Method for improving effective utilization rate and processing quality of reproduced tobacco leaves

A technology for reconstituted tobacco leaves and processing quality, applied in the application, tobacco, preparation of tobacco and other directions, can solve the problems of low proportion of reconstituted tobacco leaves, decreased sensory quality of cigarettes, easy to fall off, etc. The effect of quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

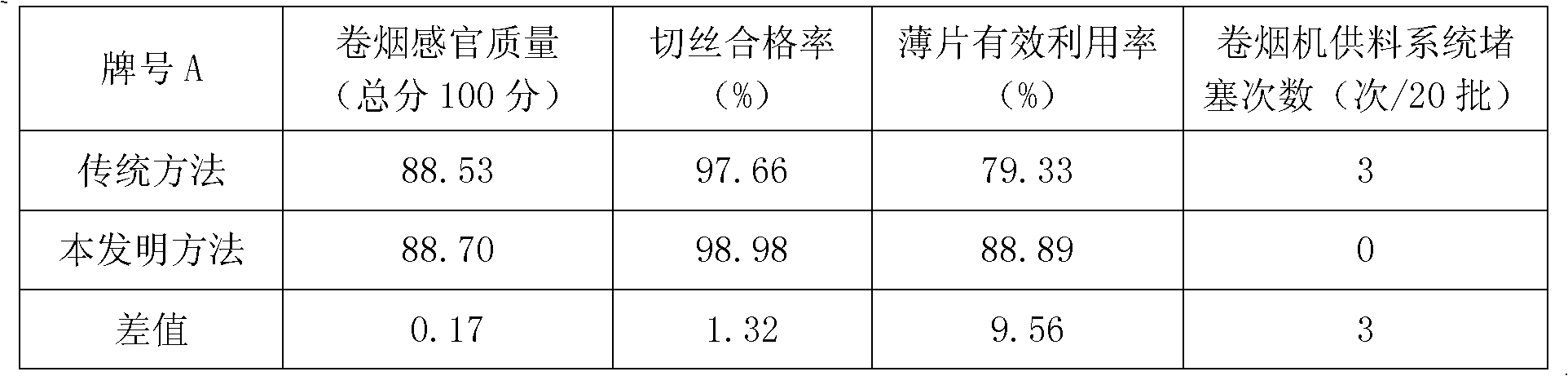

Examples

Embodiment 2

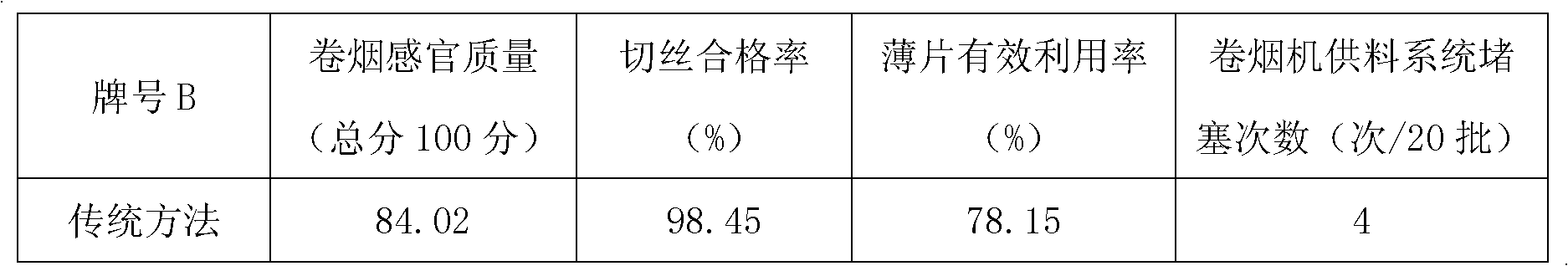

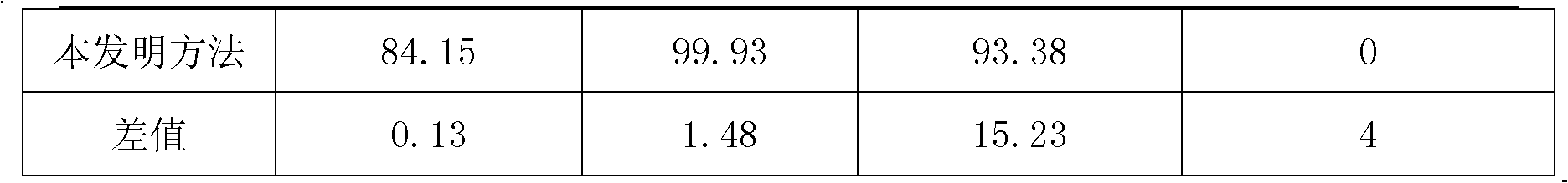

[0018] Select a certain second-class flue-cured tobacco brand B using reconstituted tobacco leaves, and compare it with the traditional method, blending the same proportion (10%) of paper-making tobacco sheet. The leaf group formula of brand B is divided into: tobacco leaf group B1 and sheet group B2. Flake group B2 follows the process flow of brand B, reducing the processing intensity of some processes, that is, the number of vacuum rehydration process cycles is adjusted from 2.5 to 1.5, and the hot air temperature in the loose rehydration and feeding process is adjusted from 58-75°C to 45-57°C (eg, 45°C), the moisture before shredding is adjusted from 20-21% to 18-19% (eg, 18.5°C), and the pressure of the HT process (heating and humidifying process) is adjusted from 0.2-0.4MPa to 0-0.15MPa (eg, 0.1MPa), and the temperature of the cylinder wall in the drying process is adjusted from 110 to 145°C to 90 to 105°C (eg, 100°C).

[0019] Sheet group B2 uses specific parameters suc...

Embodiment 3

[0025] Select a certain three types of flue-cured tobacco brand C that uses reconstituted tobacco leaves, and compare it with the traditional method, blending the same proportion (12%) of paper-making tobacco sheet. First, evaluate the sensory quality of flakes, shredded leaves, shredded stems, and their compatibility and harmony, and combine the physical and chemical indicators of flakes, and add different liquids and flavors in a targeted manner, with the purpose of compensating the aroma, Reduce miscellaneous air and improve its harmony with the leaf group. On the basis of the above-mentioned Example 2, adjust the formulation of the feed liquid and essence, and in order to increase the aroma of the flakes under the condition that the total amount of the feed liquid and the addition ratio remain unchanged, the dosage of the sugar material XQ-2003 is changed from the original 0.20% to 0.20%. 0.40% (eg, 0.34%) is adjusted to 0.50% to 0.80% (eg, 0.56%); in order to reduce the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com