Patents

Literature

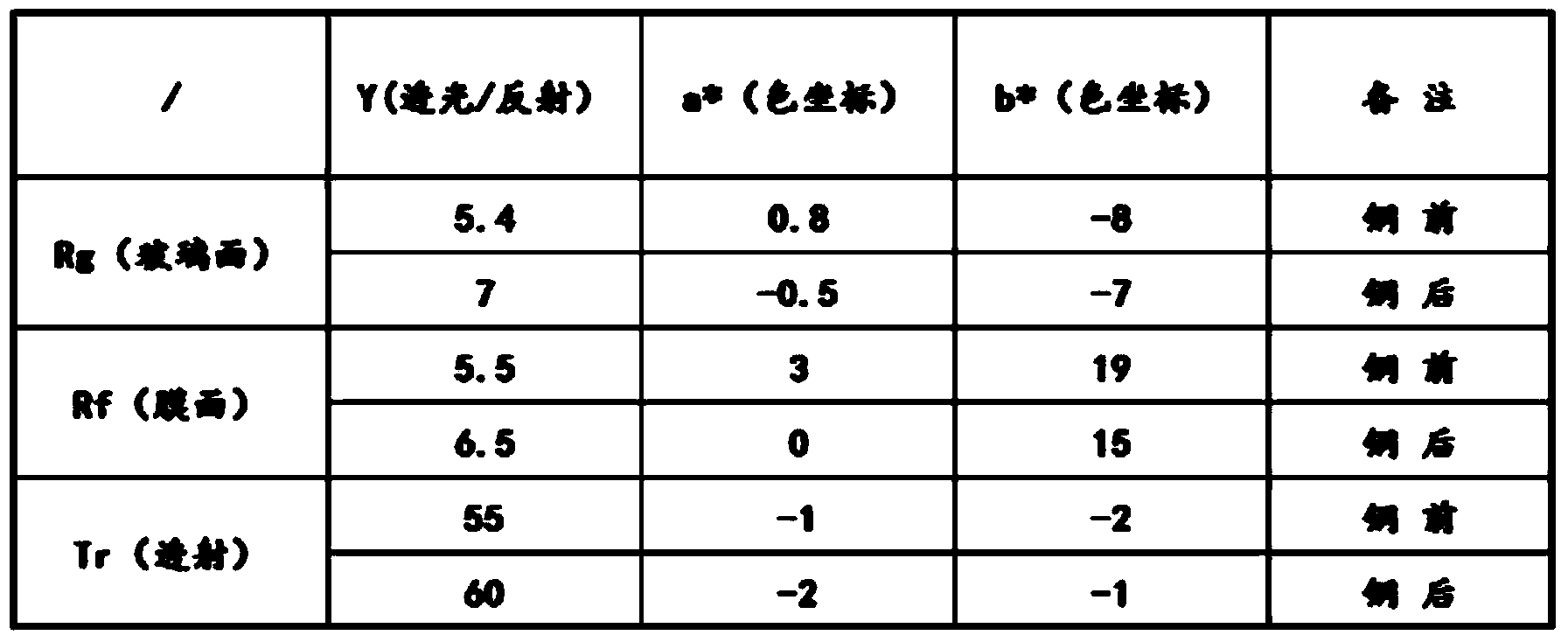

159results about How to "Improve processing resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

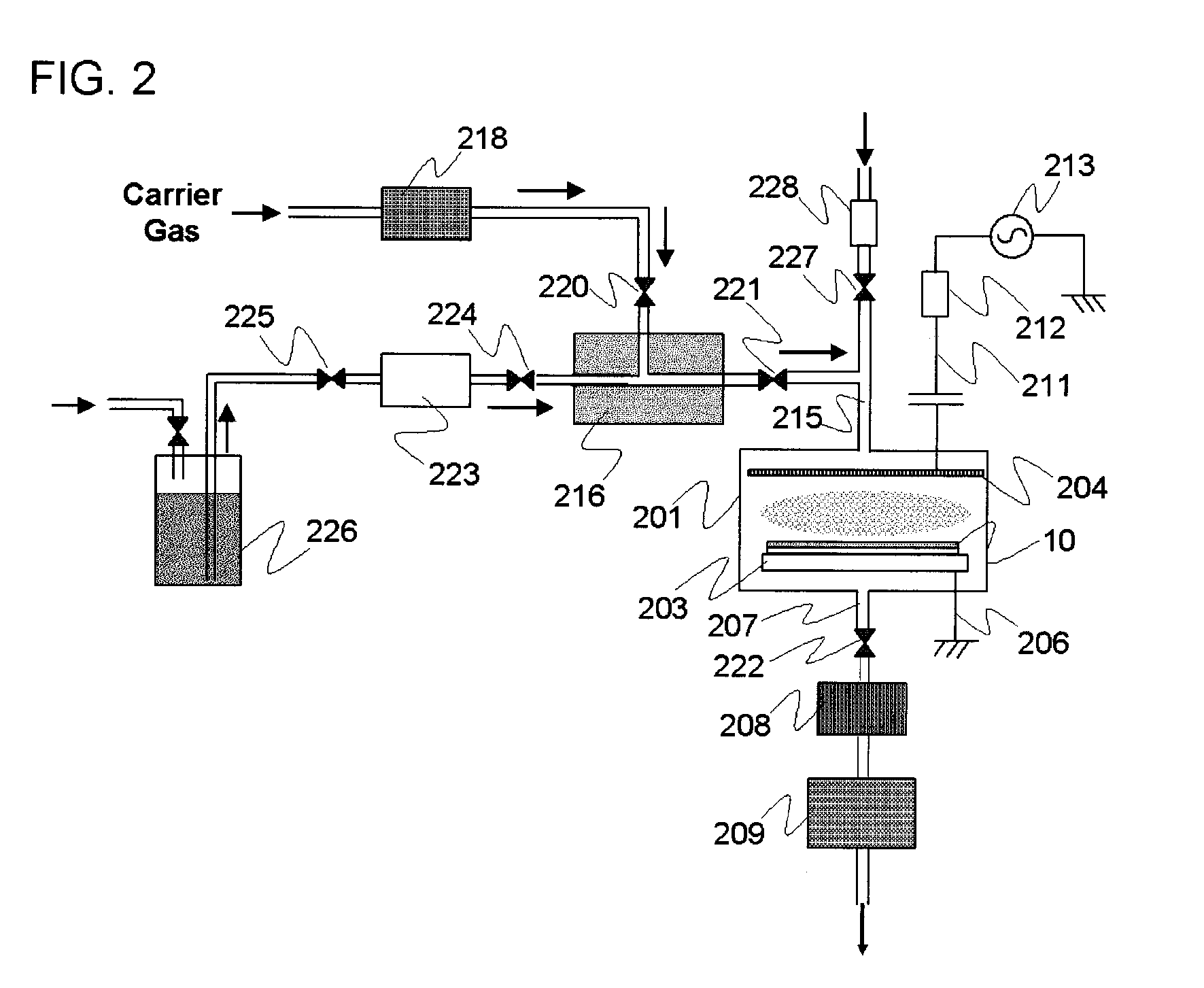

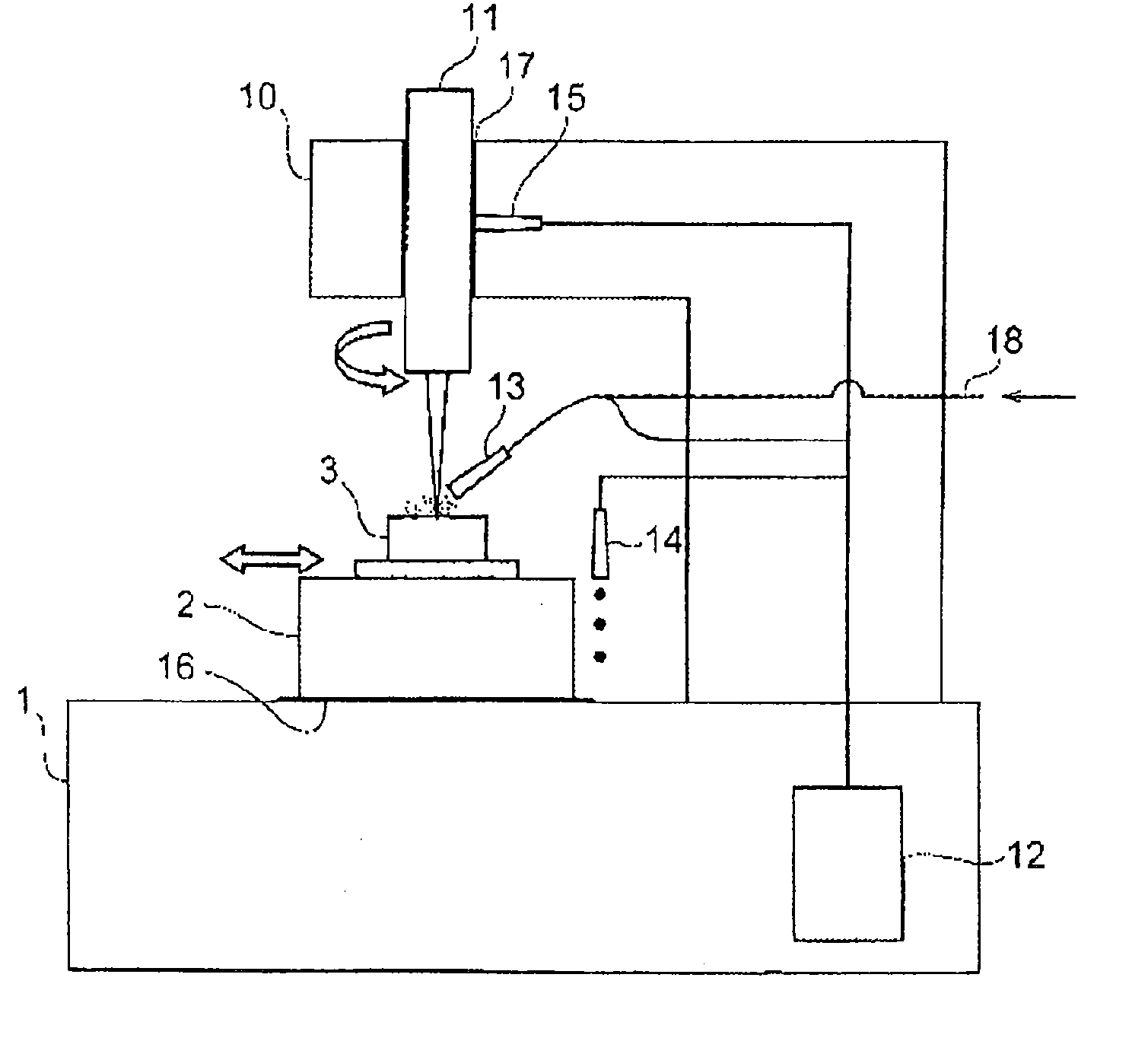

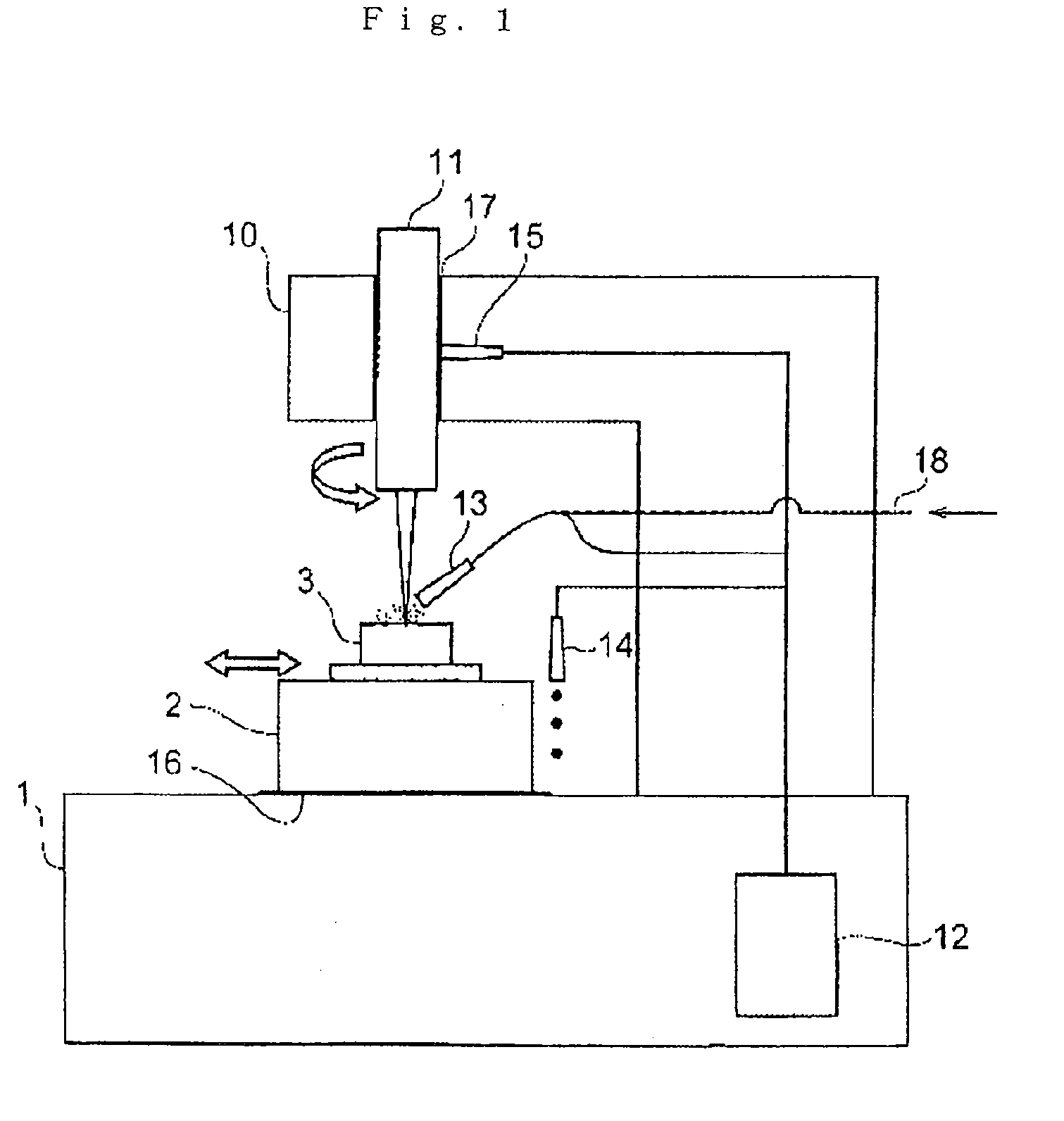

Method of manufacturing semiconductor device

InactiveUS20110171775A1Without deteriorating reliability of deviceHigh bonding strengthSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductorPlasma polymerization

A method of manufacturing a semiconductor device includes forming a first insulating film over an underlying film by plasma polymerization of cyclic siloxane, and forming a second insulating film on the first insulating film by plasma polymerization of the cyclic siloxane continuously, after forming the first insulating film. The deposition rate of the first insulating film is slower than the deposition rate of the second insulating film.

Owner:RENESAS ELECTRONICS CORP

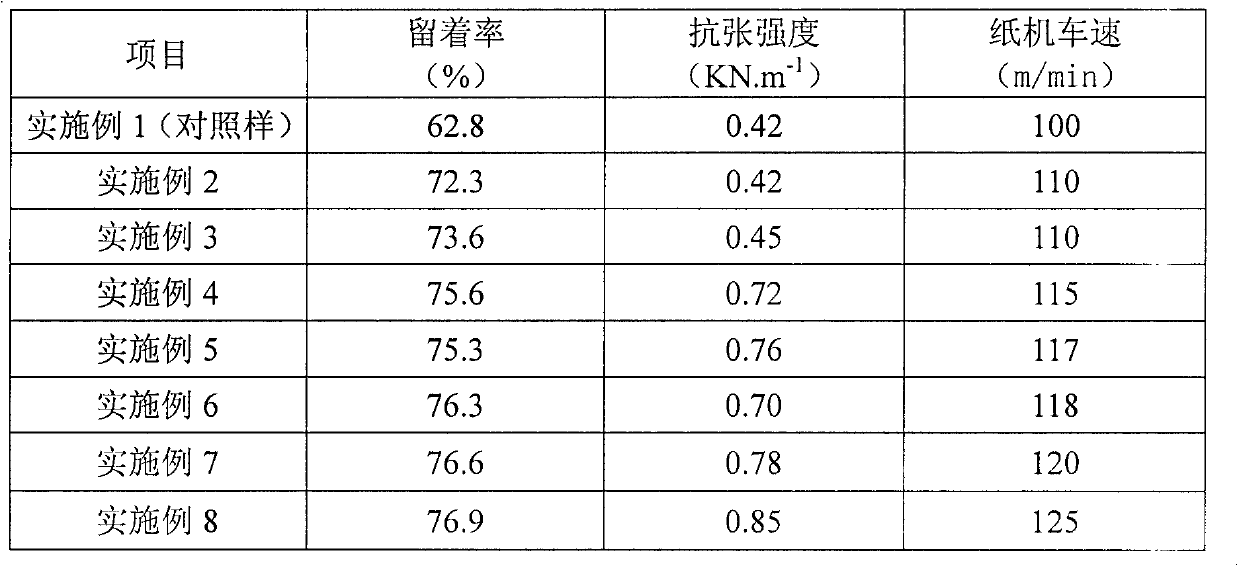

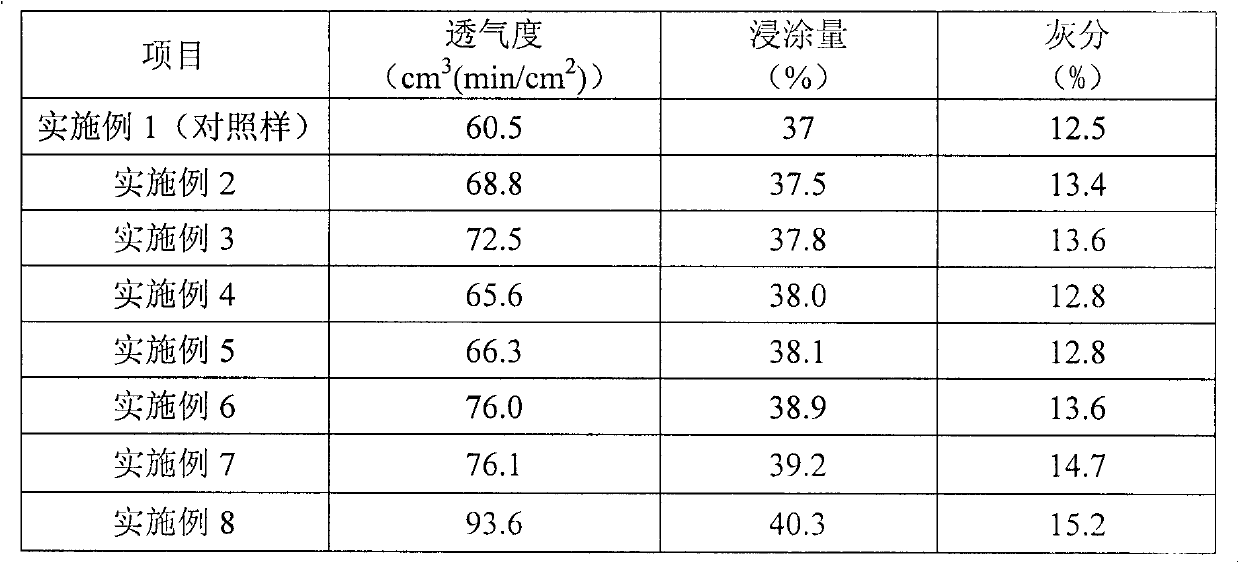

Preparation method for paper-making process tobacco sheet and finished product of paper-making process tobacco sheet

ActiveCN103141928AImprove single layer retentionImprove breathabilityTobacco preparationPlant fibrePaper based

The invention belongs to the field of tobacco industry and relates to a preparation method for a functional harm-reduction and tar-reduction paper-making process tobacco sheet and a finished product of the paper-making process tobacco sheet. The preparation method for the paper-making process tobacco sheet comprises the following steps of extracting and concentrating effective components of tobacco; mixing formulas; pulping and blending fibers; manufacturing paper with pulp; dipping, drying and tearing and shaping. The blending process comprises the following steps of: adding non-tobacco plant fiber pulp of which the beating concentration is 3-4 percent and the Schopper-Riegler (SR) beating degree is 18-28 to tobacco mixed fiber pulp, adding filling to a machine chest, regulating the pulping concentration to 2-3 percent by water, and evenly mixing. By the use or the combine use of the filling and the non-tobacco plant fiber pulp, the combustion state of the sheet can be improved while physical properties, such as the air permeability, the retention and the tensile strength of a paper base, are improved, i.e., harmful ingredients of smoke, such as tar and carbon monoxide of the paper-making process tobacco sheet, can be effectively reduced, and hazard indexes of cigarettes are reduced. Meanwhile, technical-economic indicators, such as the speed and the input- output efficiency of a paper machine, also can be improved.

Owner:杭州利群环保纸业有限公司

Method for producing tobacco sheets by paper making method

ActiveCN101695407AIncrease the content of reaction intermediatesPromotes Maillard reactionTobacco preparationMaillard reactionPhosphate

The invention relates to a method for producing tobacco sheets by a paper making method, which is characterized by using acidic proteinase, pectase and amylase to carry out biological degradation on sheet materials, improving the content of Maillard reactants in a tobacco extraction liquid, utilizing Maillard reaction catalysts, namely phosphate, phosphate, dibasic alkaliine, dihydric phosphate, propanediol and the like, and regulating and controlling the condition of reaction medium, on-line promoting the Maillard reaction in a tobacco aqueous solution, and improving the content of Maillard reaction intermediates and products in concentrated solution. The method for producing the tobacco sheets by the paper making method can reduce acrimony and offensive taste of the sheets, coordinate smell, improve after taste and improve comfort level of sheet suction.

Owner:CHINA TOBACCO ANHUI IND CO LTD

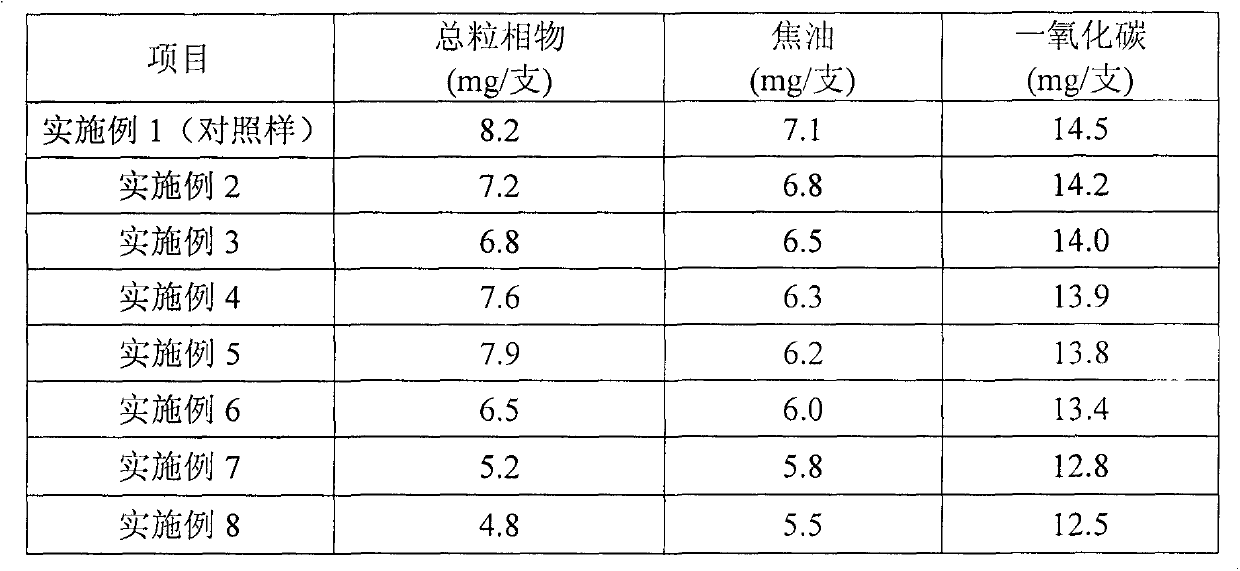

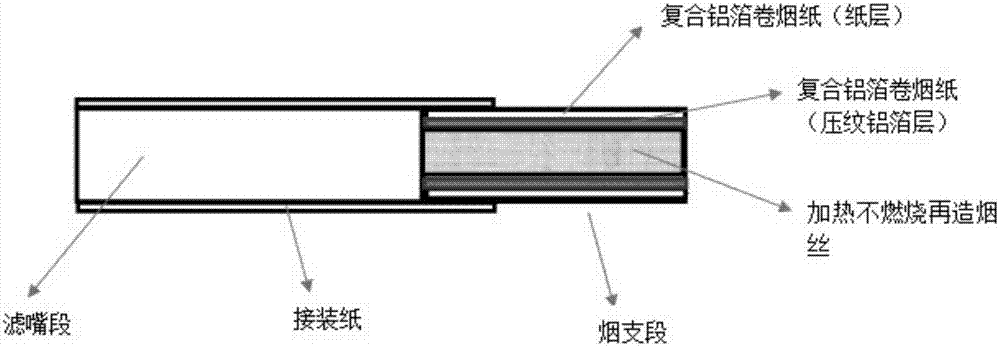

Method for preparing heating but incombustible cigarettes and application thereof

ActiveCN107981405AIncrease frictionLow costTobacco preparationCigarette manufactureKnurlingEngineering

The invention discloses a method for preparing heating but incombustible cigarettes and application thereof. The method and the application have the advantages that novel knurling rolling technologiesare adopted, accordingly, heating but incombustible reconstituted tobaccos with certain thicknesses have uneven surfaces, the surface areas can be enlarged, atomization effects can be enhanced, and surface frictional force can be enlarged; embossed composite aluminum-foil cigarette paper is adopted, accordingly, friction between the reconstituted tobaccos and aluminum-foil pattern surfaces of thecomposite aluminum-foil cigarette paper which is a cigarette making and plug assembling material can be greatly enhanced when the reconstituted tobaccos and the composite aluminum-foil cigarette paper are loaded in a cigarette making and plug assembling machine and cigarette making and plug assembling are powered on in later periods, the heating but incombustible cigarettes are easy to process, equipment shutdown frequencies can be reduced, the heating but incombustible cigarettes can be continuously produced, the production efficiency can be improved, and the material cost and the productioncost can be reduced; low-temperature cigarettes have short cut tobacco sections, accordingly, friction can be improved, the method is beneficial to reducing cut tobacco dropping, and the shortcomingsof low frictional force between smooth surfaces of existing heating but incombustible reconstituted tobaccos and non-embossed aluminum-foil paper which is a wrapping material, severe slipping, frequent equipment shutdown due to incapability of driving cigarette paper, influence on production efficiency, low frictional force due to short cut tobacco sections of existing low-temperature cigarettes,vulnerability to dropping of low-temperature cut tobaccos of the existing low-temperature cigarettes and the like can be overcome.

Owner:HUBEI CHINA TOBACCO IND

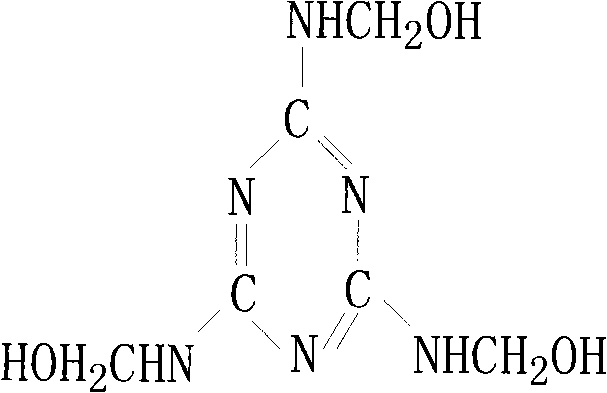

Heat-storage and heat-preservation microcapsules and preparation method and application thereof

ActiveCN102002343AImprove processing resistanceImprove wear resistanceFibre treatmentHeat-exchange elementsTemperature controlIn situ polymerization

The invention relates to phase-change energy-storage microcapsules and a preparation method and application thereof, in particular to heat-storage and heat-preservation microcapsules by taking a core material as a phase-change energy-storage material, and a preparation method and application thereof. Each microcapsule consists of a core, an internal nuclear shell and an external nuclear shell, wherein the core material is an organic phase-change material; the internal nuclear shell takes vinyl monomers as polymerizing monomers and packs the core through interfacial polymerization; and the external nuclear shell takes etherified melamine resin prepolymers as polymerizing monomers and packs the internal nuclear shell through in-situ polymerization. The heat-storage and heat-preservation microcapsules have thermosetting properties of microcapsule walls, high processing resistance, high abrasive resistance and high durability. The heat-storage and heat-preservation microcapsules can be used for heat-preservation finishing of textiles and building heat-preservation materials and can ensure the higher phase change energy of the organic phase-change materials of the cores of the heat-storage and heat-preservation microcapsules, the organic phase-change materials cannot flow or shift after phase change, so that a temperature control function can be enduringly kept.

Owner:溧阳常大技术转移中心有限公司

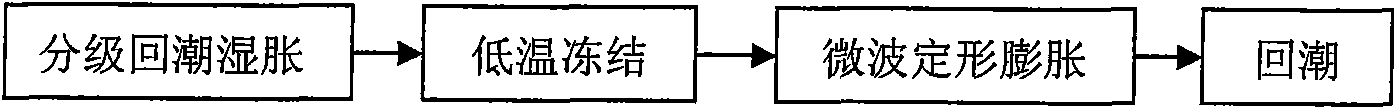

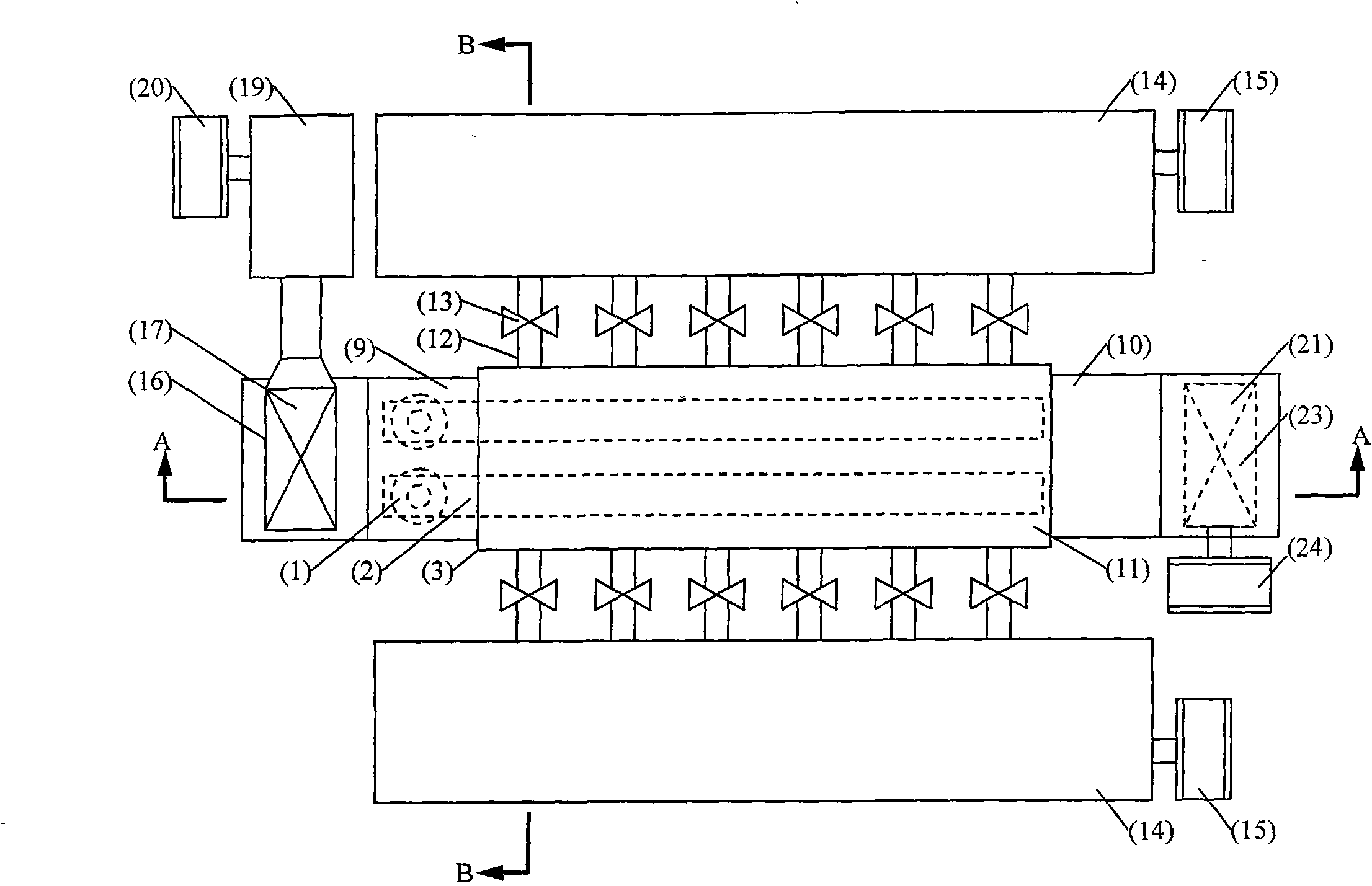

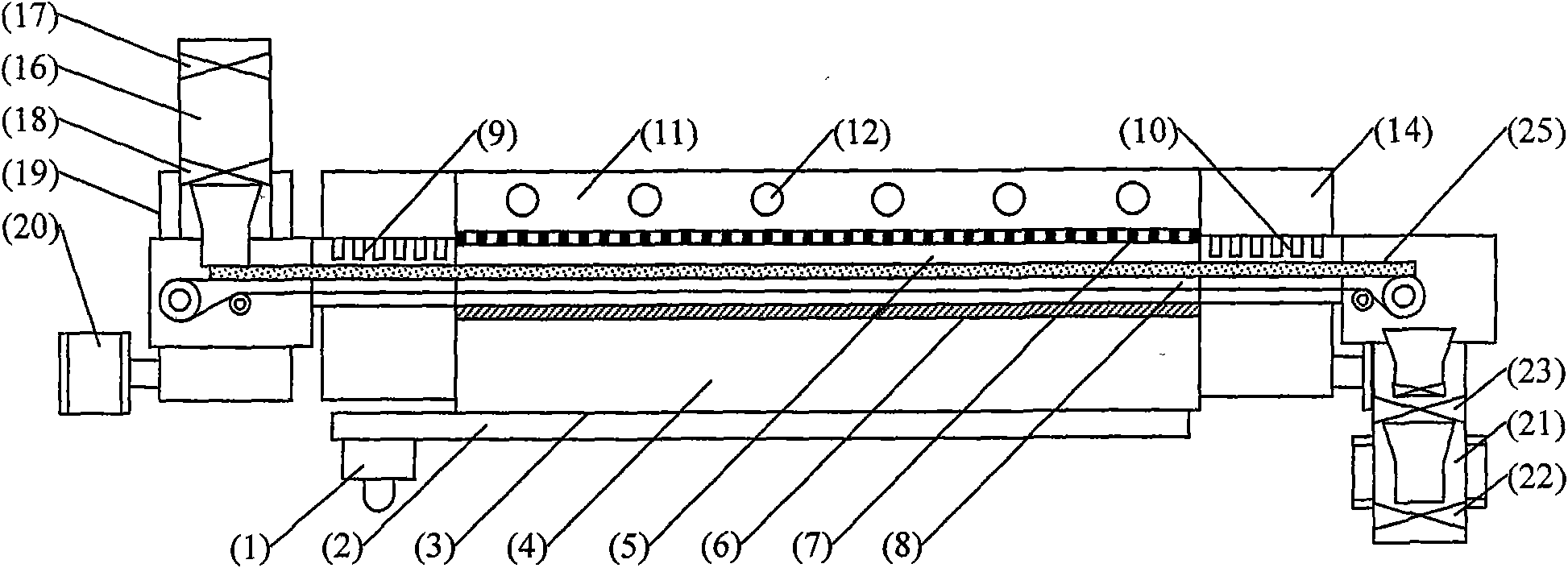

Low-temperature microwave expansion process of cut tobacco

The invention relates to a low-temperature microwave expansion process of cut tobacco. The process comprises the following steps of: putting expanded cut tobacco with the water content of 40-70 percent by rating resurgence in a die; then, freezing into blocks at a temperature of 55 DEG C below zero to 35 DEG C below zero; conveying the cut tobacco blocks into a microwave continuous freeze-dried system to sublimate and dry until the water content is 3-8 percent; and finally resurging to the water content of 12-13 percent to obtain a finished product of expanded cut tobacco. The cut tobacco is expanded by the process of the invention has the advantages of remarkable aroma and fragrance, lower breakage rate, remarkably lessened odor and controllable expansion degree.

Owner:周川

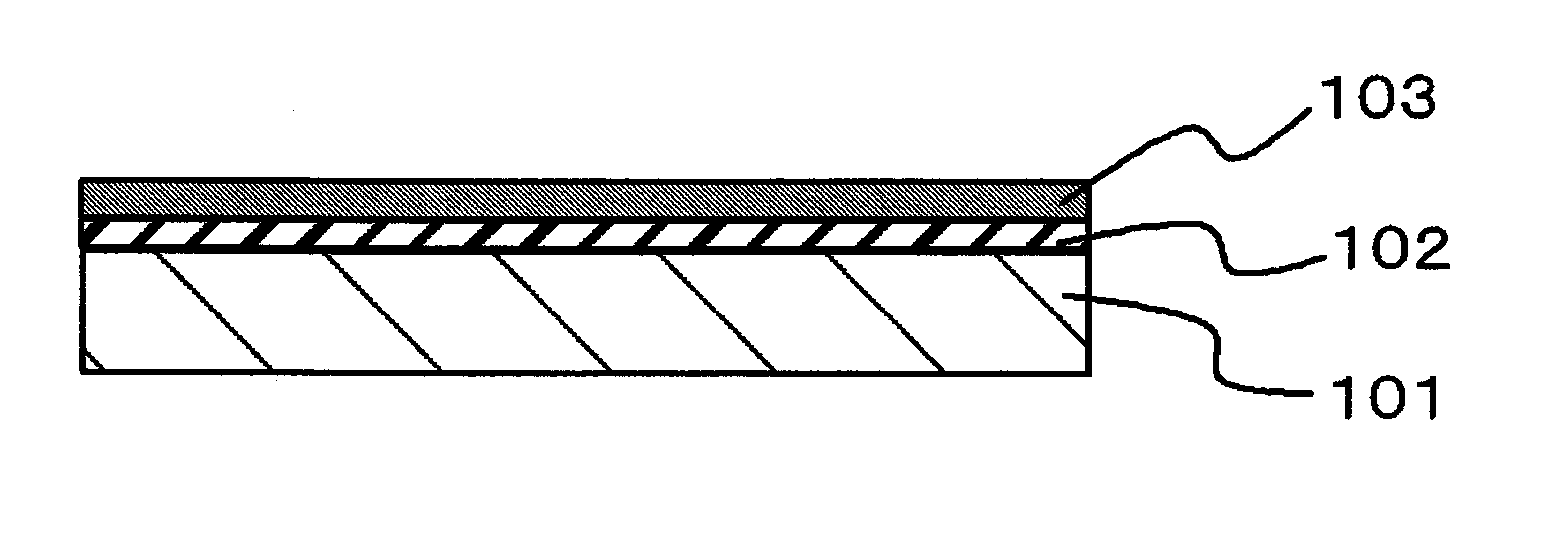

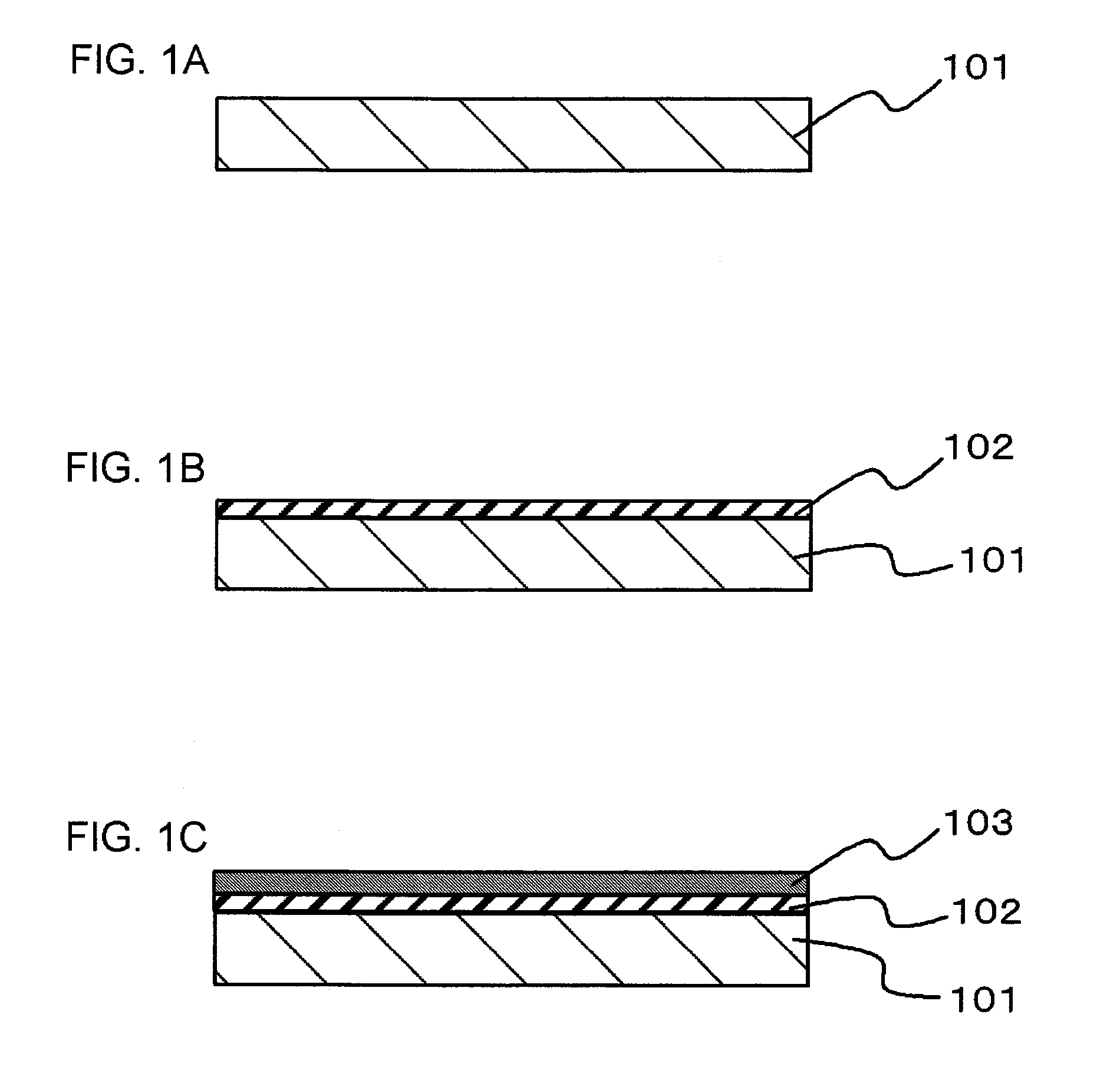

Insulating film and method of forming the same

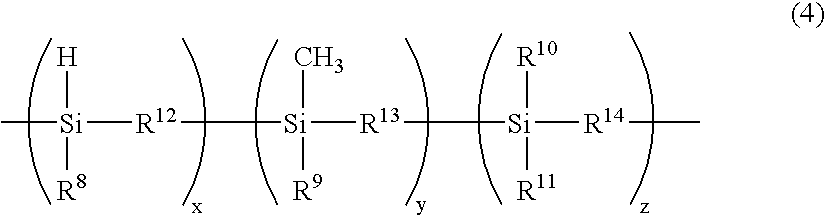

InactiveUS20060210812A1Increase in of multilayeringLow dielectric constantLiquid surface applicatorsSemiconductor/solid-state device detailsSilane compoundsCompound (substance)

A method of forming an insulating film includes: forming a polysiloxane insulating film on a substrate; forming a polycarbosilane insulating film on the polysiloxane insulating film; and forming an organic insulating film on the polycarbosilane insulating film. The polysiloxane insulating film is formed by hydrolysis and condensation of a silane compound, and the polycarbosilane insulating film is formed by applying a solution, obtained by dissolving a polycarbosilane compound in a solvent, to the polysiloxane insulating film, and heating the resulting coating,

Owner:JSR CORPORATIOON

Photochromic double-shell microcapsule and preparation method and application thereof

InactiveCN102886233AHas thermosetting propertiesImprove processing resistanceTenebresent compositionsMicroballoon preparationIn situ polymerizationWear resistant

The invention relates to a photochromic double-shell microcapsule and a preparation method and application thereof. The microcapsule comprises a core, an internal shell and an external shell, wherein the core is manufactured by a photochromic material; the internal shell adopts vinyl monomer as polymerizing monomer, and wraps the core in an interfacial polymerization way; and the external shell adopts etherifying melamine resin prepolymer as polymerizing monomer, and wraps the internal shell in an in-situ polymerization way. The photochromic double-shell microcapsule provided by the invention is simple in preparation technology, and is non-toxic and innocuous; the wall of the microcapsule is high in toughness, is wear-resistant, heat-proof and water-proof, is good in processability, and is capable of permanently implementing a photochromic function; and the photochromic double-shell microcapsule can be applied to the field of textile and printing, and meets the demands on personalization and counterfeiting prevention.

Owner:CHINA TEXTILE ACAD JIANGNAN BRANCH

Nonwoven material and its processing method

InactiveCN101457479AImprove water absorptionLarge water absorption (about 8-11 times), high water absorption speedFibre typesMonocomponent polyolefin artificial filamentFiltrationNonwoven fabric

The invention provides a non-woven material and a processing method thereof. The non-woven material is produced by processing 4 layers of materials, melt-blown nonwovens are placed between two layers of spunbond nonwovens to produce SMS compound nonwovens in accordance with SMS compound manufacturing technique, then the laminating technology is adopted to compound waterproof breathable layers on the SMS compound nonwovens to produce four layers of spunmelt hydrophilic anti-infiltration non-woven material, the non-woven material is finally made after going through the steps such as feeding, meltdown, filtration, measurement, spinning, stretching, cooling, web formation, hot air air-thru bonding and winding; the non-woven material is flexible, safe, sanitary and cheap, thus being widely applied in hospitals, nursing rooms, hotels and other hygiene medical systems.

Owner:山东省非织造材料工程技术研究中心

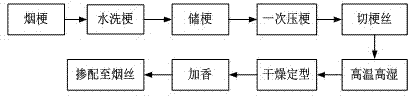

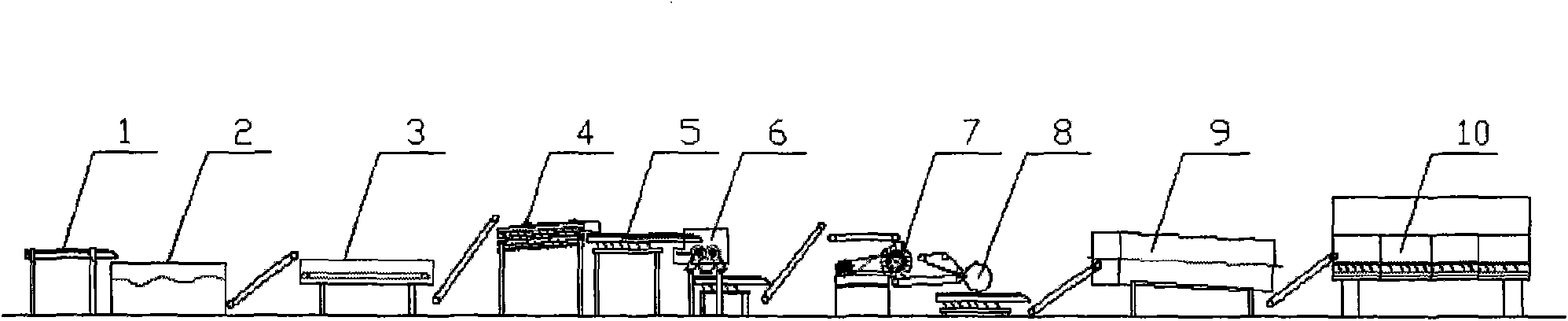

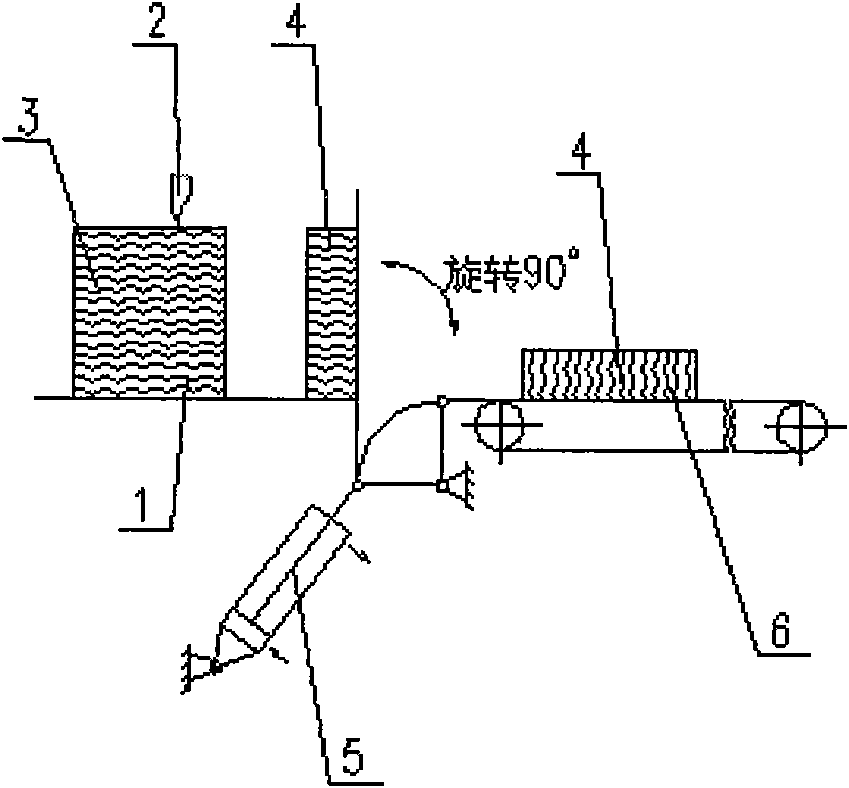

Tobacco stem pressing and shredding technology

The invention discloses a tobacco stem pressing and shredding technology and belongs to the technical field of tobacco processing. The technology comprises the steps of conducting high-temperature high-pressure and decompression preprocessing on tobacco stems, conducting microwave expansion on tobacco stems, humidifying and storing tobacco stems, heating and humidifying tobacco stems, pre-pressing tobacco stems, conducting secondary stem pressing, conducting ternary stem pressing, feeding stems, shredding stems, shaping and drying stem shreds, and perfuming and storing stem shreds. The technology has the advantages that the quality consistency of stem shreds is good, the physical property of stem shreds is closer to that of leaf shreds, organoleptic quality and padding value are high, the uniformity, stability and blending ratio of stem shreds blended with leaf shreds are improved, cigarette quality is improved, the application range and utilization rate of stem shreds in cigarettes are increased, and tar reduction, harm reduction, cost reduction and benefit increasing are realized.

Owner:CHINA TOBACCO YUNAN NEW MATERIAL

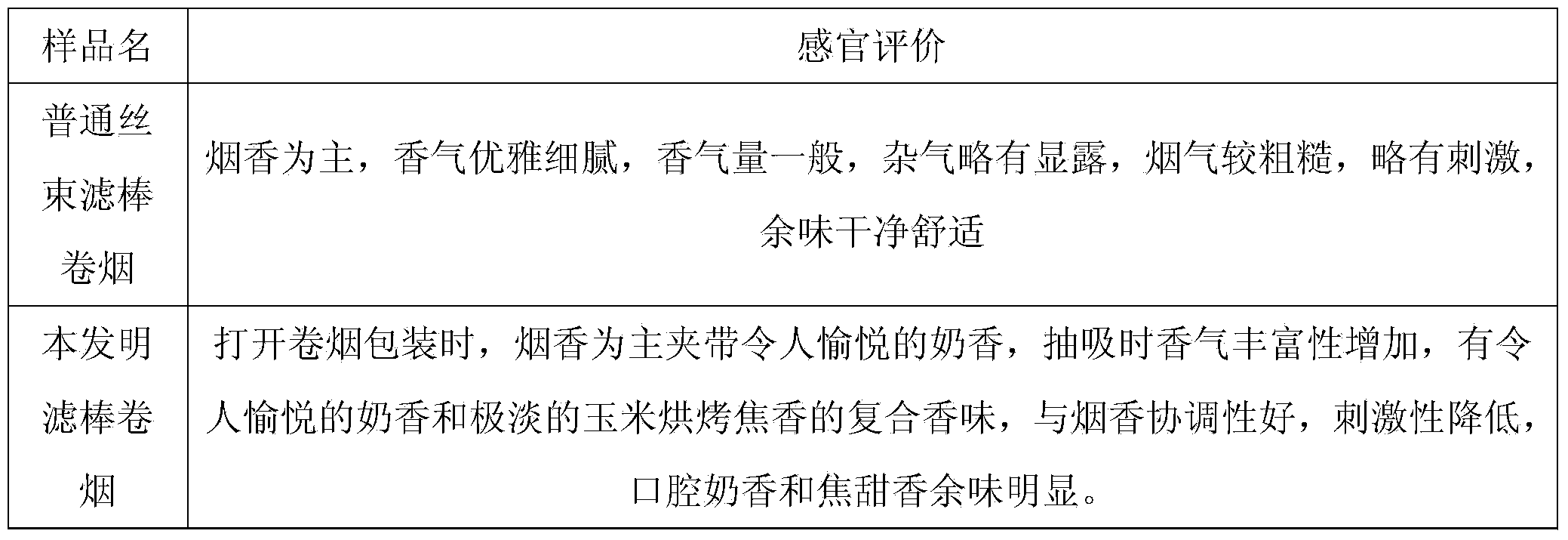

Fragrance enhanced granular additive for filter sticks and preparation method and application thereof

The invention discloses a fragrance enhanced granular additive for filter sticks and a preparation method and application thereof. The fragrance enhanced granular additive for the filter sticks is prepared and obtained by mixing fragrant edible powder, vegetal granular powder, a binding agent and a swelling agent via a solution, squeezing for granulation and microwave drying; the prepared fragrance enhanced granular additive for the filter sticks is added in the filter sticks of cigarettes to enhance fragrance and lower tar content in smoke; the fragrance enhanced granular additive is few in add amount and great in tar content lowering; specific composite fragrance is provided with the cigarettes are smoked, and more abundant experience in taste and smell is brought to smokers. In addition, the preparation method of the fragrance enhanced granular additive for the filter sticks is simple and low in production cost, and industrial production can be realized.

Owner:CHINA TOBACCO HUNAN INDAL CORP

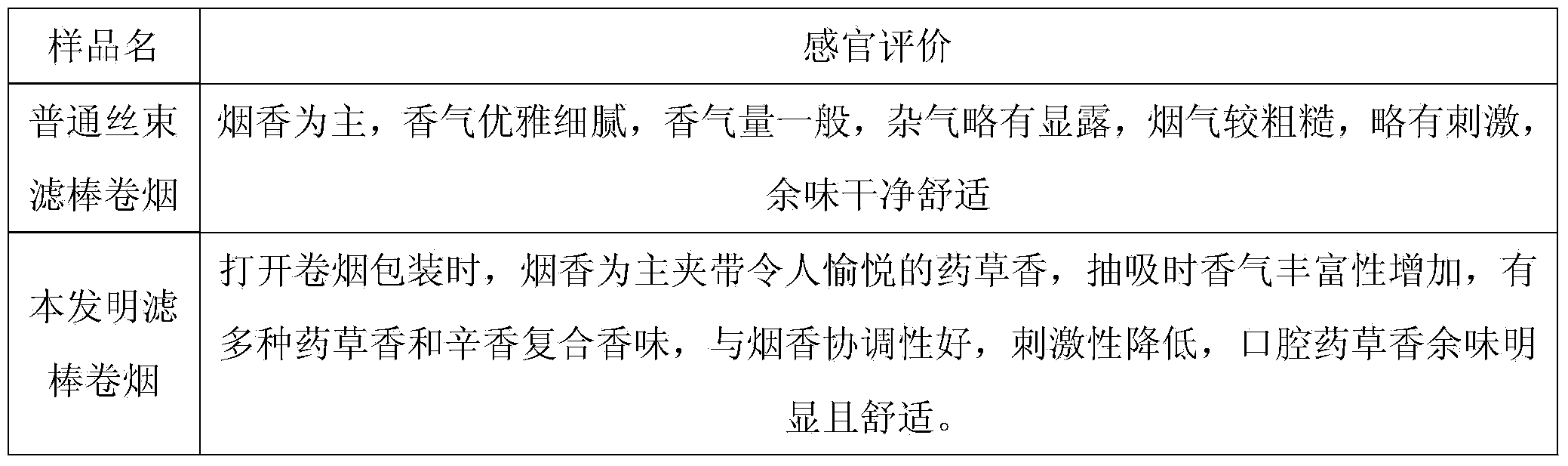

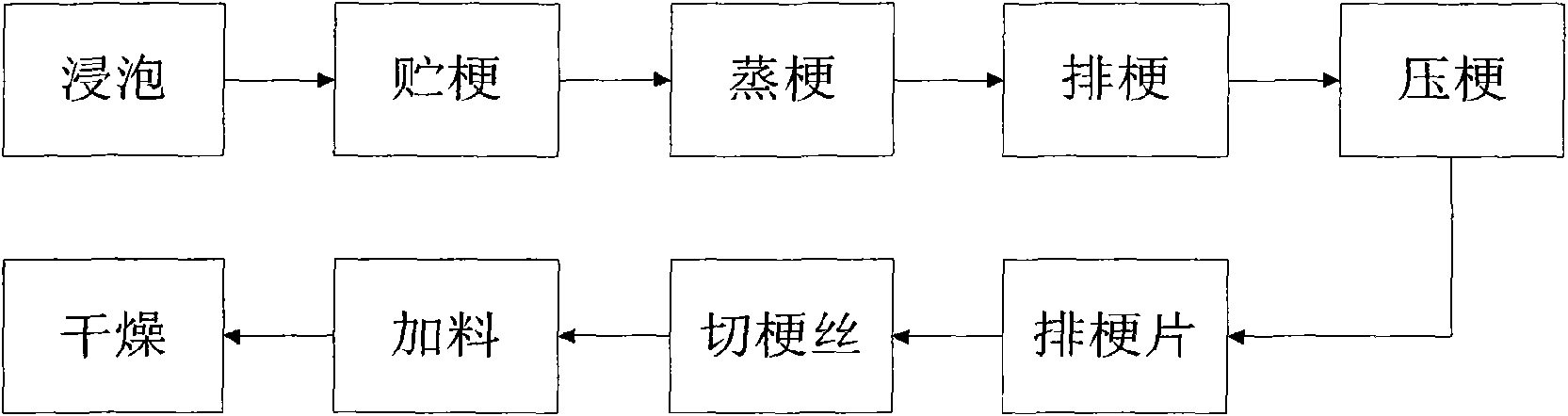

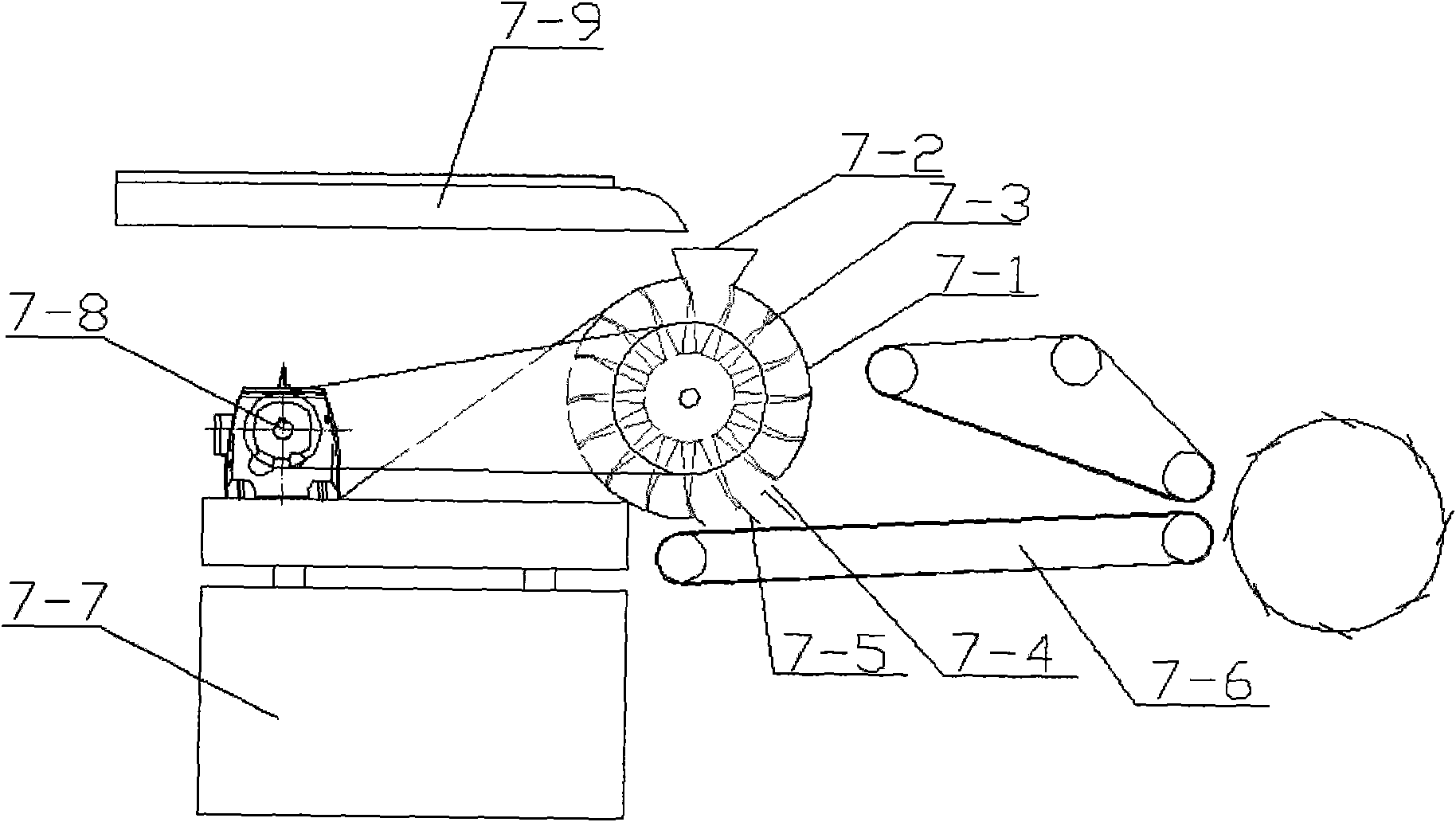

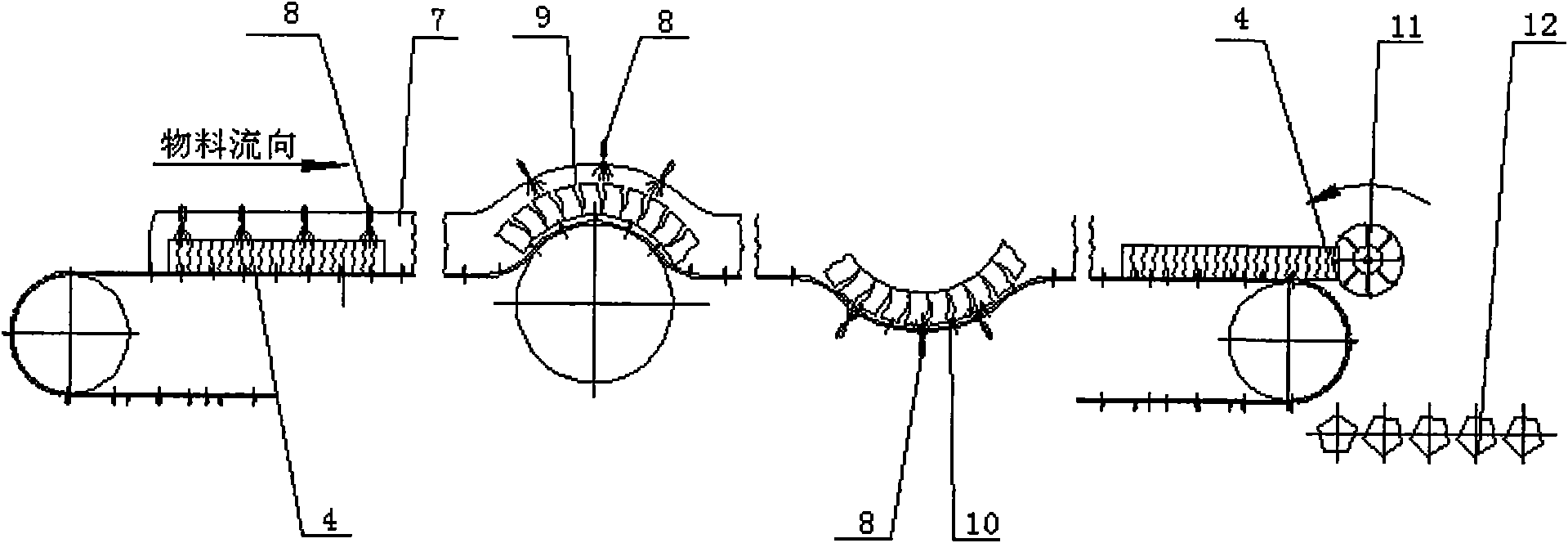

Cabo shredding process and equipment

ActiveCN101647600AFully softenedReduce overlapTobacco treatmentAgricultural engineeringMachining process

The invention relates to a cabo shredding process and equipment. The process comprises the following steps: soaking, cabo storing, cabo braizing, cabo arranging, cabo pressing, cabo slice arranging, cabo shredding, charging and drying. The equipment for realizing the process comprises a soaking device, a cabo storing cabinet, an HT cabo braizing machine, a cabo arranging device, a cabo pressing machine, a cabo slice arranging device, a shredder, a charging machine, a cabo drying machine and united conveyer equipment among the soaking device, the cabo storing cabinet, the HT cabo braizing machine, the cabo arranging device, the cabo pressing machine, the cabo slice arranging device, the cabo shredder, the charging machine and the cabo drying machine. The invention has the advantages that crumbling during the cabo machining process is lower, and the shape of the produced cabo shred is similar to leaf shed; moreover, the processability is good, and the invention can improve the quality and the stability of cigarette products and reduce the cigarette cost can be reduced.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

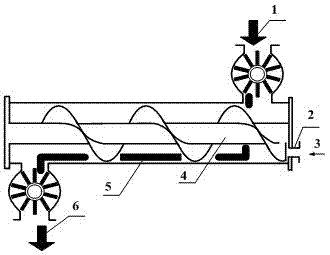

Preparation method of low-temperature coffee-flavored cigarette material of heated-non-combustible cigarette

InactiveCN109393542ARetain aroma substancesGreat tasteTobacco preparationTobacco treatmentFiberAdhesive

The invention discloses a preparation method of a low-temperature coffee-flavored cigarette material of a heated-non-combustible cigarette. The preparation method comprises the following steps: preparing 40-80 parts of coffee grounds, 10-50 parts of wood pulp fibers and 10-15 parts of stuffing in parts by mass; extracting the coffee grounds, and concentrating an extracting solution, so that a coffee ground extract is obtained; mixing and uniformly stirring no more than 5% of the coffee ground extract, 15-50% of an atomizing agent, 0-10% of an adhesive and 0-20% of a perfume in percentage by mass as well as the balance of water, so that coating liquid is obtained; degrading fibers of the extracted coffee grounds or crushing the coffee grounds, mixing the processed coffee ground with the wood milk fibers and the stuffing and making milk, and making a sheet substrate; and coating the coating liquid on the sheet substrate, and implementing drying so as to obtain the low-temperature coffee-flavored cigarette material. The cigarette material prepared by the preparation method provided by the invention reserves a cigarette flavoring material, and the cigarette material is good in taste and is excellent in refreshing and sensory effects; a shortcoming of existing non-tobacco non-combustible cigarettes which are poor in sensory effect is overcome, and the cigarette material, which is free from tar in conventional cigarettes, is quite slight in harm to human body health. The invention also achieves effective utilization of waste coffee grounds; and the low-temperature coffee-flavoredcigarette material is energy-saving and environment-friendly.

Owner:YUNNAN REASCEND TOBACCO TECH GRP

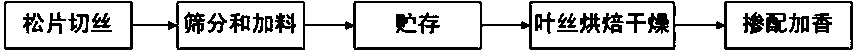

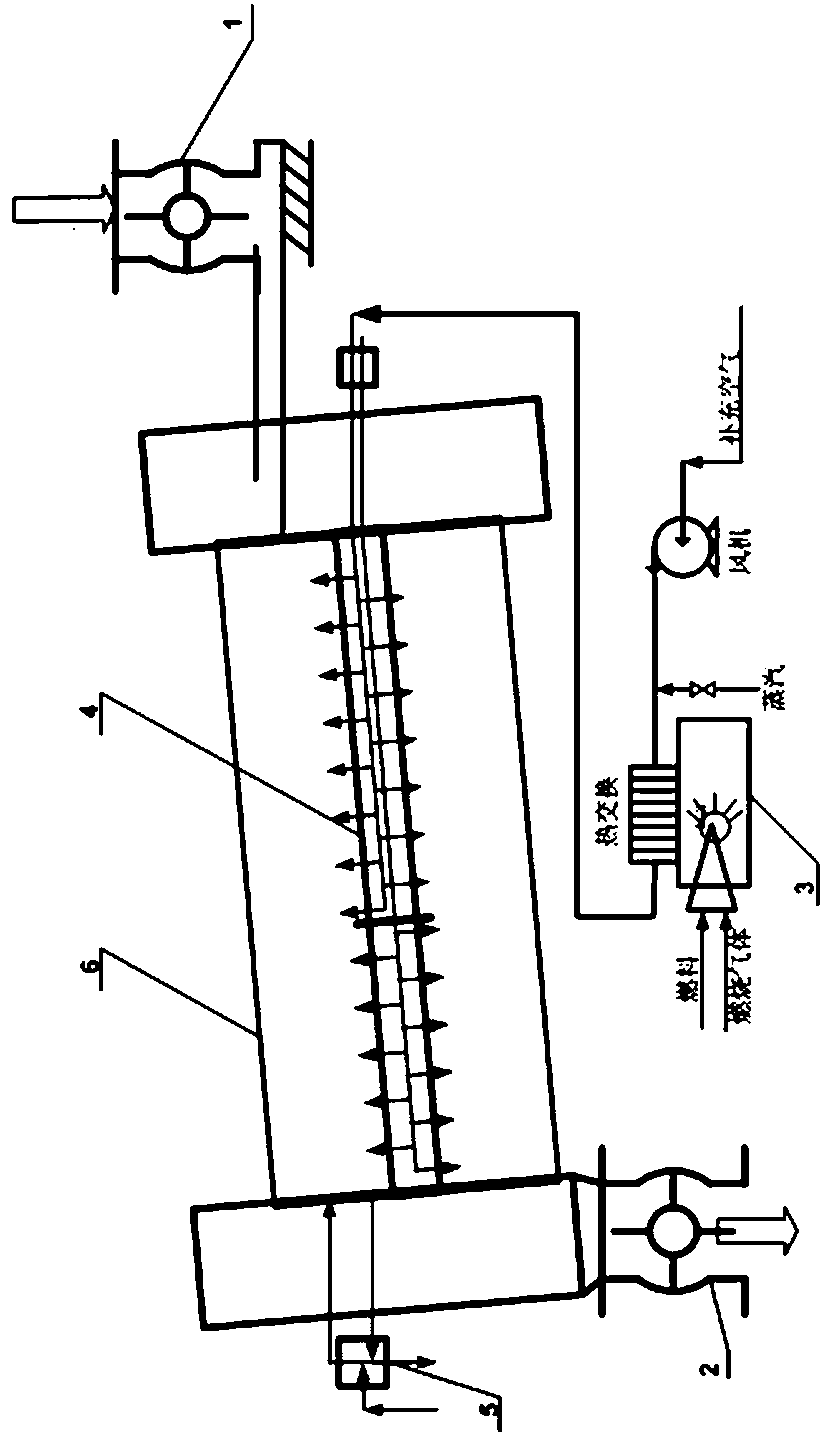

Processing technology of low-quality flue cured tobacco leaf

ActiveCN103300465AThe processing process is reasonableLow process temperatureTobacco preparationCombustionProcess engineering

The invention discloses a processing technology of low-quality flue cured tobacco leaf. Technologies of pine flake thread-cutting and leaf and thread charging are adopted, namely a charging device at the back end of a loose moisture-regain machine is utilized for charging tobacco sheets, and then charging the leaf threads after thread-cutting; components such as moisture-maintaining agent are added to tobacco sheet charging solution, the sheet charging proportion is 1%-3%, and components such as style reinforcing agent are added in leaf thread charging solution, wherein the thread charging proportion is 3%-5%, and the water adding proportion is 7%-10%; with a leaf thread baking and drying technology, a baking machine adopts drum-type construction, a material inlet end and a material outlet end adopt gas lock feeding control, hot source supply adopts two heat transfer manners of cylinder wall heat transfer and combustion furnace hot wind convection, and the processing time of a baking and drying machine is set to be 10-12 minutes. Aiming at the processing characteristics of the low-quality flue cured tobacco leaf, the processing technology of the low-quality flue cured tobacco leaf improves the sensory quality of cigarette, and is more pertinent in the procedure of the processing technology, more reasonable in the processing manner and more flexible in parameters of the processing technology.

Owner:CHINA TOBACCO FUJIAN IND

Loosening and dampening method of tobacco leaves under condition of low intensity

ActiveCN101953507AAvoid excessive heatAvoid "water stained" smokeTobacco preparationTobacco treatmentEngineeringUltimate tensile strength

Owner:SHANGHAI TOBACCO GRP CO LTD +1

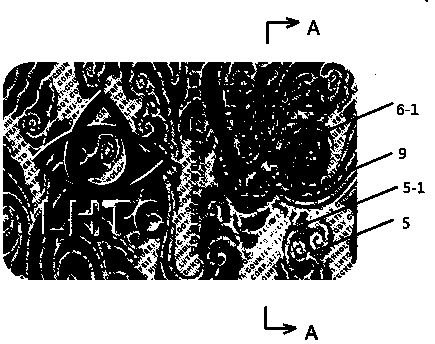

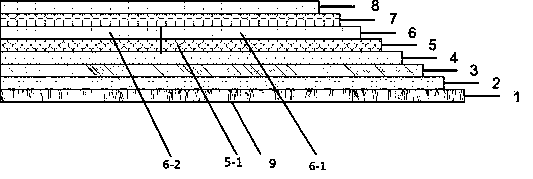

Manufacturing method for double-layer holographic anti-counterfeiting film

InactiveCN104070869ASolve the problem of low inspection and anti-counterfeitingNo loss of functionalityStampsDuplicating/marking methodsInformation layerEngineering

The invention relates to the holographic anti-counterfeiting printing industry, in particular to a manufacturing method for the double-layer holographic anti-counterfeiting film. Printing ink is partially printed between a laser information layer and an aluminum-plated layer, and random anti-counterfeiting holographic color piece carrier dope partially coats the part between the laser information layer and the aluminum-plated layer to form double-layer hologram to prepare a product with the double-layer holographic film; the manufacturing method also can prepare double-layer hologram which is completely coated with the random anti-counterfeiting holographic color piece carrier dope through secondary coating; when identifying, the anti-counterfeiting holographic color piece in the partially anti-counterfeiting holographic color piece carrier dope layer is manually peeled from a product body by an identifying person to server as independent anti-counterfeiting holographic information material; the identifying person inspects the product authenticity in an experience mode, a traditional anti-counterfeiting method is combined with a two-dimensional code, the conversion of the anti-counterfeiting mode provides a lot of product information, different unique anti-counterfeiting methods are used, and the two-dimensional code and the randomly sprayed color piece make up a variety of unique patterns to meet the anti-counterfeiting uniqueness requirement; the double-layer holographic anti-counterfeiting film is a new anti-counterfeiting identifying mode, enables the anti-counterfeiting data information amount to be expanded, is convenient to identify and enables the laser anti-counterfeiting identifying efficiency to be improved.

Owner:HUBEI LHTC ANTI COUNTERFEITING TECH CO LTD

Method of minimal quantity lubrication cutting/grinding processing and oil composition used therefor

ActiveUS20100011923A1Improve processing resistanceImproving cutting and grinding propertyGrinding feed controlAutomatic grinding controlLubricationEngineering

The present invention provides a method of minimal quantity lubrication cutting and grinding that can improve cutting and grinding properties and extend the life of tools. The minimal quantity lubrication cutting and grinding method of the present invention comprises supplying a compressed fluid containing 0.1 to 15 percent by volume of oxygen together with a cutting and grinding oil (particularly preferably an oil composition comprising an ester) to processing spots of a workpiece.

Owner:NIPPON OIL CORP

Low-temperature Microwave Vacuum Drying Technology of Shredded Tobacco

The invention relates to a low-temperature microwave vacuum drying process for tobacco shreds and belongs to the field of processing of the tobacco shreds. The process comprises the following step of: after carrying out moisture regaining, moisture balancing and low-temperature treatment on the tobacco shreds, feeding the tobacco shreds into vacuum drying equipment to be dried so as to obtain tobacco shred finished products with the moisture content of 11.5 percent to 13.5 percent. The drying process is carried out under the conditions of a vacuum pressure of 200Pa to 30kPa, a temperature of 0 DEG C to 70 DEG C and higher moisture content of 30 percent to 70 percent of the tobacco shreds, so that not only color, aroma and taste of the tobacco shreds are maintained, but also a certain filling value is improved. Moreover, the low-temperature microwave vacuum drying process for the tobacco shreds has low tobacco damage ratio and processing resistance performance. Odor and foreign flavor are obviously decreased.

Owner:康琪

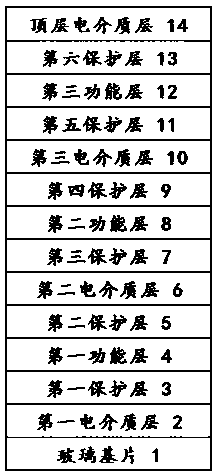

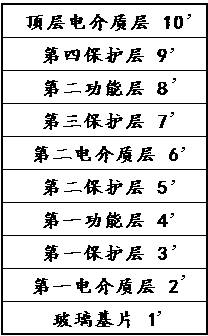

Tempering low-emissivity coated glass containing silver alloy

ActiveCN103802379AGrain refinementHigh hardnessGlass/slag layered productsMetal layered productsLow emissivityHardness

The invention provides tempering low-emissivity coated glass containing silver alloy. The glass comprises a glass substrate and a coating layer deposited on the glass substrate, and is characterized in that the coating layer comprises two or more functional layers, at least one of the functional layers is a silver alloy layer, and the silver alloy layer is made from one of Ag-Cu-Ni or Ag-Cu-Al or Ag-Cu-Pt. According to the tempering low-emissivity coated glass containing the silver alloy provided by the invention, a traditional Ag layer is substituted by the silver alloy layer, a small quantity of alloy metal elements are doped in the Ag layer, Ag crystal particles are refined, the hardness, the abrasive resistance and the burning loss resistance of silver are improved, the optical performance of Ag is changed, the overall glass is perspective and grey, the outdoor color is neutral and is close to natural color which is real and beautiful, and thus the demand of people on the color is satisfied; meanwhile, the processability of the glass is improved, and the oxidation resistance of the glass is enhanced.

Owner:CHANGJIANG GLASS TAIBO

Plant granular aromatic bead and preparation method and application thereof

The invention provides a plant granular aromatic bead and preparation method and application thereof. Dried aromatic plants are ground into a certain mush number of powder, and mixed with nano-calcium carbonate, corn modified starch, water-soluble chitosan, degummed hemp fiber powder and water to obtain a wet material; the wet material is dried after granulation forming, the whole round polishing and atomizing aromatic flavoring steps are carried out after the wet material is dried, the plant granular aromatic bead with regular roundness and size is obtained. The plant granular aromatic bead is added when filament bundles of a filter rod are formed. After the filter rod is formed, the aromatic bead is located in the center of the filter rod and wrapped by the filament bundles. The filter rod is made into cigarettes, harmful substances such as tar content in cigarette smoke are reduced, meanwhile the aroma of the cigarettes is increased, and further rich aroma of cigarette products is provided to meet the pursuit of cigarette aroma of consumers.

Owner:CHINA TOBACCO JIANGXI IND CO LTD +1

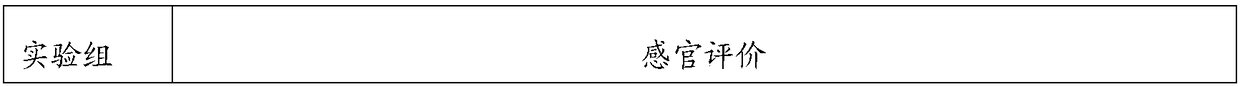

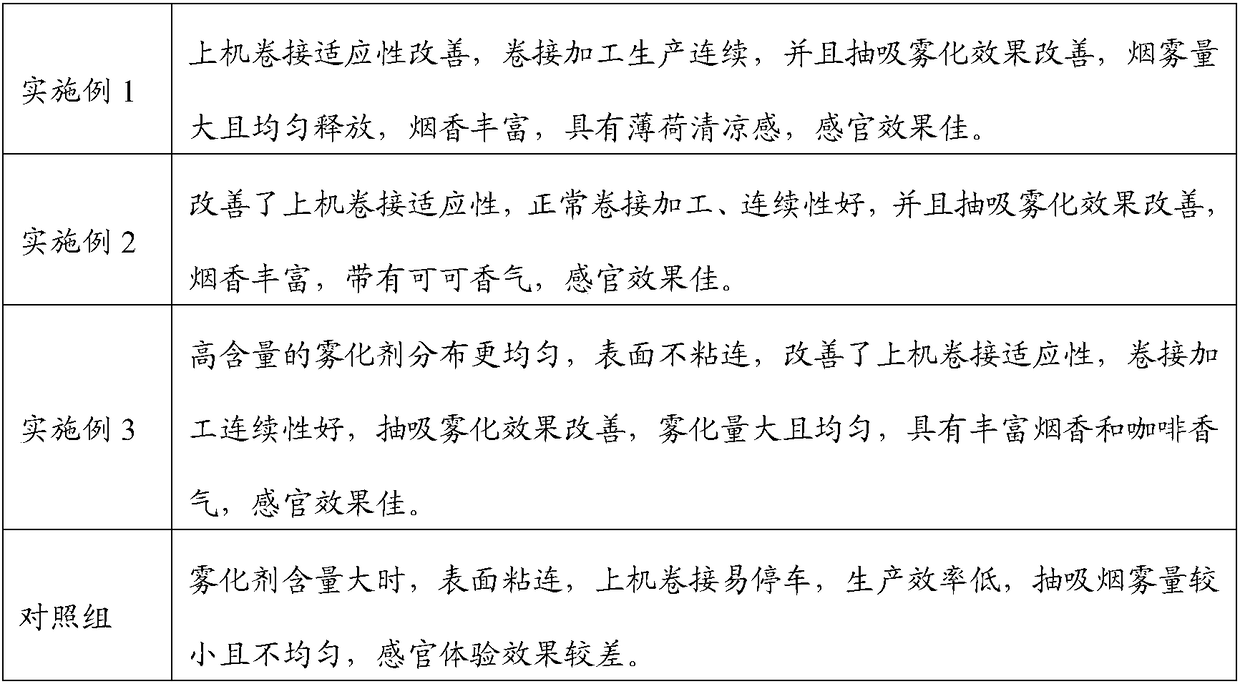

Atomized reconstituted tobacco processing method and application thereof

ActiveCN108208907AWith strengthReduce the broken rateTobacco preparationFood additiveChemical reaction

The invention provides an atomized reconstituted tobacco processing method and application thereof. On the basis of a rolling process, in a process of producing low-temperature reconstituted tobacco,food additives containing carbonate and bicarbonate radical and an acid pickling step are adopted, a chemical reaction is carried out, porous bubbles are produced therein, and the internal surface area is enlarged, so that the high-content atomizing agent is uniform in distribution, surface adhesion is avoided, the strength of the reconstituted tobacco is high, and on-board rolling adaptability ofthe atomized reconstituted tobacco is improved. Therefore, the conventional rolling unit is capable of realizing normal rolling, the production continuity is excellent, the production efficiency is high, and the reconstituted tobacco is improved in smoking and atomizing effect, rich in cigarette aroma and excellent in sensory effect.

Owner:HUBEI CHINA TOBACCO IND +1

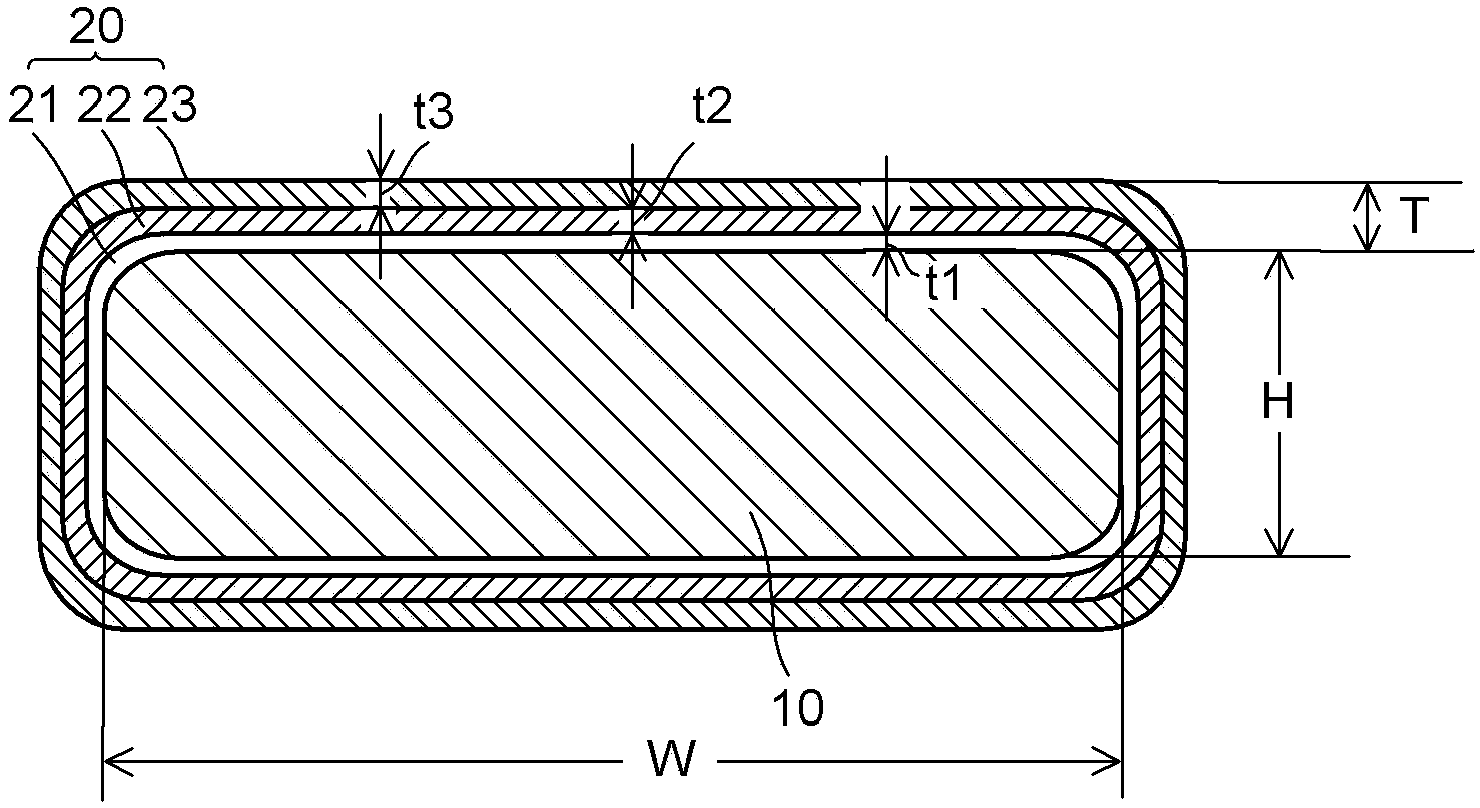

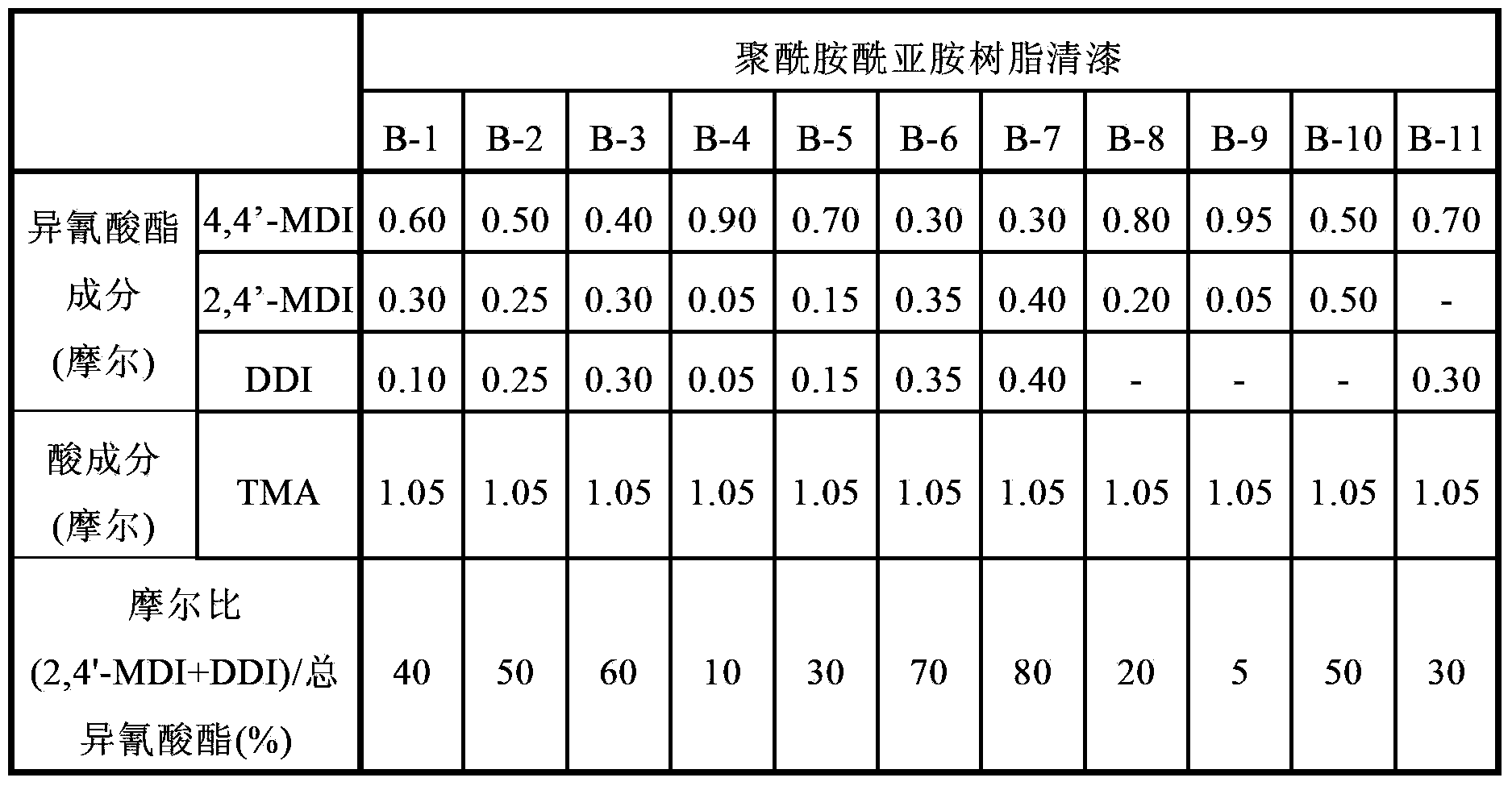

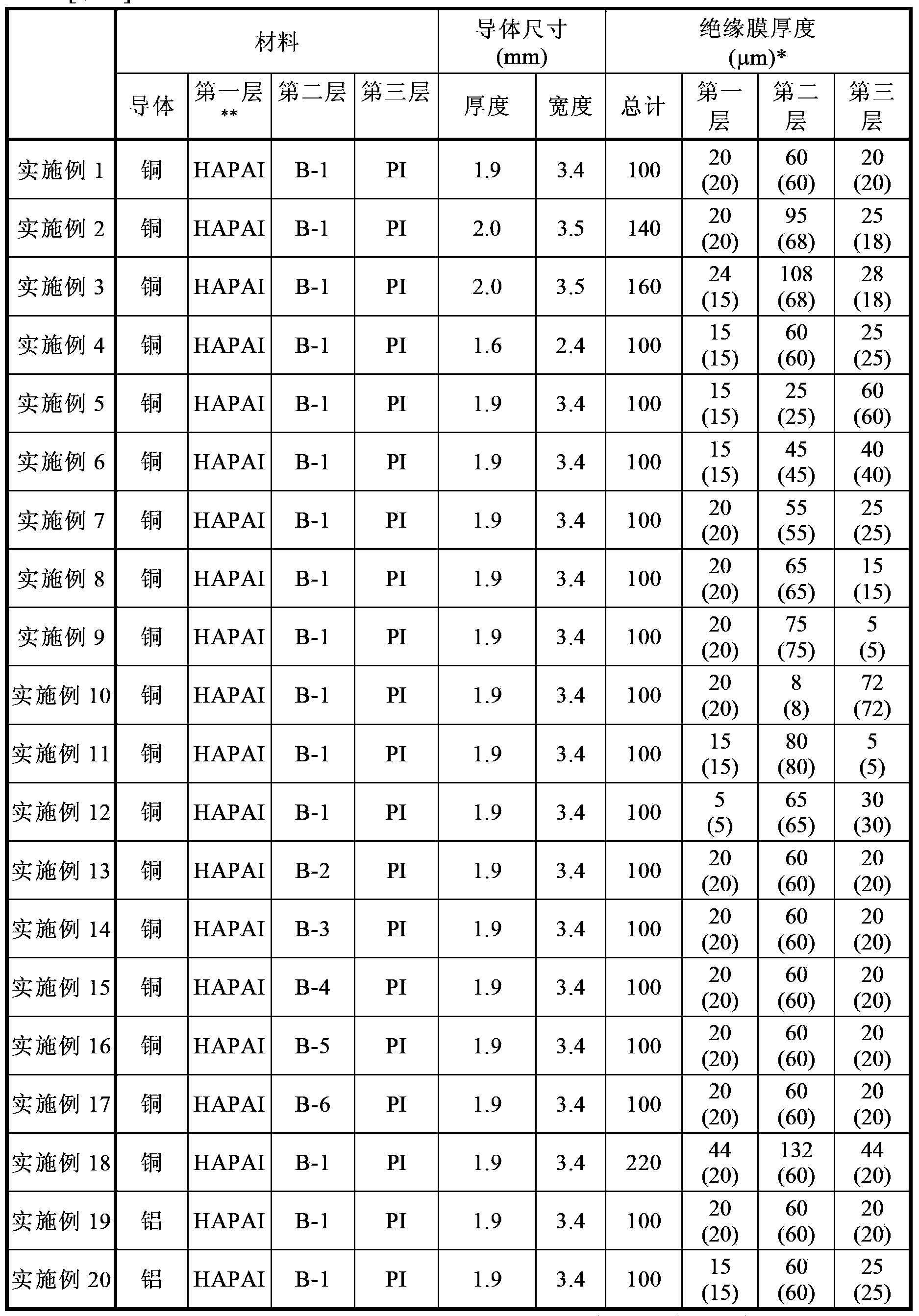

Insulated electric wire

ActiveCN103578618AImprove processing resistanceImprove heat resistanceInsulated cablesTransformers/inductances detailsElectrical conductorPolyamide-imide

The invention relates to an insulated electric wire. According to one embodiment, an insulated electric wire is disclosed. The insulated electric wire includes a conductor and an insulating film formed on the conductor, the insulating film including a first layer of a first polyamideimide containing an adhesion improver, a second layer of a second polyamideimide obtained by reacting an isocyanate component containing 10 to 70 mol % in total of 2,4'-diphenylmethane diisocyanate and dimer acid diisocyanate react with an acid component formed on the first layer, and a third layer of a polyimide formed on the second layer.

Owner:DENSO CORP +1

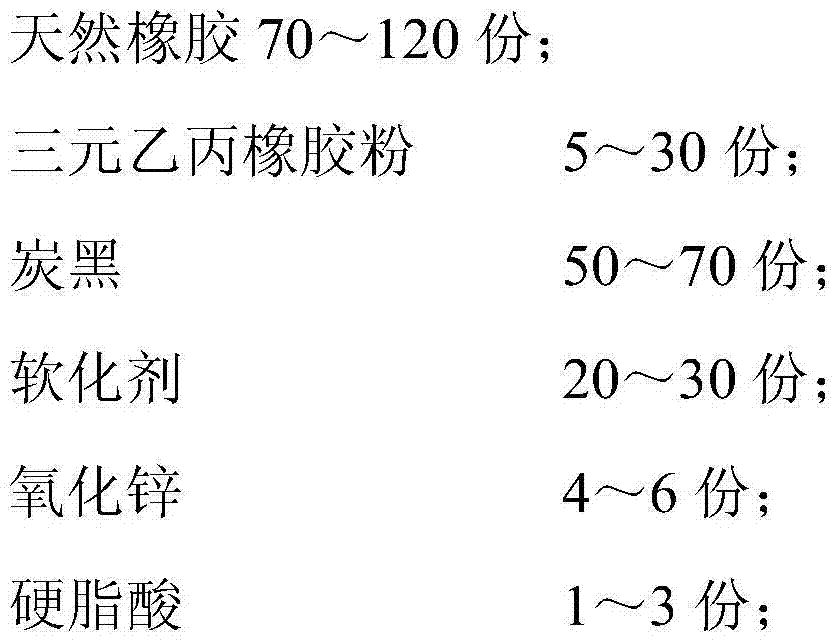

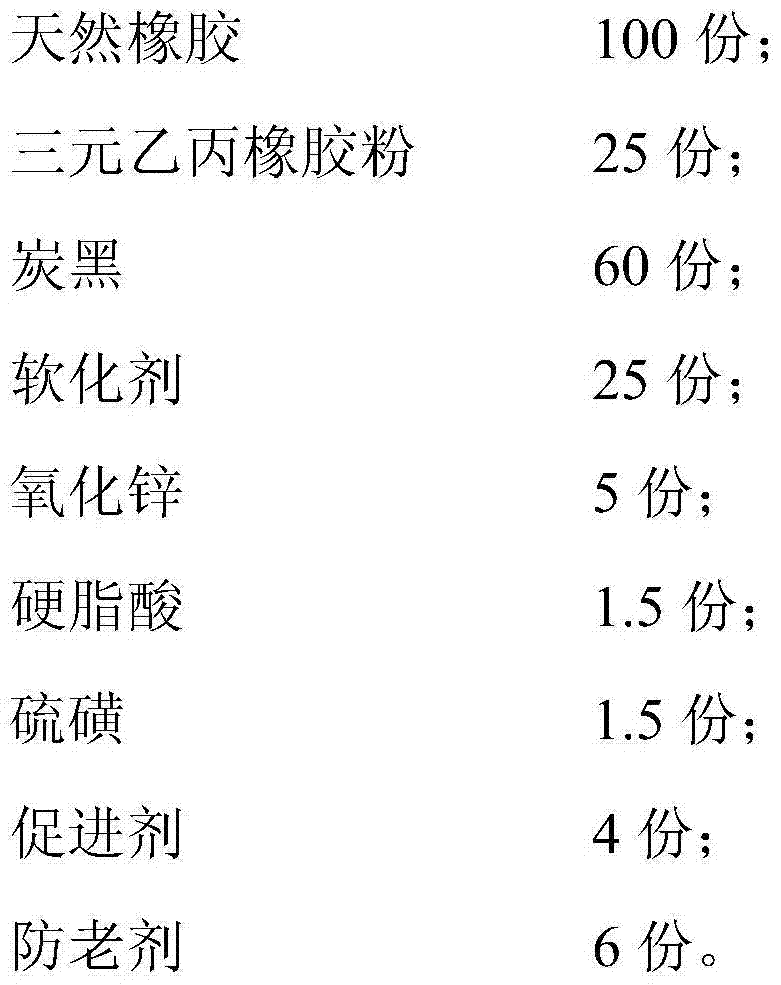

Machinable and ozone-resistant rubber material and preparation method thereof

ActiveCN103756037AExcellent ozone resistanceImprove processing resistanceRubber materialPolymer science

The invention discloses a machinable and ozone-resistant rubber material and a preparation method thereof. The rubber material consists of the following materials in parts by mass: 70-120 parts of natural rubber, 5-30 parts of ethylene-propylene-diene monomer (EPDM) rubber powder, 50-70 parts of carbon black, 20-30 parts of a softening agent, 4-6 parts of zinc oxide, 1-2 parts of stearic acid, 1-2 parts of sulfur, 3-5 parts of an accelerant and 4-8 parts of an anti-aging agent. According to the rubber material and the preparation method thereof, ozone-resistant performance of the natural rubber is enhanced through adding the EPDM rubber powder which is relatively high in content of a third monomer to the natural rubber; the EPDM rubber powder has good compatibility with the natural rubber, so that machining resistance of the rubber material is improved and cost is reduced.

Owner:NINGGUO ZHENGDAO RUBBER & PLASTIC PARTS

Tobacco stem porous particle and application thereof in cigarette

ActiveCN103689785AUniform sizeStable physical and chemical propertiesTobacco treatmentTobacco smoke filtersHydroxypropylmethyl celluloseMethyl cellulose

The invention discloses a tobacco stem porous particle and application thereof in cigarettes. The tobacco stem porous particles with a particle size of 20 meshes to 60 meshes are prepared by using microwave expanded tobacco stem powder with a particle size of 100 meshes to 160 meshes as raw materials, using one kind or several kinds of hydroxypropyl methyl cellulose and sodium carboxymethyl starch as binding agent and adopting a fluidized bed top spraying technology. The particle has the advantages that the surface is rough, the specific surface area is larger, the effective contact area of particle materials and cigarette smoke can be obviously improved, and hydrogen cyanide in the cigarette smoke can be selectively adsorbed; the particle not only has a function of reducing the harm, but also can effectively reduce the irritation of the cigarette smoke and improve the remaining flavor and has an efficacy of improving the smoke sweetness; the production process is simple, the operability and the standardization capability are strong, the raw materials are easy to obtain, the cost is low, the realization of industrial production is facilitated and the application prospect is good.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

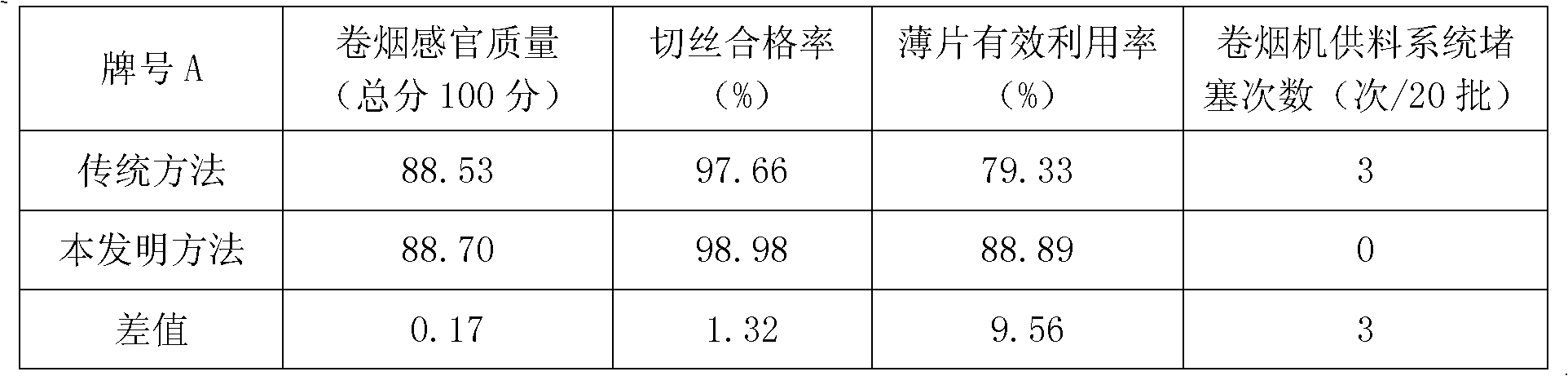

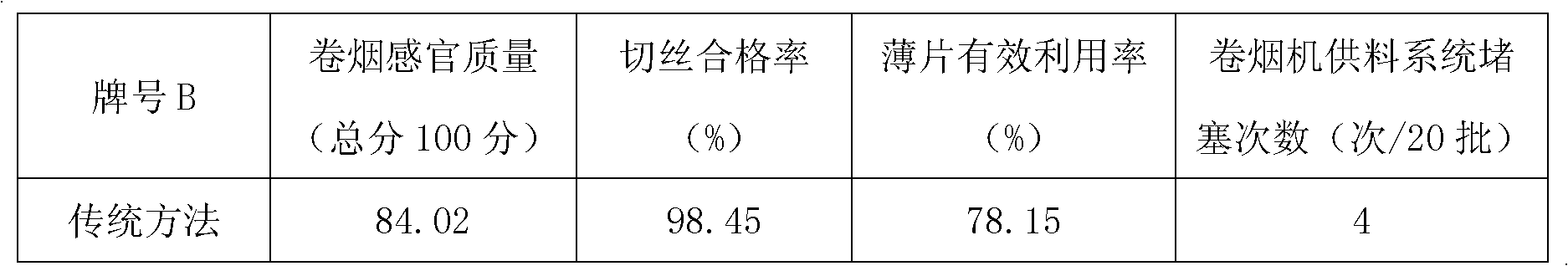

Method for improving effective utilization rate and processing quality of reproduced tobacco leaves

ActiveCN102178336AImprove processing resistanceImprove effective utilizationTobacco preparationEngineeringPhysical property

The invention provides a method for improving effective utilization rate and processing quality of reproduced tobacco leaves that are separately processed as a type of tobacco leaf raw materials. The reproduced tobacco leaves are thin tobacco sheets by a paper making method. After separately processed by a prime line, the thin tobacco sheets by a paper making method are blended proportionally prior to addition of fragrance, with other procedures and parameters remaining unchanged, and finally the finished product of tobaccos are made through a packing machine. The method selects different processing intensities specific to the physical property and reproduced tobacco leaves and physiochemical different of tobacco leaves. The method can improve the effective utilization rate and processingquality of reproduced tobacco leaves.

Owner:CHONGQING CHINA TOBACCO IND CO LTD +1

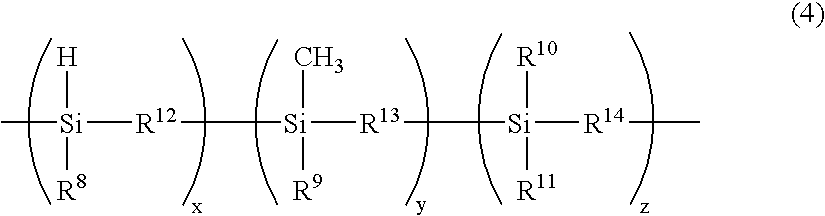

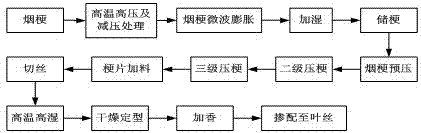

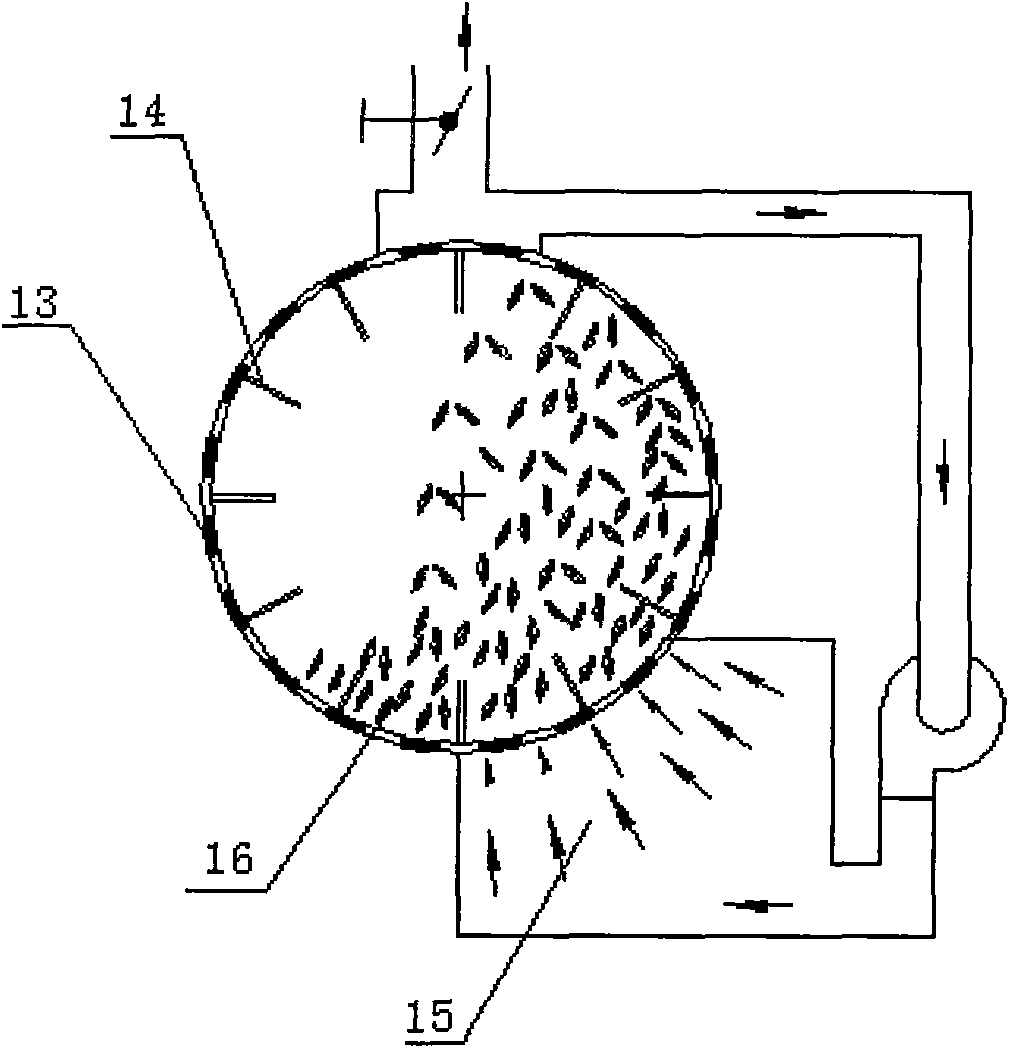

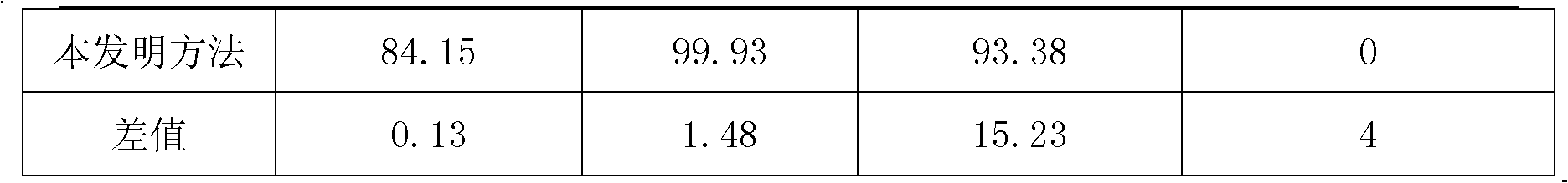

Method of fumigating tobacco material

InactiveCN101036529AKeep clean and tidyGuaranteed lossTobacco preparationWaste streamPulp and paper industry

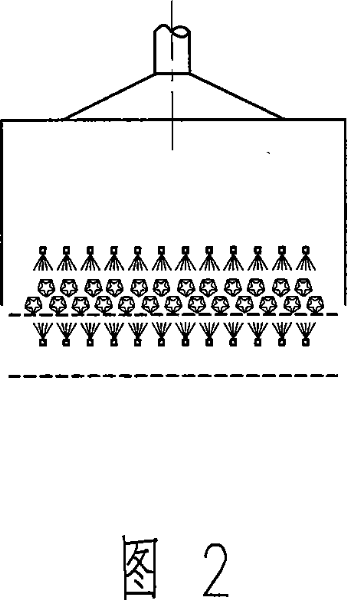

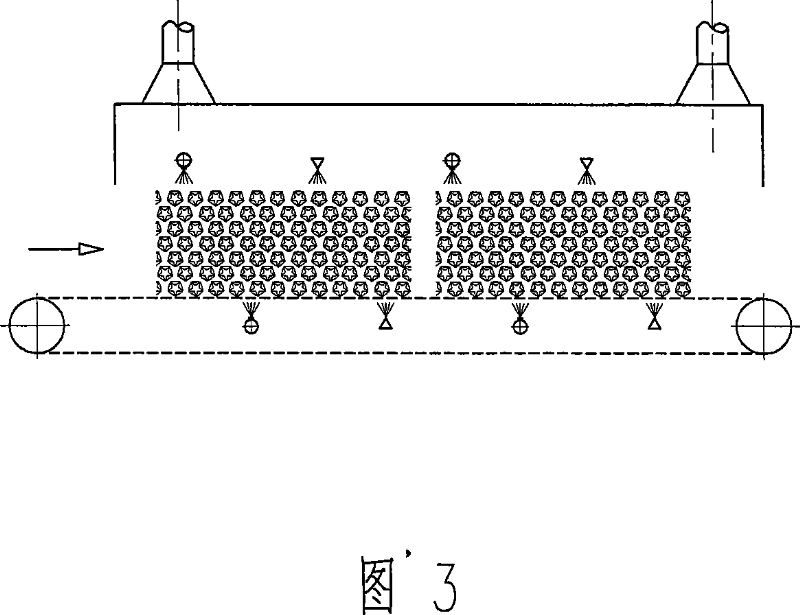

A tobacco material suffocating process method is disclosed, wherein the tobacco material is arranged on the transporting guipure or the reticular lamina (3) for forward movement, meanwhile insufflating the water spray and the steam to the material from the upper and the lower part of the transporting guipure or the reticular lamina, for suffocating the material. The transporting guipure or the material suffocating section of the reticular lamina are arranged in the suffocating body formed by the casing (6), and a waste stream suction device (7) is arranged on the casing (6). The invention has good heating resurgence effect to ensure the resurgence effect, meanwhile simplifying the resurgence device structure, and convenient to maintain, which greatly reduces the device energy consumption, ensures the cleanness and nattiness of the plant environment, also can reduce the loss generated in the working process for the tobacco material caused by the tatter.

Owner:YUNNAN KUNMING SHIPBUILDING DESIGN & RESEARCH INSTITUTE

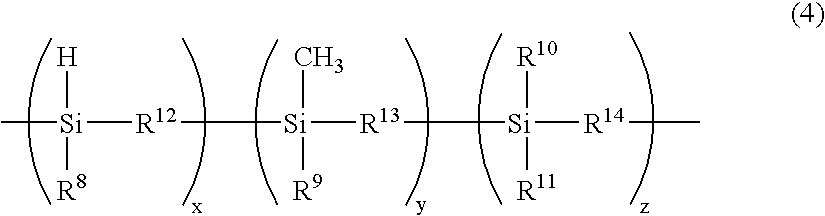

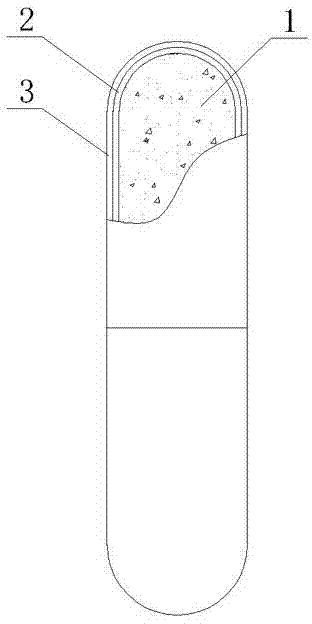

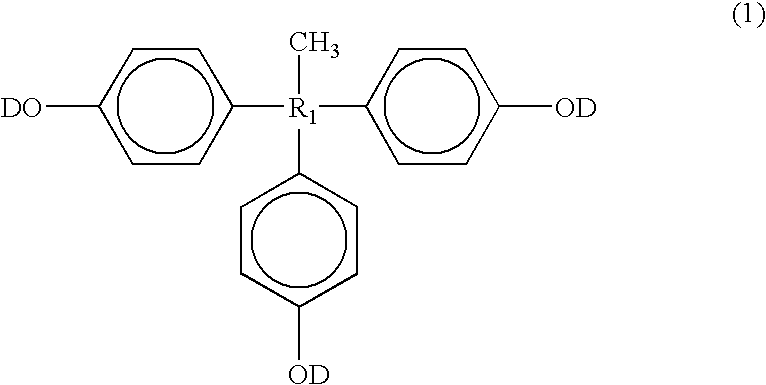

Positive type photosensitive resin composition

ActiveUS20060211797A1Good storage stabilityWide process marginOrganic chemistryOrganic compound preparationQuinoneHydrogen atom

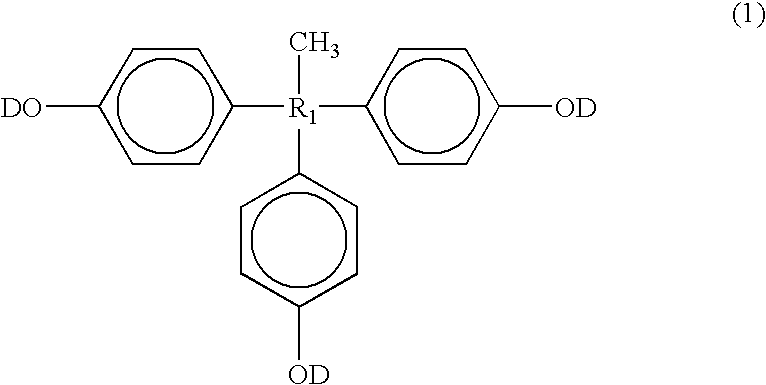

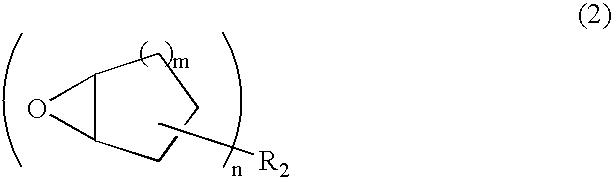

The present invention provides a positive photosensitive resin composition which can form a cured film excellent in process resistance such as heat resistance, solvent resistance or long-time baking resistance and transparency, and which is excellent in photosensitive properties such as resolution and sensitivity, and which has high storage stability and a wide process margin. Further, the present invention provides a positive photosensitive resin composition having such high reliability that no deterioration of electrical characteristics will be led in its application for liquid crystal display devices. A positive photosensitive resin composition characterized by comprising an alkali-soluble resin which is a copolymer essentially comprising an unsaturated carboxylic acid derivative and an N-substituted maleimide and which has a number average molecular weight of from 2,000 to 20,000, a 1,2-quinone diazide compound represented by the formula (1): (wherein each of D independently is a hydrogen atom or an organic group having a 1,2-quinone diazide group, R1 is a tetravalent organic group, provided that at least one of D is an organic group having a 1,2-quinone diazide group), and from 5 to 50 parts by weight, per the alkali-soluble resin, of a crosslinking compound represented by the formula (2): (wherein n is an integer of from 2 to 10, m is an integer of from 0 to 4, and R2 is a n-valent organic group).

Owner:NISSAN CHEM IND LTD

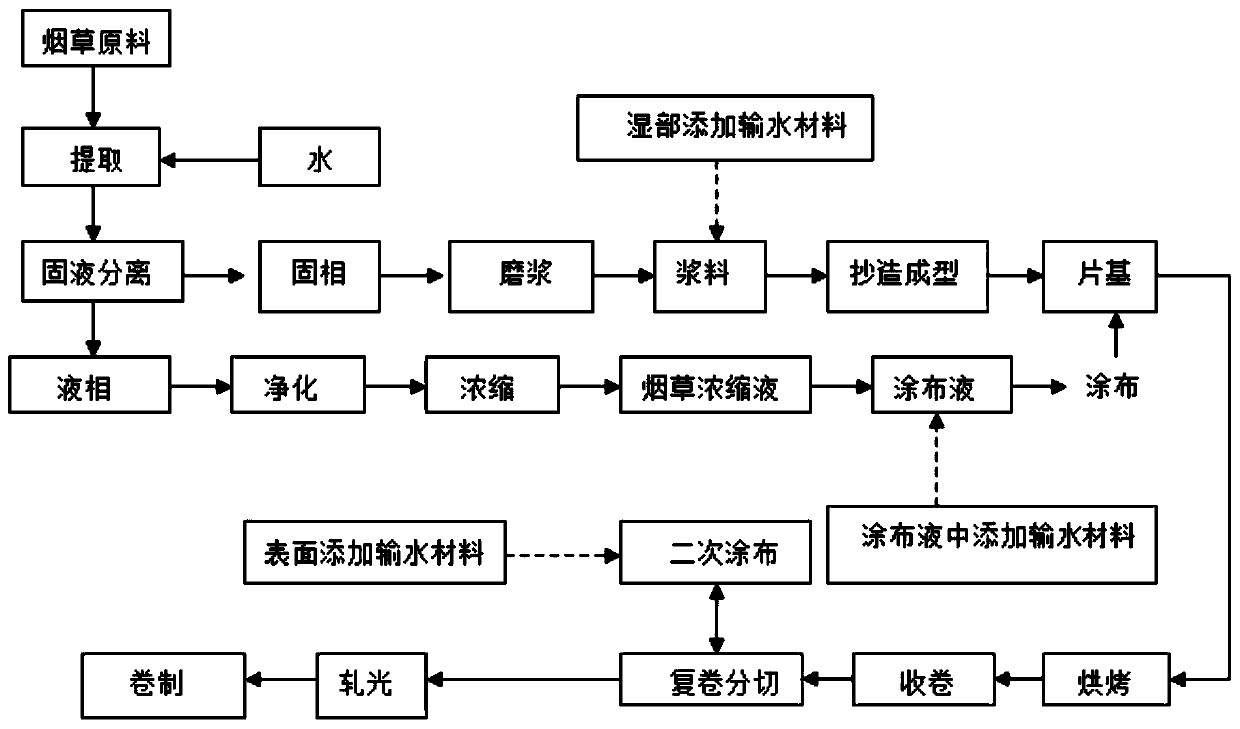

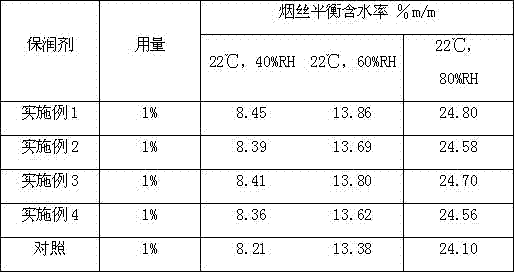

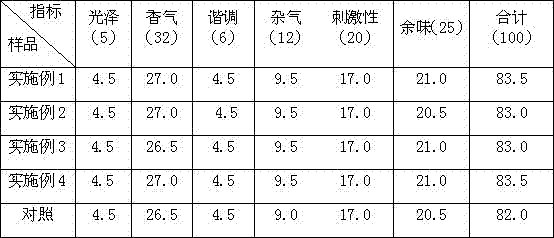

Preparation process of improving moisture absorption of heat-not-burn cigarette core materials

InactiveCN110250555AImprove processing resistanceIncrease concentrationTobacco preparationTobacco treatmentMoisture absorptionHeat not burn

The invention belongs to the field of novel tobacoo products, and particularly relates to a preparation process of improving the moisture absorption of heat-not-burn cigarette core materials. The preparation process is based on the traditional paper-making process to add hydrophobic materials to the production process of reconstituted tobacoo; and the hydrophobic materials can be added into a wet part, a coating liquid of the primary coating process or the surface of the secondary coating process. According to the method, the problems of poor heat conduction performance and less smoke and aroma emission of the heat-not-burn tobacoo leaves caused by the high moisture absorption of the heat-not-burn reconstituted tobacoo leaves prepared by the traditional papaer0making method are solved, the prepared heat-not-burn reconstituted tobacoo leaves have good processing resistance, high smoke and aroma concentration and good sensory quality in simulating cigarette suction.

Owner:ZHONGYAN SHIWEICE (YUNNAN) RECONSTITUTED TOBACCO CO LTD

Natural eutecticevaporate solvent tobacco humectant and preparing method and application thereof

ActiveCN107136560AImprove processing resistanceReduce breakageTobacco treatmentSynthesis methodsSolvent

Provided is a natural eutecticevaporate solvent tobacco humectant and a preparing method and application thereof. The humectant is characterized in that the humectant is prepared from 10-15% of natural eutecticevaporate solvent, 0.1-0.5% of preservative, 0.1-0.5% of defoamer and the balance water and pH of the humectant is neutral. The humectant is applied to tobacco humidity preservation, through the cigarette humectant, not only can the degrading resistance property be improved, tobacco breakage is reduced, and the tobacco consumption of the cigarette in the manufacturing process is reduced, but also the taste and flavor can be improved, the effects such as smoke stimulation are reduced, and the effect of simultaneously improving the physical and sensory humidity preservation of the tobacco is improved. The natural eutecticevaporate solvent tobacco humectant and the preparing method and application thereof have the advantages that the natural eutecticevaporate solvent is simple in synthesis method, non-volatile, and nonflammable; synthesis materials are all natural products, are components contained in the tobacco, and are green and environmentally friendly; meanwhile, the synthesis materials are smoke fragrance precursors as well, have a certain effect on improving cigarette sensory fragrance, and have a potential popularization and application prospect.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

Peony porous particle and application thereof to cigarettes

ActiveCN103689795AUniform sizeStable physical and chemical propertiesTobacco smoke filtersOperabilityRadix Ophiopogonis

The invention discloses a peony porous particle and application thereof to cigarettes. The peony porous particle adopts peony powder with the water content being 10 to 12 percent and the particle diameter being 100 to 160 meshes and lactose or cane sugar as raw materials, and adopts polyvinylpyrrolidone and gelatin as bonding agents, a fluidized bed top spraying process is adopted for preparation, and 20 to 60 meshes of radix ophiopogonis porous particles are obtained. The particle has the advantages that the surface is rough, the specific surface area is higher, the effective contact area of the particle materials and the smoke gas of the cigarettes can be obviously increased, and hydrocyanic acid and phenol in the smoke gas of the cigarettes can be selectively adsorbed. The irritation of the smoke gas of the cigarettes can be effectively reduced, the cigarette fragrance can be enriched, and meanwhile, the effect of enhancing the sweet and moistening feeling of the smoke gas is also realized. The peony porous particle has the advantages that the production process is simple, the operability and the standardability are high, the raw materials can be easily obtained, the cost is low, the industrial production can be conveniently realized, and good application prospects are realized.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com