Method for preparing artificial wetland matrix material by using powdered waste red brick block

A technology for artificial wetlands and matrix materials, which is applied in the fields of construction waste recycling, recycling technology, chemical instruments and methods, etc., can solve the problems of excessive total phosphorus in effluent, blockage of wetland matrix, and inability to provide them, and achieves increased nutrient content and is operable. Strong and simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

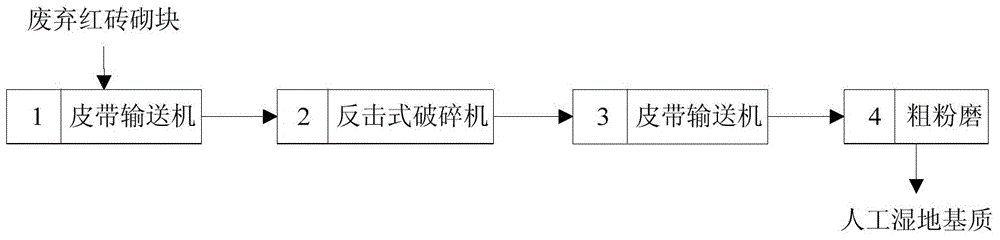

[0021] The preparation method of artificial wetland substrate of the present invention comprises the following steps:

[0022] A certain quality of construction waste waste red brick blocks is sent to the impact crusher 2 through the belt conveyor 1 for crushing; then, the crushed components are sent to the coarse powder mill 4 through the belt conveyor 3 for crushing, The pulverized product is the constructed wetland matrix prepared in the present invention.

[0023] The characteristics of the discarded red brick blocks used in the present invention are: the maximum diameter is no more than 250mm, is a kind of construction waste, and is mainly composed of red bricks.

[0024] The main parameters of belt conveyor 1 and belt conveyor 3 adopted in the present invention are: belt width 400mm, conveying length 12-20m, power 2.2-4kW, conveying speed 1.25-2.0m / s, conveying capacity 5-15t / h .

[0025] The main parameters of the impact crusher 2 used in the present invention are: sp...

Embodiment 1

[0029] 10t of waste red brick blocks from construction waste are sent to the impact crusher 2 through the belt conveyor 1 for crushing; then, the crushed components are sent to the coarse powder mill 4 through the belt conveyor 3 for crushing. The product is the constructed wetland matrix prepared in the present invention.

[0030] The characteristics of the discarded red brick blocks used in the present invention are: the maximum diameter is not more than 250 mm, it is a kind of construction waste, and its mass is 10 tons.

[0031] The main parameters of belt conveyor 1 and belt conveyor 3 adopted in the present invention are: belt width 400mm, conveying length 12-20m, power 2.2-4kW, conveying speed 1.25-2.0m / s, conveying capacity 5-15t / h .

[0032] The main parameters of the impact crusher 2 used in the present invention are: specification Φ1000mm×700mm, feed inlet size 400mm×730mm, maximum feed size 250mm, processing capacity 10-20t / h, electrode power 10-20kW.

[0033] Th...

Embodiment 2

[0036] Send 15t of waste red brick blocks from construction waste to the impact crusher 2 through the belt conveyor 1 for crushing; then, send the crushed components to the coarse powder mill 4 through the belt conveyor 3 for crushing, after crushing The product is the constructed wetland matrix prepared in the present invention.

[0037] The characteristics of the discarded red brick blocks used in the present invention are: the maximum diameter is not more than 250 mm, it is a kind of construction waste, and its mass is 10 tons.

[0038] The main parameters of belt conveyor 1 and belt conveyor 3 adopted in the present invention are: belt width 400mm, conveying length 12-20m, power 2.2-4kW, conveying speed 1.25-2.0m / s, conveying capacity 5-15t / h .

[0039] The main parameters of the impact crusher 2 used in the present invention are: specification Φ1000mm×700mm, feed inlet size 400mm×730mm, maximum feed size 250mm, processing capacity 10-20t / h, electrode power 10-20kW.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com