Patents

Literature

155results about How to "Improve water filtration performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oxygen delignify treating method for grass group unbleached chemical pulp

ActiveCN101082187ALow percussionImprove water filtration performanceCellulosic pulp after-treatmentPulping with inorganic basesCelluloseMagnesium salt

The invention relates to an oxygen delignification processing method of grass unbleached chemical pulp. The oxygen delignification of the pulp is processed after cooking and before bleaching. Its rigidity before the oxygen delignification is potassium permanganate value 16-28 (equals to karber value 26-50). After pumping into the oxygen delignification reaction tower and inflating sodium hydroxide, magnesium salt and oxygen, the chemical pulp happen the oxygen delignification in the reaction tower. The chemical pulp with rigidity of potassium permanganate value 10-14 (equals to karber value 14-18) is achieved after the oxygen delignification. The invention can remove the lignin in the pulp effectively and the removal rate is 86-98%. It reduces the degradation of the cellulose to simplify the bleaching process and cut down the dosage of the chemicals. The bleached pulp has good rigidity and drainability. The breaking length of the pulp can reach 4500-8000m and its fold-resistant times can reach 20-70.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

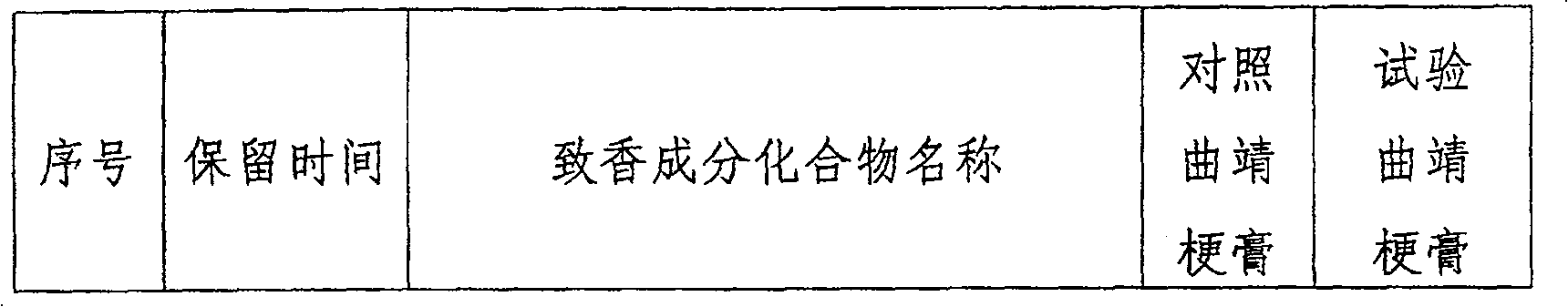

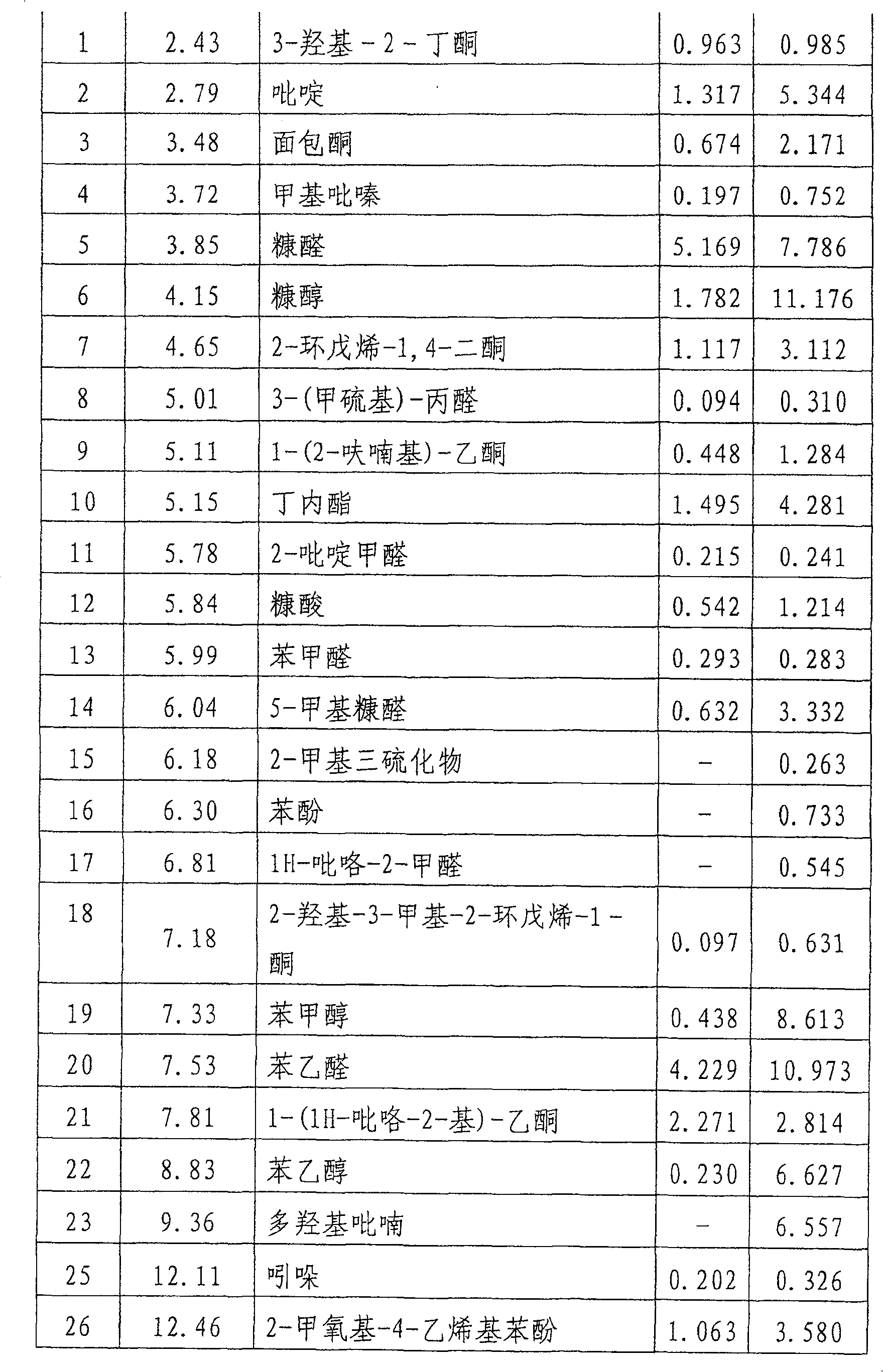

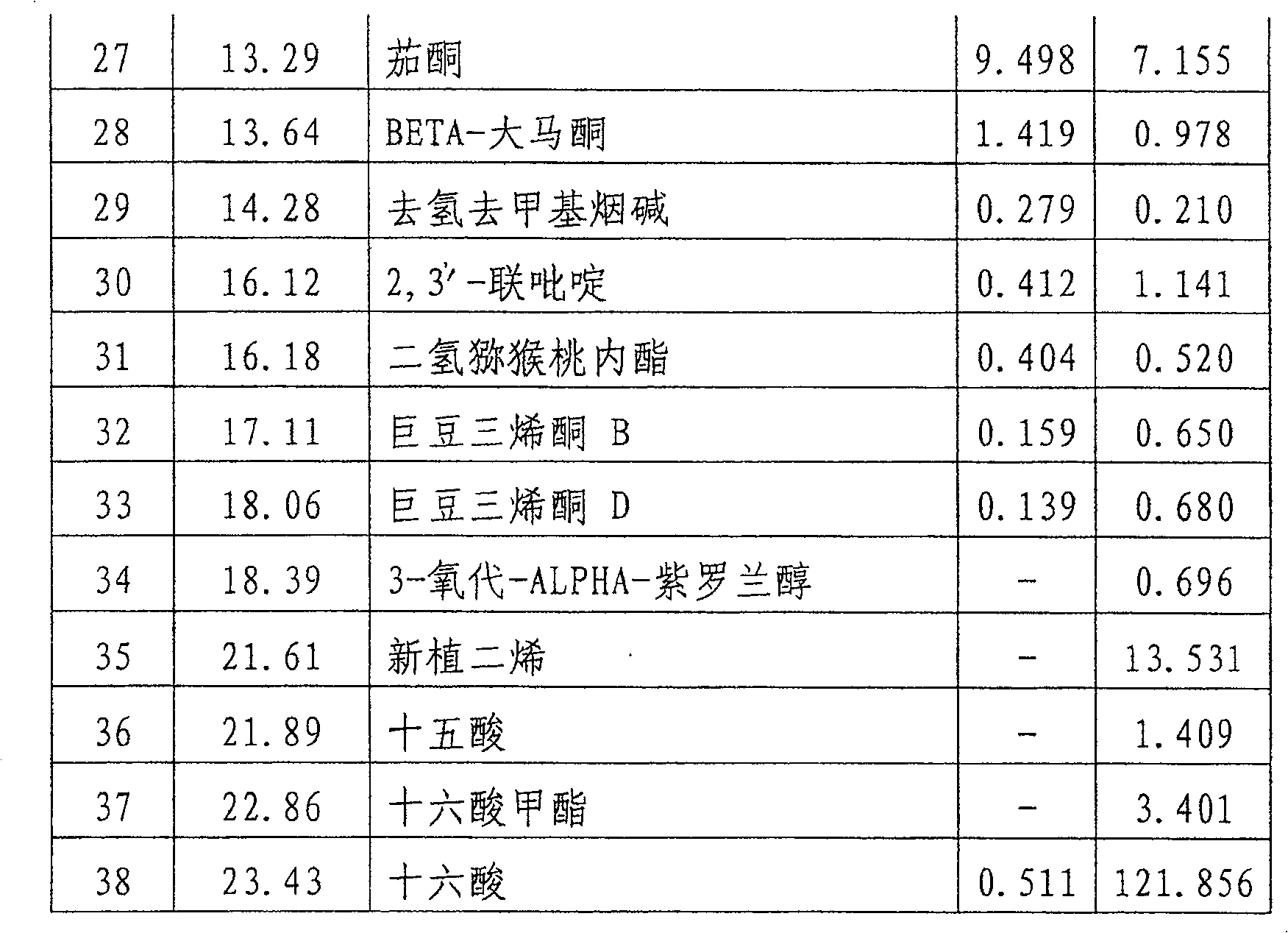

Preparation method for paper-making process tobacco sheet and finished product of paper-making process tobacco sheet

ActiveCN103141928AImprove single layer retentionImprove breathabilityTobacco preparationPlant fibrePaper based

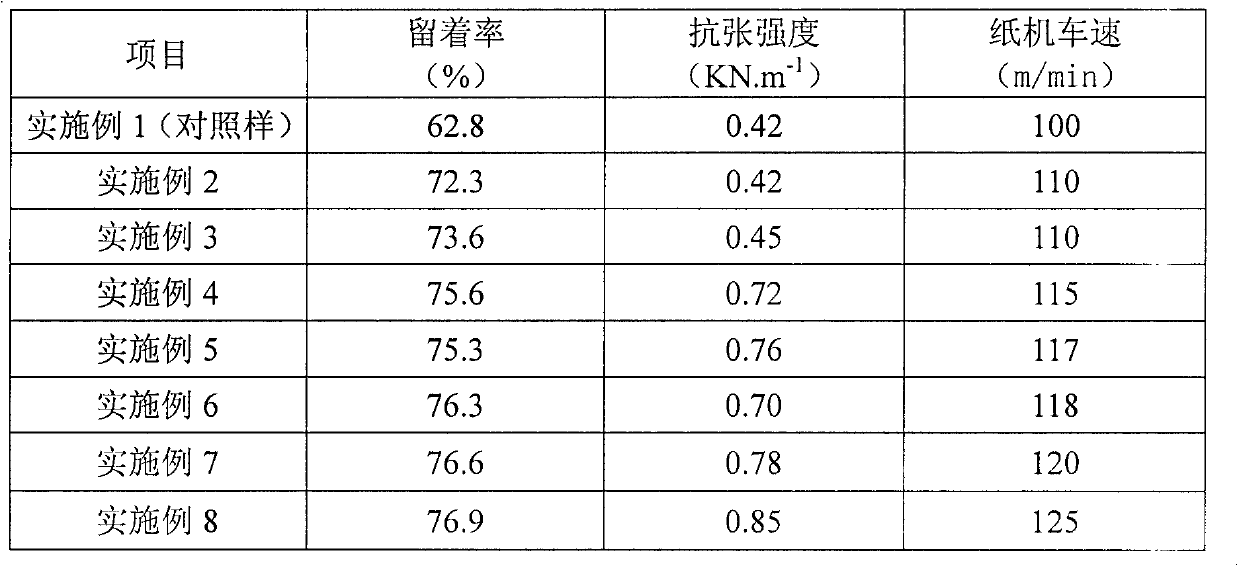

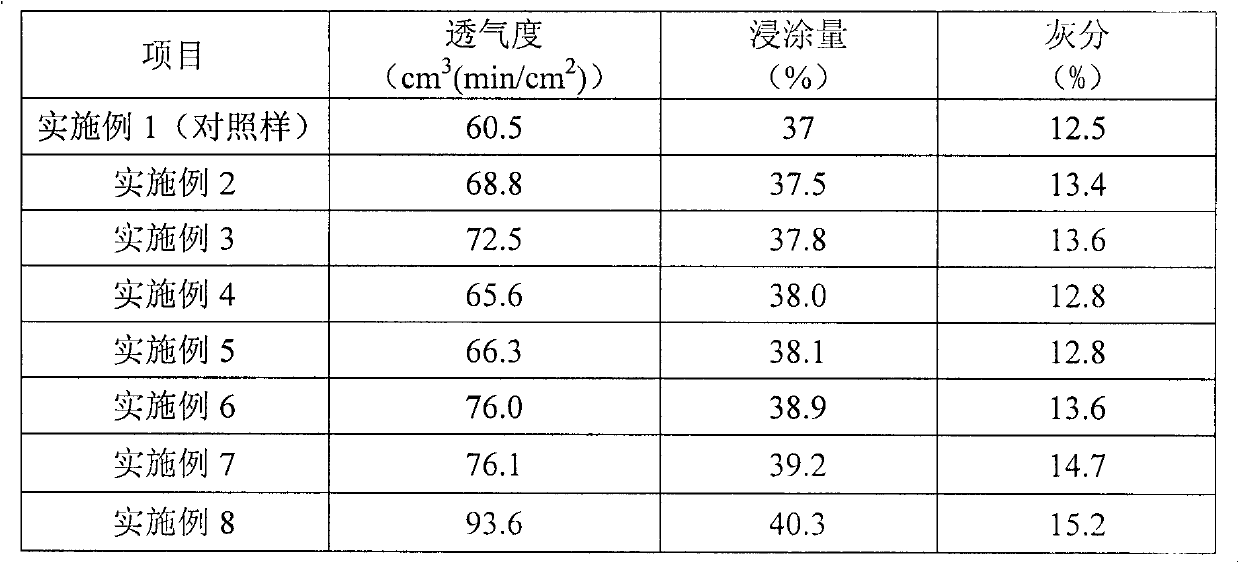

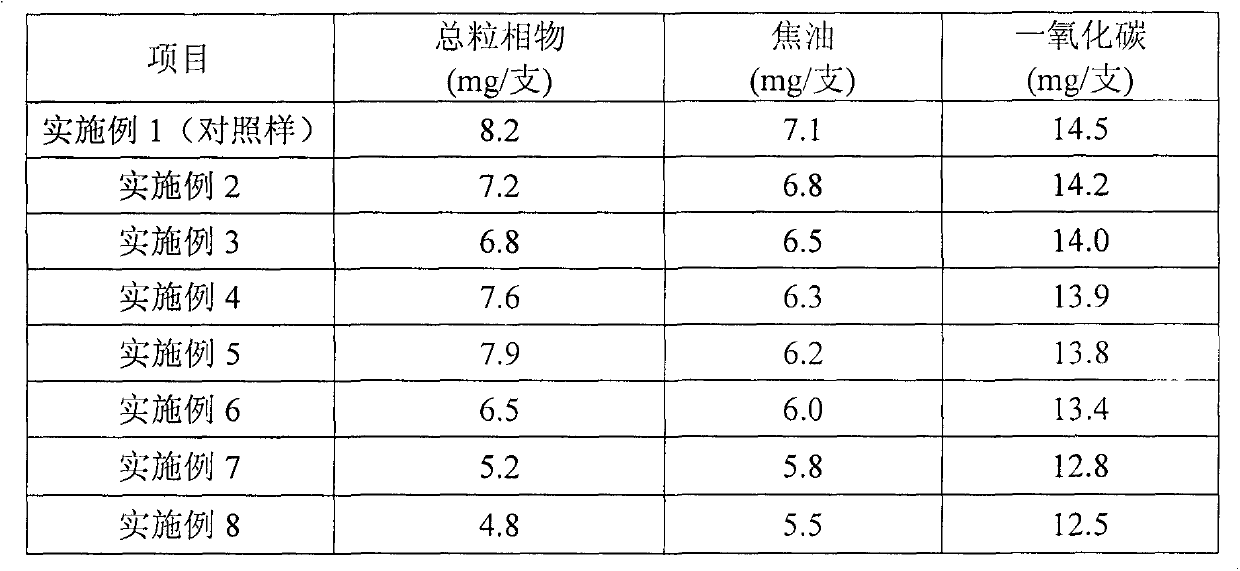

The invention belongs to the field of tobacco industry and relates to a preparation method for a functional harm-reduction and tar-reduction paper-making process tobacco sheet and a finished product of the paper-making process tobacco sheet. The preparation method for the paper-making process tobacco sheet comprises the following steps of extracting and concentrating effective components of tobacco; mixing formulas; pulping and blending fibers; manufacturing paper with pulp; dipping, drying and tearing and shaping. The blending process comprises the following steps of: adding non-tobacco plant fiber pulp of which the beating concentration is 3-4 percent and the Schopper-Riegler (SR) beating degree is 18-28 to tobacco mixed fiber pulp, adding filling to a machine chest, regulating the pulping concentration to 2-3 percent by water, and evenly mixing. By the use or the combine use of the filling and the non-tobacco plant fiber pulp, the combustion state of the sheet can be improved while physical properties, such as the air permeability, the retention and the tensile strength of a paper base, are improved, i.e., harmful ingredients of smoke, such as tar and carbon monoxide of the paper-making process tobacco sheet, can be effectively reduced, and hazard indexes of cigarettes are reduced. Meanwhile, technical-economic indicators, such as the speed and the input- output efficiency of a paper machine, also can be improved.

Owner:杭州利群环保纸业有限公司

Process for de-inking waste newspaper by biologic enzyme

InactiveCN101718050AReduce usageImprove water filtration performancePaper recyclingWaste paper working-upHigh concentrationPrinting ink

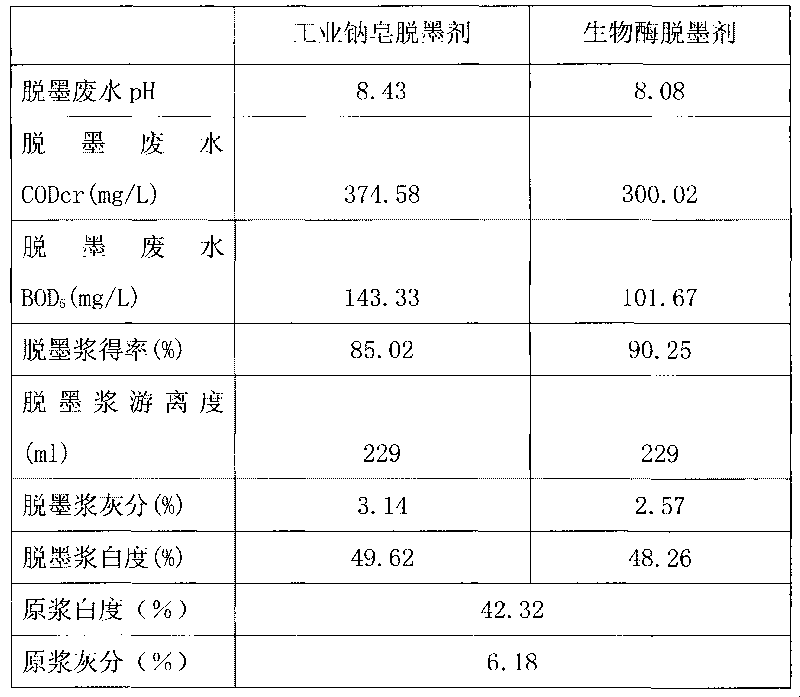

The invention provides a process for de-inking waste newspaper by a biologic enzyme, which relates to the process of the pulping of waste paper. The process is characterized by comprising the following technological procedures of: (1) preparing a de-inking agent: adding one or several of alkali lipase, amylase and xylanase into cellulase to prepare a composite enzyme and then adding 0.05-0.15 kilogram of surfactant into the composite enzyme with the weight to form the de-inking agent, wherein the composite enzyme comprises the following components in proportion: 2000-10000U of cellulase, 10000-100000U of alkali lipase, 1000-5000U of xylanase and 8000-15000U of amylase; (2) pulping by using a high-concentration pulper: adding 40-60 DEG C water into the high-concentration pulper, counting by 100 kilograms of absolutely dry paper, putting 10-150 grams of de-inking agent and 0.2-0.4 kilogram of sodium metassilicate nonahydrate into waste newspaper and journal paper and stopping after starting the pulper for 10-30 minutes; and (3) carrying out the procedures of floatation and printing ink separation to obtain the de-inked pulp. The invention has the advantages that sodium hydroxide and hydrogen peroxide are not used, and the production cost and the wastewater pollution are lowered.

Owner:FUJIAN JIAFENG BIOCHEM

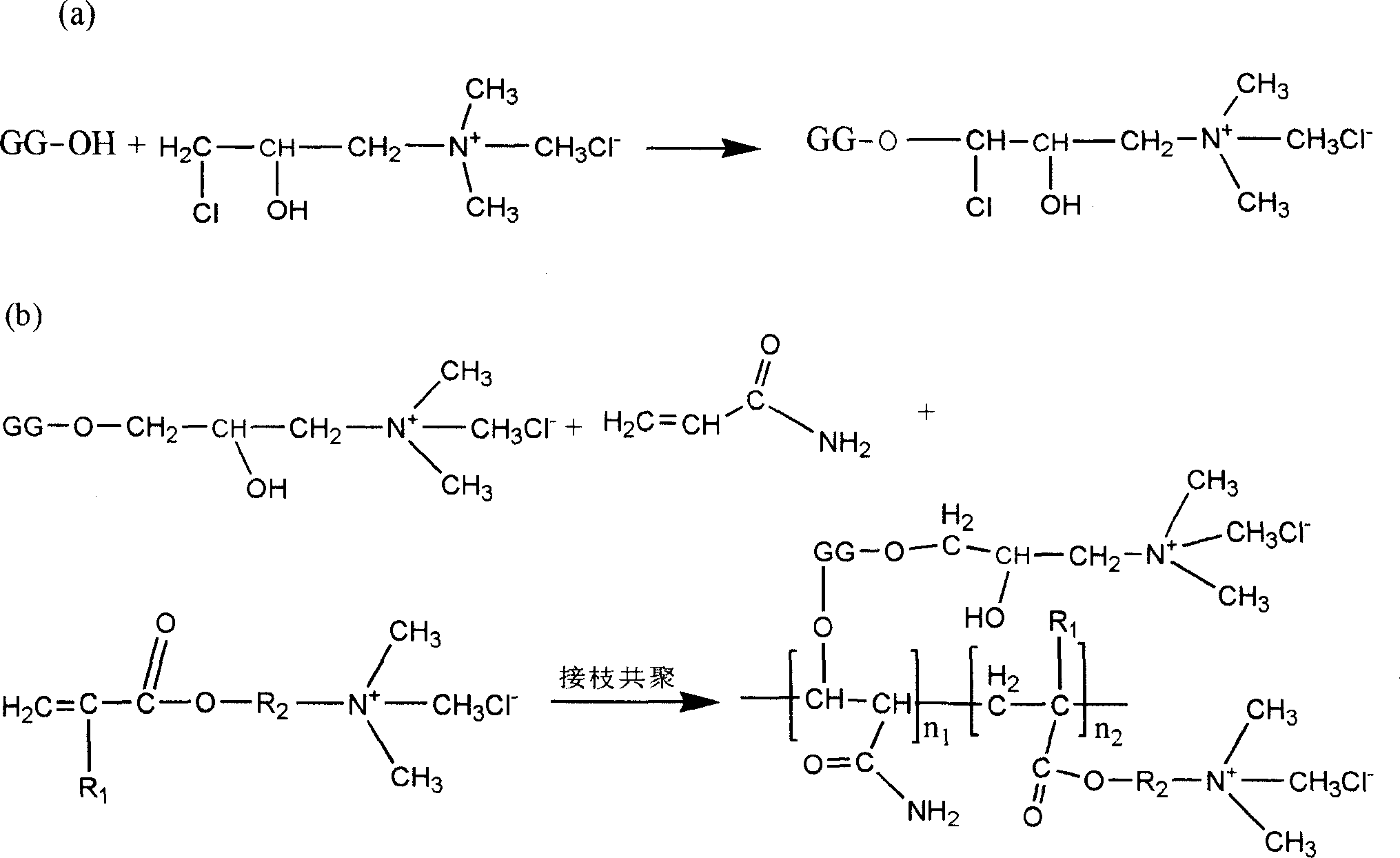

Hydroxyalkyl cationic guar gum and its preparation method and application

InactiveCN1757827ASolve forming problemsImprove adsorption capacityPaper/cardboardRetention agents additionAlcoholGraft reaction

A process for preparing the cationic hydroxyalkyl guar gum includes such steps as dispersing the raw powder of guar gum in the aqueous solution of low-carbon alcohol, adding high-alkaline catalyst, immersing, adding cationic etherifying agent, cationic graft reaction, adding phase-transfer catalyst and alkoxy etherifying agent, hydro-xyalkylating reaction, neutralizing and filtering. It can be used as the retention aid or filter aid of paper pulp.

Owner:SOUTH CHINA UNIV OF TECH

Method for improving performance of paper stock in retention and drainage aiding

InactiveCN101634120AImprove retentionGood filterabilityInorganic compound additionPaper-making machinesFiberSlurry

The invention provides a method for improving the performance of paper stock in retention and drainage aiding. The method comprises the following steps: firstly, dispersing plant fiber materials for papermaking in water, beating the plant fiber materials with the beating degree being controlled to 25 to 70 DEG SR (Schopper-Riegler); secondly, feeding the evenly mixed slurry into the approach flow system of a paper machine, and adding CPAM (cationic polyacrylamide) as retention agent before feeding the slurry into a fan pump of the approach flow system; then, adding electronegative bentonite before feeding the slurry into a pressure screen or a head box, and adding APAM (anionic polyacrylamide) before feeding the slurry into the head box; and finally, papermaking forming on the paper machine, drying and obtaining the qualified paper. By adding excessive CPAM to the paper machine, the invention allows the action between CPAM and bentonite to form fine particles, and the further combination with APAM to form floccules, thereby providing draining channels in good conditions and further improving the drainage capacity during the forming process of the paper stock.

Owner:SHAANXI UNIV OF SCI & TECH

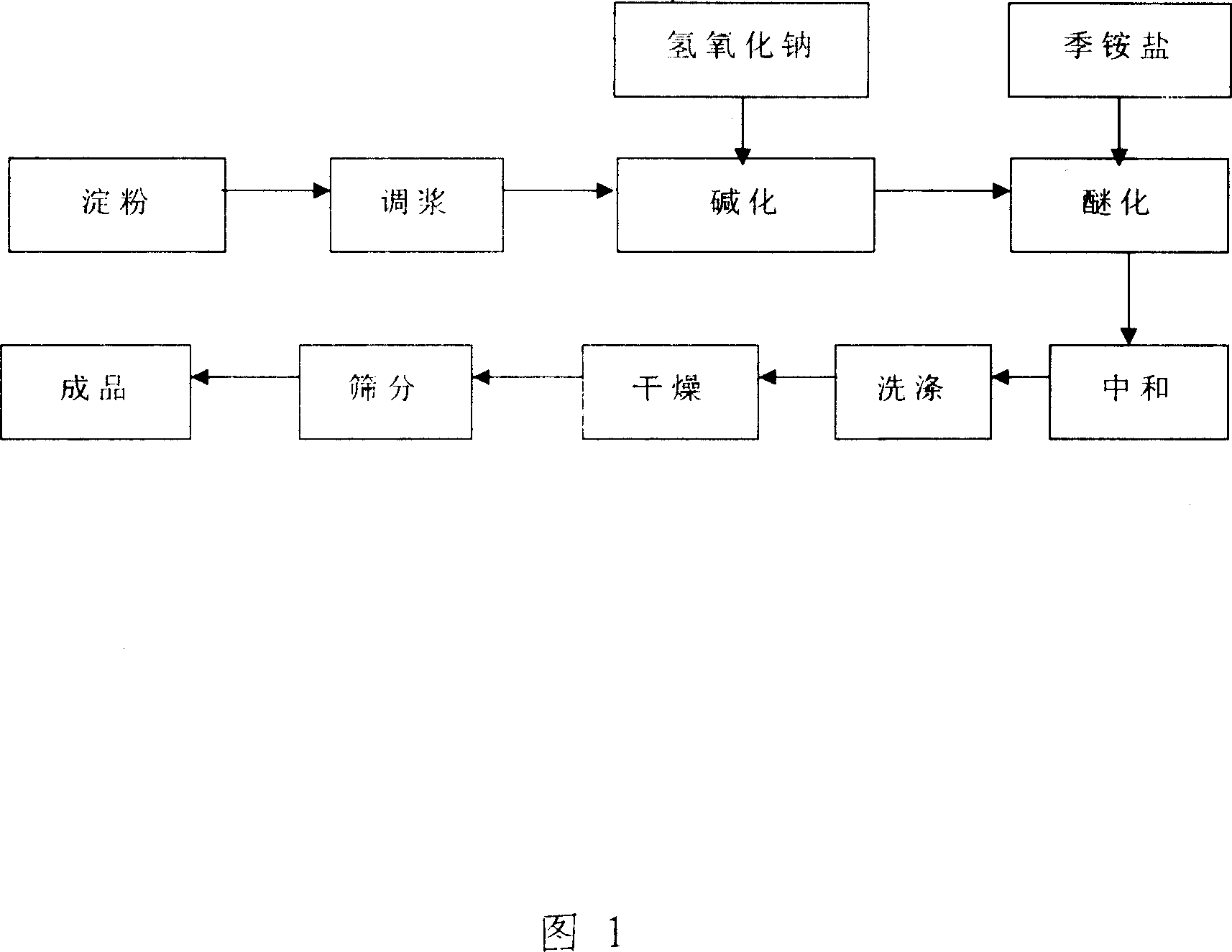

Method of preparing quaternary ammonium type cationic starch

InactiveCN101033260AReasonable production processReduce the temperatureQuaternary ammonium cationSynthesis methods

This invention relates to a synthesis method of quaternary ammonium cationic starch, which takes starch, quaternary ammonium, and sodium hydroxide as raw materials in water medium, and conducts eight steps of conditioning, alkalization, etherification, neutralization, washing, drying, screening, and packaging. The product is white powder, and gels to be the thick translucent gel heated to 50~66deg.C in water with DS values of 0.01 to 0.05. This invention is reasonable, makes the general starch has cationic performance and higher substitution, lowers the gelatinization temperature and freezing, so its effect can completely achieve the requirement of paper industry.

Owner:四平帝达变性淀粉有限公司

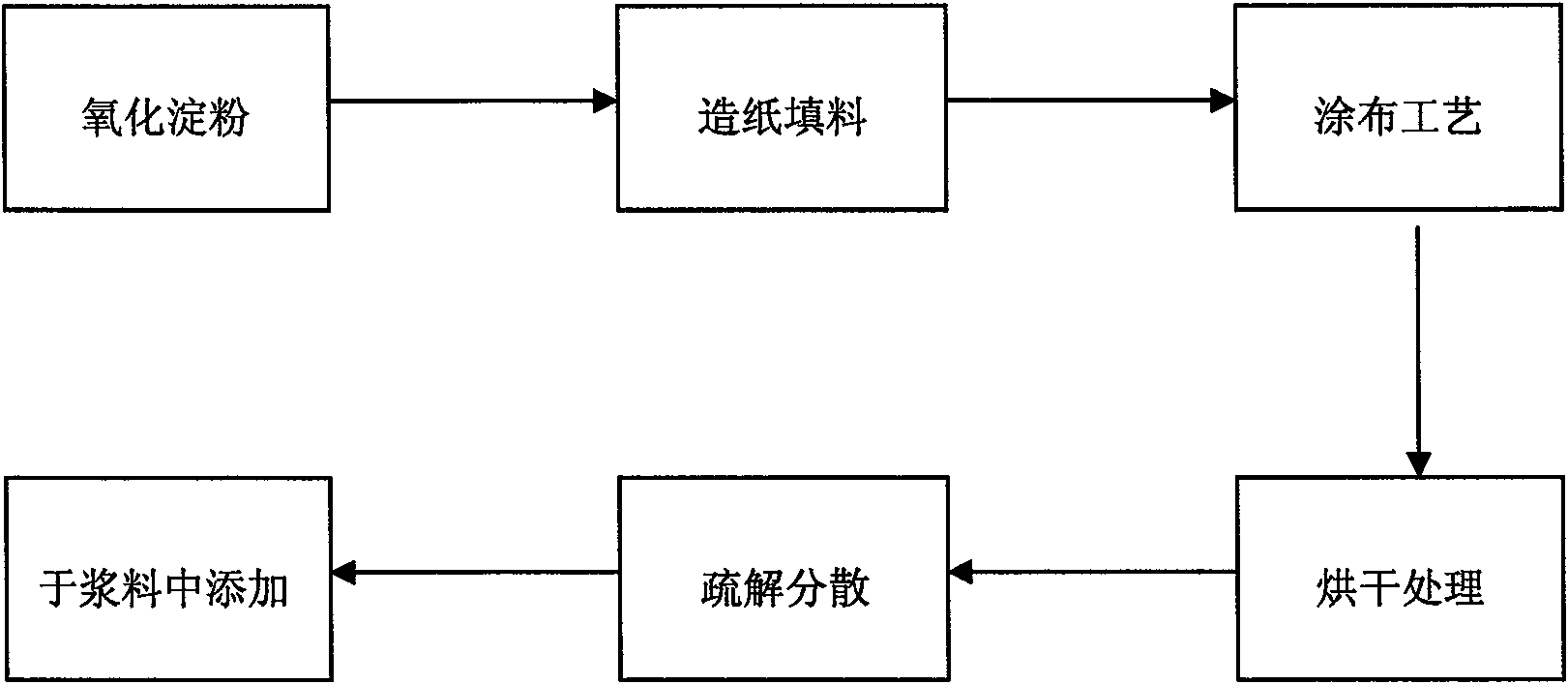

Method for applying starch modified stuffing in paper making

InactiveCN101570947AImprove retentionHigh strengthPaper/cardboardInorganic compound additionFiberWater temperature

The invention discloses a method for applying starch modified stuffing in paper making, which comprises the following steps: firstly, mixing cooked oxidized starch and stuffing to prepare a coating, evenly coating the coating on the surface of paper, then drying the paper, and breaking and scattering the coated paper to replace partial pulp to be added into a paper making system. The surface of the modified stuffing is wrapped by the starch, so the dissolution phenomenon does not occur under the water temperature condition of a paper machine system, the loss amount of the stuffing in a white water system is reduced, the combination capabilities between the fibers and between the fiber and the stuffing are increased when the stuffing is added into the paper, the drainage property of a system is improved, and the production cost is lowered.

Owner:GOLD EAST PAPER JIANGSU

Additives for modifying reproduced tobacco leaves, prepn. method and use thereof

ActiveCN1947606AReduce energy consumption for beatingImprove drainageTobacco treatmentMacromolecular SubstancesChemistry

A modifying additive for preparing the tobacco leaf sheet by paper-making method is prepared through proportionally adding acidic proteinase, composite pectase, composite neutral cellulase and neutral lipase in water, stirring, filtering and taking clear liquid. It can be used to treat tobacco stems for improving the flavouring component in liquid extract and the physical properties of tobacco stem and the looseness of tobacco leaf sheet.

Owner:YUNNAN REASCEND TOBACCO TECH GRP

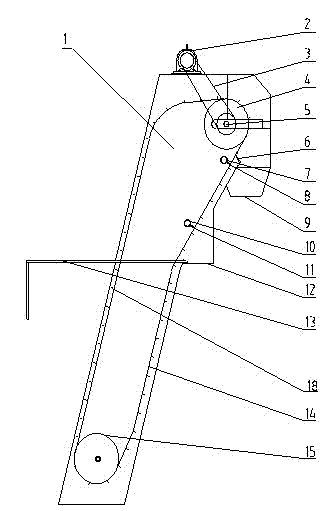

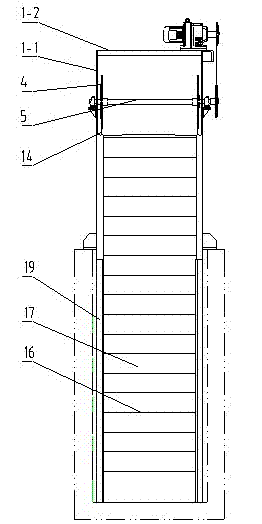

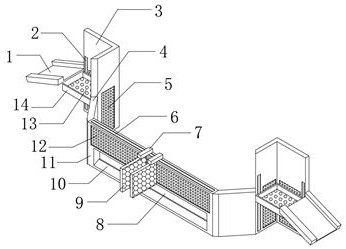

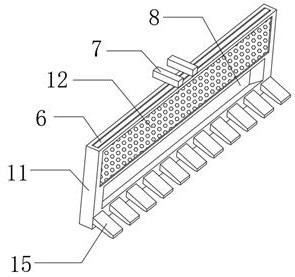

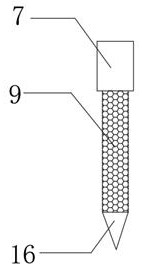

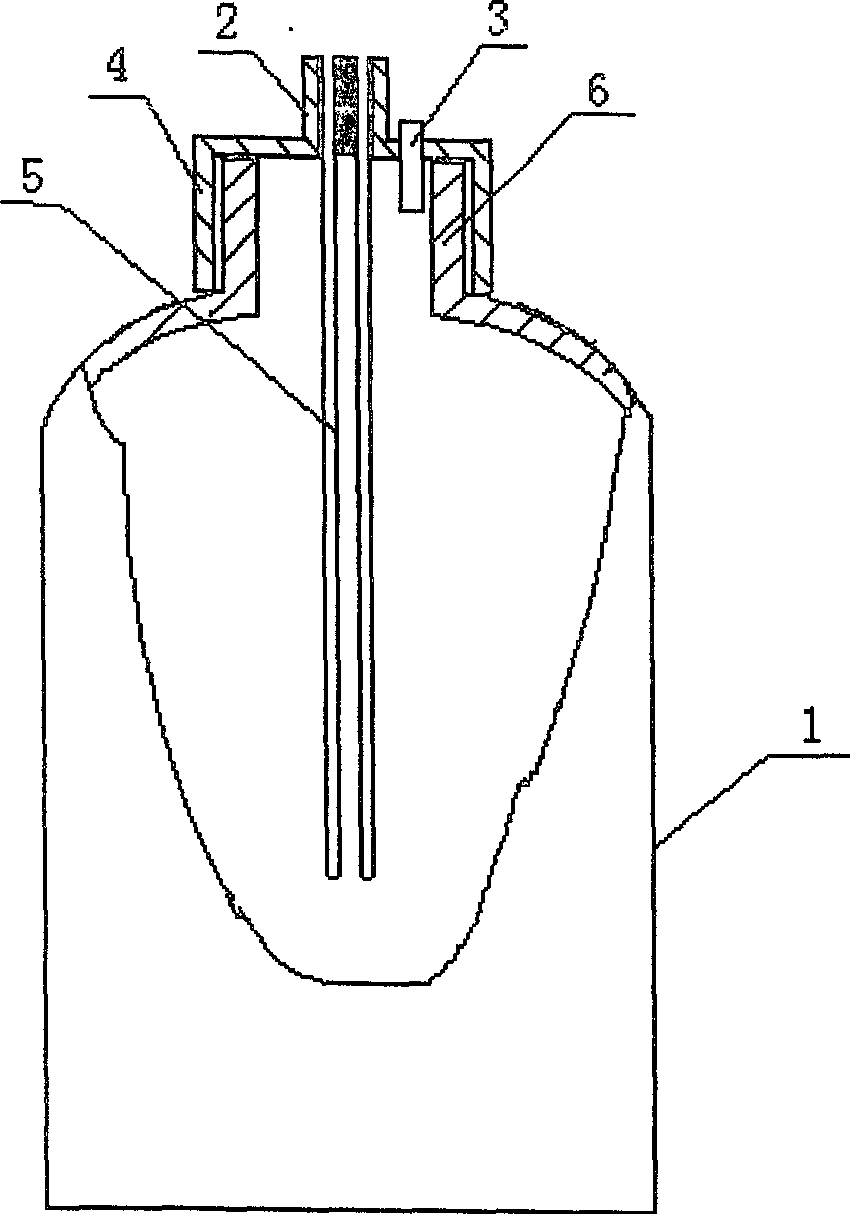

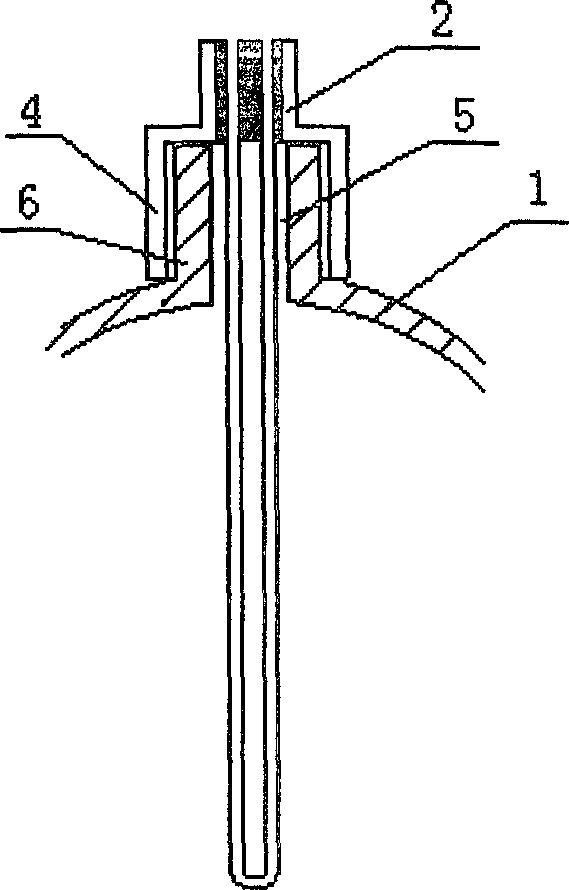

Rotary filter screen type bar screen cleaner

The invention discloses a rotary filter screen type bar screen cleaner. The rotary filter screen type bar screen cleaner comprises a frame, a driving device, a transmission chain, two main chain wheels, a main shaft, a cleaning brush, an air inlet pipe, an air nozzle, two traction chains, two secondary chain wheels, a filter frame, a filter screen, a mesh plate, a water stopping plate, and an air compressor; the driving device is fixedly connected to a top plate of the frame, the main shaft is fixed on a side plate of the frame; one end of the transmission chain is sleeved on a power output shaft of the driving device, and the other end is sleeved on a power input end of the main shaft; the main chain wheels are fixedly connected to the main shaft, and the secondary chain wheels are fixed to the lower part of the frame; two traction chains are respectively sleeved to one main chain wheel and one secondary chain wheel; the end part of the filter frame is fixedly connected to the traction chains, the filter screen and the mesh plate are arranged on the filter frame; the cleaning brush is fixed inside the side plate of the frame, brush bristle of the cleaning brush is contacted with the filter screen. By adopting the rotary filter screen type bar screen cleaner, fine floater and suspending solid matters in sewage can be intercepted; and furthermore, cleaning efficiency is high.

Owner:LANSHEN GRP CORP LTD

Biological treatment method of non-wood pulp

InactiveCN1924188AImprove water filtration performanceImprove bindingNon-fibrous pulp additionPaper/cardboardFiberCellulase

This invention relates to non-wood paper pastry biological process method, which comprises the following steps: adding enzyme into paper pastry before beating pastry with enzyme as 10-500g / ton, pastry concentration for 3-20 percentage, temperature for 20 to 60 degrees, time for 0.5 to 4 hours, pH 5.0 to 8.5, wherein, the said enzyme is of fiber enzyme or semi-fiber enzyme. This invention adopts fiber enzyme or semi-fiber enzyme to process non-wood pastry to add brooming in beating pastry process.

Owner:QILU UNIV OF TECH

Preparation method and use of cation guar gum graft copolymer retention and drainage agent

InactiveCN1919449APromote flocculation and sedimentationImprove mechanical propertiesOther chemical processesAdjuvantGuar gum

The invention discloses a preparing method and application of positive ionic guar gum grafted copolymer retention and filter aid, which comprises the following steps: dispersing non-purified guar gum powder in the low-carbon alcohol / water solution, aerating nitrogen, stirring evenly at indoor temperature, adding positive ionic etherifying agent solution, dripping strong-alkaline catalyst, reacting at 40-75 deg.c to obtain positive ionic guar gum, allocating into colorless transparent solution, adding triggering agent, acrylamide and vinyl cationic monomer, adding adjuvant, reacting at 10-65 deg.c for 2-24h to obtain the product.

Owner:SOUTH CHINA UNIV OF TECH

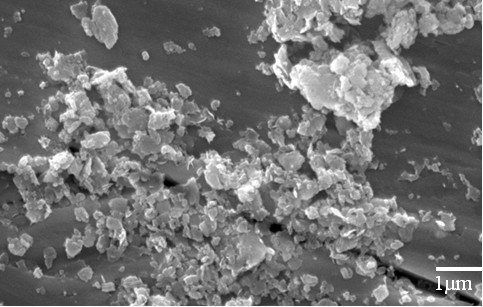

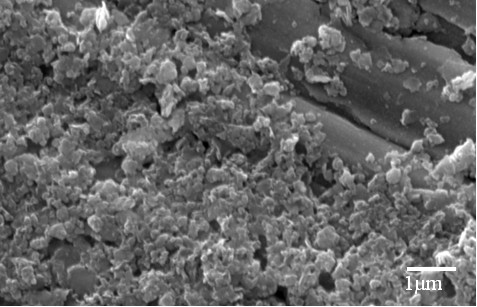

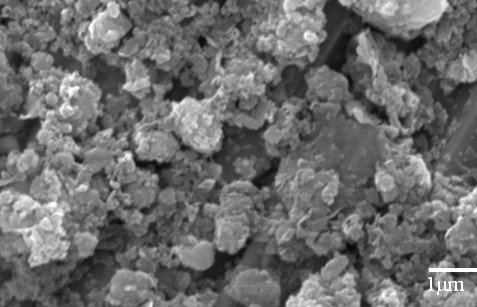

Preparation method and application of ball-milling organic modified bentonite for retention and filter aids in papermaking

InactiveCN102182110AReduce pollution loadEasy to prepareSilicon compoundsRetention agents additionActive agentSurface-active agents

The invention relates to a preparation method and application of ball-milling organic modified bentonite for retention and filter aids in papermaking. The preparation method comprises the steps of: dispersing the bentonite in water, stirring and ultrasonically dispersing to form a bentonite suspension; adding octodecyl trimethyl ammonium bromide as a surface active agent into the bentonite suspension, stirring and undergoing a water bath reaction to obtain a reaction liquid; and washing the reaction liquid by utilizing distilled water, carrying out pumping filtration till the filtrate has no white precipitate under the AgNO3 titration, drying the obtained filter cake and carrying out ball-milling to obtain the ball-milling organic modified bentonite. The prepared ball-milling organic modified bentonite has smaller particle size, the particles are basically in submicron to nanometer scale and the size distribution is more uniform; and when the prepared ball-milling organic modified bentonite is cooperated with other retention aids such as cationic polyacrylamide (CPAM), phenolic resin polymer and the like to be applied to paper pulp retention and filter systems, the problems of paper stock molding and shearing can be more effectively solved, the pulp drainage property can be enhanced, the retention effect can be improved, the speed of a paper machine can be enhanced, and therefore, the production efficiency can be increased.

Owner:SOUTH CHINA UNIV OF TECH

Method of improving retention rate of pulp molded fibers

ActiveCN103103894AImprove water filtration performanceReduce pulp consumptionNon-fibrous pulp additionPaper/cardboardChemistryPolyacrylamide

The invention provides a method of improving a retention rate of pulp molded fibers. The principle of the method of the retention rate of pulp molded fibers is that pulp is defibered and dried, chemical assistant agents such as oil-proof agents and water-proof agents are added into the pulp. The mixture is evenly stirred and added with cationic polyacrylamide. A huge flocculation cluster is formed through a flocculation reaction of the cationic polyacrylamide and pulp fibers. After tiny pulp fibers are combined with the assistant agents and form the flocculation cluster, as the physico-chemical property is changed so that the pulp are not prone to sweep away by water currents and the retention rate of the pulp is improved. Thus, quality of paper products is ensured and at the same time, economic loss and resource waste due to the fact that the pulp fibers run off are avoided and development prospect and market value are good.

Owner:SHAONENG GRP GUANGDONG LVZHOU PAPER MOLD PACKING PROD CO LTD

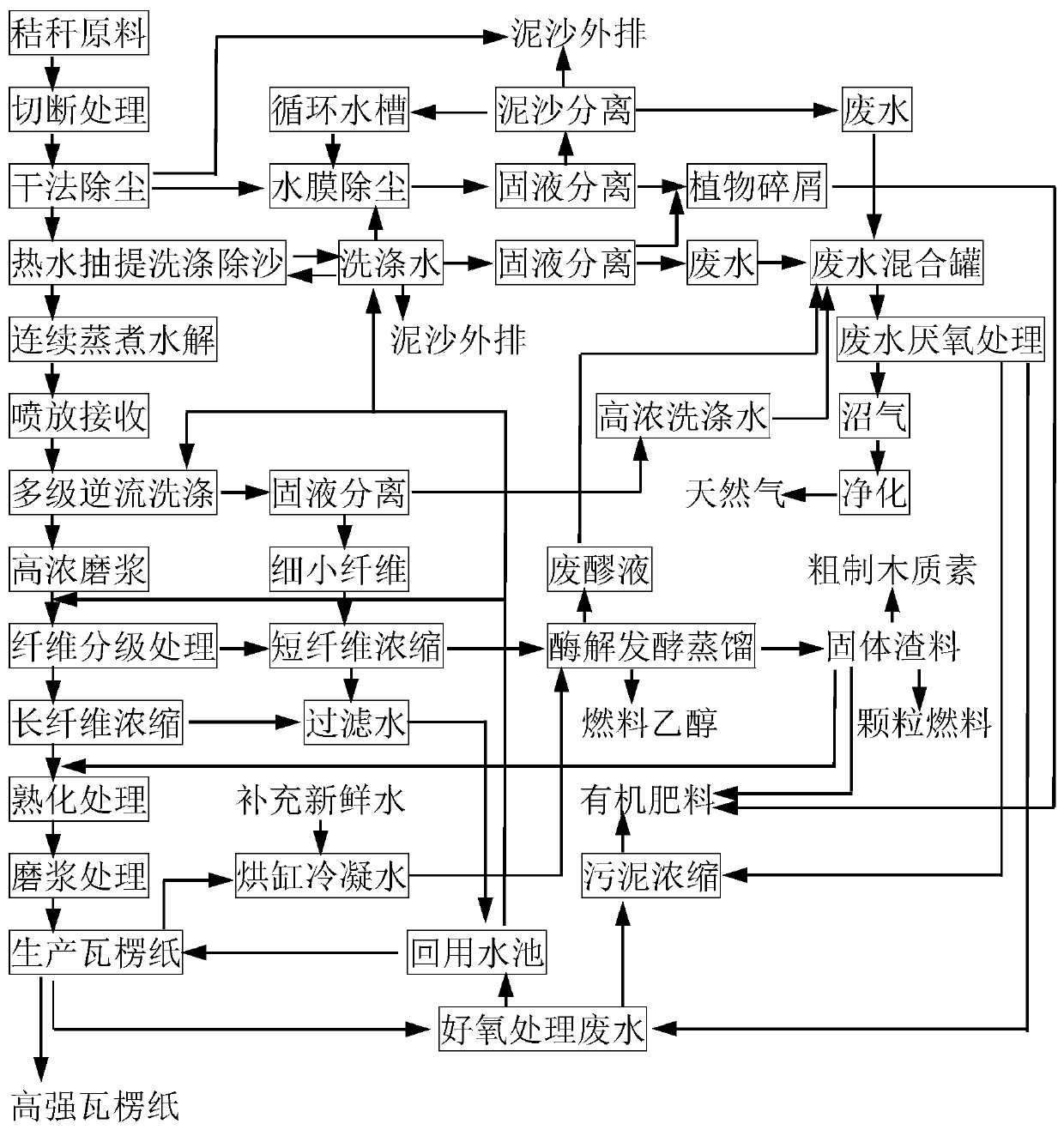

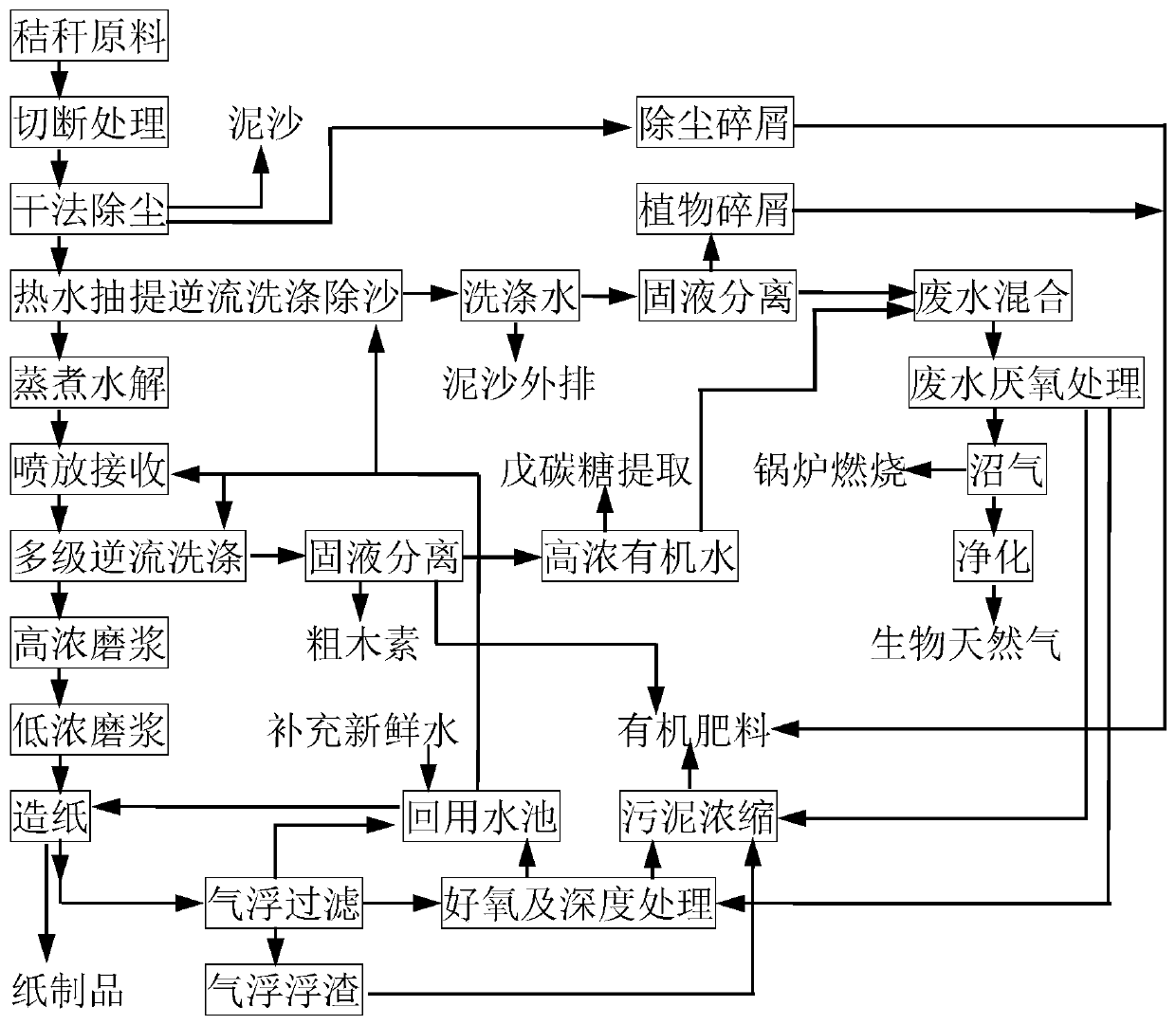

Method of utilizing straw to produce biomass fuel, corrugated paper and organic fertilizer

InactiveCN110129380AImprove water filtration performancePromote degradationPretreatment with water/steamSludge treatment by de-watering/drying/thickeningDistillationHigh concentration

The invention relates to a method of utilizing straw to produce biomass fuel, corrugated paper and organic fertilizer. The method includes: cutting the straw, dusting through a dry process and a waterfilm, washing through hot water extraction for desanding, continuously boiling for hydrolysis, blowing and receiving, performing multistage countercurrent washing, jordaning at high concentration, treating fiber in a staged manner, concentrating long fiber, curing the long fiber, jordaning the long fiber, and using the long fiber to produce the corrugated paper; concentrating the short fiber, subjecting fine and broken fiber to enzymolysis, fermentation and distillation to produce cellulose alcohol, and separating waste mash for utilization. By the method, high-value comprehensive utilizationof each component of the straw is realized, wastewater COD biochemical degradability is high, inorganic salt accumulation is avoided, biogas is produced by high-concentration wastewater in the process and purified as natural gas, and low-concentration wastewater is recycled after being treated, so that a water system is a closed cycle, and there is no wastewater emission; a fine and broken fibercomponent is large in specific surface area and high in enzymolysis efficiency; the corrugated paper produced by a long fiber component is high in strength and quality, and cost of the cellulose alcohol can be lowered; biological natural gas and biomass particle fuel can reduce consumption of mineral fuel.

Owner:吴学军 +5

Application of modified nano-microcrystalline cellulose serving as retention and drainage aid for papermaking

InactiveCN103726380AGood biocompatibility and biodegradabilityImprove water filtration performanceRetention agents additionChemistryBiocompatibility Testing

The invention relates to an application of a modified nano-microcrystalline cellulose serving as a retention and drainage aid for papermaking. Nano-microcrystalline cellulose is prepared by taking wood pulp, microcrystalline cellulose or cotton as raw materials and by adopting an acid hydrolysis method or a bio-enzyme hydrolysis method; the retention and drainage aid for the papermaking is obtained by oxidizing and modifying the obtained nano-microcrystalline cellulose by utilizing a 2,2,6,6-tetramethyl-1-piperidinyloxy-NaBr-NaClO system at the pH value of 10.0 to 10.5 or utilizing a 4-acetamido-2,2,6,6-tetramethyl-1-piperidinyloxy-NaClO2-NaClO system at the pH value of 4.5 to 4.8. The retention rate of fine fibers and fillers can be improved and the filtration performance of paper pulp can be improved by adding 0.05 percent to 2.0 percent modified nano-microcrystalline cellulose into the paper pulp, so that the operating performance of a paper machine is improved. The retention and drainage aid for the papermaking disclosed by the invention is an environment-friendly and green product and has high biocompatibility and biodegradability; the surface negative charge density is high; the retention and drainage aiding effects are good; and moreover, the uniformity of finished product can be improved.

Owner:QILU UNIV OF TECH

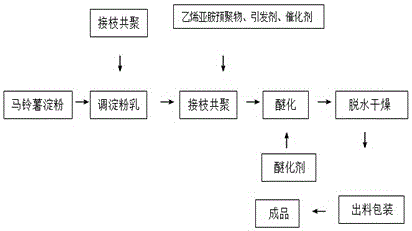

Multifunctional macromolecule paper making promoter and preparation method thereof

InactiveCN101225621AImprove water filtration performanceImprove adsorption capacityReinforcing agents additionPaper/cardboardEmulsionAqueous sodium hydroxide

The invention relates to a paper making addition agent, in particular to a multifunction and macromolecule paper making addition agent and the preparation method, which is prepared by Hofmann reaction with the molar ratio of acrylamide styrene copolymer acrylamide link: sodium hypochlorite: sodium hydroxide=1: (0.5-1): (1-9). A quantitative sodium hypochlorite and sodium hydroxide solution are added while stirred in the reaction temperature of 0 DEG C to 45 DEG C; white or light yellow emulsion is obtained after 0.5 h to 8 h reaction, and just preserved at ambient temperature. The paper making addition agent is used for paper making; when the addition agent is added to a sizing agent, in particular to a regeneration corrugated paper pulp, the dry-wet tensile strength and ring crush strength of paper are significantly increased, meanwhile the aqueous of sizing agent is effectively improved, and the retention of micro-component is increased; the paper making addition agent can be used as the paper dry strength agent, paper wet strength agent, ring crush strength agent and retention-drainage agent for paper making, in particular to corrugated paper production.

Owner:FUJIAN NORMAL UNIV

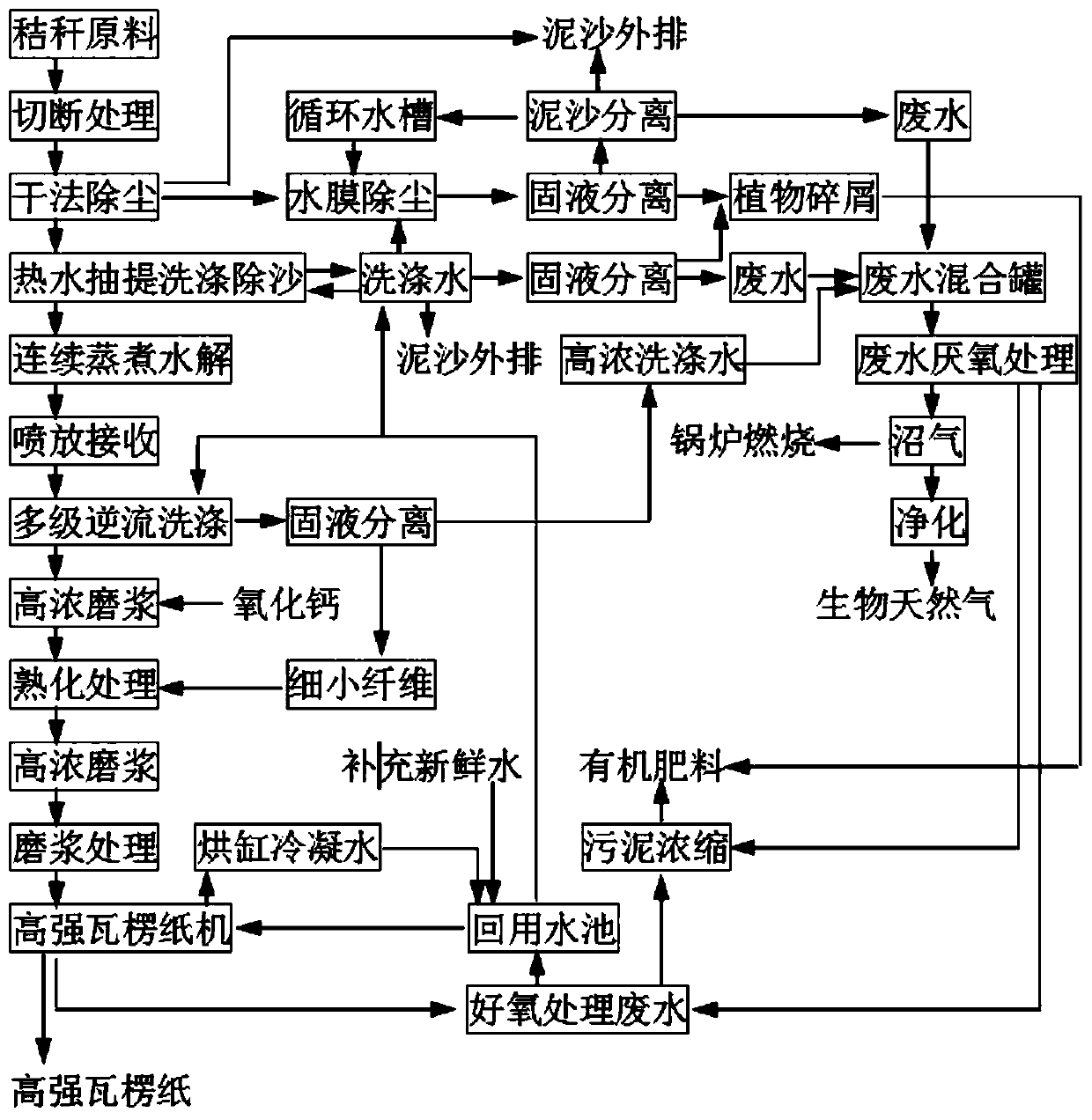

Methods for producing corrugated paper, natural gas and organic fertilizer from straws

InactiveCN110318288AImprove water filtration performanceReduce consumptionCalcareous fertilisersWashing/displacing pulp-treating liquorsHigh concentrationFiber

The invention discloses methods for producing corrugated paper, natural gas and organic fertilizer from straws. The method for producing the corrugated paper includes: (1) cutting the straws; (2) dedusting by a dry method; (3) dedusting by a water membrane; (4) extracting and washing with hot water to remove sand; (5) hydrolyzing by continuous steaming; (6) sprinkling and collecting; (7) backwashing in multiple stages; (8) grinding into high-concentration liquid firstly; (9) ripening; (10) grinding into high-concentration liquid and low-concentration liquid; (11) producing the corrugated paper. The method for producing the natural gas includes the steps of: (1) subjecting high-concentration wastewater to anaerobic treatment; (2) subjecting the treated wastewater to aerobic treatment; (3) purifying marsh gas obtained from anaerobic treatment to obtain the natural gas. The method for producing the organic fertilizer is also provided. The methods for producing the corrugated paper, the natural gas and the organic fertilizer from straws are environmentally friendly, the wastewater obtained in the processes can be recycled, self-producing capability of pulp for industrial packing paperincluding the corrugated paper and the like can be improved, the difficulty of fibrous material shortage in our country can be alleviated, and reliance on imported waste paper can be reduced.

Owner:吴学军 +4

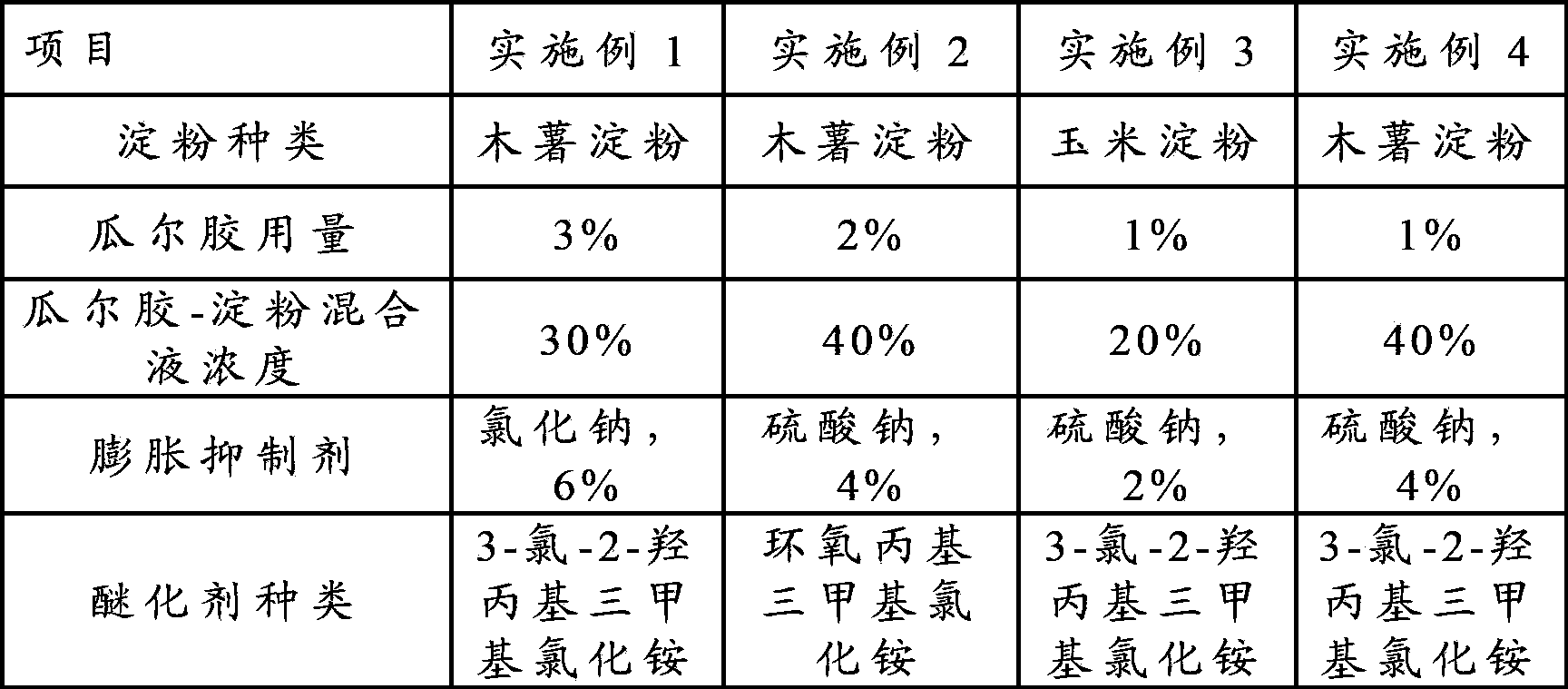

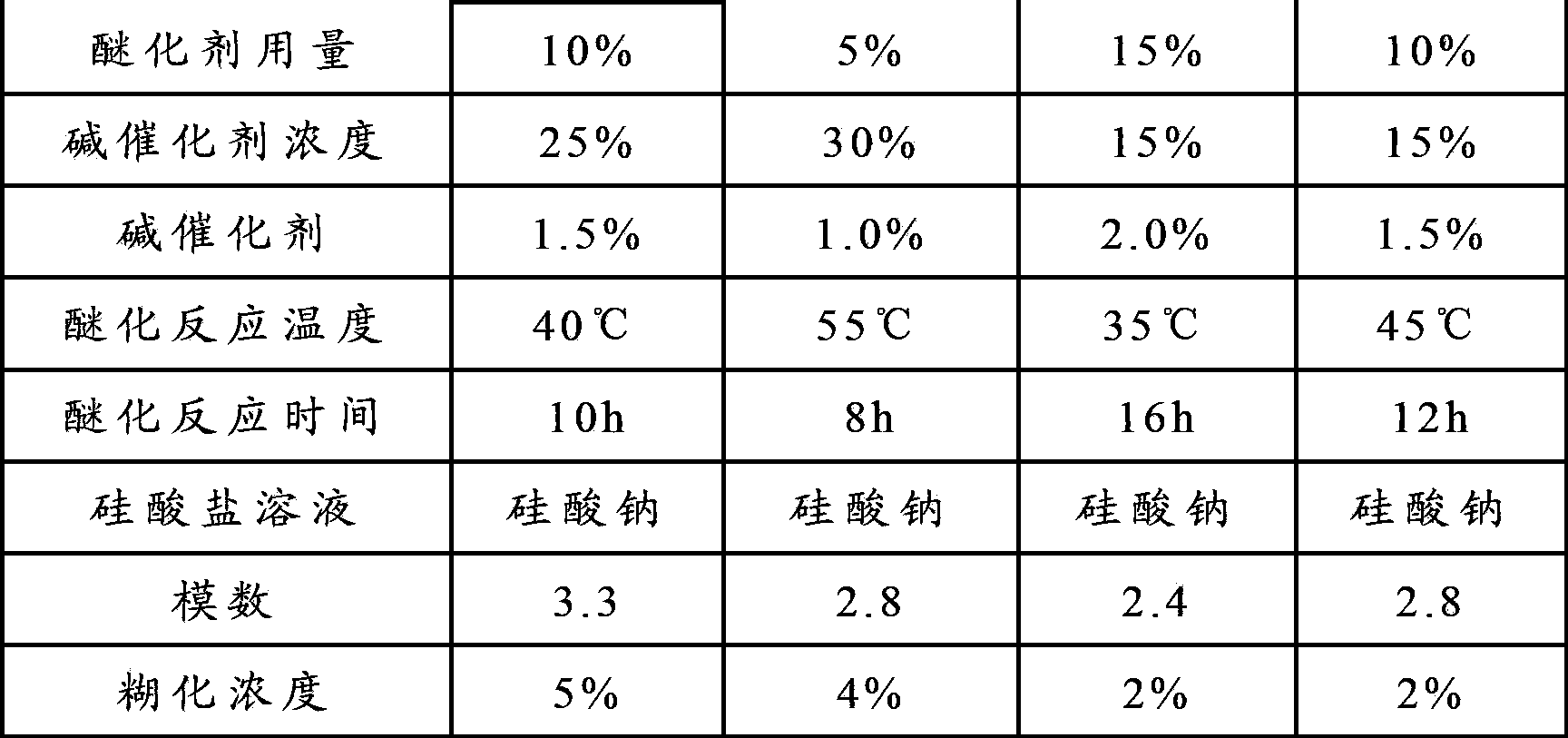

Starch composition, preparation method thereof and pulp using the starch composition

ActiveCN103741543AImprove retentionImprove water filtration performanceReinforcing agents additionPaper/cardboardGuar gumMetal

The invention provides a modified starch composition used in the paper-making field. The modified starch composition comprises reaction products by mixing guar gum, an etherified modified compound of starch, a metal silicate and water, wherein the etherified modified compound of starch is an etherified modified compound of original starch and a cationic etherifying agent pre-activated by an alkaline catalyst, the mass of the cationic etherifying agent in the cationic etherifying agent pre-activated by the alkaline catalyst is 5%-15% of the total dry mass of the original starch and the guar gum, the mass of the alkaline catalyst is 1.0%-2.0% of the total dry mass of the original starch and the guar gum; the dry mass of the guar gum is 1.0%-3.0% of the dry mass of the original starch, and the dry mass of the metal silicate is 10%-30% of the total dry mass of the original starch and the guar gum. The invention also provides a preparation method of the modified starch composition and pulp using the modified starch composition. The modified starch composition can effectively improve the retention and drainage properties of the pulp.

Owner:GOLD EAST PAPER JIANGSU

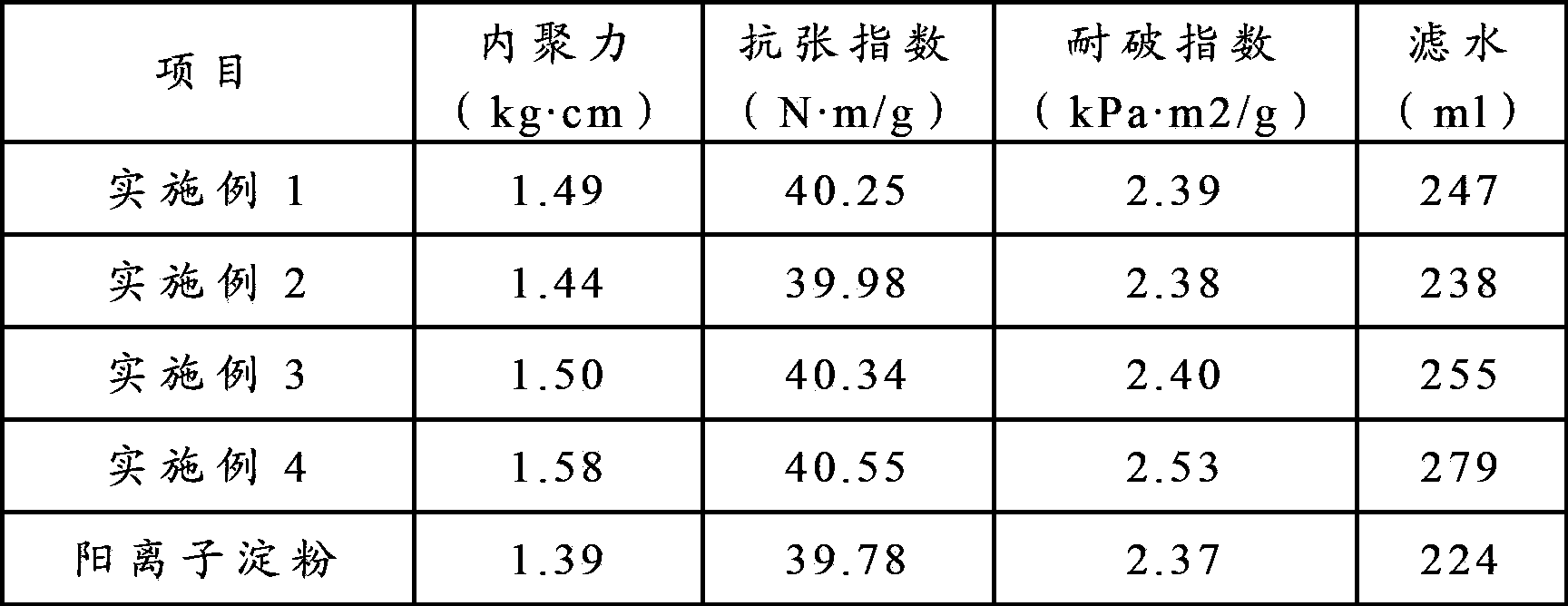

Papermaking enhancer and preparation method thereof

ActiveCN105061774AReduce consumptionImprove water filtration performanceReinforcing agents additionPolymer sciencePapermaking

The invention discloses a papermaking enhancer and a preparation method thereof. The papermaking enhancer is white or faint yellow powder, and has the water content of 15% or below and cation substitution degree of 0.03 or above, and the main effective component of the papermaking enhancer is a starch-polymine graft copolymer. Compared with the common papermaking enhancer, the papermaking enhancer is wide in application field, excellent in property, reduced in starch dosage in the papermaking production process, and lowered in production cost of paper plants.

Owner:DONGXIANG HEDA IND CO LTD

Method for reducing food packaging paper pulp molded product fiber dosage

ActiveCN103103893ALose weightReduce manufacturing costPaper/cardboardInorganic compound additionFlocculationFiber

The invention provides a method for reducing food packaging paper pulp molded product fiber dosage. The method for reducing the food packaging paper pulp molded product fiber dosage can be achieved through the following technical scheme: in the process of paper pulp molding forming, adding an environment-friendly food grade CaCo3 padding to replace partial plant fiber, and supplementing cationic polyacrylamide (CPAM) of eight million molecular weight to use as a retention auxiliary agent; forming large-size flocculation perssad and achieving modified effect by mix and flocculation effects of the CPAM, the fiber and the CaCO3 padding. The CaCo3 padding and the fine plant fiber have good absorption capacity, the surface of the CaCo3 padding can be better absorbed with the plant fiber, and therefore the purposes of improving fiber retention and reducing pulp product fiber dosage are achieved. The method for reducing the food packaging paper pulp molded product fiber dosage has the advantages of being environment-friendly and high-efficiency, simple and practical, and high in application value.

Owner:SHAONENG GRP GUANGDONG LVZHOU PAPER MOLD PACKING PROD CO LTD

Straw comprehensive utilization method

InactiveCN110791990AImprove porosity and drainageReduced steam and power consumptionPretreatment with water/steamClimate change adaptationBiogasAgricultural crops

The invention discloses a straw comprehensive utilization method comprising the following steps: 1, paper product production: (1) straw cutting off; (2) dry dedusting; (3) hot water extraction, countercurrent washing and sand removal; (4) cooking and hydrolyzing; (5) spraying and receiving; (6) multistage countercurrent washing; (7) high-concentration pulping; (8) low-concentration pulping; and (9) papermaking; 2, natural gas production: (1) anaerobic treatment; (2) aerobic treatment; and (3) biogas purification; 3, production of an organic fertilizer: (1) extracting chippings generated by drydedusting in the step 1, plant chippings filtered by hot water extraction countercurrent washing water in the step 1, and solids obtained by solid-liquid separation of multi-stage countercurrent washing water for fermentation production of the organic fertilizer; and (2) mixing the concentrated sludge produced by anaerobic treatment and aerobic treatment in the step 2 with air flotation dross andplant debris, and fermenting to produce the organic fertilizer. The straw comprehensive utilization method provided by the invention is environment-friendly, realizes process wastewater resource utilization, can improve the slurry self-production capability in China, alleviates the problem of lack of fiber raw materials in China, can effectively utilize crop straws, and increases agricultural income.

Owner:吴学军 +5

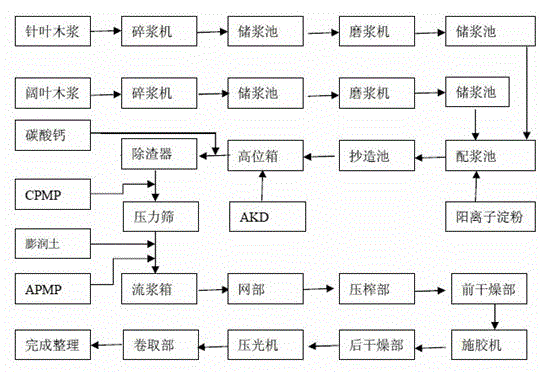

Method for producing highly quantitative two-side offset paper

ActiveCN103603225AImprove water filtration performanceReduce poor qualityChemical/chemomechanical pulpPaper-making machinesSulfatePulp and paper industry

The invention belongs to papermaking technologies and relates to a method for producing highly quantitative two-side offset paper. The method comprises the following steps: sequentially performing pulping, size mixing, sizing, manufacturing paper with pulp, pre-drying, surface sizing, after-drying, press polish and rolling on basic raw materials such as bleached sulfate needlebush pulp and bleached sulfate broadleaf wood pulp, and finally finishing into paper; and allowing the materials in the pulping process to sequentially pass through a pulper, a pulp storage pool, a pulp grinder and the pulp storage pool according to a material transfer sequence, wherein in the pulping process, the pulping beating degree of the bleached sulfate needlebush pulp in the basic raw materials is required to be 25-320SR, and the pulping beating degree of the bleached sulfate broadleaf wood pulp is required to be 24-330SR. According to the method, the highly quantitative two-side offset paper can be manufactured with pulp, and the manufactured paper is high in surface strength, high in internal binding force, high in smoothness and small in two-side difference.

Owner:ZHENJIANG DADONG PULP & PAPER

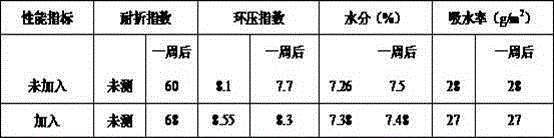

Method for repairing wilting bamboo slip by swelling

InactiveCN101412236AReduce intensityHigh blacknessWood impregnation detailsBursting strengthDistilled water

The invention discloses a method for restoring shriveled inscribed bamboo slips through swelling, and relates to a method for restoring cultural relics of the inscribed bamboo slips, in particular to components of a material for restoring low intensity inscribed bamboo slips and the shriveled inscribed bamboo slips which are obtained in archaeological excavation, and a method for preparing and restoring the same. The method comprises the following steps: (1) cleaning the shriveled inscribed bamboo slips by using distilled water; (2) soaking the cleaned shriveled inscribed bamboo slips in a bamboo swelling material for 3 to 7 days; (3) soaking the swollen shriveled inscribed bamboo slips in a bamboo restoring material for 7 to 10 days; and (4) placing the obtained bamboo slips at a cool and ventilated place to be dried naturally. The method obviously improves the intensity of the shriveled inscribed bamboo slips, strengthens the folding strength, the tearability, the bursting strength and the tensile strength, and improves the drainability. Besides, the method is suitable for restoring the shriveled inscribed bamboo slips through swelling.

Owner:陈子繁

Cation polyacrylamide retention and drainage aids and preparation method thereof

ActiveCN106188436AImprove retentionImprove water filtration performancePaper/cardboardRetention agents additionAlcoholSolvent

The invention discloses cation polyacrylamide retention and drainage aids. The cation polyacrylamide retention and drainage aids are characterized in that cation polyacrylamide retention and drainage aids take a liquefied product for conducting acid catalytic liquefaction on bamboo wood in an alcohols solvent as a cation monomer, cation polyacrylamide is modified, and the cation polyacrylamide retention and drainage aids are obtained. The invention further discloses a preparation method of the cation polyacrylamide retention and drainage aids. According to the cation polyacrylamide retention and drainage aids and the preparation method thereof, the retention rate of paper pulp can be effectively increased, the smoothness, evenness and strength of the surface of the paper are improved, and meanwhile compared with a conventional polyacrylamide product, the biodegradability of cation modified polyacrylamide is greatly improved.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Water gate garbage intercepting and cleaning device for water conservancy project

InactiveCN112030904AAvoid cloggingGuaranteed stabilityBarrages/weirsWater cleaningWater filterElectric machinery

The invention belongs to the technical field of water conservancy projects, and particularly relates to a water gate garbage intercepting and cleaning device for a water conservancy project. The watergate garbage intercepting and cleaning device aims to solve the problem that an existing water gate garbage intercepting and cleaning device is manually cleaned, and manpower is wasted. According tothe scheme, the water gate garbage intercepting and cleaning device comprises a first supporting plate, wherein a first opening is formed in the outer wall of the top of one end of the first supporting plate, and a third filter screen plate is fixedly installed on the inner wall of the first opening; and a water guide opening is formed in the outer wall of the bottom of one end of the first supporting plate, an inclined opening plate is fixedly installed on the inner wall of the bottom of the water guide opening, and second supporting plates which are arranged at equal intervals are fixedly installed on the outer wall of the bottom of the other end of the first supporting plate. According to the water gate garbage intercepting and cleaning device for the water conservancy project, a vibration motor is arranged, the vibration motor can drive a fourth filter screen plate to vibrate, so that the water filtering effect is improved, the weight caused by water in the garbage recovery processis reduced, and the convenience of garbage recovery is improved.

Owner:钱银龙

Bamboo pulp refining process

InactiveCN102296475AImprove water filtration performanceQuality improvementPulp beating/refining methodsPaper sheetFiber

A bamboo pulp refining process, when bamboo pulp is used to make paper, it is first screened to obtain long-fiber pulp components and fine fiber components, and the long-fiber pulp components are refined so that the long-fiber pulp components The effect of chemicalization is obvious, and then mixed evenly with fine fiber components, the final slurry has enhanced water filtration ability, which is suitable for papermaking by paper machine. During the refining process, the long fiber components of bamboo pulp are difficult to separate into filaments, while the cell walls of the fine fiber components are easily broken, and the water absorption and swelling are obvious. The density rises quickly, but because only part of the long fiber components in the pulp are divided into fibers, the surface is fluffed, and the final paper quality is poor; the invention separates the fine fiber components in the bamboo pulp, and only the long fibers are separated. The fiber component is refined by a refiner, so that the long fiber of bamboo pulp is divided into filaments evenly, and then the fine fiber component is added, so that the water filtration capacity of the final pulp is improved, and the quality of the paper is improved.

Owner:SHAANXI UNIV OF SCI & TECH

Use of N-(2-hydroxy-3-trimethyl) propyl ammonium chloride chitosan and nano silicon dioxide

InactiveCN1616765AReduce usageExcellent performancePaper/cardboardInorganic compound additionChemistryAmmonium chloride mixture

The present invention discloses the use of N-(2-hydroxy-3-trimethyl) propyl ammonium chloride chitosan and nanometer silicon dioxide as papermaking retention and filter aid. In condition of pulp slurry pH of 7-8, the retention and filter aid raises the water filtering performance of straw pulp slurry of beating degree of 38-50 deg SR by 15-26 %, raises the fine fiber and hemi-cellulose retaining rate by 30-50 %, and makes the CaCO3 retaining rate reach 80-89 %. Under the same flocculating effect on CaCO3 suspension, the chitosan quarternary salt has consumption 4-8 % that of cationic starch.

Owner:WUHAN UNIV

Water purifying bottle and water purifying method

InactiveCN1821101AImprove water filtration performanceAvoid easy cloggingWater/sewage treatmentFiberWater source

The present invention discloses a kind of water purifying bottle and its water purifying method. The water purifying bottle includes an elastic bottle body, a membrane assembly and a non-return valve. The membrane assembly consists of a connecting part connected to the mouth of the elastic bottle body, and a hollow fiber film with at least one end connected to the connecting part. The non-return valve is connected to the elastic bottle body, the bottle mouth or the connecting part. The water purifying method is to purify water through adding different water treating adsorption or exchange filtering material based on the pollutant in the water to be treated. The present invention is suitable for field use to obtain purified water and may be also used in secondary purification of tap water.

Owner:INST OF HYGIENE & ENVIRONMENTAL MEDICINE PLA ACAD OF MILITARY MEDICAL

Additives for modifying reproduced tobacco leaves, prepn. method and use thereof

A modifying additive for preparing the tobacco leaf sheet by paper-making method is prepared through proportionally adding acidic proteinase, composite pectase, composite neutral cellulase and neutral lipase in water, stirring, filtering and taking clear liquid. It can be used to treat tobacco stems for improving the flavouring component in liquid extract and the physical properties of tobacco stem and the looseness of tobacco leaf sheet.

Owner:YUNNAN REASCEND TOBACCO TECH GRP

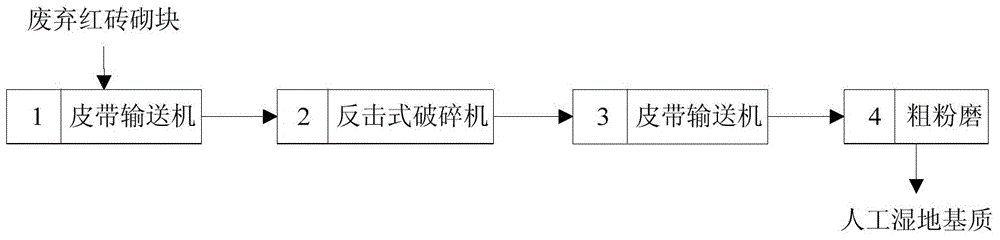

Method for preparing artificial wetland matrix material by using powdered waste red brick block

InactiveCN103978009AWide variety of sourcesSimple processConstruction waste recoverySolid waste disposalPorosityConstructed wetland

The invention discloses a method for preparing an artificial wetland matrix material by using powdered waste red brick block, and belongs to the technical field of wastewater treatment. The invention mainly solves the problem of disposal of construction waste of waste red brick block; and the waste red brick block is subjected to crushing and grinding to obtain a powdered waste red brick block, which is prepared into an artificial wetland matrix material. The artificial wetland matrix material prepared by the invention has high specific surface area and porosity, is not easily blocked, and can filter and adsorb pollutants in water; and Al<3+>, Ca<2+>, Fe<3+>, Mg<2+> contained in the matrix material can generate a precipitation reaction with phosphorus in water, and are conducive to the removal of phosphorus in wastewater, and trace elements are conducive to the growth of wetland plants. Therefore, the artificial wetland matrix material prepared by the invention can changes the powdered waste redbrick block into treasure, and efficiently utilize resources.

Owner:CHANGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com