Machinable and ozone-resistant rubber material and preparation method thereof

A rubber material and ozone resistance technology, applied in the field of rubber materials, can solve the problems of poor ozone resistance, poor processing performance and high production cost, and achieve the effects of improving ozone resistance, processing resistance, and good compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

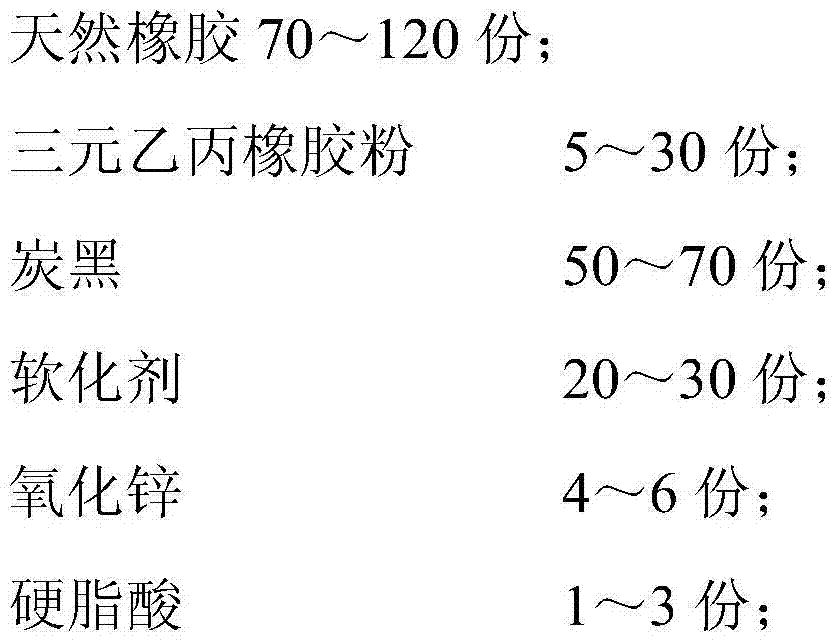

Method used

Image

Examples

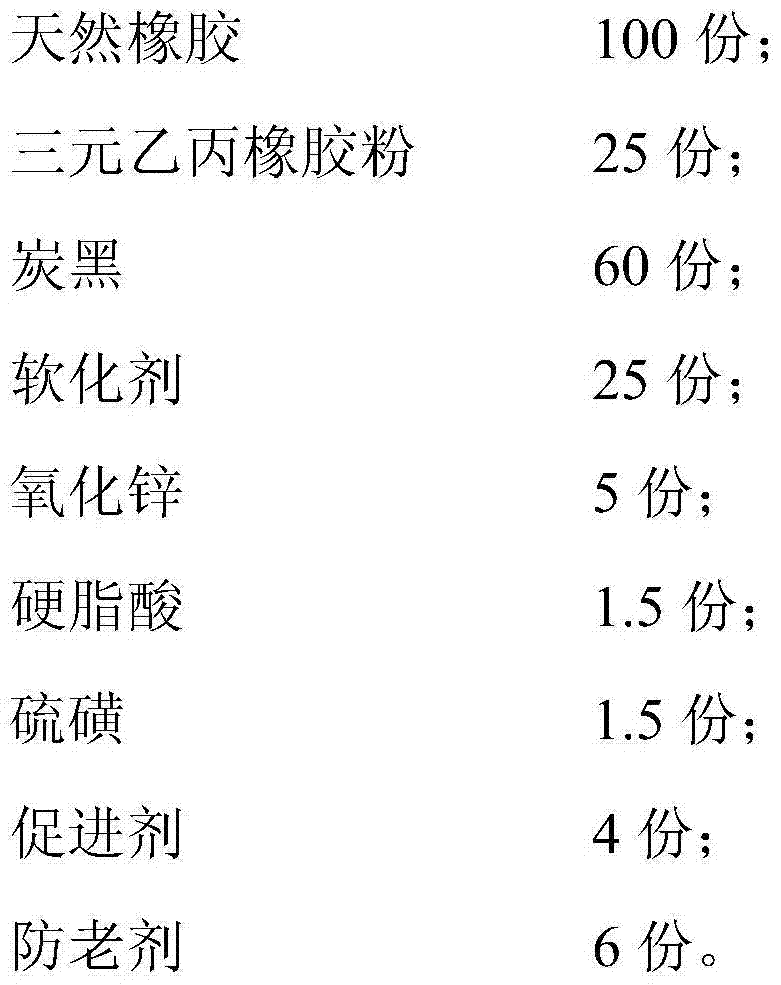

Embodiment 1

[0030] Example 1: Put 100 parts by mass of natural rubber into an internal mixer at one time and masticate at 60°C for 1-2 minutes to obtain plasticized raw rubber. Add 6 parts by mass of antioxidant RD, 5 parts by mass of zinc oxide, and 1.5 parts by mass of stearic acid to the plasticized raw rubber to start banburying. After some time, mix 25 parts by mass of EPDM powder, 60 parts by mass of Add carbon black N550 together and continue banburying. When more than 80% of the powder is finished, feed 25 parts by mass of naphthenic oil to continue banburying. When the temperature rises to 90°C, lift the pressure cover to the upper position, and after cleaning, press down the pressure cover to continue banburying with 1.5 parts by mass of sulfur S-80 and 4 parts by mass of accelerator CZ. When the temperature rises to 110°C, remove the glue to obtain the banbury rubber. Put the banbury rubber into the open mill, adjust the roller distance of the open mill to 6-10mm, cut the rub...

Embodiment 2

[0031] Example 2: Put 100 parts by mass of natural rubber into an internal mixer at one time and masticate at 60° C. for 1-2 minutes to obtain plasticized raw rubber. Add 6 parts by mass of antioxidant RD, 4 parts by mass of zinc oxide, and 1.5 parts by mass of stearic acid to the plasticized raw rubber to start banburying. After some time, mix 25 parts by mass of EPDM powder, 60 parts by mass of Add carbon black N550 together and continue banburying. When more than 80% of the powder is finished, feed 25 parts by mass of naphthenic oil to continue banburying. When the temperature rises to 90°C, lift the pressure cover to the upper position. After cleaning, press down the pressure cover to continue banburying with 1 mass part of sulfur S-80 and 4 mass parts of accelerator CZ. When the temperature rises to 110°C, remove the glue to obtain the banbury rubber. Put the banbury rubber into the open mill, adjust the roller distance of the open mill to 6-10mm, cut the rubber powder ...

Embodiment 3

[0032] Example 3: Put 100 parts by mass of natural rubber into an internal mixer at one time and masticate at 60° C. for 1-2 minutes to obtain plasticized raw rubber. Add 6 mass parts of antioxidant RD, 6 mass parts of zinc oxide, and 1.5 mass parts of stearic acid to the plasticized raw rubber to start banburying. After some time, 25 mass parts of EPDM powder, 70 mass parts Add carbon black N550 together and continue banburying. When more than 80% of the powder is finished, feed 30 parts by mass of naphthenic oil to continue banburying. When the temperature rises to 90°C, lift the pressure cover to the upper position. After cleaning, press down the pressure cover to continue banburying with 1 mass part of sulfur S-80 and 4 mass parts of accelerator CZ. When the temperature rises to 110°C, remove the glue to obtain the banbury rubber. Put the banbury rubber into the open mill, adjust the roller distance of the open mill to 6-10mm, cut the left and right sides of the mixed ru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com