Tobacco piece scattering regionalization dampening system and process

A technology for loosening and blockage of cigarettes, which is applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of large chipping, poor loosening rate of tobacco sheets, and large crushing, so as to improve the quality of cigarettes, reduce tobacco costs, and reduce The effect of cigarette weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

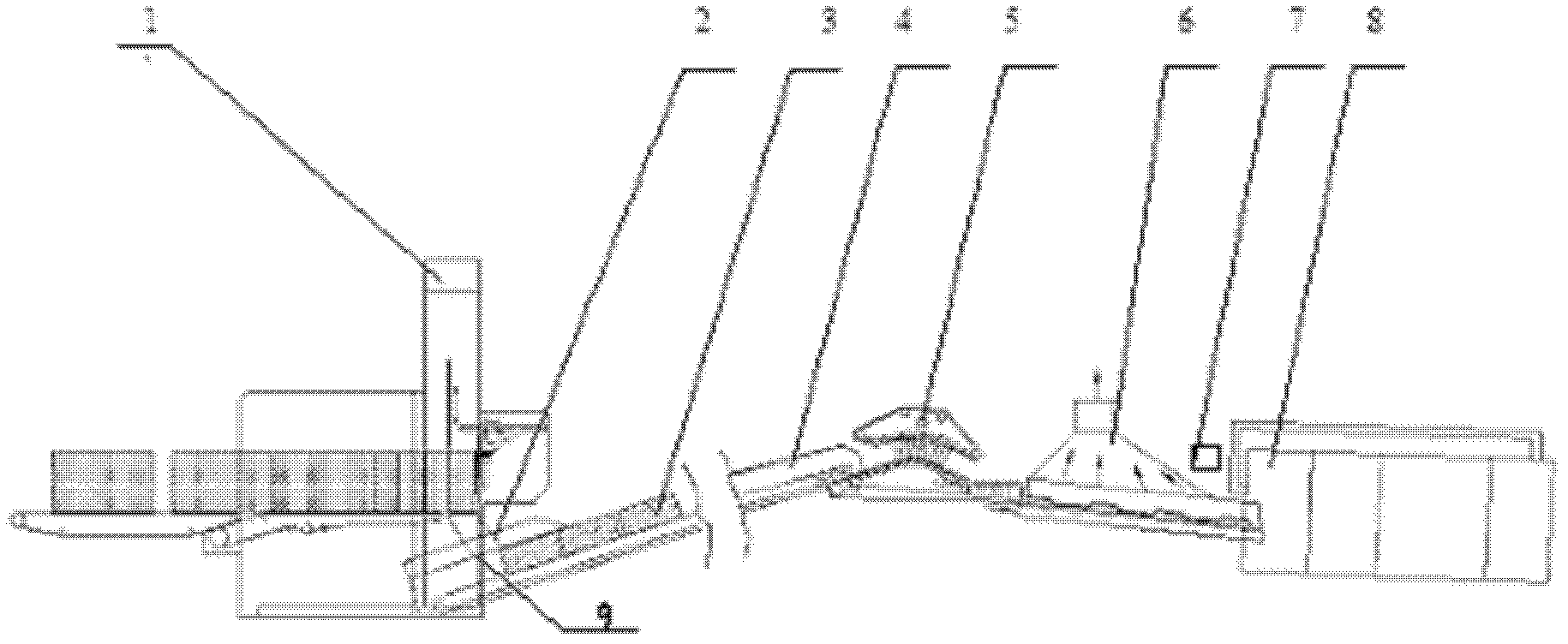

[0042] A moisture regain system for loose partitions of cigarette blocks, such as figure 1 As shown, it includes a vertical slitter 1 , a natural loose slitter 5 , a vibrating heating loosening machine 6 and a partitioned polygonal dampening cylinder 8 arranged in sequence. A conveyor belt 4 is provided between the vertical slitter 1 and the natural loose slitter 5 . A guide chute 2 is provided between the vertical slitter 1 and the conveyor belt 4 , and the guide chute 2 is connected to the discharge port of the vertical slitter 1 .

[0043] The guide chute 2 and the conveyor belt 4 are respectively provided with a photoelectric switch 9 to control the discharge interval of the cigarette blocks 3 and guide the sliced cigarette blocks 3 to be evenly and continuously arranged to avoid blockage in the natural loose cutting machine 5 . The natural bedding of the cigarette block 3 vertically cut is perpendicular to the surface of the conveyor belt 4 . The conveyor belt 4 is al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com