Patents

Literature

34results about How to "Wide process margin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

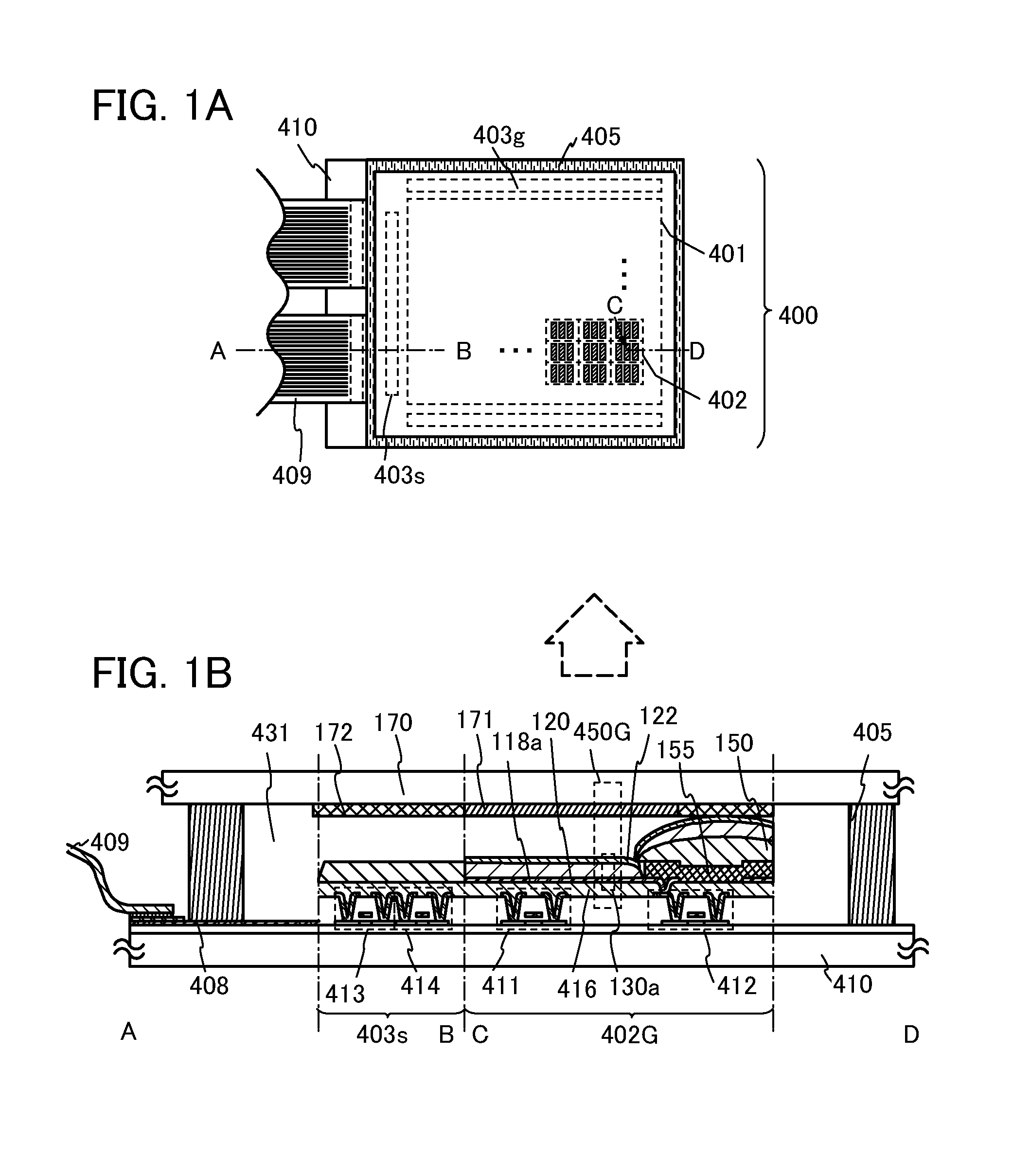

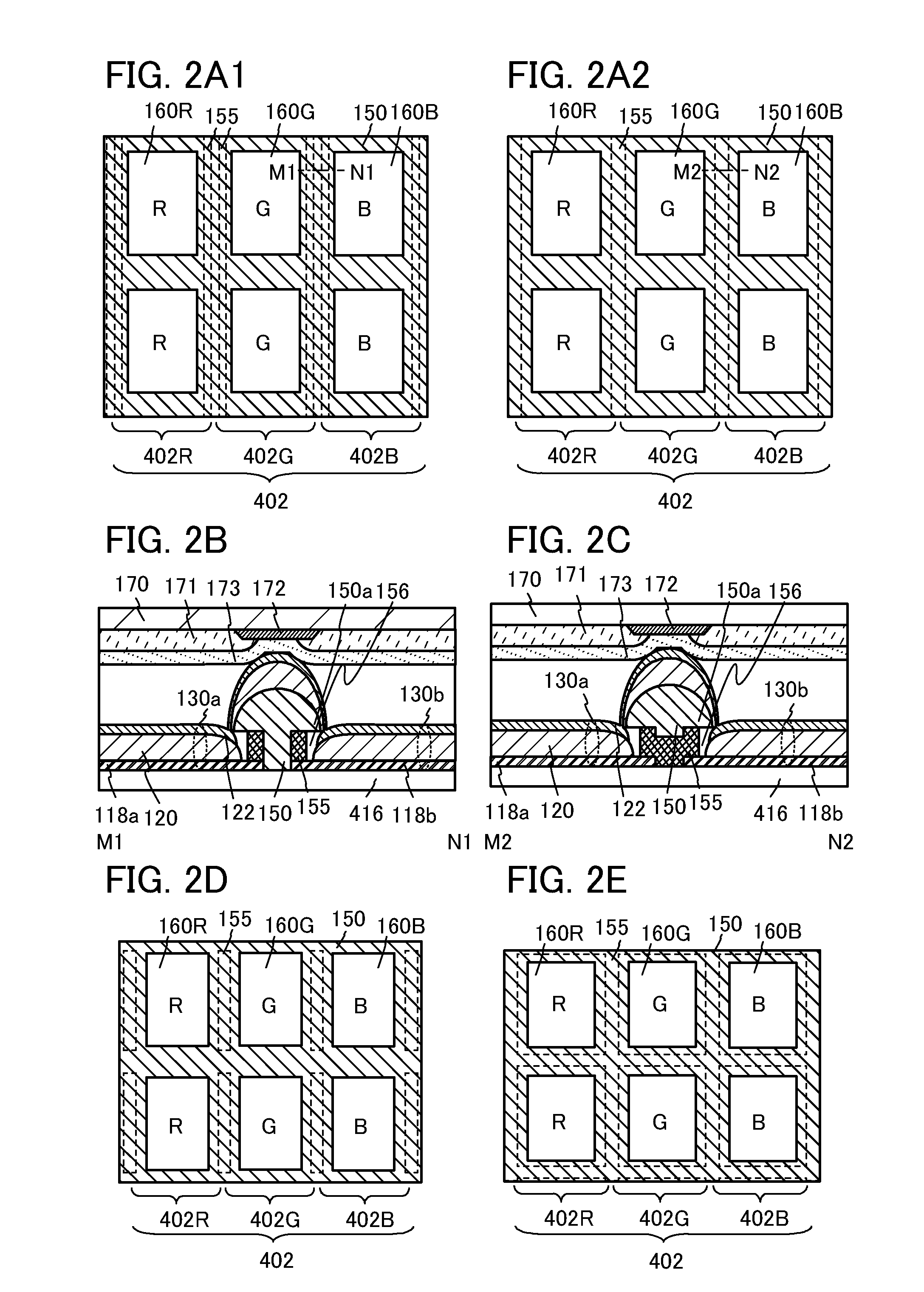

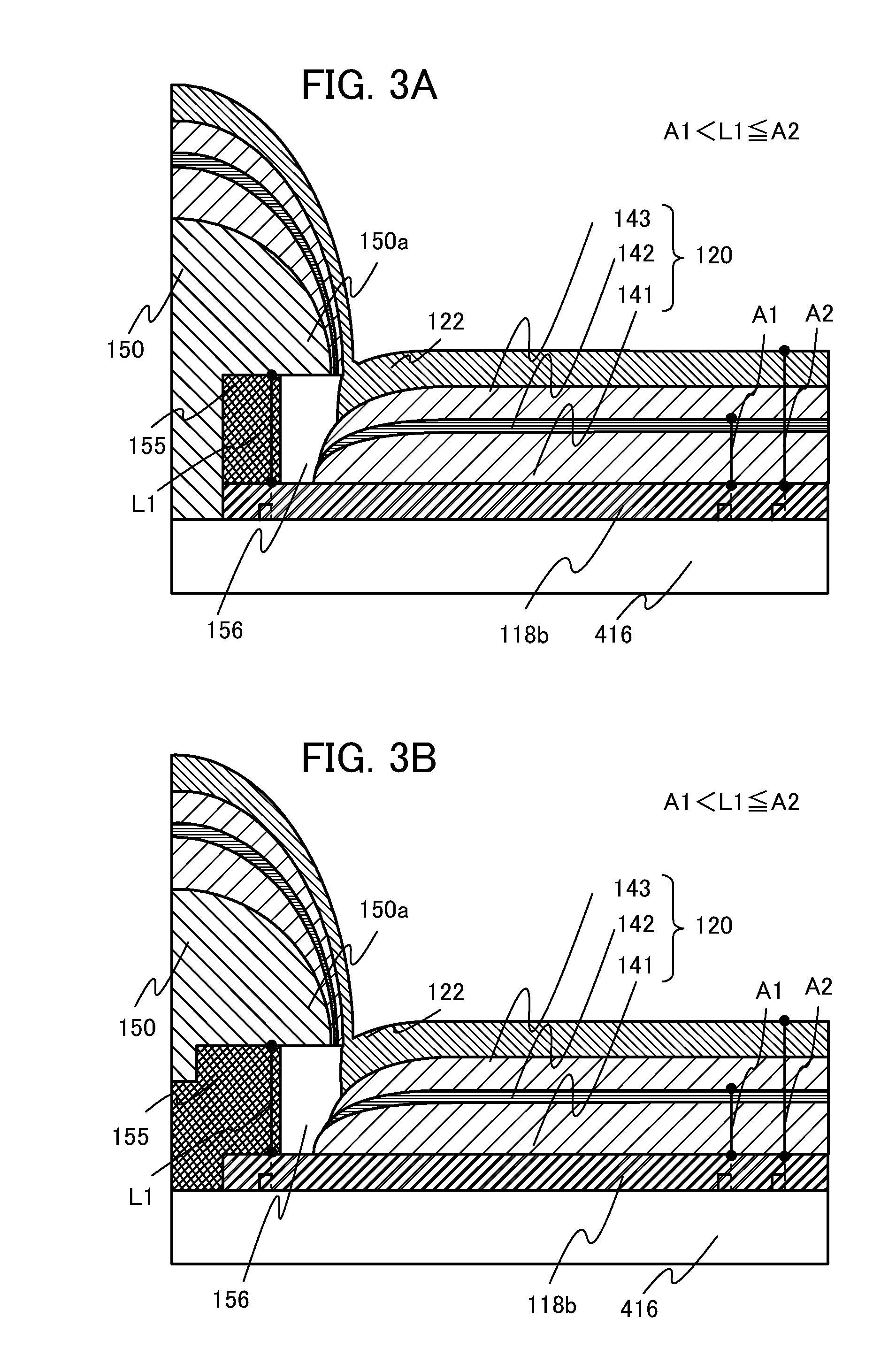

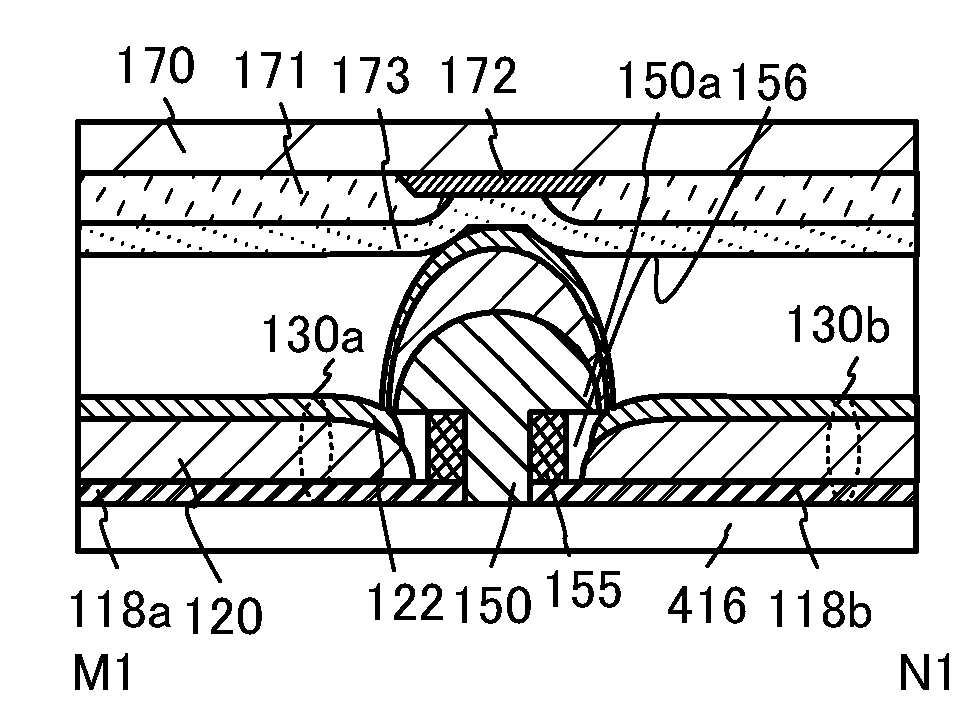

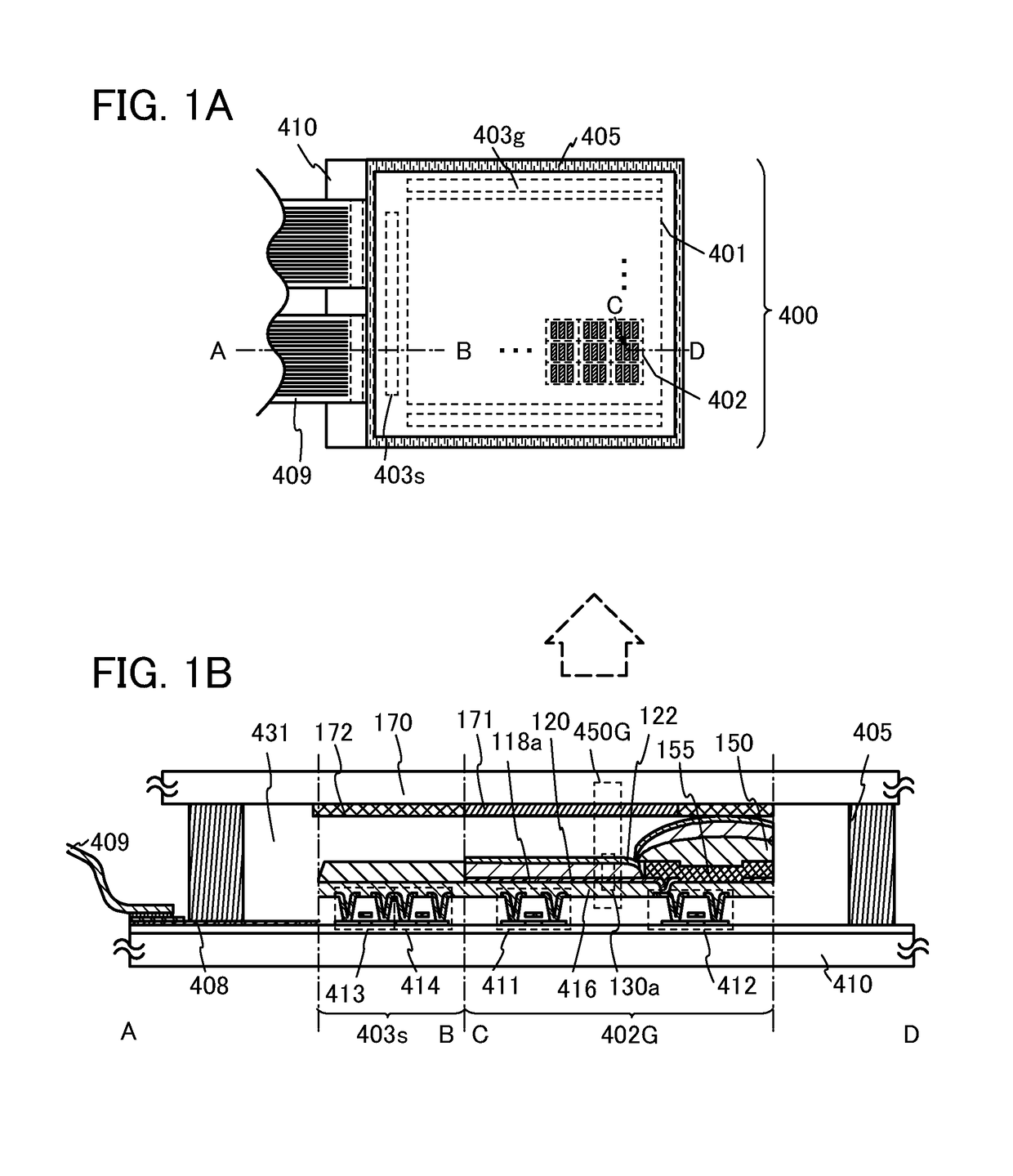

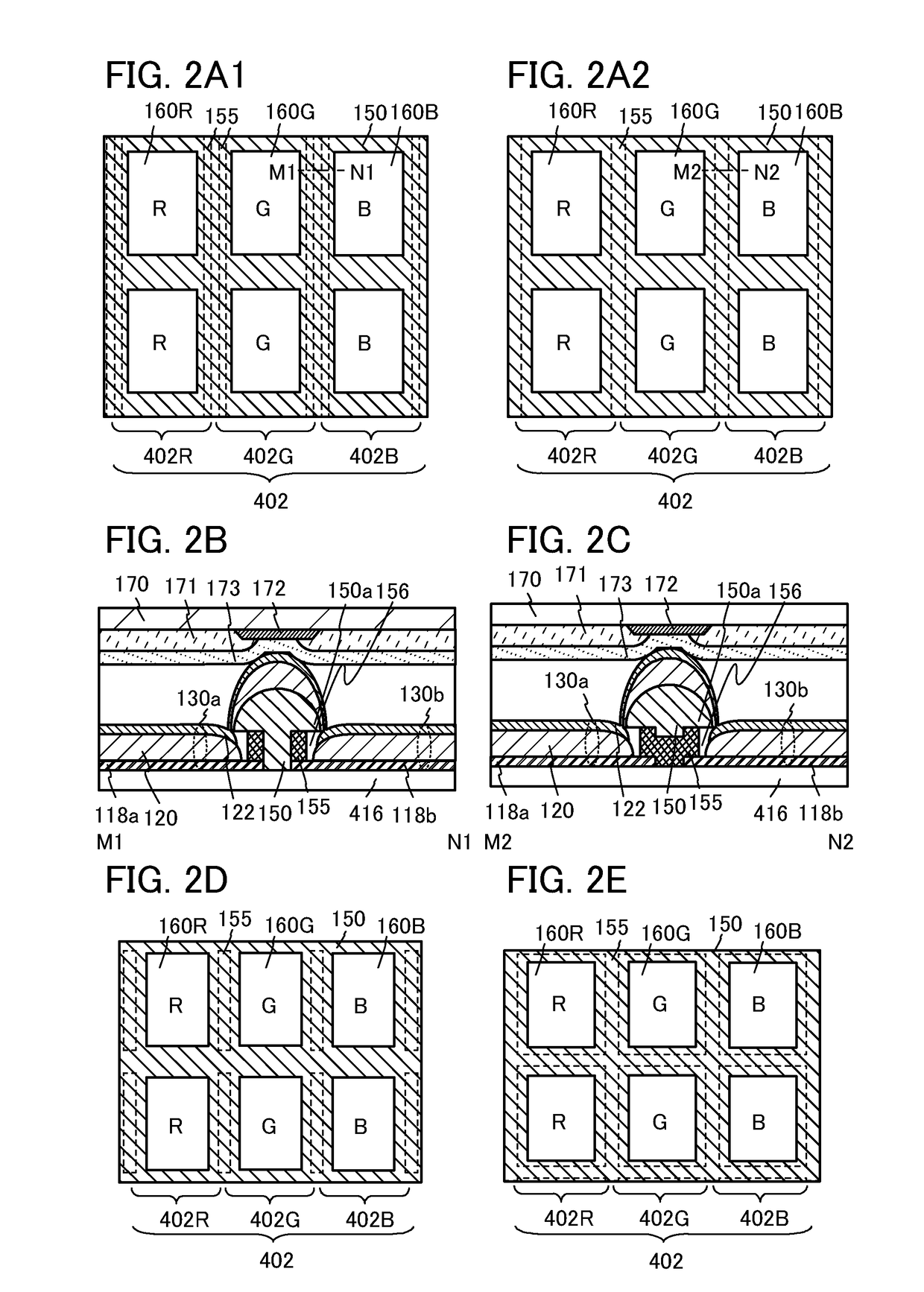

Light-emitting device and method for manufacturing the same

ActiveUS20140103385A1InhibitionWide process marginSolid-state devicesSemiconductor/solid-state device manufacturingLight emitting deviceMaterials science

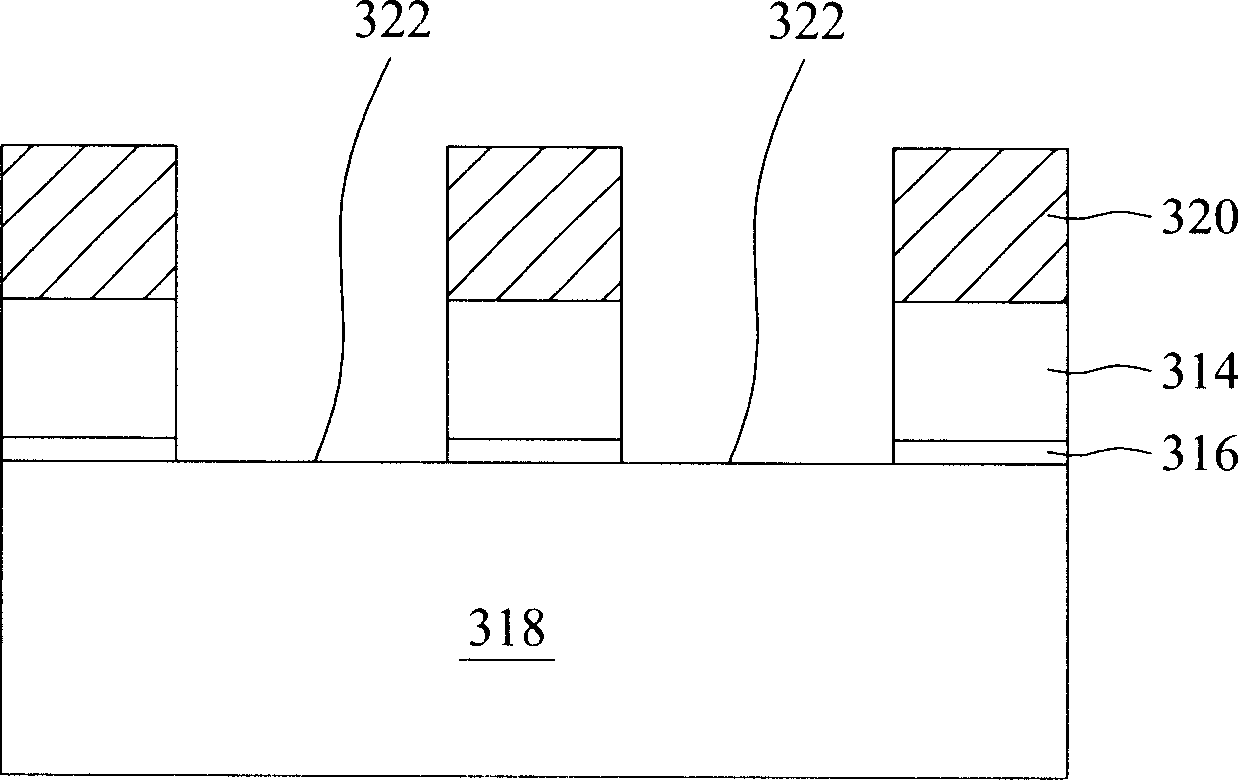

Occurrence of a crosstalk phenomenon in a light-emitting device including a tandem element is suppressed. A light-emitting device includes: lower electrodes over an insulating layer; a partition over a portion between the lower electrodes, which includes an overhang portion over an end portion of each of the lower electrodes; a first light-emitting unit over each of the lower electrodes and the partition; an intermediate layer over the first light-emitting unit; a second light-emitting unit over the intermediate layer; and an upper electrode over the second light-emitting unit. The distance between the overhang portion and each of the lower electrodes is larger than the total thickness of the first light-emitting unit and the intermediate layer over the lower electrode.

Owner:SEMICON ENERGY LAB CO LTD +1

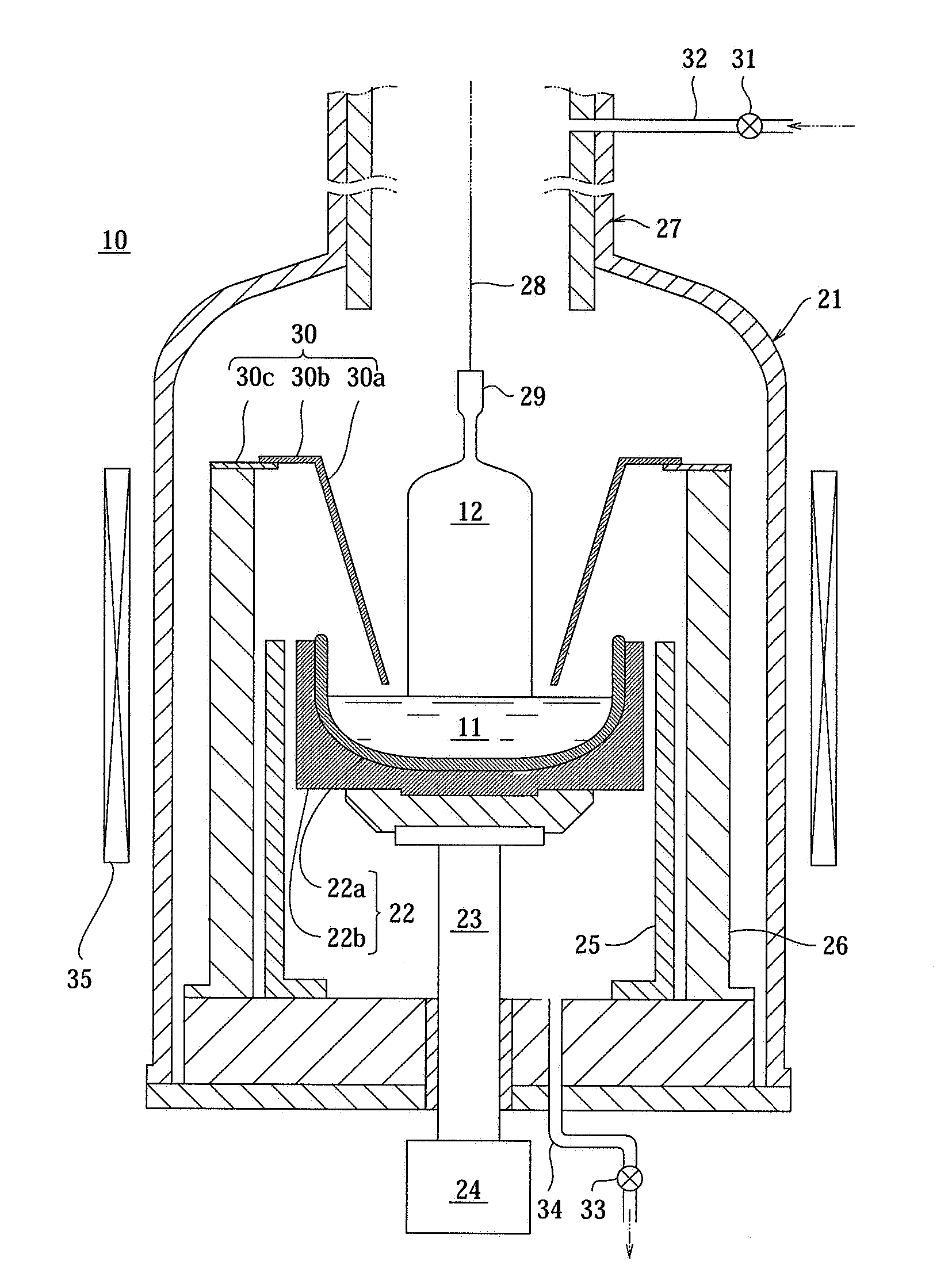

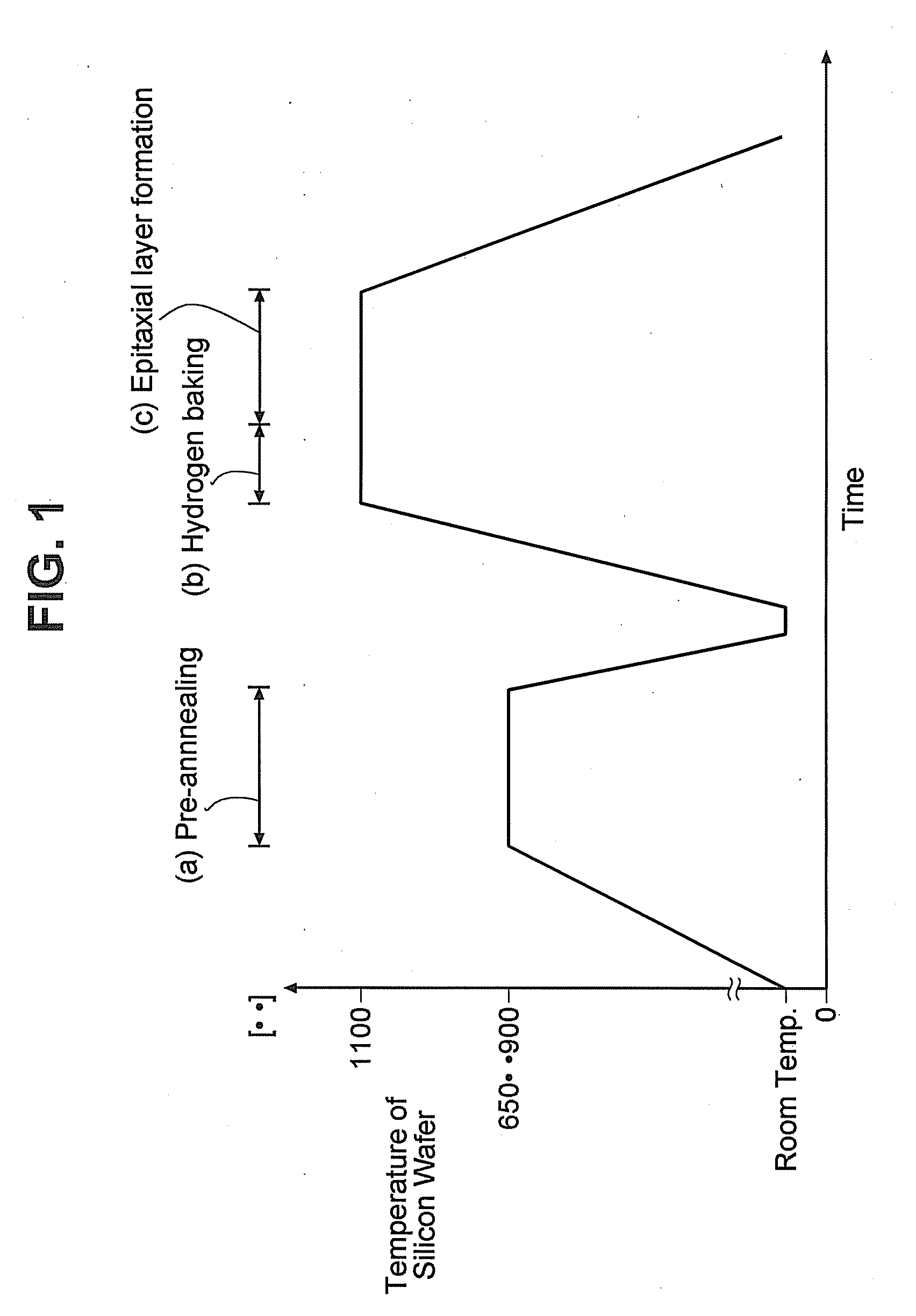

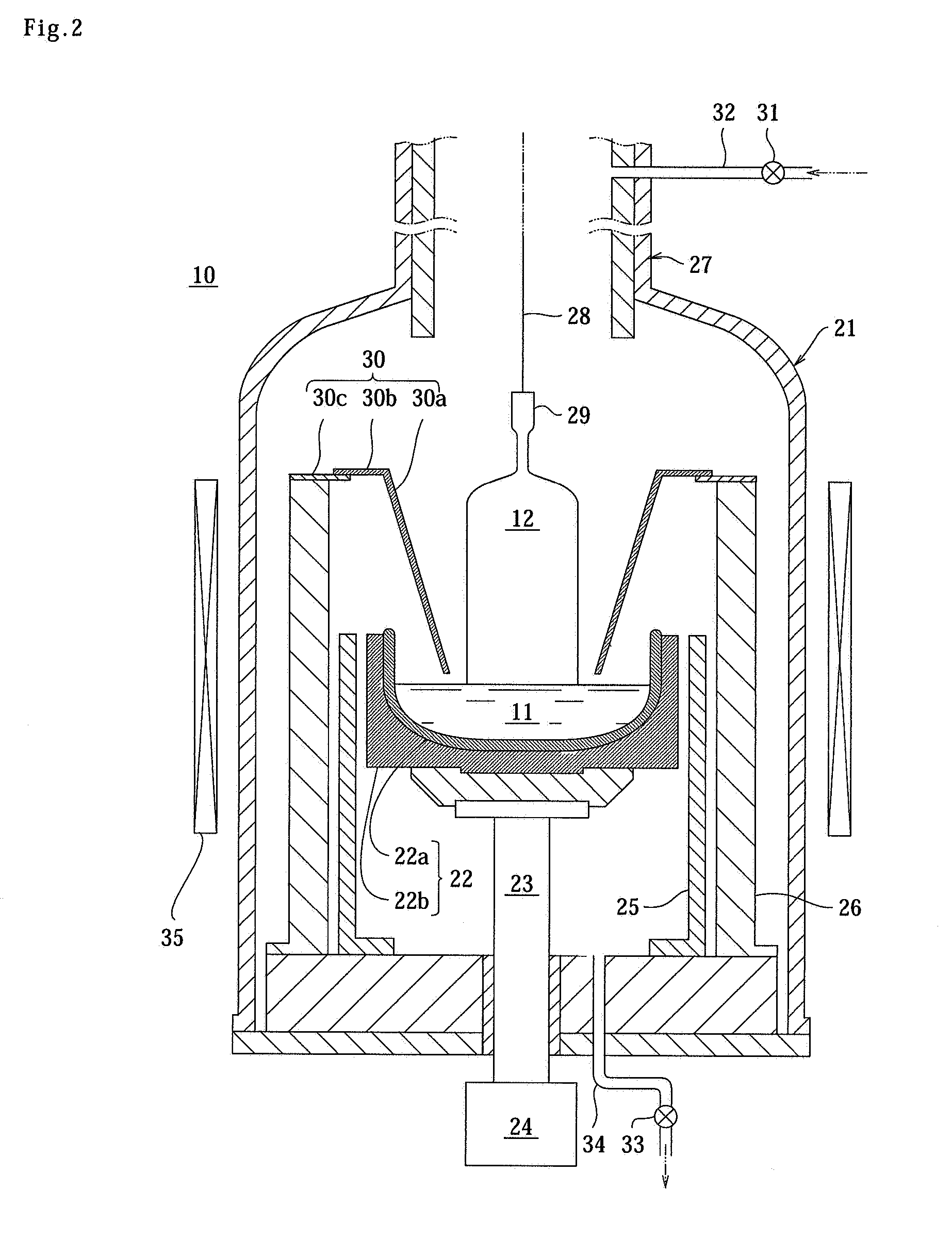

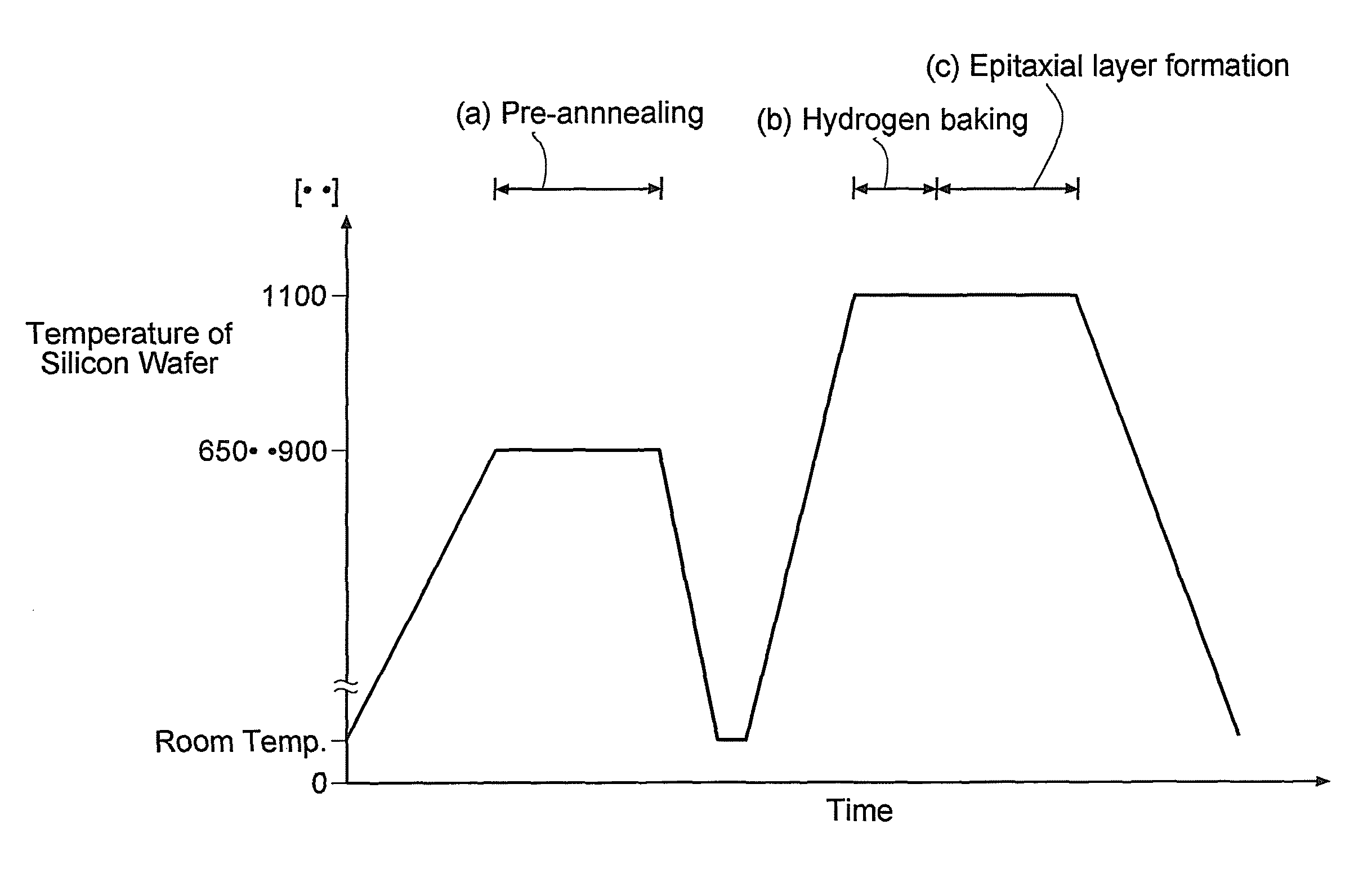

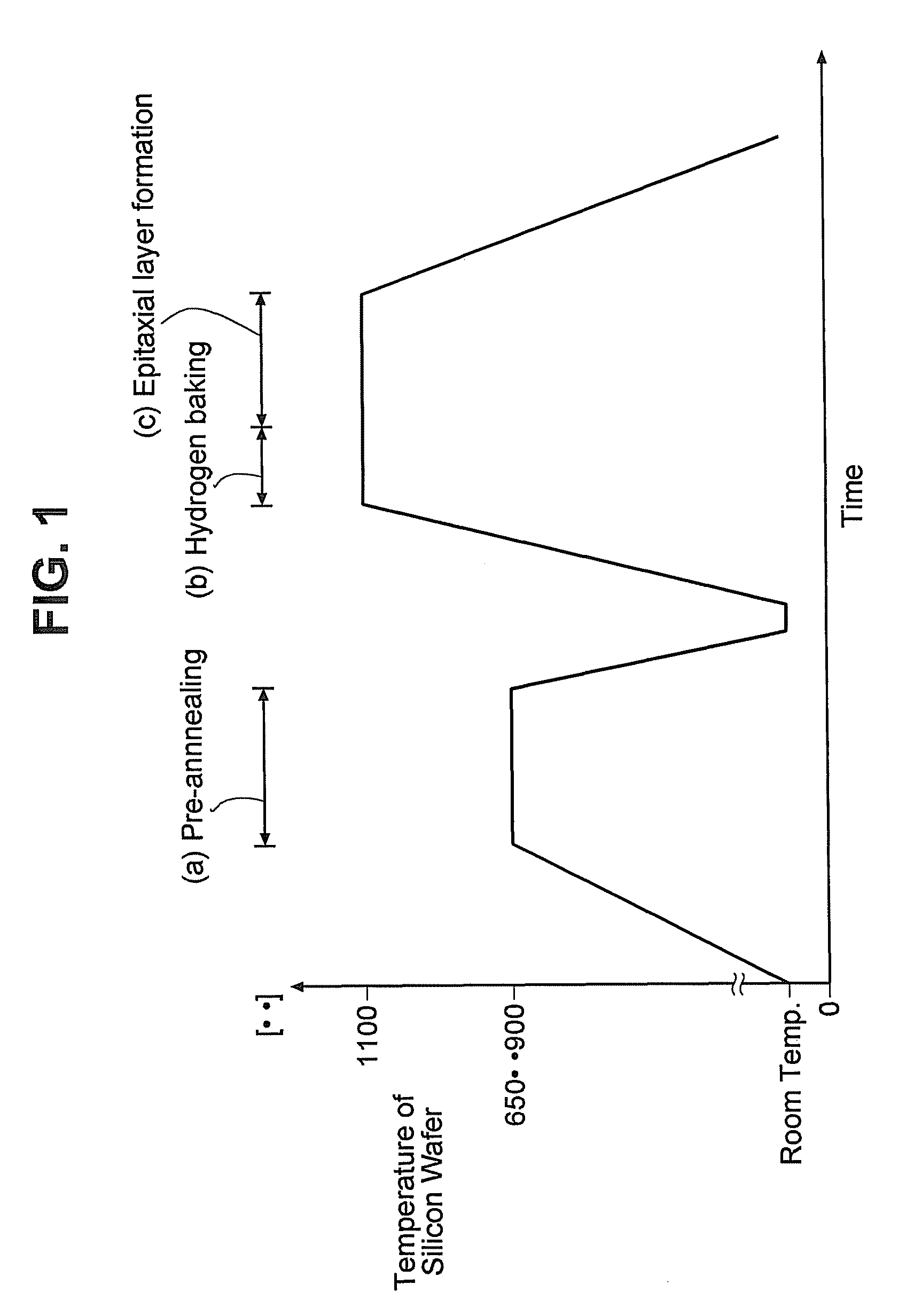

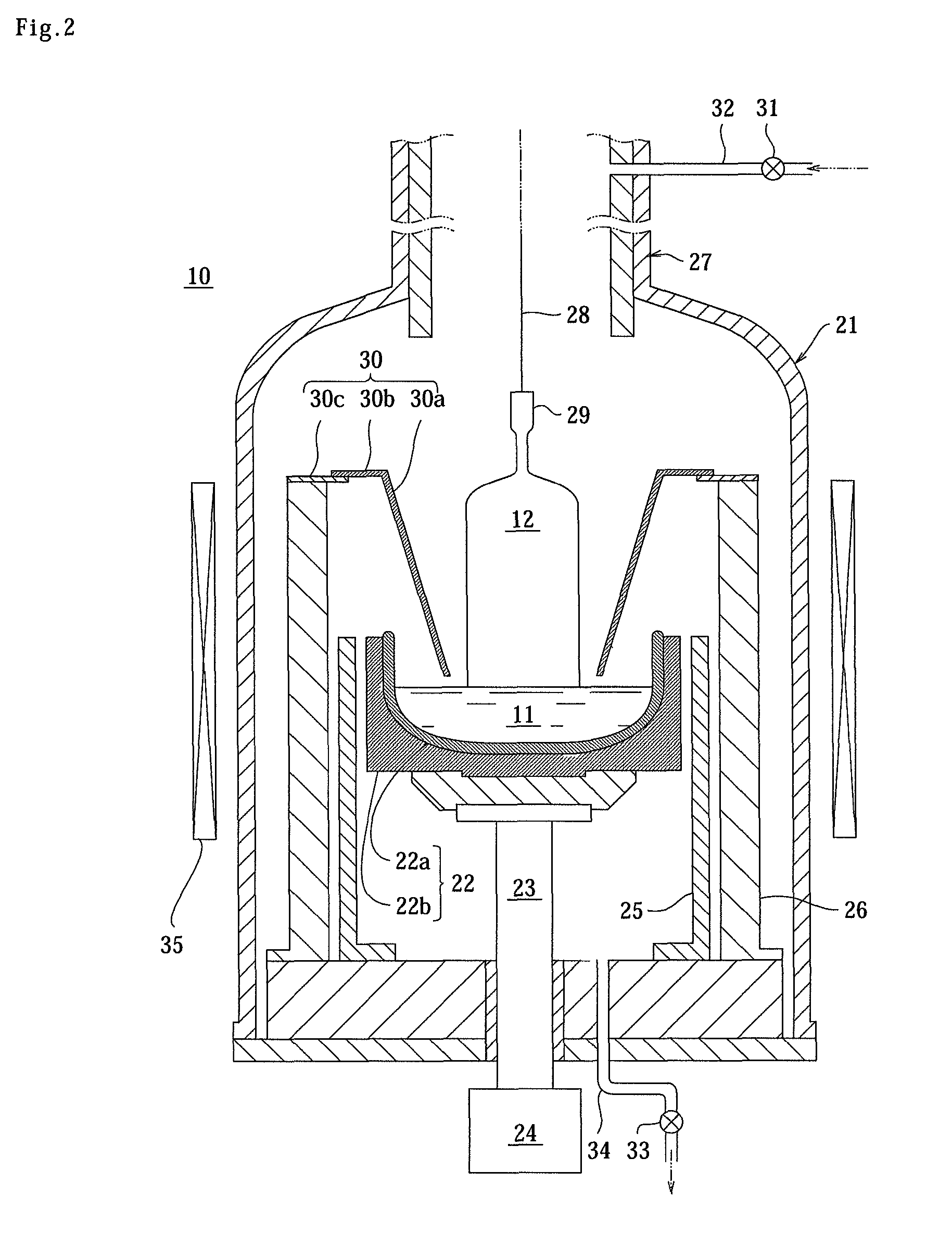

Method For Manufacturing Epitaxial wafer

ActiveUS20080286565A1High IG effectFew epitaxial defectLayered productsSemiconductor/solid-state device manufacturingWaferingSingle crystal

A method for manufacturing an epitaxial wafer includes: a step of pulling a single crystal from a boron-doped silicon melt in a chamber based on a Czochralski process; and a step of forming an epitaxial layer on a surface of a silicon wafer sliced from the single crystal. The single crystal is allowed to grow while passed through a temperature region of 800 to 600° C. in the chamber in 250 to 180 minutes during the pulling step. The grown single crystal has an oxygen concentration of 10×1017 to 12×1017 atoms / cm3 and a resistivity of 0.03 to 0.01 Ωcm. The silicon wafer is subjected to pre-annealing prior to the step of forming the epitaxial layer on the surface of the silicon wafer, for 10 minutes to 4 hours at a predetermined temperature within a temperature region of 650 to 900° C. in an inert gas atmosphere. The method is to fabricate an epitaxial wafer that has a diameter of 300 mm or more, and that attains a high IG effect, and involves few epitaxial defects.

Owner:SUMCO CORP

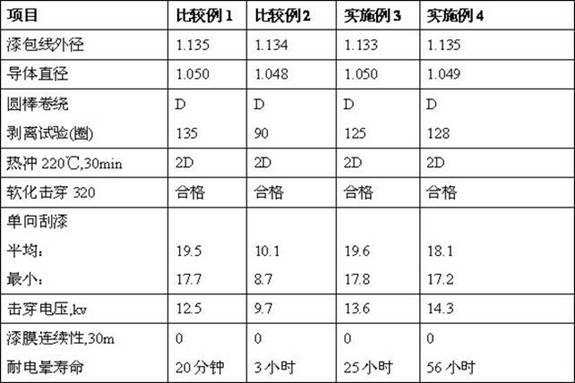

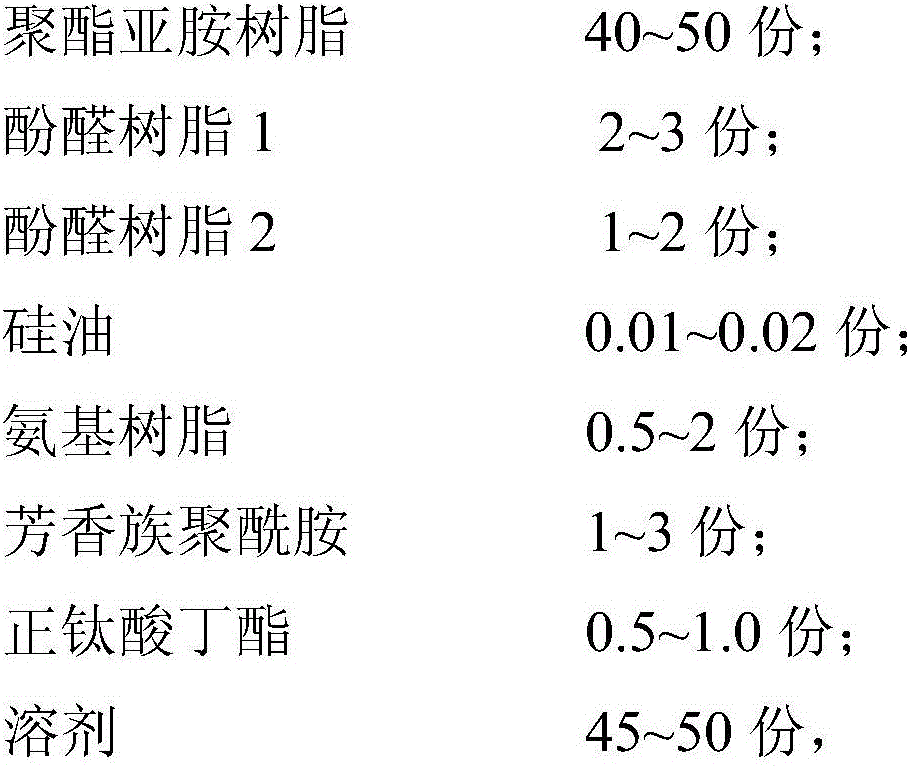

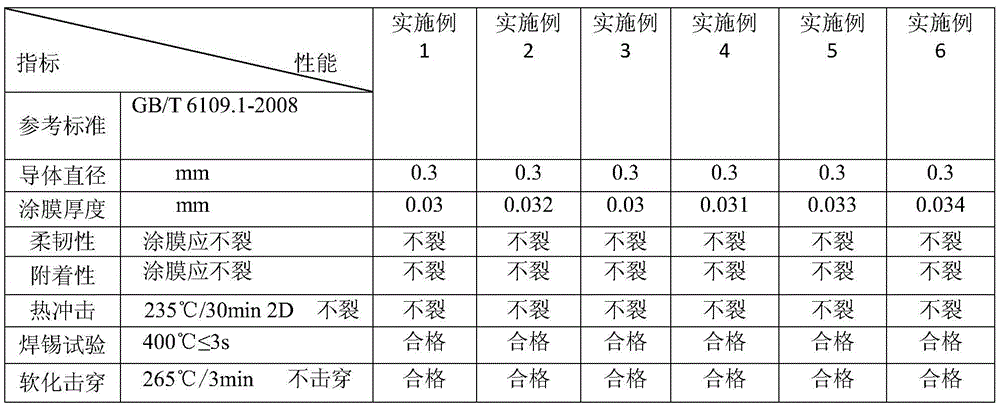

Preparation method of high-heat-resistance and high-wear-resistance polyesterimide enameled wire insulating paint

The invention relates to a preparation method of a high-heat-resistance and high-wear-resistance polyesterimide enameled wire insulating paint, which takes 100 parts of reacted polyesterimide enameled wire insulating paint by weight with medium molecular weight as a basal body. At least the following components in parts by weight are added: 1-20 parts of amino resin, 1-20 parts of thermoplastic phenolic resin and 0.5-5 parts of siloxane. Enameled wires which are made by using the paint has the advantages that the paint film adhesiveness is excellent, the stripping and twisting K value of the enameled wires can reach more than 155 and the K value is higher than the K value (which is 110) of the existing conventional products by more than two grades; the scratch resistance is excellent and the unidirectional scratch resistance can reach more than 2000g when the wire is combined with the polyesterimide paint; the heat resistance can reach 200 while the heat resistance of the conventional polyesterimide enameled wires is 180; and the process redundancy is wide and the realization of stable process production is facilitated.

Owner:艾仕得绝缘材料(安徽)有限公司

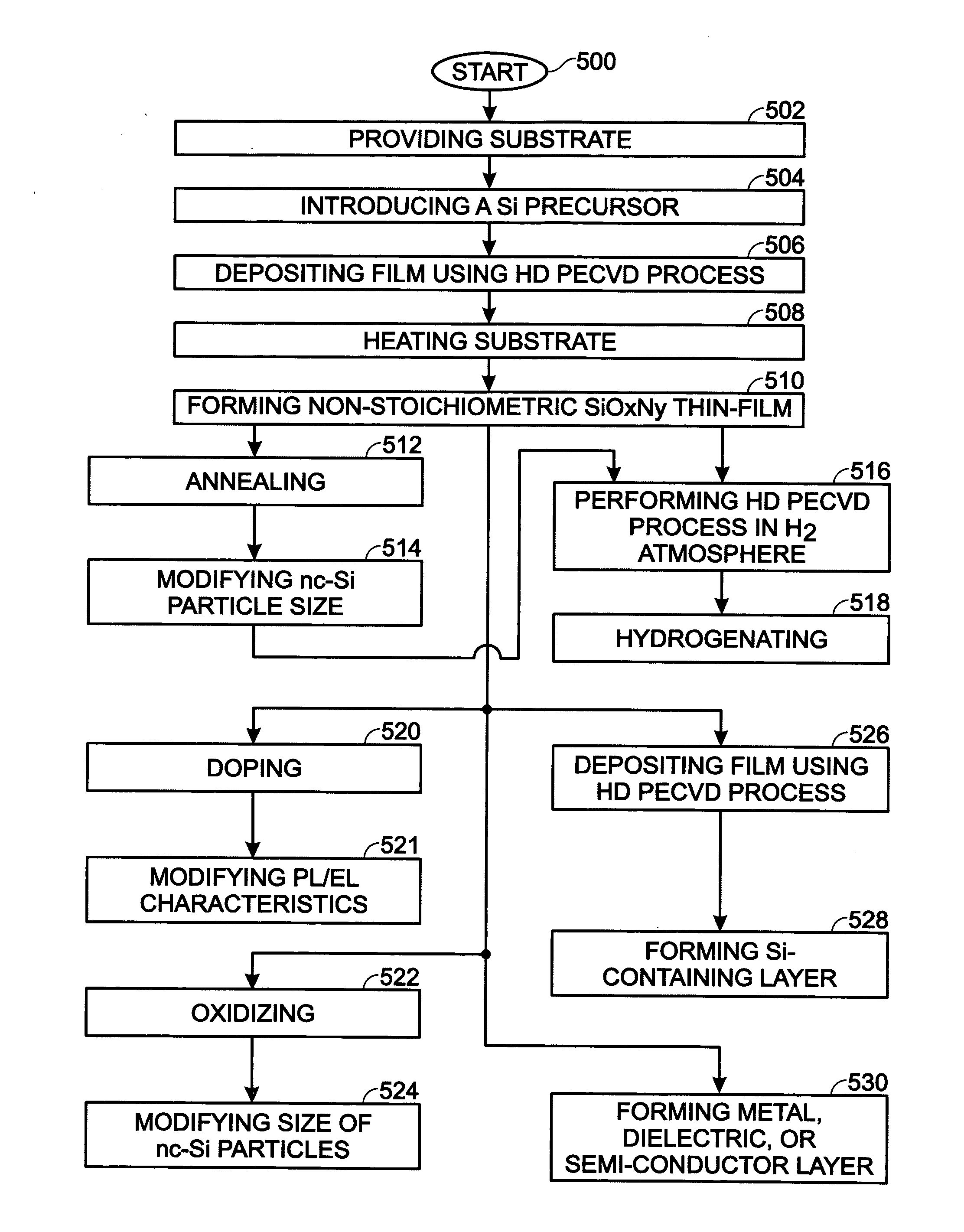

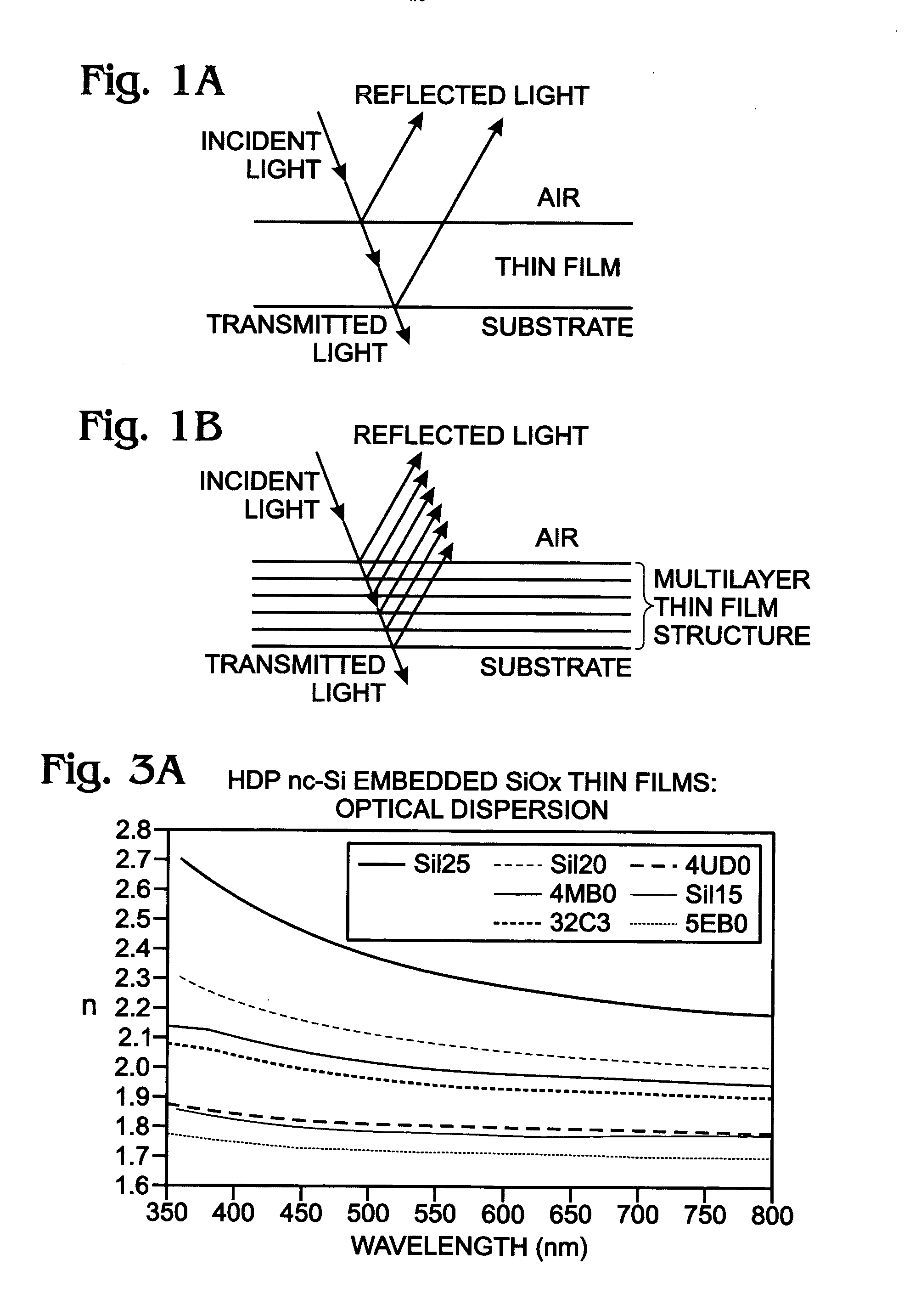

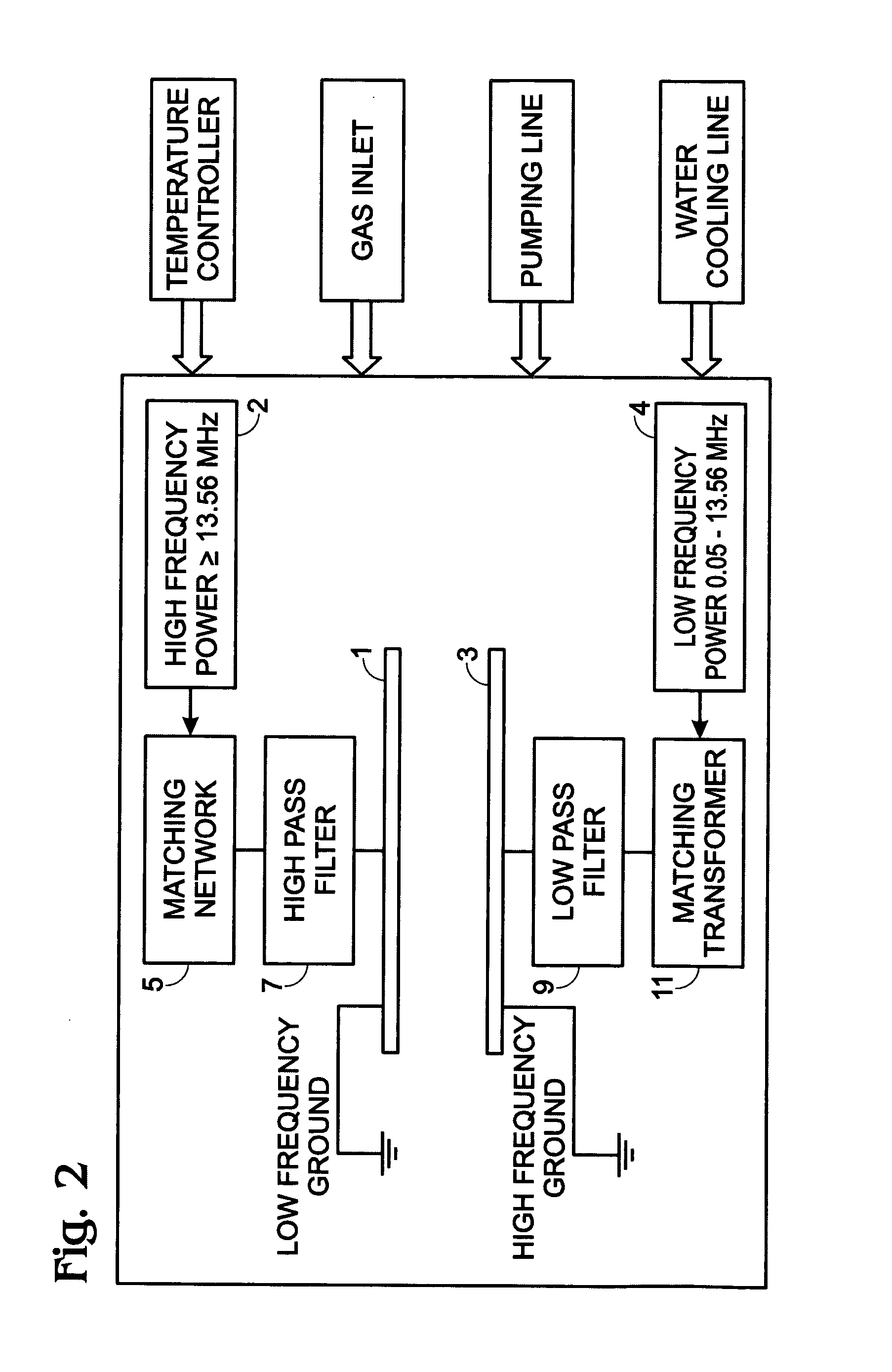

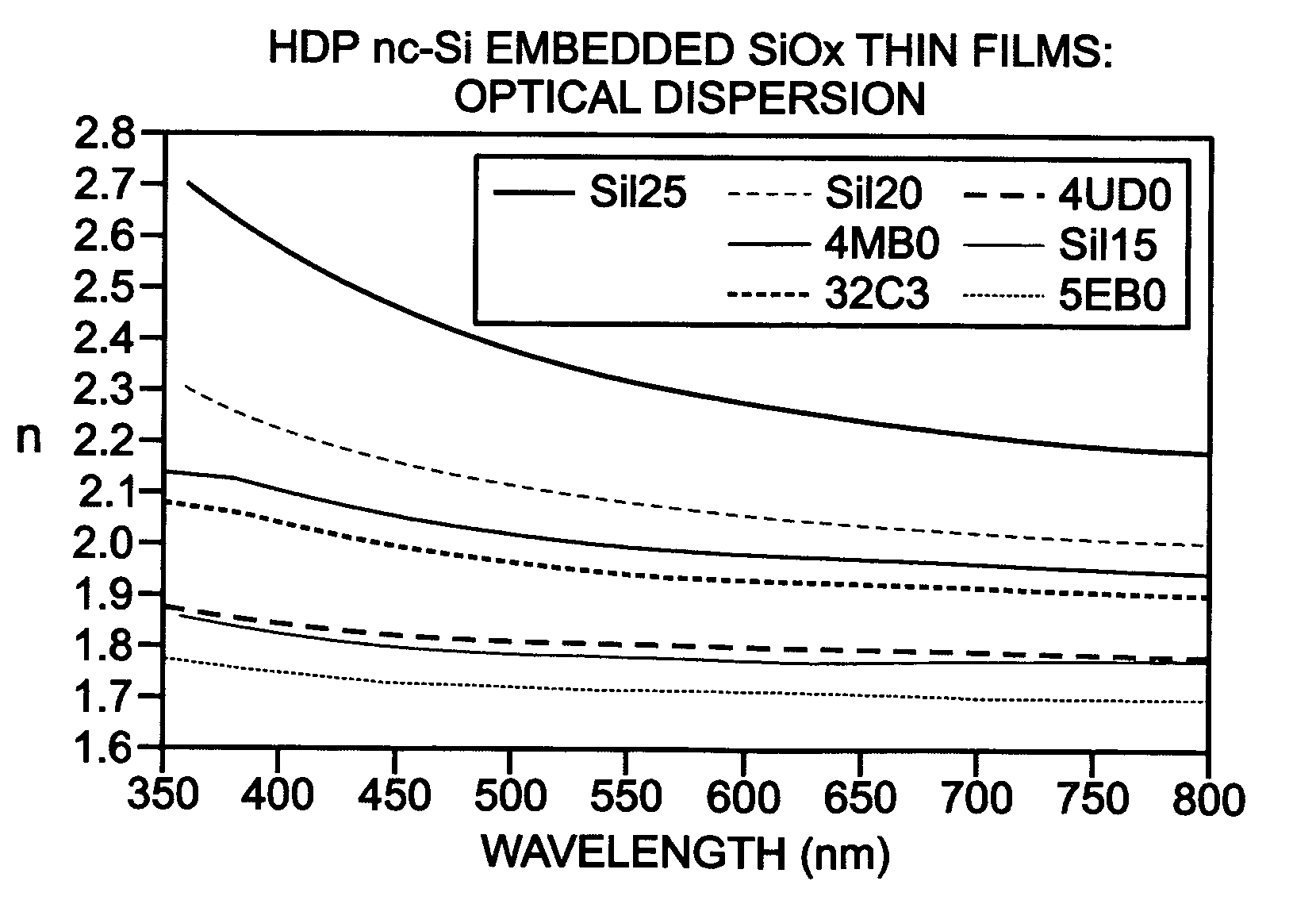

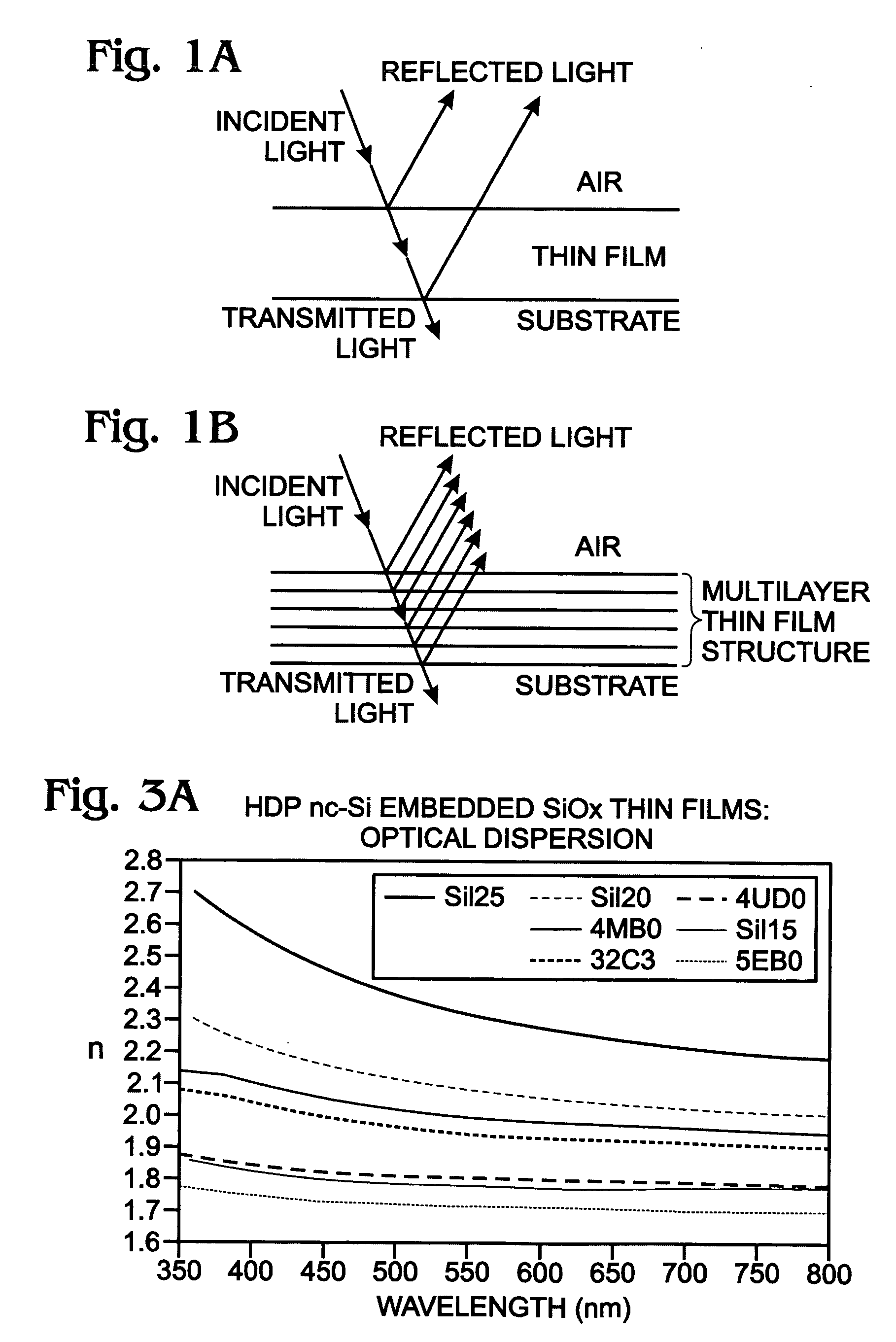

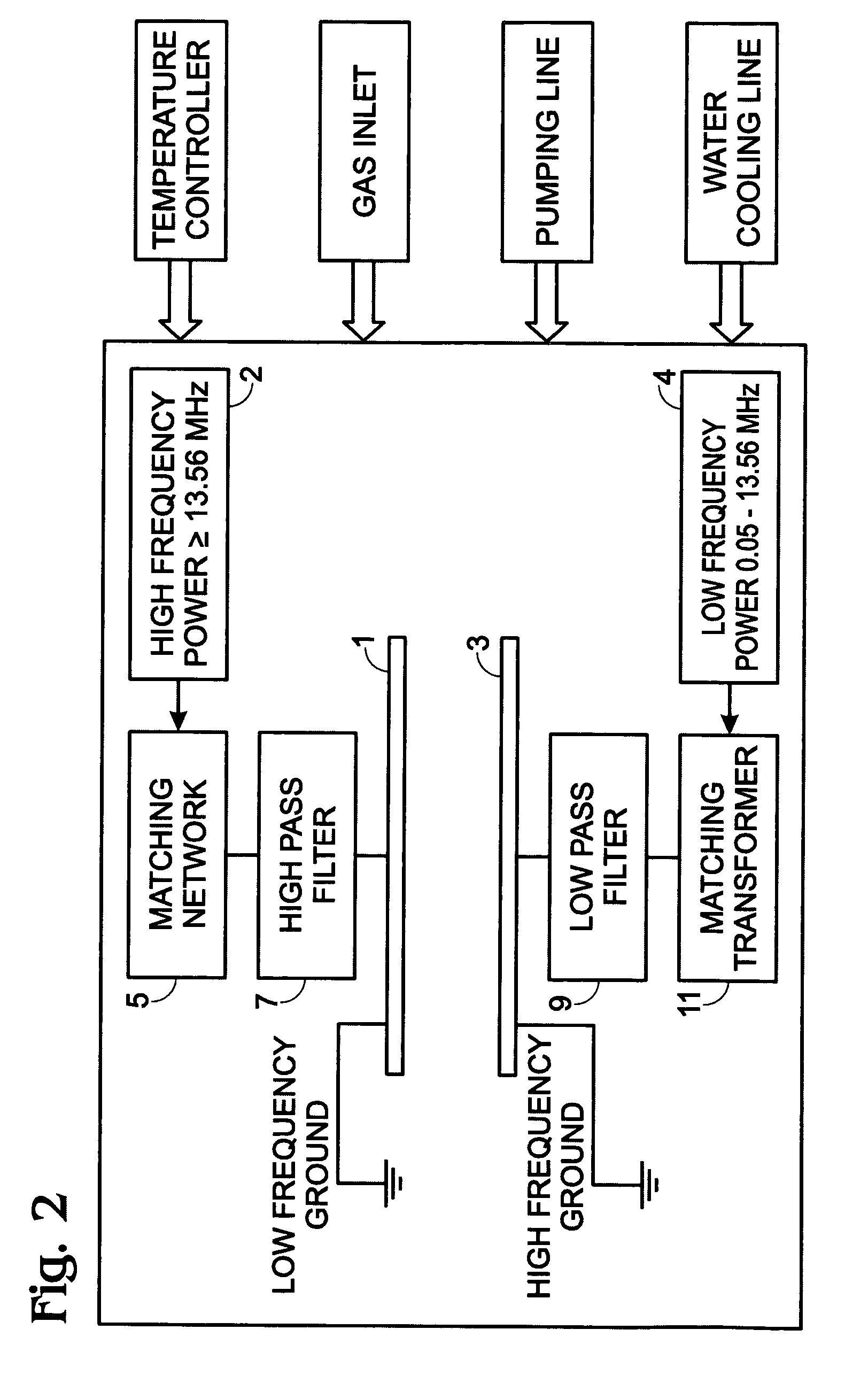

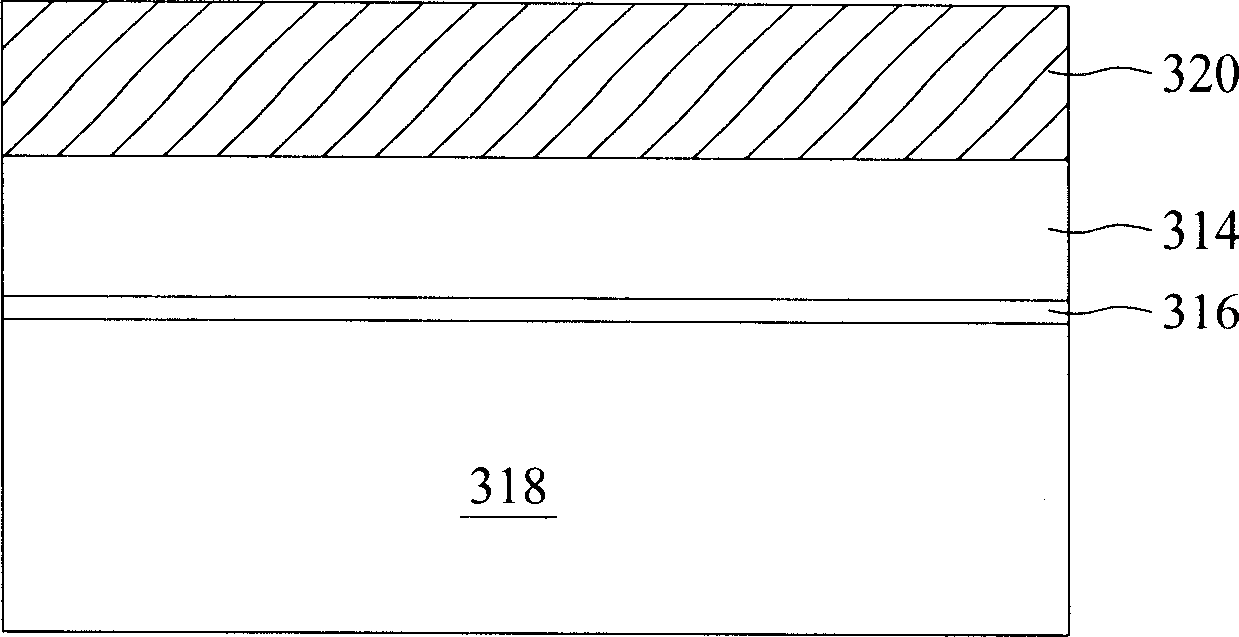

High density plasma non-stoichiometric SiOxNy films

InactiveUS20070155137A1Wide optical dispersionWide process marginSemiconductor/solid-state device manufacturingChemical vapor deposition coatingHigh densityGas phase

A high-density plasma method is provided for forming a SiOXNY thin-film. The method provides a substrate and introduces a silicon (Si) precursor. A thin-film is deposited overlying the substrate, using a high density (HD) plasma-enhanced chemical vapor deposition (PECVD) process. As a result, a SiOXNY thin-film is formed, where (X+Y<2 and Y>0). The SiOXNY thin-film can be stoichiometric or non-stoichiometric. The SiOXNY thin-film can be graded, meaning the values of X and Y vary with the thickness of the SiOXNY thin-film. Further, the process enables the in-situ deposition of a SiOXNY thin-film multilayer structure, where the different layers may be stoichiometric, non-stoichiometric, graded, and combinations of the above-mentioned types of SiOXNY thin-films.

Owner:SHARP KK

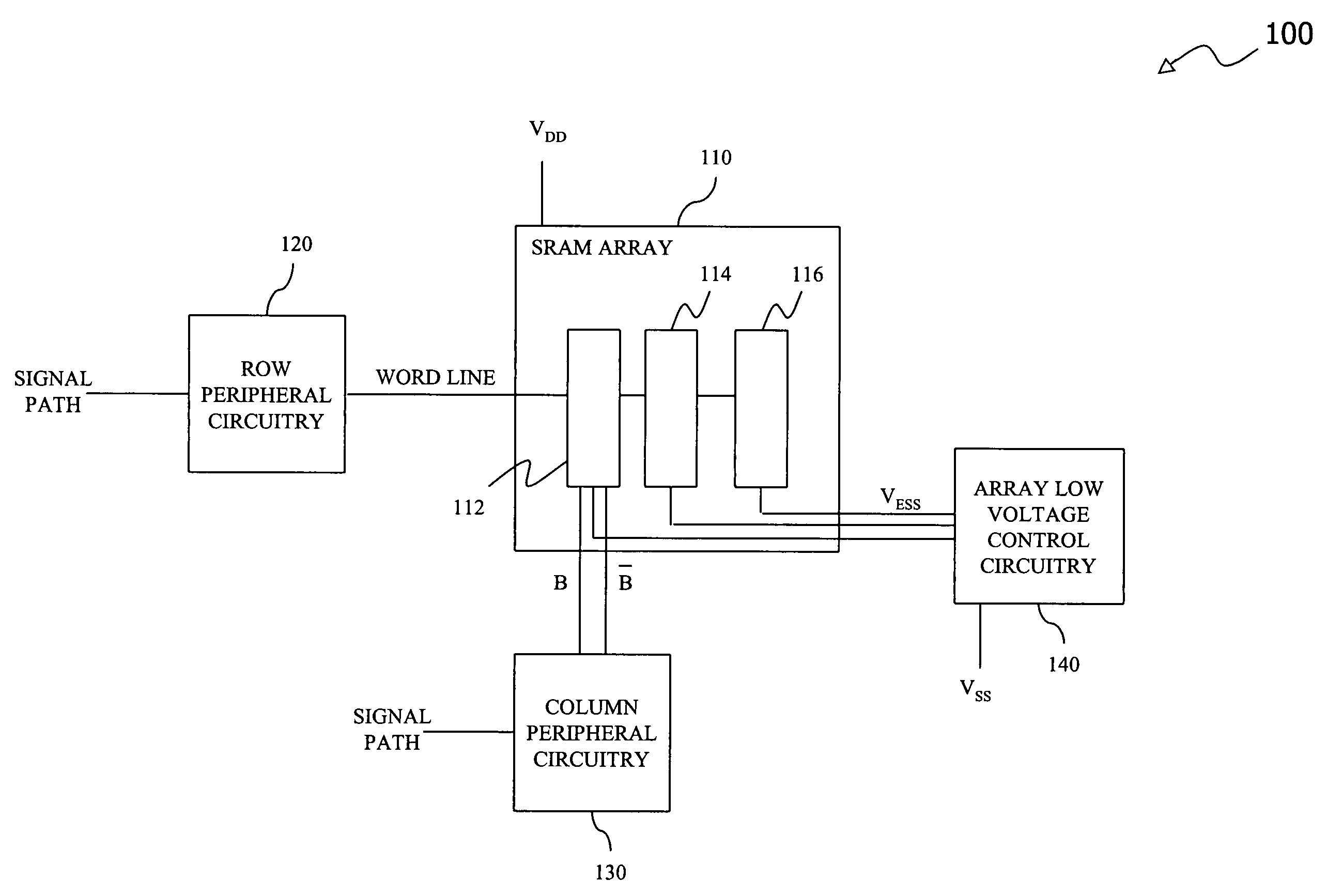

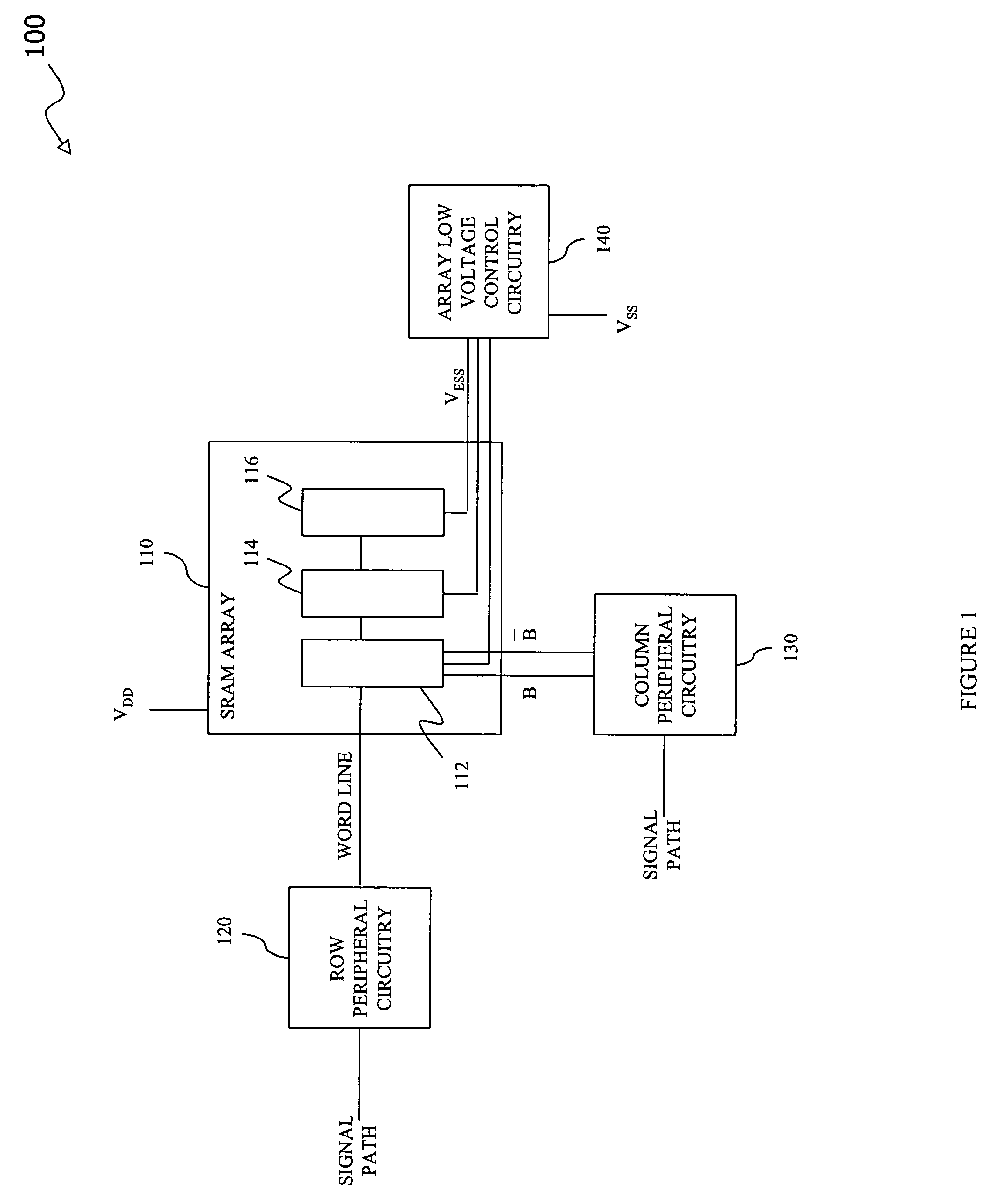

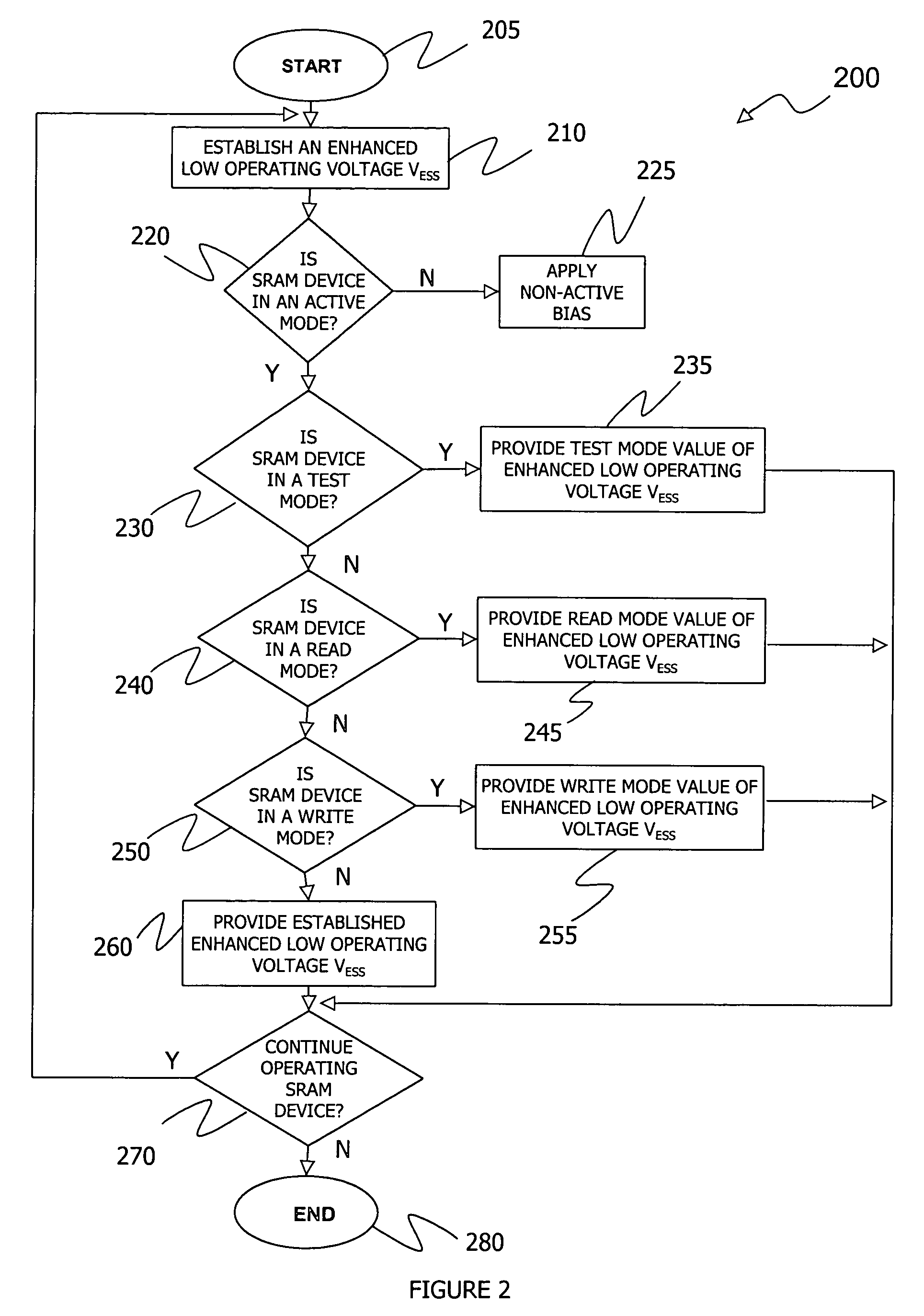

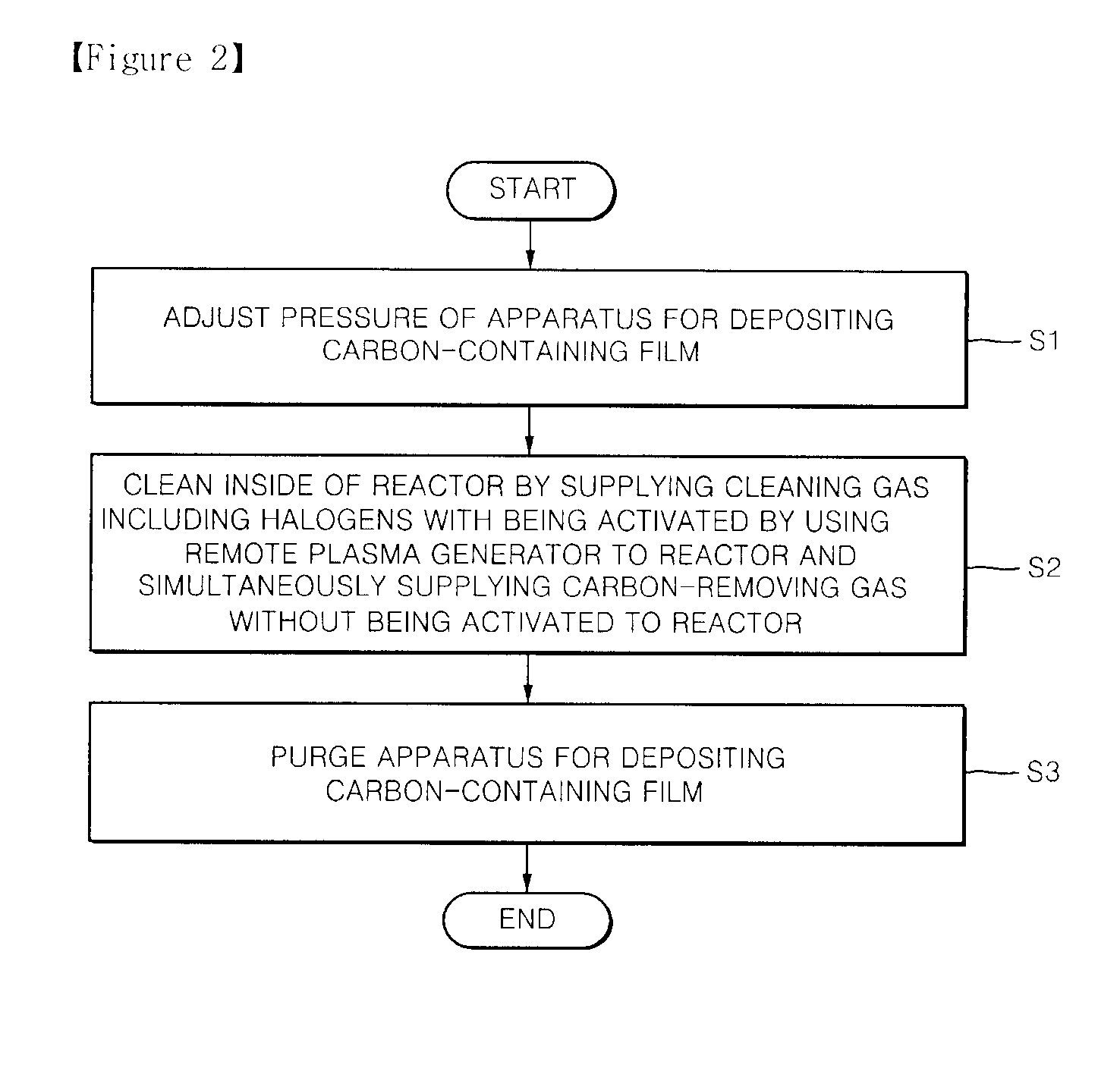

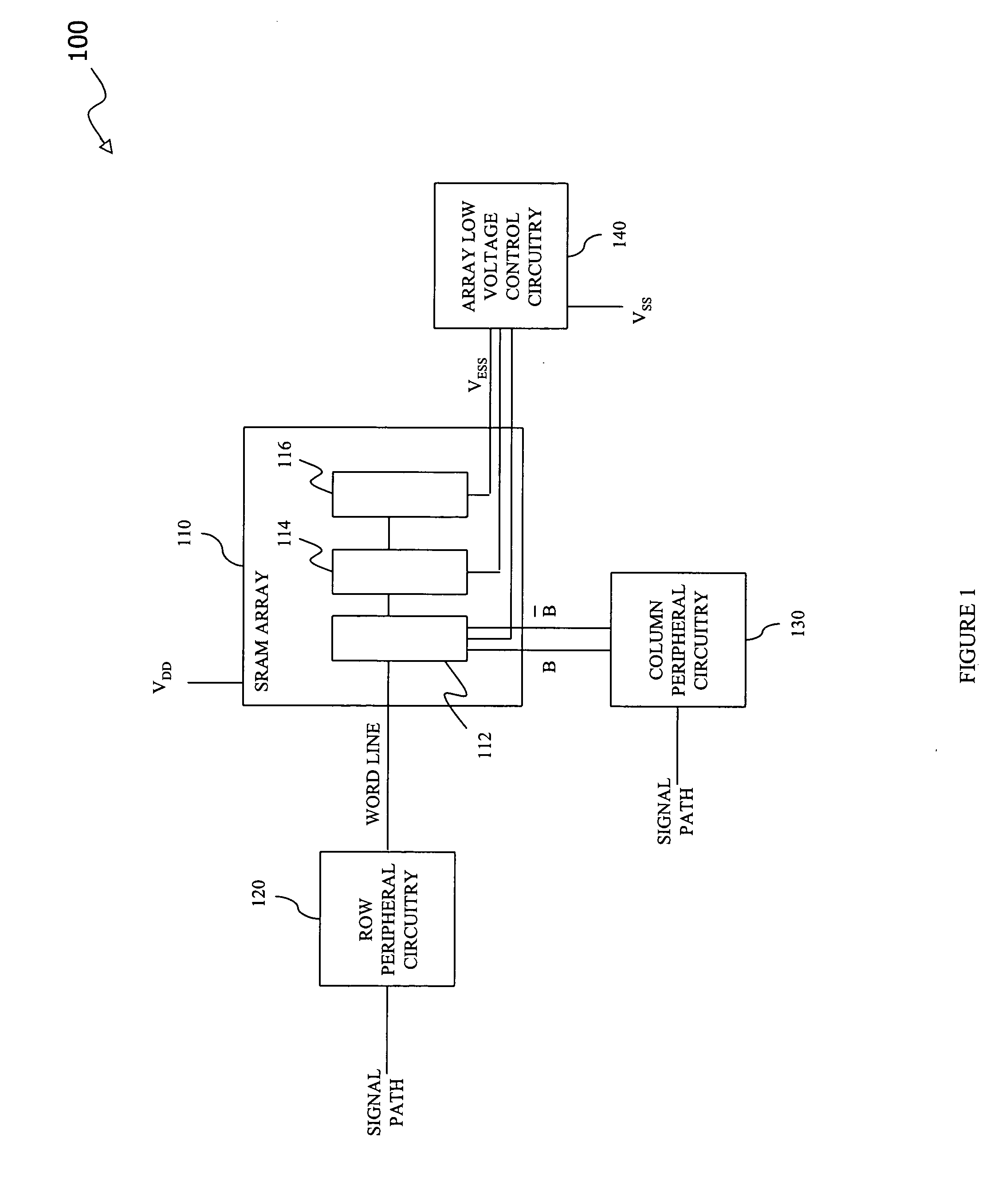

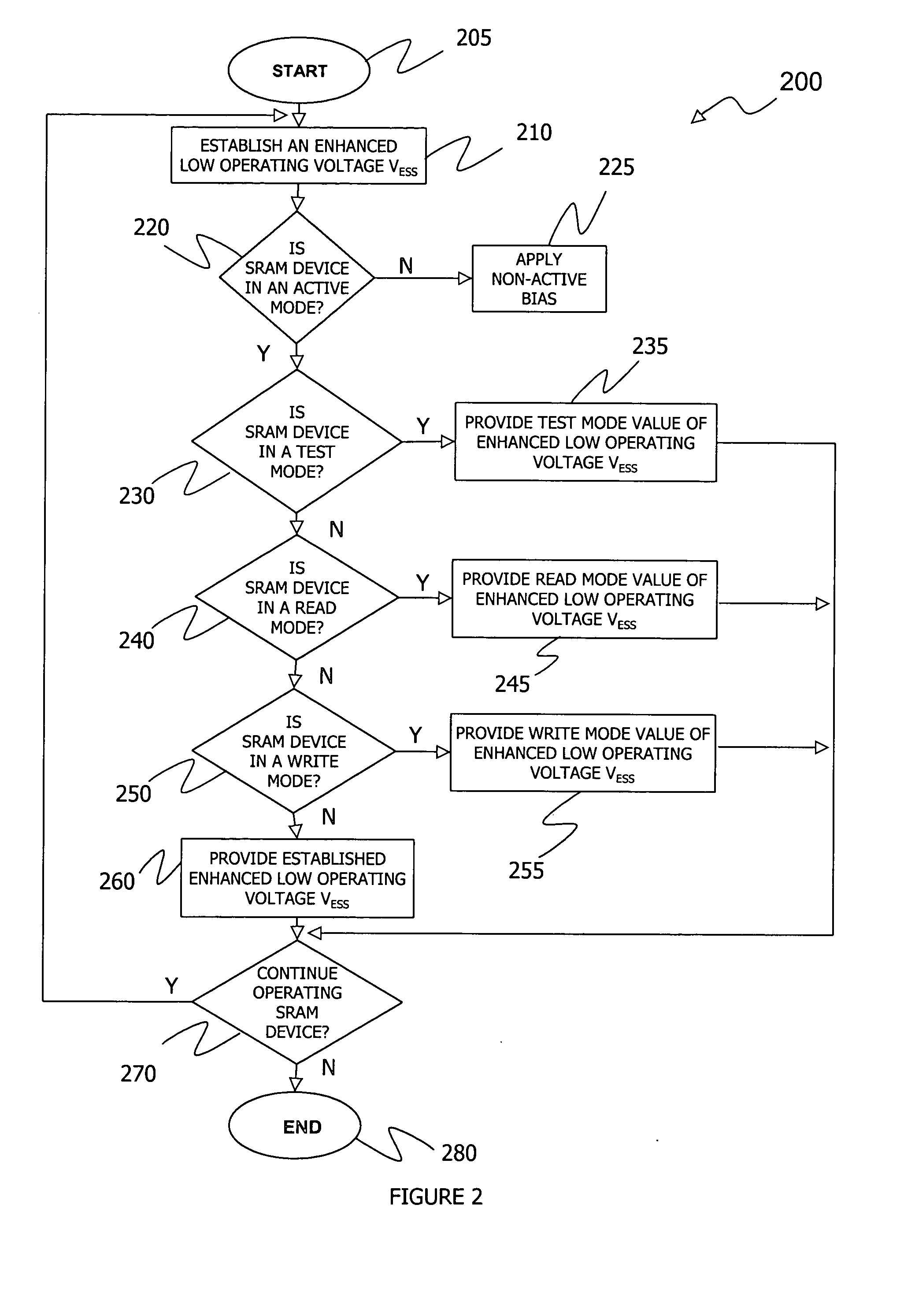

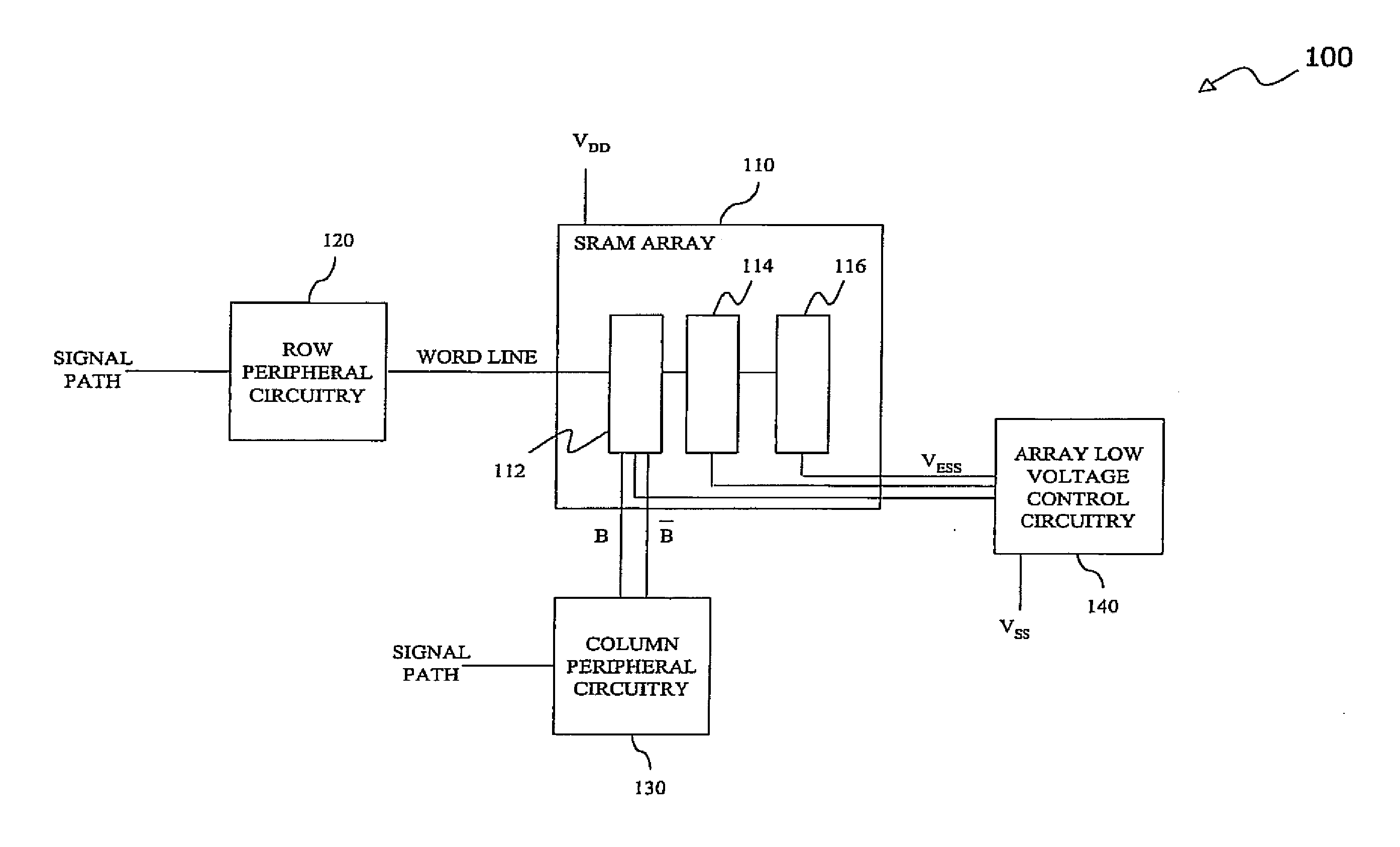

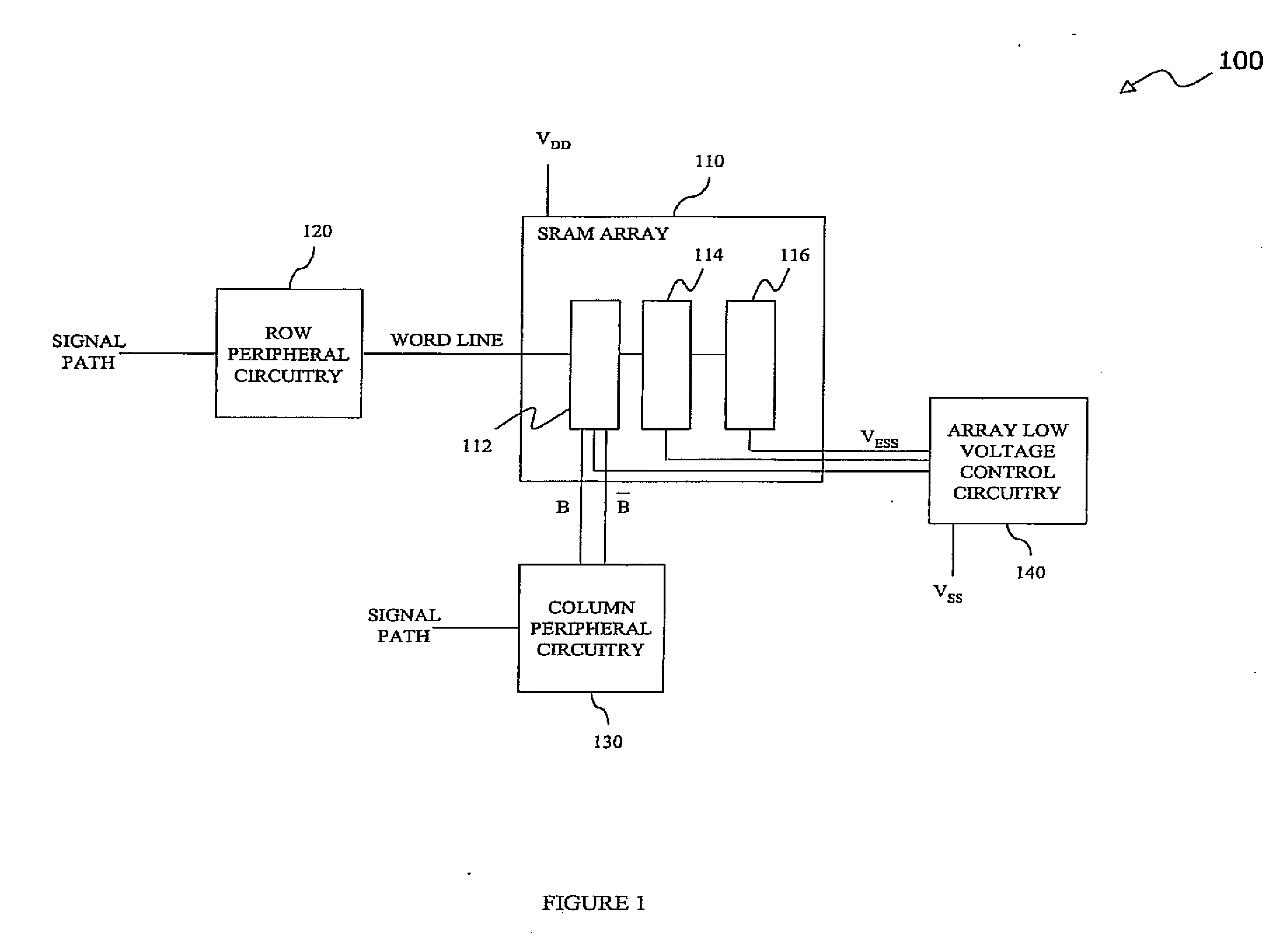

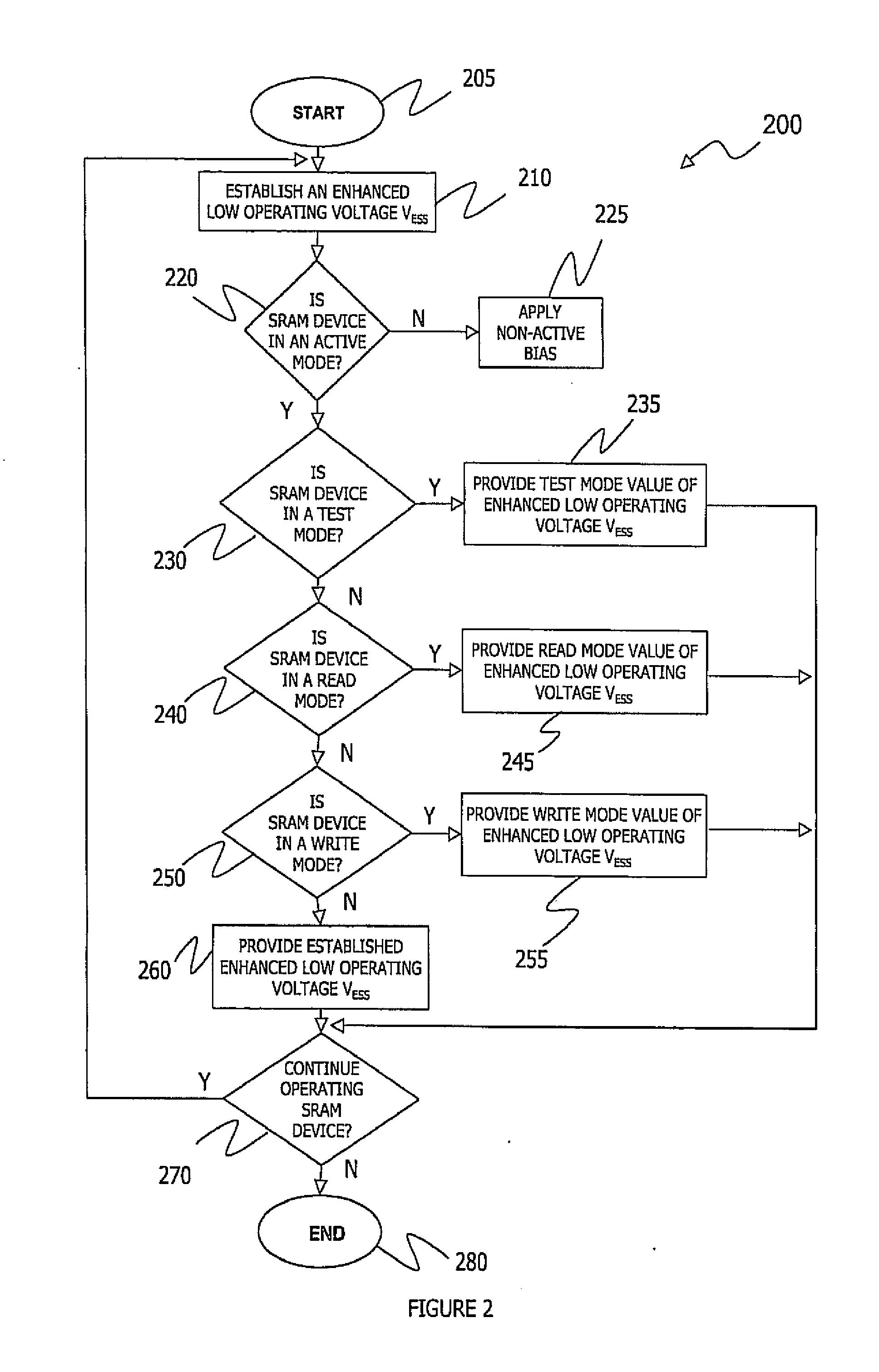

Static random access memory device having reduced leakage current during active mode and a method of operating thereof

ActiveUS7333357B2Improve powerBetter SNM and write trip voltageDigital storageBit lineStatic random-access memory

An Static Random Access Memory (SRAM) device and a method of operating the same. In one embodiment, the SRAM device includes: (1) an SRAM array coupled to row peripheral circuitry by a word line and coupled to column peripheral circuitry by bit lines and (2) an array low voltage control circuitry that provides an enhanced low operating voltage VESS to the SRAM array during at least a portion of an active mode thereof.

Owner:TEXAS INSTR INC

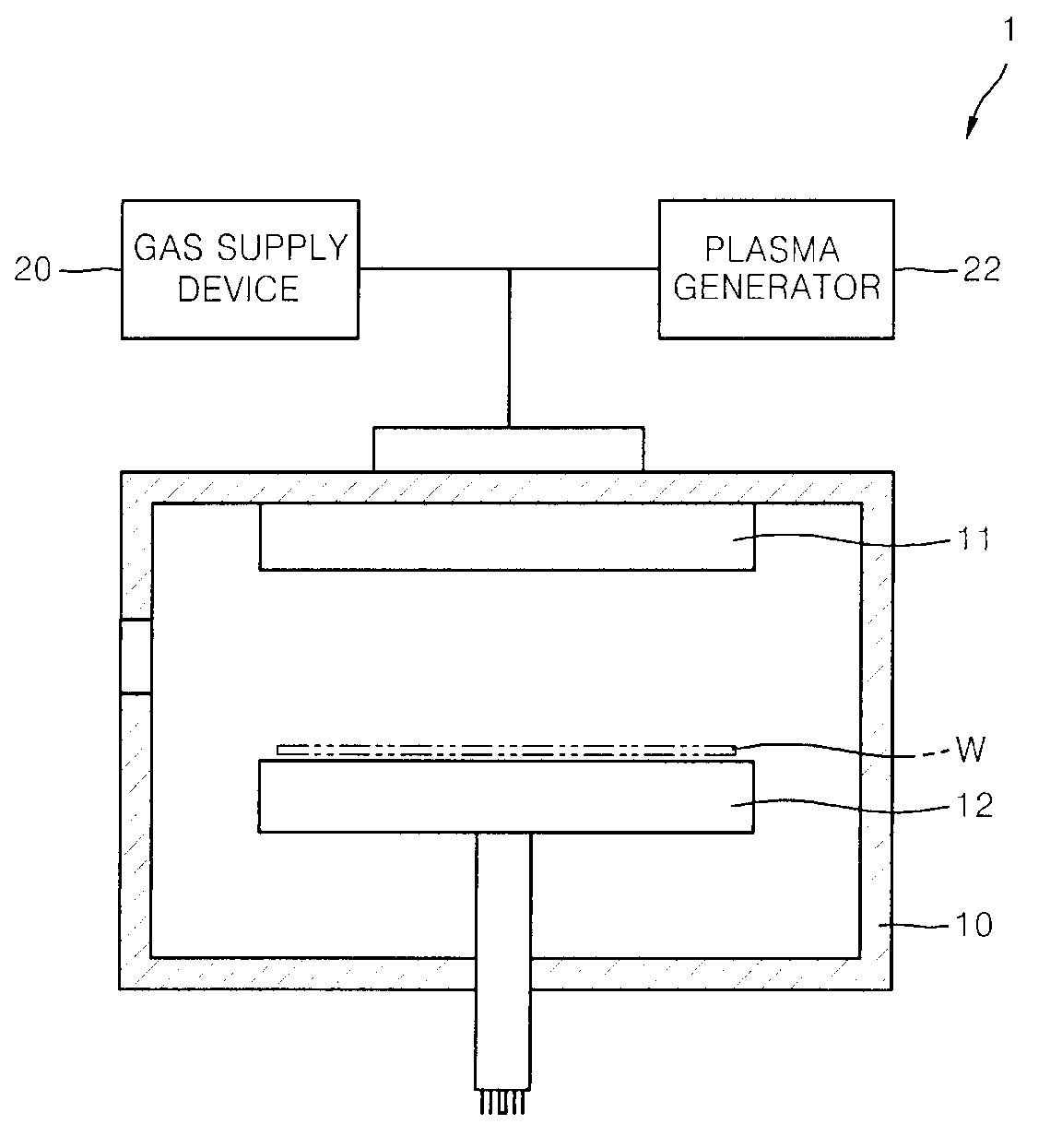

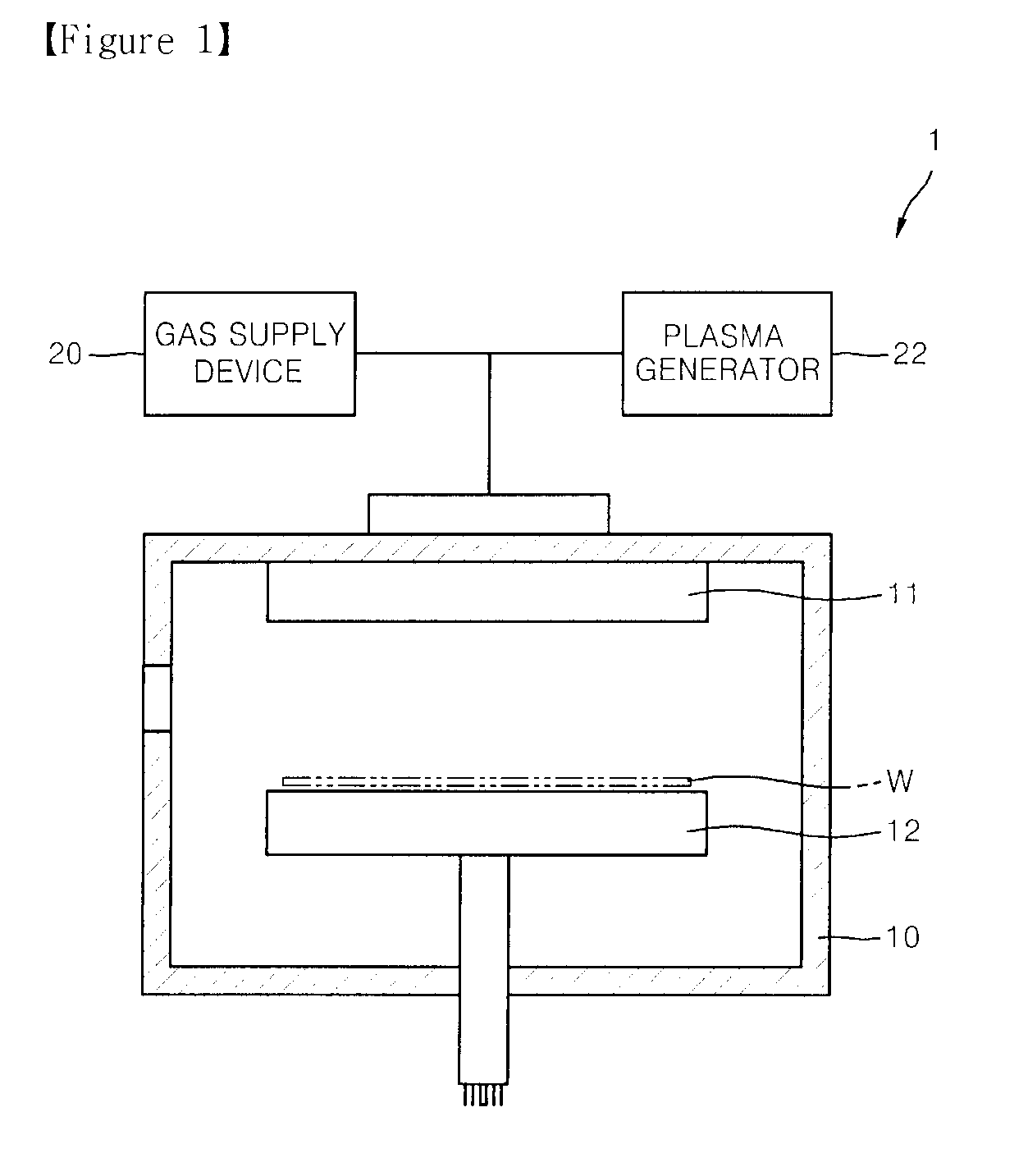

Cleaning method of apparatus for depositing carbon containing film

InactiveUS20110114114A1Wider cleaning process marginGood reproducibilityElectrostatic cleaningChemical vapor deposition coatingRemote plasmaCleaning methods

A dry cleaning method of an apparatus for depositing a carbon-containing film is provided. The method includes in-situ cleaning an inside of a reactor of the apparatus, wherein the cleaning of the inside of the reactor of the apparatus comprises supplying a cleaning gas including halogens with being activated by using a remote plasma generator to the reactor and simultaneously supplying a carbon-removing gas without being activated to the reactor. In the method, a by-product in a solid form is not generated, and in-situ cleaning can be performed without stopping the apparatus for depositing a carbon-containing film after a predetermined amount of wafers are treated, such that productivity of the apparatus for depositing a carbon-containing film can be maximized.

Owner:WONIK IPS CO LTD

Static random access memory device having reduced leakage current during active mode and a method of operating thereof

ActiveUS20050128790A1Improve powerBetter SNM and write trip voltageDigital storageBit lineStatic random-access memory

An Static Random Access Memory (SRAM) device and a method of operating the same. In one embodiment, the SRAM device includes: (1) an SRAM array coupled to row peripheral circuitry by a word line and coupled to column peripheral circuitry by bit lines and (2) an array low voltage control circuitry that provides an enhanced low operating voltage VESS to the SRAM array during at least a portion of an active mode thereof.

Owner:TEXAS INSTR INC

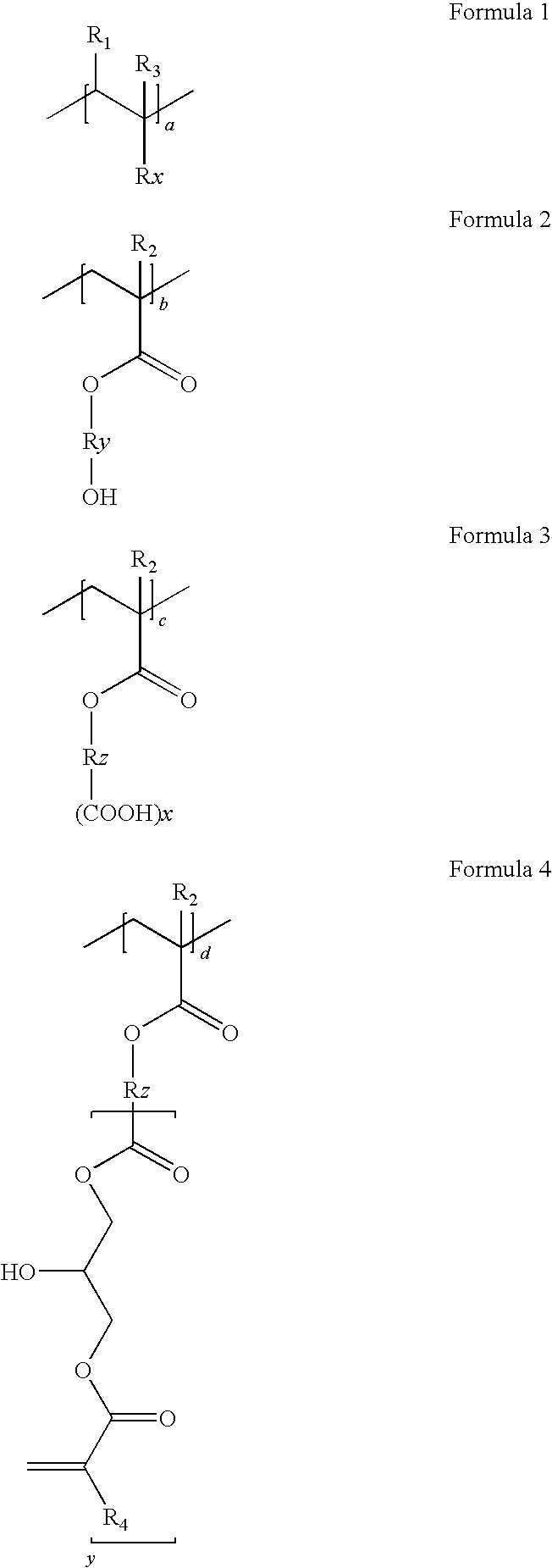

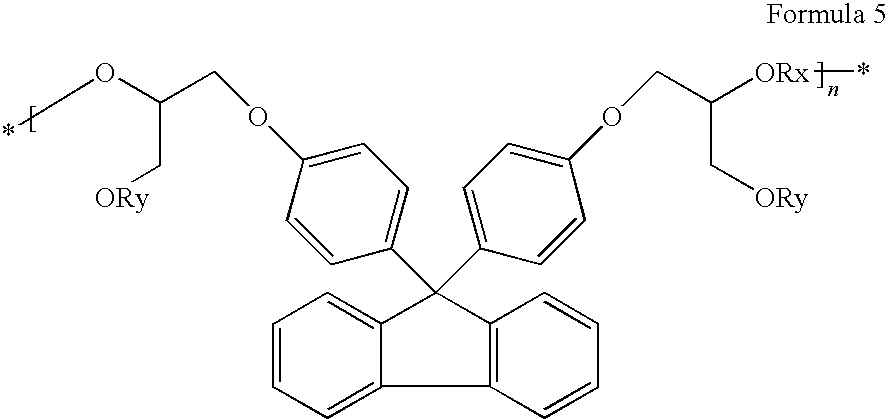

Colored dispersion, photoresist composition and black matrix

ActiveUS20100104981A1Improve adhesionWide process marginPhotosensitive materialsLayered productsDispersion stabilityResist

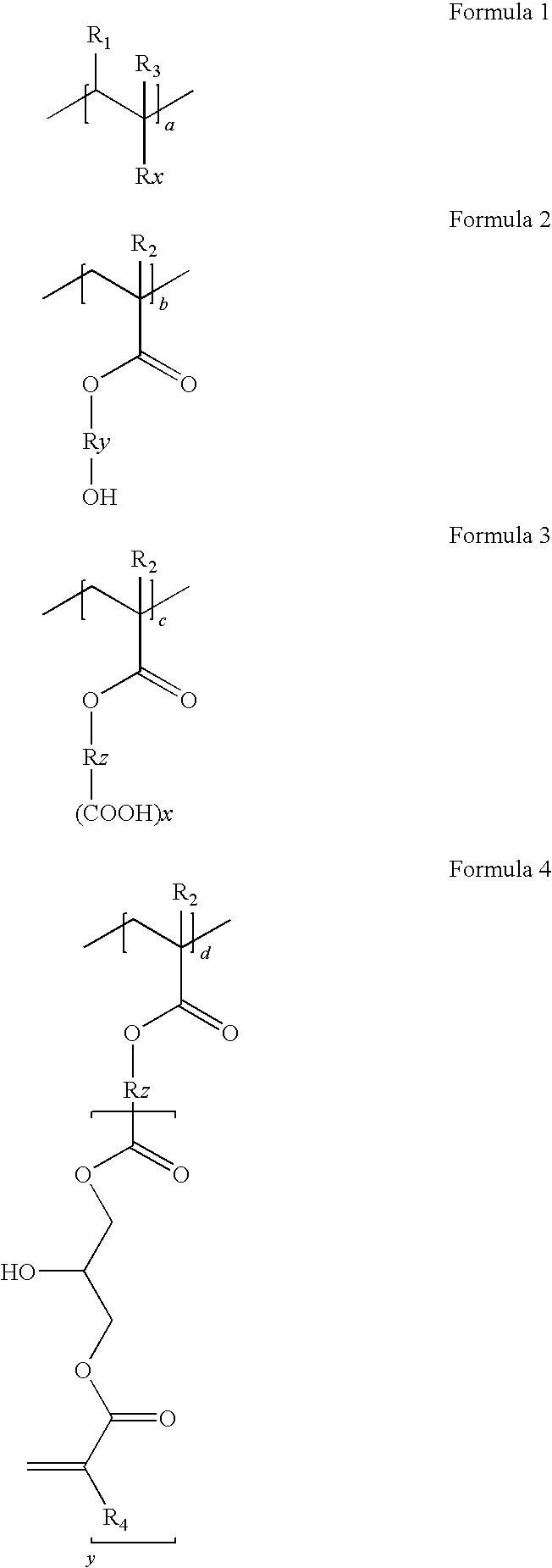

A colored dispersion according to the present invention comprises a resin including monomers of Formulas 1 to 4, as a binder resin.Accordingly, a photoresist composition for a black matrix of a high light shielding property, which has the dispersion stability of the colored dispersion according to the present invention, could be provided, and a black matrix of high sensibility having an uniform process characteristic while maintaining a high light-shielding property could be produced.

Owner:LG CHEM LTD

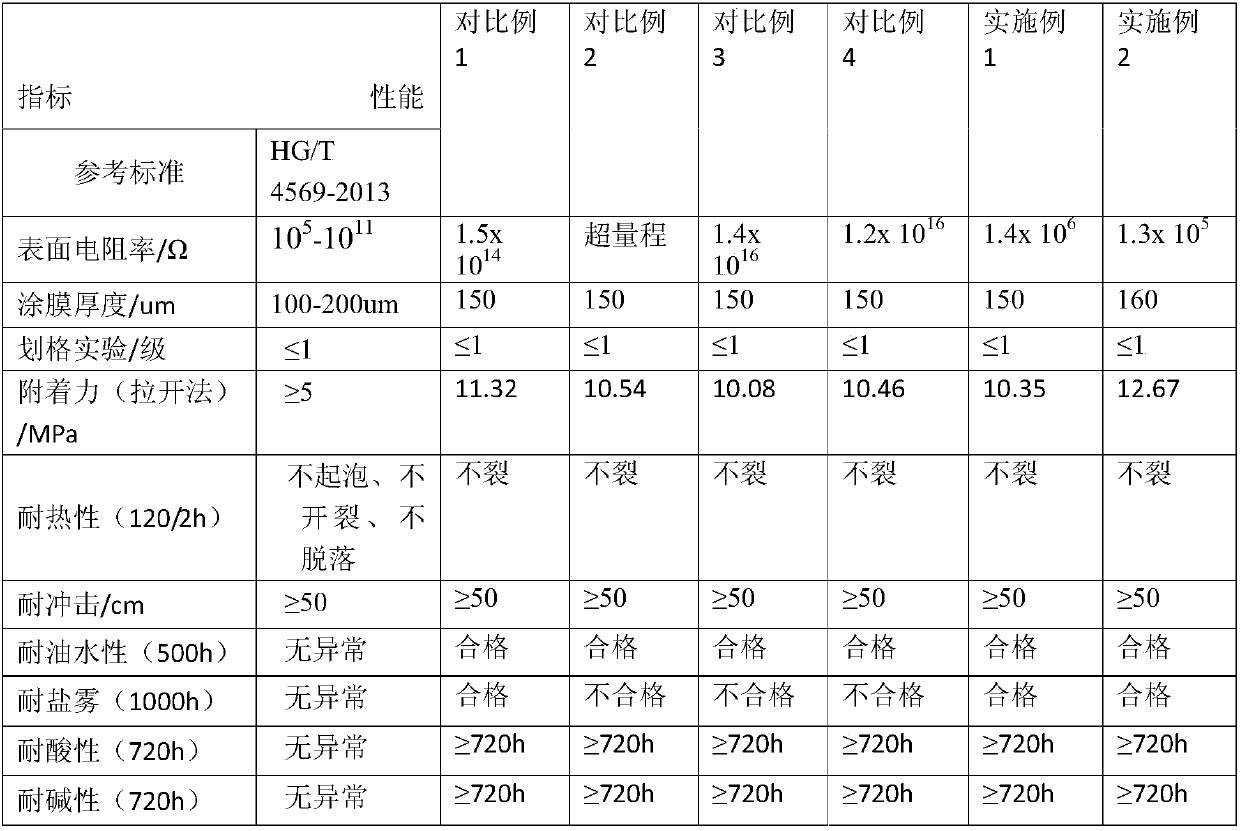

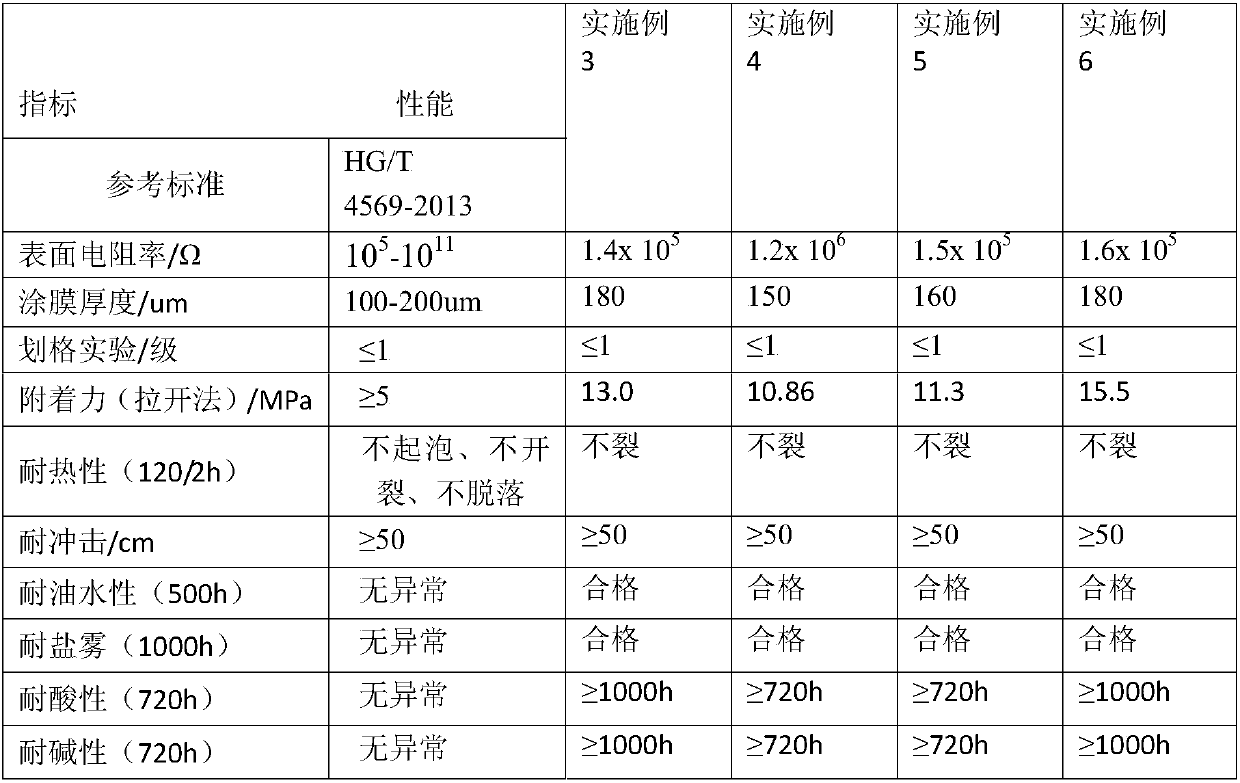

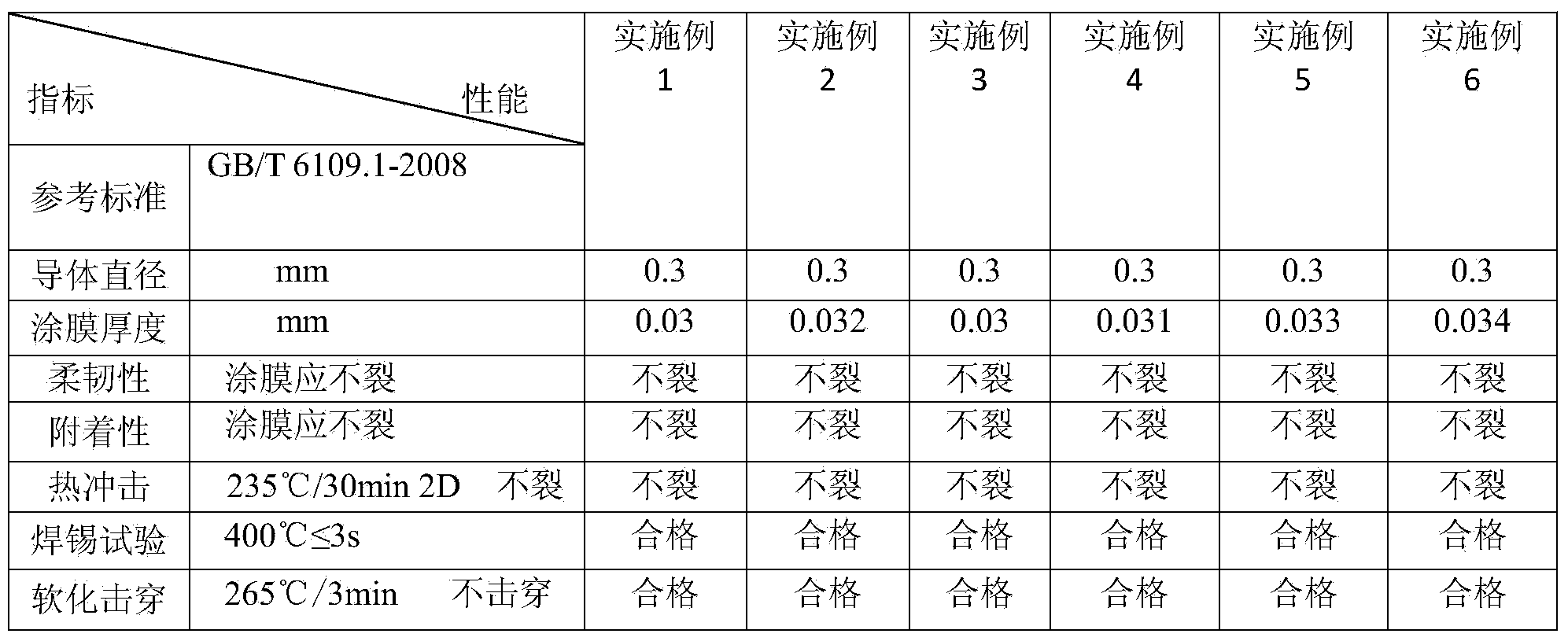

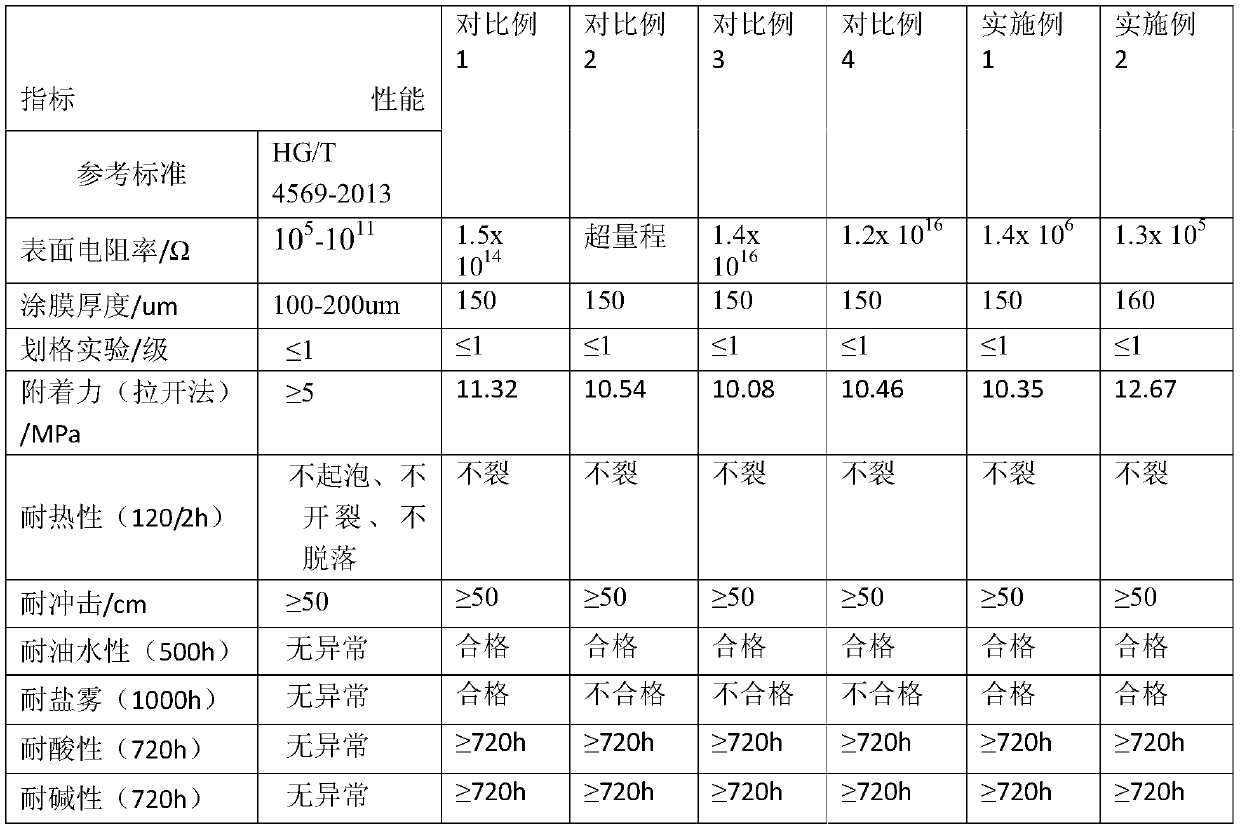

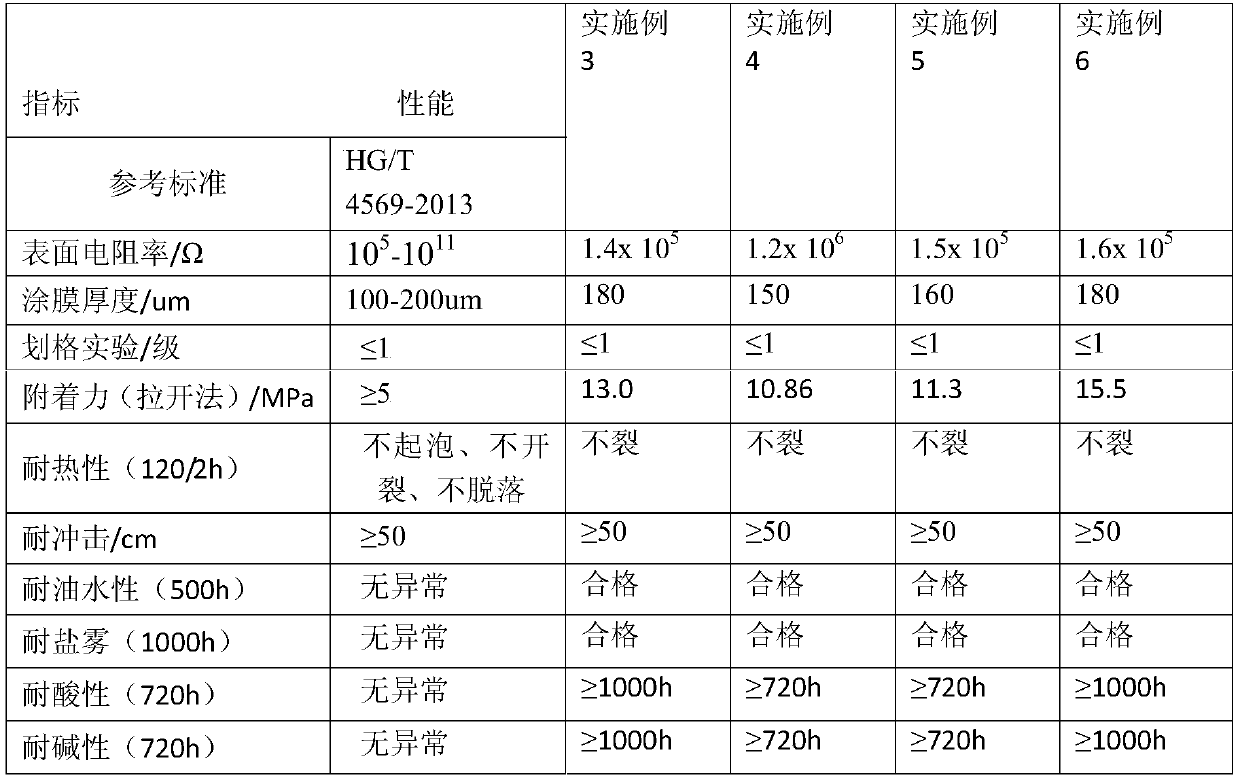

Graphene-flaky conductive mica oil tank static electricity conduction anticorrosive paint and preparation method thereof

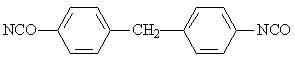

ActiveCN107201071ASimple processReaction is easy to controlAnti-corrosive paintsEpoxy resin coatingsEpoxyGraphene

The invention discloses a graphene-flaky conductive mica oil tank static electricity conduction anticorrosive paint and a preparation method thereof. The paint uses epoxy resin as matrix resin, uses modified graphene and conductive mica as a two-component conductive filler, and adopts an isocyanate curing agent. The paint has the advantages of static electricity conduction, heat conduction, corrosion resistance and the like, the method is simple in technology, and the sources of the raw materials are wide. The preparation method of the graphene-flaky conductive mica oil tank static electricity conduction anticorrosive paint provided by the invention mainly comprises the following steps: synthesis of modified graphene, synthesis of isocyanate tripolymer and preparation of the oil tank static electricity conduction anticorrosive paint, wherein the graphene and the flaky conductive mica serve as the two-component conductive filler, the epoxy resin serves as the matrix resin, and an appropriate amount of a solvent is added, so that the graphene-flaky conductive mica oil tank static electricity conduction anticorrosive paint is obtained.

Owner:NANJING CHANGJIANG PAINT

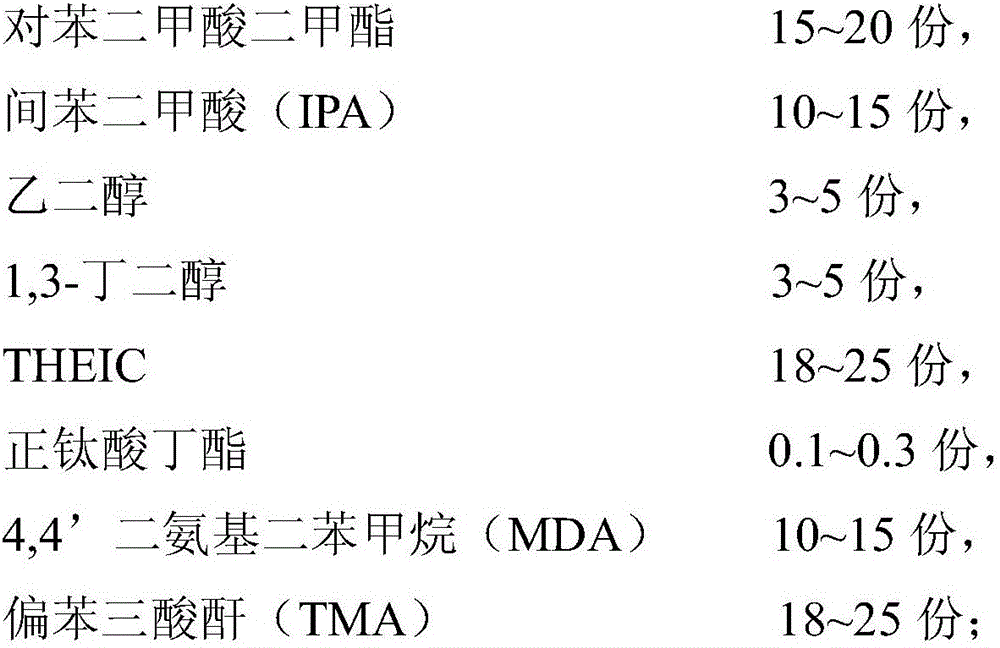

Synthetic method of polyester type polyurethane enamelled wire varnish with high heat-resistant grade

ActiveCN103965764ASimple processReaction is easy to controlPolyurea/polyurethane coatingsPolymer scienceDistillation

The invention discloses a synthetic method of a polyester type polyurethane enamelled wire varnish with a high heat-resistant grade, the enamelled wire varnish prepared by adopting the method has high heat-resistant performance and the heat-resistant grade reaches 200 or above. The synthetic method disclosed by the invention is characterized by comprising the synthetic processes of imine and ethanol amine modified polyester resin as follows: adding diethylene glycol, diethanol amine, trimethylol propane, tris-(2-hydroxyethyl) cyanuric acid and a catalyst into a reactor; heating the mixture to 100 to 120 DEG C; further adding dimethyl terephthalate, partial dianhydride and modified imine dicarboxylic acid; heating to 140 to 150 DEG C; reacting for more than 4 h; heating to 220 to 230 DEG C; reacting for more than 12 h; conducting vacuum operation when the temperature of a distillation head is below 65 DEG C until the viscosity is between 1300 to 1800 mPa.s (25 DEG C); adding cresol and xylene and stirring for dissolving and clarifying to obtain the imine and ethanol amine modified polyester resin until the solid content reaches 44%.

Owner:江苏四达特材科技有限公司 +1

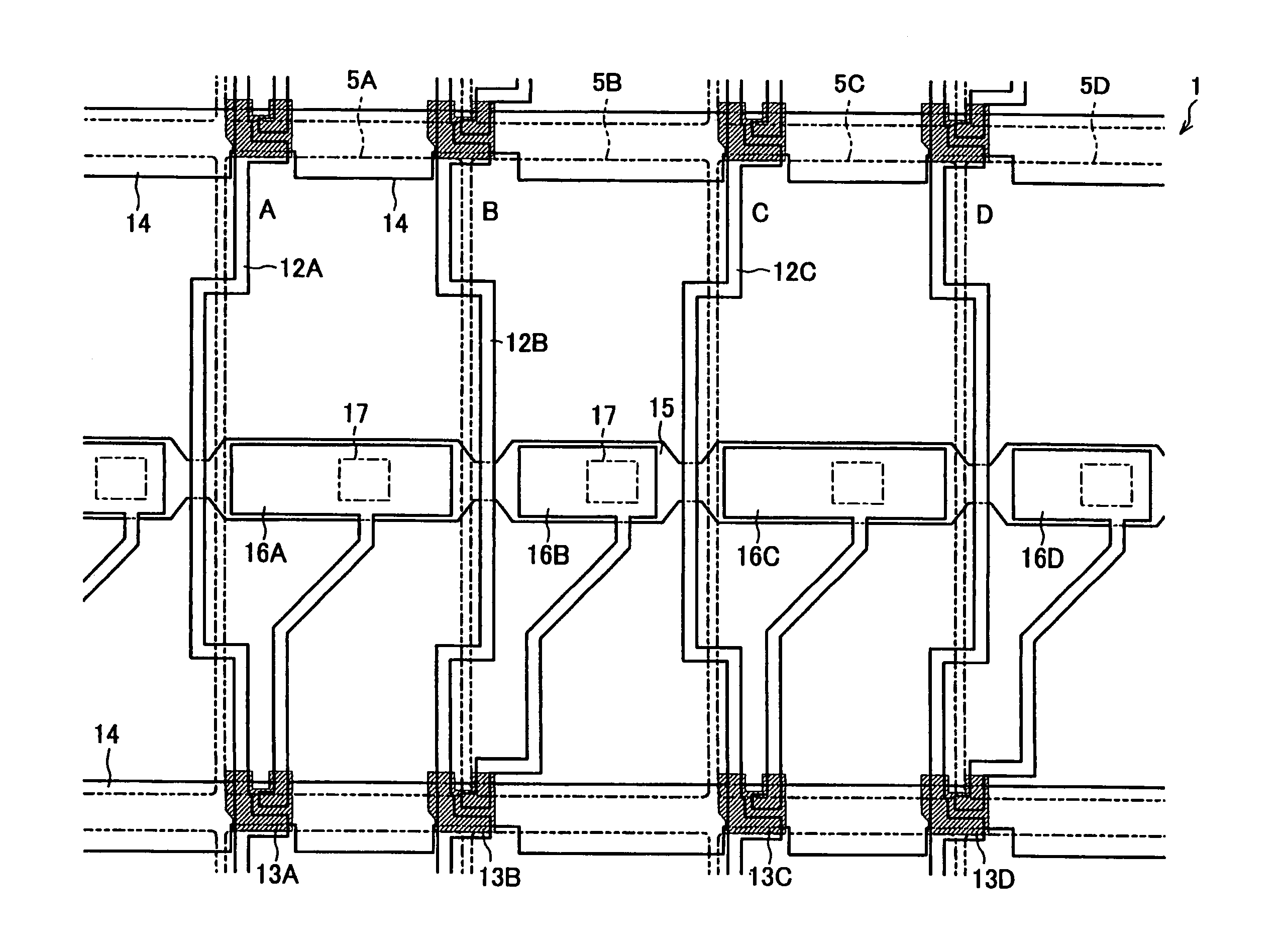

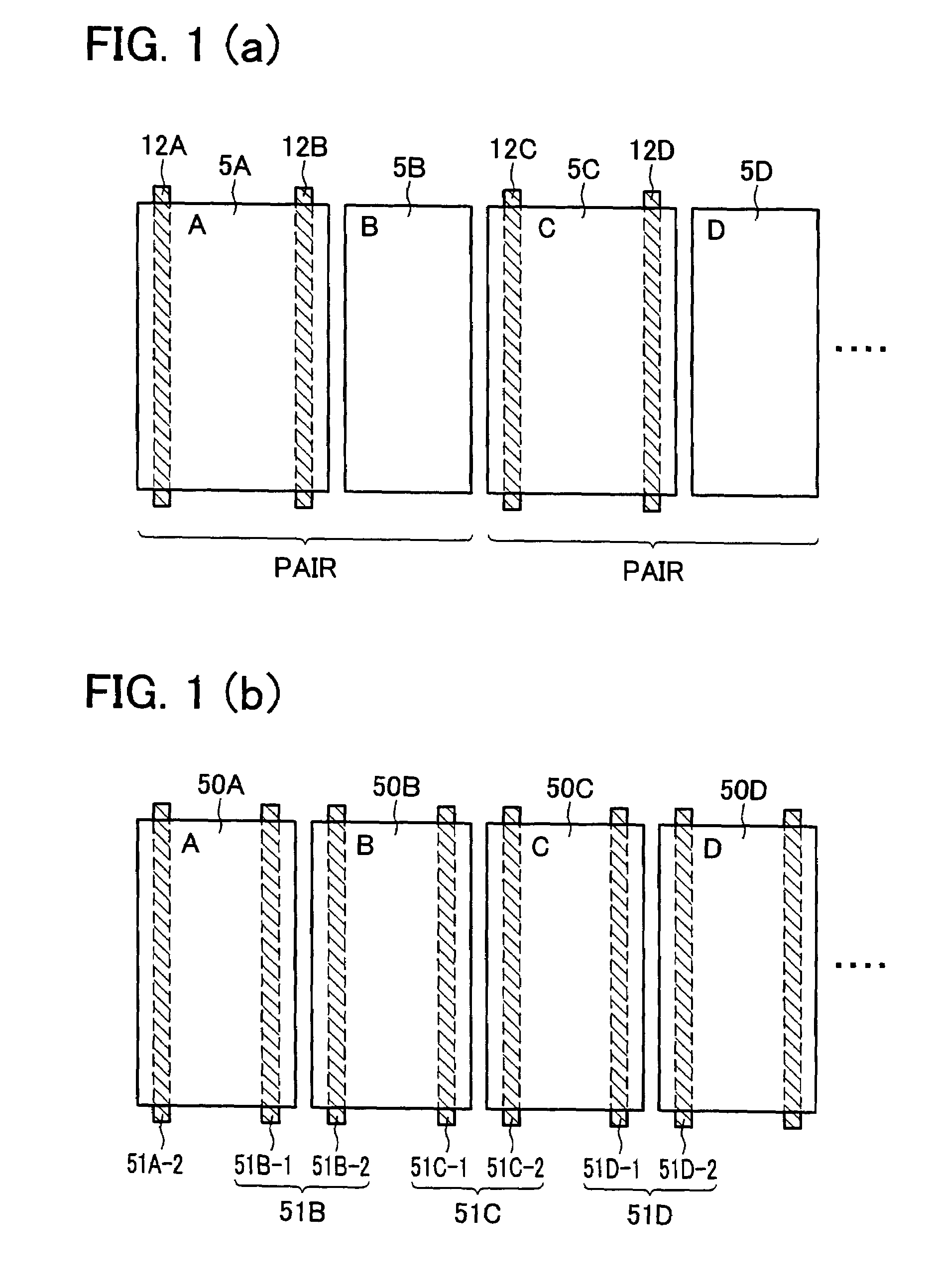

Active element substrate with simplified signal line arrangement having active elements and pixel electrodes and liquid crystal display device using the same

ActiveUS7196745B2Convenient ArrangementWide process marginTransistorStatic indicating devicesCapacitanceLiquid-crystal display

An active element substrate and an opposed substrate sandwich a liquid crystal layer to constitute a liquid crystal display device. On the active element substrate, two signal lines respectively charge a pair of pixels that are adjacent to each other in a direction parallel to scanning lines. The two signal lines are provided intensively on a pixel electrode of one of the pair of pixels. In the direction parallel to the scanning lines, a pixel electrode on which signal lines are provided, and a pixel electrode on which signal lines are not provided, are arrayed alternately. This arrangement makes it possible to reduce, while ensuring a wide process margin, the fluctuation of the potential of a terminal to be connected to a pixel electrode (the fluctuation of the potential occurs during OFF-period of an active element due to capacitances respectively provided at superimposed portions of signal lines and a pixel electrode), to simplify the arrangement of signal lines, and to improve the aperture ratio.

Owner:SHARP KK

Preparation method of 180 grade polyurethane enamelled wire insulating paint used for ultra-fine wire

InactiveCN102936451AImprove the level ofNo sparklePolyurea/polyurethane coatingsUltra fineZinc Acetate Dihydrate

The invention relates to 180 grade polyurethane enamelled wire insulating paint used for an ultra-fine wire. The insulating paint is prepared by the following components of 14-20 parts of an imide-modified polyester resin, 36-50 parts of a blocked isocyanate resin, 0.02 part of zinc acetate, 0.35-0.75 part of an amino condensation compound, 0.02-0.05 part of silicone oil, 0.2-0.6 part of acrylic ester, 17-27 parts of dimethylbenzene, 7-17 parts of phenol and 5 parts of n-butyl alcohol. High heat grade non-pinhole rapid direct-welding polyurethane enamelled wire insulating paint is produced by mixing paint with the above materials at a temperature of 60-70 DEG C. Compared with a conventional insulating paint, the enamelled wire insulating paint provided by the invention has good leveling property, and can meet the requirements of a production process with specification of 0.02 mm and production speed of 1500 m / min. The prepared enamelled wire has smooth and bright surfaces and has no shining points. The prepared enamelled wire has high a soft breakdown temperature which is higher than 260 DEG C. The prepared enamelled wire has good salt-water pinhole resistant performance and is resistant to knead and stretch salt-water pinholes in salt water. The prepared enamelled wire has good directly welding performance and is capable of being directly welded at a temperature of 375 DEG C. The prepared enamelled wire has wide process redundancy and is convenient for realizing stable process production.

Owner:上海晟然绝缘材料有限公司

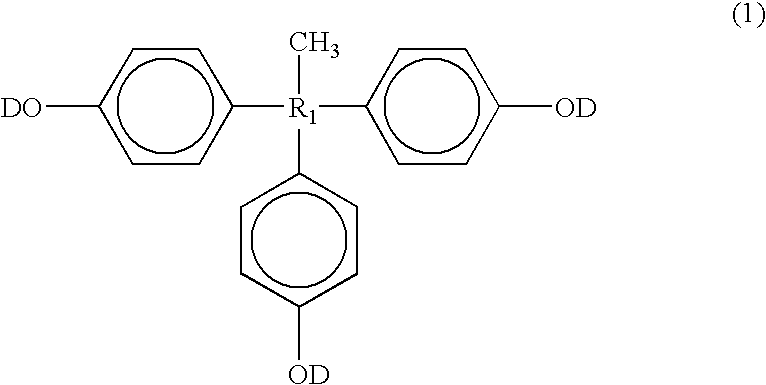

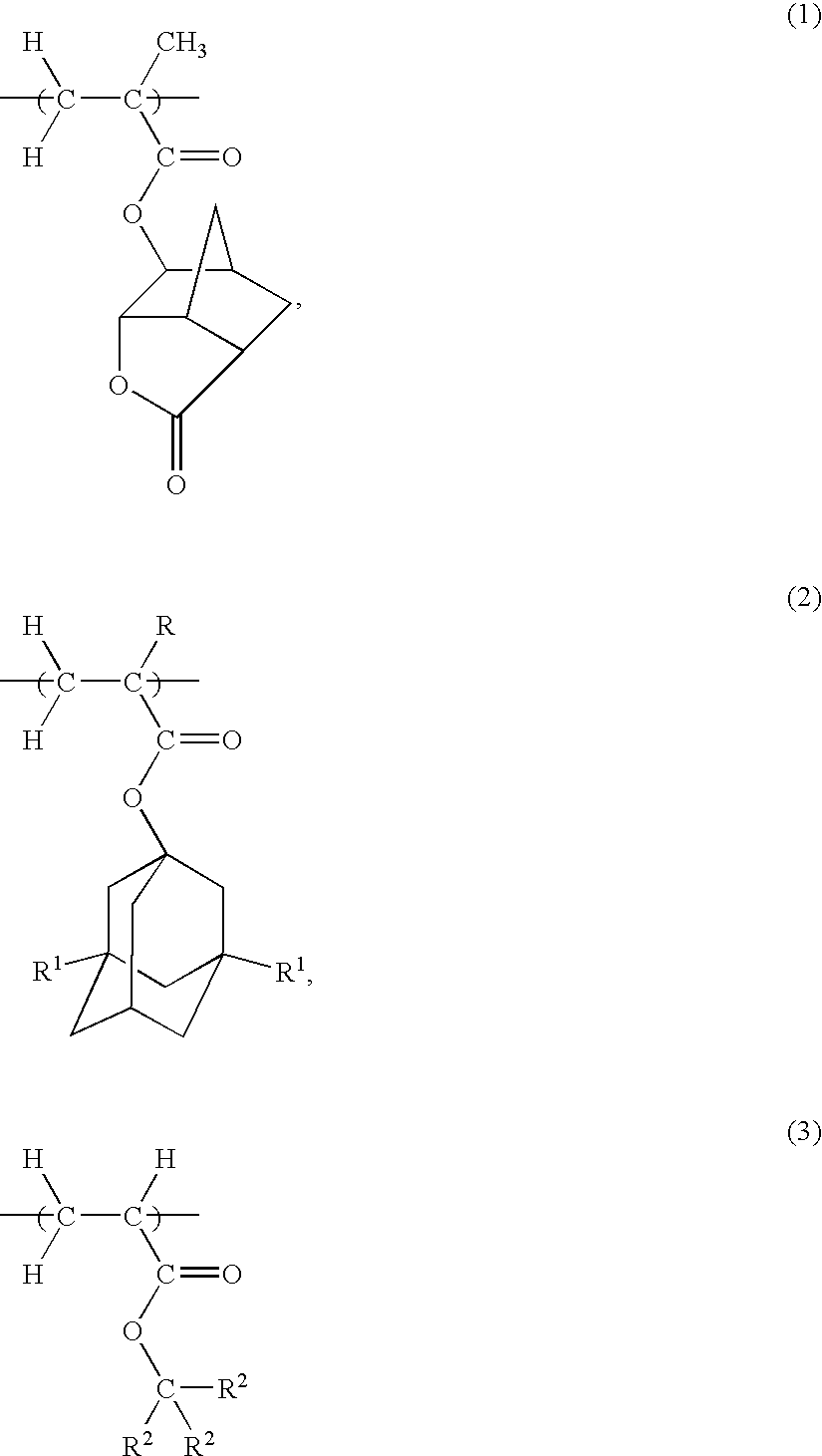

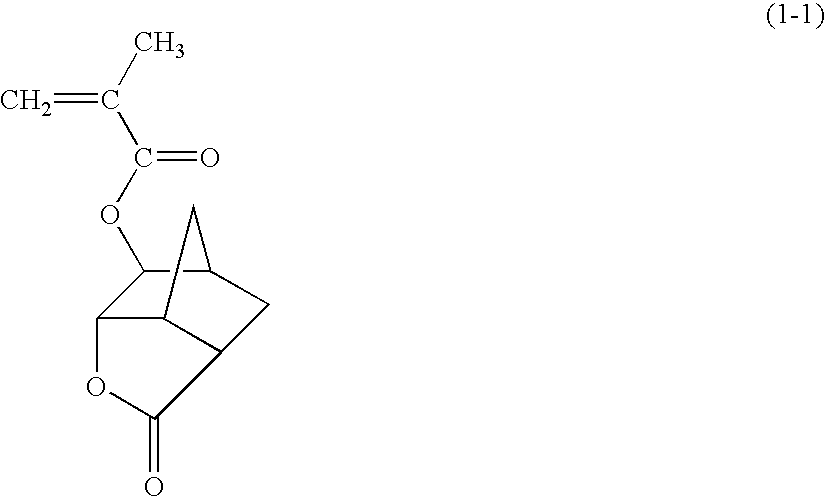

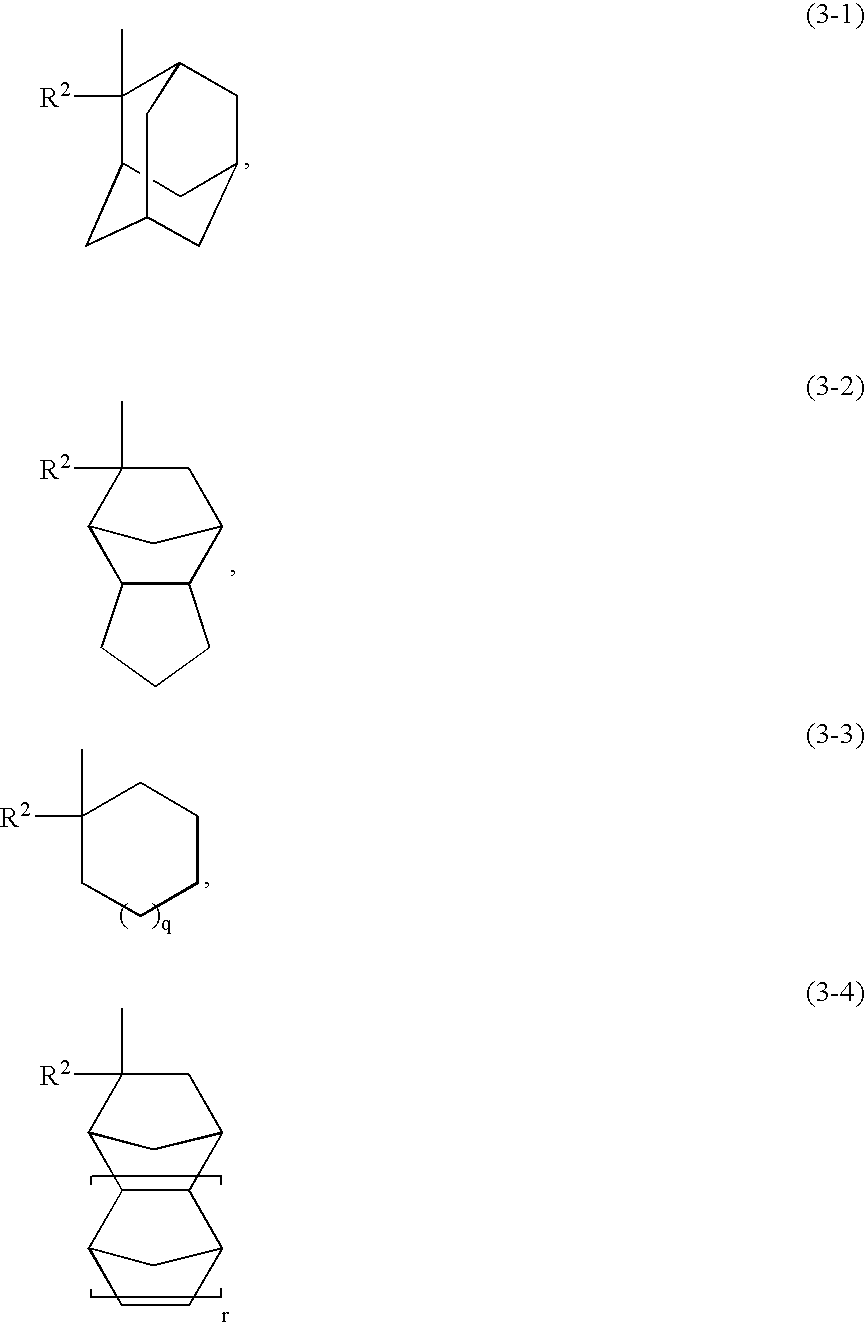

Positive type photosensitive resin composition

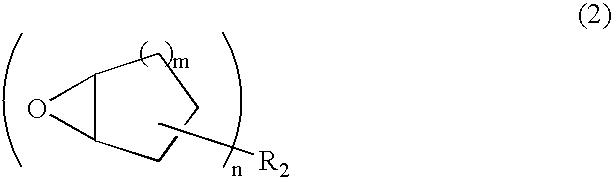

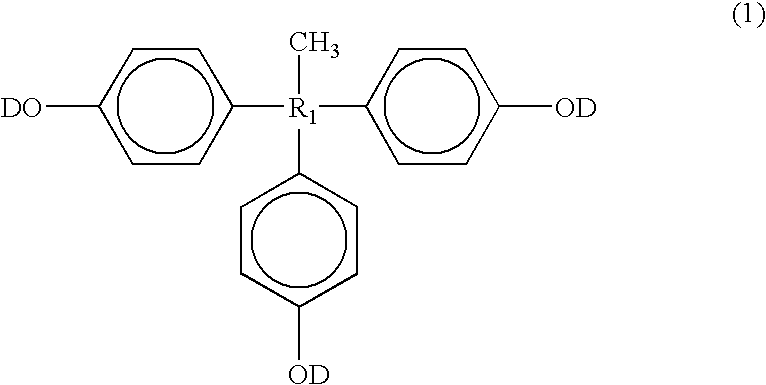

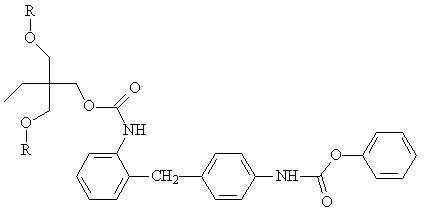

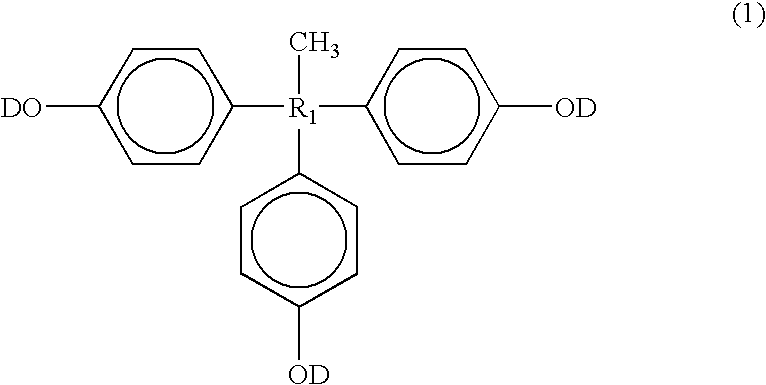

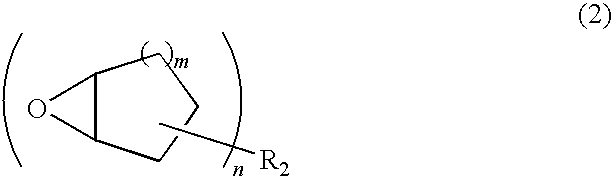

ActiveUS20060211797A1Good storage stabilityWide process marginOrganic chemistryOrganic compound preparationQuinoneHydrogen atom

The present invention provides a positive photosensitive resin composition which can form a cured film excellent in process resistance such as heat resistance, solvent resistance or long-time baking resistance and transparency, and which is excellent in photosensitive properties such as resolution and sensitivity, and which has high storage stability and a wide process margin. Further, the present invention provides a positive photosensitive resin composition having such high reliability that no deterioration of electrical characteristics will be led in its application for liquid crystal display devices. A positive photosensitive resin composition characterized by comprising an alkali-soluble resin which is a copolymer essentially comprising an unsaturated carboxylic acid derivative and an N-substituted maleimide and which has a number average molecular weight of from 2,000 to 20,000, a 1,2-quinone diazide compound represented by the formula (1): (wherein each of D independently is a hydrogen atom or an organic group having a 1,2-quinone diazide group, R1 is a tetravalent organic group, provided that at least one of D is an organic group having a 1,2-quinone diazide group), and from 5 to 50 parts by weight, per the alkali-soluble resin, of a crosslinking compound represented by the formula (2): (wherein n is an integer of from 2 to 10, m is an integer of from 0 to 4, and R2 is a n-valent organic group).

Owner:NISSAN CHEM IND LTD

High thermal grade non-pinhole rapid direct welding polyurethane enameled wire insulation varnish and preparation method thereof

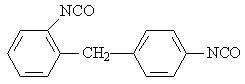

InactiveCN102277079AImprove heat resistanceGood direct solderabilityPolyurea/polyurethane coatingsLacquerCyanate compound

The invention relates to a high-heat-grade non-pinhole rapid direct welding polyurethane enameled wire insulating varnish and a preparation method thereof. The preparation method comprises: the preparation of polyester resin; using TMP, MDI, phenol or m-cresol to synthesize blocked isocyanic acid resin in two steps; Cyanic acid resin, 15 parts by weight of xylene, 10 parts by weight of phenol, and 5 parts by weight of n-butanol are mixed and painted at 60-70°C to form a high-heat level non-pinhole fast direct-welding polyurethane enameled wire insulating varnish. The produced enameled wire has high heat resistance, the thermal class can reach 180, the softening breakdown is above 230°C, and the hot shock temperature is 200°C (the test method refers to IEC60851); it can be directly welded at 330°C, and there is no residue after direct welding; Kneading and stretching salt water pinholes in water; the flue loss in the oven is relatively small, and there is no obvious cracking product on the surface of the enameled wire. When using this product to manufacture enameled wire, the process margin is wide, which facilitates the realization of robust process production.

Owner:上海晟然绝缘材料有限公司

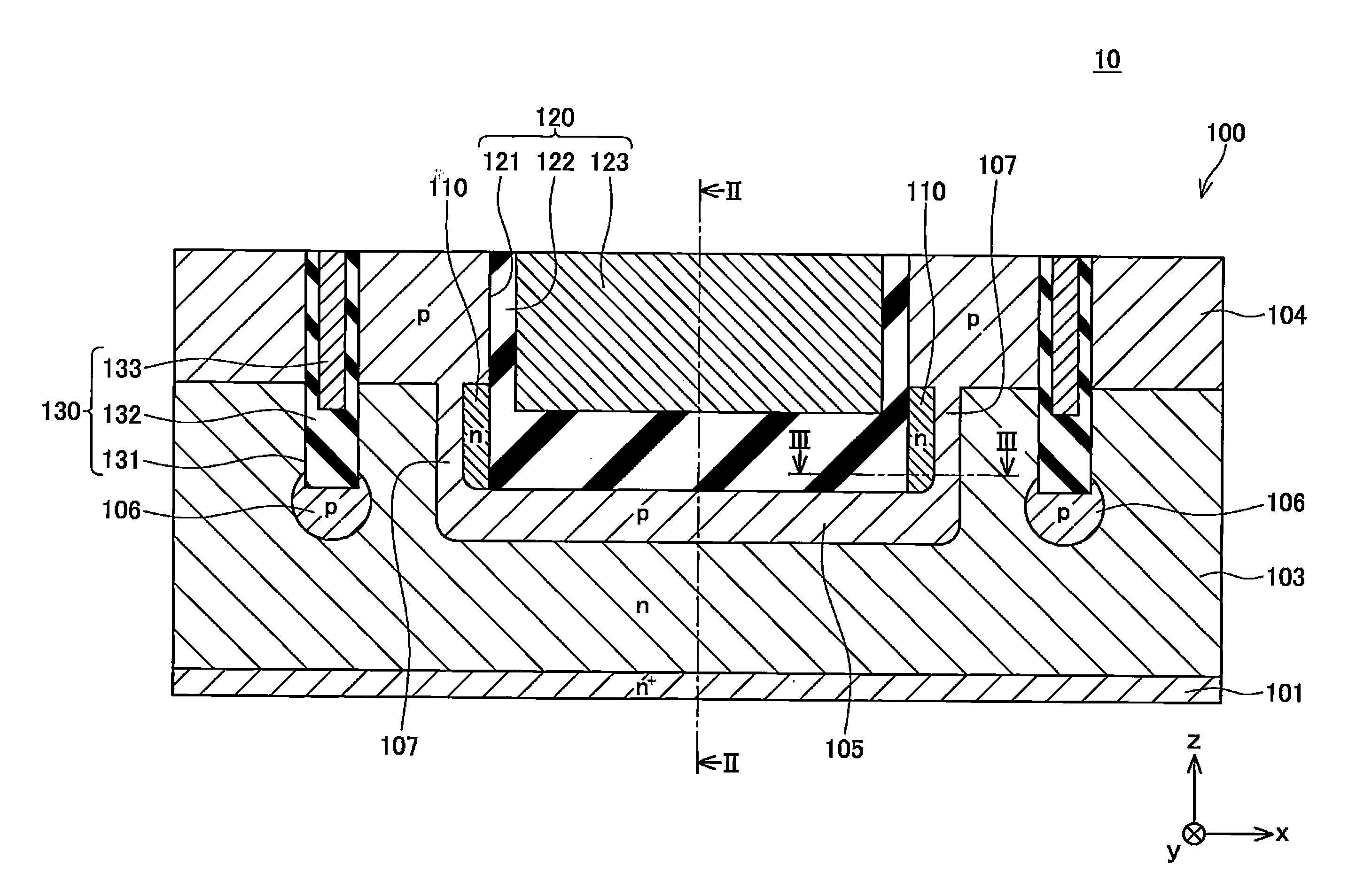

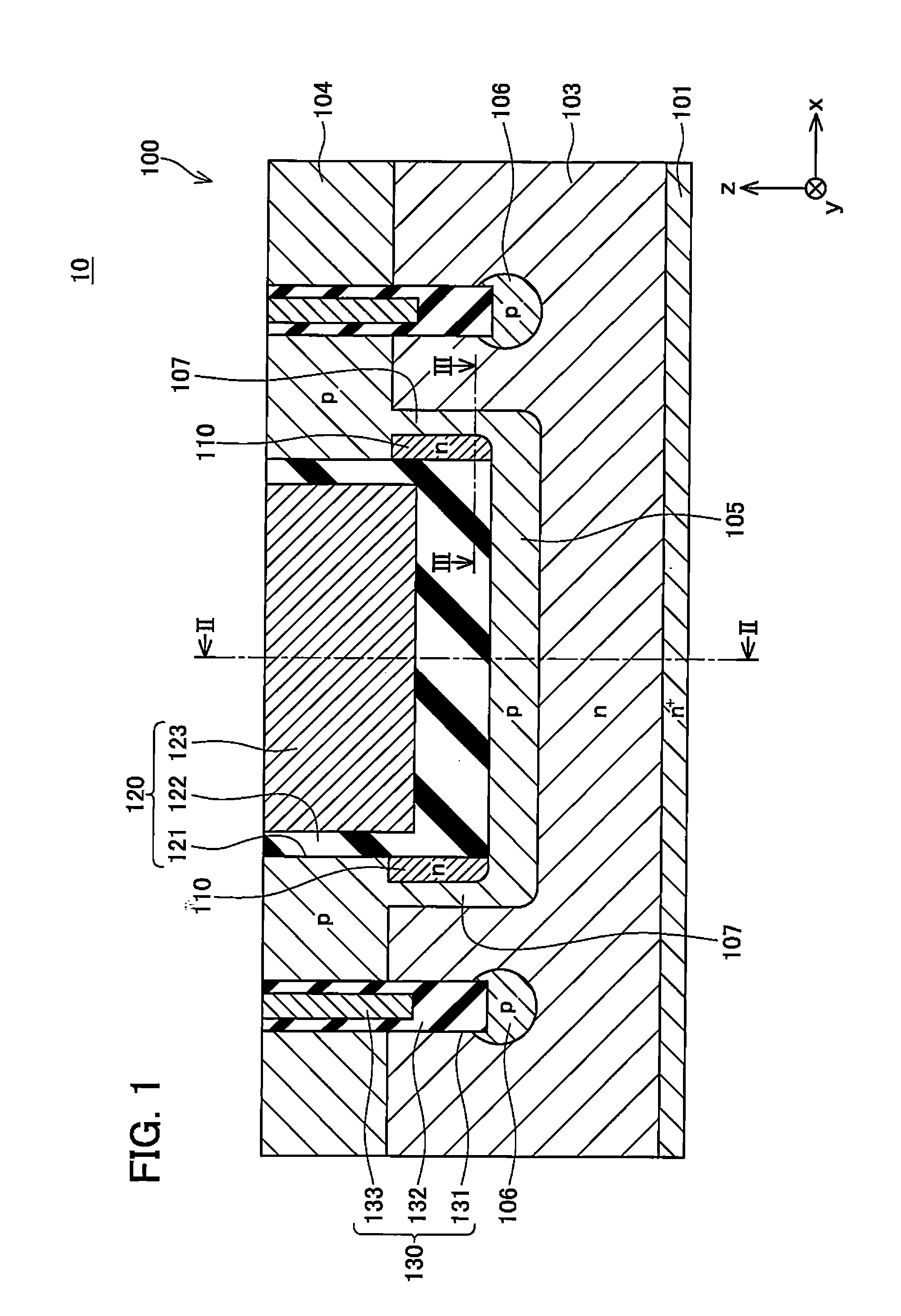

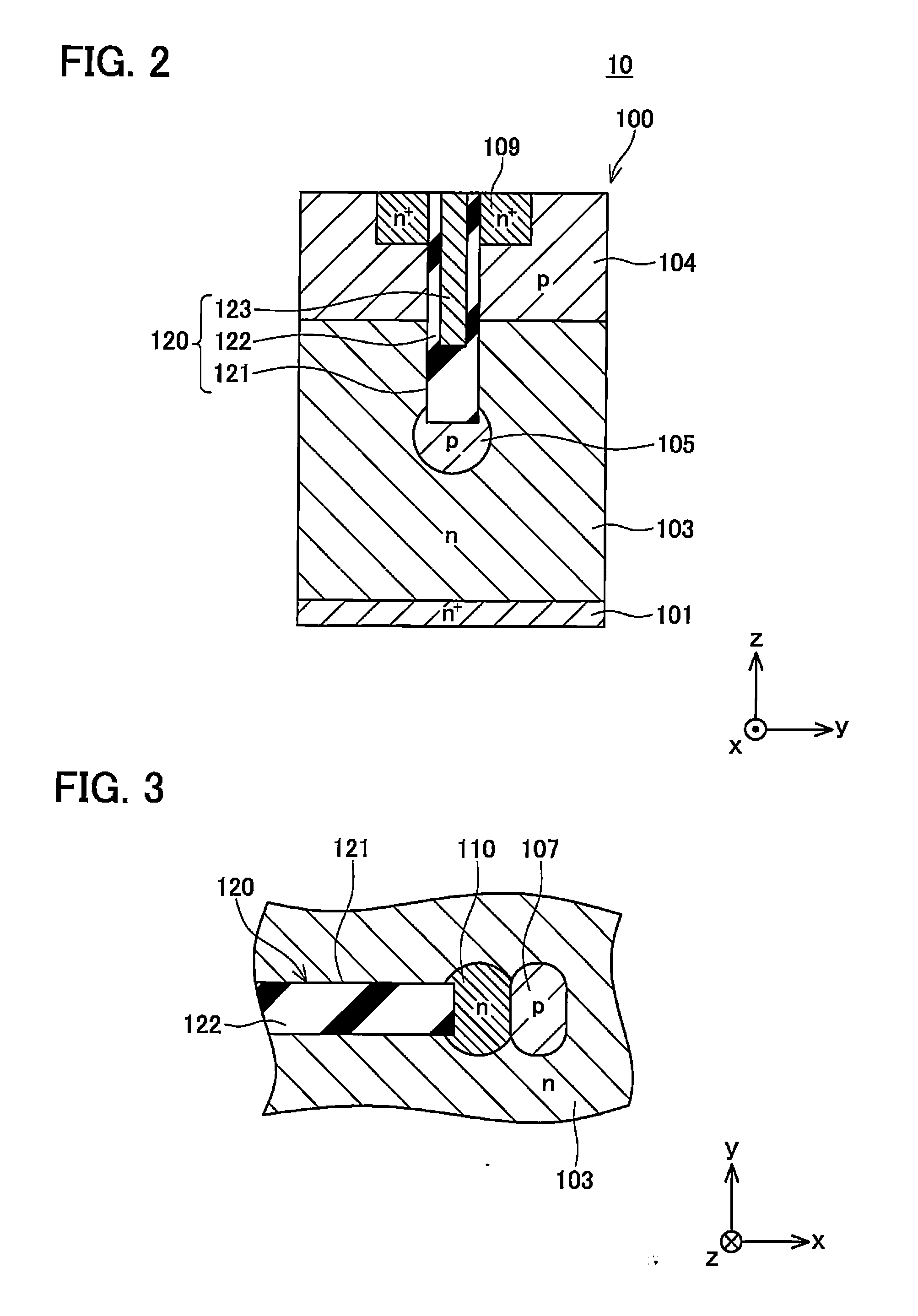

Semiconductor device

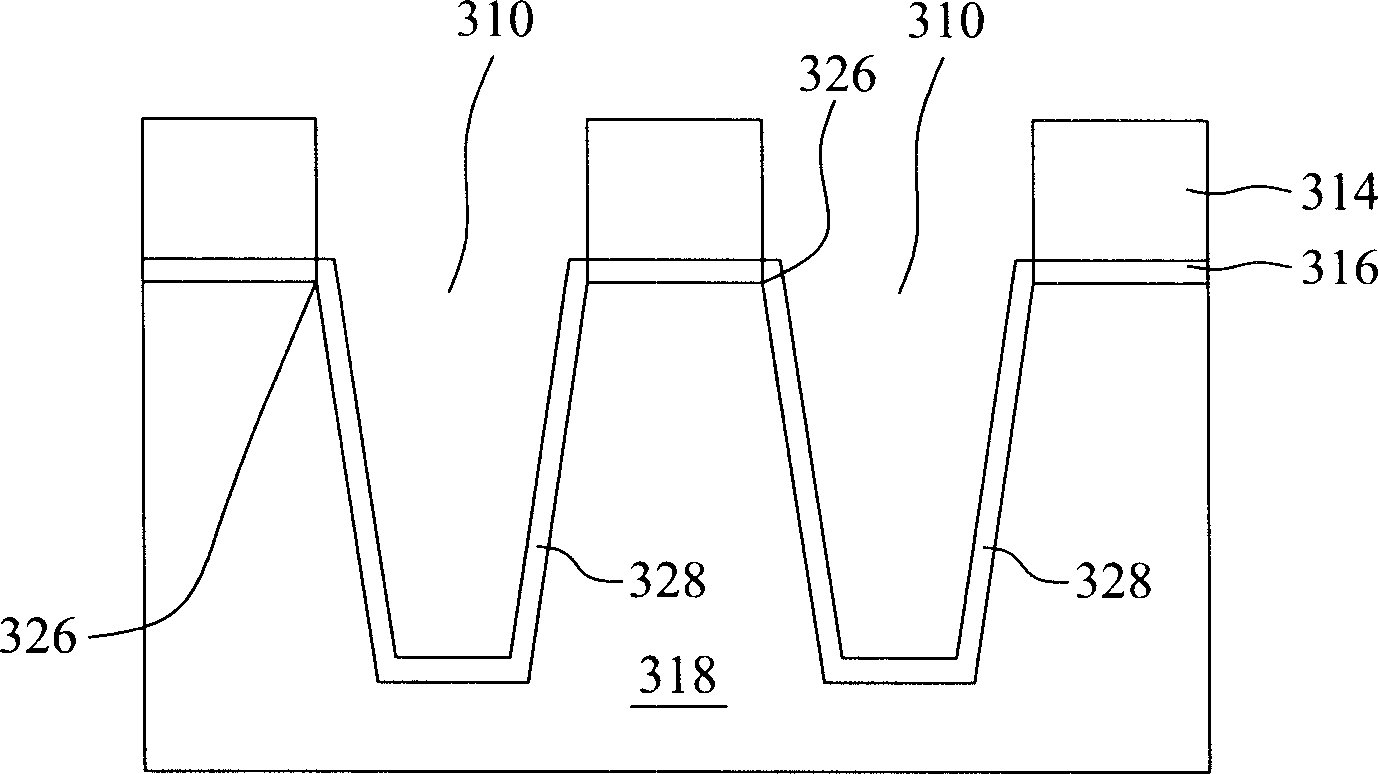

ActiveUS20150041887A1Wide process marginExcellent on-resistance property and yieldSemiconductor/solid-state device manufacturingSemiconductor devicesElectrical conductorTrench gate

A semiconductor device includes a first semiconductor layer surrounding a bottom of the trench gate, a second semiconductor layer disposed along one of end portions of the trench gate in a longitudinal direction of the trench gate, one of end portions of the second semiconductor layer contacting the body layer and the other of the end portions of the second semiconductor layer contacting the first semiconductor layer, and a connecting layer, one of end portions of the connecting layer being connected to the body layer and the other of the end portions of the connecting layer being connected to the first semiconductor layer, the connecting layer contacting the second semiconductor layer, and the connecting layer being separated from the one of the end portions of the trench gate in the longitudinal direction of the trench gate by the second semiconductor layer.

Owner:TOYOTA JIDOSHA KK

High density plasma non-stoichiometric SiOxNy films

InactiveUS7807225B2Wide optical dispersionWide process marginSemiconductor/solid-state device manufacturingChemical vapor deposition coatingHigh densityChemical measurement

Owner:SHARP KK

Semiconductor component and its forming method

ActiveCN1838412ARemove Thinning ProblemsImprove integritySolid-state devicesSemiconductor/solid-state device manufacturingDielectricElectrical conductor

A method and system for isolation trenches includes forming isolation trenches in a semiconductor substrate, filling the trenches with a filler material, creating voids near top edges of the trenches and annealing by a gaseous ambient to reflow the edges of the trenches causing the edges to become rounded and overhang the trench. The filler material may be a dielectric. Transistors are then formed in close proximity to the trenches and may include source / drain regions formed in the rounded portion of the semiconductor substrate that overhangs the trench.

Owner:TAIWAN SEMICON MFG CO LTD

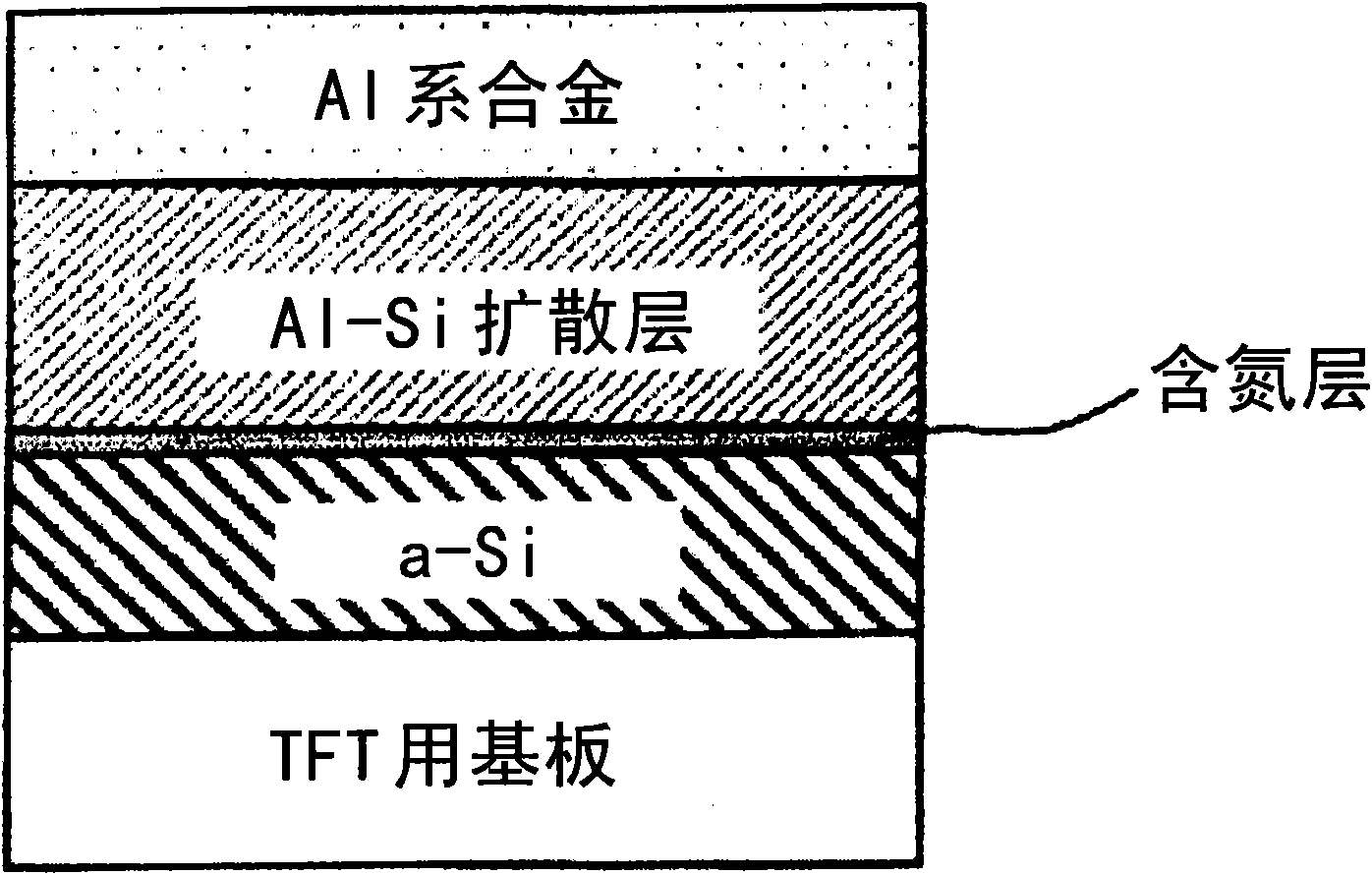

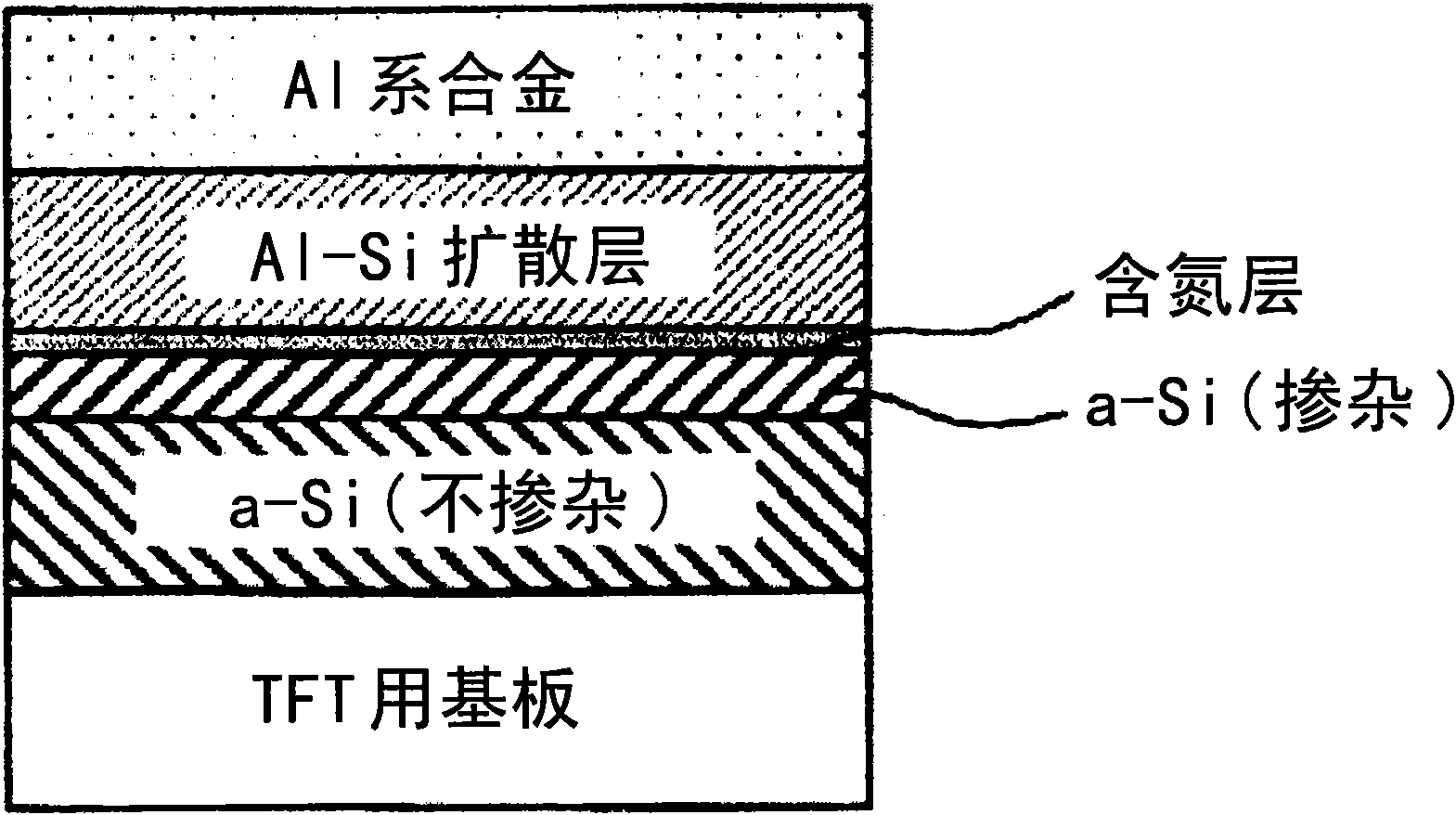

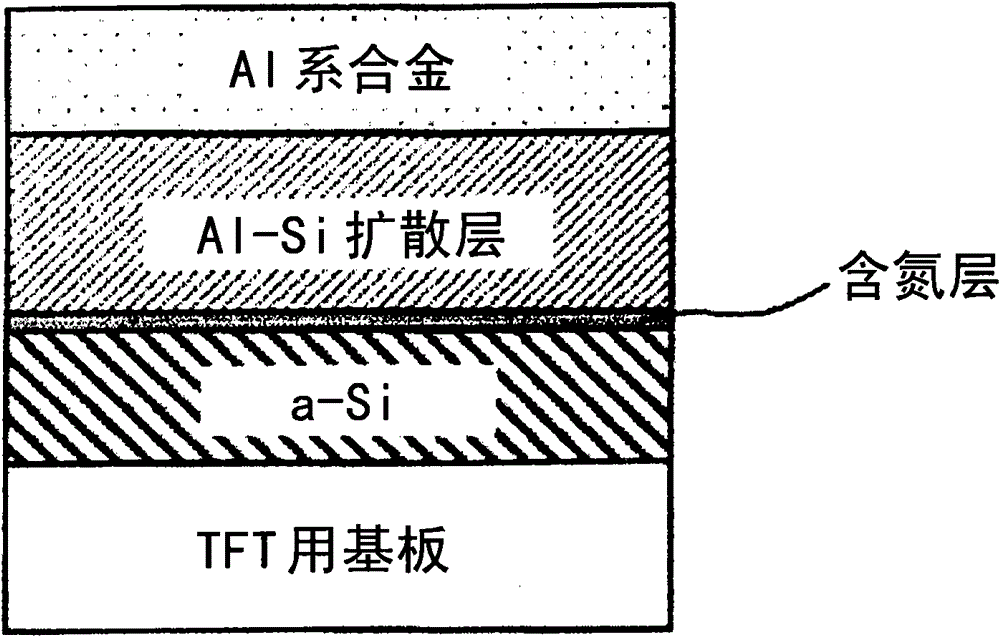

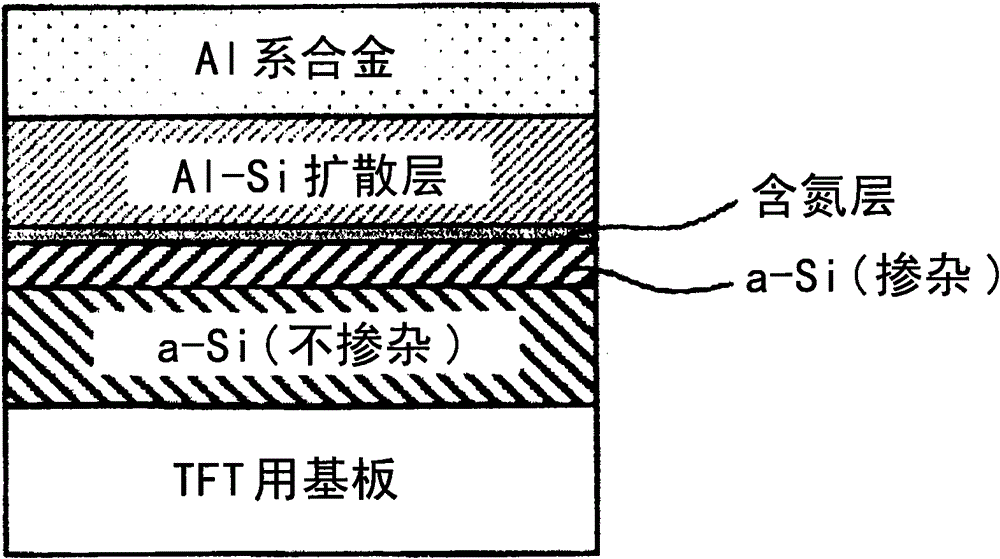

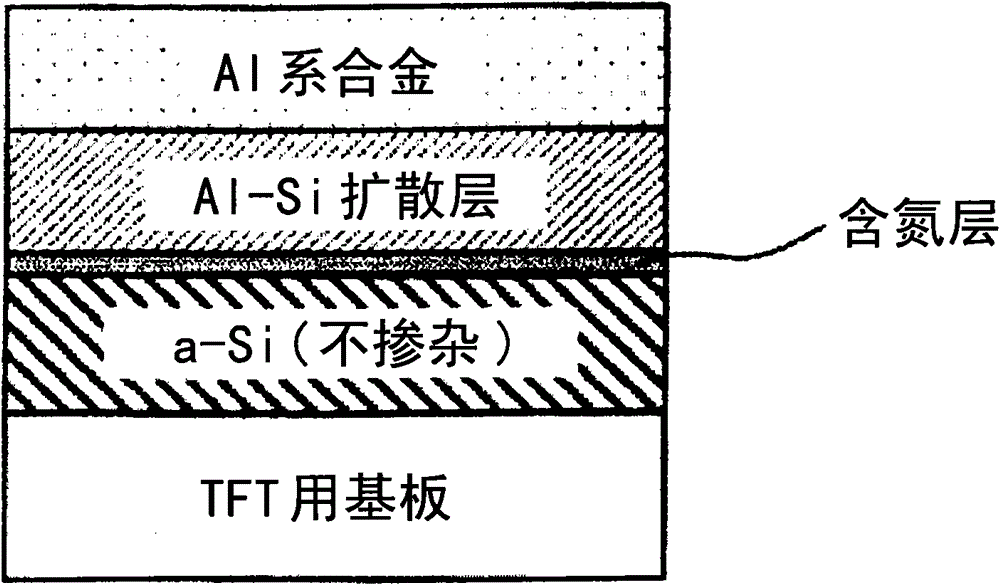

Interconnection structure, a thin film transistor substrate, and a manufacturing method thereof, as well as a display device

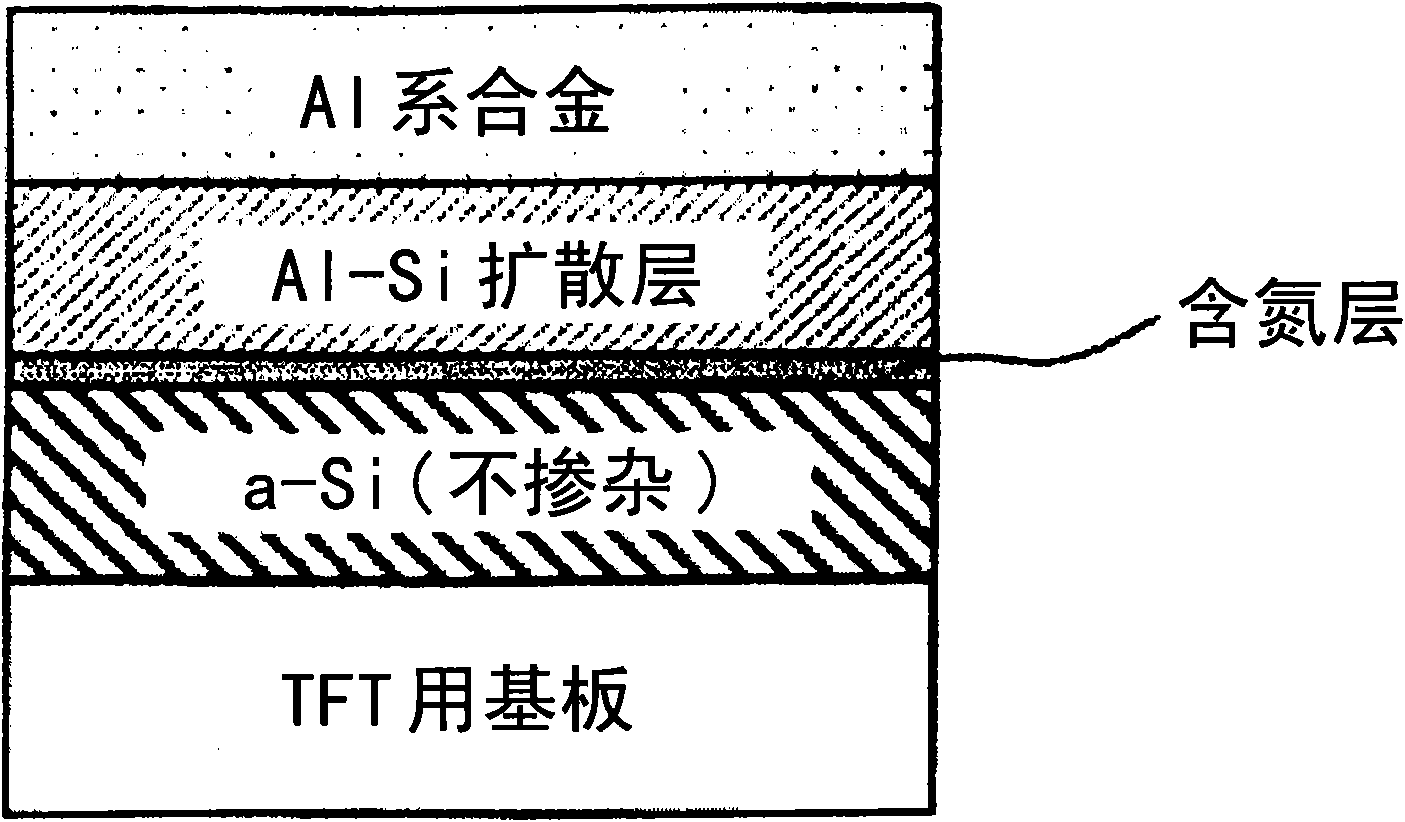

InactiveCN101971294AIncrease contact resistanceExcellent productivityTransistorSemiconductor/solid-state device detailsDisplay deviceNitrogen

Provided is a direct contact technology by which a barrier metal layer between an Al alloy wiring composed of pure Al or an Al alloy and a semiconductor layer can be eliminated and the Al alloy wiring can be directly and surely connected to the semiconductor layer within a wide process margin. In a wiring structure, the semiconductor layer, and the Al alloy film composed of the pure Al or the Al alloy are provided on the substrate in this order from the substrate side. A multilayer structure of an (N, C, F) layer containing at least one type of an element selected from among a group composed of nitrogen, carbon and fluorine, and an Al-Si diffusion layer containing Al and Si is included in this order from the substrate side, between the semiconductor layer and the Al alloy film. At least the one type of the element, i.e., nitrogen or carbon or fluorine contained in the (N, C, F) layer, is bonded with Si contained in the semiconductor layer.

Owner:KOBE STEEL LTD

Positive type photosensitive resin composition

ActiveUS7847003B2Good storage stabilityWide process marginOrganic chemistryOrganic compound preparationQuinoneSolvent

The present invention provides a positive photosensitive resin composition which can form a cured film excellent in process resistance such as heat resistance, solvent resistance or long-time baking resistance and transparency, and which is excellent in photosensitive properties such as resolution and sensitivity, and which has high storage stability and a wide process margin. Further, the present invention provides a positive photosensitive resin composition having such high reliability that no deterioration of electrical characteristics will be led in its application for liquid crystal display devices.A positive photosensitive resin composition characterized by comprising an alkali-soluble resin which is a copolymer essentially comprising an unsaturated carboxylic acid derivative and an N-substituted maleimide and which has a number average molecular weight of from 2,000 to 20,000, a 1,2-quinone diazide compound represented by the formula (1):(wherein each of D independently is a hydrogen atom or an organic group having a 1,2-quinone diazide group, R1 is a tetravalent organic group, provided that at least one of D is an organic group having a 1,2-quinone diazide group), and from 5 to 50 parts by weight, per the alkali-soluble resin, of a crosslinking compound represented by the formula (2):(wherein n is an integer of from 2 to 10, m is an integer of from 0 to 4, and R2 is a n-valent organic group).

Owner:NISSAN CHEM IND LTD

Static random access memory device having reduced leakage current during active mode and a method of operating thereof

InactiveUS20080043542A1Improve powerBetter SNM and write trip voltageDigital storageBit lineStatic random-access memory

An Static Random Access Memory (SRAM) device and a method of operating the same. In one embodiment, the SRAM device includes: (1) an SRAM array coupled to row peripheral circuitry by a word line and coupled to column peripheral circuitry by bit lines and (2) an array low voltage control circuitry that provides an enhanced low operating voltage VESS to the SRAM array during at least a portion of an active mode thereof.

Owner:TEXAS INSTR INC

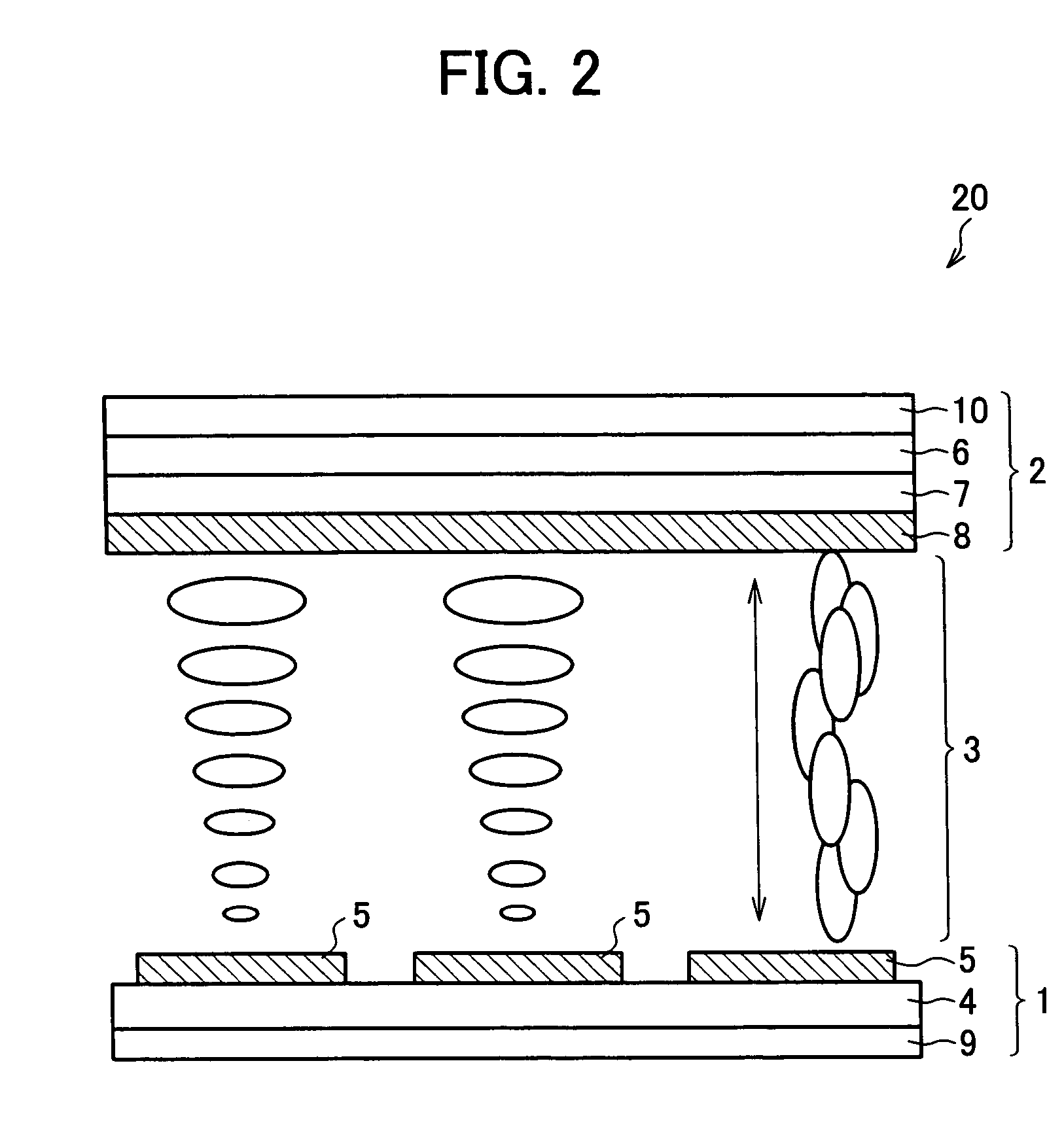

Light-emitting device comprising partition including overhang portion

ActiveUS9728693B2InhibitionWide process marginSolid-state devicesSemiconductor/solid-state device manufacturingInter layerEngineering

Occurrence of a crosstalk phenomenon in a light-emitting device including a tandem element is suppressed. A light-emitting device includes: lower electrodes over an insulating layer; a partition over a portion between the lower electrodes, which includes an overhang portion over an end portion of each of the lower electrodes; a first light-emitting unit over each of the lower electrodes and the partition; an intermediate layer over the first light-emitting unit; a second light-emitting unit over the intermediate layer; and an upper electrode over the second light-emitting unit. The distance between the overhang portion and each of the lower electrodes is larger than the total thickness of the first light-emitting unit and the intermediate layer over the lower electrode.

Owner:SEMICON ENERGY LAB CO LTD +1

Application of silica nano material in polyester-imide enameled wire insulating varnish

The invention relates to an application of a silica nano material in polyester-imide enameled wire insulating varnish. The method for dispersing nano-silica in polyester-imide varnish comprises the following steps in sequence: predispersing 6-8 parts of nano-silica and 0.6 parts of gamma-aminopropyl triethoxysilane (KH550) in 40 parts of modified polyester varnish, feeding silica into the above pre-dispersion A for not less than three times at intervals of 20-40 min so as to generate a pre-dispersion A; adding 50 parts of polyester-imide enameled wire insulating varnish and 10 parts of modified polyester enameled wire insulating varnish into the pre-dispersion A, dispersing for 1 hour to generate a pre-dispersion B; performing circulating continuous dispersion of the pre-dispersion B in a rod-pin dispenser for 3 hours, wherein the temperature of a dispersing cavity is controlled to be not more than 70 DEG C. Enameled wires prepared by the method of the invention have corona resistance which is up to above 100 times of that of common enameled wires; the prepared enameled wires have smooth surfaces without bright spots; the storage life of the insulating varnish is up to 1 year; the process has wide redundancy, and is convenient for the realization of robust process production.

Owner:上海晟然绝缘材料有限公司

Acrylic copolymer and radiation-sensitive resin composition

ActiveUS7452655B2High transparencyOutstanding propertyPhotosensitive materialsPhotosensitive materials for photomechanical apparatusResistDry etching

An acrylic copolymer having a specific structure and a radiation-sensitive resin composition comprising the acrylic copolymer having high transparency to radiation, excelling in basic properties as a resist such as sensitivity, resolution, dry etching resistance, and pattern shape, and, in particular, excelling in forming contact holes and lines-and-spaces.

Owner:JSR CORPORATIOON

A kind of flexible polyesterimide enameled wire insulation varnish and preparation method thereof

Owner:艾仕得绝缘材料(安徽)有限公司

Method for manufacturing epitaxial wafer

ActiveUS8920560B2High IG effectFew epitaxial defectSemiconductor/solid-state device manufacturingBy pulling from meltSingle crystalOxygen

A method for manufacturing an epitaxial wafer includes: a step of pulling a single crystal from a boron-doped silicon melt in a chamber based on a Czochralski process; and a step of forming an epitaxial layer on a surface of a silicon wafer sliced from the single crystal. The single crystal is allowed to grow while passed through a temperature region of 800 to 600° C. in the chamber in 250 to 180 minutes during the pulling step. The grown single crystal has an oxygen concentration of 10×1017 to 12×1017 atoms / cm3 and a resistivity of 0.03 to 0.01 Ωcm. The silicon wafer is subjected to pre-annealing prior to the step of forming the epitaxial layer on the surface of the silicon wafer, for 10 minutes to 4 hours at a predetermined temperature within a temperature region of 650 to 900° C. in an inert gas atmosphere. The method is to fabricate an epitaxial wafer that has a diameter of 300 mm or more, and that attains a high IG effect, and involves few epitaxial defects.

Owner:SUMCO CORP

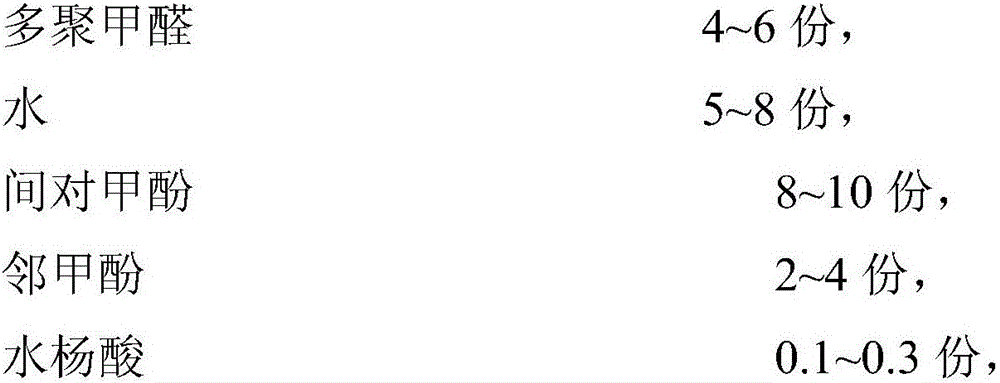

Wire enamel with high thermal level and high abrasion resistance and preparation method of wire enamel

The invention discloses wire enamel with a high thermal level and high abrasion resistance. The wire enamel is characterized by being prepared from raw materials in parts by weight (kilogram) as follows: 11-13 parts of phenolic resin, 11-15 parts of nylon 12, 3-6 parts of precipitated barium sulfate, 12-16 parts of polyurethane resin, 11-17 parts of E-12 epoxy resin, 1-2 parts of butyltin oxide, 2-3 parts of polyvinylpyrrolidone, 5-7 parts of phenyl glycidyl ether, 8-10 parts of neopentyl glycol, 2-4 parts of diphenylmethane diisocyanate, 1-3 parts of a silane coupling agent KH550, 7-9 parts of trimethylolpropane triacrylate, 1-2 parts of potassium acetate, 7-9 parts of an assistant, 95-115 parts of m, p-cresol and 100-120 parts of xylene. According to the wire enamel with the high thermal level and high abrasion resistance and a preparation method of the wire enamel, the preparation method is simple, the cost is low, a wire enamel film prepared with the preparation method has good adhesiveness and excellent scratch resistance, the temperature classification of the prepared wire enamel can be up to 200 DEG C, the oil resistance is good, the process redundancy is high, and steady technological production can be realized conveniently.

Owner:铜陵天河特种电磁线有限公司

A kind of synthesis method of high heat-resistant grade polyester type polyurethane wire enamel

ActiveCN103965764BSimple processReaction is easy to controlPolyurea/polyurethane coatingsPolymer scienceDistillation

The invention discloses a synthetic method of a polyester type polyurethane enamelled wire varnish with a high heat-resistant grade, the enamelled wire varnish prepared by adopting the method has high heat-resistant performance and the heat-resistant grade reaches 200 or above. The synthetic method disclosed by the invention is characterized by comprising the synthetic processes of imine and ethanol amine modified polyester resin as follows: adding diethylene glycol, diethanol amine, trimethylol propane, tris-(2-hydroxyethyl) cyanuric acid and a catalyst into a reactor; heating the mixture to 100 to 120 DEG C; further adding dimethyl terephthalate, partial dianhydride and modified imine dicarboxylic acid; heating to 140 to 150 DEG C; reacting for more than 4 h; heating to 220 to 230 DEG C; reacting for more than 12 h; conducting vacuum operation when the temperature of a distillation head is below 65 DEG C until the viscosity is between 1300 to 1800 mPa.s (25 DEG C); adding cresol and xylene and stirring for dissolving and clarifying to obtain the imine and ethanol amine modified polyester resin until the solid content reaches 44%.

Owner:江苏四达特材科技有限公司 +1

Interconnection structure, a thin film transistor substrate, and a manufacturing method thereof, as well as a display device

InactiveCN101971294BIncrease contact resistanceImprove productivityTransistorSemiconductor/solid-state device detailsNitrogenDisplay device

An interconnection structure, containing a substrate and, in the following order from a side of the substrate: (I) a semiconductor layer; (II) a multilayer structure including (II-a) a first layer containing at least one type of an element selected from the group consisting of nitrogen, carbon and fluorine and (II-b) an Al—Si diffusion layer containing Al and Si; and (III) an Al film of pure Al or an Al alloy, wherein the at least one of element selected from the group consisting of nitrogen, carbon, and fluorine in the first layer is bonded with Si contained in the semiconductor layer.

Owner:KOBE STEEL LTD

A kind of graphene-sheet conductive mica oil tank electrostatic conductive anti-corrosion coating and preparation method thereof

ActiveCN107201071BSimple processReaction is easy to controlAnti-corrosive paintsEpoxy resin coatingsGraphene flakeFirming agent

The invention discloses a graphene-flaky conductive mica oil tank static electricity conduction anticorrosive paint and a preparation method thereof. The paint uses epoxy resin as matrix resin, uses modified graphene and conductive mica as a two-component conductive filler, and adopts an isocyanate curing agent. The paint has the advantages of static electricity conduction, heat conduction, corrosion resistance and the like, the method is simple in technology, and the sources of the raw materials are wide. The preparation method of the graphene-flaky conductive mica oil tank static electricity conduction anticorrosive paint provided by the invention mainly comprises the following steps: synthesis of modified graphene, synthesis of isocyanate tripolymer and preparation of the oil tank static electricity conduction anticorrosive paint, wherein the graphene and the flaky conductive mica serve as the two-component conductive filler, the epoxy resin serves as the matrix resin, and an appropriate amount of a solvent is added, so that the graphene-flaky conductive mica oil tank static electricity conduction anticorrosive paint is obtained.

Owner:NANJING CHANGJIANG PAINT

Preparation method of high-heat-resistance and high-wear-resistance polyesterimide enameled wire insulating paint

The invention relates to a preparation method of a high-heat-resistance and high-wear-resistance polyesterimide enameled wire insulating paint, which takes 100 parts of reacted polyesterimide enameled wire insulating paint by weight with medium molecular weight as a basal body. At least the following components in parts by weight are added: 1-20 parts of amino resin, 1-20 parts of thermoplastic phenolic resin and 0.5-5 parts of siloxane. Enameled wires which are made by using the paint has the advantages that the paint film adhesiveness is excellent, the stripping and twisting K value of the enameled wires can reach more than 155 and the K value is higher than the K value (which is 110) of the existing conventional products by more than two grades; the scratch resistance is excellent and the unidirectional scratch resistance can reach more than 2000g when the wire is combined with the polyesterimide paint; the heat resistance can reach 200 while the heat resistance of the conventional polyesterimide enameled wires is 180; and the process redundancy is wide and the realization of stable process production is facilitated.

Owner:艾仕得绝缘材料(安徽)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com