Natural eutecticevaporate solvent tobacco humectant and preparing method and application thereof

A technology of deep eutectic solvent and humectant, which is applied in the fields of tobacco, application, and treatment of tobacco, which can solve the problems of increased content of harmful substances, and achieve the effects of improved processing resistance, simple synthesis method, and excellent water retention performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

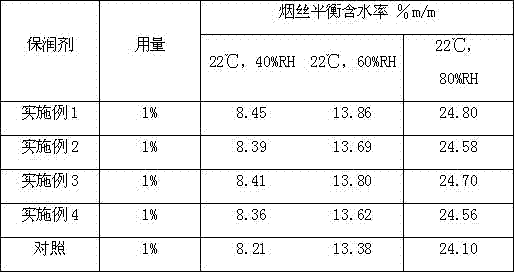

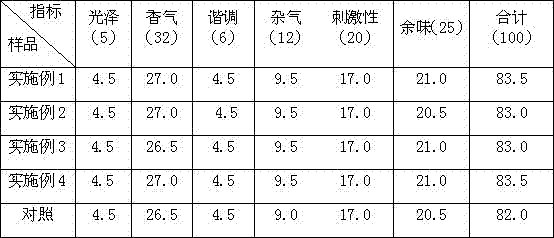

Embodiment 1

[0016] Embodiment 1. Weigh D-(+)-glucose and D, L-malic acid solid powder, according to mol ratio 1:1, add in round bottom flask, 80 o The C water bath was heated and stirred until a clear liquid was formed, and the water bath reaction time was 2.5 hours. 200 ml of water was added to 100 g of the synthesized D-(+)-glucose-D,L-malic acid natural deep eutectic solvent, and 5% sodium hydroxide solution was added dropwise to adjust the pH to be neutral. D-(+)-glucose-D,L-malic acid natural deep eutectic solvent emollient can be prepared by adding 1.0g preservative and 1.0g defoamer. Weigh 10g of moisturizing agent and spray it evenly on 1000g of cut tobacco. The amount of moisturizing agent is 1% of the mass of tobacco leaves. Cigarette samples were prepared from the cut tobacco.

Embodiment 2

[0017] Example 2. Weigh D / L-proline and malonic acid solid powder, according to the molar ratio of 1:2, the total weight of 100g, was added to a round-bottomed flask, and 20 ml of water was added simultaneously, 60 o The C water bath was heated and stirred until a clear liquid was formed, and the reaction time of the water bath was 3 hours. Add 180 ml of water to the synthesized D / L-proline-malonic acid natural deep eutectic solvent, dropwise add 5% sodium hydroxide solution by mass fraction to adjust the pH to be neutral, add 1.0 g of preservative and 1.0 g of D / L-proline-malonic acid natural deep eutectic solvent moisturizing agent can be prepared by defoaming agent. Weigh 10g of moisturizing agent and spray it evenly on 1000g of cut tobacco. The amount of moisturizing agent is 1% of the mass of tobacco leaves. Cigarette samples were prepared from the cut tobacco.

Embodiment 3

[0018] Embodiment 3. take by weighing sodium phytate, betaine solid powder, according to mol ratio 1:1, total weight 100 g, join in round-bottomed flask, 80 o The C water bath was heated and stirred until a clear liquid was formed, and the reaction time of the water bath was 2 hours. 300 ml of aqueous solution was added to the synthesized sodium phytate-betaine natural deep eutectic solvent, and 5% hydrochloric acid solution was added to adjust the pH to be neutral. The sodium phytate-betaine natural deep eutectic solvent emollient can be prepared by adding 1.2g of preservative and 1.2g of defoamer. Weigh 10g of moisturizing agent and spray it evenly on 1000g of cut tobacco. The amount of moisturizing agent is 1% of the mass of tobacco leaves. Cigarette samples were prepared from the cut tobacco.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com