Patents

Literature

128results about How to "Clean aftertaste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing tobacco sheets by paper making method

ActiveCN101695407AIncrease the content of reaction intermediatesPromotes Maillard reactionTobacco preparationMaillard reactionPhosphate

The invention relates to a method for producing tobacco sheets by a paper making method, which is characterized by using acidic proteinase, pectase and amylase to carry out biological degradation on sheet materials, improving the content of Maillard reactants in a tobacco extraction liquid, utilizing Maillard reaction catalysts, namely phosphate, phosphate, dibasic alkaliine, dihydric phosphate, propanediol and the like, and regulating and controlling the condition of reaction medium, on-line promoting the Maillard reaction in a tobacco aqueous solution, and improving the content of Maillard reaction intermediates and products in concentrated solution. The method for producing the tobacco sheets by the paper making method can reduce acrimony and offensive taste of the sheets, coordinate smell, improve after taste and improve comfort level of sheet suction.

Owner:CHINA TOBACCO ANHUI IND CO LTD

Perfume for tobacco and its preparing method

InactiveCN1899140AThe effect of modifying the aroma of cigarettes is obviousClean aftertasteTobacco treatmentEssential-oils/perfumesFlavorMicroorganism

The present invention is a kind of tobacco perfume and its preparation process. The tobacco perfume is prepared through the following steps: 1. crushing the materials including balloon flower root 150-250 weight portions, fritillary bulb 30-80 weight portions, root of straight lady bell 150-250 weight portions, licorice 30-80 weight portions, tuckahoe 150-250 weight portions and Dangshen 70-130 weight portions, adding water and inoculating microbe strain to ferment to obtain fermented product; and 2. extracting the fermented product with water soluble solvent, concentrating the extracted liquid to obtain tobacco perfume paste. Compared with available technology, the present invention has the advantages of the microbial fermentation process, mallow flavor and obvious cigarette modifying effect of the tobacco perfume.

Owner:YUNNAN REASCEND TOBACCO TECH GRP

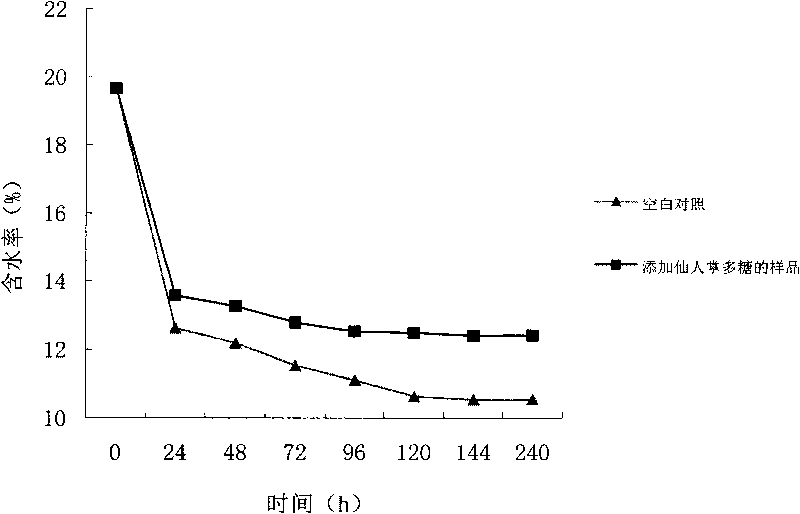

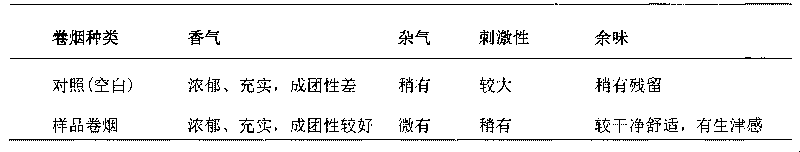

Extraction method of cactus polysaccharide and application thereof in cigarettes

ActiveCN101704900AImproves moisture retentionMoisturizing effect is obviousTobacco treatmentIrritationFiltration

The invention discloses an extraction method of cactus polysaccharide, which is characterized by comprising the following steps: high temperature enzyme inactivation; drying and crushing; extraction, centrifugal separation and filtration; filtrate concentration, adding into alcohol, precipitation, and crude cactus polysaccharide collection; dissolving of the crude cactus polysaccharide and purification; and obtaining of the cactus polysaccharide after collecting, washing and vacuum drying the precipitation. The cactus polysaccharide is applied to tobacco threads along with feed liquid after being dissolved with water, therefore, the smoke has no peculiar smell when a person smokes, the cactus polysaccharide can improve quality of aroma, mellow degree and sweet taste, improve oral comfort, reduce unpleasant smell and irritation, improve the dry sensation to a certain degree and obviously improve the moisturizing performance. The cactus polysaccharide does not change the original properties and the original processing technology of cigarettes, and does not change or influence the smoking quality of the cigarettes, thus having practical production significance and value.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

Preparation method of mint essential oil burst beads for cigarettes

ActiveCN107723091AImprove compactnessImprove the airtightness of the cyst wallTobacco smoke filtersEssential-oils/perfumesWater soluble polymersIon

The invention provides a preparation method of mint essential oil burst beads for cigarettes, belonging to the technical field of cigarette processing. The preparation method of burst beads comprisesthe following steps: performing high-speed homogenization and emulsification on mint essential oil, a calcium ion water solution and a surfactant to form an emulsion, directly and dropwisely adding emulsion drops into a sodium alginate water solution through an orifice by controlling the flow velocity of the emulsion at 1-5mL / minute by using a peristaltic pump, enabling the emulsion drops to stayin the sodium alginate solution for 2-40 minutes to obtain calcium alginate beads, taking out the beads, washing the beads with distilled water, putting the beads into an oxidizer water solution, performing soaking for 1-20 minutes, taking out the beads, washing the beads with distilled water, soaking the beads in a water-soluble polymer solution for 5-30 minutes, taking out the beads, washing thebeads with distilled water, and performing natural air drying, thereby preparing the mint essential oil burst beads for cigarettes, of which the grain size is 1-20mm. The mint essential oil burst beads for cigarettes are applied to cigarette filters to achieve the goal of improving the quality of cigarettes.

Owner:WUHAN YELLOW CRANE TOWER NEW MATERIAL TECH DEV

Brewing method of moso bamboo shoot wine

ActiveCN103409284AEfficient use ofHigh degreeAlcoholic beverage preparationMicroorganism based processesBamboo shootGeneral Appearance

The invention provides a brewing method of moso bamboo shoot wine. The brewing method comprises the following steps of (1) preparing materials and removing shells; (2) washing; (3) crushing; (4) distributing materials; (5) cooking; (6) saccharifying; (7) degrading cellulase and feeding sugar; (8) fermenting; (9) distilling; and (10) aging, mixing and packaging. The brewing method provided by the invention is simple in process and short in fermentation time; the general appearance of the brewed moso bamboo shoot wine is colorless, is bright and transparent and has no suspension matter and sediment; all tastes of the wine are coordinated and the wine is fragrant and pure, has a long-time sweet taste and is sweet and soft; the aftertaste is pure and cool.

Owner:HUNAN ACAD OF FORESTRY

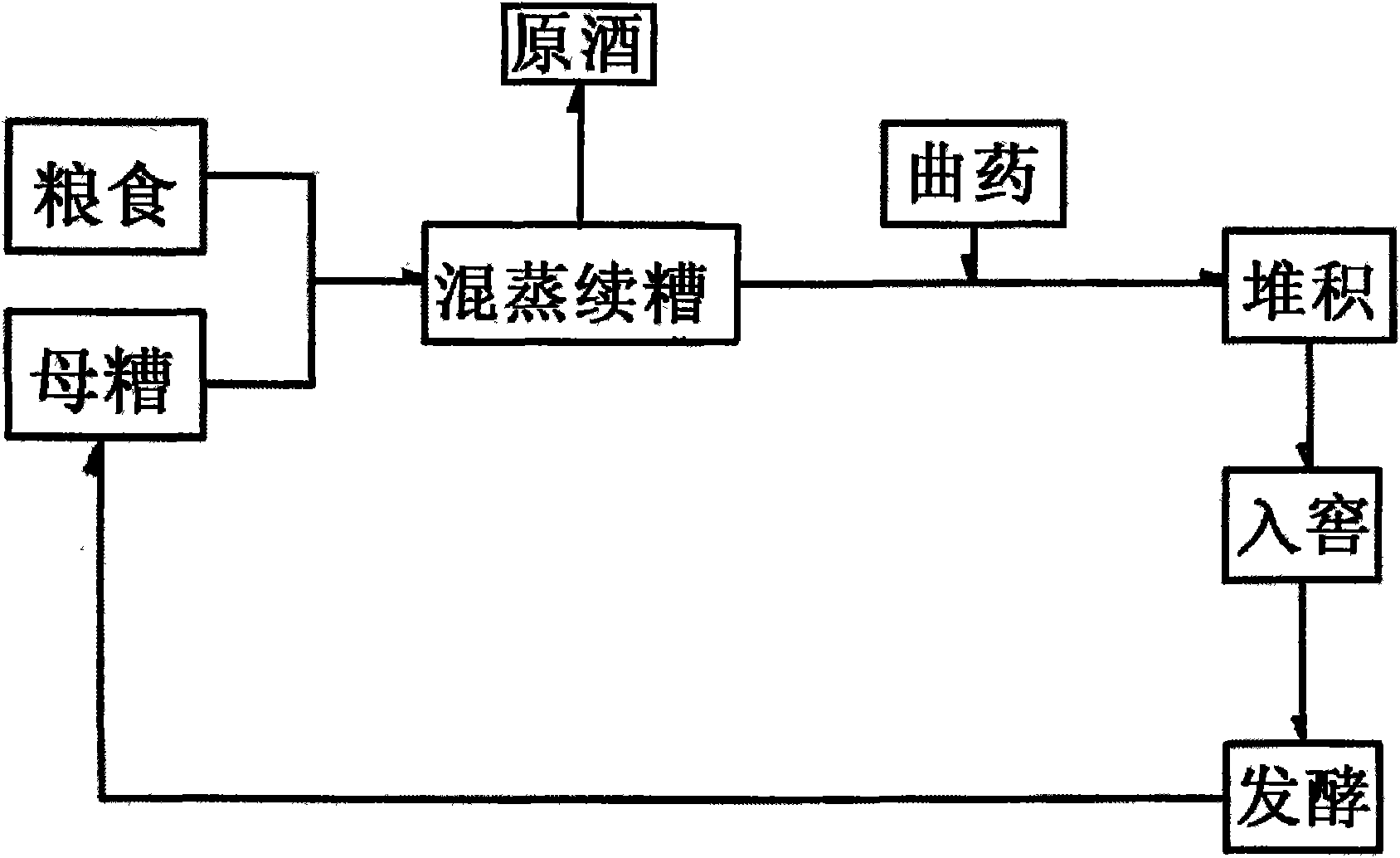

Method for producing multi-grain liquor of Luzhou-flavor and Maotai-flavor

The invention relates to a method for producing multi-grain liquor of Luzhou-flavor and Maotai-flavor, comprising the steps of taking grains, crushing the grains and then adding the grains in mother lees, uniformly mixing the grains, steaming the grains and the mixture of the mother lees in a mixing manner to continuously obtain the mother lees and distil out original liquor; adding a yeast in the distilled grains and the mixture of the mother lees, mixing uniformly, stacking, putting in a pit, and fermenting in the mud pit to prepare the mother lees, adding the mother lees into the grains for the next working procedure, and steaming the mixture in a mixing manner to continuously obtain the mother lees and distil out original liquor. The useful effects of the invention are that the product has strong multi-grain flavor of the multi-grain flavor type, the wine body is full bodied, mellow and compatible, and the aftertaste is clean. The method also has the advantages of the wine body produced by a Maotai-flavor technology that the wine body is exquisite and neat, the aftertaste is long and the Maotai-flavor is obvious. The technology fills up the blank of the single fermentation technology of multi-grain liquor of Luzhou-flavor and Maotai-flavor in China. The method is an innovation for the technology of liquor Luzhou-flavor and Maotai-flavor produced by blending original liquor after the original liquor is individually stored according to individual standard through the known Luzhou-flavor fermentation and Maotai-flavor fermentation in China.

Owner:四川省宜宾市叙府酒业股份有限公司

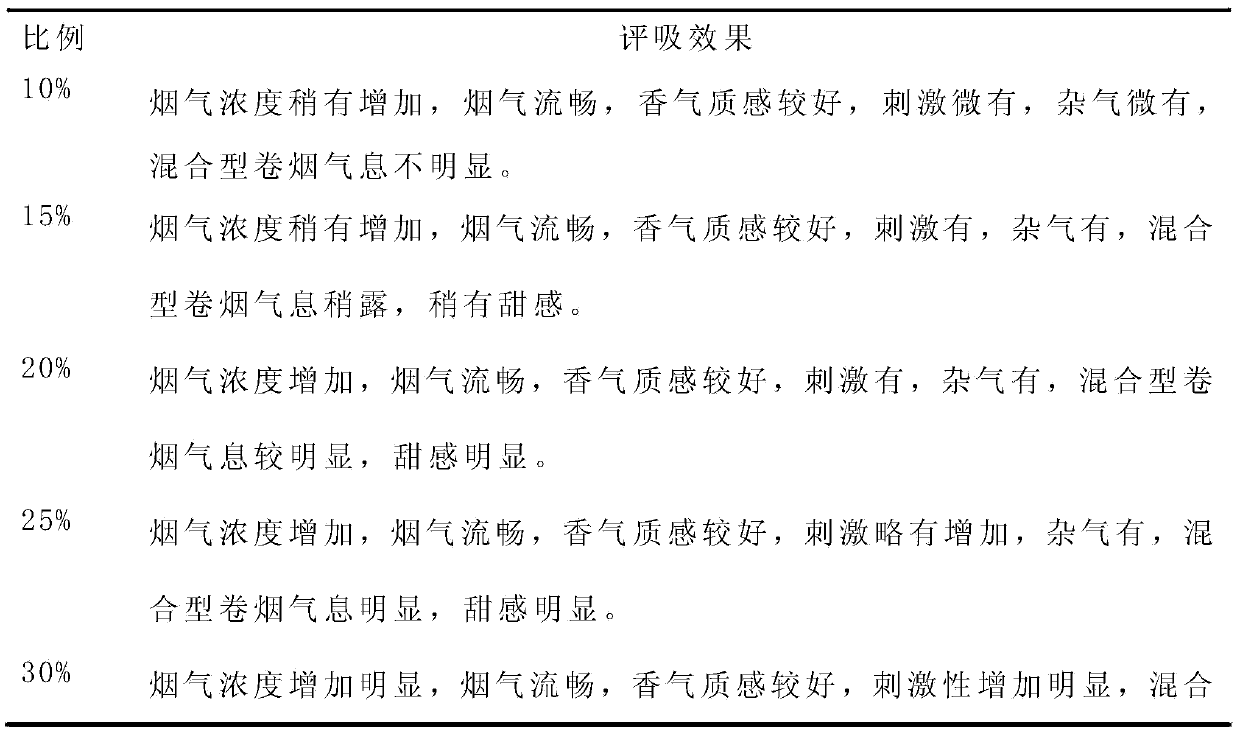

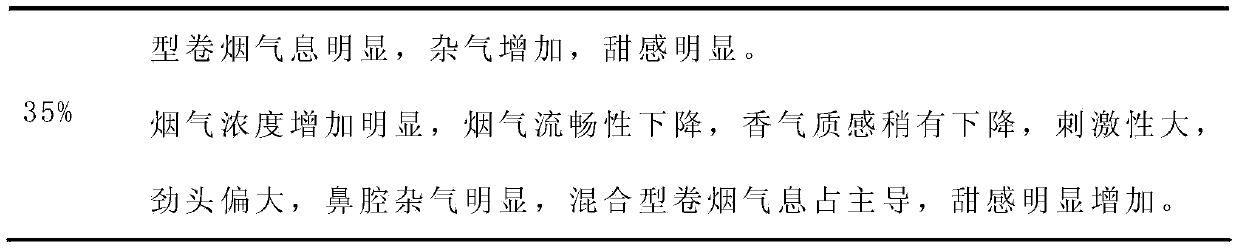

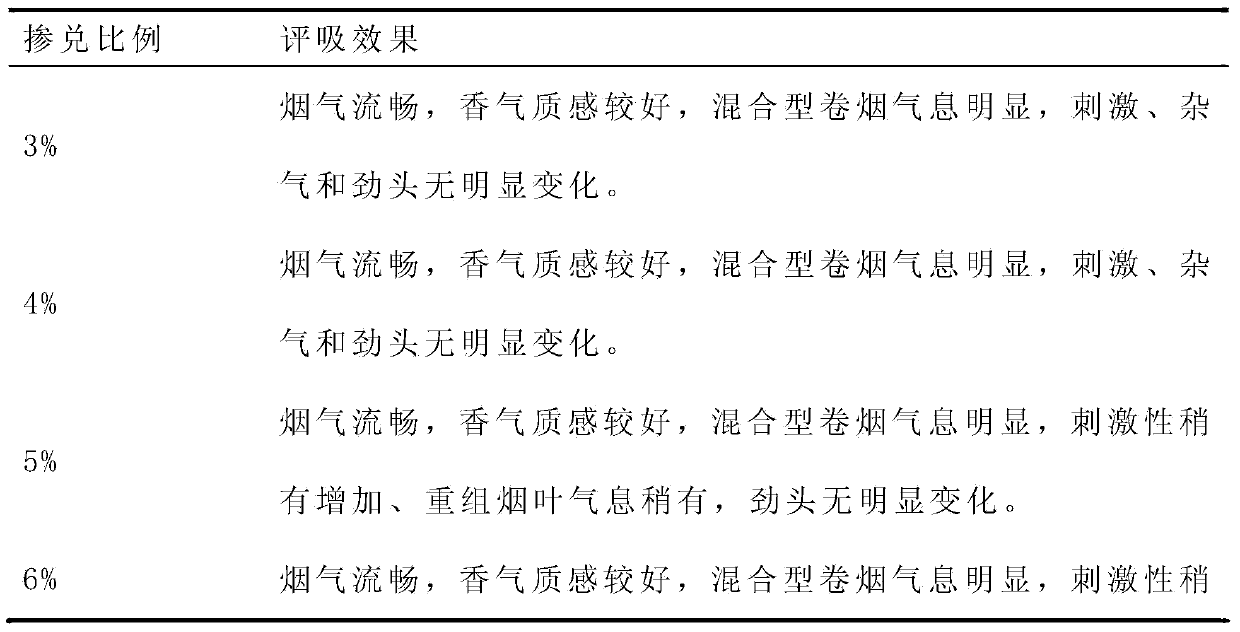

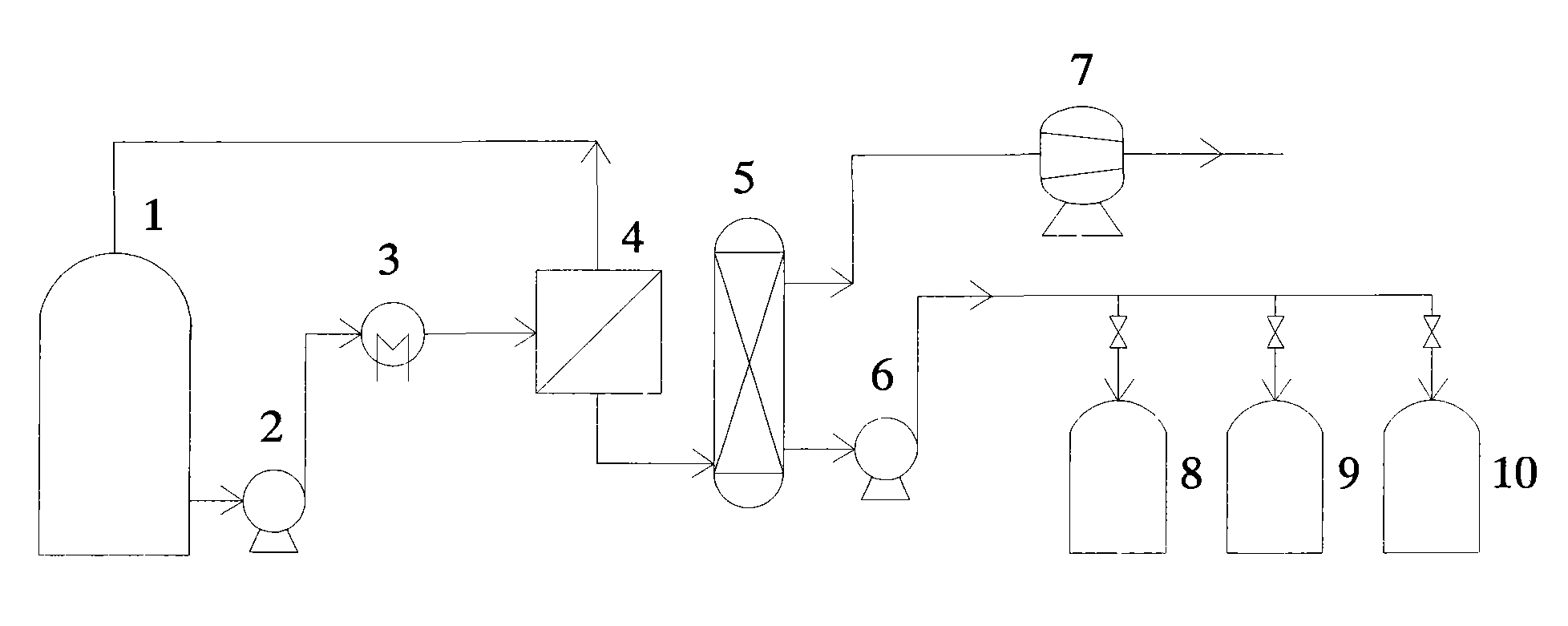

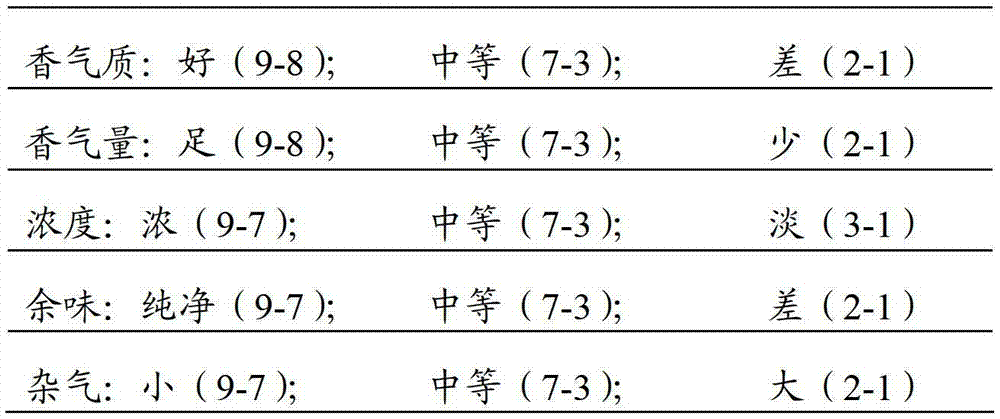

Method for producing novel blended type cigarettes with flue-cured tobacco styles

The invention belongs to the technical field of cigarette production, and particularly relates to a method for producing novel blended type cigarettes with flue-cured tobacco styles. The method comprises extracting Hubei Enshi burley tobacco and American burley tobacco with ethyl alcohol in a concentration of 30%; subjecting the extracted tobacco to high-temperature processing in a baking oven, and performing charging for spare; meanwhile, performing charging and perfuming on functional module cut tobaccos according to requirements of blended type cigarette styles; adding an appropriate number of the functional module cut tobaccos, tobacco flake cut tobaccos expanded cut stems and expanded cut tobaccos with cut flue-cured tobaccos serving as basic cut tobaccos, performing evaluation, analysis and screening repeatedly and determining a cigarette blending formula finally. The novel blended type cigarettes produced by the method have the advantages of being delicate in fume, rich and harmonious in fragrance, heavy and soft in fume, comfortable in flavor, and clear and sweet in aftertaste; the style of the novel blended type cigarettes is similar to the style of Chinese flue-cured tobacco type cigarettes, besides, the cigarettes have characteristics of international blended type cigarettes, and requirements of different consumers can be met.

Owner:HUBEI CHINA TOBACCO IND

Osmosis evaporation separation recombination white spirit

InactiveCN101186872ASelective separationStrong fragranceAlcoholic beverage preparationEvaporationVacuum pump

A process for improving the quality of novel alcohol by permeation, evaporation, separation and reforming relates to application of separation technique with pervaporation membrane in the field of alcohol. The technique of the invention is that raw material alcohol is maintained in constant relatively low temperature, the liquor is transferred to a silastic composite membrane device by a pump and the liquor conducts circular flow in the upper reaches of the membrane, the lower reaches of the membrane is maintained in vacuum state by a vacuum pump, ethanol and volatile flavoring substances are selectively separated by pervaporation and turn into permeation vapor, representative mouth feeling and flavoring substances are reformed or concentrated in vapor, a low temperature condenser is equipped in the lower reaches of the membrane, condensed liquor with different components quantity of mouth feeling and flavoring substances is achieved by time steps of condensing of the permeation vapor, the liquor made by time steps of condensing is reformed and novel alcohol with high quality is blended. The process has the advantages of simple technological process, compact equipment, high maneuverability, short treatment period, which can develop novel alcohol with low cost and poor quality into novel alcohol with high price and good quality.

Owner:SICHUAN UNIV

Tobacco essence capable of improving cigarette taste and aroma

ActiveCN103113989ASmoke is soft and delicateClean aftertasteTobacco preparationTobacco treatmentSalvia miltiorrhizaIrritation

The invention relates to tobacco essence capable of improving cigarette taste and aroma and also relates to application of the tobacco essence in cigarettes. The tobacco essence mainly comprises propylene glycol, loquat leaf extract, salvia miltiorrhiza extract, labdanum oil, rhodinol, mint lactone, guaiacol, carvone, acetic acid isobutyl ester and alpha-pinene. The tobacco essence has the effects of softening and smoothening the smoke, cleaning the residual odor, reducing the irritation and moisturizing, and the tobacco quality is improved.

Owner:HUABAO FLAVOURS & FRAGRANCES CO LTD

Electronic mouth cavity atomized liquid using multi-element ethanediol series lower alcohols as base solution

The invention discloses electronic mouth cavity atomized liquid using multi-element ethanediol series lower alcohols as a base solution. The electronic mouth cavity atomized liquid is composed of 3%w / v to 5%w / v of tobacco leaf extracts, 30%w / v to 80%w / v of the lower alcohols, 5%w / v to 10%w / v of pure water, 3%w / v to 5%w / v of tobacco essence, 0%w / v to 3%w / v of nicotine, 0.2%w / v to 1.0%w / v of stabilizers, 3%w / v to 8%w / v of thickeners and 15%w / v to 20%w / v of taste modifiers, wherein the lower alcohols are the mixtures of triethylene glycol and / or tetraethylene glycol and / or pentaethylene glycol and / or hexaethylene glycol and / or heptaethylene glycol and / or octaethylene glycol and / or nonaethylene glycol. The electronic mouth cavity atomized liquid has the advantages that remaining taste is clear, fragrance lasts for a long time, and safety is realized after the electronic mouth cavity atomized liquid is used.

Owner:FEELLIFE BIOSCI INT

Effervescence tablets for appeltizing stomaching and digesting

InactiveCN1833713AGreat tasteIncrease softnessDigestive systemPill deliveryEffervescent tabletVitamin C

An effervescent tablet of ordinary food, health-care food, or OTC for promoting appetite, helping digestion and invigorating function of stomach is prepared from 7 Chinese-medicinal materials including aloe, tangerine peel, yam, haw, etc, acid component, alkali component, adhesive, lubricant, sweetening agent and flavouring. It is possible to add VC.

Owner:谭艳

Rose-type essence for cigarettes for women and application of flavor

ActiveCN104388192ADeployment breakthroughLess irritatingTobacco treatmentEssential-oils/perfumesBenzoic acidPhenethyl alcohol

The invention discloses a rose-type essence for cigarettes for women. The rose-type essence is prepared by mixing the following components: 1.0-2.5% of rose flower essential oil, 0.1-0.5% of clove bud oil, 0.01-0.1% of anise oil, 1.5%-3.0% of citronellol, 0.1-0.5% of geraniol, 0.2-0.5% of linalool, 0.5-1.5% of phenethyl alcohol, 0.1%-1.0% of ethyl isobutyrate, 0.2-1.5% of phenylethyl phenylacetate, 0.1-0.3% of menthyl acetate, 0.5-1.0% of ginkgo biloba extract, 0.1-1.0% of mango extract, 0.05-0.5% of coffee extract, 0.1-1.0% of emblica extract, 1.0-2.0% of ebony extract, 0.5-1.0% of red date extract, 0.01-0.05% of fenugreek extract, 0.5-1.5% of aromatic tobacco extract, 0.01-0.1% of lactic acid, 0.02-0.08% of benzoic acid, 0.02-0.05% of oxoisophorone, 0.5%-1.0% of megastigmatrienone, 0.5-1.0% of honey, 40.0-60.0% of 70% ethanol and the balance of propylene glycol. By adding rose-type essence into tobacco shreds, the tobacco shreds are rolled into cigarettes having the advantages of delicate and soft smoke, pleasant mouth feeling, clean aftertaste, pure and mild taste, harmonious smoke incense and the like.

Owner:HUBEI CHINA TOBACCO IND +1

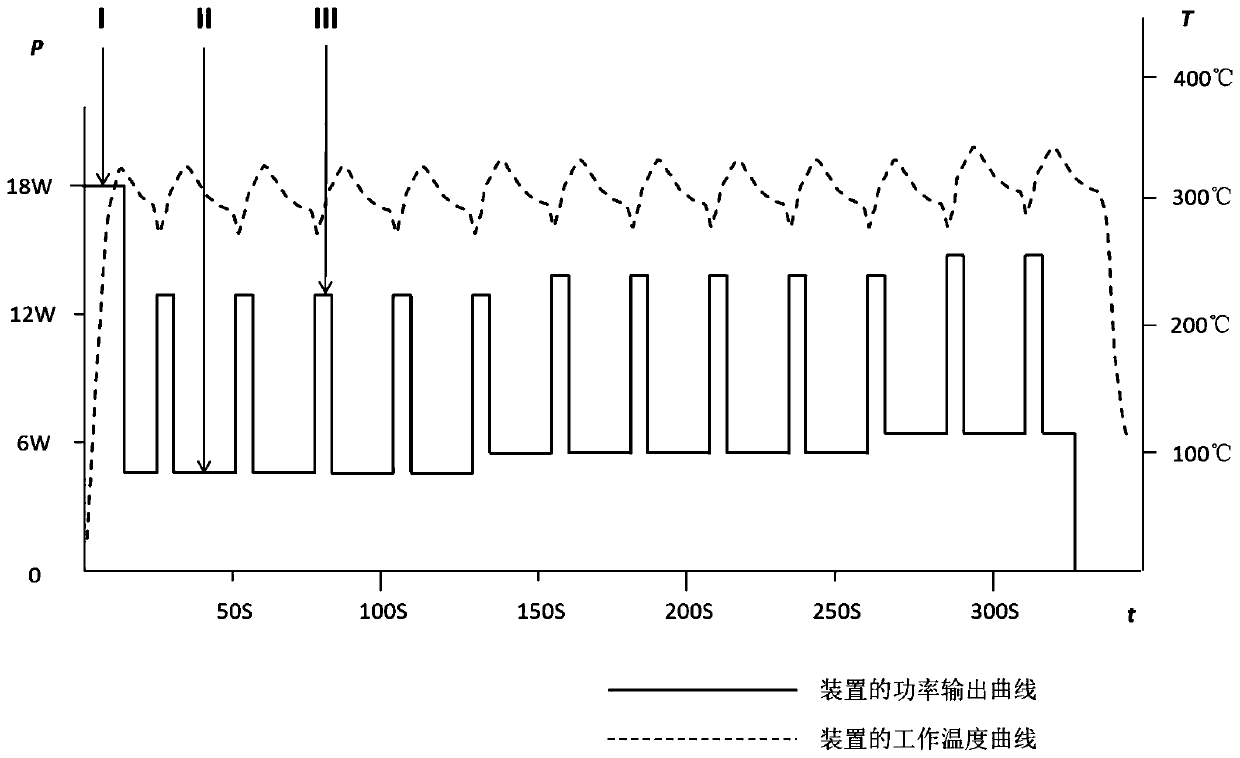

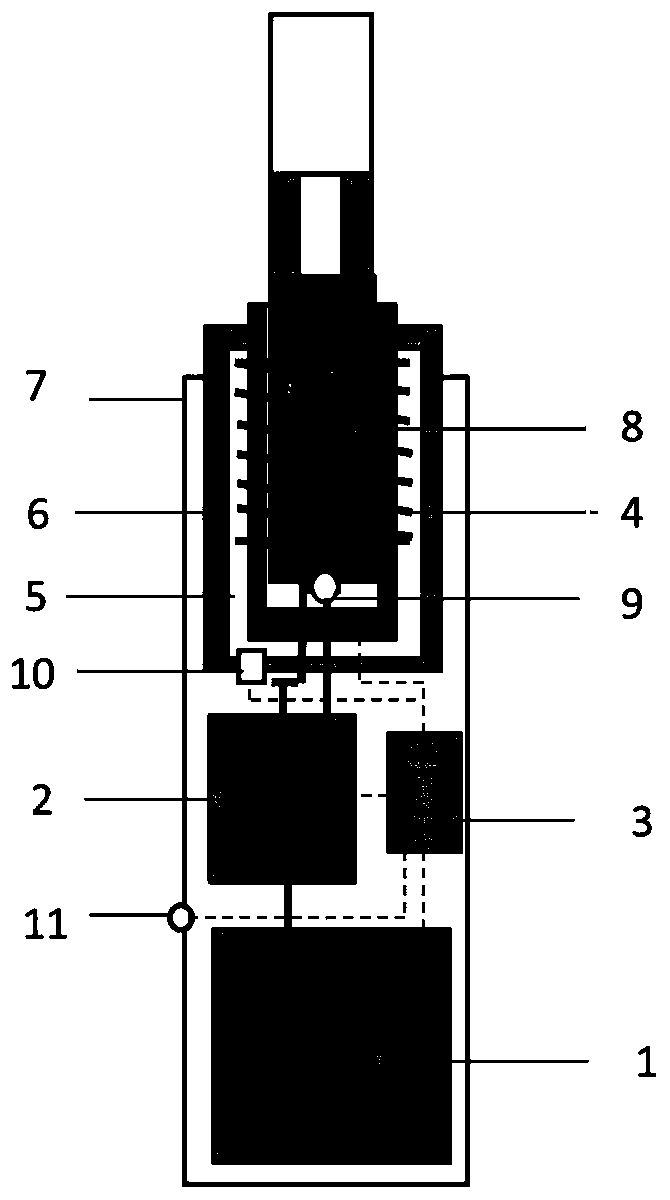

Control method for realizing sustained release of smoke of heating non-combustion tobacco products

The invention relates to a control method for realizing sustained release of smoke of heating non-combustion tobacco products. According to the control method, a heating device adopts the heating modecomprising a preheating stage I, as well as a thermal insulation stage II and a smoking stage III which are circularly and alternately carried out, wherein the circulating times of the thermal insulation stage II and the smoking stage III is 5-20 times. With the control method, the puff number can be controlled, the smoke amount is sufficient, the irritation is small, the aftertaste is clean, theobvious miscellaneous qi and residue do not exist, the strength is moderate, the temperature of the smoke is moderate and free of the burning heat sensation, and when not in smoking, no sidestream smoke is emitted.

Owner:CHINA TOBACCO ANHUI IND CO LTD

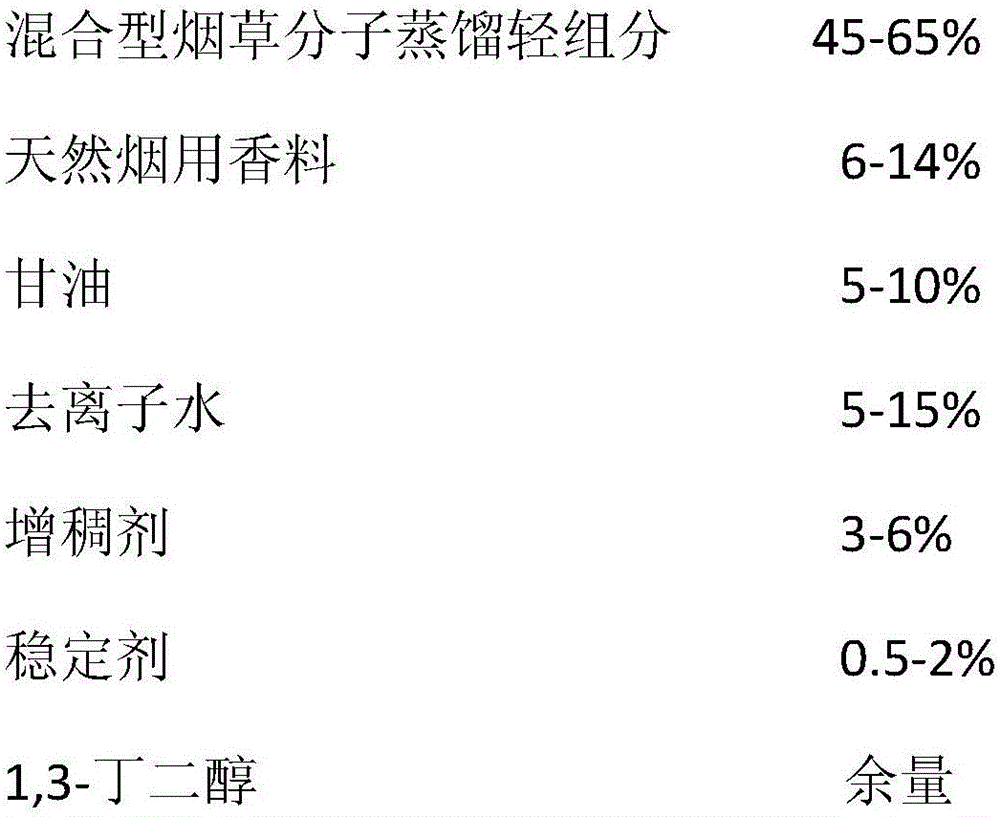

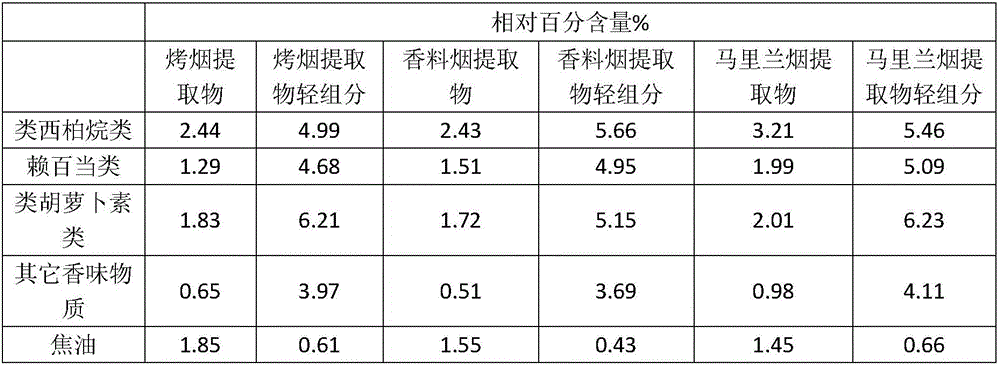

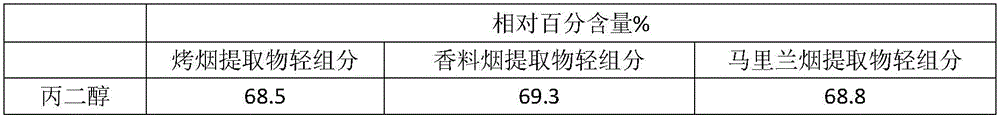

Mixed type tobacco molecular distillation light component electronic tobacco liquid and preparation method thereof

ActiveCN106333384AImprove satisfactionIncrease aromaTobacco treatmentTobacco devicesDistillationLiquid smoke

The invention provides mixed type tobacco molecular distillation light component electronic tobacco liquid and a preparation method thereof. The electronic tobacco liquid is obtained by heating deionized water, adding a thickening agent and a stabilizing agent, sufficiently stirring, then adding a mixed type tobacco molecular distillation light component, stirring uniformly to obtain mixed liquid, subsequently adding natural tobacco essence, glycerol and 1,3-butanediol into the mixed liquid, and stirring at room temperature. The mixed type tobacco molecular distillation light component is prepared by mixing and blending a flue-cured tobacco molecular distillation light component, an aromatic tobacco molecular distillation light component and a Maryland tobacco molecular distillation light component, and the natural tobacco essence is prepared by blending a liquorice extract, a beta vulgaris extact, a barbary wolfberry fruit extract and a red dates extract according to mass percent. The electronic tobacco liquid prepared by the invention enables tar to be relatively low, meanwhile enables the smokers to have high satisfaction, has sufficient fragrance, harmonized taste and pure retaining taste, is fragrant, and is endowed with the fragrance with tobacco characteristics.

Owner:HUBEI CHINA TOBACCO IND

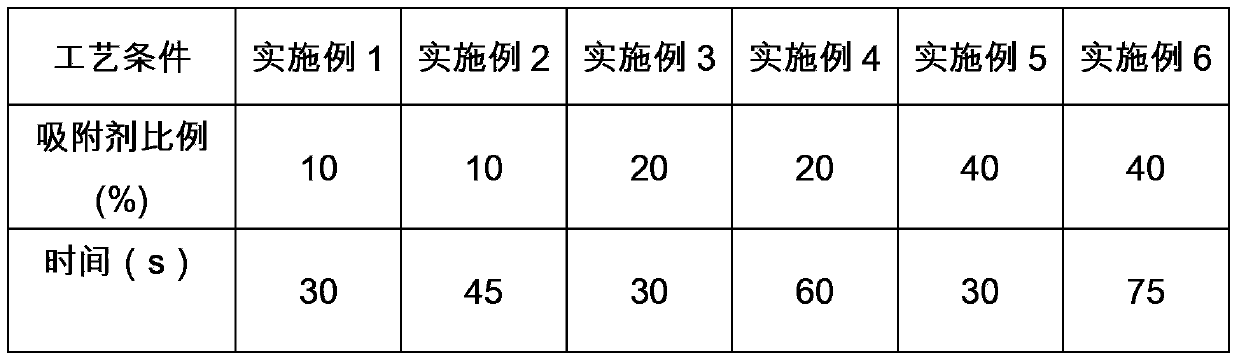

Absorbent composition for decreasing nicotine in tobacco extract and absorption method thereof

ActiveCN103357382AWide variety of sourcesLower nicotine levelsTobacco treatmentOther chemical processesSorbentFilm base

The invention belongs to the field of tobacco industry, and especially relates to an absorbent composite for decreasing nicotine in tobacco extract and an absorption method thereof. The absorbent composite for decreasing nicotine in tobacco extract comprises following raw materials in parts by weight: 30 to 80 parts of active carbon, 5 to 30 parts of bamboo charcoal, 1 to 15 parts of zeolite, 5 to 35 parts of starch, and 5 to 30 parts of chitosan. The raw materials sources are wide, and the raw materials belong to regenerative resources. The absorbent composite can obviously reduce the nicotine content in mother liquid of tobacco stems and tobacco powder, has no effect on potassium or chlorine and has part effect on sugar. The nicotine can be reduced by 10 to 50%. The mother liquid is condensed and a film base is coated with the mother liquid, and the re-produced tobacco leaves made of the film base have the advantages of clean residual smell and mild smoke. The absorbent composite largely improves the adjusting and controlling performances of nicotine in the tobacco chemistry indexes of re-produced tobacco leaves, at the same time has the effect on reducing harm, and reduces pollution to the environment.

Owner:杭州利群环保纸业有限公司

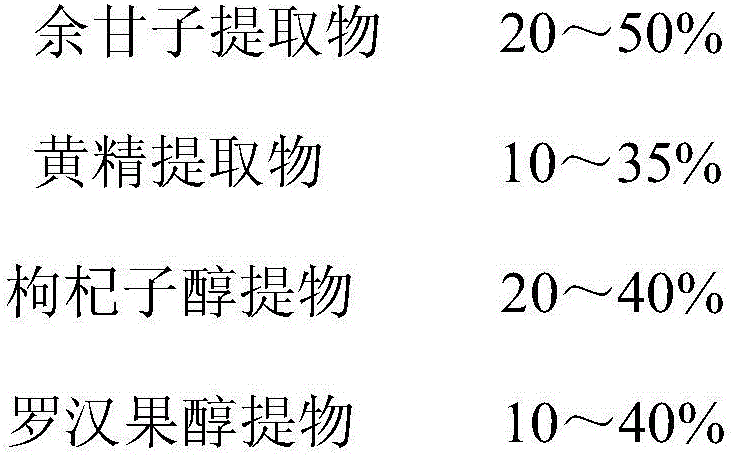

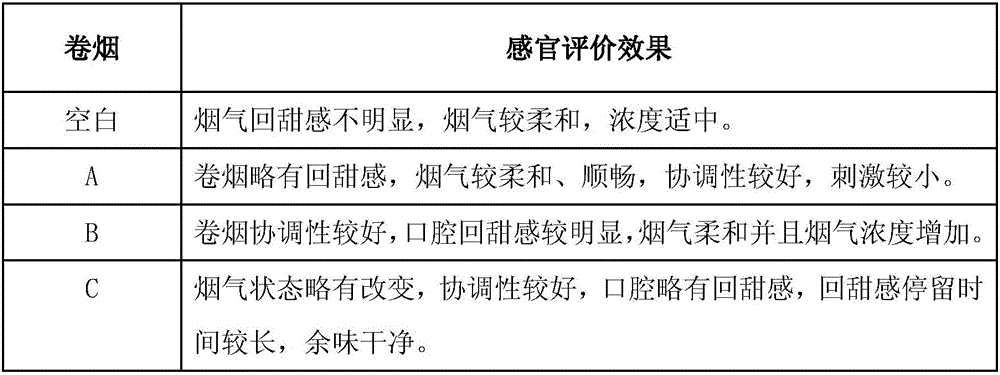

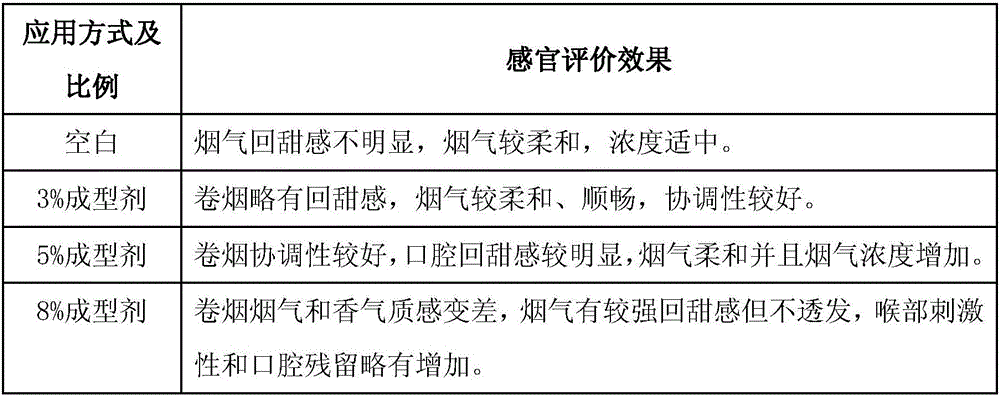

High-sweet-returning-feeling spice for cigarettes and preparation method and application of high-sweet-returning-feeling spice

ActiveCN106418669AReduce extractionSolve the problem of poor sensory evaluation effectTobacco preparationTobacco treatmentAlcohol ethylProcess engineering

The invention provides high-sweet-returning-feeling spice for cigarettes and a preparation method and application of the high-sweet-returning-feeling spice. The high-sweet-returning-feeling spice for the cigarettes is prepared by mixing emblic leafflower fruit extract, rhizoma polygonati extract, Chinese wolfberry fruit alcohol extract and momordica grosvenori fruit extract, and the emblic leafflower fruit extract and the rhizoma polygonati extract are prepared in the mode that emblic leafflower fruits and rhizoma polygonati are adopted as extracting raw materials, hot water is added, the mixture is placed in a water bath pot for water bath extraction, the product is concentrated to be 0.5-1 time of the weight of the extracting raw materials, then the product is cooled to room temperature, 50%-75% ethyl alcohol is added for alcohol precipitation, sediment is filtered out, the product is concentrated to be 0.4-1 time of the weight of the extracting raw materials again, and the extract is obtained. The spice for the cigarettes is completely prepared from the plant extract and added to a forming agent or tipping paper, the sweet returning feeling of smoke can be effectively increased, the sweet returning feeling of the cigarettes can be increased, and softness of the smoke can be kept.

Owner:HUBEI CHINA TOBACCO IND

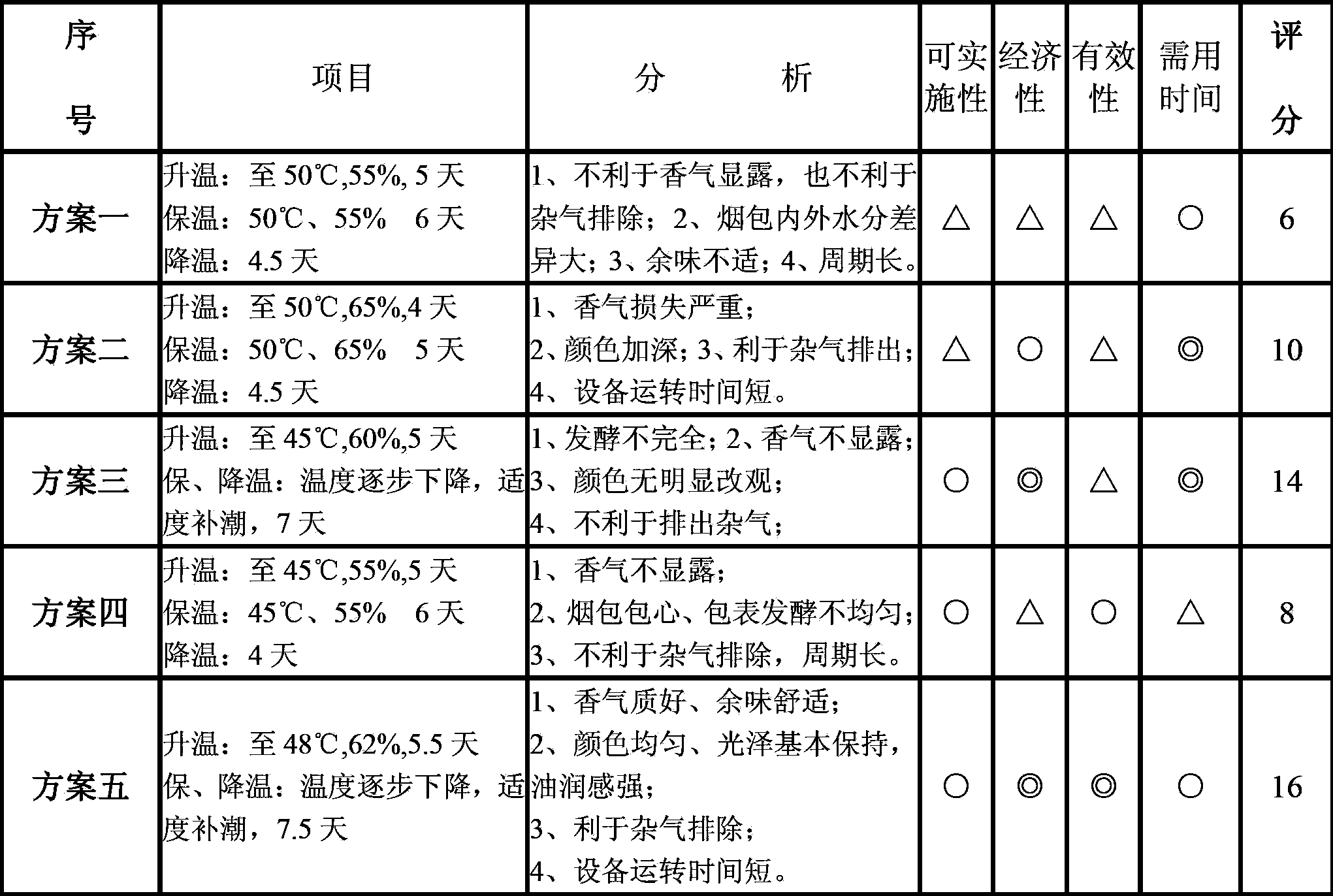

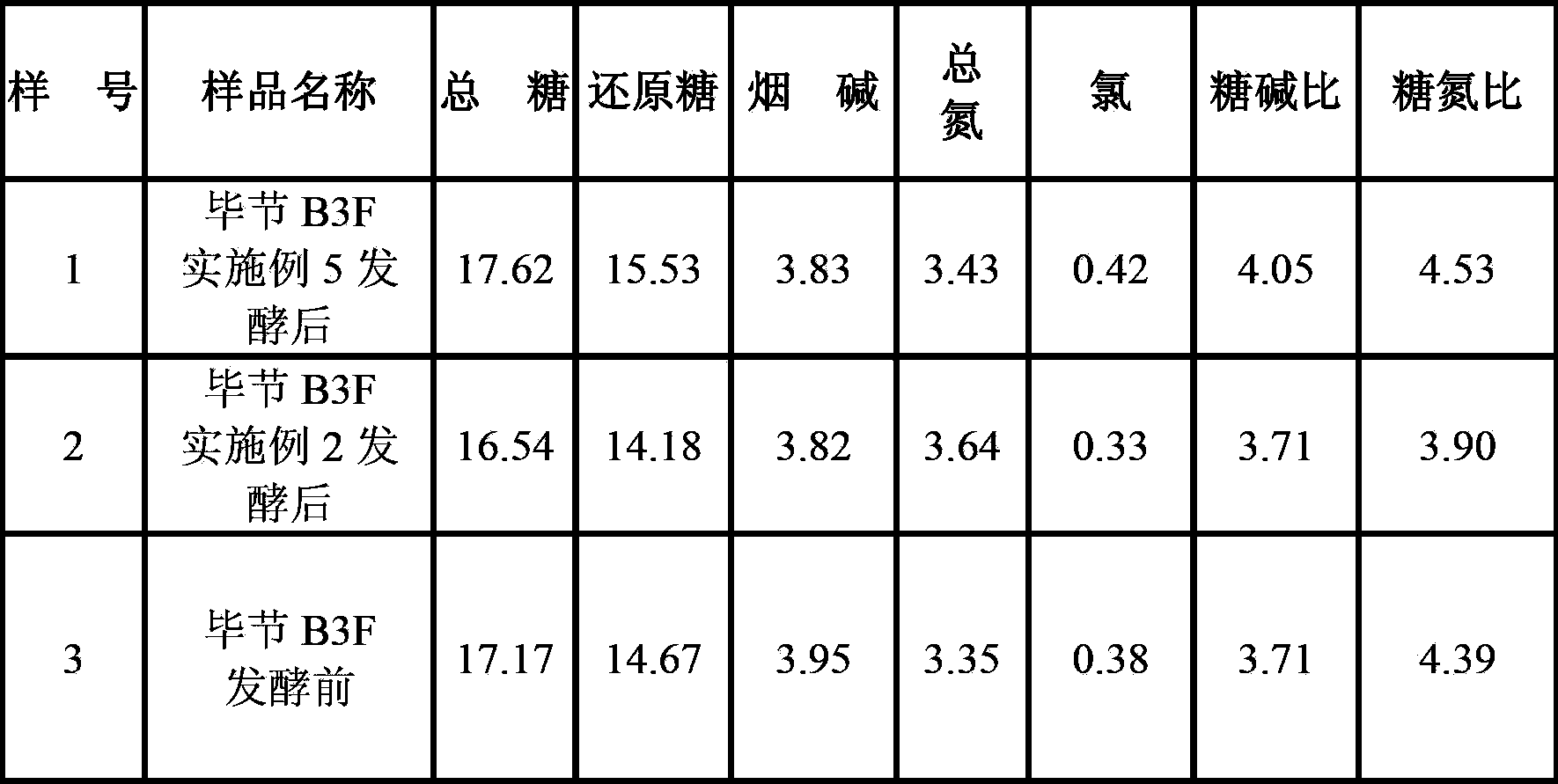

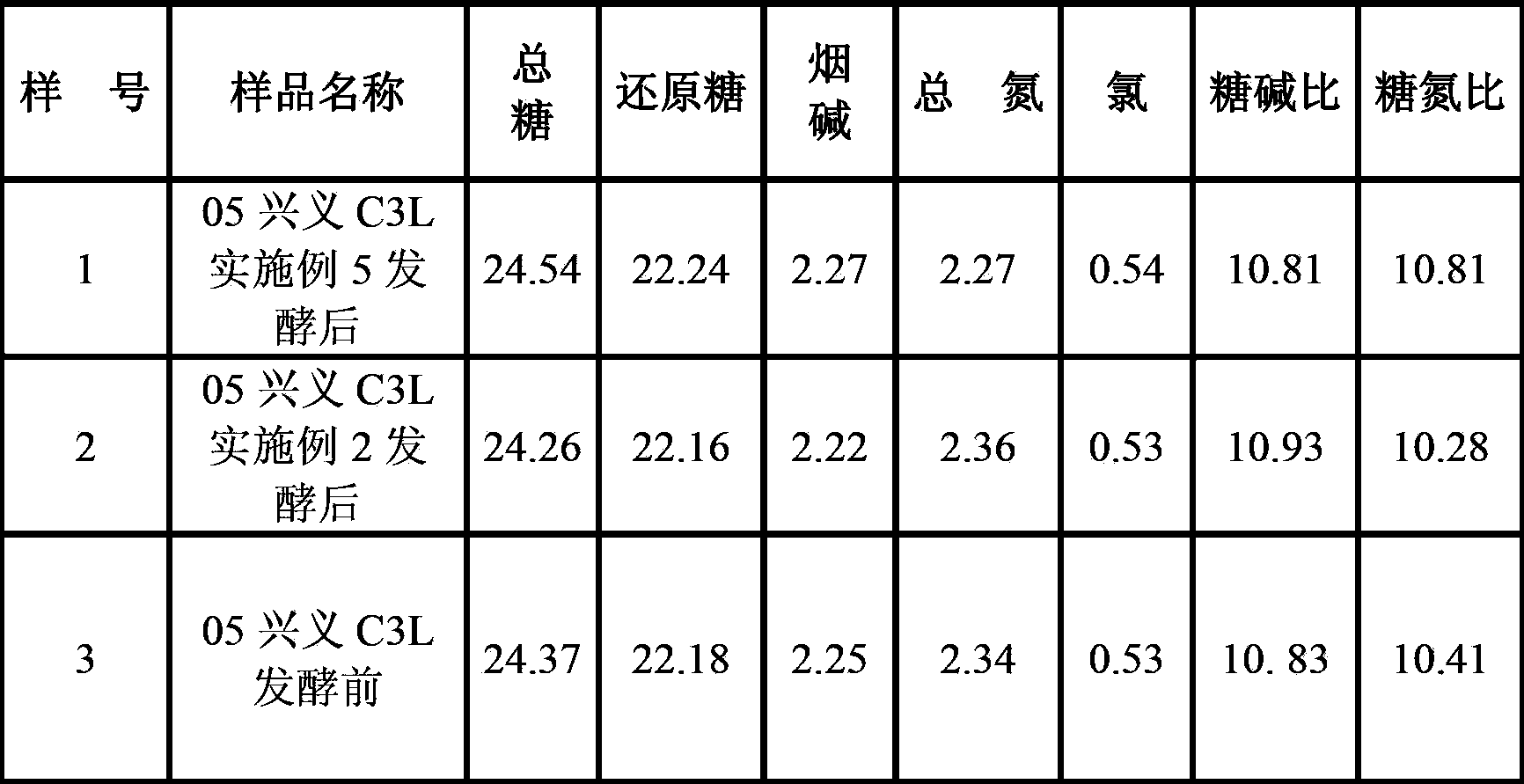

Flue-cured tobacco fermentation process

The invention relates to the field of tobacco processing, in particular to a flue-cured tobacco fermentation process. The process includes the steps of 1, intensifying, namely heating a tobacco bale gradually to 47-49 DEG C for 5-5.5 days, and controlling the ambient humidity to be 61-63% during heating; 2, mellowing, namely, cooling the tobacco bale gradually to 30-33 DEG C for 7.5-8 days, and supplying moisture moderately during cooling. The tobacco produced by the process has uniform color, significantly enhanced oily moistness, obvious fragrance, significantly reduced stimulus, comfortable taste and clear aftertaste. Compared with the traditional process, the flue-cured tobacco fermentation process has the advantages that energy consumption is decreased by 20-30% and economic benefit is significant.

Owner:CHINA TOBACCO GUIZHOU IND

Tobacco composition for paper-making method reconstituted tobacco leaves and application thereof to heat-not-burn cigarettes

InactiveCN110150723AIntact void structurePromote absorptionTobacco preparationTobacco treatmentHeat not burnEngineering

The invention discloses a tobacco composition for paper-making method reconstituted tobacco leaves and application thereof to heat-not-burn cigarettes. The tobacco composition is prepared from a stemgroup raw material and a leaf group raw material dividedly, based on a conventional paper-making reconstituted tobacco leaf process, a stem group tobacco powder wet part is added into a film base before film base forming, leaf group tobacco powder is added into coating liquid, and the core material paper-making method reconstituted tobacco leaves applied to the heat-not-burn cigarettes are prepared. By utilizing the tobacco composition, the absorption property of the film base of the paper-making method reconstituted tobacco leaves can be improved, the adding requirement of a high-content smoke agent is met, an aroma framework of the heat-not-burn cigarettes is perfected, the quality pursuit of the heat-not-burn cigarettes is reached in the aspect of sensory quality, the aroma quality is good, the smoke concentration is high, the strength is high, the texture is fine and smooth, mixed gas slightly exists, the remaining taste is clear, and harmoniousness is good.

Owner:ZHONGYAN SHIWEICE (YUNNAN) RECONSTITUTED TOBACCO CO LTD

Cigarette flavoring coating material and application thereof

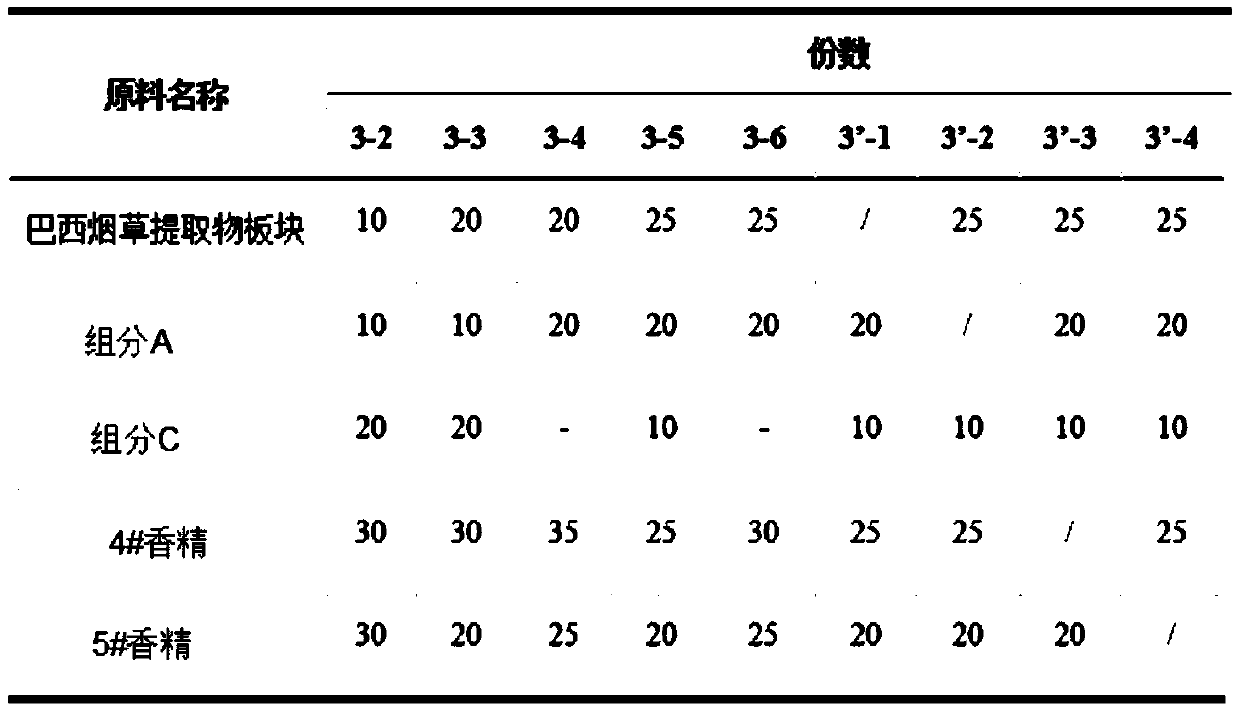

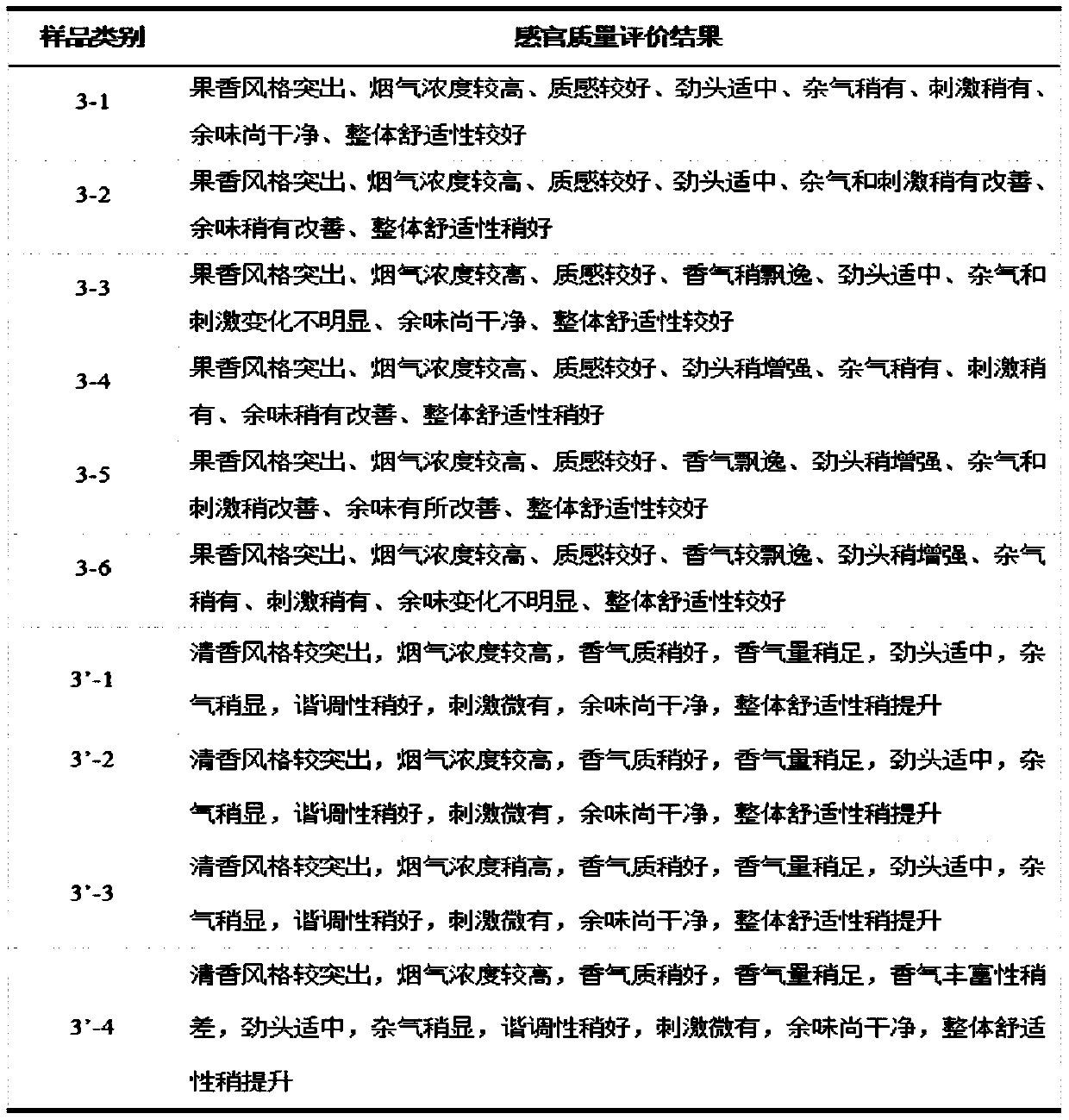

InactiveCN109875098AImprove comfortIncrease concentrationTobacco preparationTobacco treatmentFlavorHeat not burn

The invention discloses a cigarette flavoring coating material and application thereof. The cigarette flavoring coating material is prepared from, by mass, 10-40% of a component A, 0-40% of a component B, 0-30% of a component C and 0-70% of an essence. By selecting suitable essence and spice raw materials and adjusting compounding and dosage of the raw materials, the cigarette flavoring coating material which is high in overall smoke concentration, fine and soft in smoke, good in richness and harmony, moderate in strength, clean in remaining taste and good in sweet-and-moisturized feeling andoverall comfort is finally formed. The cigarette flavoring coating material is used for preparing and developing heat-not-burn cigarettes; the feasible cigarette flavoring coating material is providedfor low-temperature cigarettes, and powerful technical support is provided for conducting further development and improving the quality and mouthfeel of reconstituted tobacco.

Owner:CHINA TOBACCO GUANGDONG IND +1

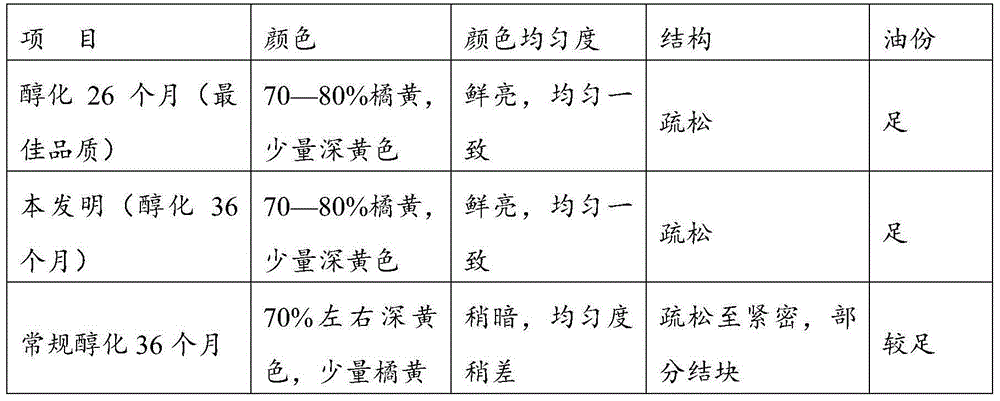

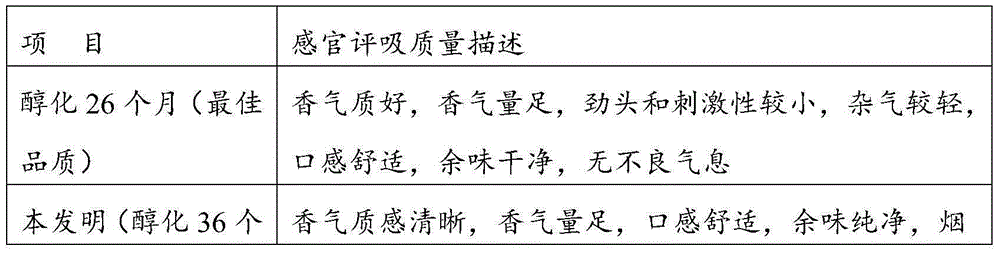

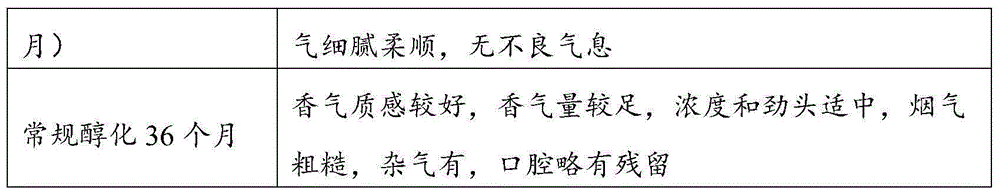

Tobacco leaf treatment method with advantage of prolonging mellowing period of laminae

ActiveCN105167171AExtended use timeImproving the quality of sensory evaluationTobacco treatmentEngineeringSpecific storage

The invention provides a tobacco leaf treatment method with the advantage of prolonging the mellowing period of laminae. The tobacco leaf treatment method comprises the following steps: (1) conducting box-by-box treatment on laminae of which the mellowing quality reaches the standard, in a storehouse: opening smokeboxes, untying lining bags, inflating CO2 gas after vacuumizing, sealing the plastic lining bags after circulating the steps for two times to three times, finally repacking the smokeboxes, and sealing the upper openings and the lower openings of the smokeboxes; (2) transferring the sealed smokeboxes in a specific storage environment, controlling the temperature and the humidity, wherein the temperature is required to 10-20 degrees, and the humidity is required to 45%-55%, and requiring single-layer stacking when the smokeboxes are stored; and (3) unsealing the smokeboxes and the lining bags in 7-10 days before production of the batch of laminae, and gradually rising the environment temperature to 30-35 degrees in 1-2 days and increasing the humidity to 65%-70%. The tobacco leaf treatment method has the advantages that the cigarette formulating and using time of the laminae can be prolonged, the best laminae mellowing quality is ensured, the contradiction that mellowed mature laminae are urgently used is relieved, and the formulating efficiency and the using level are improved.

Owner:HUBEI CHINA TOBACCO IND

Tobacco essence capable of improving cigarette taste and fragrance

ActiveCN103343053ASmoke is soft and delicateClean aftertasteTobacco preparationEssential-oils/perfumesMethyl linoleateEnvironmental health

The invention relates to a tobacco essence capable of improving cigarette taste and fragrance, and relates to an application of the tobacco essence in cigarette. The tobacco essence mainly contains propylene glycol, a Chinese date extract, a salvia extract, a rosa laevigata extract, rhodinol, guaiacol, carvone, methyl linoleate and alpha-pinene. By using the tobacco essence provided by the invention, the smoke has the effects of being exquisite, soft, clean in aftertaste, less in irritation and moistening, and the tobacco quality is improved.

Owner:HUABAO FLAVOURS & FRAGRANCES CO LTD

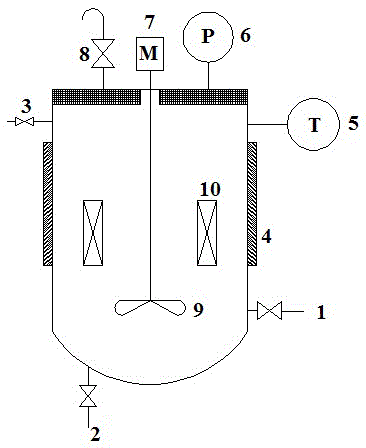

Microbial compound inoculant and preparation method and application thereof

ActiveCN111117901AIncrease the ester contentShorten fermentation timeFungiMicroorganism based processesHansenula anomalaAspergillus oryzae

The invention discloses a microbial compound inoculant and a preparation method and application thereof. The inoculant is prepared by mixing mould and yeast according to a weight ratio of (3-5):1. Themould is formed by mixing Aspergillus oryzae and Rhizopus oryzae according to a weight ratio of 1:(1-3); and the yeast is formed by mixing Saccharomyces cerevisiae, Hansenula anomala abnormal variant, Hansenula anomala and Wickerhamomyces anomalus according to a weight ratio of 1:(0.5-1.5):(0.5-1.5):(0.5-1.5). The fen-flavor liquor brewed by the microbial compound inoculant is pure in fen flavor,mellow, sweet, soft, natural, harmonious, refreshing in aftertaste, and high in liquor yield and high-quality liquor yield.

Owner:HENAN YANGSHAO LIQUOR IND CO LTD

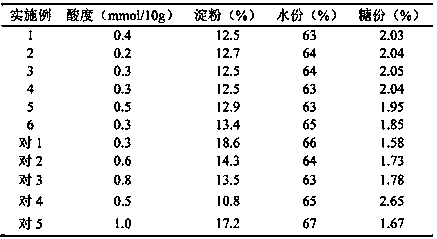

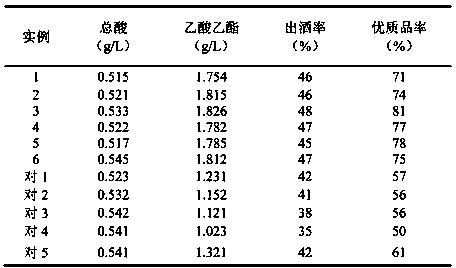

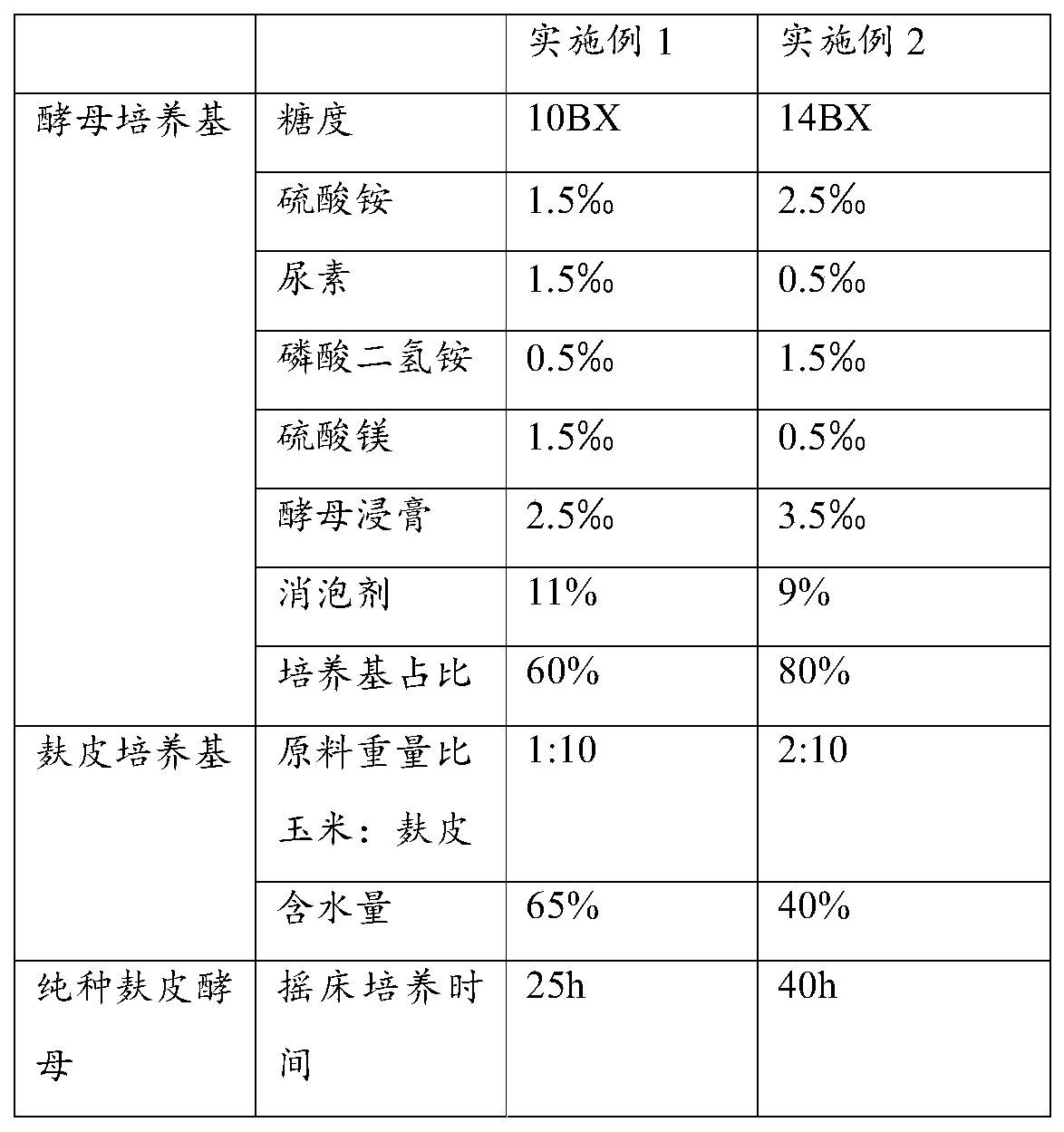

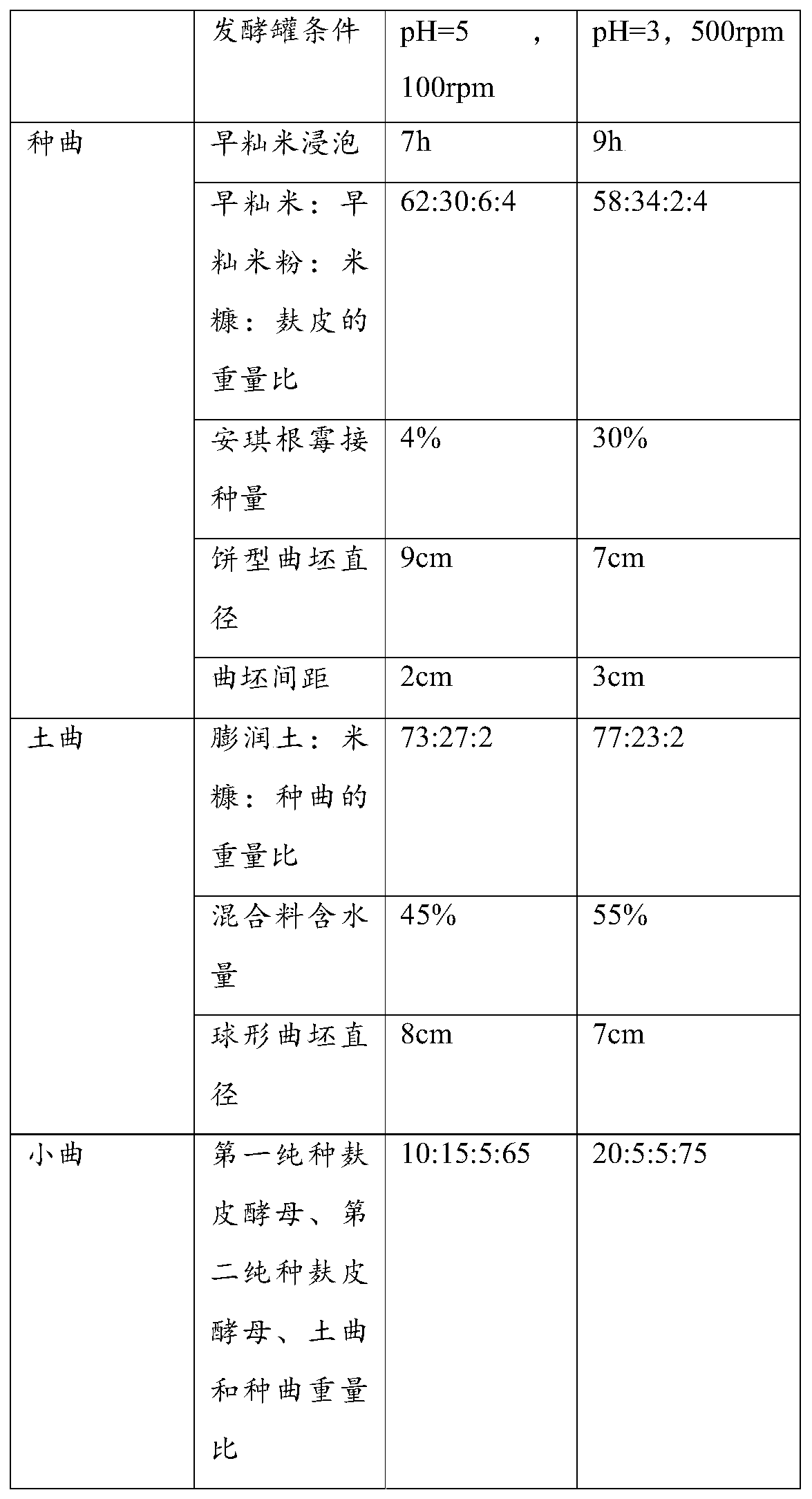

Koji for fermented baijiu, application, fen-favor koji baijiu and preparation method

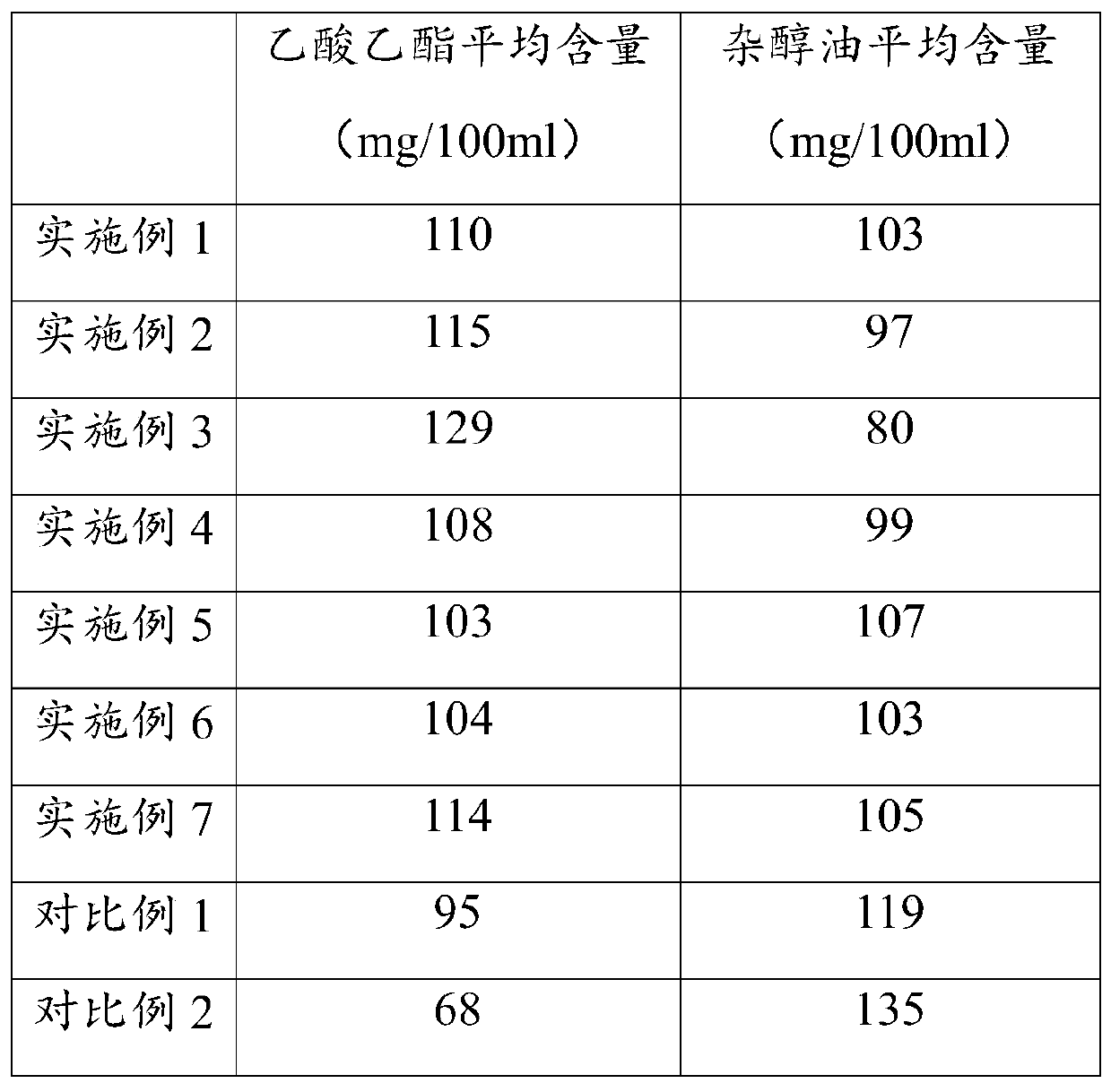

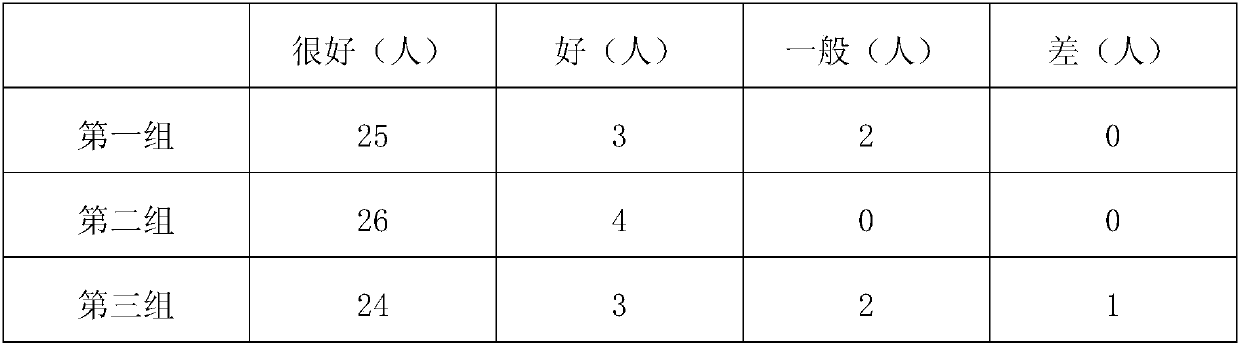

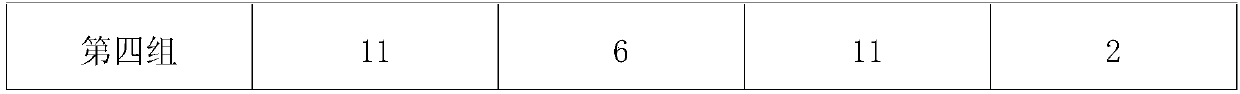

PendingCN110106048AImprove playbackQuality improvementMicroorganism based processesAlcoholic beverage preparationAcetic acidYeast

The invention relates to the field of brewing technologies, and particularly relates to koji for fermented baijiu, application, fen-favor koji baijiu and a preparation method. The koji for the fermented baijiu is mainly prepared from first pure bran yeast, second pure bran yeast, traditional distiller's yeast and seed koji in a mass ratio of (10-20):(5-15):5:(65-75). The koji for the fermented baijiu adopts a combination of high-yield ethyl acetate yeast and low-yield fusel oil yeast, and the technical gap that in the prior art, there is no technology to achieve the aims of increasing the content of ethyl acetate in the baijiu and reducing the content of the fusel oil in the baijiu at the same time by using mixed yeast from the perspective of the koji is filled up. The preparation method of the fen-favor koji baijiu comprises the steps that the koji for the fermented baijiu is inoculated into a fermentation raw material for mixing, and after sequential cultivation saccharification, vinasse mixing, fermentation and distillation, the fen-favor koji baijiu is obtained.

Owner:JING BRAND

Strong fragrance type baijiu with pressure reduction and blood activating functions and preparation method of baijiu

The invention provides strong fragrance type baijiu with pressure reduction and blood activating functions and a preparation method of baijiu and relates to the technical field of processing of agricultural products. The strong fragrance type baijiu is prepared from raw materials in parts by weight as follows: 50-60 parts of glutinous sorghum, 20-30 parts of corn flour, 15-20 parts of barley, 3-6 parts of L-theanine, 15-20 parts of distiller's yeast and a proper amount of water. The strong fragrance type baijiu with pressure reduction and blood activating functions contains complete and sufficient nutrition, food materials have the best effect and tastes in a specific formula with a secrete preparation method, the baijiu is clear, transparent, pleasantly fragrant, mellow, sweet and luscious, has strong flavor of baijiu in a mild aromatic flavor, baijiu in a strong aromatic flavor and baijiu in a Maotai flavor, has a refreshing aftertaste, integrates strong aromatic baijiu, Maotai-flavor baijiu and mild aromatic baijiu, has a novel taste, performs the body-building healthcare function, is safe and reliable and has no toxic or side effects.

Owner:韦朝胜

Aging accelerating method on basis of baijiu aging accelerating agents

InactiveCN105647772ANo pollution in the processAging effect unchangedAlcoholic beverage preparationSide effectAdditive ingredient

The invention discloses an aging accelerating method on the basis of baijiu aging accelerating agents. The aging accelerating method includes arranging the aging accelerating agents and baijiu liquid in an aging tank with a jacket according to certain mass and volume ratios, filling the jacket with hot water to guarantee the aging temperatures and intermittently carrying out stirring, gas filling and aging on the baijiu liquid for a certain period of time; mixing fibrous iron-loaded attapulgite-based aging accelerating auxiliaries and attapulgite with one another to obtain mixtures, and granulating and calcining the mixtures to obtain granules with the sizes of 10-20 meshes. The granules are used as the baijiu aging accelerating agents applied to industrial production. The aging accelerating method has the advantages that the baijiu aging accelerating agents are safe, are free of toxic and side effects and can be reused; aging accelerating processes are simple, and conditions are easy to control; the level of strong-flavor baijiu treated by the aid of the aging accelerating method for 20 d is equivalent to the level of baijiu which is stored under usual production conditions for approximately 1 year, and chromatography framework ingredients of the strong-flavor baijiu are obviously different from chromatography framework ingredients of untreated comparison baijiu; as shown by sensory evaluation of baijiu tasters, obvious age flavor effects can be realized by the treated baijiu, a baijiu body of the baijiu is harmonious, and the baijiu is soft, sweet and mellow and has clean and cool aftertaste.

Owner:庞全岭

Huai style strong fragrance type Baijiu

ActiveCN105087342AOvercome biasOvercome the defects of unaccustomed drinkingAlcoholic beverage preparationThroatContinuous fermentation

The invention discloses Huai style strong fragrance type Baijiu. The production method of the Huai style strong fragrance type Baijiu includes the steps of firstly, strong fragrance culturing; secondly, Maotai-flavor fermenting; thirdly, cross-steaming; fourthly, storing and aging, to be more specific, respectively placing various types of qujiu obtained in the first, second and third steps into pottery jars and sealing, storing at 20-25 DEG C for more than a year, marking, and blending after formation. The Huai style strong fragrance type Baijiu has the advantages that the Baijiu combines Maotai flavor, multi-grain strong fragrance, sesame fragrance, Xiaoqu fragrance and medicine fragrance, raw materials such as sorghum, rice, wheat, sticky rice and corn are added at the same time, a mud aged fermentation pit and a fermentation pit with a stone wall and a mud bottom are used to perform multiple continuous fermentation of different fragrance stages, multiple steaming and multiple Baijiu taking are performed, storing is performed according to fermentation times and level, long-term aging is performed, and elaborate blending is performed; the produced Baijiu has multi-grain strong fragrance, the Maotai flavor, fragrance, sesame fragrance, unique flavor and multiple flavor and fragrance, is coordinated in flavor, and is soft, thick, smooth, fine, throat cooling, refreshing, and long in after taste.

Owner:ANHUI LETIAN BREWING

Glutinous rice wine and preparation technology thereof

InactiveCN107828588APromote secondary fermentationGreat tasteMetabolism disorderAntipyreticBiotechnologyPolygonum fagopyrum

The invention provides glutinous rice wine and a preparation technology thereof, and relates to the technical field of alcoholic beverage. The glutinous rice wine comprises 60 to 85 parts of glutinousrice, 20 to 35 parts of barley, 10 to 15 parts of lycium barbarum, 10 to 20 parts of buckwheat, 5 to 9 parts of distillery yeast, and 15 to 25 parts of a functional agent. The glutinous rice wine iscomplete and sufficient in nutrition, sufficiently realizes efficacy and taste of all food materials through a specific recipe and a secretly-made preparation method, is clear, transparent, fresh, strong and fragrant in maotai-flavour, pleasant, mellow, rounded, harmonious, and enjoyable in aftertaste, combines three Baijiu flavors of strong flavor, maotai-flavor and fragrance, is fresh in mouthfeel, meanwhile can achieve the body building health care effect, is safe and reliable, and does not have any toxic and side effects.

Owner:广西驰胜农业科技有限公司

Homemade lepidium meyenii, jujube, and sorghum co-fermented white liquor with enhanced yeast

InactiveCN106434170AImprove glycationImprove liquefactionMicroorganism based processesAlcoholic beverage preparationPectinaseTriticeae

The invention discloses homemade lepidium meyenii, jujube and sorghum co-fermented white liquor. The liquor is prepared by the following raw materials in parts by weight: the balance of distilled water, the balance of monascus strain, the balance of aspergillus niger, the balance of yeast strain, 0.06-0.0.07 part of sterile water, 2500-2600 parts of sorghum, 9-10 parts of wheat, 1-1.2 parts of barley, 1-2 parts of banana, polygonum hydropiper, 200-220 parts of lepidium meyenii, 150-160 parts of Xinjiang Ruoqiang jujube, 0.7-0.8 part of cellulase, and 0.7-0.8 part of pectinase. The base of the homemade lepidium meyenii, jujube and sorghum co-fermented white liquor is made of enhanced yeast, has the advantages of pure scent, refreshing aftertaste, and long taste. The healthcare effects of lepidium meyenii and jujube are integrated. Compared with conventional grain liquor, the homemade lepidium meyenii, jujube and sorghum co-fermented white liquor better conforms to the concept of health drinking, and is worthy of popularization.

Owner:马鞍山市太白酒厂

Method for preparing reconstructed tobacco-leaf cigarette paper by replacing part of wood pulp with bamboo pulp

InactiveCN105040511AImprove physical performanceImprove suction qualityPaper coatingPulping with inorganic basesPulp and paper industryPhysical property

The invention discloses a method for preparing reconstructed tobacco-leaf cigarette paper by replacing part of wood pulp with bamboo pulp. The method comprises the steps such as boiling of bamboo chips, bamboo pulping, wood pulping, preparation of base paper and coating. The method has the advantages that the bamboo pulp is utilized for replacing part of the wood pulp for preparation of the reconstructed tobacco-leaf cigarette paper, so that not only can the physical property of the reconstructed tobacco-leaf cigarette paper be improved, but also the suction character of the reconstructed tobacco-leaf cigarette paper and the smoke quality can be improved; moreover, wood gas, odors doped in cigarette aroma, and the irritation are reduced, so that the smoke can be more fragrant and the remaining taste can be cleaner.

Owner:HUBEI CHINA TOBACCO IND +1

Cigarette essence capable of improving quality of cigarettes

ActiveCN103351951ASmoke is soft and delicateClean aftertasteTobacco preparationEssential-oils/perfumesApple peelIrritation

The invention relates to a cigarette essence capable of improving the quality of cigarettes. The cigarette essence comprises alcohol, an apple peel extract, a tomato extract, a platycodon grandiflorum extract, vanillin, bergamot oil, methyl ionone, cinnamon oil, phenylethyl propionate and propylene glycol. The cigarette essence provided by the invention has the effects of causing smoke to be fine and smooth, and clean in remaining taste, reducing irritation and keeping moisture; therefore, the quality of cigarettes is improved.

Owner:HUABAO FLAVOURS & FRAGRANCES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com