Method of fumigating tobacco material

A technology of tobacco materials and processing methods, which is applied in the fields of tobacco, tobacco preparation, food science, etc., and can solve equipment reliability, insufficient impact on the workshop environment, heavy equipment maintenance workload, poor processing resistance of tobacco sheets, etc. problems, to achieve the effect of meeting the requirements of subsequent processing technology, reducing equipment energy consumption, and simplifying the structure of dampening equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

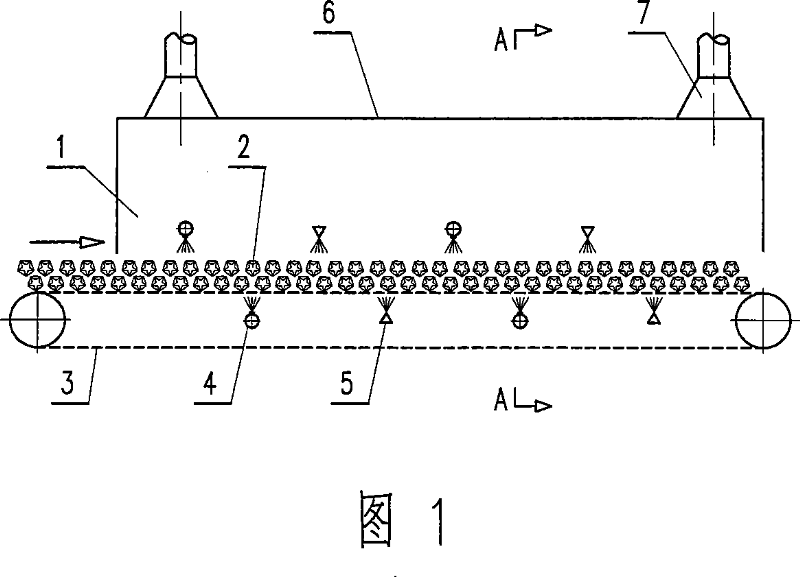

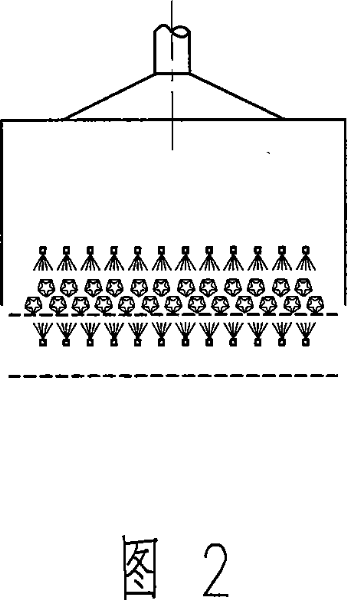

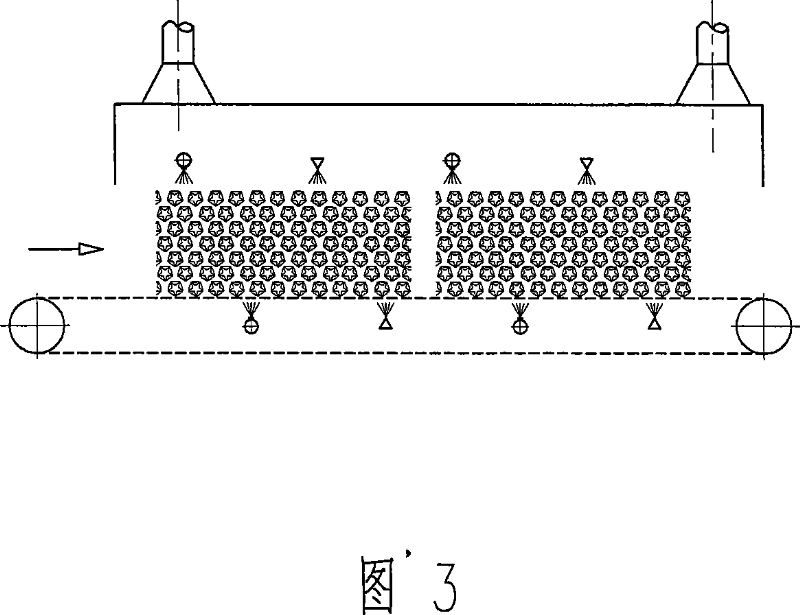

[0013] As shown in Figure 1, the method of the present invention is to place the tobacco material on the conveying mesh belt or the mesh plate 3 and move forward, while as shown in Figure 2, use the water mist nozzle 4 that is arranged on the conveying mesh belt or the mesh plate top and bottom And the steam nozzle 5 sprays water mist and steam to the material, and the material is fumigated. When the conveyed material is a thicker laminar cigarette bale as shown in Figure 3, sprinklers 8 can be added on both sides of the cigarette bale as shown in Figure 4, and water can be sprayed towards the material from both sides of the conveying mesh belt or mesh plate. Fog and steam assist in the fumigation of materials, and realize the comprehensive fumigation of cigarette packs. In order to make the material evenly fumigated, the mesh belt or mesh plate is controlled to run at a constant speed. Conveying mesh belt or web plate 3 can be circular conveying device, also can be linear co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com