Flue-cured tobacco fermentation process

A fermentation process and tobacco leaf technology, applied in tobacco, tobacco processing, application, etc., can solve the problems of long natural fermentation cycle, large warehouse area, not economical and practical, etc., to reduce energy consumption, reveal aroma, and enhance oily feeling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

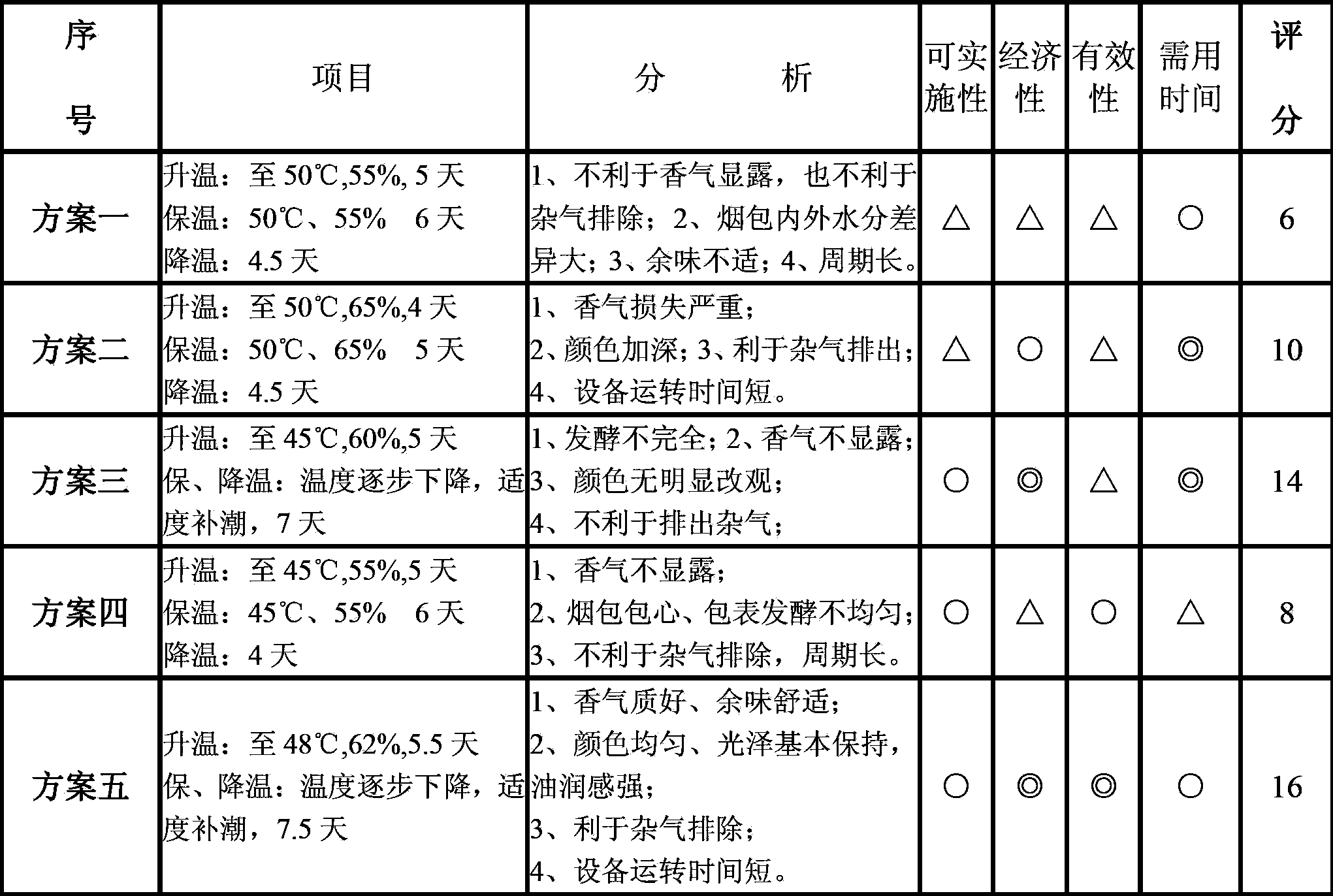

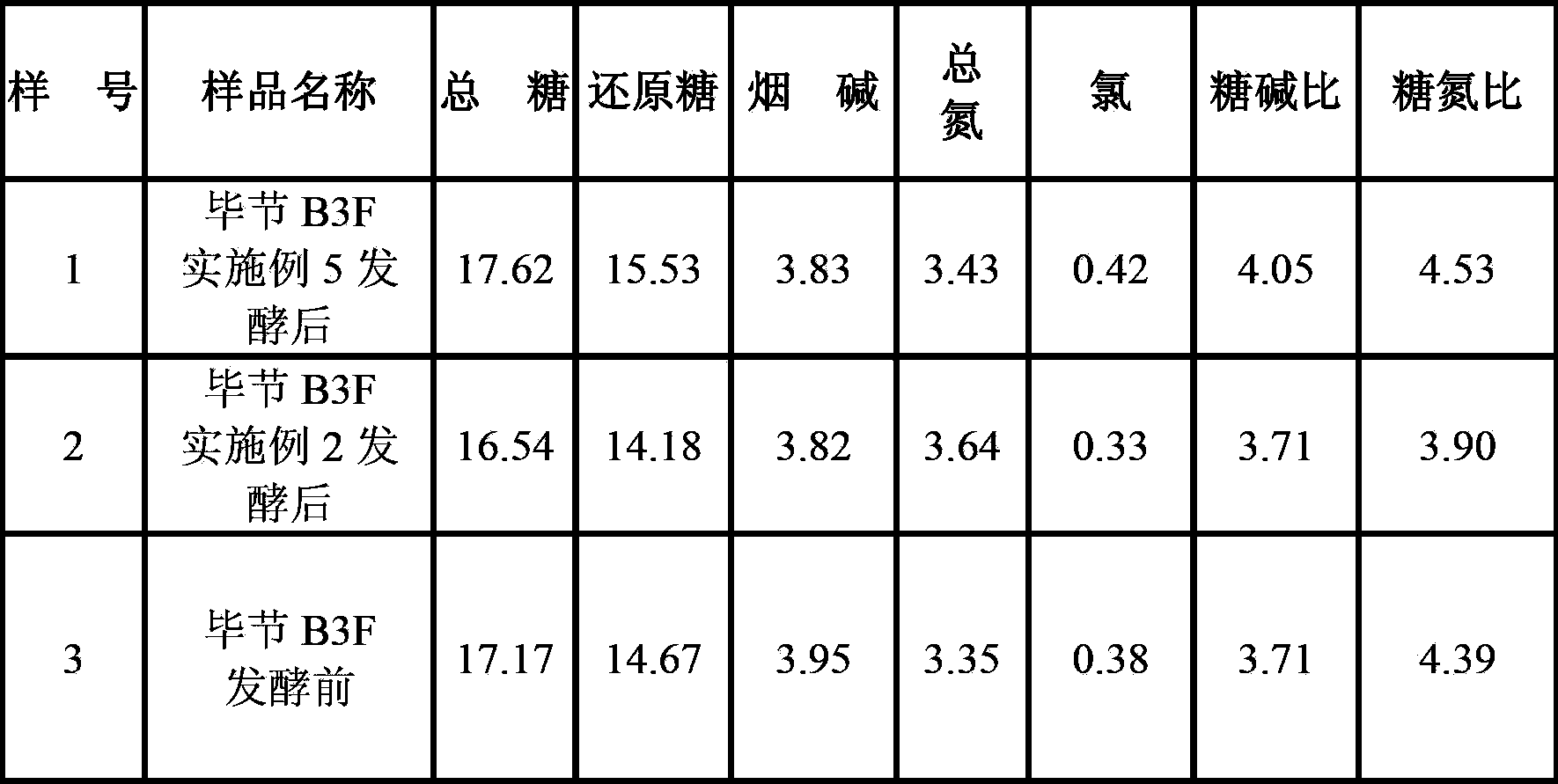

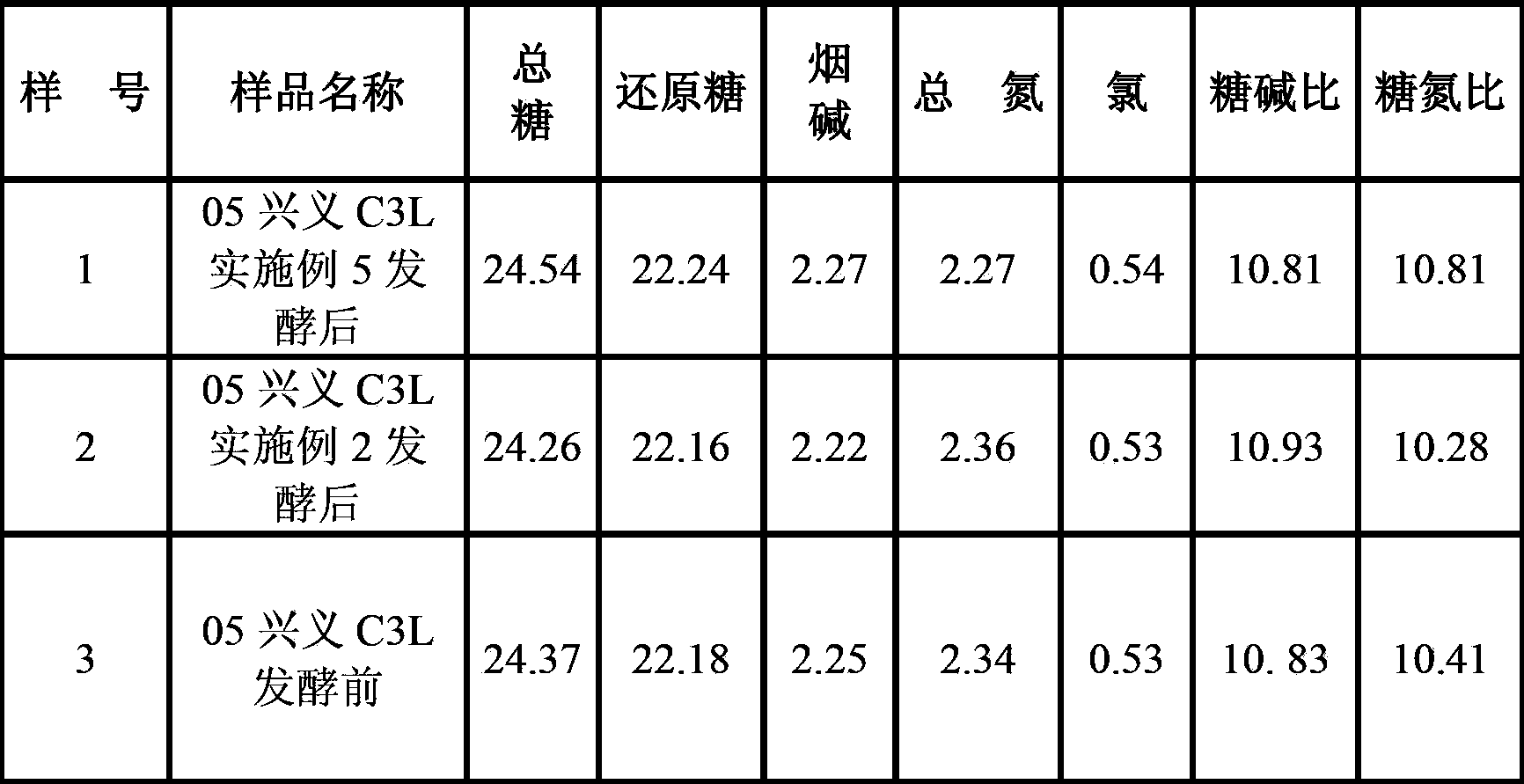

[0029] Fermentation tests on B3F (Bijie, Guizhou) and C3L (Xingyi, Guizhou) tobacco leaves:

[0030] 1) Gradually increase the temperature of the cigarette package to 50°C. During the temperature increase process, the ambient humidity is 55%, and the duration of the entire temperature increase process is 5 days;

[0031] 2) Keep the cigarette package at 50°C and 55% ambient humidity for 6 days;

[0032] 3) Gradually lower the temperature of the cigarette pack to 30-33°C, and the duration of the entire cooling process is 4.5 days.

[0033] After combining the fermentation results of the two tobacco leaves, the specific evaluation results are shown in Table 1.

Embodiment 2

[0035] Fermentation tests on B3F (Bijie, Guizhou) and C3L (Xingyi, Guizhou) tobacco leaves:

[0036] 1) Gradually increase the temperature of the cigarette package to 50°C. During the temperature increase process, the ambient humidity is 65%, and the duration of the entire temperature increase process is 4 days;

[0037] 2) Keep the cigarette package at 50°C and 65% ambient humidity for 5 days;

[0038] 3) Gradually lower the temperature of the cigarette pack to 30-33°C, and the duration of the entire cooling process is 4.5 days.

[0039] After combining the fermentation results of the two tobacco leaves, the specific evaluation results are shown in Table 1.

Embodiment 3

[0041] Fermentation tests on B3F (Bijie, Guizhou) and C3L (Xingyi, Guizhou) tobacco leaves:

[0042] 1) Gradually increase the temperature of the cigarette package to 45°C. During the temperature increase process, the ambient humidity is 60%, and the duration of the entire temperature increase process is 5 days;

[0043] 2) Gradually lower the temperature of the cigarette package to 30-33°C, and the duration of the entire cooling process is 7 days.

[0044] After combining the fermentation results of the two tobacco leaves, the specific evaluation results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com