Patents

Literature

792results about How to "Full-bodied" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

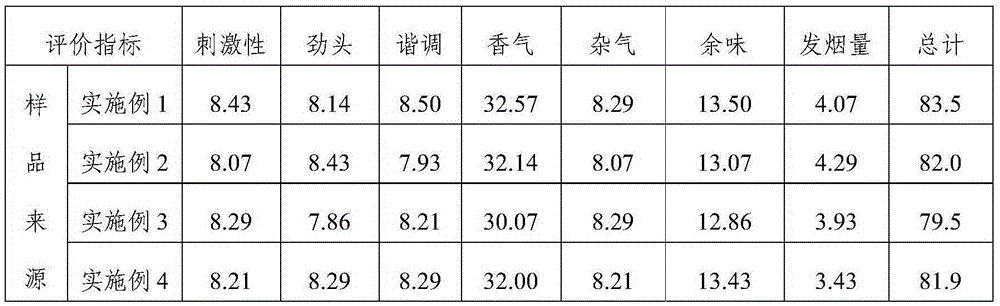

Fragrance type heating nonflammable tobacco product and preparation method thereof

InactiveCN105249524AThe fragrance is remarkableImprove your energyTobacco preparationTobacco treatmentTobacco productChemistry

The invention relates to a fragrance type heating nonflammable tobacco product. The fragrance type heating nonflammable tobacco product includes the following materials by weight: 1 to 6 parts of tobacco extract, 0.5 to 5 parts of tobacco flavor, 0.5 to 3 parts of taste and flavor conditioning agent, 0.5 to 6 parts of fragrance type liquor, 0.5 to 15 parts of fogging agent, and 75 to 95 parts of tobacco carrier. The invention also provides a preparation method of the tobacco product. According to the invention, the tobacco product is low in danger to a human body and an environment; the tobacco extract is added to improve the tobacco flavor concentration of the tobacco product at the low temperature, and meanwhile, smoke vigor and satisfaction can be improved; the fragrance type liquor is added to allow smoke to be fragrant, prominent, elegant and exquisite, and the liquor is rich and is long in aftertaste; the content of the fogging agent is improved, so that the amount of the smoke can be assured to the greatest extent when a consumer smokes at the low temperature, and the feel more similar to the feel of the traditional cigarettes is provided.

Owner:CHINA TOBACCO GUIZHOU IND

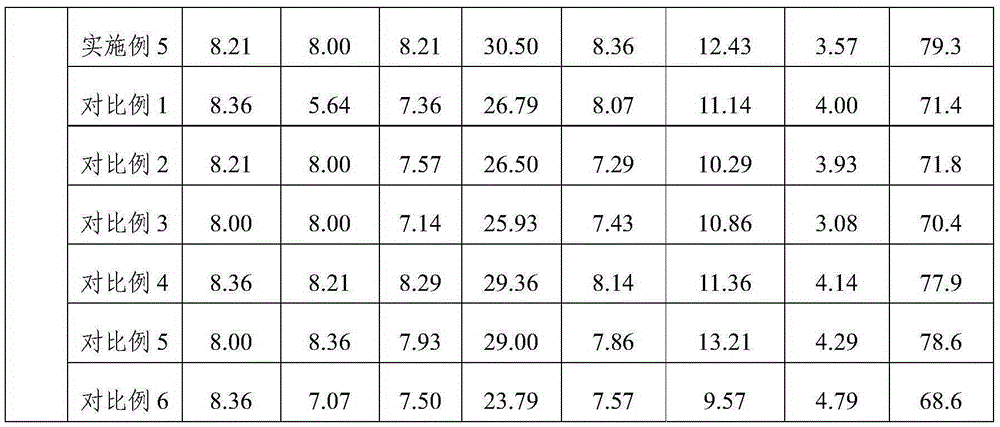

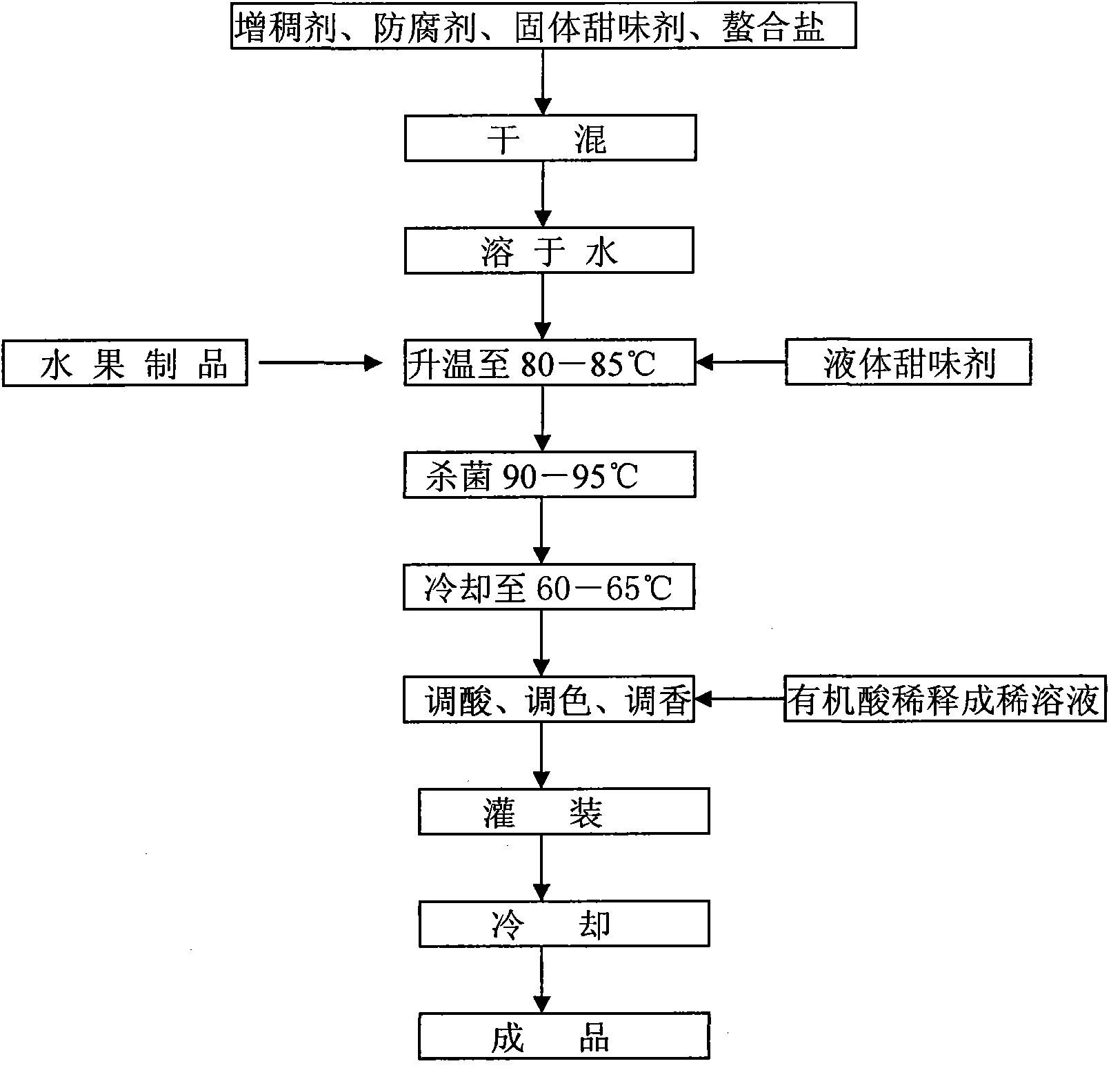

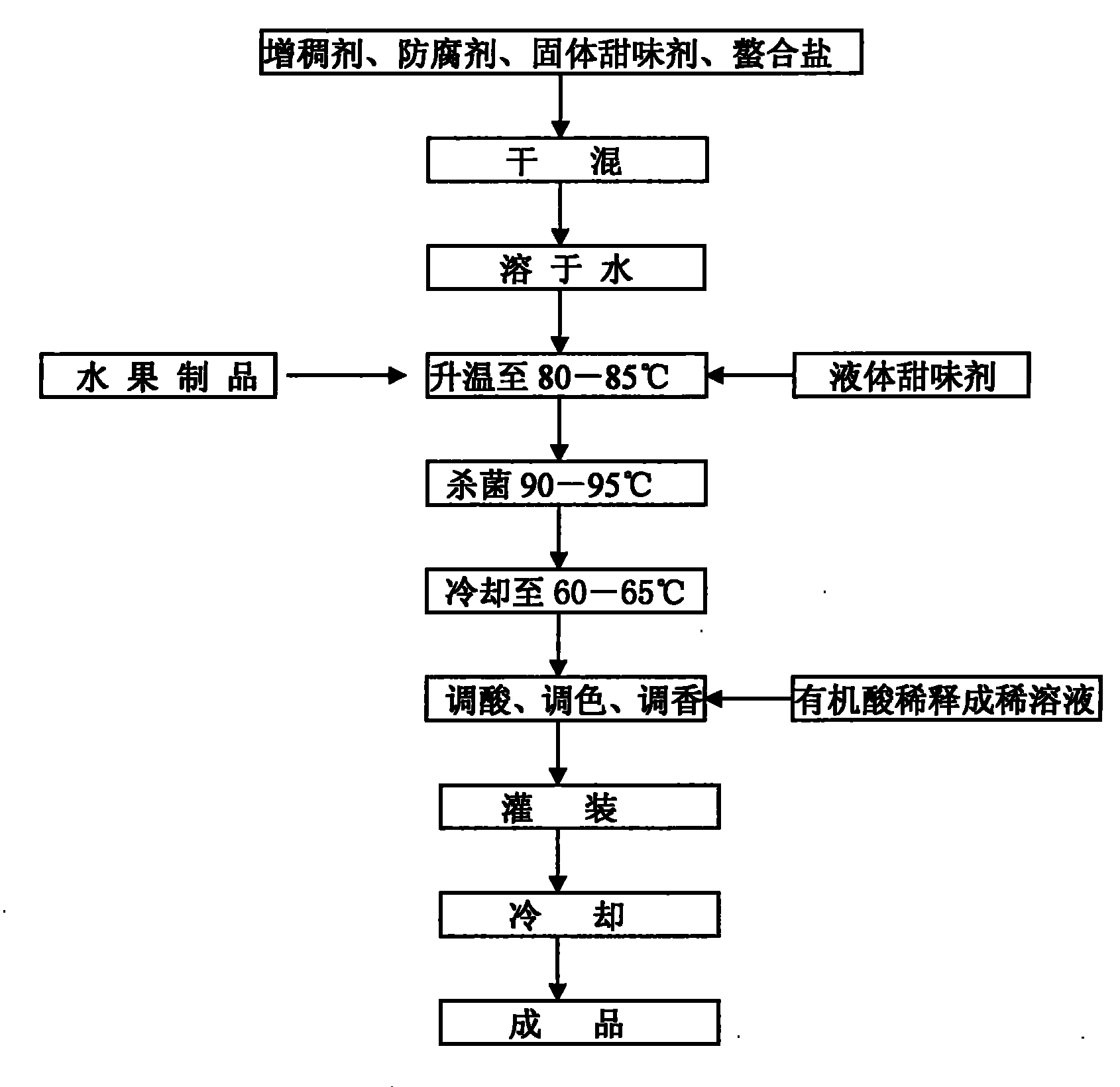

High-temperature baking resistant jam and preparation method and application thereof

ActiveCN101843306AImprove high temperature resistanceSolve prone to collapseBakery productsFood preparationOrganic acidFlavor

The invention discloses a high-temperature baking resistant jam and a preparation method and application thereof. The preparation method comprises the following steps of: uniformly mixing a thickening agent, a preservative, a solid sweetening agent and chelated salt, and dissolving the mixture in water; raising the temperature to a temperature of between 80 and 85 DEG C with continuous stirring, adding a liquid sweetening agent and fruit products, and sterilizing at the temperature of between 90 and 95 DEG C for 10 to 15 minutes; and cooling to the temperature of between 60 and 65 DEG C, and adding a food flavor, a food color and prepared organic acid solution to obtain the high-temperature baking resistant jam. The jam has good high temperature resistance, can be baked at a high temperature for more than 20 minutes without deformation, off-flavor and discoloration, has high transparency, and is suitable to be used as sandwich, stuffing, surface decoration and seasoning of baked goodssuch as cakes, bread and the like. The high-temperature baking resistant jam has the advantages of simpleness and wide sources of raw materials, simpleness and easy operation of the preparation method, and no need of complicated equipment, and can be produced by slightly adjusting the conventional production lines of manufacturers for fruit drinks and seasonings.

Owner:广州合诚实业有限公司

Method for producing acerbity-removing persimmon wine

ActiveCN101215498AReduce astringencyTypical styleAlcoholic beverage preparationMicroorganism based processesYeastAlcohol

The invention discloses a production method for persimmon wine to remove acerbity, which comprises the following procedures: (1) selecting fruits, cleaning and beating; (2) protecting the color; (3) enzymolysising; (4) removing acerbity and clarifying; (5) adjusting ingredient; (6) fermenting; (7) ageing; (8) filtering, filling in bottles and sterilizing; (9) stocking, wherein removing acerbity and clarifying is completed via charging 0.3-0.6g gelatin into one kilogram persimmon juice, standing for 30-40 minutes, clarifying and filtering. The invention protects the color of persimmon juice and reduces oxidation by adding ascorbic acid and citrate, applies gelatin to remove acerbity and clarify, which can effectively remove acerbity and suspended granules in persimmon juice and enable persimmon wine without acerbity and to be easily clarified,) and employs brewing dry yeast to ferment at higher temperature, which has short ferment period. The persimmon wine is clear, transparent, lucidus and free of sediment, which has typical style, good taste, pure flavour, coordinated alcohol and acerbity, full wine body, tasty, good aftertaste, no objectionable odour, fresh persimmon flavour and wine flavour.

Owner:ZHONGKAI UNIV OF AGRI & ENG

Chicken essence and preparation method thereof

ActiveCN103750254ALong storage timeGreat tasteFood homogenisationFood dryingMaillard reactionMonosodium glutamate

The invention relates to a preparation method of chicken essence. The method comprises the steps of weighing chicken breast and chicken skeleton, adding water, boiling at high temperature, and then, passing through a colloid mill, so as to obtain colloidal chicken juice; hydrolyzing the colloidal chicken juice, then, carrying out enzyme deactivation and filtrating, so as to obtain enzymolysis chicken juice; uniformly mixing the enzymolysis chicken juice, L-cysteine hydrochloride, ribose, L-proline, xylose, dextrose monohydrate, L-glycine, water and chicken oil, and then, adding the mixture into a reaction kettle for Maillard reaction, so as to obtain a chicken juice reactant; uniformly mixing the chicken juice reactant, salt, white granulated sugar, monosodium glutamate, modified starch, maltodextrin, cyclodextrin, water, I+G, chicken oil and chicken flavoring base, then, passing through a colloid mill, filtrating to obtain colloidal chicken cream, emulsifying the colloidal chicken cream, and then, carrying out spray drying on the emulsified colloidal chicken cream through a homogenizer, thereby obtaining the chicken essence. The invention further relates to a product of the preparation method of the chicken essence. Compared with the existing products, the chicken essence prepared by the method has the advantages that the chicken fragrance is unique, the flavor is harmonious, the taste of chicken is strong and full, and the fragrance and the flavor can be of long-term coexistence.

Owner:GUANGZHOU TIANHUI FOOD

Preparation method of tea liquor

The invention relates to a preparation method of tea liquor, which comprises the following steps of: 1) preparation of tea leaf liquid; 2) preparation of sticky rice mash; 3) preparation of distiller's yeast; 4) mixed fermentation of the tea leaf liquid and the sticky rice mash; 5) distillation, aging, filtration and filling to obtain finished products. The preparation method of the tea liquor has the advantages of simplicity in preparation and easiness in realization of industrialization. The prepared tea liquor not only has the fragrances of fermented liquor and tea leaves, but also reserves the nutritive values of the tea leaves and sticky rice, tastes soft, full-bodied, mellow and fine, can take the effects of preventing diseases and building bodies when the tea liquor is drunk frequently, and is nutritive healthcare liquor.

Owner:QINGDAO LANGYATAI GRP

Method for brewing a yellow wine using enzyme preparation and multi-bacteria

InactiveCN101676377AReduce rice crude fatFully fermentedAlcoholic beverage preparationIsomaltooligosaccharideNeutral protease

The invention provides a method for brewing a yellow wine using enzyme preparation and multi-bacteria, characterized in that: the concrete steps are that: soaking glutinous rice in clean water and adding lipase; steaming the glutinous rice and cooling, and adding alpha-amylase and neutral protease into the mixture and incubating and liquefying the mixture; adjusting the pH of mash and adding acid-resistant glucoamylase and incubating, saccharifying and cooling the mixture; adding bran koji, saccharomyces cerivisiae, ester-producing yeast and saccharifying and fermenting the mixture until the alcohol content is 12 degrees; continuously fermenting the mixture until the alcohol content is larger than 15 degrees and squeezing and filtering the mixture; adding stachyose, oligoisomaltose, honey,medlar leach solution and lycopene antioxidant into the filtered solution; processing the above mixture using a microwave alcoholic ripening machine and adding diatomite absorbent into the mixture and quickly freezing the mixture to clarify the mixture and then using a diatomite filter machine to filter the mixture and finally using membrane micro-straining technology to strain and degerm the product. The advantages of the invention are that: the wine taste is rich and strong; the wine body is full and soft and the wine is a health-care wine capable of adjusting the micro-ecological balance of the human digestive system.

Owner:SHANGHAI CHUANGBO ECOLOGICAL ENG

Preparation method for taste base peptide for steamed savory flavoring

The invention discloses a preparation method for taste base peptide for steamed savory flavoring, and belongs to the field of food additives. The method comprises the following steps: performing enzymolysis on defatty grouts to prepare raw material peptide; performing maillard reaction on the raw material peptide and sugar to prepare the taste base peptide; taking the raw material peptide and reducing sugar as raw materials, common salt and / or cysteine as accessories, and 6 to 16g / 100ml raw material peptide, 0.5 to 4.5g / 100ml reducing sugar, 2 to 10g / 100ml common salt, and 1 to 5g / 100ml cysteine as ingredients of the maillard reaction, controlling the temperature to 80 to 130 DEG C, and reacting for 0.5 to 3.5 hours; and cooling a reaction solution by ice water, and spray drying the reaction solution to obtain the taste base peptide. The taste base peptide is a light yellow powder base, and the content of taste potentiating peptide with 1,000-5,000 Da is as high as 20 to 30 percent; compared with a product prepared by the conventional method, the content of amino acid with bitterness of a product prepared by the method is decreased by 10 to 60 percent, and the browning rate is decreased by 40 to 80 percent; and the taste base peptide can be taken as an additive, applied to the steamed savory flavoring, and effectively overcomes the disadvantages of dark color, strong and pungent top note, inadequate mouthfeel, and the like of national savory flavoring products.

Owner:JIANGNAN UNIV

Preparation method for English pale ale

ActiveCN104232388AHigh alcohol contentFull bodiedBeer fermentationMicroorganism based processesYeastFiltration

The invention relates to a preparation method for English pale ale. The method comprises the following steps: (1) mixing raw materials and water,saccharifying the mixture, raising the temperature, stopping saccharifying, boiling the mixture with addition of hops in stages after filtration, and performing precipitation to obtain wort; (2) inoculating upper beer yeasts into the wort for fermentation, and storing the fermented product for 20 to 30 days to obtain fermentation broth after fermentation is stopped; (3) adding extract into the fermentation broth, inoculating lower yeast liquid, performing heat storage, and storing at reduced temperature to obtain the English pale ale. According to the method, a conventional process for the English pale ale is improved, and by secondary fermentation, the ale is more mellower on the premise that the high alcohol content and hop bitterness of the conventional ale are kept.

Owner:山东山科酵爵生物制品有限公司

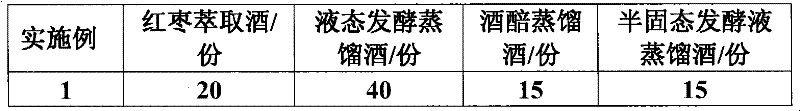

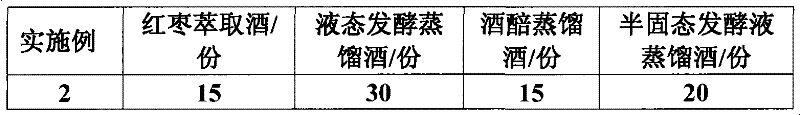

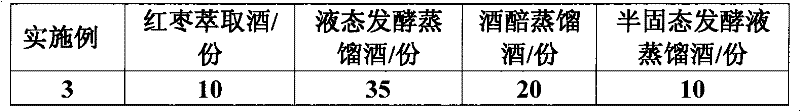

Red jujube health-care liquor and production process thereof

InactiveCN102051321AUnique flavorPromote circulationAnthropod material medical ingredientsAlcoholic beverage preparationAdditive ingredientChinese Jujube

The invention discloses red jujube health-care liquor and a production process thereof. Liquor, red jujubes, grape pips, roses and the like are selected as raw materials, and the red jujube health-care liquor is obtained by heat soaking, low-temperature soaking and repeated treatment of the raw materials. The red jujube health-care liquor is integrated with a plurality of functional raw materials, contains a plurality of effective ingredients such as general flavone, rhodioloside, crude polysaccharides and total saponins, and has multiple health-care efficacies of alleviating fatigue, enhancing immunity, promoting metabolism, promoting blood circulation, removing blood stasis, helping people maintain beauty and keep young, and removing chloasma. The red jujube health-care liquor is crystal and transparent, has unique flavor and health-care efficacy, and is suitable for long-term drinking. The product is clear, glossy, fragrant and pure and mild in taste, sweet and chill, refreshing and soft, and representative, and has a balanced body, long-lasting flavor and unique style. The production method is simple, raw materials used in preparing the red jujube health-care liquor are easy to obtain, and the red jujube health-care liquor is easy for popularization.

Owner:山西悦卜林创业投资有限公司

Raspberry and grape foaming wine brewing process

ActiveCN104789403AImprove freshnessLow costMicroorganism based processesWine preparationYeastFruit wine

The invention relates to a foaming fruit wine processing technology, particularly to a fresh sulfur-free raspberry and grape foaming wine and a production technology thereof. The raspberry and grape foaming wine is prepared from raspberry and grape according to certain proportion ratio through high-temperature extraction and low-temperature fermentation. A brewing method for the raspberry and grape foaming wine is simple to operate, and all processes of low-temperature fermentation, tank sealing pressure boosting, yeast separation and fragrance formation are finished in one fermentation tank; enough pressure is achieved by carbon dioxide generated by self fermentation, and no secondary fermentation is needed; in the whole brewing process, no sulfur dioxide or other preservative is needed, and the wine is beneficial to human health. The wine is bright red, ruby red, purple red, brownish red and the like, has special fruity flavor and wine flavor, is strong and harmonious in fragrance, pure and refreshing in taste, full in wine body, lasting in aftertaste and strong in typicality, and belongs to the fresh foaming wine.

Owner:宁夏泾河源农业科技发展有限公司

Method for making composite high-degree liquor combining sesame flavor, maotai flavor and strong aromatic flavor

ActiveCN102154072AReasonable collocationFull bodiedMicroorganism based processesAlcoholic beverage preparationWhite liquorChemistry

The invention discloses a method for making composite high-degree liquor combining sesame flavor, maotai flavor and strong aromatic flavor, which selects the following raw materials for making the liquor in part by weight: 90 to 120 parts of broomcorn, 8 to 12 parts of wheat, 20 to 30 parts of rice, 8 to 10 parts of bran and 10 to 15 parts of rice hull, and also selects various saccharification leavens. The method comprises the following process steps: moisturizing raw materials, steaming in clear soup, adding yeasts, piling at high temperature, performing double-wheel fermentation in a pit with brick wall and mud bottom, distilling and storing. In the invention, the raw materials are mixed reasonably, the saccharification leavens made by mixing various yeasts are added to give full play to the respective characteristics of the yeasts, and the 50-to-70-degree white liquor combining the sesame flavor, maotai flavor and strong aromatic flavor is made by direct fermentation. The high-degree liquor with combined flavor reaches a balance among sesame flavor, maotai flavor and strong aromatic flavor, is mellow and full, and has a lingering aftertaste and prominent style.

Owner:QINGDAO LANGYATAI GRP

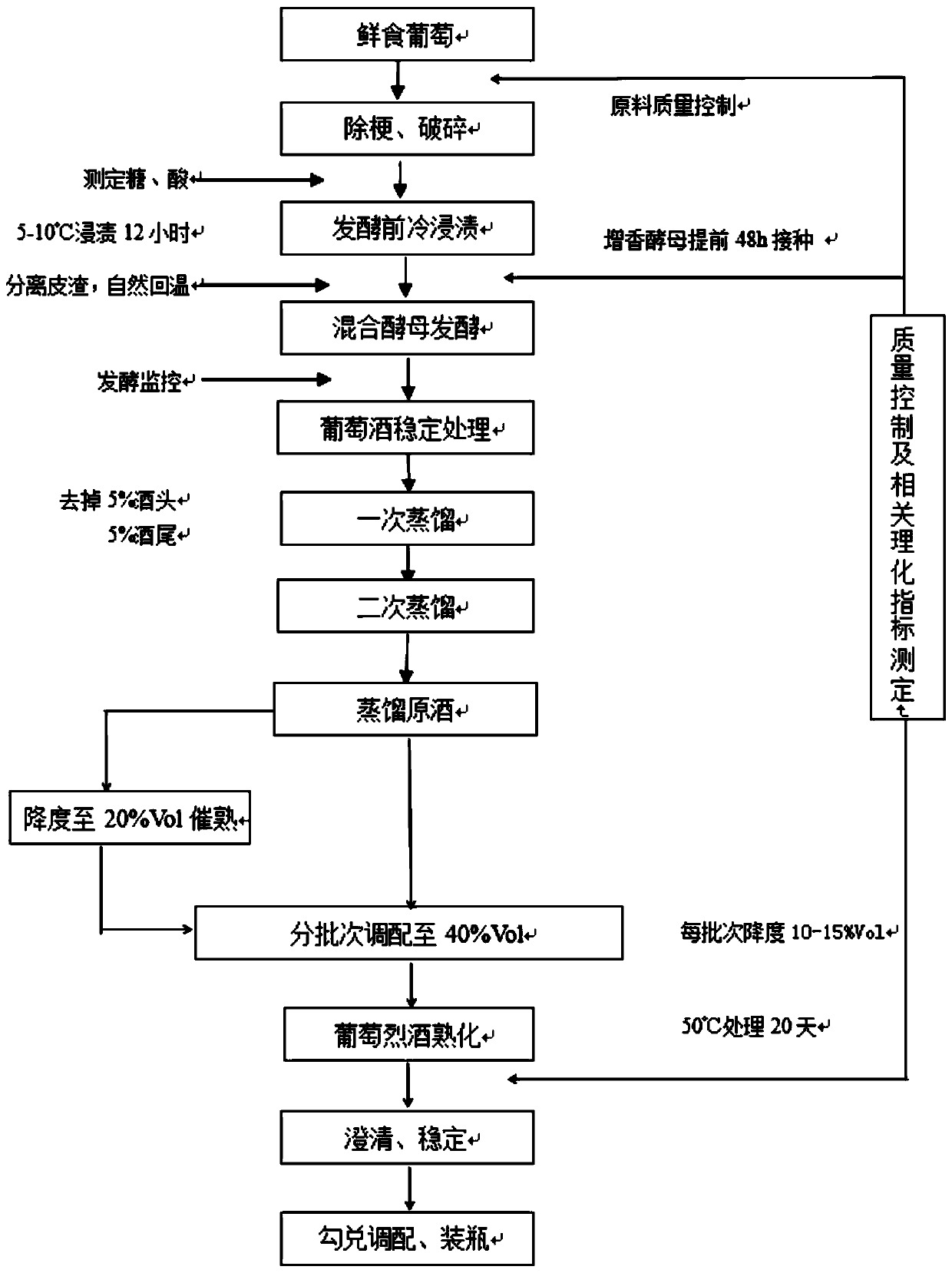

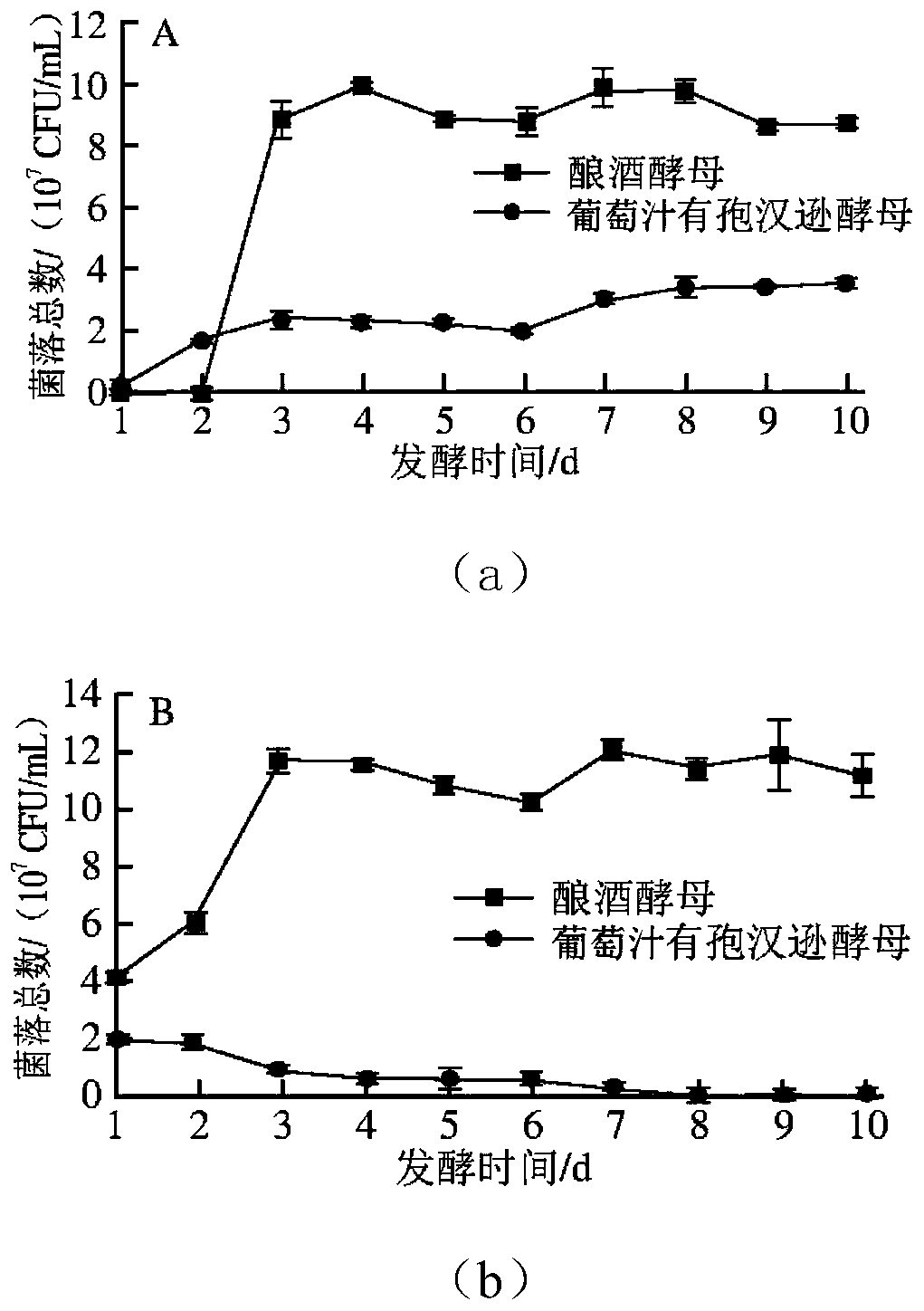

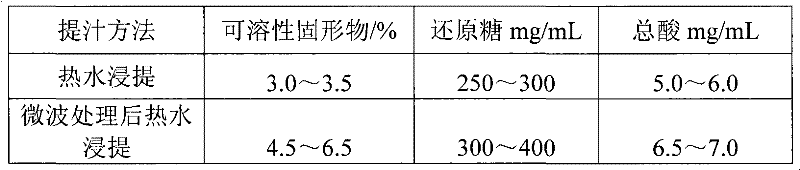

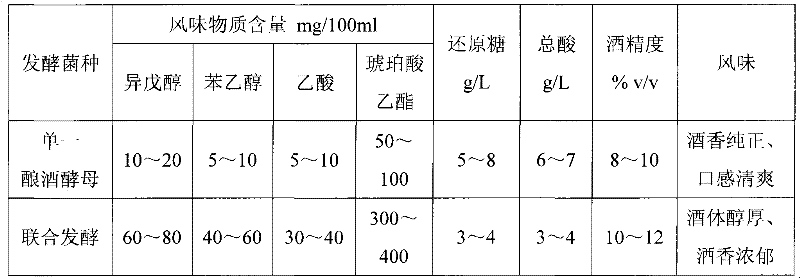

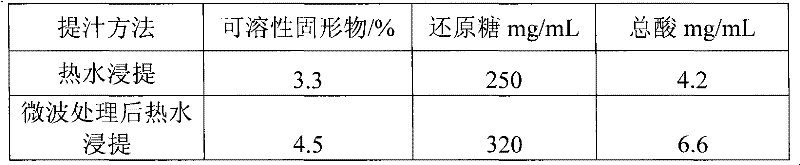

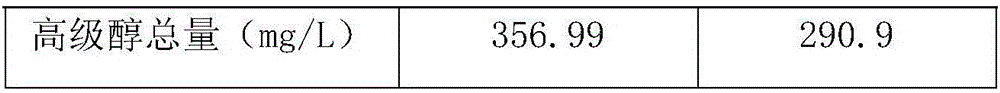

Aroma-enhancing brewing technology of table grape brandy

PendingCN110923080AFacilitated releaseImprove purityMicroorganism based processesWine preparationGrape juicesHanseniaspora uvarum

The invention relates to the technical field of brewing of wine and fruit wine, in particular to an aroma-enhancing brewing technology of table grape brandy. Through mixed fermentation of preferred Hanseniaspora uvarum and Saccharomyces cerevisiae, the content of a grape variety aroma component and the content of fermentation esters in fermented brut are improved, by optimizing parameters of a secondary distillation technology, off-flavors of fusel and organic acids are removed, and then optimal integration of alcohol-decreasing ageing and blending technologies is conducted. The aroma-enhancing brewing technology of the table grape brandy comprises the operation steps of (1) table grape raw material control, (2) cold soaking before fermentation, (3) grape juice clarification, (4) mixed fermentation, (5) brut stabilization treatment, (6) distillation, (7) alcohol-decreasing treatment of distilled brut, (8) wine ageing treatment, (9) clarification and stabilization, (10) blending and allocating, and (11) bottling.

Owner:镇江瑞德酒业有限公司

Raspberry compound health preserving wine and production process thereof

ActiveCN103275849APromotes nutrient absorptionFull bodiedMicroorganism based processesAlcoholic beverage preparationAlcoholSugar

The present invention relates to a raspberry compound health preserving wine, which comprises the following fresh fruits, by weight, 50-70 parts of red raspberry, 15-25 parts of black raspberry, 5-15 parts of mulberry, 1-10 parts of medlar, and 1-10 parts of blackcurrant. According to the present invention, the raspberry compound health preserving wine produced by using the formula and the production process meets the national dry wine standard, has characteristics of low sugar and low alcohol, and completely provides health preserving effects of various raw materials in the formula, wherein effectively components in the raw materials are completely extracted through low temperature wall breaking and yeast fermentation so as to easy nutrient absorption of drinking people. In addition, the raspberry compound health preserving wine has characteristics of full wine body, bright color and pleasant aroma, and completely reflects ideas of homology of medicine and food, and treatment before sick in the traditional Chinese medicine culture.

Owner:青岛富润康元健康科技有限公司

Red date fruit wine and method for preparing the same

InactiveCN101492640ARich in vitaminsFat-producing and flavor-enhancingAlcoholic beverage preparationMicroorganism based processesBiotechnologyYeast

The invention relates to a red date wine and a preparation method thereof. The red date wine is prepared by the components with the weight percentage as follows: 60 to 85 percent of Xinjiang ziziphus jujube cv. Huizao juice as well as 15 to 40 percent of Xinzheng ziziphus jujube cv. Huizao juice. The invention uses the advantages of red dates of different varieties to carry out composite mixing on the materials and employs secondary composite fermentation to brew the high quality red date fermentation wine with alcohol content larger than 20V / V. The red date wine fully applies and combines the medical value and fragrance of the Xinzheng ziziphus jujube cv. Huizao juice as well as advantage of the Xinjiang ziziphus jujube cv. Huizao juice that the high-sugar content is beneficial to fermentation; the primary fermentation of grape wine dry yeasts is beneficial to generating the fruit fragrance, the nutrition and the pigment of the red date; the aroma-producing yeast employed by after fermentation of the grape wine dry yeasts has the advantages of producing grease, increasing fragrance, removing foreign flavors, and leading a wine body to be full and harmonious.

Owner:河南省新郑金叶香料有限公司

Method for producing Maotai-flavor liquor through liquid fermentation

ActiveCN104120066AShorten the fermentation cycleReduce manufacturing costMicroorganism based processesAlcoholic beverage preparationAdditive ingredientFood flavor

The invention discloses a method for producing Maotai-flavor liquor through liquid fermentation and belongs to the technical field of liquor brewing. The method for producing the Maotai-flavor liquor comprises the following steps: unshelling, moderately smashing and cooking broomcorn, adding high temperature yeast powder to carry out pretreatment, adding water and ingredients to carry out the liquid fermentation and distilling after the fermentation is finished to obtain the Maotai-flavor liquor, wherein the fermentation process comprises the following three stages: 1, adding brewers yeast to carry out alcohol producing fermentation; 2, adding Maotai-flavor producing bacteria to carry out Maotai-flavor matter producing fermentation; 3, adding ester producing yeast to carry out esterification reaction. The method has the advantages that a traditional solid fermentation way is replaced by the liquid fermentation way to brew the Maotai-flavor liquor, so that the production cycle of the Maotai-flavor liquor is greatly shortened and the production cost is reduced; the Maotai-flavor liquor obtained through the method disclosed by the invention is yellowish and transparent, outstanding in Maotai-flavor, mellow in liquor body, long in aftertaste and high in content of total acid, total ester and total alcohol.

Owner:HUBEI UNIV OF TECH

Strong plant aroma type white spirit and preparation process thereof

InactiveCN1502685ASimple processSimple and fast operationAlcoholic beverage preparationWhite liquorWork in process

The present invention discloses a strong aromatic Chinese white liquor with plant fragrance. It contains (by wt%) 0.5%-60% of flavouring liquor and 40%-99.5% of strong aromatic Chinese white liquor with high alcohol content, and its taste is paratefull. Said invention also provides its preparation method.

Owner:SICHUAN SWELLFUN

Brewing method of red date wine through multi-strain combined fermentation

InactiveCN102051310AImprove qualityGreat tasteAlcoholic beverage preparationMicroorganism based processesPichia pastorisFruit wine

The invention discloses multi-strain combined fermentation red date wine and a brewing method thereof, which belongs to the technical field of brewing. The red date wine is produced by taking red date as raw materials through such processes as pretreatment, digestion, enzymolysis, sterilization, fermentation, aging and clarification. The adopted Candida, Kloeckera, Hanseniaspora and Pichia pastoris move at the early stage of fruit wine fermentation generally, so that a great deal of aromatic substances and special flavor components can be generated, the quality of fruit wine is improved, and positive impact is generated on the total flavour of the red date wine. Non-brewing yeast and brewing yeast are accessed at different fermentation stages, the species and content of the flavor substances in the date wine can be increased through the combined fermentation of multiple strains, thereby improving the mouthfeel of the date wine and the quality of the date wine; the date wine has unique style, rich wine body, sweet and pure bouquet, fresh mouthfeel and typicality.

Owner:太原市汉波食品工业有限公司

Method of preparing liquor seasoning wine or liquor seasoning liquid mainly to taste

InactiveCN101445776ASolve pollutionRecycle resourcesAlcoholic beverage preparationDipotassium hydrogen phosphateSodium acetate

The invention discloses a method of preparing liquor seasoning wine or liquor seasoning liquid mainly to taste by liquid state fermentation taking waste produced in solid-state fermentation liquor production as composite strain. The composite strain comprises Clostridium butyricum with strain number SICC1.91, Klinefelter Clostridium with strain number SICC1.13 and Pap Acetobacter with strain number SICC1.2; the composite strain fermentation medium is yellow water: tail water: groove liquid: spent wash=7-8:0.5-1:0.5-1:0.5-1, sodium acetate 1.5%, dipotassium hydrogen phosphate 0.04%, adjusting pH of ammonium bicarbonate to 6.5-7.0, adding 2% 95 degrees ethanol after sterilization; sterilizing 20 minutes under 105 degrees centigrade. The invention solves the pollution problem of the waste produced in solid-state fermentation liquor production process to the water environment, the added liquor being more coordinated, avoids the shortcomings that the added monomer products being easy to produce floating fragrance; the liquor has strong natural sense; the recovered strain mud and other residual nutrients are recycled in fermentation process, which avoids the secondary pollution.

Owner:SICHUAN YINFAN BIOTECH LTD

Brewing method of moso bamboo shoot wine

ActiveCN103409284AEfficient use ofHigh degreeAlcoholic beverage preparationMicroorganism based processesBamboo shootGeneral Appearance

The invention provides a brewing method of moso bamboo shoot wine. The brewing method comprises the following steps of (1) preparing materials and removing shells; (2) washing; (3) crushing; (4) distributing materials; (5) cooking; (6) saccharifying; (7) degrading cellulase and feeding sugar; (8) fermenting; (9) distilling; and (10) aging, mixing and packaging. The brewing method provided by the invention is simple in process and short in fermentation time; the general appearance of the brewed moso bamboo shoot wine is colorless, is bright and transparent and has no suspension matter and sediment; all tastes of the wine are coordinated and the wine is fragrant and pure, has a long-time sweet taste and is sweet and soft; the aftertaste is pure and cool.

Owner:HUNAN ACAD OF FORESTRY

Lychee liqueur and brewing method thereof

The invention discloses a lychee liqueur and a brewing method thereof. The brewing method comprises the steps of: squeezing lychee to obtain juice, adjusting the sourness of the juice, and carrying out low-temperature fermentation on the juice to obtain lychee fermented wine; carrying out component adjustment, low-temperature fermentation, distillation by stages, storage in a wine tank and aging storage in an oak tank on the lychee residues to obtain 68-72vol% lychee brandy; mixing the lychee fermented wine and the lychee brandy in a certain proportion, blending, freezing, testing and packaging to obtain a lychee liqueur finished product. The lychee liqueur obtained in the invention is golden in color, clear and transparent, and has pure and dense lychee flavor, wine flavor and oak flavorand soft, natural and mellow tastes.

Owner:广州市顺昌源酒业有限公司

Production method of strong aromatic Chinese spirits

ActiveCN102994317AIncrease contentDoes not affect styleAlcoholic beverage preparationMicroorganism based processesTetramethyl pyrazineHusk

The invention discloses a production method of strong aromatic Chinese spirits. The production method comprises the following steps of: preparing fermented grains by using 1000-1200 parts of unprocessed food grains, 100-200 parts of steamed rice husk steamed, and 4000-5000 parts of middle-level fermented grains fermented at the upper row; filling the fermented grains in a steaming bucket for cooking, mixing cooking wine of the fermented grains, fermented at the upper row while cooking the raw materials so as to obtain the cooked fermented grains and large dreg wine after ending cooking; taking out the cooked grain wine and placing for aeration cooling, adding 200-250 parts of middle-temperature Daqu, 30-50 parts of bacterial mouldy bran, firstly placing 1000-1200 parts of upper fermented grains fermented at the upper row in a pit, then placing 5500-6500 parts of the grain wine obtained in the previous step in a pit, and fermenting for 60-70 days; filling 1000-1200 parts of lower fermented grains fermented at the lower row in the steaming bucket for cooking, thereby obtaining double-turn wine; and after operating once according to the steps, mixing the large dreg wine and the double-turn wine obtained in the next turns to obtain the strong aromatic Chinese spirits. The production method has the advantages that the content of tetramethylpyrazine in the strong aromatic Chinese spirits is increased, and the style of the strong aromatic Chinese spirits is not affected.

Owner:山东景芝白酒有限公司

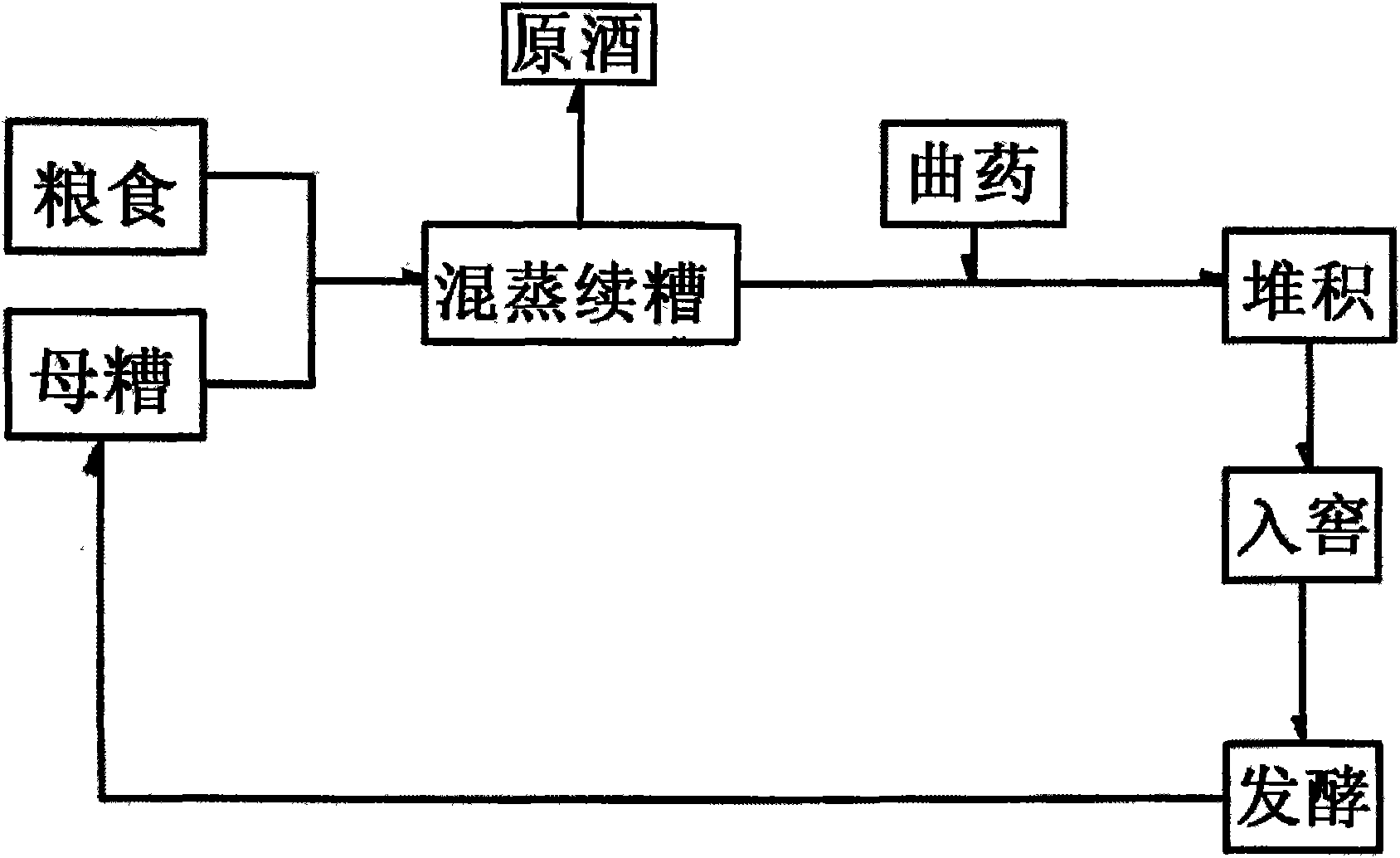

Method for producing multi-grain liquor of Luzhou-flavor and Maotai-flavor

The invention relates to a method for producing multi-grain liquor of Luzhou-flavor and Maotai-flavor, comprising the steps of taking grains, crushing the grains and then adding the grains in mother lees, uniformly mixing the grains, steaming the grains and the mixture of the mother lees in a mixing manner to continuously obtain the mother lees and distil out original liquor; adding a yeast in the distilled grains and the mixture of the mother lees, mixing uniformly, stacking, putting in a pit, and fermenting in the mud pit to prepare the mother lees, adding the mother lees into the grains for the next working procedure, and steaming the mixture in a mixing manner to continuously obtain the mother lees and distil out original liquor. The useful effects of the invention are that the product has strong multi-grain flavor of the multi-grain flavor type, the wine body is full bodied, mellow and compatible, and the aftertaste is clean. The method also has the advantages of the wine body produced by a Maotai-flavor technology that the wine body is exquisite and neat, the aftertaste is long and the Maotai-flavor is obvious. The technology fills up the blank of the single fermentation technology of multi-grain liquor of Luzhou-flavor and Maotai-flavor in China. The method is an innovation for the technology of liquor Luzhou-flavor and Maotai-flavor produced by blending original liquor after the original liquor is individually stored according to individual standard through the known Luzhou-flavor fermentation and Maotai-flavor fermentation in China.

Owner:四川省宜宾市叙府酒业股份有限公司

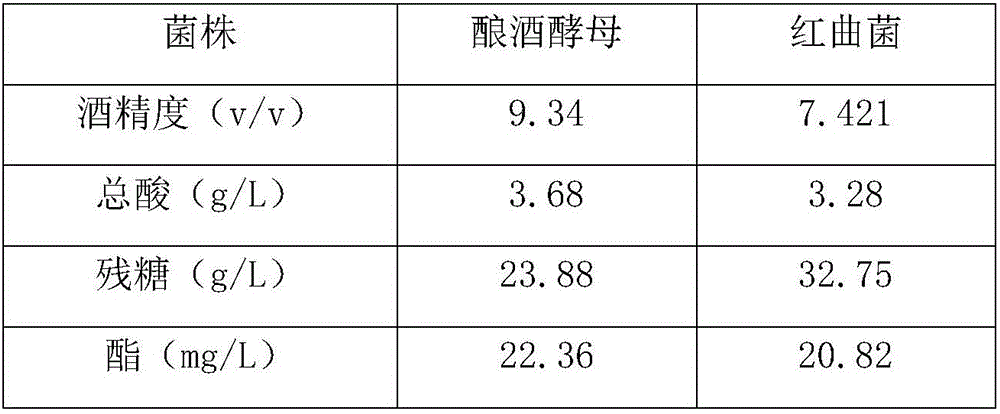

Monascus fruit wine and preparation method thereof

InactiveCN106520451AAbility to ferment alcoholReduce higher alcohol contentMicroorganism based processesAlcoholic beverage preparationFruit wineFlavor

The invention discloses monascus fruit wine and preparation method thereof. According to the monascus fruit wine, monascus is used as a leavening agent, fresh fruits are used as main raw materials, the fresh fruits are treated by a conventional method to obtain juice or pulp, the juice or pulp is inoculated with the monascus to be fermented, precipitate is separated, and the juice or pulp is subjected to ageing to obtain the monascus fermented fruit wine. The fruit wine is fermented by the monascus, most of reducing sugar in the juice can be converted into ethanol, and the alcohol fermenting ability is high. In a monascus alcohol fermenting process, metabolic by-products such as higher alcohols and esters are generated. Compared with brewer's yeast, the monascus has the characteristics that the content of the produced higher alcohols is low, but the ester production ability is not weak. In the brewing method, the monascus is used as the leavening agent, the ester content of the brewed fruit wine is high, and types of flavor substances are abundant. The monascus fruit wine has aroma, particular ester flavor of the monascus and full-bodied fruity flavor, tastes fresh, is clear in color and is full-bodied.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Purple skin onion wine and preparation process thereof

The invention discloses purple skin onion wine and a preparation process thereof, and belongs to the technical field of wine making. The invention discloses a purple skin onion wine technology. The purple skin onion wine comprises the following main raw materials in percentage by weight: 70 to 90 percent of fresh grapes, 5 to 20 percent of purple skin onion, and 5 to 15 percent of skin of purple skin onion. The purple skin onion wine is prepared by the following brewing working procedures of: 1, pulping and mixing; 2, performing alcoholic fermentation; 3, performing malic acid-lactic acid fermentation; 4, storing in an oak barrel; and 5, performing stability treatment, and finally, filtering, filling and bottling. The purple skin onion health-care wine is advanced in process, and has the advantages that the content of flavonoid substances is higher, the fragrance of onions is coordinated with the fragrance of wine, and the stability of the wine is higher; the purple skin onion health-care wine has the health-care effect of preventing arteriosclerosis and cardiovascular and cerebrovascular diseases; and the purple skin onion health-care wine has good economic and environmental protection benefits.

Owner:QILU UNIV OF TECH

Method for brewing Rosa roxburghii fruit and hollow plum compound fruit wine

The invention discloses a method for brewing Rosa roxburghii fruit and hollow plum compound fruit wine. The method comprises the steps of freezing and juicing, performing hydrolysis and impregnation, performing strain activation, regulating components, performing main fermentation, performing post-fermentation, aging, filtering, bottling and the like. Compared with the prior art, an alcohol degree of the compound fruit wine is higher than 13%vol, the colour and luster is light yellow, clear and transparent, the astringency flavor is reduced, the sugar content is lowered to 3-4g / L, the wine body is plentiful and complete, the compound fruit wine has compound fruit aroma of the Rosa roxburghii fruit and the hollow plum, is mellow and refreshing, and long in aftertaste.

Owner:GUIZHOU INST OF BIOLOGY

Persimmon wine and brewing method thereof

InactiveCN101798555ALess suspended particlesSimple filterMicroorganism based processesAlcoholic beverage preparationPectinaseYeast

Persimmon wine and a brewing method belong to the technical field of brewing science and engineering. The invention aims to solve the technical problem of providing the persimmon wine keeping the original flavor of persimmons and a brewing method of the persimmon wine. The process is as follows: 1. selecting fruit; 2. breaking and sterilizing; 3. adding yeast and primarily fermenting for 1d; 4. juicing and separating pomace; 5. adding sugar and secondarily fermenting; 6. filtering residue and can sealing; 7. clarifying with pectinase and filtering; and 8.cryotreating and canning. The persimmon wine is characterized in that the persimmon wine is faint yellow, clear and transparent and has pure, fine, refreshing and harmonious aroma. The invention has the following advantages: 1. full persimmons are extracted and the juice is used for fermentation, without adding water; and 2. pectinase is not added in the processes of juice extraction and fruit wine brewing, and astringency removal process is omitted. The invention plays important roles in promoting reasonable processing and utilization of the persimmon resources, forming the post-harvest processing industrial chain and adjusting the fruit processing industrial structure.

Owner:HEBEI AGRICULTURAL UNIV.

Disperse/activated one-emulsion paste printing dye and printing technology thereof

The invention discloses a disperse / activated one-emulsion paste printing dye, mainly prepared from the following components: composite paste slurry, an alkaline agent, reserve salt, urea, activated dye, disperse dye and water, wherein the composite paste is mainly prepared from the following components: 60% of sodium alginate, 20-30% of sodium polyacrylate, 5-15% of polyethylene glycol 2000 and 5% of polyvinyl pyrrolidone. A printing technology of the one-emulsion paste printing dye comprises the steps of printing, drying, baking (at the temperature of 180 DEG C for 7 minutes), washing by cold water, washing by alkaline water (at the temperature of 95 DEG C for 3 minutes), washing by hot water (at the temperature of 80-90 DEG C), washing by cold water, neutralizing and drying; after that, carrying out post-boarding and tentering. The disperse / activated one-emulsion paste printing dye successfully solves the problems that a disperse dye and an activated dye are poor in compatibility during one-emulsion paste printing, the paste pH value is sensitive to the disperse dye, the disperse dye and the activated dye are low in color yield percentage and serious in white ground contamination, a cloth cover effect is poor since the disperse dye and the activated dye are large in dyeing difference of fibers, and the like; the printing technology is more reasonable in process, clean and environment-friendly in production and stable in product quality.

Owner:ZHEJIANG JIAXIN SILK

Method for preparing sweet red jujube wine

InactiveCN101892141ABrix richFull bodiedAlcoholic beverage preparationMicroorganism based processesZiziphus jujubaHydroxycitric acid

The invention relates to a method for preparing sweet red jujube wine. The method comprises the following steps of: cleaning and boiling high-quality dried big jujubes by using water and smashing jujube skin to obtain jujube liquid; adding citric acid and mixed enzymes into the jujube liquid, performing enzymolysis on the jujube liquid and then separating and extracting jujube juice; determining the sugar degree of the jujube juice, controlling the sugar degree of the jujube juice to be between 15 and 24 DEG, adding leaven into the jujube juice according to a principle that 1.75 DEG of sugar is transformed into 1 DEG of wine, and finishing a fermentation process when the sugar degree of mash is lowered to 6 DEG; separating the wine by using siphonage after finishing the fermentation, adding pectinase into the wine to clarify the wine, and separating the wine by using a diatomite filtration method; regulating the sugar degree of the separated wine to be 8 DEG by using clear jujube juice and jujube flower honey and then adding white granulated sugar into the wine to control the sugar degree to be between 9 and 11 DEG; and performing heat treatment and cold treatment on the sweet wine, separating sediments out, removing large sediments by using the diatomite filtration method, then filtering the sweet wine by using a micro-membrane, and finally performing high-temperature short-time sterilization on the sweet wine to obtain the sweet red jujube wine. The sweet red jujube wine prepared by the invention has the characteristics of: alcohol content of 50 to 10 percent, sugar degree of 8 to 11 DEG, purplish red color, strong jujube fragrance and full wine body.

Owner:SHAANXI RES INST OF AGRI PRODS PROCESSING TECH

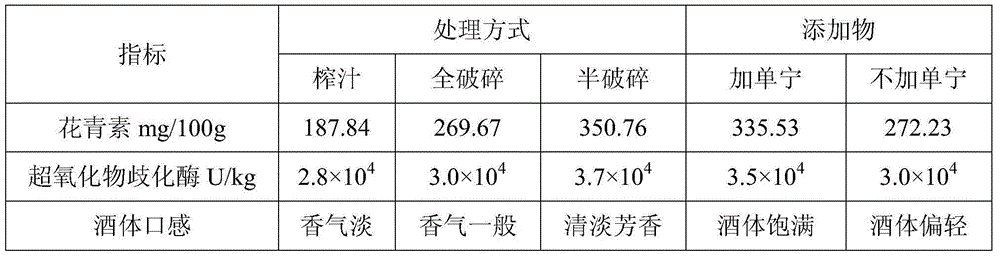

Brewing method of fermented blueberry wine

InactiveCN105087277AKeep the flavorElegant and soft aromaAlcoholic beverage preparationPectinaseGrape wine

The invention discloses a brewing method of fermented blueberry wine. The brewing method comprises the following steps: selecting Bluecrop blueberries and Duke blueberries; crushing moderately till the blueberries are in half-grain state; adding potassium metabisulfite and tannin into the half-grain blueberries, and mixing the potassium metabisulfite and tannin with the half-grain blueberries uniformly; adjusting the temperature to 20-30 DEG C, and adding pectinase into the mixture; inoculating by adopting wine brewer's yeast; fermenting under stirring every two hours till the content of residual sugar is not larger than 4g / L wherein the fermentation temperature is not higher than 30 DEG C; carrying out mechanical extruding after fermentation is finished for separating skin dregs from wine liquid; carrying out fining and clarification; carrying out stability analysis; regulating the concentration of free sulfur dioxide and the alcoholic strength; and filtering and storing. According to the brewing method, the proper blueberry variety is selected for producing the blueberry wine, thus the taste of a product is guaranteed; through the half-broken and half-grain fermentation method, the prepared blueberry wine is soft and elegant in aroma; and through color protection of tannin, the colour and luster, the taste and the nutrition of the product are guaranteed, and the wine body is relatively mature and plump.

Owner:WOLIN QINGDAO FOOD CO LTD

Process for brewing and producing compound-flavor type distilled spirits

ActiveCN105018296AConducive to expansion and reproductionPromote generationAlcoholic beverage preparationEngineeringProcess engineering

The invention discloses a process for brewing and producing compound-flavor type distilled spirits. The process is integration and adjustment to a Luzhou-flavor distilled spirits producing process, a fen-flavor distilled spirits producing process and a sesame-flavor distilled spirits producing process, production processes such as compound grain brewing, mud sump and old cellar, steaming and sediment renewal, ventilation and accumulation, combination with rough husks, layered vinasse removal and layered spirits distillation are adopted, and the compound-flavor type distilled spirits are obtained through the classified spirits picking, differentiated storage and elaborate blending. The compound-flavor type distilled spirits produced through the process have the advantages of having the 'sesame flavor' of the sesame-flavor distilled spirits, the 'soft-sweet, cool and clear flavor' of Luzhou-flavor distilled spirits, the 'clean, clear and elegant feature' of fen-flavor distilled spirits and the like, and the flavor integration requirement of treating the market and consumers as the main bodies is satisfied.

Owner:ANHUI GOLDEN SEED WINERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com