Preparation process of improving moisture absorption of heat-not-burn cigarette core materials

A heat-not-burn, preparation process technology, applied in the preparation of tobacco, tobacco, treatment of tobacco and other directions, can solve problems such as strong hygroscopicity and product moisture fluctuation, and achieve high smoke and aroma concentration, good smoking sensory quality, and durability. Good processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

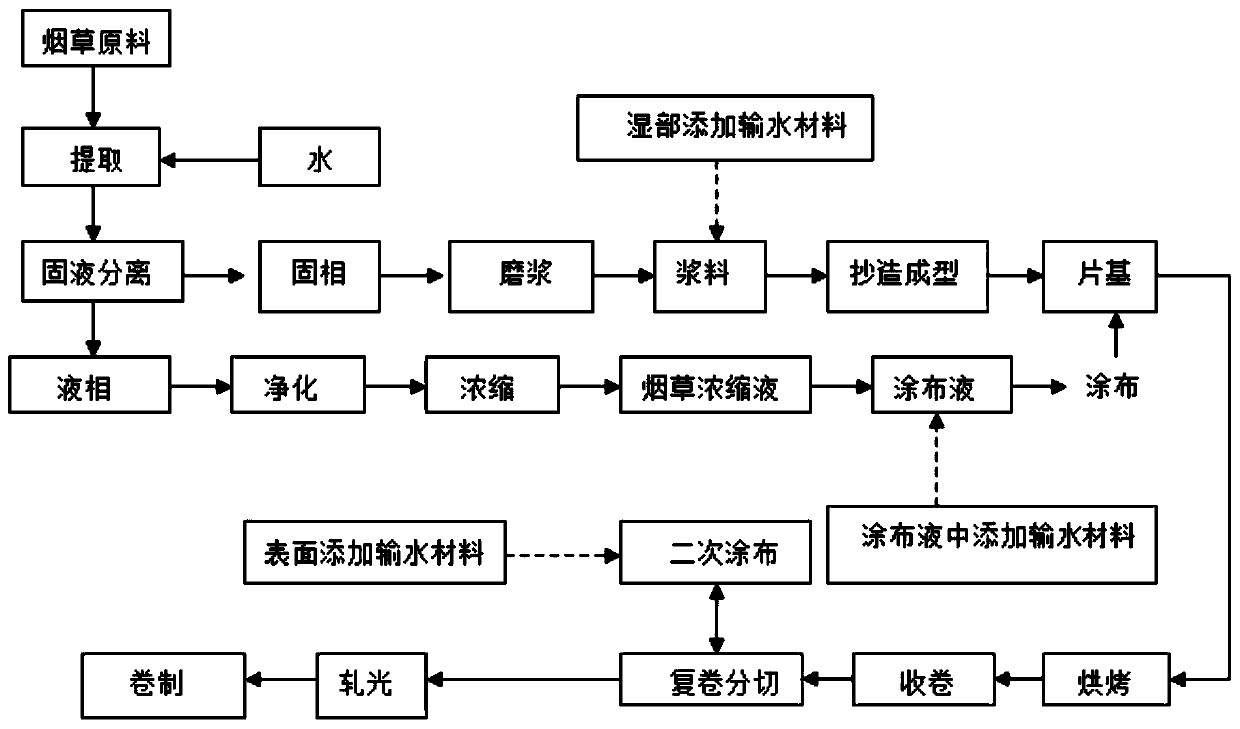

[0020] A preparation process for improving the hygroscopicity of heat-not-burn tobacco core materials. The process is based on the addition of hydrophobic materials to the traditional papermaking reconstituted tobacco production process. The hygroscopicity of the burning wick material ensures the processing strength of the heat-not-burn wick material.

Embodiment 2

[0022] On the basis of Example 1, the process includes adding hydrophobic materials to the wet end.

[0023] The addition of hydrophobic materials in the wet end can be used as a retention aid to form a greater fiber bonding rate between the fibers of the reconstituted tobacco pulp in the papermaking method, reduce the loss rate of fine fibers, and increase the product yield; at the same time, due to the retention of fine fibers, the papermaking method can The base material of the reconstituted tobacco leaf is more compact to improve the processing strength of the product.

Embodiment 3

[0025] On the basis of Example 1, the process includes adding a hydrophobic material to the coating solution in one coating process.

[0026] Since a solution system can be introduced into the coating solution to coat the substrate of reconstituted tobacco leaves by papermaking method, adding hydrophobic materials to the primary coating solution can evenly disperse or even dissolve the hydrophobic material in the coating solution. Take the coating liquid, and after baking, the hydrophobic material forms a hydrophobic film on the surface of the substrate, which isolates the heat-not-burn product from the moisture in the air, thereby improving the hygroscopicity of the heat-not-burn product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com