Patents

Literature

202results about How to "High alcohol content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High alcohol content foaming compositions with silicone-based surfactants

ActiveUS20070179207A1Little dryingEasy to spreadBiocideCosmetic preparationsAlcohol contentAerosol composition

This invention relates to a “high lower alcohol content” (>40% v / v of a C1-4 alcohol) liquid composition able to be dispensed as a stable foam with the use of non-propellant foam dispensing devices from non-pressurized containers The liquid compositions comprise an alcohol, C1-4 (>40% v / v), a silicone-based surfactant of at least 0.001% by weight to prepare a foamable composition, 0-10% w / w of additional minor components added to obtain the desired performance (a foamable composition), and the balance being purified water. The compositions may include emulsifier-emollients and mosturizers, secondary surfactants, foam stabilizers, fragrances, antimicrobial agents, other type of medicinal ingredients, and the like ingredients or additives or combinations thereof commonly added to alcohol gels or foams, aerosol compositions or to toiletries, cosmetics, pharmaceuticals and the like.

Owner:DEB IP

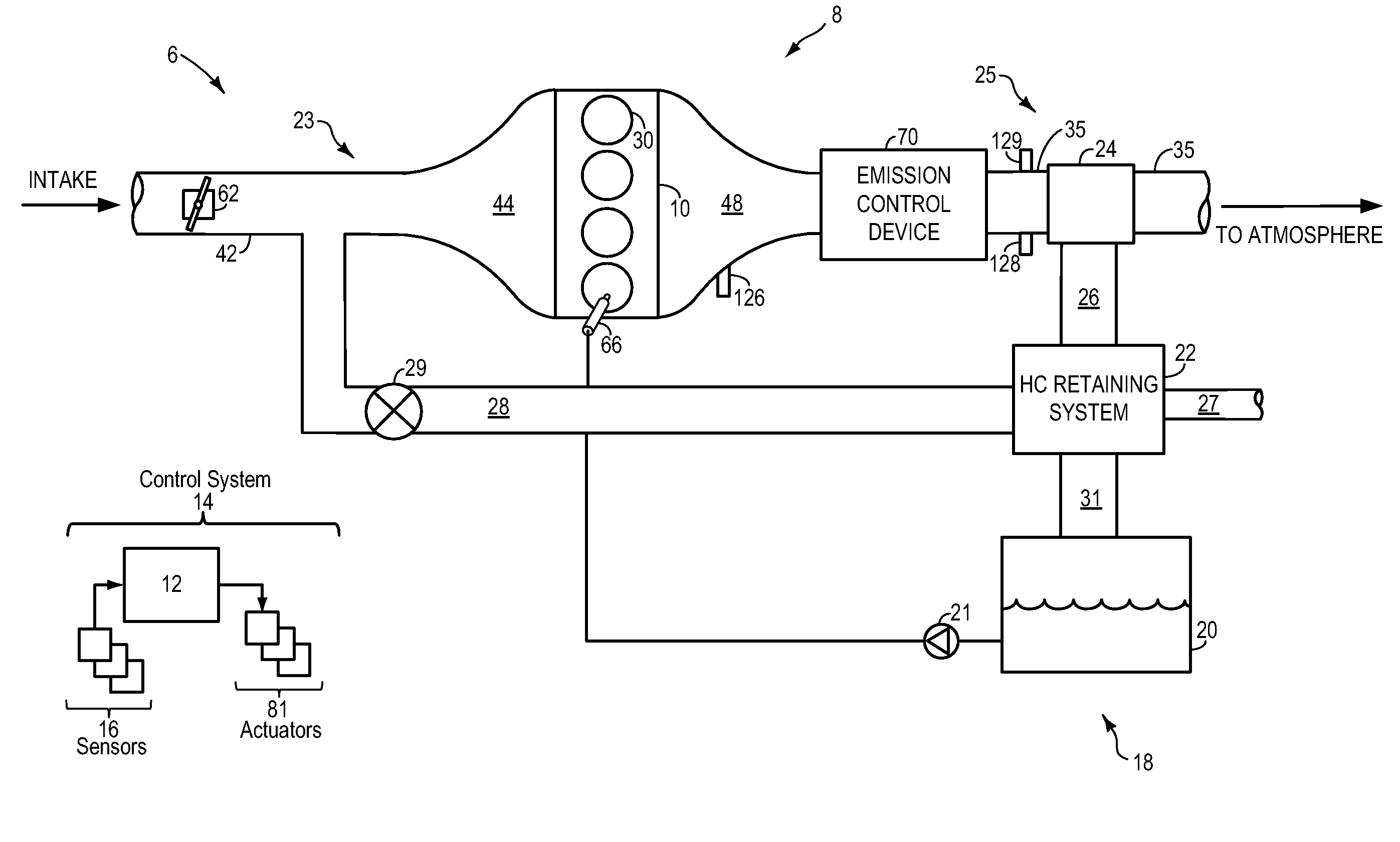

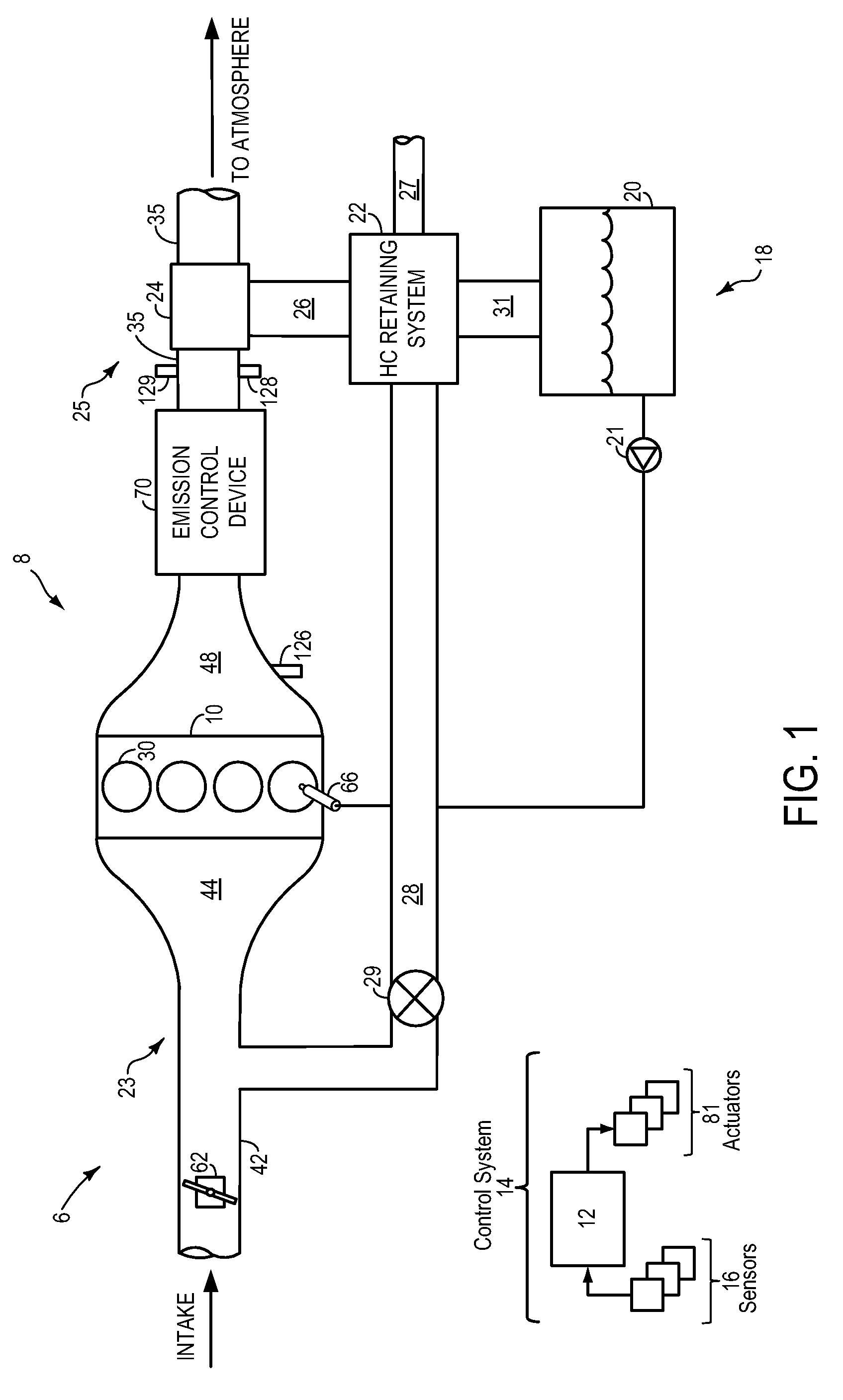

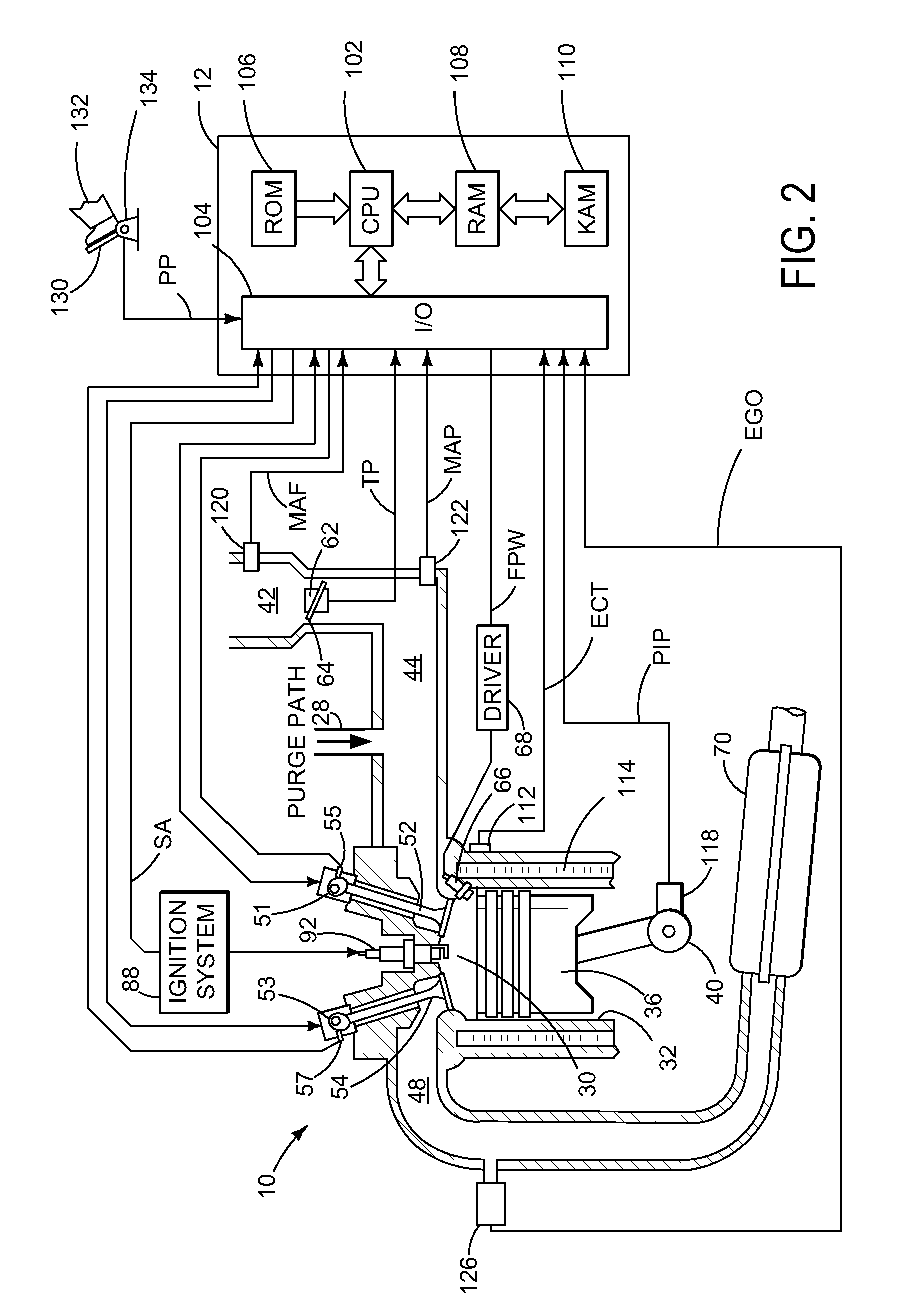

Hydrocarbon Retaining System for Flex-Fuel Combustion Engine

InactiveUS20090120071A1Reduce breakthroughLow alcohol contentElectrical controlNon-fuel substance addition to fuelCombustionProcess engineering

Systems, methods, and computer readable storage media are described in which exhaust gas is routed to a hydrocarbon retaining device during starting, and purged to the engine intake manifold. Various alternative approaches are described for controlling operation and diagnosing degradation. Further, various interrelated configurations are described.

Owner:FORD GLOBAL TECH LLC

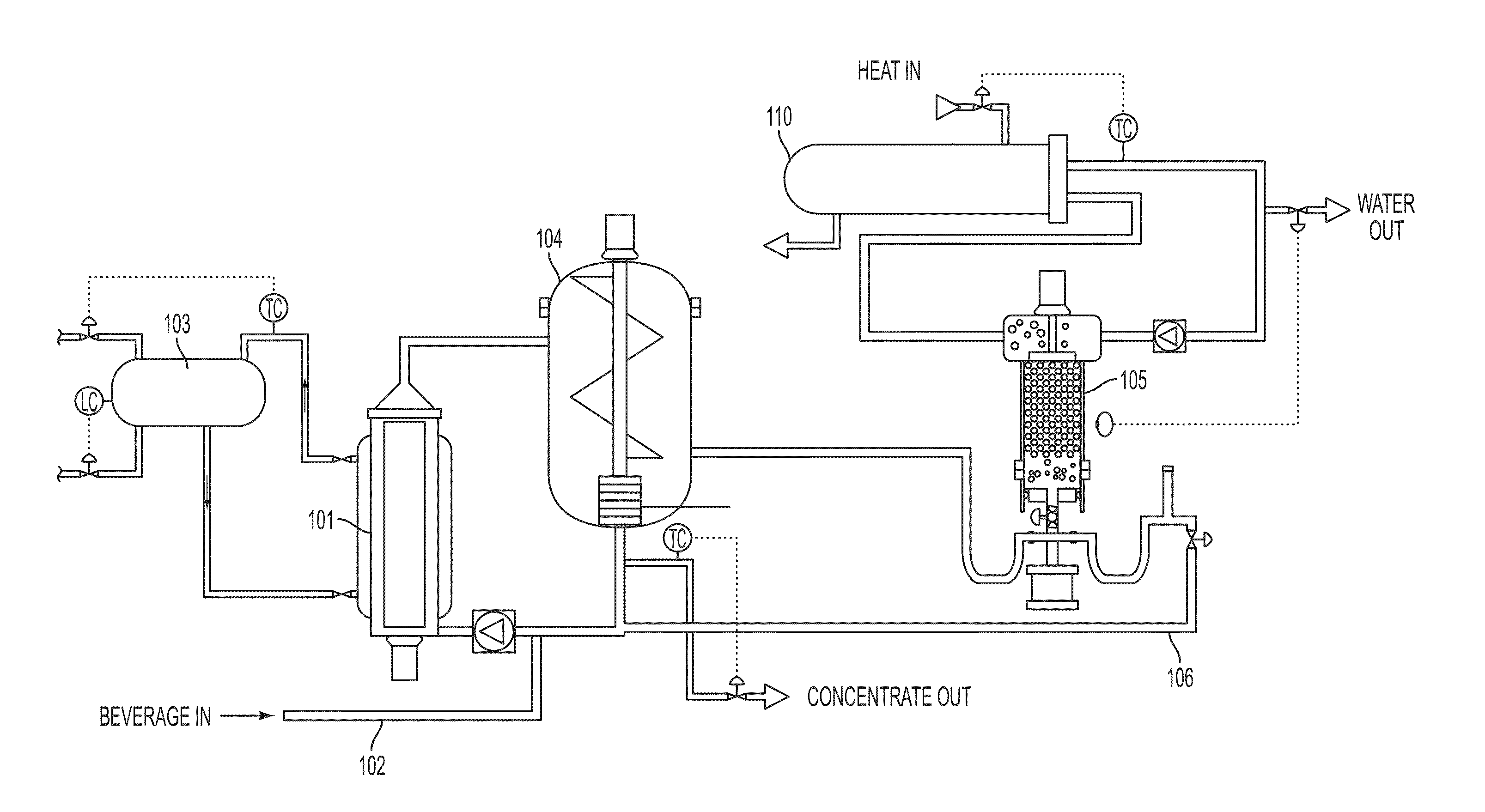

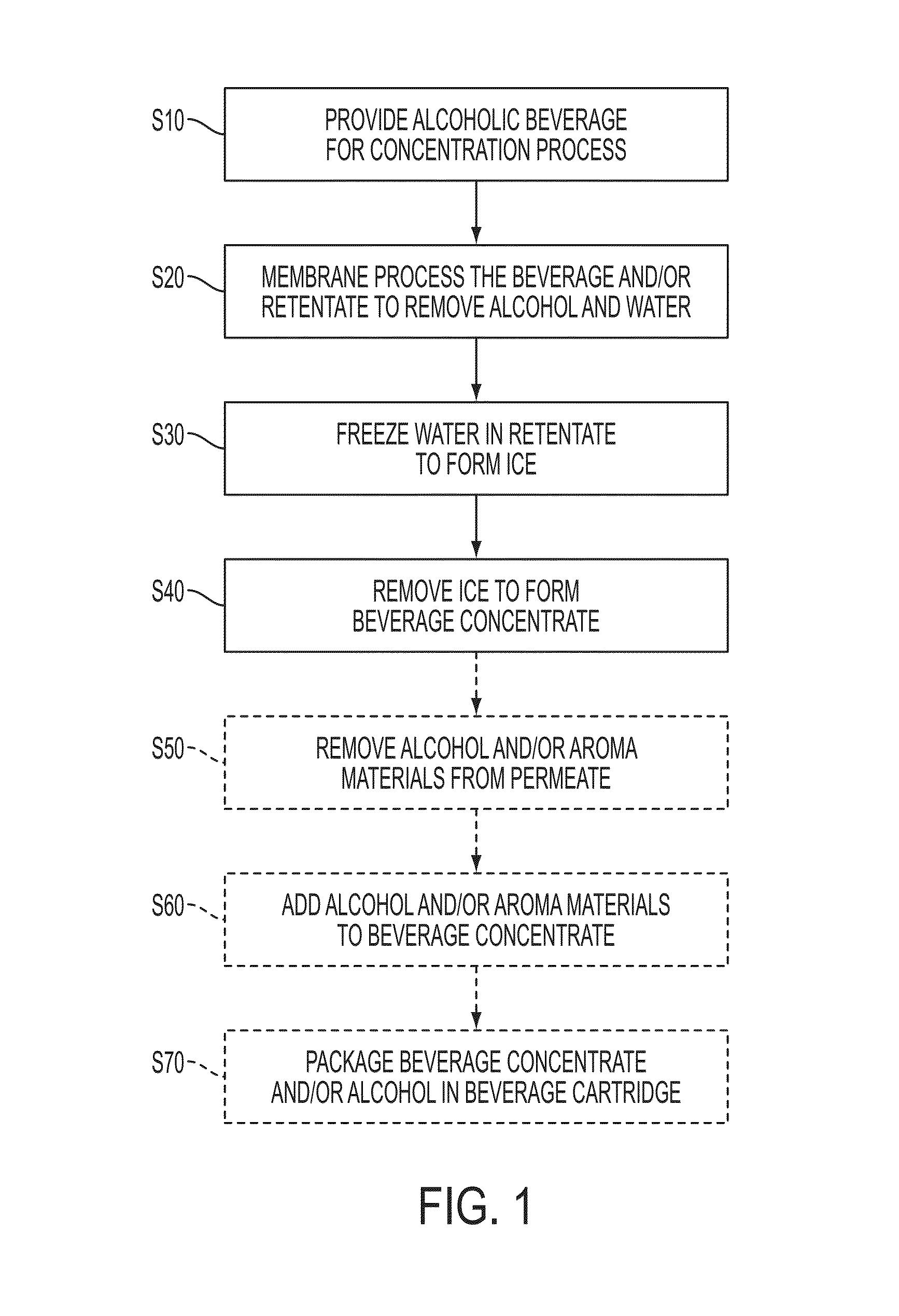

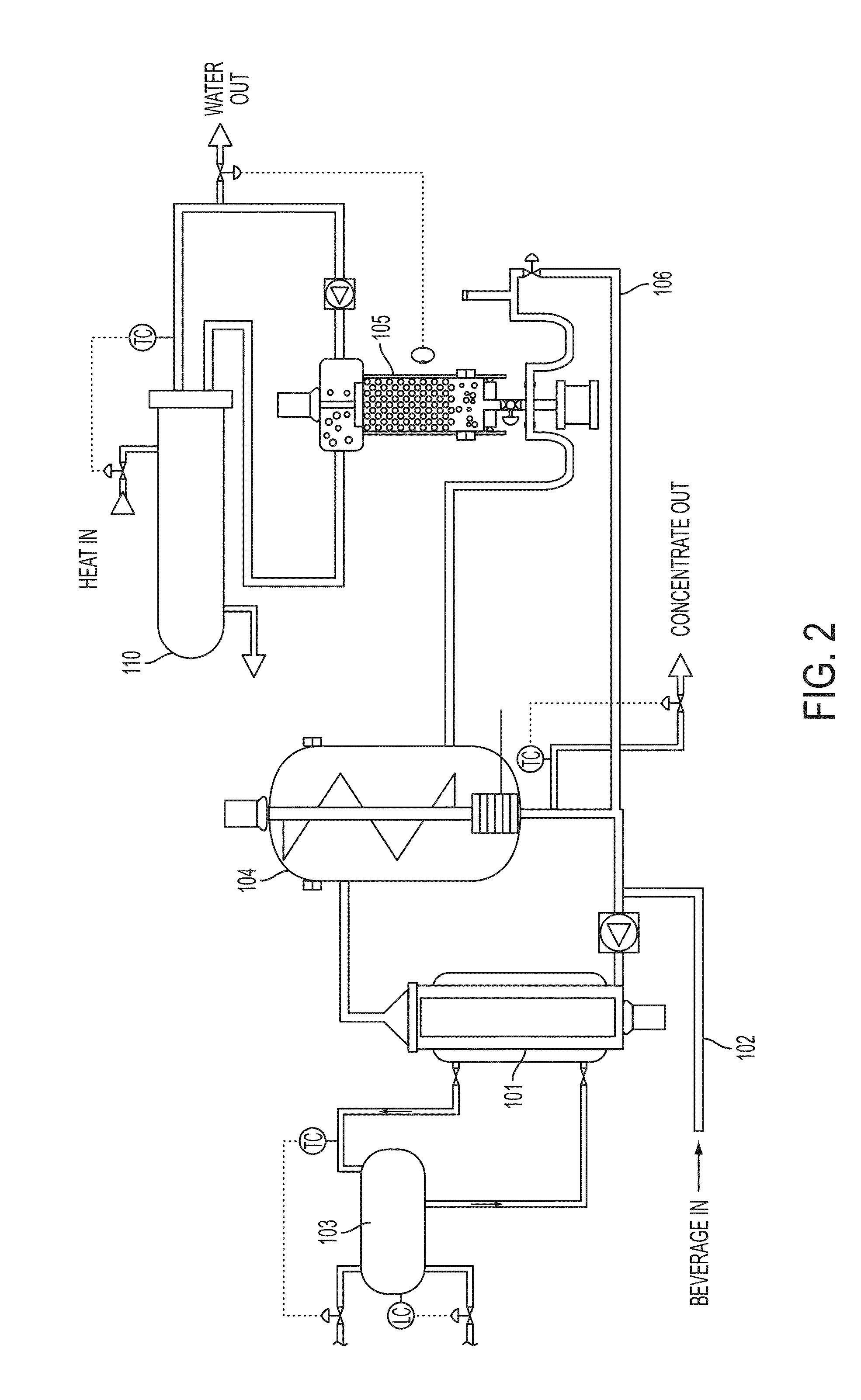

Alcoholic beverage concentrate process

ActiveUS20160230133A1Increase turbidityHigh alcohol contentBeer fermentationAlcoholic beverage preparationAlcohol contentWater content

Methods and systems for forming a concentrate from an alcoholic beverage, such as a beverage made by fermentation processes. A membrane process may be used to reduce water and alcohol content, followed by freeze concentration to further reduce water content.

Owner:BEDFORD SYST LLC

High alcohol content gel-like and foaming compositions

ActiveUS20050129626A1High alcohol contentLittle dryingCosmetic preparationsBiocideLiquid compositionFluorosurfactant

This invention relates to a “high lower alcohol content” (>40% v / v of a C1-4 alcohol) liquid composition able to be either dispensed as a stable foam with the use of non-propellant foam dispensing devices from non-pressurized containers or as an alcohol gel composition which does not use thickener and gelling agents that leave undesirable deposits or a sticky after-feel and that has a final viscosity less than 4,000 cps. The liquid compositions comprise an alcohol, C1-4 (>40% v / v), a fluorosurfactant of at least 0.001% by weight to prepare a foamable composition or from 0-2.0% to prepare a gel-like composition of a final viscosity less than 4,000 cps, 0-10% w / w of additional minor components added to obtain the desired performance (a foamable composition or a gel-like composition with a viscosity less than 4,000 cps), and the balance being purified water. The compositions may include emulsifier-emollients and mosturizers, secondary surfactants, foam stabilizers, fragrances, antimicrobial agents, other type of medicinal ingredients, and the like ingredients or additives or combinations thereof commonly added to alcohol gels or foams, aerosol compositions or to toiletries, cosmetics, pharmaceuticals and the like.

Owner:DEB IP

Method for preparing blueberry raw wine

The invention relates to the field of brewing processes, and discloses a method for preparing a blueberry raw wine. The method for preparing the blueberry raw wine comprises the following steps of: adding acid-degradation wine yeast in an amount being 0.008-0.012 percent by mass of blueberry pulp into the blueberry pulp, fermenting until the sugar degree is less than 5g / L, filtering and collecting blueberry juice; and adding lactic acid bacteria in an amount being 0.008-0.012 percent by mass of the blueberry juice into the blueberry juice, fermenting until total acidity of the blueberry juiceis less than or equal to 10g / L and filtering to obtain the blueberry raw wine. The invention also provides the blueberry wine which comprises the blueberry raw wine prepared by using the method and common additives for fruit wine. By adopting the method, the total acidity in the blueberry raw wine is reduced; each process is convenient and simple; and the method can be widely applied to wine industry. Meanwhile, the blueberry wine has low total acidity, good mouthfeel, low sugar, low alcohol, high raw wine content and rich nutrient components and is suitable for general consumers.

Owner:BAISHAN LINYUANCHUN ECOLOGY TECH

Tea wine and preparation method thereof

InactiveCN103305371AHigh alcohol contentSweet and mellow tasteAlcoholic beverage preparationFlavorAlcohol

The invention provides a tea wine and a preparation method thereof. The tea wine is prepared by mixing a tea extraction solution and a grain saccharification solution and fermenting. The preparation method provided by the invention comprises the following steps of: firstly leaching tea to prepare the tea extraction solution; secondly mixing Chinese sorghum, rice and corn according to a certain proportion, crushing, steaming, boiling and saccharifying to obtain the saccharification solution, mixing with the tea extraction solution, adding koji, and forming a tea fermentation solution by liquid-state fermentation; and finally performing sterilization, blending, fining, filtering, aging and secondary filtration to obtain the tea wine. The tea wine is characterized in that a product provided by the invention has the characteristics of heavy tea fragrance, sweet and mellow taste, coordination of various flavors, long after-taste and the like; and furthermore, compared with the traditional tea wine, the tea extraction solution is adopted for performing fermentation together with the Chinese sorghum, the rice and the corn, the functional active ingredients in the tea can be retained to the greatest extent, the blending of a base wine is simultaneously performed after fermentation, the shortcomings of low alcohol degree of the fermented wine and complex process and pungent smell of the distilled wine can be overcome, the softness of the tea and the rigidity of the wine can be perfectly combined, and the species of tea and wine products are enriched.

Owner:四川省广汉市常乐春酒厂(普通合伙)

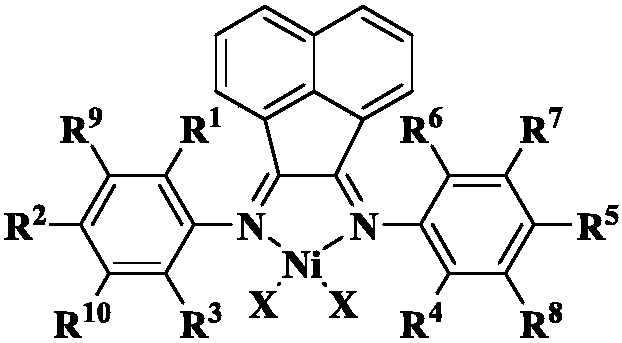

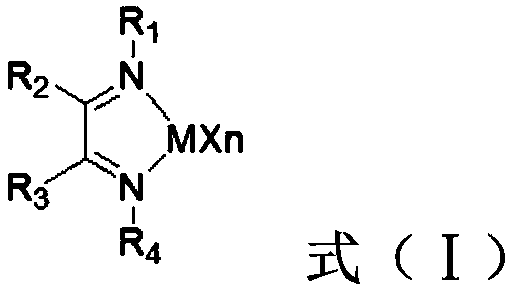

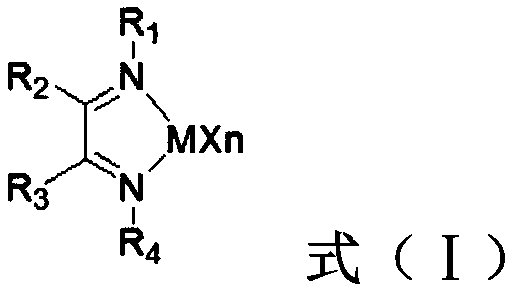

Catalytic system for olefin- olefin alcohol polymerization, olefin-olefin alcohol copolymerization method and polymer

The invention relates to the field of polymers, the invention discloses a catalytic system for olefin- olefin alcohol copolymerization, an olefin-olefin alcohol copolymerization method and a polymer.The catalytic system comprises the following components: (1) a main catalyst which is selected from at least one of the group consisting of metal complexes as shown in formula (I), in the formula (I),R1 and R4 are each selected from a C1-C30 hydrocarbyl group or heterohydrocarbyl group; R2 and R3 are each selected from a hydrogen atom, a chlorine atom, a C1-C20 hydrocarbon group, and the like, and R2 and R3 may be optionally bonded to each other into a ring. M is a Group VIII metal; X is selected from the group consisting of halogen, hydrocarbyl and alkoxy; n is an integer satisfying the valence of the M; 2) a cocatalyst; 3) an olefin; 4) an alkene alcohol; 5) an alkane solvent; and a 6) chain transfer agent; the polymer has a high alcohol content and weight average molecular weight, a narrow molecular weight distribution, and does not contain a carboxylic acid or an alkali metal salt, and the catalyst has better thermal stability and a higher polymerization activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method for English pale ale

ActiveCN104232388AHigh alcohol contentFull bodiedBeer fermentationMicroorganism based processesYeastFiltration

The invention relates to a preparation method for English pale ale. The method comprises the following steps: (1) mixing raw materials and water,saccharifying the mixture, raising the temperature, stopping saccharifying, boiling the mixture with addition of hops in stages after filtration, and performing precipitation to obtain wort; (2) inoculating upper beer yeasts into the wort for fermentation, and storing the fermented product for 20 to 30 days to obtain fermentation broth after fermentation is stopped; (3) adding extract into the fermentation broth, inoculating lower yeast liquid, performing heat storage, and storing at reduced temperature to obtain the English pale ale. According to the method, a conventional process for the English pale ale is improved, and by secondary fermentation, the ale is more mellower on the premise that the high alcohol content and hop bitterness of the conventional ale are kept.

Owner:山东山科酵爵生物制品有限公司

Sweetmuscat wine and brewing process thereof

The invention aims at providing sweet muscat wine which uses muscat grapes as a raw material, is rosy in appearance color, is clear and transparent, typical, rich, fresh and elegant in aroma, mellow and full in taste, smooth in wine body, balanced in taste, lasting in aftertaste and high in alcohol degree and a brewing process thereof, belonging to the technical fields of wines. The technical scheme is as follows: the brewing process of the sweet muscat wine adopts a segmented fermentation method,an impregnation process and a fermentation process are not fully synchronized, the impregnation is performed for a fixed time of 96h in an alcohol fermentation process I, peel and pomace are separated and then an alcohol fermentation process II is performed, and the impregnation time length is fixed and appropriate.

Owner:山西戎子酒庄有限公司

Method for preparing hawthorn fruit vinegar beverage by continuously fermenting various mixed strains

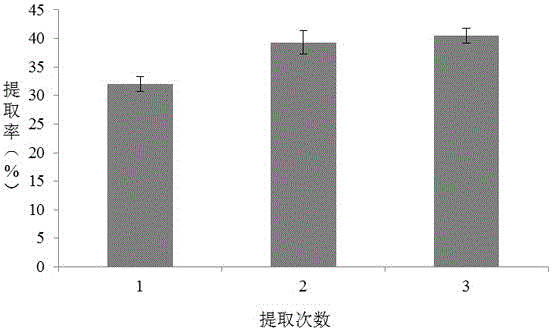

ActiveCN103907987AShorten extraction timeImprove leaching rateYeast food ingredientsLactobacillusNutrientLactobacillus sp

The invention discloses a method for preparing hawthorn fruit vinegar beverage by continuously fermenting various mixed strains. The method comprises the following steps: (1) preparing materials; (2) carrying out vacuum leach and enzymolysis; (3) carrying out alcoholic fermentation: inoculating saccharomycetes into leaching solution and fermenting for 10 days at temperature of 25-32 DEG C; (4) carrying out lactobacillus fermentation: inoculating lactobacilli into fermented liquid after the alcoholic fermentation and ending the lactobacillus fermentation at the temperature of 37-40 DEG C when the alcoholic strength is 6-8%; (5) carrying out acetic fermentation: inoculating bacillus aceticus AS1.41 and fermenting for 72-84 hours at the fermentation temperature of 30 DEG C; and (6) sequentially cleaning, blending, homogenizing and sterilizing to acquire the hawthorn fruit vinegar beverage. The hawthorn fruit vinegar beverage prepared through the method is red and brown in color and properly sweet and sour; the hawthorn fruit vinegar beverage has excellent flavor and taste of flavor substances on basis of keeping original nutrient substances; meanwhile, continuous fermentation can be carried out and the production efficiency is high.

Owner:TIANDI YIHAO BEVERAGE JIANGMEN CITY

Method for preparation of lychee wine by freeze concentration and ultralow temperature fermentation

ActiveCN1840635AIncrease Natural BrixHigh alcohol contentAlcoholic beverage preparationPre treatmentBrewing

The disclosed brewing method for leechee wine comprises: preprocessing the material, pressing to obtain juice, taking ultra-high-temperature sterilization and freeze-concentration to ferment for 25-40day at 3-10Deg, aging, preparing, clarifying, and filtering to obtain the product. This invention has nice color and feeling, and rich nutrition with low cost.

Owner:广东帝浓酒业有限公司

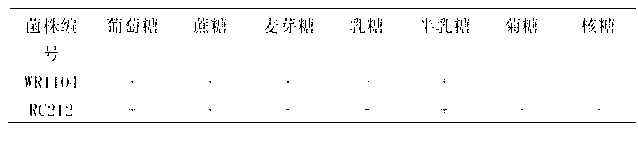

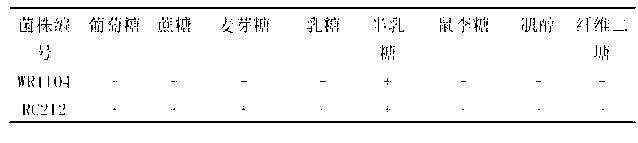

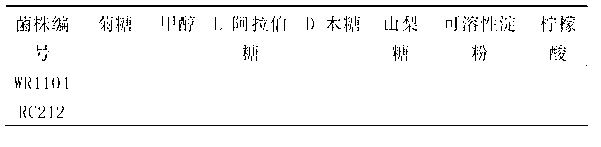

Saccharomyces cerevisiae and application of the same in dry red wine brewing

ActiveCN103215195AStrong stress resistanceImprove permeabilityFungiMicroorganism based processesFruit wineCLARITY

The present invention provides a strain of saccharomyces cerevisiae, wherein a preservation number is CCTCC NO:M 2012500. The saccharomyces cerevisiae has characteristics of strong stress resistance, high sugar resistance, high temperature resistance, high alcohol resistance, good permeability, and high alcoholicity of the produced wine, can be widely used for brewing excellent quality red wines of various characteristic red grape varieties in China production regions, and can further be used for brewing blue berry wines, jujube wines, and other high-end fruit wines with various characteristics and ordinary fruit wines. According to the present invention, compared to a new wine fermented by commercial yeast RC212, a new wine brewed by fermenting a merlot grape raw material through the saccharomyces cerevisiae has characteristics of good clarity, rich aroma, soft and pleasure taste, good attachment to wall, and good mellow taste; compared to the new wine fermented by commercial yeast RC212, a new wine brewed by fermenting a Cabernet Sauvignon grape raw material has characteristics of good clarity, rich aroma, mellow taste, and good attachment to wall; and the saccharomyces cerevisiae of the present invention is suitable for fermenting Syrah, Cabernet Gernischt and other red grape varieties, and can further be used for fermenting blue berry wines, jujube wines, and other high-end fruit wines with various characteristics, and brewing ordinary fruit wines.

Owner:QINGDAO VLAND BIOTECH GRP

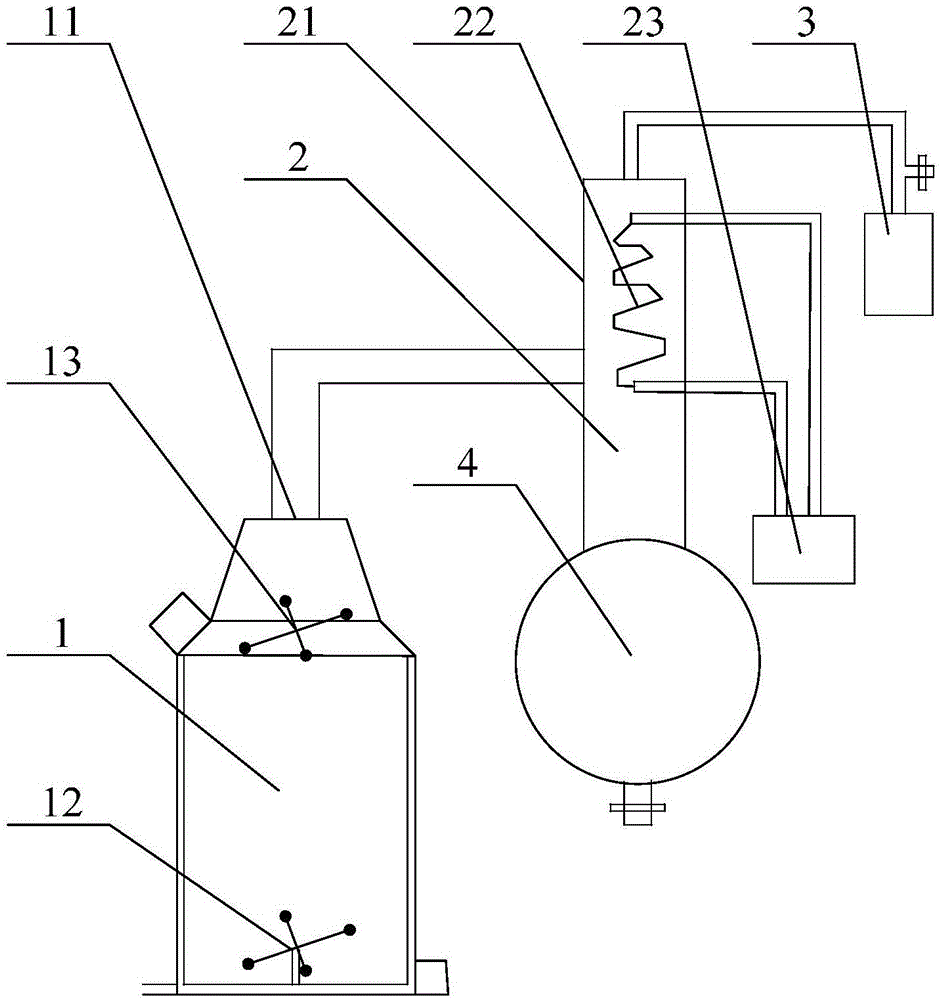

Distilling system and method of distilled liquor

The invention relates to the technical field of alcohol brewing, in particular to a distilling system of distilled liquor. The distilling system comprises a material cooking tank, a condensing device and a vacuum pump. The material cooking tank is communicated with the condensing device. The vacuum pump is communicated with the condensing device. Fermented grains or fermented liquor is contained in the material cooking tank and produces steam under the negative pressure condition, and the steam enters the condensing device. The condensing device is used for condensing the steam. The vacuum pump is used for controlling the gas pressure states in the material cooking tank and the condensing device. The gas pressure of the system is controlled through the vacuum pump, negative-pressure distillation is conducted at a room temperature or a low temperature, and therefore the damage of high temperature to evaporative flavor substances is avoided, the alcoholic strength of raw liquor is improved, loss of flavor components is reduced, the distilling efficiency is improved, and the distilling system is suitable for various types of distilled liquor; by means of the distilling system, corresponding novel room-temperature negative-pressure distilled liquor can be produced.

Owner:TIBET AGRI & ANIMAL HUSBANDRY COLLEGE

Method for brewing fresh litchee juice wine

ActiveCN101671616AIncrease Natural BrixHigh alcohol contentAlcoholic beverage preparationMicroorganism based processesYeastFruit juice

The invention discloses a method for brewing fresh litchee juice wine. The method includes that litchi raw material is subject to pretreatment, then super high temperature sterilization and freeze concentration and then ultralow temperature long fermentation, ageing, juice alcoholization, formulation, clarification and filtering, thus obtaining the fresh litchee juice wine. The ultralow temperature long fermentation includes that active dried yeast growing at low temperature and food grade sulfinic acid solution containing SO2 are added into juice after sterilization, the content of the activedried yeast in juice after sterilization is 200-400mg / L; and fermentation is carried out for 20-35 days at 2-12 DEG C. the invention adopts freeze concentration method to improve natural sugar degreeof litchee juice, brewing cost of litchee wine is low, alcoholic strength is high, mouthfeel is full, no exogenous saccharides is required to be added, and natural nutrients and flavor of fresh litchee juice are kept and fine, smooth and elegant litchee wine mouthfeel while stable and permanent litchee fruity can be obtained.

Owner:广东帝浓酒业有限公司

Method for making green plum fruit wine

InactiveCN101942373AInnovativeUnique craftAlcoholic beverage preparationMicroorganism based processesYeastFruit wine

The invention discloses a method for making green plum fruit wine. Green plum fruits are used as a raw material. The method for making the green plum fruit wine comprises preparation of a culture medium, pulp blending, amplified culture of active dry yeast, main fermentation, post fermentation, blending, inspection and storage. The method has the advantages of innovativeness of the fermentation process, unique process, low cost, full space utilization and capability of improving the utilization rate and comprehensive economic value of the green plum resource; and the brewed green plum fruit wine has high total flavone content (141.48mg / L), high wine yield (260.1 percent) and high alcoholic strength (10.2 percent).

Owner:ANHUI AGRICULTURAL UNIVERSITY

Fermented milk-wine drink and processing method

ActiveCN101070516AEliminate lesion responseReduce contentAlcoholic beverage preparationChemistryAmino acid

One kind of fermentation milk liquor drink and its the processing method, relates to one kind of liquor drink and its the processing method. Its liquor precision 5-15%, total acid 3-7g / L, in total sugar 40g / L, B vitamin total quantity above race 0.2mg / L, the amino acid condition nitrogen has achieved above 0.10g / l. Also it completes by the below step: A, the whey powder by 8-15 time of tap water dilution, and to this atthe beginning of initial expectations fluid carries on sterilization; B, thenl sterilize the after at the beginning of initial expectations fluid adjustment temperature to 40 degree C +-2 degree C, will carry on the enzymolysis with the lactase and the proteins, after the enzymolysis completes at 95 degree C maintains 20 minutes to extinguish the enzyme; C, cooling extinguishes the enzyme the material fluid to 35 degree C+-2 degree C, joins at the beginning of the initial expectations fluid weight1.5-2.5% to arrive the lactic acid fungus seed fluid, the constant Temperature ferments for 2-3 days; then joins the white granulated sugar, according to at the beginning of initial expectations fluid weight 10-30%, again joins the yeast seed for the beginning of the fluid the initial expectations fluid weight 2-4%, the constant temperature ferments for 6-10 days; E, then ferment the base liquor will filter, mixes, the sterilization, fills the attire to make the end product.

Owner:内蒙古百吉纳奶酒股份有限公司

Process for brewing yellow wine with high alcohol content

InactiveCN101544940AHigh alcohol contentAchieve strengthMicroorganism based processesAlcoholic beverage preparationMonascusChemistry

The invention discloses a process for brewing yellow wine with high alcohol content, which comprises the following steps that: 25 kilograms of steamed sticky rice, 38 kilograms of water and 1.5 kilograms of Gutian red yeast rice are poured to a wine jar, evenly stirred, fermented for 2 to 3 months at a temperature of between 8 and 35 DEG C till the mixture is fully fermented; then lees in the mixture is separated by a squeezing method to obtain the clear yellow wine; 18 kilograms of the steamed sticky rice, 38 kilograms of the clear yellow wine and 1 kilogram of the Gutian red yeast rice are poured to the wine jar once again, evenly stirred and fermented for 15 days at a temperature of between 4 and 25 DEG C; the jar is sealed, moved to a shade, fermented for 2 to 3 months; the leavening is subjected to filter pressing, wine decoction and clarification to finally obtain a finished product, namely the yellow wine with the high alcohol content; and the alcohol content is between 21 and 23 percent vol. The yellow wine achieves the rigidity of white wine, is nutritious and healthy and has mellower mouthfeel.

Owner:陈清

Preparation method of Abbey strong Ale beer

InactiveCN109321394AIncrease bodyGood foaming performanceMicroorganism based processesBeer brewingYeastAlcohol

The invention relates to a preparation method of Abbey strong Ale beer. The preparation method comprises the following steps of (1) mixing malt and water, saccharifying, filtering, boiling, adding hops, and rotationally settling, so as to obtain wheat juice; (2) performing primary fermentation on the wheat juice in a fermenting tank, adding fermentable sugar and dry hops to perform secondary fermentation; after the secondary fermentation is finished, using no production of gas as the endpoint, centrifuging to remove yeast, adding Belgian Kitty candy, inoculating a second type of surface yeast,loading into bottles, putting into a cold storage for tertiary fermentation. The preparation method has the advantages that in the latter stage of the primary fermentation, the fermentable sugar anddry hops are added; after the secondary fermentation is finished, the yeast is removed, the fermentable sugar is added, and the new surface yeast is inoculated to perform the tertiary fermentation. The finally produced beer has the advantages that the degree of alcohol is high, the beer body is mellow, and the fragrance of the malt and the hops and the sweet taste of the beer are highly balanced.

Owner:QILU UNIV OF TECH

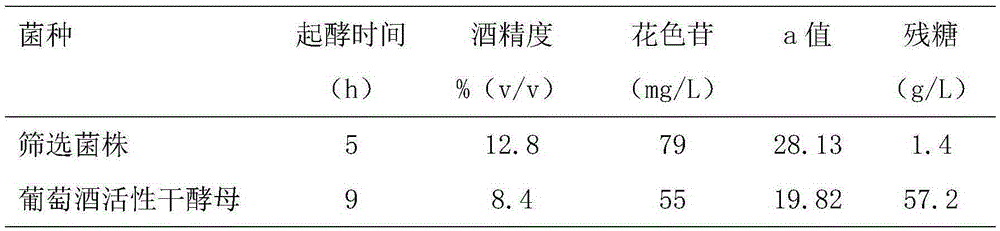

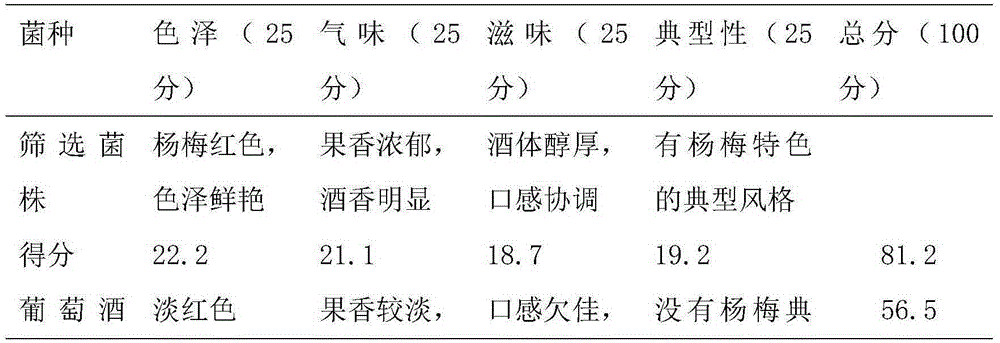

Saccharomyces cerevisiae strain and high quality red bayberry fruit wine preparation method

ActiveCN105349443ANo typicalHigh alcohol contentFungiAlcoholic beverage preparationBiotechnologyFruit wine

The present invention discloses a saccharomyces cerevisiae strain and a high quality red bayberry fruit wine preparation method. The saccharomyces cerevisiae strain is screened from naturally fermented mash of fresh red bayberry, red bayberry juice with pH of 3.0 can be directly fermented to obtain high quality red bayberry fruit wine with high alcohol content (13.5%), bright color (a = 27.64), high anthocyanin retention rate (77mg / L), low residual sugar (< 2g / L), rich fruity taste and harmonious taste, the saccharomyces cerevisiae strain is preserved in China Type Culture Collection CCTCC on October 20, 2015, and the accession number is CCTCC NO:M2015627. The high quality red bayberry fruit wine is prepared by the following steps: raw material processing, bacteria activation, main fermentation and post fermentation. In the fermentation process, no SO2 is added, and by sterilization for 5min at 100 DEG C, the method has a very significant effect on color and anthocyanin retention rate of the fermented red bayberry fruit wine.

Owner:JIANGNAN UNIV

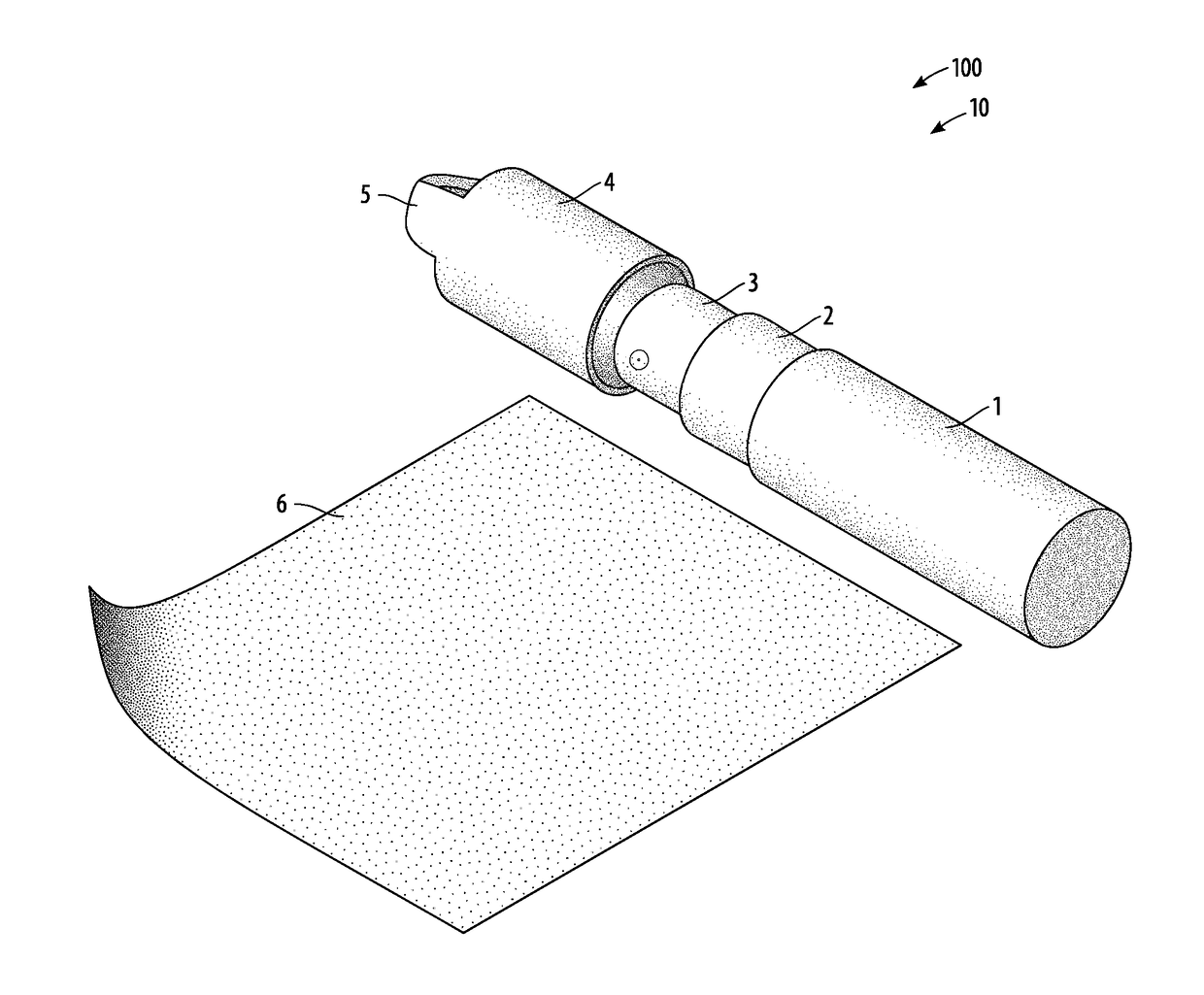

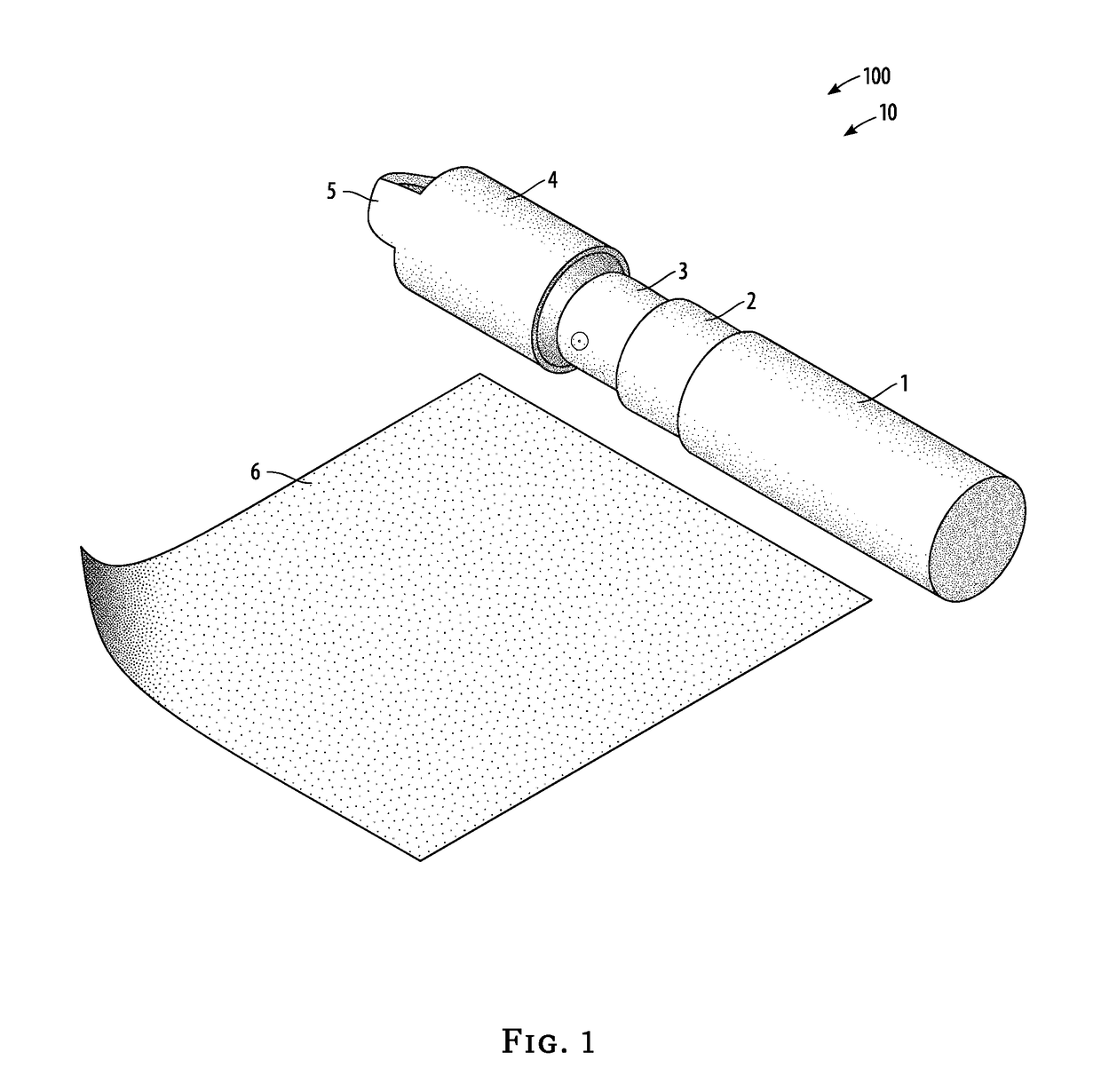

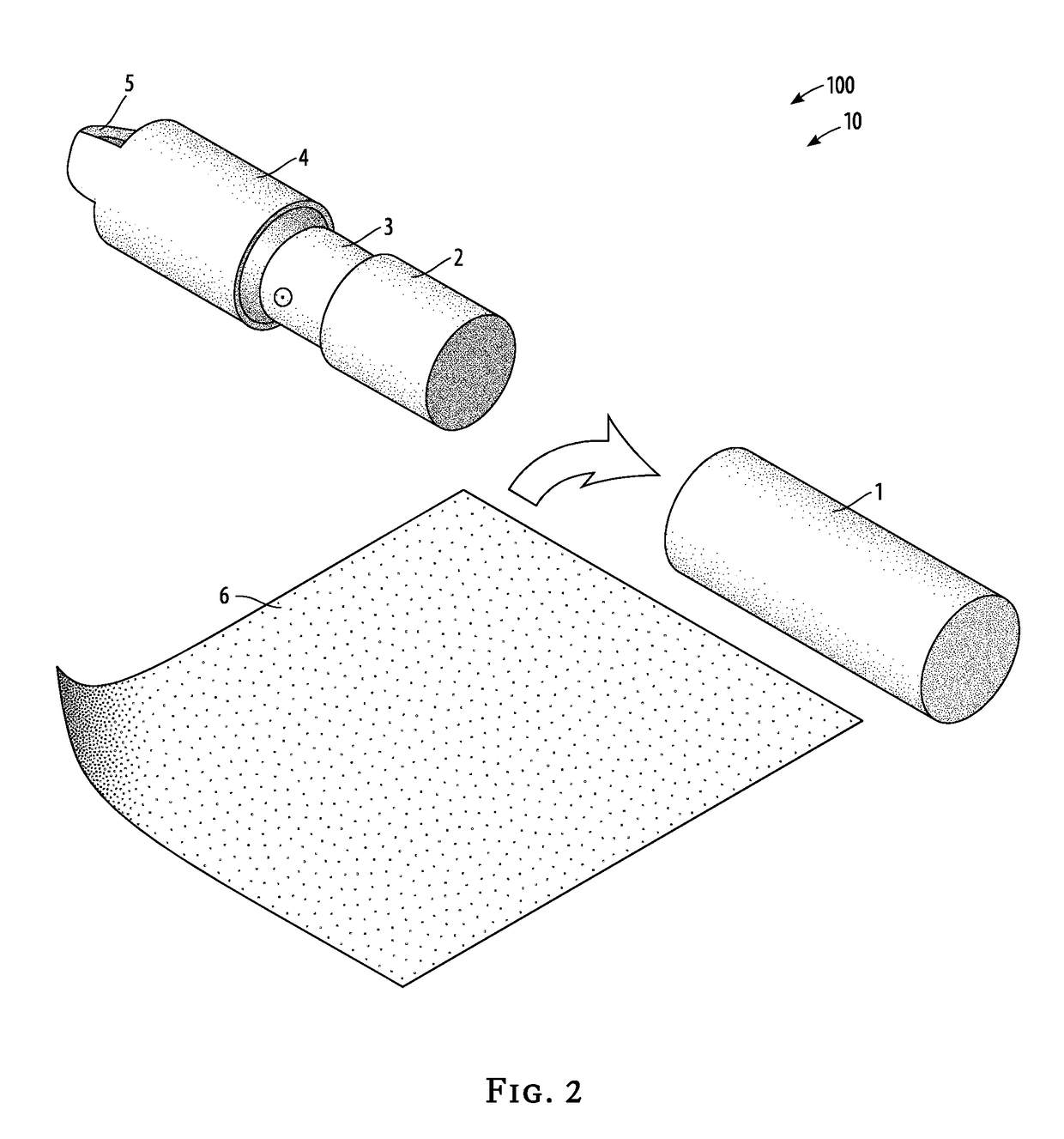

Electronic-device sanitizer product and method

InactiveUS20170320106A1Improve antibacterial propertiesHigh alcohol contentCarpet cleanersFloor cleanersAlcohol freeSprayer

An electronic-device sanitizer product and method for sanitizing cellphones, smartphones, and other portable electronic devices, that is easy to carry, easy to find when needed, and easy to use, allowing frequent cleaning, having an alcohol-free sanitizing liquid, a misting sprayer, and a microfiber material for distributing and absorbing the sanitizing liquid, all enclosed in a slim tube-shaped package that can be carried on a keyring. Optionally, the sanitizing liquid can be provided with any of a number of distinctive scents that will be imparted to the electronic device.

Owner:CELLSOAP LLC

Method for making fresh gastrodia elata fermentation wine

InactiveCN101255391ANot easy to extractNot easy to brownAlcoholic beverage preparationYeastProteinase activity

A preparation of fresh gastrodia tuber fermented wine, including washing gastrodia tuber, immersing with SO2 aqueous solution, grinding paste, adjusting acidity in pH value range of 3.0-6.0, sugar degree between 22%-38%, carrying out enzymolysis with pectic enzyme of 40-65ppm and protease of 20-50ppm, adding yeast, fermenting of 22 days with temperature controlled in 18-22 DEG C, separating wine stone, storing naturally, gastrodia tuber fermented wine is obtained with alcohol strength between 8%(V / V) and 18%(V / V) after aging with ultrasonics.

Owner:XINJIANG YUZUN LIQUOR

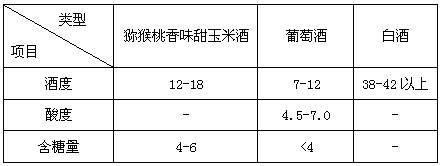

Brewing method of kiwi-flavored sweet corn wine

InactiveCN102586057ATaste and texture are mellow and harmoniousHigh alcohol contentMicroorganism based processesAlcoholic beverage preparationBiotechnologyKiwi fruit

The invention discloses a brewing method of kiwi-flavored sweet corn wine. The brewing method comprises the steps as follows: selecting fresh brewing sweet corn ears which are pollinated 25 days before, adding water, homogenizing to obtain sweet corn juice, and cleaning and homogenizing green kiwi fruit to obtain kiwi raw juice; mixing 75-85% of brewing sweet corn juice with 25-15% of pea juice to obtain a distiller's yeast culture medium, inoculating with yeast subjected to slant culture, and carrying out progressive amplification culture in distiller's yeast seeding tanks to obtain liquid distiller's yeast; adding the kiwi raw juice, the brewing sweet corn juice and the liquid distiller's yeast into a fermentation tank, fermenting at 15-20 DEG C for 21-14 days, harrowing and supplementing white granulated sugar with a ratio of 8.5-17% on the 7th -10th day of fermentation, filtering, and carrying out microwave treatment on the filtrate to obtain kiwi-flavored sweet corn wine base; pumping the kiwi-flavored sweet corn wine base into an aging tank to be stored at 16 DEG C below for more than 18 months; and adding sweet corn Brandy of which the amount accounts for 3-5% the weight ofthe aged sweet corn wine to obtain the kiwi-flavored sweet corn wine. The obtained kiwi-flavored sweet corn wine has kiwi fruit aroma and rice wine mellowness, is moderate in alcohol degree, mellow, elegant and nutrient, and satisfies the fashion of health-care driving.

Owner:窦秉德

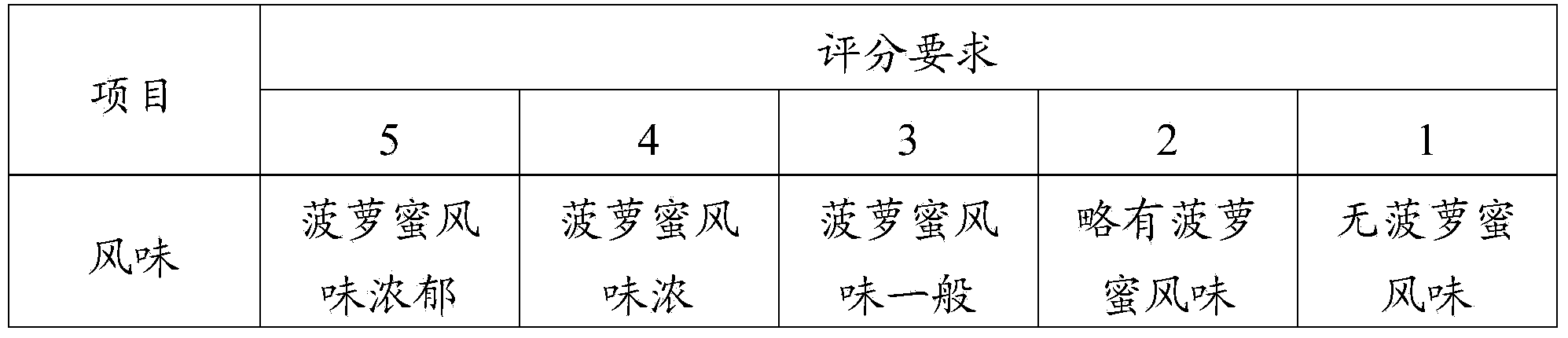

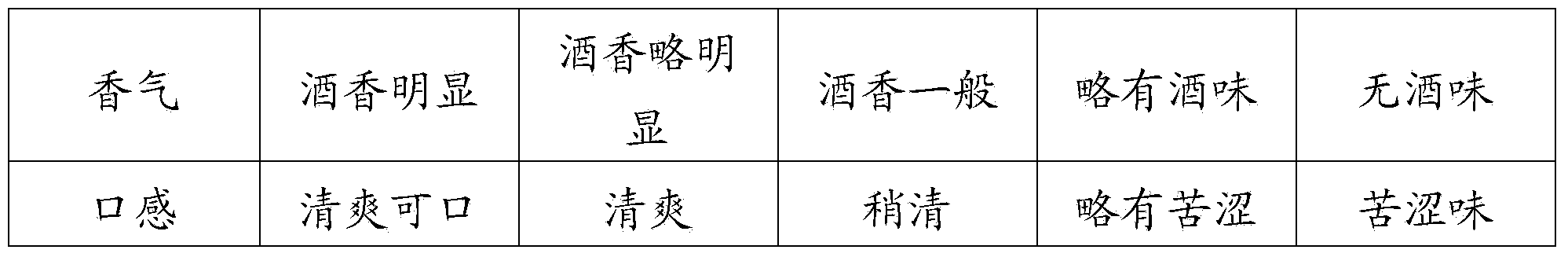

Jack fruit wine and preparation method thereof

ActiveCN103710214ARich flavorHigh alcohol contentAlcoholic beverage preparationFruit wineHydrolysate

The invention relates to the technical field of making wine, and particularly relates to jack fruit wine and a preparation method of the jack fruit wine. The method comprises steps of mixing peeled jack fruit with water and preparing into pulp; then adding amylase, cellulose and pectinase into the pulp for enzymolysis so as to obtain enzymatic hydrolysate; then mixing with water and sugar, sterilizing so as to obtain mixed liquor; adding saccharomycetes into the mixed liquor for anaerobic fermentation so as to obtain fermented liquid; filtering, sterilizing and ageing the fermented liquid so as to obtain the jack fruit wine. The preparation method is simple and has high use ratio of the fruit; the jack fruit wine prepared by the method has low alcoholic strength, rich jack fruit flavor and highlighted bouquet, and is fresh and cool.

Owner:广东桑醇酒业有限公司

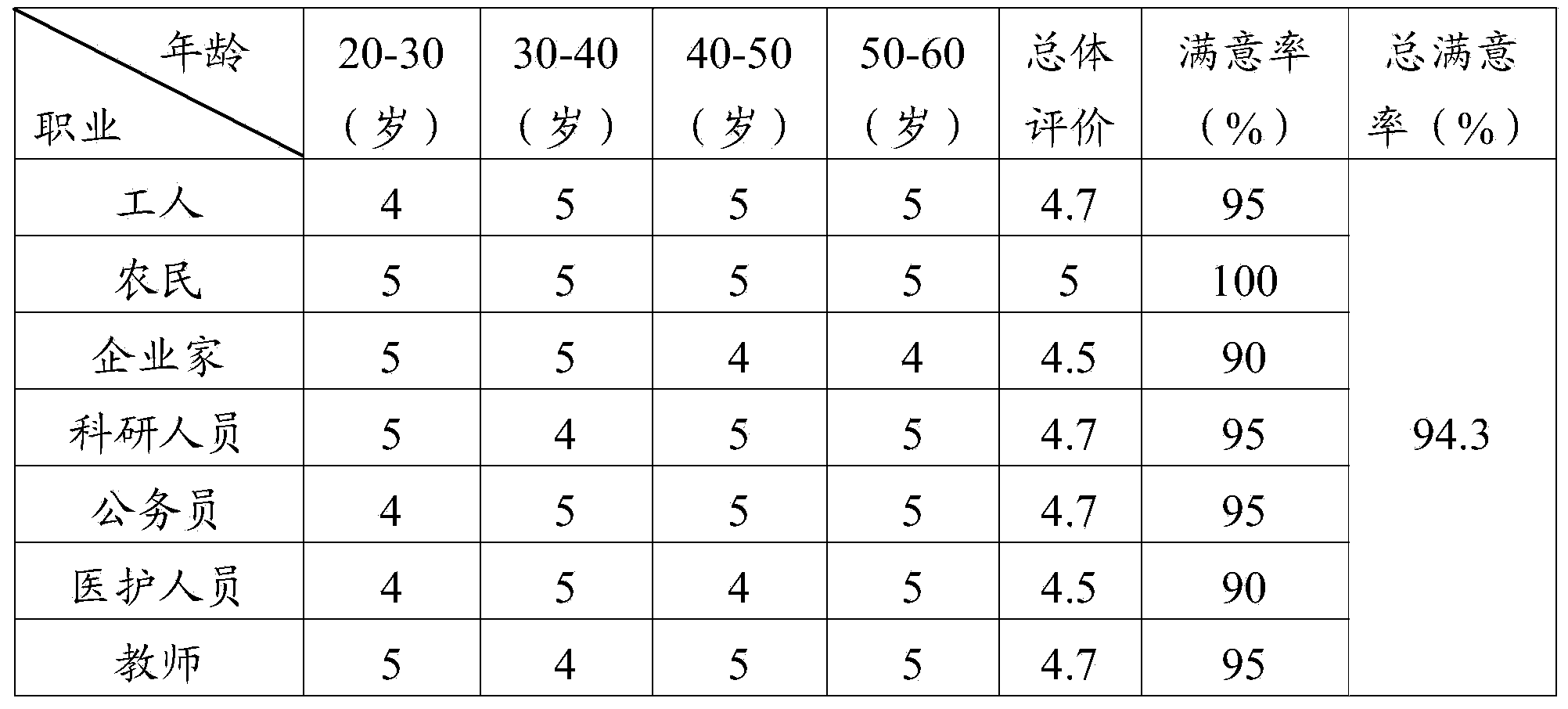

Novel brewing process for sweet osmanthus rice wine

The invention discloses a novel brewing process of sweet osmanthus rice wine, which comprises the following steps: (1) steaming rice, adding rice-koji and sweet osmanthus to the steamed rice, and carrying out diastatic fermentation; (2) after diastatic fermentation of rice, rice-koji and sweet osmanthus, separating fermented rice wine juice and rice wine vinasse; (3) adding the rice wine juice and water to rice wine in a certain ratio, and simultaneously adding yeast to the rice wine for fermenting; and (4) filtering fermented rice wine, and canning to obtain a finished product. By adopting the process, steamed rice and sweet osmanthus are fermented simultaneously and are formulated in a strict ratio, the fragrance of sweet osmanthus is retained and fused into the rice wine together with nutrients, and the mouth feel of rice wine is improved. Glutinous rice and sweet osmanthus are supplementary in nutrients, so that the sweet osmanthus rice wine is golden and clear in appearance, dense in wine smell and sweet in mouth feel. After canning to obtain the finished product, water bath sterilization is performed, so that the sterility and health of the sweet osmanthus rice wine can be guaranteed.

Owner:HUBEI GRANNY MI BIOTECH CO LTD

Sweet litchi wine and production method thereof

InactiveCN101735920AIncrease Natural BrixIncrease acidityAlcoholic beverage preparationMicroorganism based processesFruit juiceFiltration

The invention belongs to the field of food fermentation, and relates to a sweet litchi wine and a production method thereof. The production method comprises the following steps: juicing pulp of litchi at the temperature of between 0 and 10 DEG C, adding biological enzyme for hydrolysis and clarification, performing ultra-filtration and concentration on the juice, and adjusting the sugar degree of the concentrated juice to between 270 and 350g / kg and the total acid to between 4 and 7g / kg; and adding Saccharomyces cerevisiae seed liquid into the juice, fermenting at low temperature until the alcoholic strength is between 10 and 14 percent, clarifying, filtering, and fine filtering to remove bacteria to obtain the finished product wine. Under the condition of not adding exogenous sugar and acid, the method adopts low-temperature long-time fermentation, so the brewed litchi wine has high alcoholic strength, maintains high nutrient content simultaneously, and has the advantages of moderate sweetness and acidness, fine and mellow mouthfeel, elegant litchi aroma, attractive color and lustre, and limpidity.

Owner:HAINAN UNIVERSITY

Manufacturing method for scorch-aroma selenium-rich purple hybrid glutinous rice wine

InactiveCN104611168ALower sugar contentHigh alcohol contentAlcoholic beverage preparationRoom temperatureFermentation

A related manufacturing method for scorch-aroma selenium-rich purple hybrid glutinous rice wine comprises the following steps: selecting selenium-rich purple hybrid glutinous rice and common glutinous rice as raw materials according to the weight ratio of 3:1-3.5:1, airing the raw materials for 1 h-3 h and roasting; immersing the roasted raw materials for 3 h-5 h; boiling the immersed raw materials for 20 min-40 min; cooling the cooked raw materials to 30 DEG C-32 DEG C and draining water; weighting a wine starter accounting for 0.8%-1.0% by weight of the raw materials, grinding the wine starter and uniformly spreading into the drained raw materials, uniformly stirring, putting into a container and nesting; putting the container in an environment with the temperature of 30 DEG C-32 DEG C, performing saccharification fermentation for 48 h-50 h, so as to form a mixture of rice wine and wine lees; transferring the mixture subjected to saccharification fermentation to a room-temperature environment, standing for 24 h, and performing after-ripening fermentation; putting the mixture subjected to later-aging fermentation into a wine basket, squeezing at a pressure of 900 Pa-1000 Pa so as to separate rice wine and wine lees, precipitating squeezed-out rice wine for 8 h-10 h, and then putting in a wine jar and sealing.

Owner:XIHUA UNIV

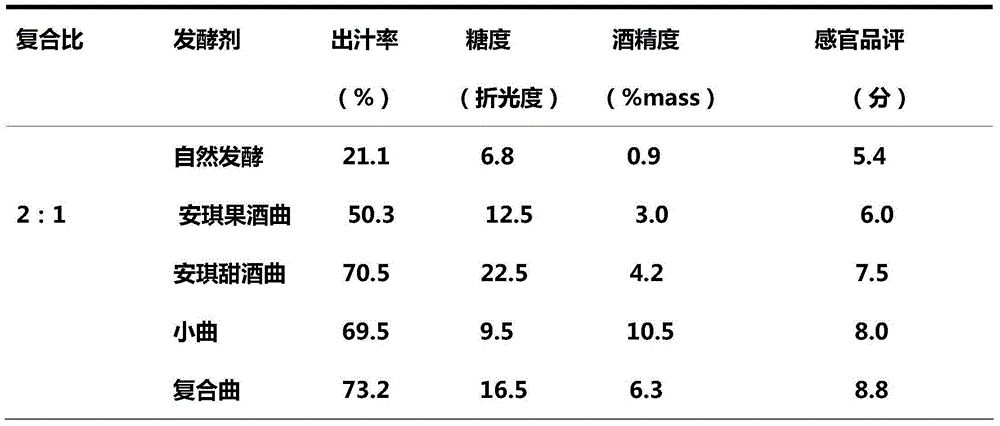

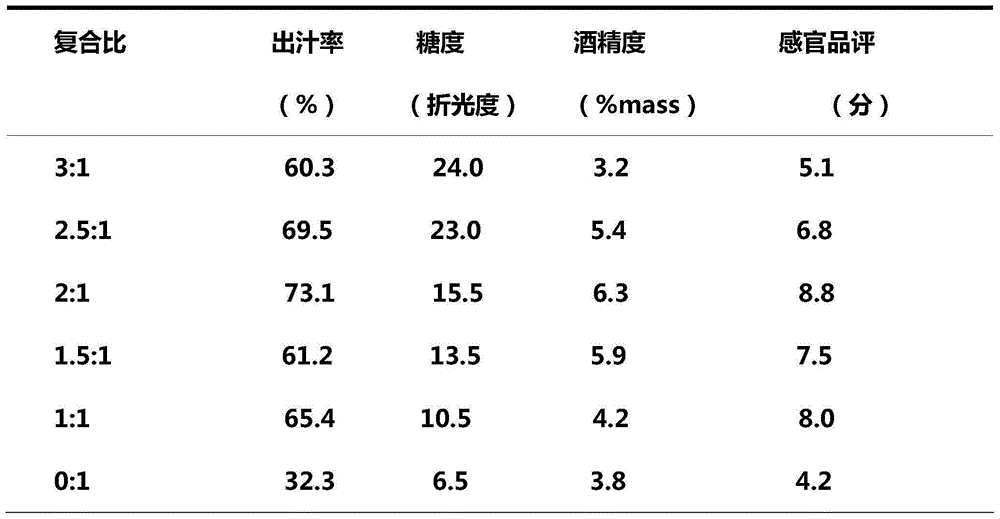

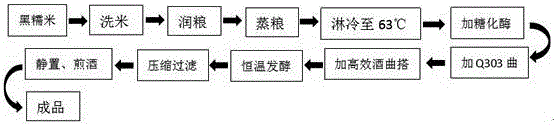

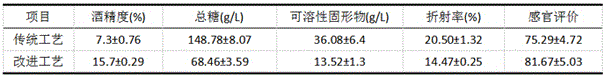

Black glutinous rice wine brewed by saccharifying enzyme and microorganisms and preparation method thereof

InactiveCN105420034AEfficient conversionMellow and sweet tasteAlcoholic beverage preparationMicroorganismRhizopus

The invention discloses black glutinous rice wine brewed by a saccharifying enzyme and microorganisms and a preparation method thereof. The method comprises the following steps: washing black glutinous rice serving as a major raw material, wetting the rice, steaming the rice, cooling the steamed rice in a rinsing way, and adding the saccharifying enzyme to saccharify in a heat preserving way; adding a certain amount of Q303 rhizopus saccharifying koji and efficient yeast fermentation koji; and carrying out the procedures of constant-temperature fermentation, squeezing, filtering, standing and boiling to obtain finished black glutinous rice wine. Compared with the conventional process, the black glutinous rice wine obtained by the method has the advantages that the fermentation time is shortened remarkably, the total sugar content is transformed effectively, the alcoholic strength is improved remarkably, the content of soluble solids in the wine is lowered, the black glutinous rice wine tastes mellow, sweet and unique and has the flavor of the black glutinous rice, the sensory quality is improved, and the industrial production of the black glutinous rice wine has a deep development potential and a wide market prospect.

Owner:GUIZHOU UNIV

Preparation method of honey and chrysanthemum alcoholic drink and product prepared by preparation method

InactiveCN106010911ASolve the waste situationIncrease productivityAlcoholic beverage preparationChlorogenic acidAdditive ingredient

The invention discloses a preparation method of honey and chrysanthemum alcoholic drink and a product prepared by the preparation method, and aims to solve the problems that as the conventional chrysanthemum wine is extracted and prepared by modes of soaking or fermentation and the like, functional ingredients in chrysanthemum are not extracted or utilized effectively, physiological activity of the chrysanthemum are not played well, the conventional chrysanthemum wine is single in variety, chrysanthemum is generally used as an ingredient, and the alcoholic content is generally high. Chrysanthemum morifolium is used as a main raw material, an ultrasonic extraction technology is used, extraction efficiency of the functional ingredients of the chrysanthemum is improved, meanwhile, honey is used as an auxiliary material, and the functional ingredients of the chrysanthemum and the honey are blended with base liquor, so that the honey and chrysanthemum alcoholic drink with a certain healthcare function is prepared. Plant components in the chrysanthemum morifolium are extracted in a targeted manner, the content of chlorogenic acid is taken as a standard, an extraction technology is optimized, so that ingredients in the chrysanthemum morifolium are fully utilized, and the quality of the product is guaranteed. Meanwhile, the honey and chrysanthemum alcoholic drink is short in production period, time is saved, energy is also saved, efficiency is high, and utilization efficiency of the chrysanthemum morifolium which is used as a medicine-food resource is improved effectively.

Owner:SICHUAN AGRI UNIV +1

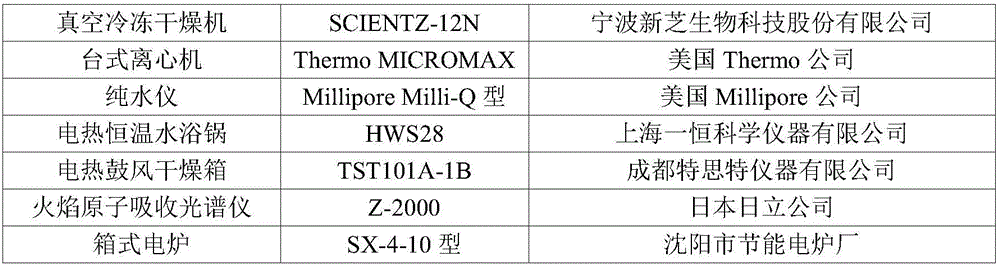

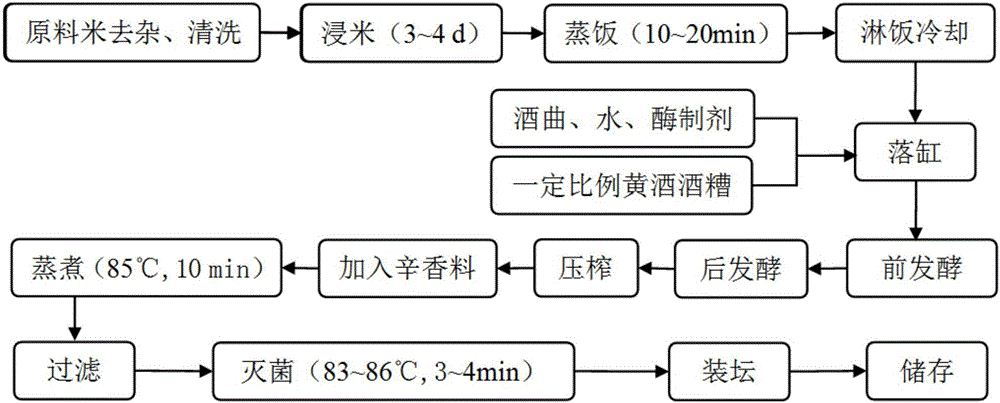

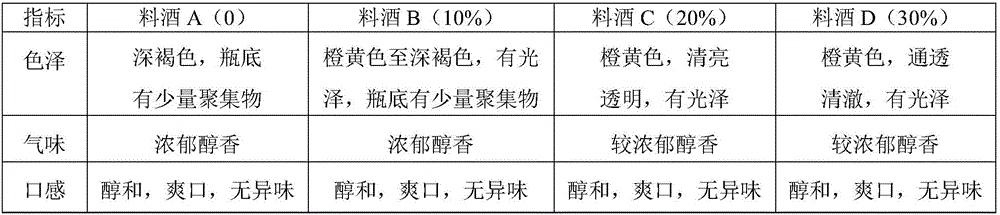

Method for producing cooking wine by replacing part of rice with waste yellow wine lees

InactiveCN106072415AGood colorNitrogen increaseYeast food ingredientsNatural extract food ingredientsRice dishesEngineering

The invention discloses a method for producing cooking wine by replacing part of rice with waste yellow wine lees. The method comprises the following steps that firstly, polished round-grained rice is soaked for 3-4 d and steamed in a steaming pot under the normal pressure for 10-20 min, rice drenching and cooling are conducted, and the rice is added into a brewing tank; the solid waste yellow wine lees of a certain proportion are crushed and then added into the brewing tank from a feeding port; enzymatic-qu and water are evenly mixed and then added into the tank together with raw material rice for primary fermentation, the primary fermentation temperature is controlled to be 28-32 DEG C, the primary fermentation time is 4-12 d, and cooling and stirring are conducted once every 6-8 h; then the product obtained after primary fermentation is transferred into a secondary fermentation tank, secondary fermentation is conducted for 50-60 d, and then squeezing is conducted; and spices and base liquor obtained after squeezing are placed in the steaming pot to be heated, heating is stopped when the temperature in the pot reaches 85 DEG C, after heat preservation is conducted for 10 min, filtering is conducted through a diatomite filtering machine to obtain cooking wine filtrate, the cooking wine filtrate is sterilized at the temperature of 83-86 DEG C for 3-4 min, bottling is conducted, and thus the finished cooking wine is obtained.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Method for brewing grape-flavor sweet corn sake

InactiveCN103666956AGreat tasteBest Technical ParametersAlcoholic beverage preparationBiotechnologyYeast

A method for brewing a grape-flavor sweet corn sake comprises the following steps: selecting fresh brewing sweet corn clusters pollinated 25 days ago, adding water and homogenizing to obtain sweet corn juice, cleaning, airing and homogenizing grape with seeds to prepare grape neat juice, mixing sweet corn juice of 75%-85% and pea juice of 25%-15% to serve as a distiller's yeast culture medium, adding a yeast subjected to slant culture, expanding the cultivation step by step through a distiller's yeast seeding tank to obtain a liquid distiller's yeast, adding the grape neat juice, the sweet corn juice and the liquid distiller's yeast into a fermentation tank, fermenting at 15-20 DEG C for 21-14 days, adding water after fermentation for 7-10 days, supplementing white granulated sugar, filtering, conducting microwave treatment on the filtrate to obtain a grape-flavor sweet corn raw wine, pumping the grape-flavor sweet corn raw wine into an ageing tank, reserving at the temperature of below 16 DEG C for more than 18 months, adding sweet corn brandy of which the weight is 3-8 % of that of the aged sweet corn wine into the aged sweet corn wine to obtain the grape-flavor sweet corn sake. The grape-flavor sweet corn sake is naturally golden in color, has the fruity flavor of grape and the faint scent of corn and is unique in style and moderate in alcohol content.

Owner:ENZYME ENG INST SHAANXI PROVINCE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com