Method for applying starch modified stuffing in paper making

An application method and starch modification technology, applied in the field of papermaking, can solve the problems of increasing factory investment risks and costs, and achieve the effects of improving water filtration performance, improving paper strength, and reducing loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

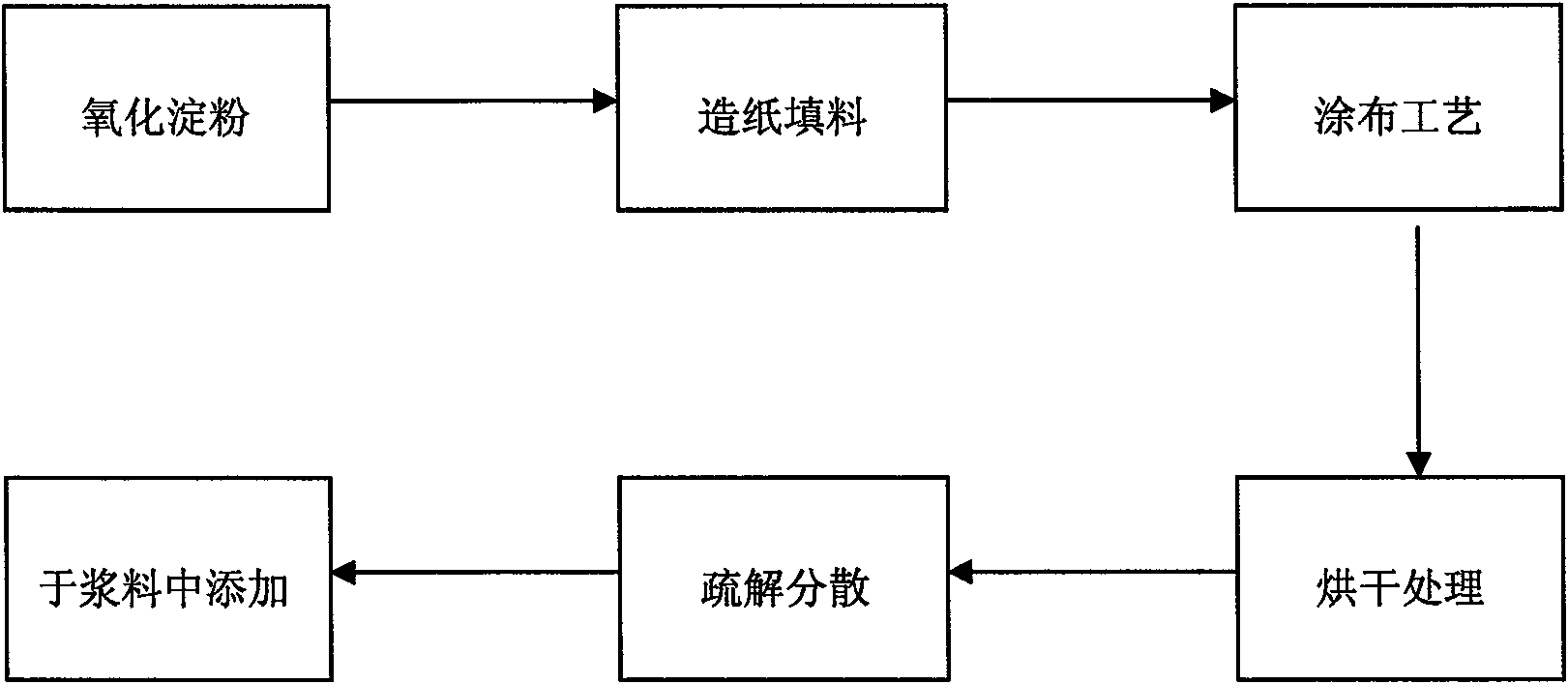

Method used

Image

Examples

Embodiment 1

[0022] First, weigh 80 g of dry corn oxidized starch, add water to 400 g, and make 20% starch concentration. After fully stirring evenly, place the emulsion in a heating bag with a temperature control system to increase the temperature, fully cook and stir, and react at 95°C for 20 minutes.

[0023] Secondly, the above-mentioned starch and heavy calcium carbonate C65 were formulated into a coating according to the ratio of 40:60, and dispersed in a high-speed disperser at 3000 R / min for 20 minutes. The solid content of the dispersed paint is about 50%, and the viscosity is about 800cps. Then use 80g / m 2 The base paper, the control coating amount is 60g / m 2 Left and right, evenly coat and dry in the coater for later use. Again, weigh 50g of foamed pulp from the spare coated paper, and evenly disperse the pulp in a pulper for 5 minutes, and set aside.

Embodiment 2

[0025] First take by weighing 160g of absolute dry tapioca oxidized starch, add water to 400g, make 40% starch concentration. After fully stirring evenly, place the emulsion in a heating bag with a temperature control system to increase the temperature, fully cook and stir, and react at 95°C for 20 minutes.

[0026] Secondly, the above-mentioned starch and heavy calcium carbonate C65 were formulated into a coating according to the ratio of 30:70, and dispersed in a high-speed disperser at 3000 R / min for 20 minutes. The solid content of the dispersed paint is about 50%, and the viscosity is about 800cps. Then use 80g / m 2 The base paper, the control coating amount is 60g / m 2 Left and right, evenly coat and dry in the coater for later use. Again, weigh 50g of foamed pulp from the spare coated paper, and evenly disperse the pulp in a pulper for 5 minutes, and set aside.

[0027] Finally, the above-mentioned paper stock was applied to the handsheet with an addition amount of 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com