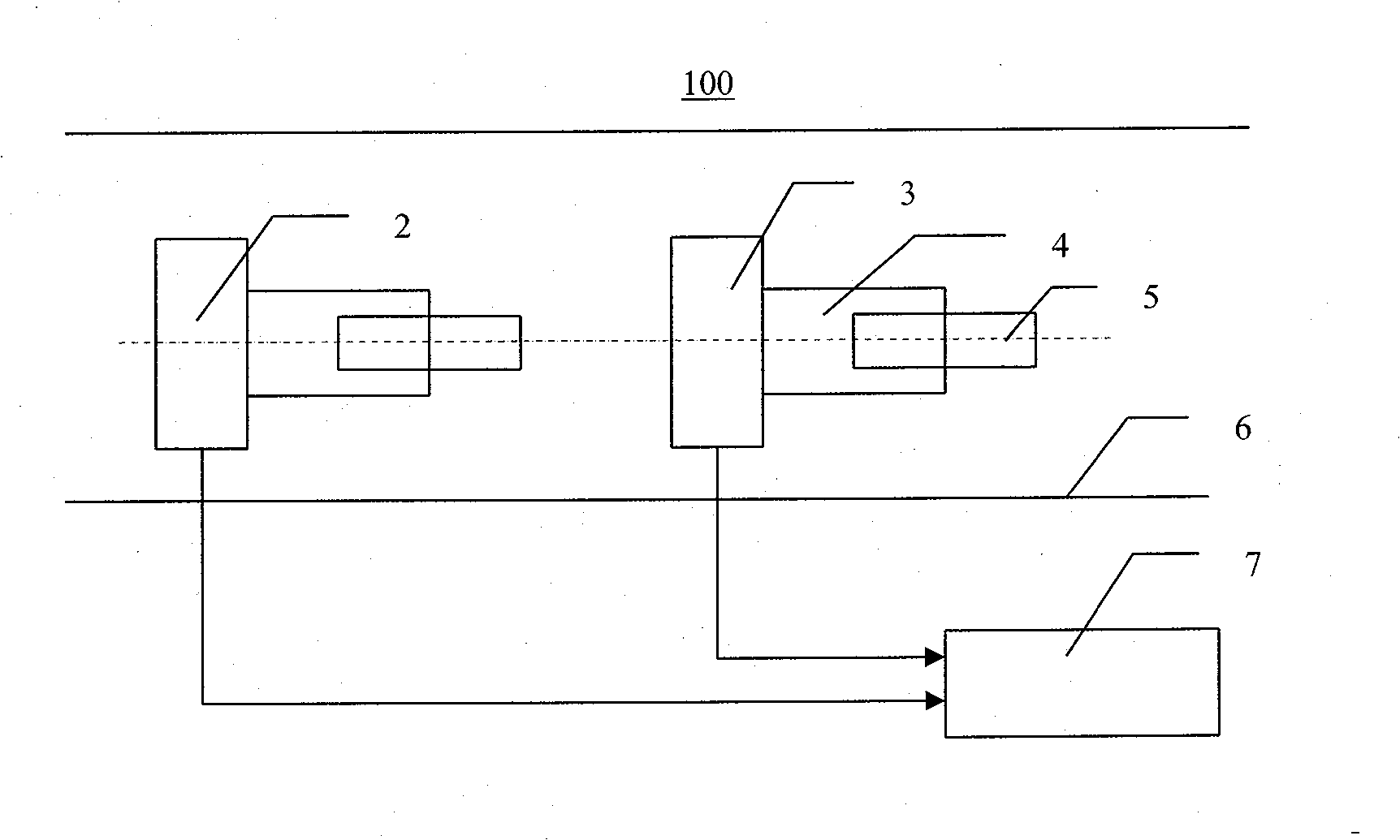

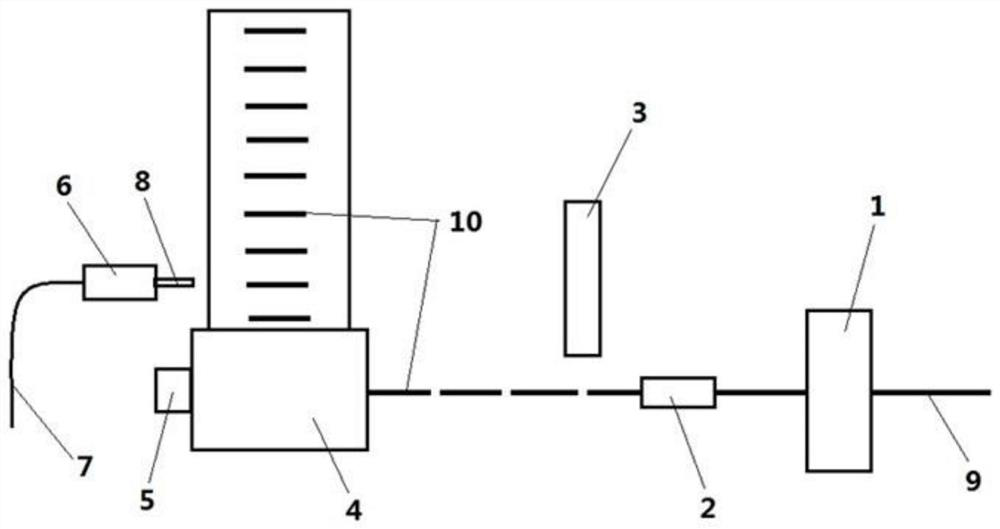

Cut tobacco elasticity on-line detection device and method thereof

ActiveCN101526454ANarrow the range of elastic fluctuationsIncrease the elasticity valueMaterial strength using tensile/compressive forcesData acquisitionEngineering

The invention discloses a cut tobacco elasticity on-line detection device and a method thereof. The on-line detection device comprises an installation bracket, at least two cut tobacco thickness-measuring devices, a conveyer belt and a data acquisition and processing system. The cut tobacco thickness-measuring devices comprise a first cut tobacco thickness-measuring device and a second cut tobacco thickness-measuring device arranged above the conveyer belt. The first cut tobacco thickness-measuring device and the second cut tobacco thickness-measuring device are sequentially arranged at the installation bracket with a set interval along the moving direction of the conveyer belt. The central lines of the first cut tobacco thickness-measuring device and the second cut tobacco thickness-measuring device are consistent with the moving direction of the conveyer belt and are parallel with each other. The data acquisition and processing system is connected with the first cut tobacco thickness-measuring device and the second cut tobacco thickness-measuring device and is used for acquiring a first signal and a second signal which are obtained by measuring the thickness of cut tobacco respectively by the first cut tobacco thickness-measuring device and the second cut tobacco thickness-measuring device when the cut tobacco is conveyed on the conveyer belt, and the data acquisition and processing system is also used for obtaining the elasticity value of the cut tobacco according to the first signal and the second signal. The invention can realize on-line detection of the elasticity of the cut tobacco.

Owner:北京邦瑞达机电设备股份有限公司

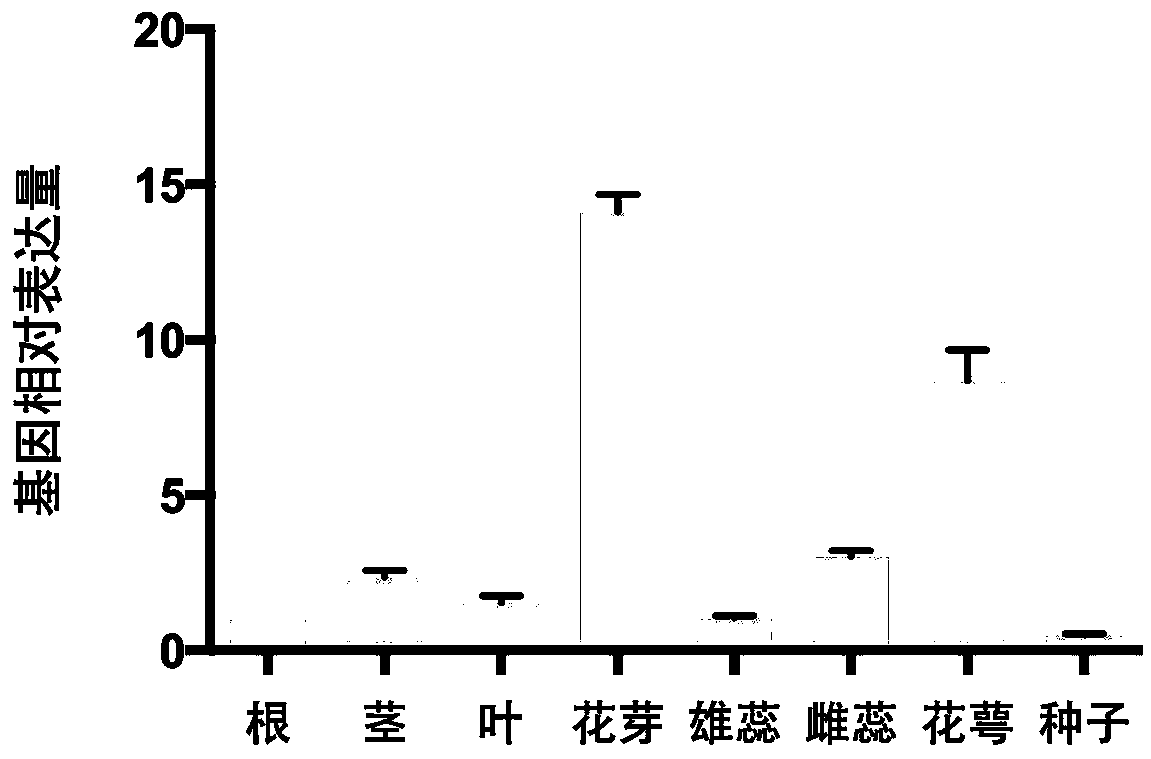

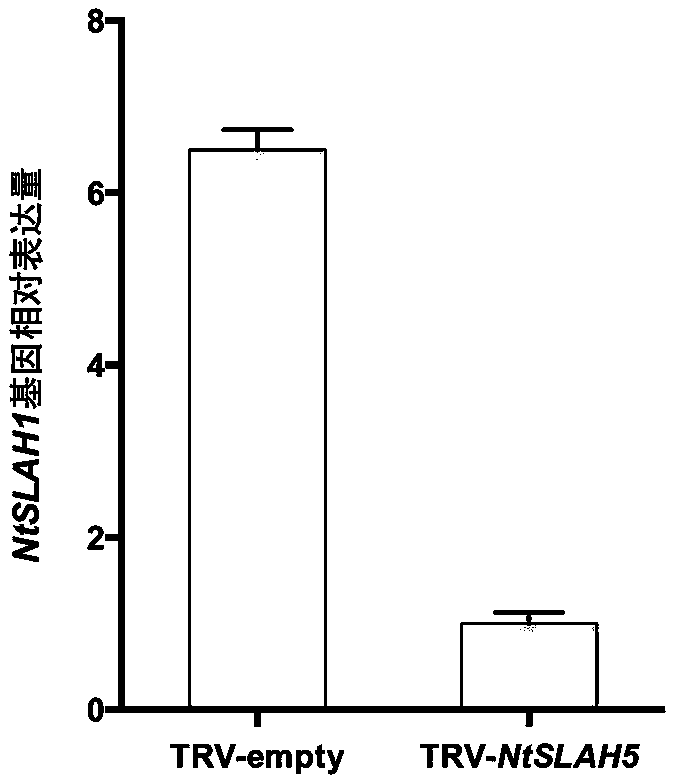

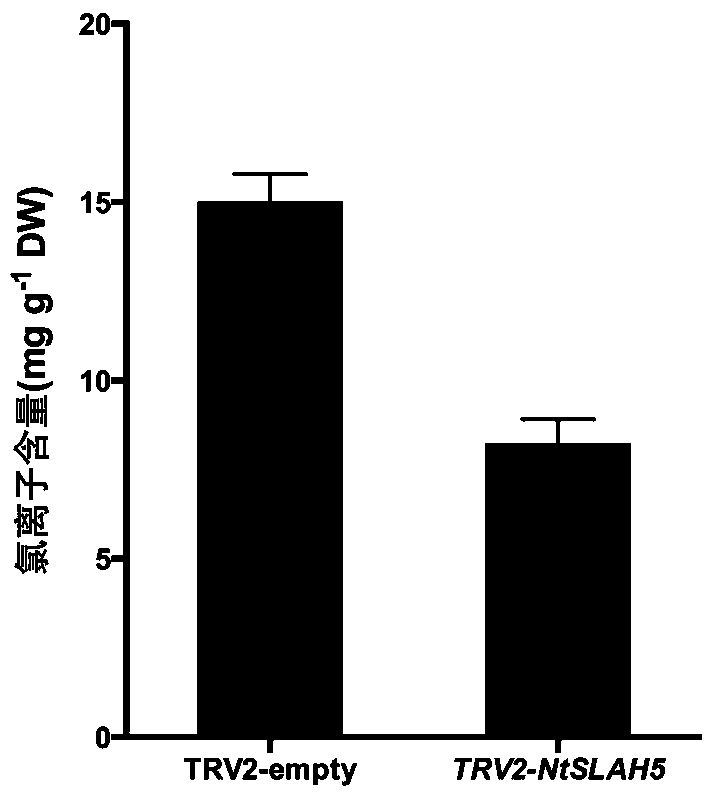

Slowly activating anion channel homologue NtSLAH5 for tobaccos and application of NtSLAH5

ActiveCN109517828AReduce Chloride ContentQuality improvementPlant peptidesFermentationNicotiana tabacumNucleotide

The invention belongs to the technical field of tobacco gene engineering and particularly relates to slowly activating anion channel homologue NtSLAH5 for tobaccos and patent application of the NtSLAH5. The CDS sequence of the gene contains an 1821bp basic group, the sequence of the basic group is represented by SEQ ID NO.1, and nucleotides 1112-1448 are specific nucleic acid fragments. The slowlyactivating anion channel homologue NtSLAH5 for the tobaccos is a key protein for the metabolism of chloride ions of the tobaccos, and the expression of the gene of the NtSLAH5 is inhibited by virtueof a virus induced gene silencing (VIGS) technique, so that the content of the chlorine ions in a transgenic silenced plant. Therefore, a good foundation can be laid for the cultivation of new speciesof low-chlorine-content tobaccos, and meanwhile, the basic technical support is provided for the quality stabilization of the tobacco leaves and the quality improvement of cigarettes.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

Filter capsule compressive strength detecting system and filter capsule compressive strength continuous detecting method

PendingCN109482516AImprove detection efficiencyEfficient Batch InspectionMaterial strength using tensile/compressive forcesSortingControl systemCompressive strength

The invention discloses a filter capsule compressive strength detecting system. The filter capsule compressive strength detecting system comprises a sealed box body, the sealed box body is connected with a pressurizing system, a feeding system, a receiving system, a cleaning system, an alarming system and a control system, and a spreading system is arranged in the sealed box body. The invention further provides a filter capsule compressive strength continuous detecting method. According to the filter capsule compressive strength detecting system and the filter capsule compressive strength continuous detecting method, through control of external pressure, the purpose that batched and quick detecting is conducted on the compressive strength of filter capsules safely and reliably, and the filter capsule quality, the filter stick quality and the cigarette quality are improved is achieved, resource wasting is greatly reduced, and the product reject ratio is greatly decreased.

Owner:CHINA TOBACCO SICHUAN IND CO LTD

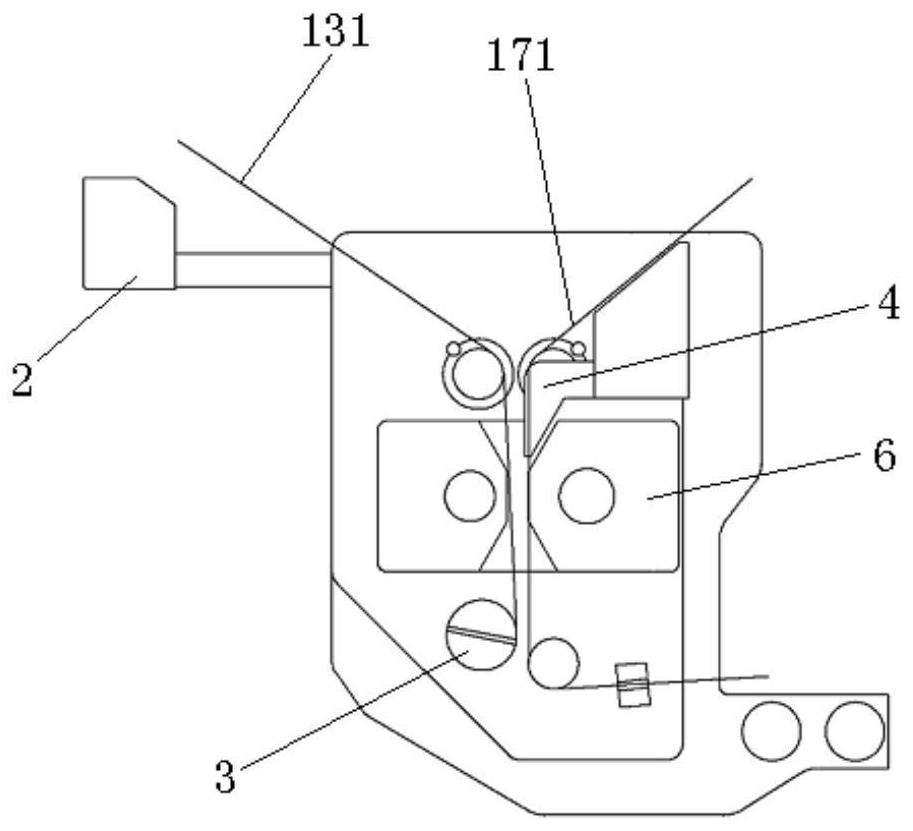

Adhesive-free strip splicing device

PendingCN113749283AImprove operational efficiencyImprove the quality of cigarettesCigarette manufactureWebs handlingPaper tapeEngineering

The invention provides an adhesive-free strip splicing device, which comprises a rack, and a transposition strip disc, an adhesive-free splicing mechanism, a new strip passing wheel set and an old strip passing wheel set which are arranged on the rack, and is characterized in that a first deviation rectifying mechanism is arranged on a new strip running path at the input end of the adhesive-free splicing mechanism, a new strip end acceleration winding mechanism is arranged on the new strip running path at the output end of the adhesive-free splicing mechanism, meanwhile, an old strip cutting and adsorbing mechanism is arranged on the adhesive-free splicing mechanism and located on an old strip running path, and a second deviation rectifying mechanism is arranged on a working strip path at the output end of the adhesive-free splicing mechanism. It can be guaranteed that the dislocation amount is within the range of + / -0.5 mm when new and old paper strips are connected, and it can be guaranteed that the transverse offset of the paper strips is within the range of + / -0.5 mm in the online conveying process. The device is high in accuracy, reliability and stability, the equipment stability can be improved, the product quality is improved, and the labor intensity of workers is reduced.

Owner:KUNMING DINGCHENG TECH +1

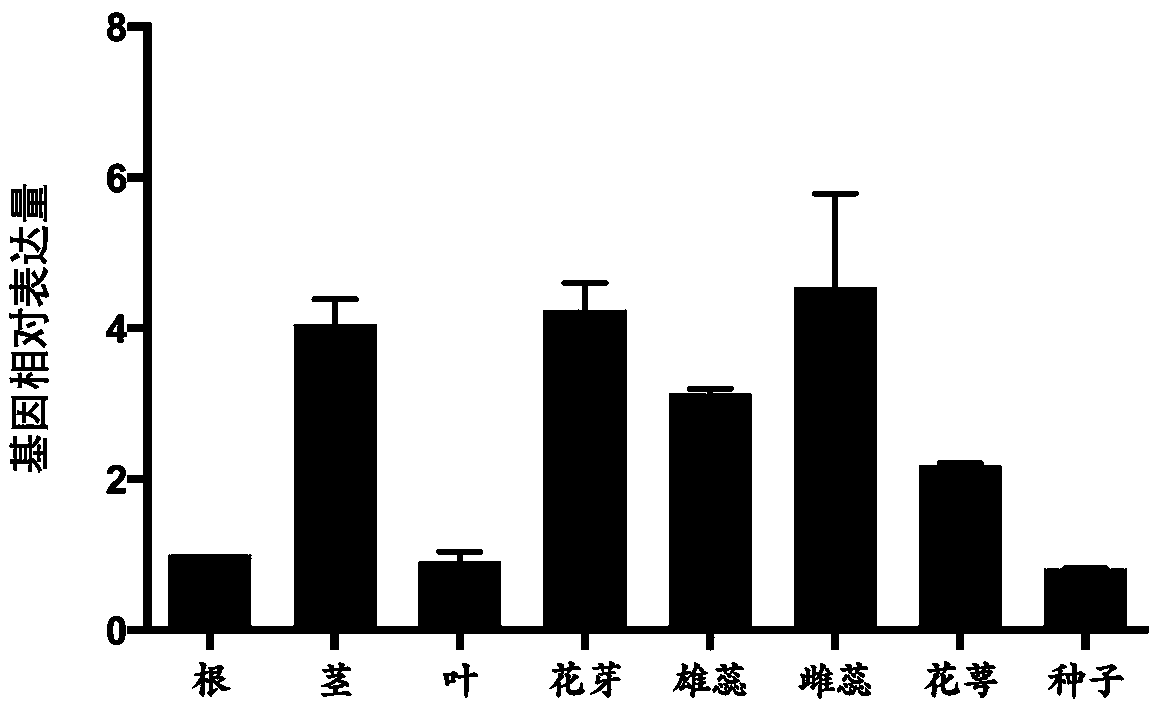

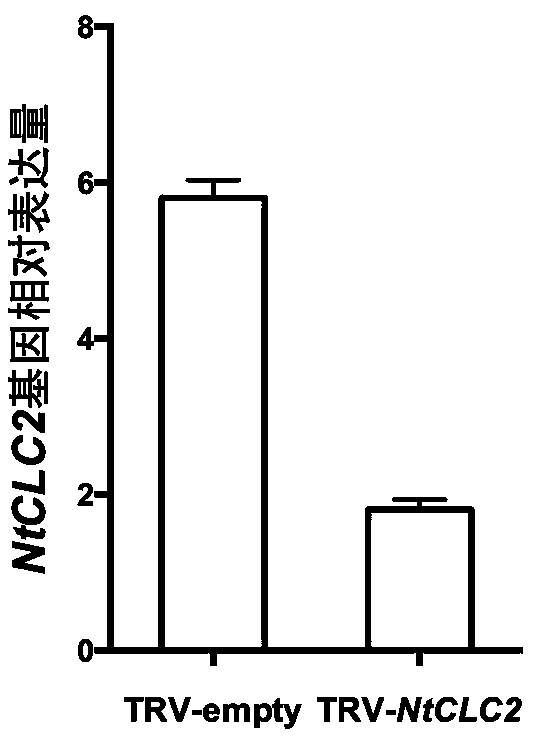

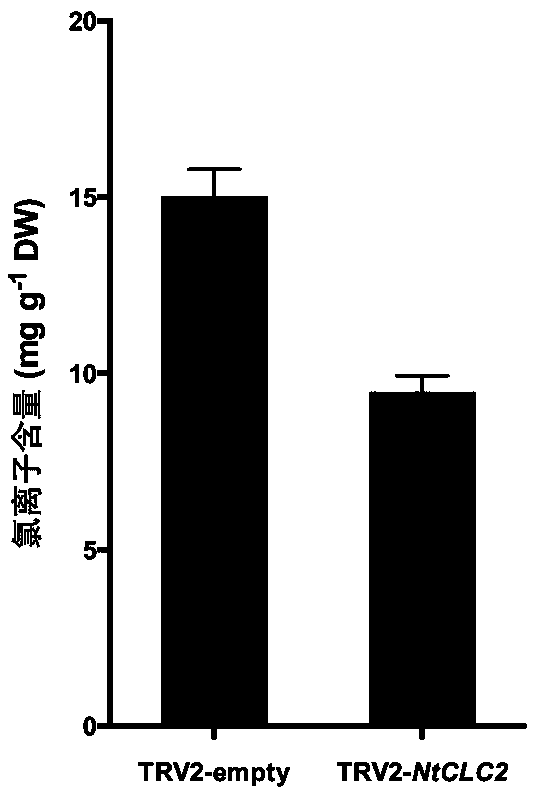

Tobacco chloride ion channel protein NtCLC2 and application thereof

InactiveCN108841834AReduce Chloride ContentQuality improvementPlant peptidesFermentationNicotiana tabacumIon Channel Protein

The invention belongs to the technical field of tobacco genetic engineering and specifically relates to a tobacco chloride ion channel protein NtCLC2 and application thereof. A gene CDS sequence comprises a 2343bp basic group; and the sequence of the basic group of the gene CDS sequence is as shown in SEQ ID NO. 1, wherein 1426th-1738th nucleotides are specific nucleotide fragments. The tobacco chloride ion channel protein NtCLC2 is a key protein metabolized by tobacco chloride ions; by using a virus induced gene silencing (VIGS) technology, the content of the chloride ions in a transgene silencing plant is obviously reduced after NtCLC2 gene expression is inhibited. Based on this, a good foundation can be laid for culturing a new variety of low chlorine content tobacco; and meanwhile, a fundamental technical support is provided for stabilizing tobacco leaf quality and improving cigarette quality.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

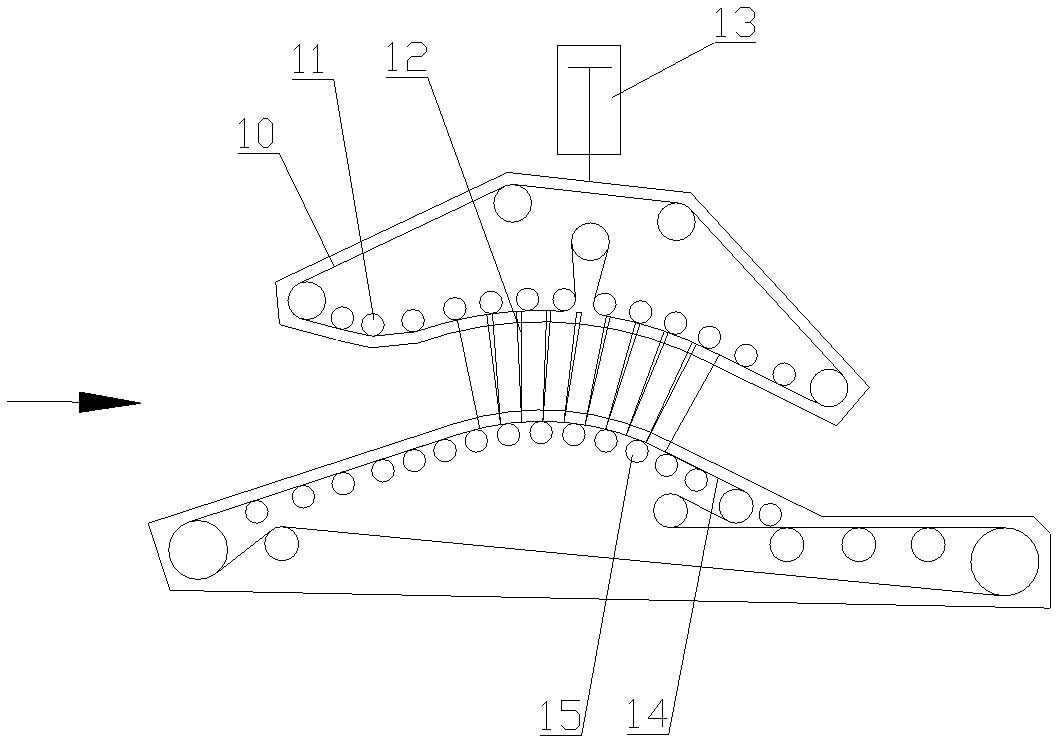

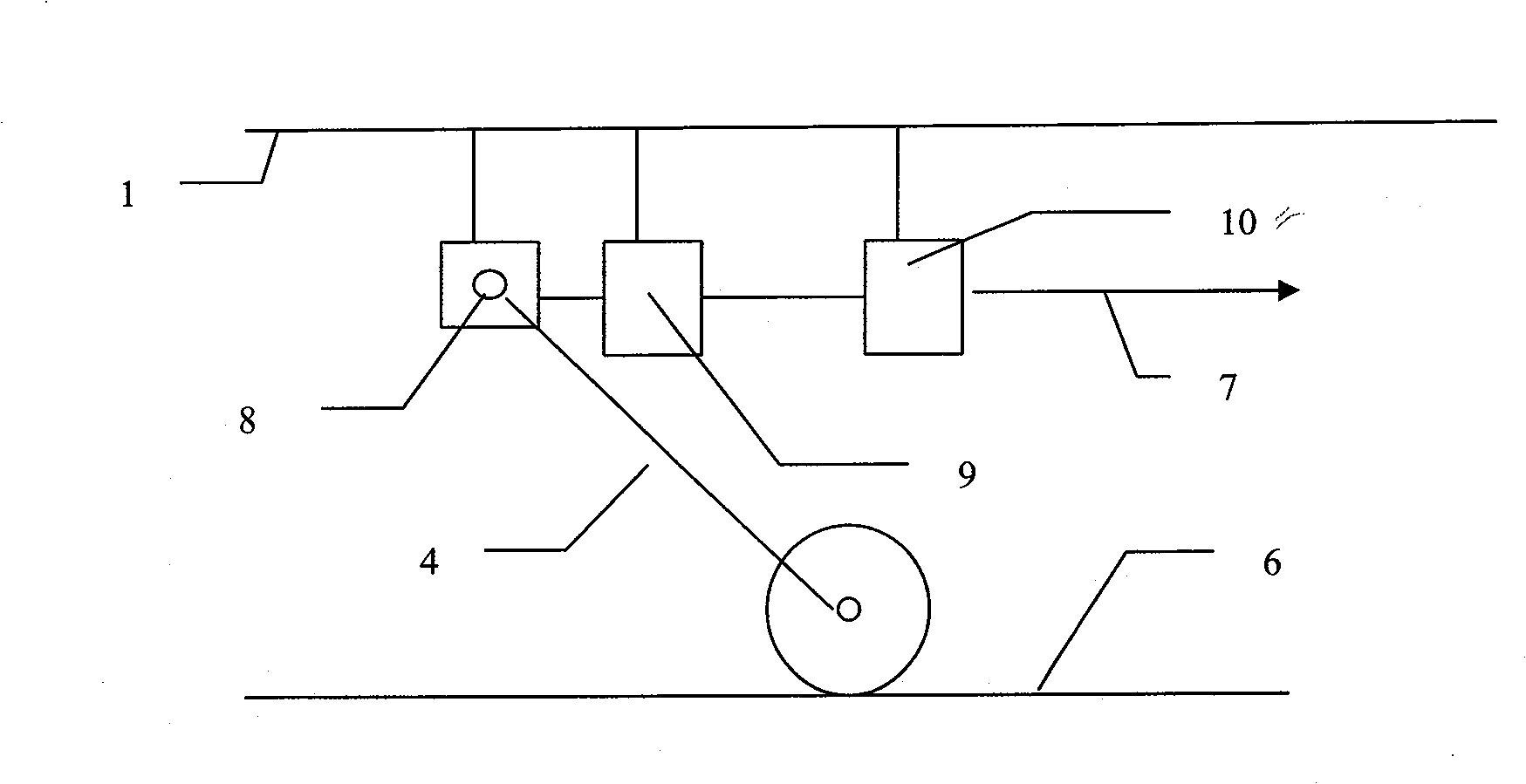

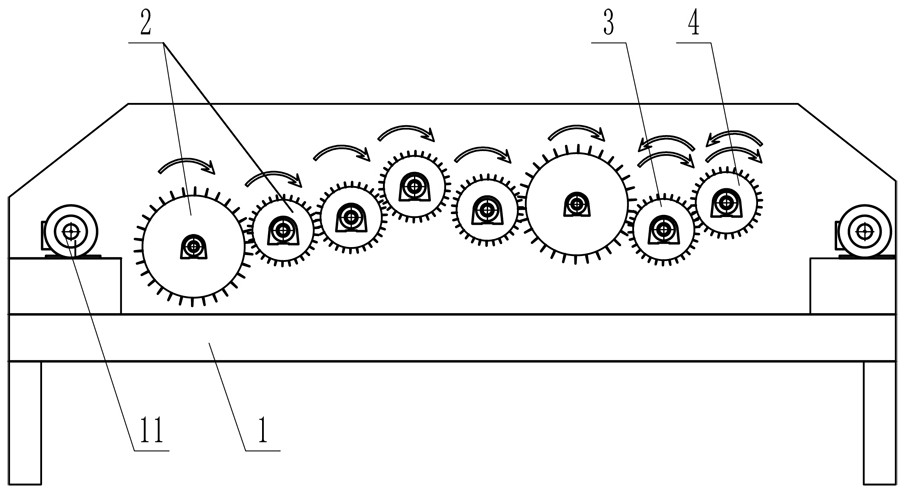

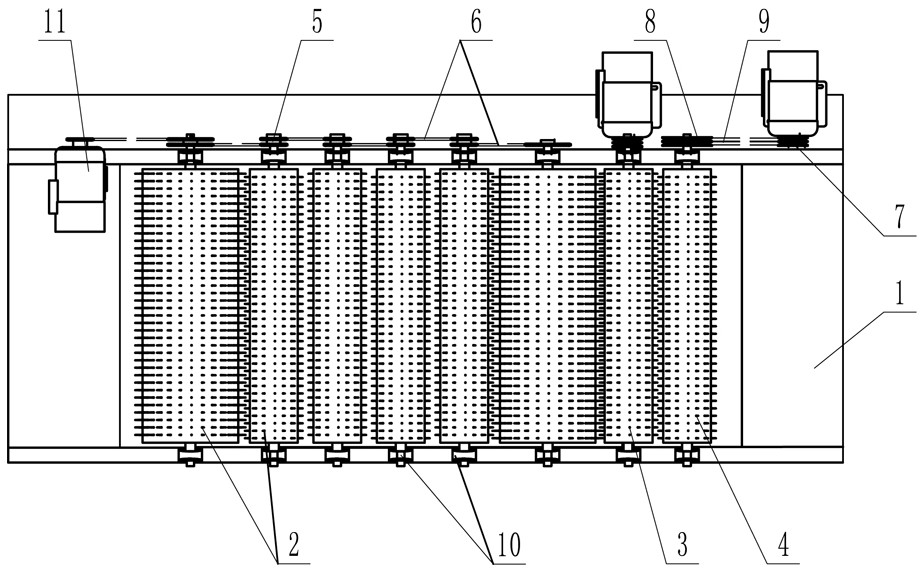

Tobacco shred specification customization system based on long tobacco shred reprocessing

PendingCN113693258AEfficient separationAdjustable speedTobacco preparationTobacco treatmentEngineeringMechanical engineering

The invention discloses a tobacco shred specification customization system based on long tobacco shred reprocessing. The tobacco shred specification customization system comprises a rack, and further comprises a long tobacco shred sorting device, a long tobacco shred pull-apart device and a cluster tobacco shred slitting device which are arranged on the rack, the long tobacco shred sorting device is adjacent to the long tobacco shred pulling-apart device, the long tobacco shred sorting device comprises a plurality of first needle rollers which are sequentially arranged in the advancing direction of the tobacco shreds, and the first needle rollers are driven by a first transmission mechanism and a first driving mechanism to rotate clockwise in the same direction; the long tobacco shred pulling-apart device is adjacent to the long tobacco shred sorting device, the long tobacco shred pulling-apart device comprises more than one second needle roller which is sequentially arranged in the advancing direction of the tobacco shreds, and the second needle rollers are driven by a second transmission mechanism and a second driving mechanism to rotate; and the cluster tobacco shred slitting device is adjacent to the long tobacco shred pull-apart device and comprises more than one third needle rollers which are sequentially arranged in the advancing direction of thetobacco shred, and the third needle rollers are driven by a third transmission mechanism and a third driving mechanism to rotate. According to the system, the uniformity of the tobacco shred structure of the thin cigarette is improved, so that the rolling requirement of the thin cigarette is met.

Owner:KAIFENG JINJIAN TOBACCO MACHINERY

Method for representing three-dimensional form of full-specification cigarette combustion cone

ActiveCN111610287AEliminate incomparabilityFacilitate quantitative comparative analysisChemical analysis using combustionUsing optical meansEngineeringMechanical engineering

The invention discloses a method for representing the three-dimensional form of a full-specification cigarette combustion cone, and belongs to the technical field of cigarette combustion state characterization. The method comprises the following steps: 1, extracting a to-be-detected cigarette sample; 2, selecting a to-be-detected position of the cigarette; 3, manufacturing a combustion cone of a point to be detected; 4, shooting the combustion cone, and calculating the three-dimensional height and the three-dimensional area of the combustion cone; 5) calculating the bump value of the combustion cone. The method not only can be used for three-dimensional representation of the shape of the combustion cone, but also provides comparability for the shape of the combustion cone of cigarette products of different specifications, and provides method support for understanding the combustion state of cigarettes, improving cigarette flameout and the falling tendency of the combustion cone and improving the comprehensive quality of the cigarettes.

Owner:HONGTA TOBACCO GRP

Cigarette machine induced-draft pipe with adjustable draft velocity

InactiveCN1421166AReasonable structural designEasy to useCigarette manufactureAir volumeAutomatic control

The cigarette machine induced-draft pipe with adjustable draft velocity includes draft pipe, flange, flowmeter and regulating throttle. The flowmeter and the regulating throttle are connected serially in the draft pipeline and are orifice flow meter and electric or hydraulic butterfly valve separately for automatic control via computer. After the present invention is installed, the computer calculates the real-time wine rate and compares it with the set value to output corresponding signal for fast regulation of the valve and stable wind rate may be obtained.

Owner:徐加贵

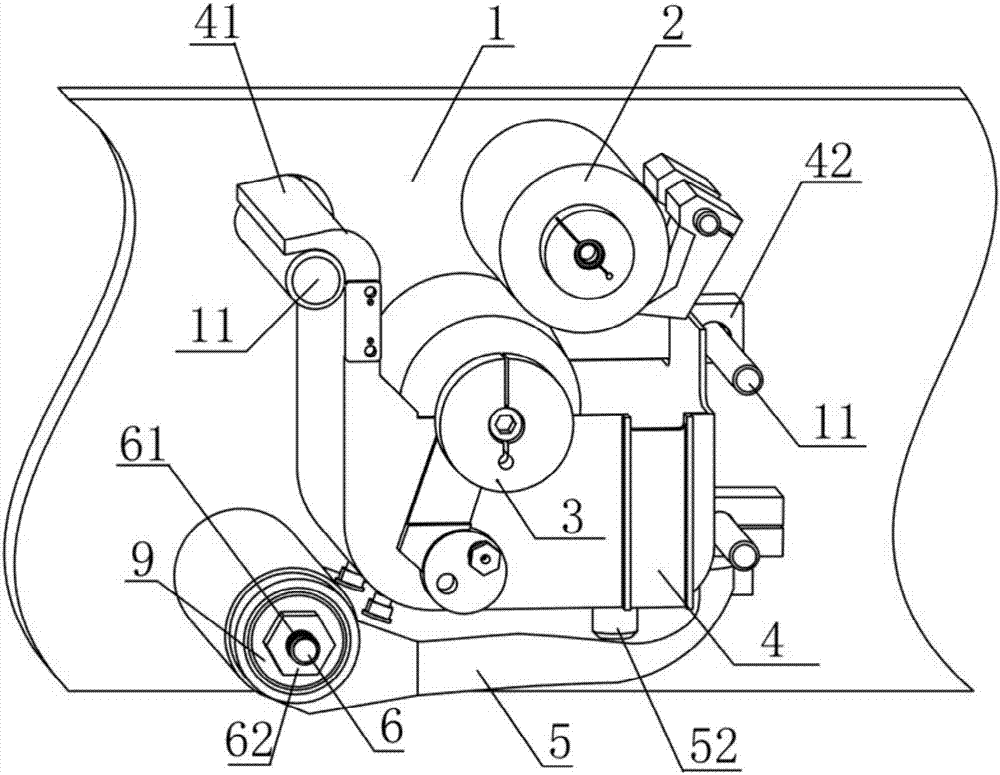

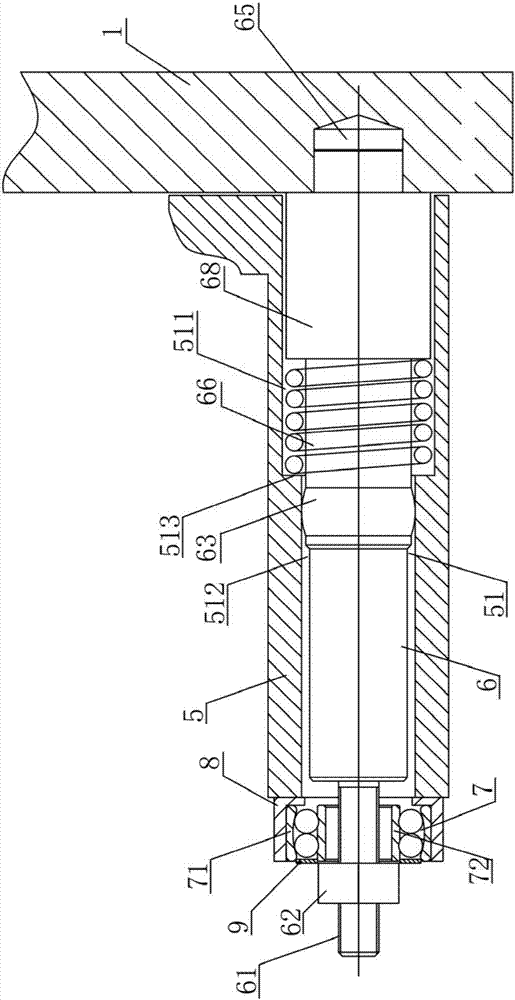

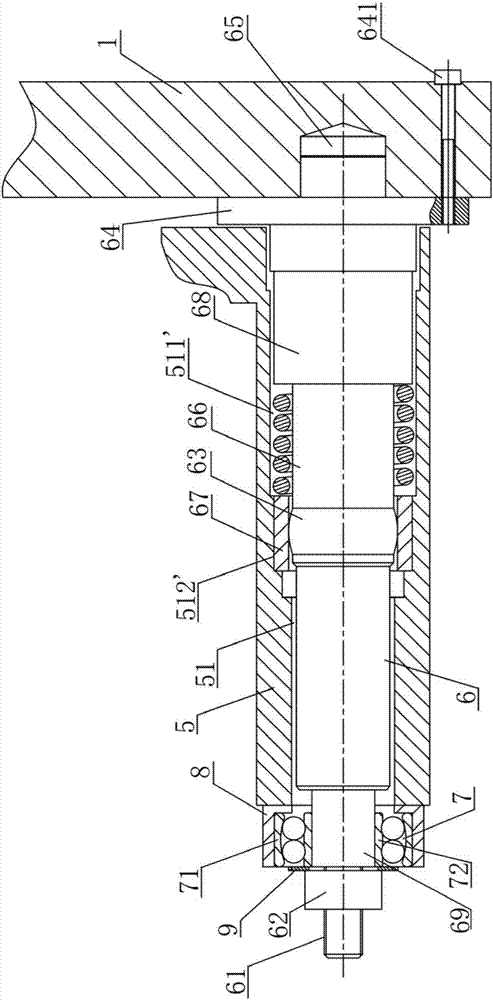

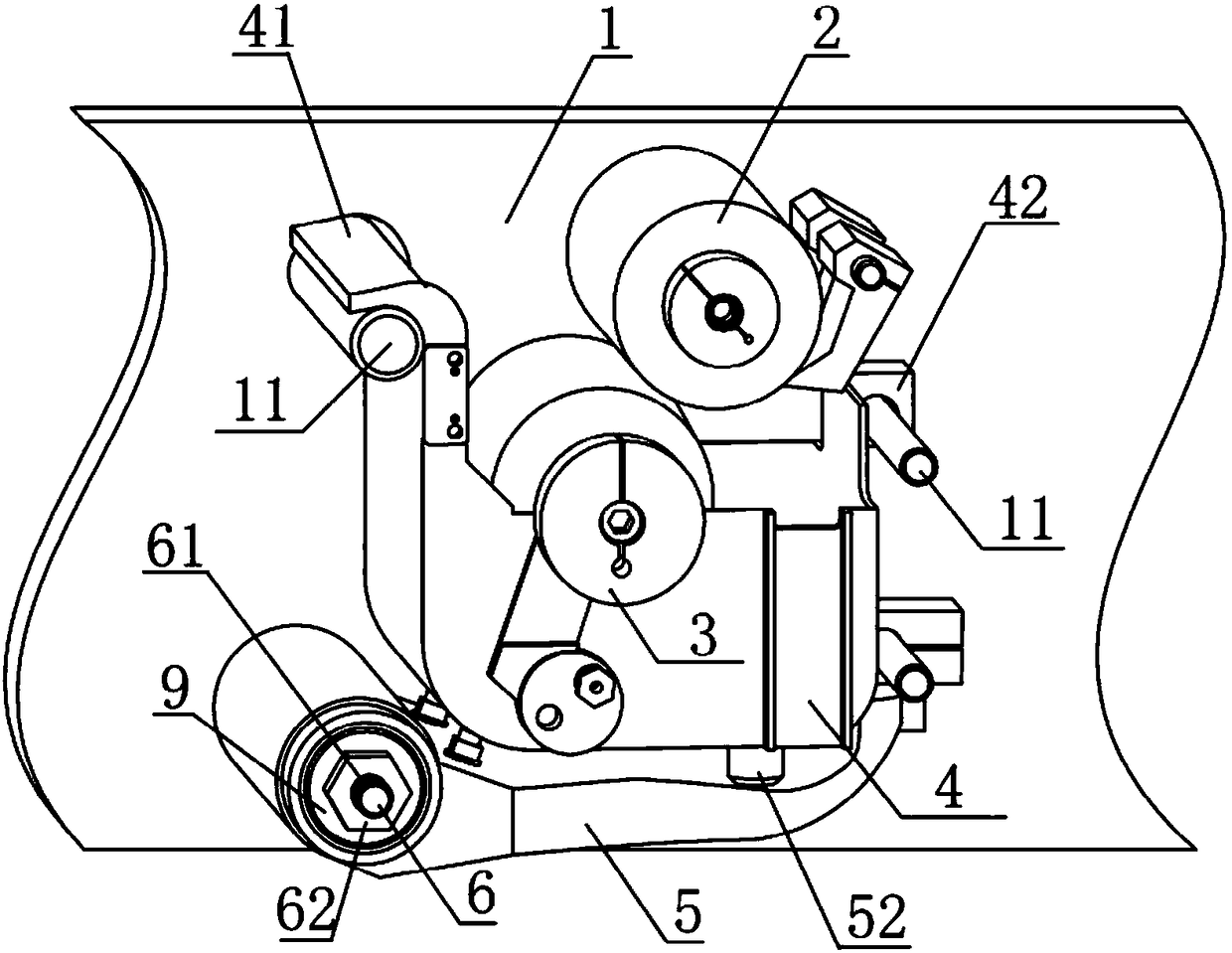

Cigarette maker glue controlling and gluing assembly

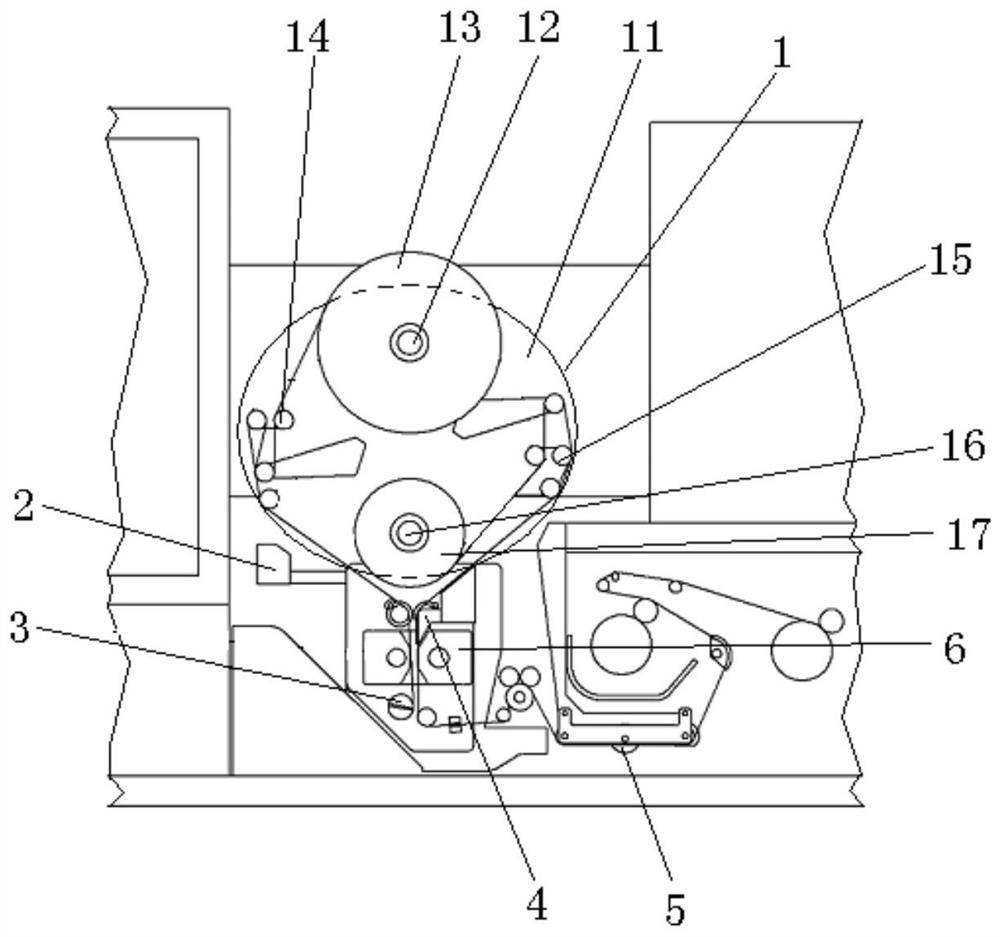

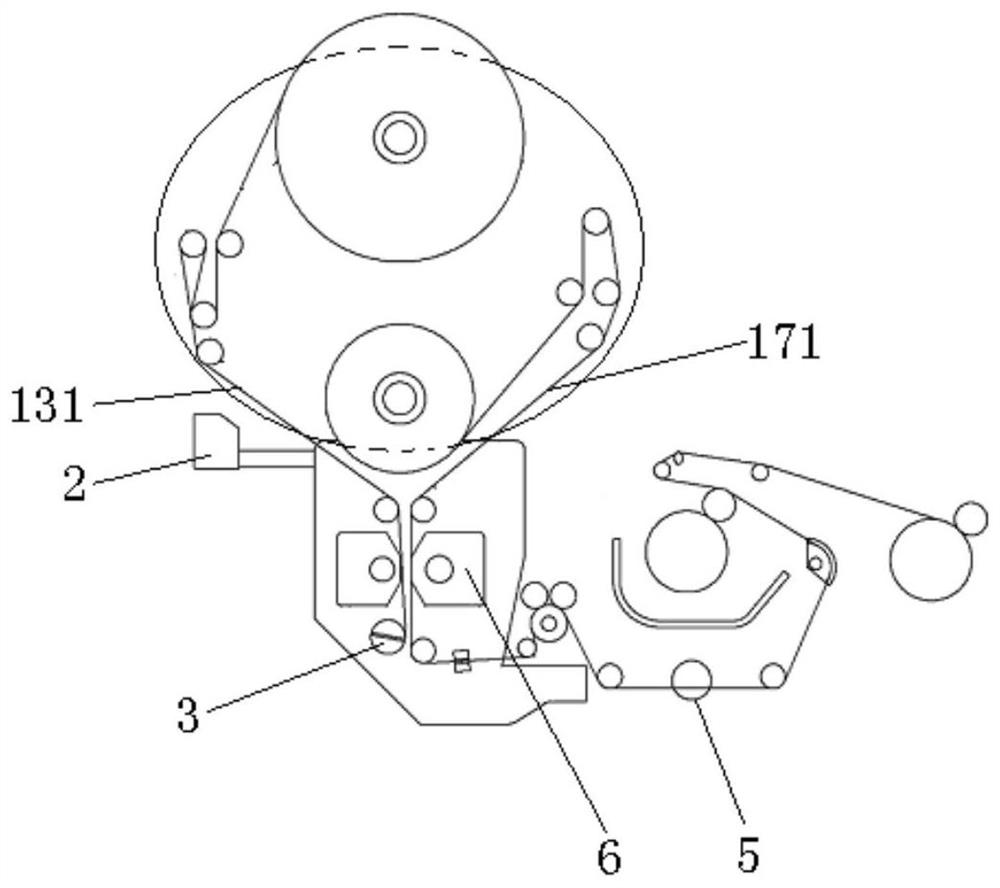

ActiveCN106937757AReduce downtimeImprove operational efficiencyCigarette manufactureCigarette MakersPulp and paper industry

A cigarette maker glue controlling and gluing assembly comprises a frame, a gluing roller, a glue controlling roller and a glue cylinder, the gluing roller is fixed on the frame through a bearing, the glue cylinder suspends on the supporting rod of the frame, the glue controlling roller is arranged in the open position of the glue cylinder through a bearing, the cigarette maker glue controlling and gluing assembly further comprises an adjustment mechanism which is in contact with the bottom of the glue cylinder, and the adjustment mechanism can adjust the position of the glue cylinder in order to make the glue controlling roller tangent to the gluing roller in parallel. The cigarette maker glue controlling and gluing assembly can automatically adjust the relative position between the gluing roller and the glue controlling roller in the assembling process to achieve a parallel tangential state in order to prevent an uneven gap between the glue controlling roller and the gluing roller, so uneven gluing of tipping paper is avoided, the quality of the cigarette is improved, the shutdown frequency of a cigarette maker is reduced, and the running efficiency of the cigarette maker is greatly increased.

Owner:HONGTA TOBACCO GRP

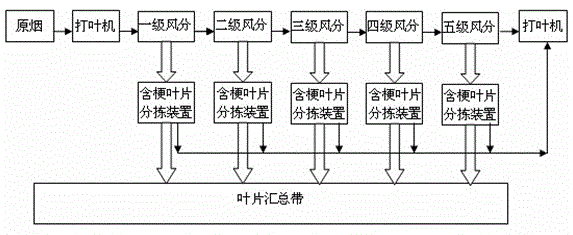

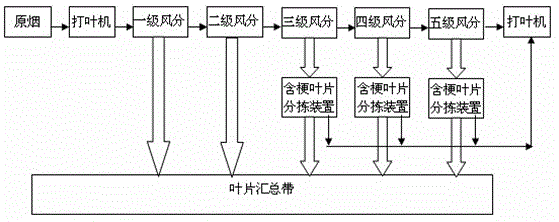

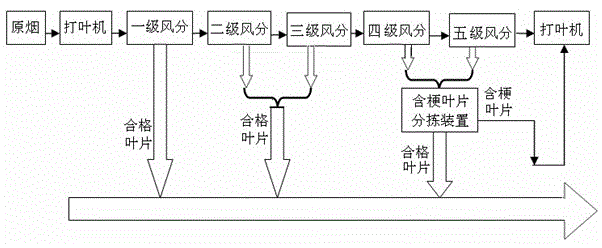

Tobacco leaf threshing and redrying process

ActiveCN103040088BReduce the number of leaf threshingReduce breakage rateTobacco treatmentHorticultureBotany

The invention provides a tobacco leaf threshing and redrying process. The tobacco leaf threshing and redrying process includes steps of a tobacco leaf wetting step, a wet tobacco leaf threshing step and a multi-stage winnowing step. The tobacco leaf threshing and redrying process is characterized in that in at least one stage of the multi-stage winnowing step, winnowed products with stem ratio lower than 2% are directly discharged, winnowed products with stem ratio higher than 2% are fed into a stem-contained tobacco leaf sorting device and are further sorted to obtain products and residues, the products are discharged, and the residues are fed back to thresh. By improving efficiency of a winnowing device, more large and medium-sized tobacco leaves and stem-contained tobacco leaves can be winnowed to the greatest extent, and by matching with the stem-contained tobacco leaf sorting device, and the stem-contained tobacco leaves can be further removed and fed back to thresh, so that rate of the large and medium-sized tobacco leaves is increased by about 7% on the original basis, and meanwhile, stem containing rate in the tobacco leaves is greatly reduced to lower than 0.5% which is much lower than the nation-regulated standard of 1-2%, and can be accurately effective controlled, tobacco stem and leaf threshing times can be reduced, smashing rate of the tobacco leaves is decreased and cigarette quality is improved.

Owner:KUNMING JULIN TECH +2

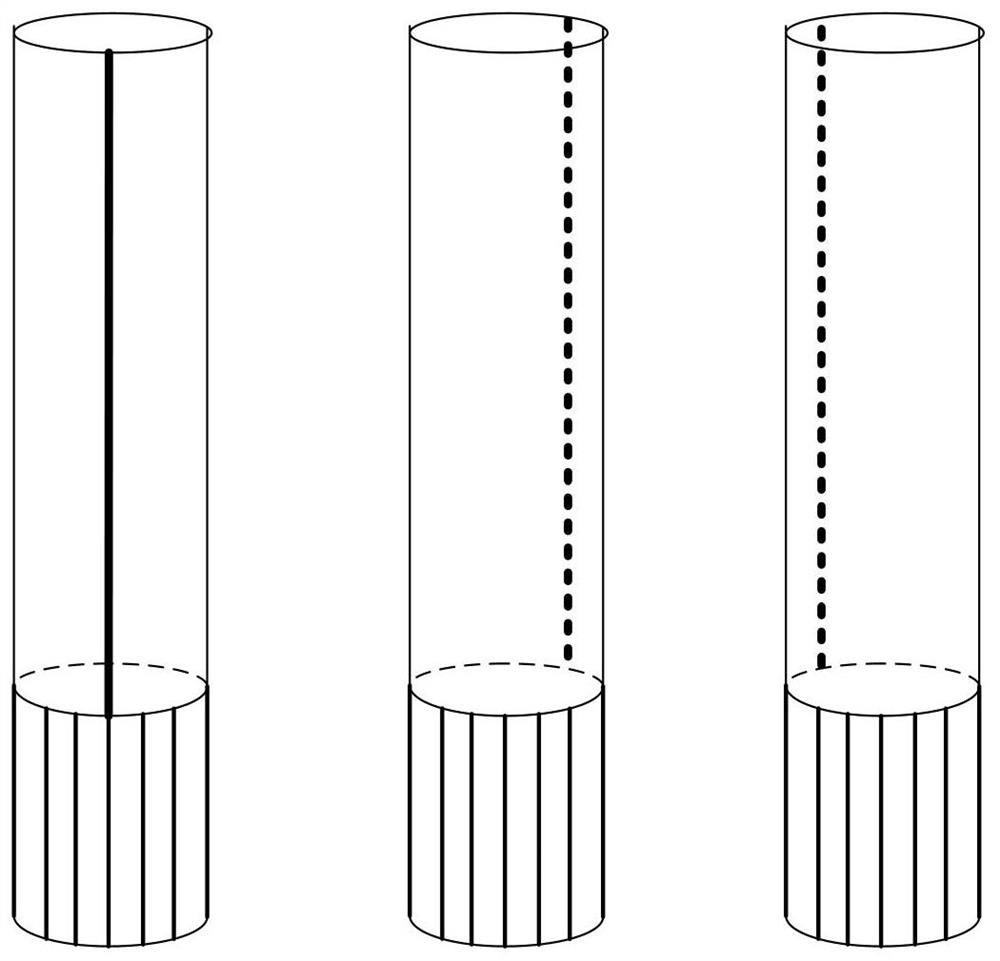

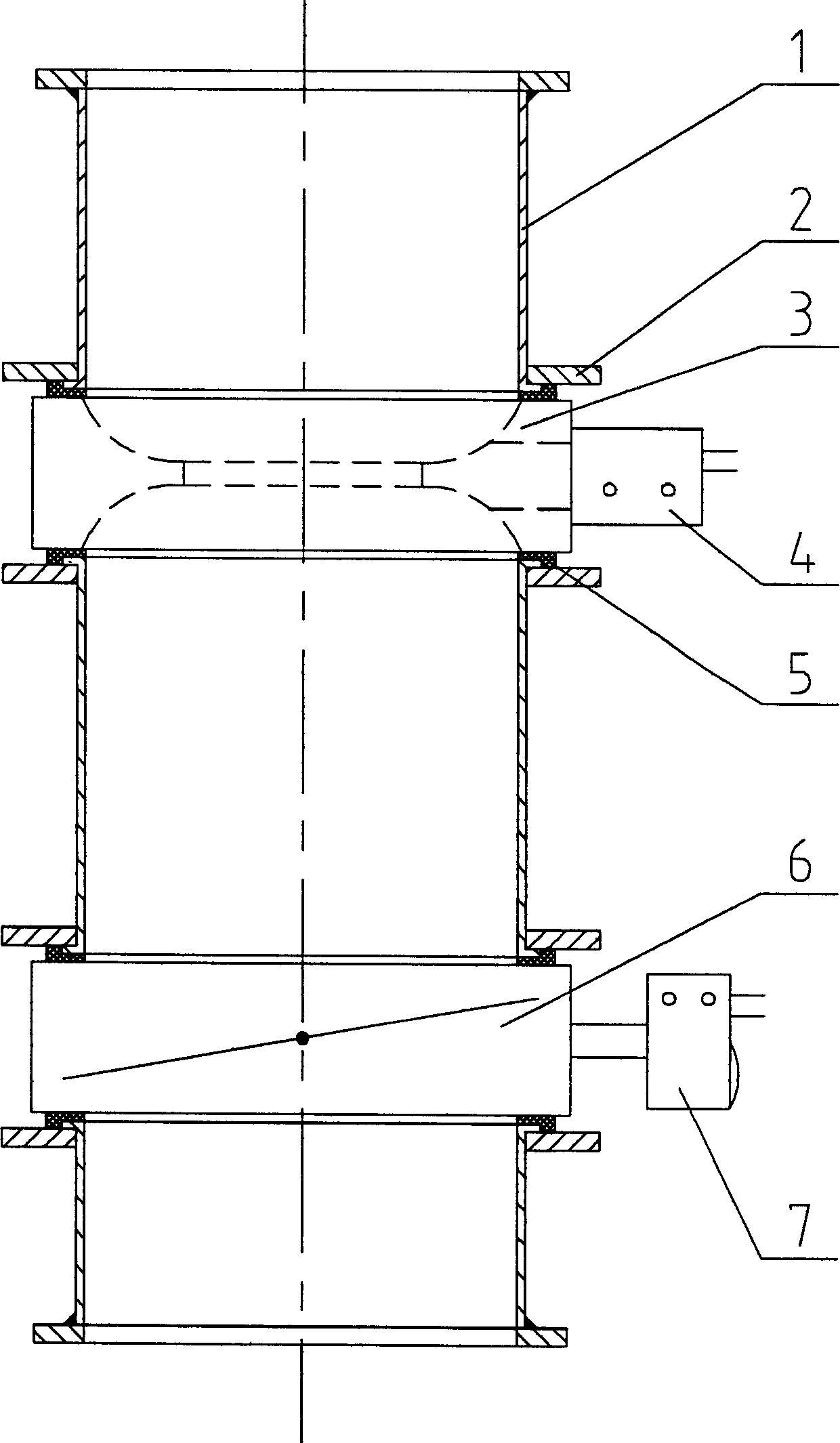

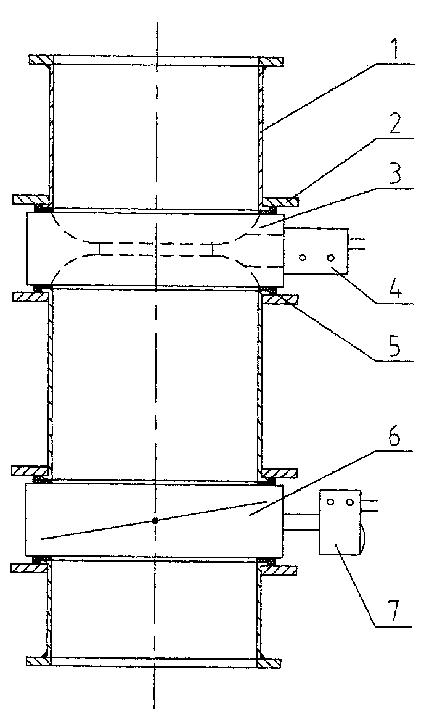

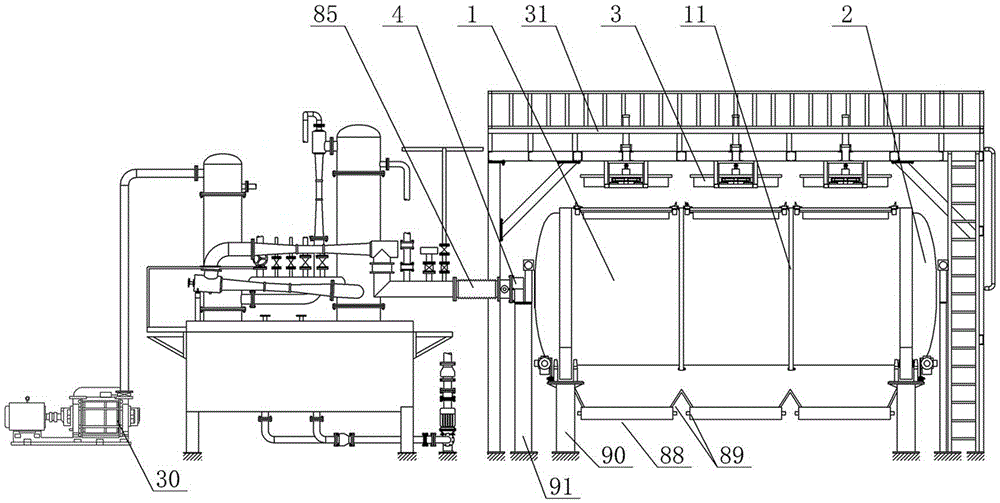

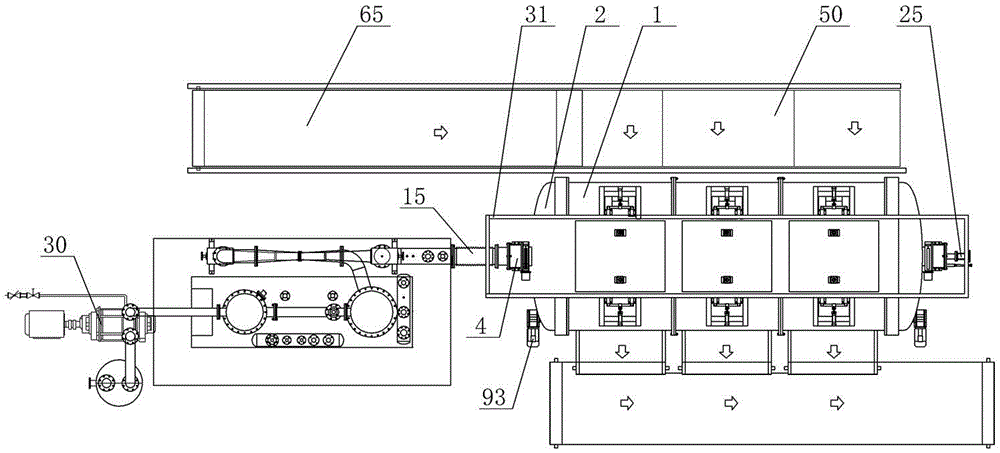

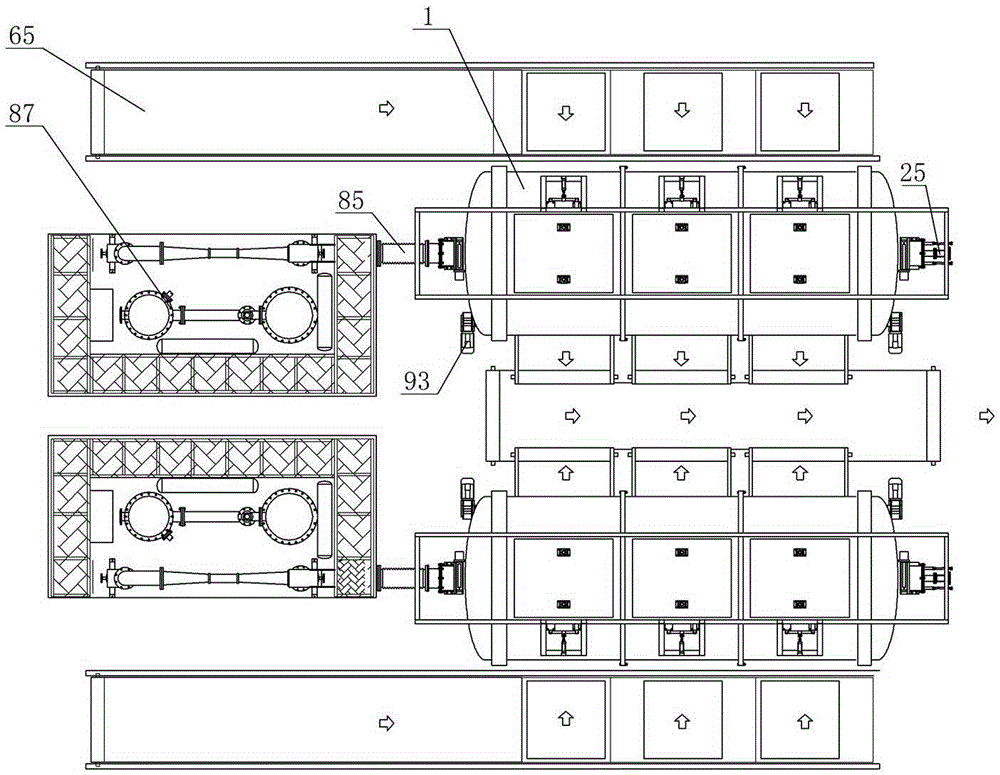

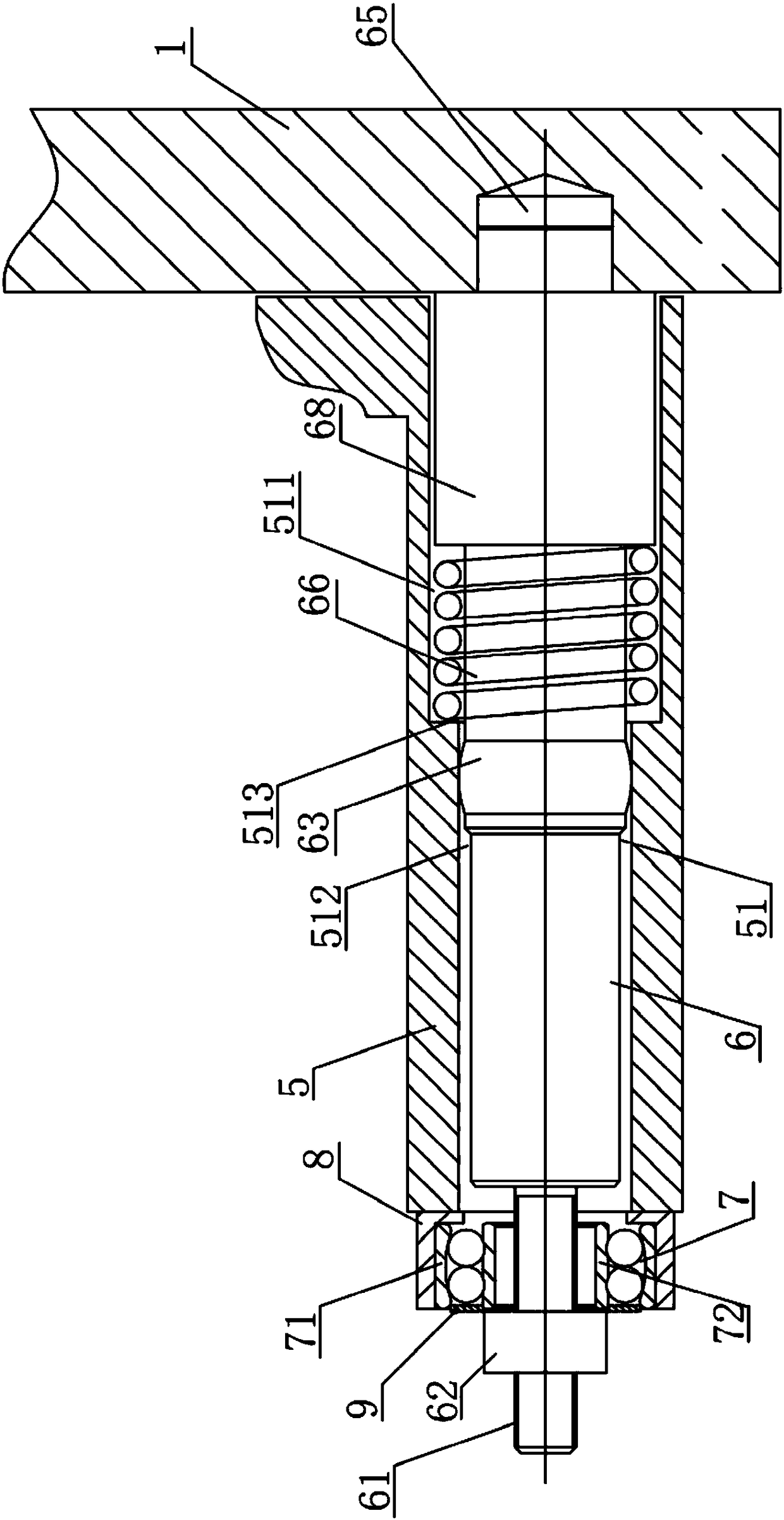

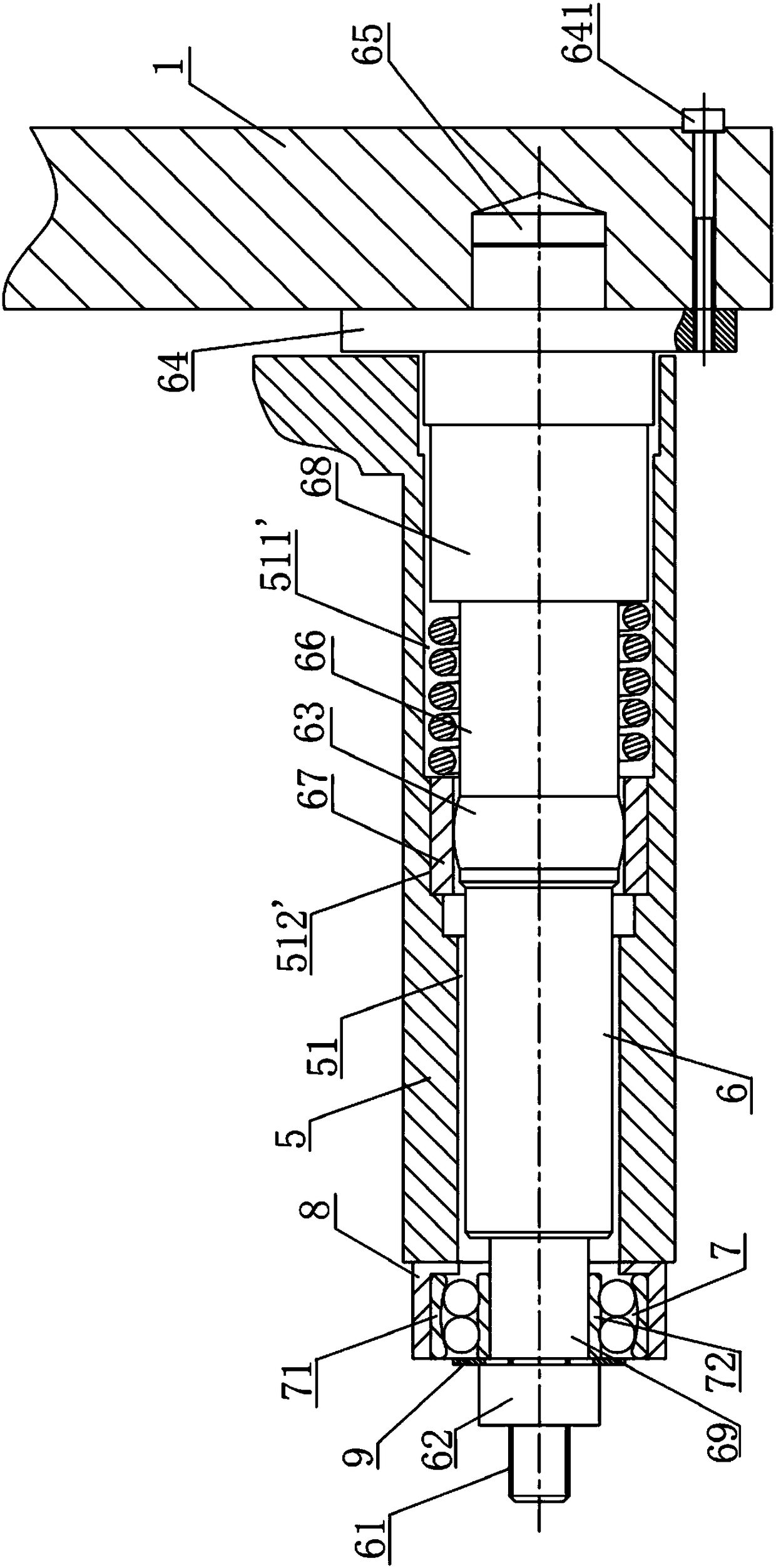

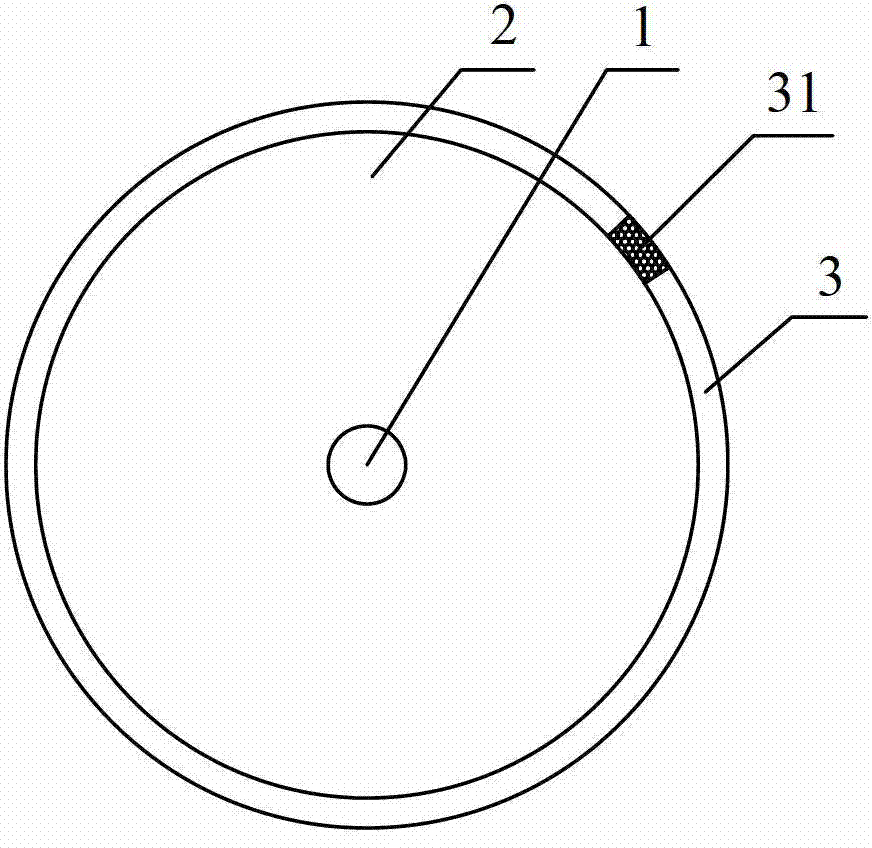

Rotary vacuum loosening and dampening machine and its loosening and dampening method

ActiveCN103653225BHigh penetration rateGuaranteed qualityTobacco preparationMoisture regainMechanical engineering

The invention relates to a rotary-type vacuum loose moisture regain machine and a loose moisture regain method thereof. The moisture regain machine comprises an incoming material conveying device, an outgoing material conveying device, a loose moisture regain barrel, a barrel body driving device, a humidifying device, a vacuum device, a rotary sealing device and a control device, a barrel body is connected with the barrel body driving device through a power transmission mechanism, the power transmission mechanism, of the barrel body driving device, arranged on the barrel body is connected with a power machine output shaft of the driving device, rotary sealing units communicated with an inner cavity of the barrel body are arranged at two ends of the barrel body, at least one sealing door for feeding and discharging is arranged on the barrel body, and a door frame is arranged around each sealing door. By the rotary-type vacuum loose moisture regain machine and the loose moisture regain method thereof, equipment and a process material thereof are in a rolling state during moisture regain, tobacco leaf moisture regain qualification rate is increased, a humidifying medium is ensured to be fully sprayed on the material, humidifying and loosening quality is improved, and the material is in a vacuum environment in the whole process, so that material return penetration rate is increased.

Owner:石峰

A cigarette machine glue control glue application assembly

ActiveCN106937757BReduce downtimeImprove operational efficiencyCigarette manufactureCigarette MakersMachine control

A cigarette maker glue controlling and gluing assembly comprises a frame, a gluing roller, a glue controlling roller and a glue cylinder, the gluing roller is fixed on the frame through a bearing, the glue cylinder suspends on the supporting rod of the frame, the glue controlling roller is arranged in the open position of the glue cylinder through a bearing, the cigarette maker glue controlling and gluing assembly further comprises an adjustment mechanism which is in contact with the bottom of the glue cylinder, and the adjustment mechanism can adjust the position of the glue cylinder in order to make the glue controlling roller tangent to the gluing roller in parallel. The cigarette maker glue controlling and gluing assembly can automatically adjust the relative position between the gluing roller and the glue controlling roller in the assembling process to achieve a parallel tangential state in order to prevent an uneven gap between the glue controlling roller and the gluing roller, so uneven gluing of tipping paper is avoided, the quality of the cigarette is improved, the shutdown frequency of a cigarette maker is reduced, and the running efficiency of the cigarette maker is greatly increased.

Owner:HONGTA TOBACCO GRP

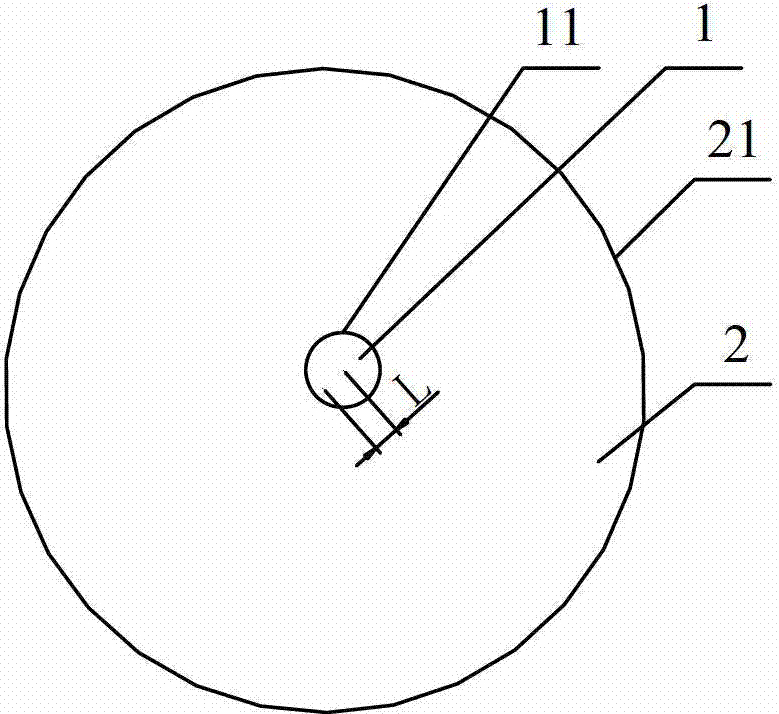

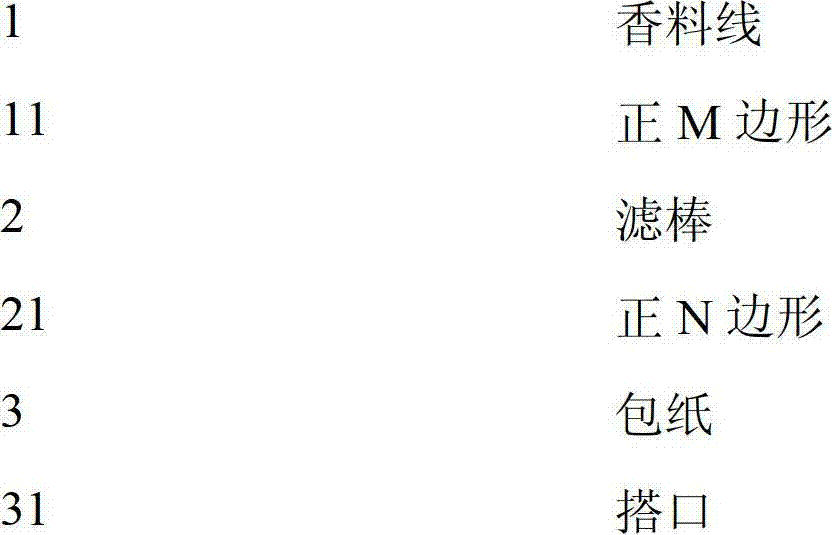

Quantitative detection method for filter stick spice line center distance

ActiveCN103063152BControl the bursting phenomenonImprove feature indexUsing optical meansComputer scienceLine filter

The invention provides a quantitative detection method for a filter stick spice line center distance. The quantitative detection method for the filter stick spice line center distance comprises the following steps: (1) cutting at least one section of detection sample, (2) collecting and detecting an endface image of the detection sample by using image acquisition equipment and guiding the endface image into a detection software, (3) drawing a N regular polygon in the detection software to surround a filter stick in the endface image and continually correcting the size and position of the N regular polygon to enable the N regular polygon and the border of the filter stick to coincide so as to obtain a center point of the N regular polygon (N > = 25), (4) drawing a M regular polygon to surround a spice line in the endface image and continually correcting the size and position of the M regular polygon to enable the N regular polygon and the border of the spice line to coincide so as to obtain a center point of the M regular polygon (M > = 25). The center distance between the center point of the N regular polygon and the center point of the M regular polygon measured by the detection software is L. If the L is up to standard, the spice line filter stick is qualified. Otherwise, the spice line filter stick is unqualified. The quantitative detection method achieves quantitative detection and effectively controls the phenomenon that the filter stick explodes into the mouth.

Owner:SHANGHAI TOBACCO GRP CO LTD +1

Calculation model for cut tobacco content of cigarette and method for controlling cigarette stability by applying calculation model

ActiveCN109602077AAccurate judgmentImprove accuracyCigarette manufactureRegression analysisNational standard

The invention discloses a calculation model for a cut tobacco content of a cigarette and a method for controlling stability of the cut tobacco content by applying the calculation model. A method for constructing the calculation model comprises the following steps: using the cut tobacco content of the cigarette as a dependent variable and using a cigarette parameter as an independent variable to construct a functional relation; performing regression analysis fitting on detection data to obtain specific coefficients of the functional relation; constructing to obtain the calculation model for thecut tobacco content of the cigarette, wherein the cigarette parameter comprises a cigarette circumference. The calculation model provided by the invention has a fitting R2 of 0.893 or higher, is notaffected by the quality of product cigarette holder, forming paper, tipping paper and cigarette paper, has advantages of high accuracy and wide applicability, can not only control fluctuation of the cigarette within a national standard range, but also control a standard deviation of the cigarette quality to be 0.02 or lower, and controls the standard deviation of smoking resistance within 0.04-0.05, so that the cigarette can ensure stable tightness, smoking smoothness and comfortable smoking mouthfeel.

Owner:CHINA TOBACCO GUANGDONG IND

Laminar blade multi-point feeding/flavoring unit

ActiveCN103330275BSeasoning/flavoring evenlyMeet production requirementsTobacco preparationEngineeringStock solution

The laminar flow blade multi-point feeding and flavoring unit of the present invention is mainly based on the existing drum type blade feeder, and a laminar flow uniform material device is added to disperse the blades, so that the blades can enter the drum in a single-layer curtain shape. Cooperate with the nozzles of the multi-point feeding / flavoring device installed in the drum, the feed liquid can be evenly sprayed on the leaves that fall in a curtain shape, so as to ensure the uniform feeding / flavoring of the leaves, which is conducive to improving the quality of cigarettes , its feeding efficiency and accuracy are significantly improved, and it can fully meet the production requirements of cigarette technology. It also has the advantages of compact structure, convenient operation and maintenance, stable and reliable performance, low energy consumption, and long life. An upgraded product, suitable for use in the cigarette industry.

Owner:BAOYING RENHENG IND

Antrodia camphorata extract and cigarette containing antrodia camphorata extract

ActiveCN101744360BImprove solubilityHazard reductionTobacco treatmentAntinoxious agentsSolubilityAdditive ingredient

The present invention discloses an antrodia camphorata extract and a cigarette containing antrodia camphorata extract. The present invention aims to realize the techniques of increasing fragrance, keeping moisture and reducing harmful ingredients in cigarettes. The antrodia camphorata extract is prepared with the following method: hot water of which the mass is 3 to 10 times of that of antrodia camphorata coarse powder is added to antrodia camphorata dried and crushed, the antrodia camphorata coarse powder is digested at a temperature of 80 DEG C to 95 DEG C, filtrate filtered is concentratedat a temperature of 60 DEG C under the reduced pressure of 0.05 MPa for 2 hours, and the antrodia camphorata extract is obtained. The cigarette containing antrodia camphorata extract is made by adding antrodia camphorata extract of which the mass accounts for 0.001 to 10% of that of tobacco shreds to the tobacco shreds. Compared with the prior art, the plant extract containing antrodia camphorataactive ingredients in the tobacco shreds has excellent solubility. The active ingredients can enter human bodies with the main smoke flow during the smoking and be absorbed by the human bodies through blood circulation. Consequently, the extract performs the functions for resisting tumours, viruses, ageing, etc. Cigarette smoke is pure and free of mixed gas. The quality of the cigarette can be improved, and the harm of the smoke to human bodies is accordingly reduced.

Owner:SHENZHEN DABAIHUI TECH

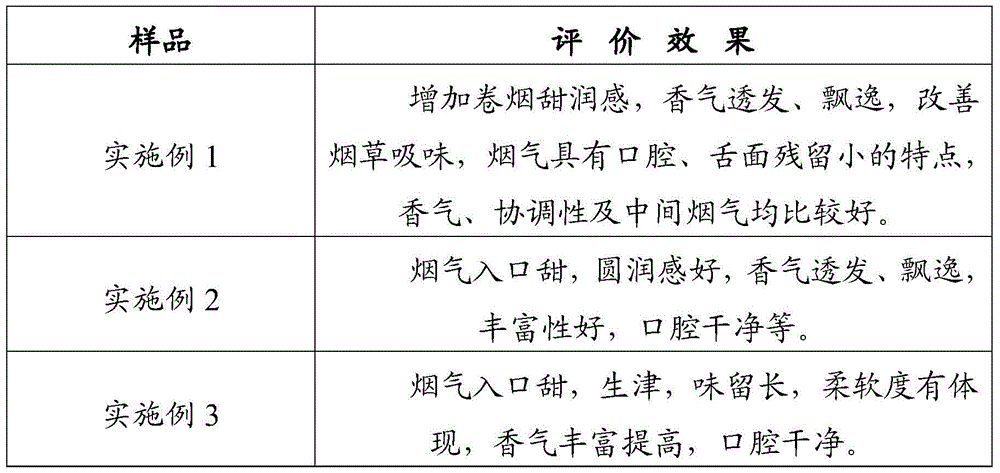

Essence for Regulating Cigarette Smoke Form

ActiveCN104450189BElegant smokeSweet smokeTobacco preparationEssential-oils/perfumesFurfuralChemistry

The invention discloses an essence for regulating the shape of smoke gas of cigarettes. The essence comprises the following raw materials in percentage by weight: 30-60% of propylene glycol, 20-40% of ethanol, 1-5% of 3-hydroxy-2-butanone, 5-15% of 2-hydroxy-3, 5, 5-trimethylcyclohexyl-2-en-1-one, 0.5-3% of furfural and 10-18% of Peru balsam. The essence for regulating the shape of smoke gas of the cigarettes, disclosed by the invention, can obviously upgrade the quality of the cigarettes, has the effects of sweet taste of the smoke gas, good mellow feeling, through and elegant fragrance, clean oral cavity and the like, and can be used as a novel essence for the cigarettes.

Owner:HUBEI CHINA TOBACCO IND +1

A tobacco slow anion channel protein ntslah1 and its application

ActiveCN108192896BReduce Chloride ContentQuality improvementPlant peptidesFermentationBiotechnologyNicotiana tabacum

The invention belongs to the technical field of tobacco genetic engineering, and specifically relates to a tobacco slow anion channel protein NtSLAH1 and a patent application for its application. The gene CDS sequence includes 1107bp bases, and its base sequence is shown in SEQ ID NO.1; wherein the 270th-615th nucleotides are specific nucleic acid fragments. Tobacco slow anion channel protein NtSLAH1 is a key protein in tobacco chloride ion metabolism, which can be inhibited by virus-induced gene silencing (VIGS) NtSLAH1 After gene expression, the chloride ion content in the transgenic silenced plants was significantly reduced. Based on this, it can lay a good foundation for the cultivation of new tobacco varieties with low chlorine content, and also provide fundamental technical support for the stability of tobacco leaf quality and the improvement of cigarette quality.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

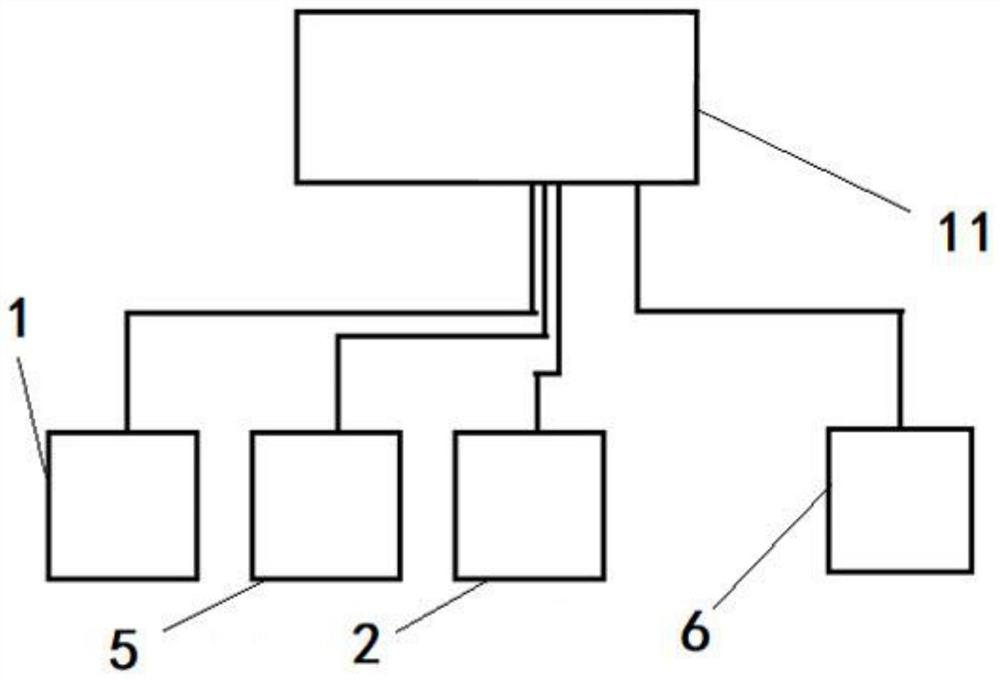

Cigarette quality detection system and detection method

PendingCN112021649AImprove the quality of cigarettesImprove product qualification rateCigarette manufactureElectromagnetic valveMechanical engineering

The invention discloses a cigarette quality detection system. The cigarette quality detection system comprises a cigarette forming assembly, a chopper device, a cigarette direction adjusting device, aPLC, a microwave scanner, an encoder, an optical fiber detector and an electromagnetic valve, wherein the microwave scanner, the encoder, the optical fiber detector and the electromagnetic valve areelectrically connected with the PLC. The cigarette quality detection method comprises the steps that the microwave scanner continuously scans a cigarette bar to form a voltage signal and transmits thevoltage signal to the PLC; when the PLC judges that the unqualified cigarettes appear according to the voltage signals, the PLC judges the serial numbers of the unqualified cigarettes; and the PLC locates the unqualified cigarettes and outputs a control signal to enable the electromagnetic valve to be communicated with a compressed air pipe and a compressed air spray head to blow out the unqualified cigarettes. The problem that an existing compound machine does not have a product quality detection function, so that unqualified products flow into a downstream procedure is solved, and the product percent of pass of heated non-combustible cigarettes is increased.

Owner:CHINA TOBACCO SICHUAN IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com