Building facade coating and preparation method thereof

A facade and coating technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of good environmental performance, good corrosion resistance, strong hydrophobicity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

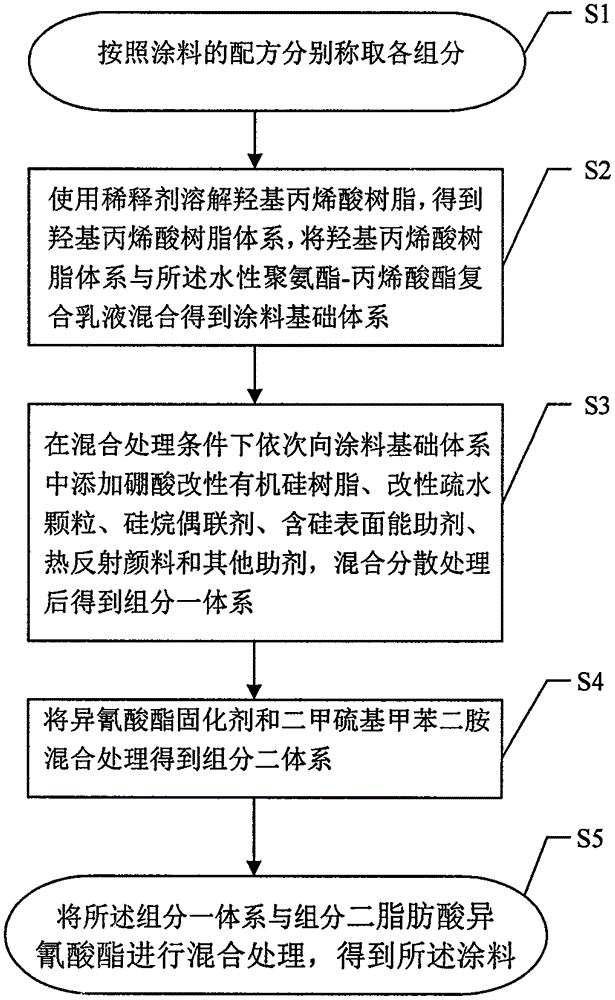

Method used

Image

Examples

Embodiment 1

[0064] Embodiment one coating component is as follows, comprises component one and component two, wherein:

[0065] The component one includes the following components in the following mass parts: 45 parts of water-based polyurethane-acrylate composite emulsion; 10 parts of hydroxyl acrylic resin; 2-parts of boric acid modified silicone resin; 5 parts of modified hydrophobic particles; 1 part of joint agent; 0.5 part of silicon-containing surface energy additive; 6 parts of heat-reflecting pigment; 3 parts of diamine.

[0066] Based on the mass of the hydroxy acrylic resin as 100%, in the hydroxy acrylic resin, the mass percentage of the hydroxyl group is 2%, and the solid content of the resin is 65%; the glass transition temperature of the hydroxy acrylic resin is - 40℃-10℃, flexibility≤1mm. Hydroxy acrylic resin has high weather resistance, and its special molecular structure makes it have very good compatibility with water-based polyurethane-acrylate, which can further im...

Embodiment 2

[0080] Embodiment two coating components are as follows, comprise component one and component two, wherein:

[0081] The component one includes the following components in parts by mass: 47 parts of water-based polyurethane-acrylate composite emulsion; 15 parts of hydroxyl acrylic resin; 5 parts of boric acid modified silicone resin; 8 parts of modified hydrophobic particles; silane coupling 2 parts of additives; 2 parts of silicon-containing surface energy additives; 7 parts of heat-reflecting pigments; 3.5 parts of amine.

[0082] Taking the mass of the hydroxy acrylic resin as 100%, in the hydroxy acrylic resin, the mass percentage of the hydroxyl group is 3%, and the solid content of the resin is 70%; the glass transition temperature of the hydroxy acrylic resin is - 40℃-10℃, flexibility≤1mm. Hydroxy acrylic resin has high weather resistance, and its special molecular structure makes it have very good compatibility with water-based polyurethane-acrylate, which can furthe...

Embodiment 3

[0091] Embodiment three coating components are as follows, comprise component one and component two, wherein:

[0092] The component one includes the following components in the following mass parts: 50 parts of water-based polyurethane-acrylate composite emulsion; 25 parts of hydroxyl acrylic resin; 10 parts of boric acid modified silicone resin; 10 parts of modified hydrophobic particles; silane coupling 3 parts of additives; 4 parts of silicon-containing surface energy additives; 8 parts of heat-reflecting pigments; 5 parts of other additives; 4 parts of amine.

[0093] Based on the mass of the hydroxy acrylic resin as 100%, in the hydroxy acrylic resin, the mass percentage of the hydroxyl group is 5%, and the solid content of the resin is 80%; the glass transition temperature of the hydroxy acrylic resin is - 40℃-10℃, flexibility≤1mm. Hydroxy acrylic resin has high weather resistance, and its special molecular structure makes it have very good compatibility with water-ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com