Fresh chilli sauce and preparation method thereof

A technology of fresh chili sauce and fresh chili, applied in food preparation, bacteria used in food preparation, food science, etc., can solve the problems of cleanliness, short shelf life, odor loss, etc., and achieve convenient production process operation and storage The effect of proper period and convenient consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A fresh chili sauce is composed of the following raw material ratios in mass fractions: 88% fresh chili, 11% table salt, 0.85% glacial acetic acid, 0.05% potassium sorbate and 0.1% lactic acid bacteria.

[0033] Prepare above-mentioned fresh chilli sauce by following steps:

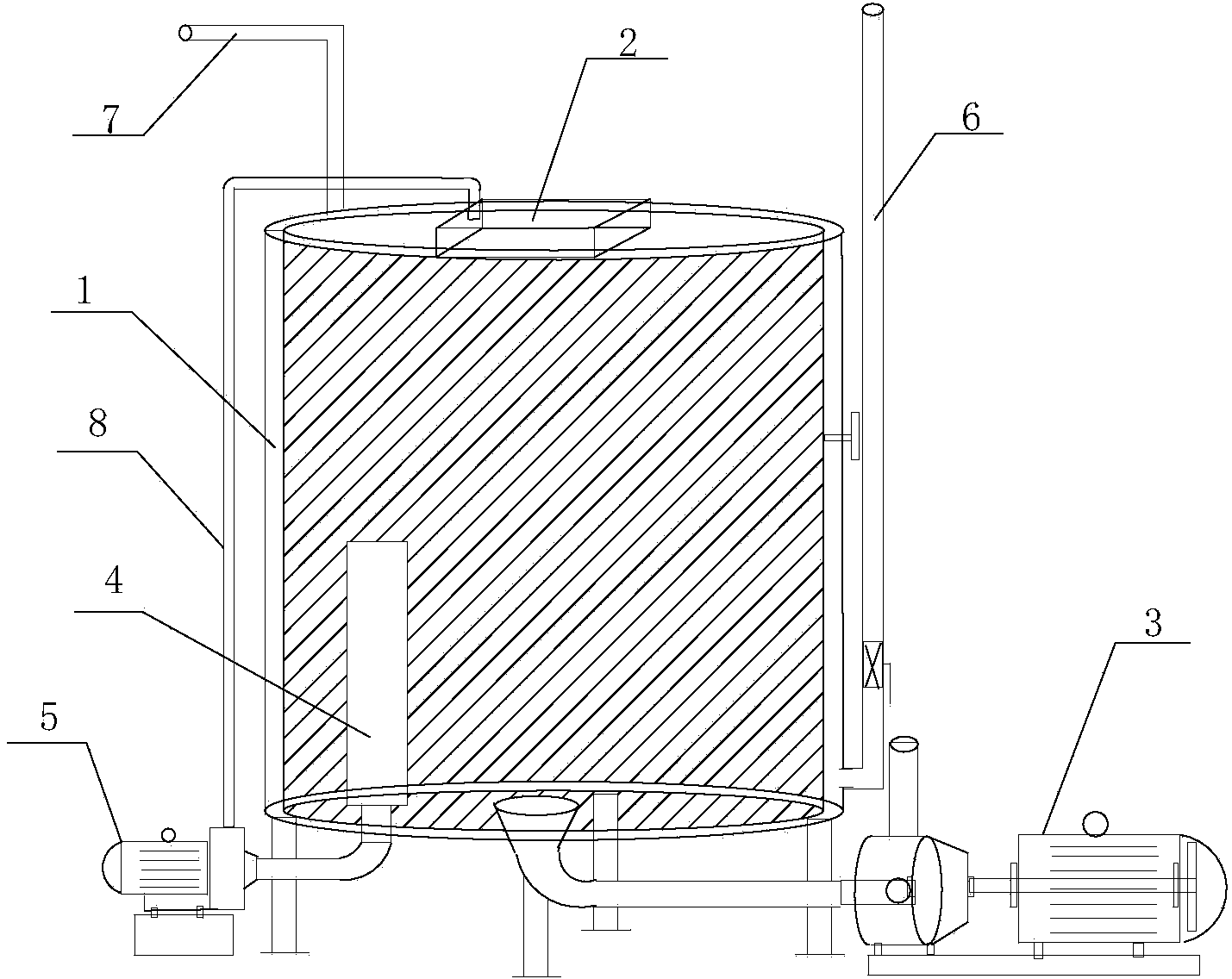

[0034] Select fresh peppers that are free from mold, rot, and insects, remove the stalks, put them in the turnover basket and wash them three times with running water, drain the water after washing, and put them in the spare basket for later use; put the fresh peppers that have been washed and drained Grind 880kg through a mincer, pass through a 6mm gong sieve, measure and weigh, transport to a mixer, add 1kg of lactic acid bacteria and 110kg of salt, mix quickly for about 30 minutes, and then transport to a fermenter for fermentation, interlayer of fermenter 1. There is circulating hot water inside. The hot water is driven by the gear pump 3. The hot water enters the interlayer circulation from th...

Embodiment 2

[0036] A fresh chili sauce is composed of the following raw material proportions in mass fraction: 86.85% of fresh chili, 12% of table salt, 1% of glacial acetic acid, 0.05% of potassium sorbate, and 0.1% of lactic acid bacteria.

[0037] Prepare above-mentioned fresh chilli sauce by following steps:

[0038] Select fresh peppers that are free from mold, rot, and insects, remove the stalks, put them in the turnover basket and wash them three times with running water, drain the water after washing, and put them in the spare basket for later use; put the fresh peppers that have been washed and drained 868.5kg is ground through a mincer, passed through a 6mm gong sieve, measured and weighed, transported to a mixer, added 1 kg of lactic acid bacteria, 120 kg of salt, mixed quickly for about 30 minutes, and then transported to a fermentation tank for fermentation. There is circulating hot water in the interlayer 1. The hot water enters the interlayer through the gear pump 3 and is ...

Embodiment 3

[0040] A fresh chili sauce is composed of the following raw material proportions in mass fraction: 89.70% of fresh chili, 10% of table salt, 0.1% of glacial acetic acid, 0.1% of sodium benzoate and 0.1% of lactic acid bacteria.

[0041] Prepare above-mentioned fresh chilli sauce by following steps:

[0042] Select fresh peppers that are free from mold, rot, and insects, remove the stalks, put them in the turnover basket and wash them three times with running water, drain the water after washing, and put them in the spare basket for later use; put the fresh peppers that have been washed and drained 897kg is ground by a mincer, passed through a 6mm gong sieve, measured and weighed, transported to a mixer, added 1 kg of lactic acid bacteria, 100 kg of refined salt, mixed quickly for about 30 minutes, and then transported to a fermenter for fermentation, fermenter There is circulating hot water in the interlayer 1. The hot water is circulated by the gear pump 3 from the inlet pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com