Synthetic method of polyester type polyurethane enamelled wire varnish with high heat-resistant grade

A technology of polyester polyurethane and wire enamel, which is applied in the synthesis of polyurethane varnish, and the synthesis field of grade polyester polyurethane wire enamel, which can solve the problems of not reaching C grade and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Synthesis of imine, ethanolamine modified polyester resin: add diethylene glycol (2mol), diethanolamine (4.5mol), trimethylolpropane (0.4mol), tri-(2-hydroxyethyl ) isocyanurate (0.6mol) and zinc acetate accounting for 0.05% of the total, heated to 100°C-120°C, then added dimethyl terephthalate (5.2mol) and 3,3',4,4 '-Biphenyltetracarboxylic dianhydride (0.8mol) and imine-modified dicarboxylic acid (0.2mol), stir and dissolve, heat up to 150°C for 4 hours, heat up to 220°C for 10-12h to react, when the distillation head When the temperature is lower than 64°C, carry out vacuum operation, the pressure first decreases and then increases, first slow and then fast, until the viscosity is between 1300-1800mPa·s (25°C), stop the vacuum operation, take a sample to measure the acid value 2.34, the hydroxyl value 149.1, Add metered cresol and xylene and keep stirring until clarified to obtain imine and ethanolamine modified polyester resin. The best solid content of polyester r...

Embodiment 2

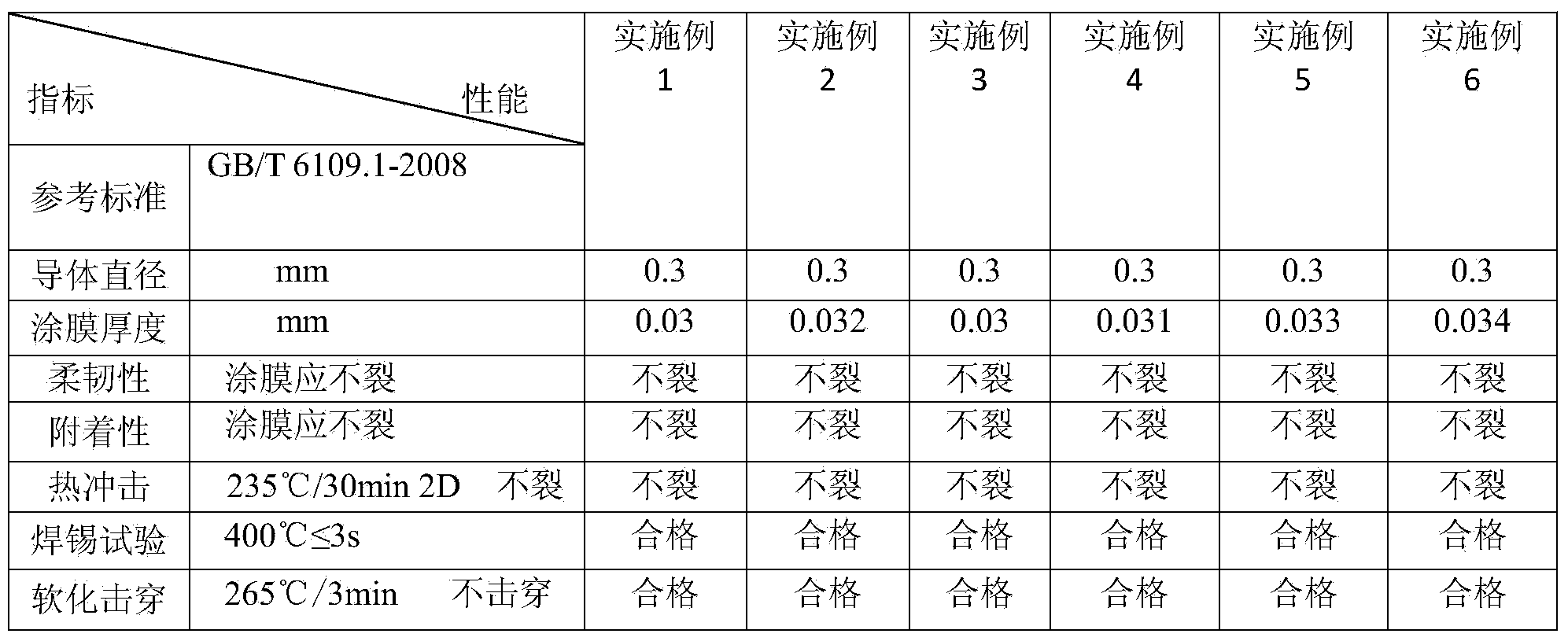

[0026]Synthesize modified polyester resin according to Example 1, wherein the molar ratio of dimethyl terephthalate and dianhydride to imine modified dicarboxylic acid is 4.5: 1. The described dianhydride is biphenyltetracarboxylic dicarboxylic acid anhydride. Synthesize sealing resin according to the method of Example 1, synthesize MDI trimer according to the method of Example 1, let the paint according to the method of Example 1, control the ratio of additives such as cresol, 60 parts of cresol, 15 parts of xylene, 30 parts of DMF , 1 part of zinc isooctanoate, 1 part of n-butanol, 4 parts of butyl ortho-titanate, heated and stirred and mixed evenly to obtain a yellow transparent paint solution with a solid content of 31.5% (180°C / 2g / 1h) and a viscosity of 33.9s (Coat 4 cups, 25°C), and make enamelled copper wire by coating the wire according to the process. The tested properties are shown in Table 1.

Embodiment 3

[0028] Synthesize modified polyester resin according to Example 1, wherein the molar ratio of dimethyl terephthalate and dianhydride to imine-modified dicarboxylic acid is 5:1, and the dianhydride is pyromellitic acid Dianhydride. Synthesize the sealing resin according to the method of Example 1, synthesize the MDI trimer according to the method of Example 1, let the paint according to the method of Example 1, control the ratio of additives such as cresol, 40 parts of cresol, 10 parts of xylene, and 60 parts of DMF , 1 part of zinc isooctanoate, 0.5 parts of n-butanol, 4 parts of butyl titanate, heated and stirred to mix evenly, and a yellow transparent paint liquid was obtained, with a solid content of 31.2% (180°C / 2g / 1h) and a viscosity of 33.8s (Coat 4 cups, 25°C), and make enamelled copper wire by coating the wire according to the process. The tested properties are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com