High thermal grade non-pinhole rapid direct welding polyurethane enameled wire insulation varnish and preparation method thereof

A polyurethane paint, pinhole-free technology, applied in the coating and other directions, can solve the problems of reduced straight weldability, poor heat resistance, and reduced salt water pinhole characteristics of enameled wires, and achieves good direct weldability and flue loss. Less and better characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

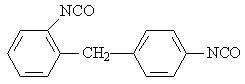

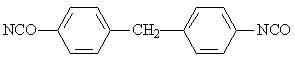

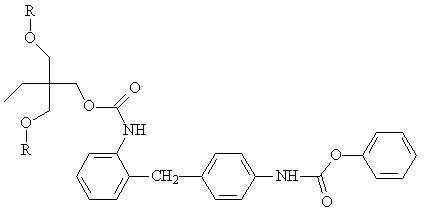

[0041] Take 20 parts of polyester resin, add 50 parts of blocked isocyanate resin (two-step synthesis, MDI brand is Yantai Wanhua's MDI-50), add 15 parts of xylene, 10 parts of m-cresol, 5 parts Stir with n-butanol for 3 hours, discharge and filter when the temperature is lowered to 45°C, and make a polyurethane enameled wire with a solid content of 30% polyurethane paint to produce a thick paint film.

Embodiment 2

[0043] Take 20 parts of polyester resin, add 50 parts of blocked isocyanate resin (two-step synthesis, MDI brand is HUNTSMAN's SUPRASEC 3051), add 15 parts of xylene, 10 parts of m-cresol, 5 parts of n-butyl when the kettle temperature is 70 °C Stir with alcohol for 3 hours, discharge and filter when the temperature is lowered to 45°C, and make a polyurethane enameled wire with a solid content of 30% polyurethane paint to produce a thick paint film.

Embodiment 3

[0045] Take 20 parts of polyester resin, add 50 parts of blocked isocyanate resin (two-step synthesis, MDI brand is BAYER's DESMODUR 2460M), add 15 parts of xylene, 10 parts of m-cresol, 5 parts of n-butyl when the temperature of the kettle is 70 °C Stir with alcohol for 3 hours, discharge and filter when the temperature is lowered to 45°C, and make a polyurethane enameled wire with a solid content of 30% polyurethane paint to produce a thick paint film.

[0046] Preparation of enameled wire sample wire:

[0047] Coating equipment: Meda QHW 4 / 1

[0048] Process parameters:

[0049] Oven inlet: 350°C; Middle oven: 380°C; Oven outlet: 420°C; Circulation fan: 1000RPM; Exhaust fan: 800RPM;

[0050] Speed: 115 m / min

[0051] Paint passes: 7

[0052] The enameled wire specification is 0.20mm.

[0053] The following table is comparative example and embodiment performance test list:

[0054] Comparative example 1 Comparative example 2 Comparative example 3 Com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com