Preparation method and application of ball-milling organic modified bentonite for retention and filter aids in papermaking

A retention and drainage aid, bentonite technology, applied in the direction of retention aid addition, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as difficulty in ensuring product uniformity, large equipment investment, and surfactant pollution, and achieve improved Retention and drainage effect, simple preparation method, effect of improving retention rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Disperse 5g of bentonite with a 200-mesh sieve in 100ml of water, stir on a magnetic stirrer for 0.5h, and place it in an ultrasonic instrument for 10min to make the bentonite fully disperse into a suspension in water;

[0035] (2) Take 16g of surfactant STAB and add 100ml of distilled water to form a solution, add 45% of the surfactant relative to the mass of bentonite to the pretreated bentonite suspension, stir for 5 minutes, and then place it in a water bath at 60°C After reacting for 3 hours, take it out, place it in a Buchner funnel, and wash it with distilled water several times under the hydraulic suction filter until the filtrate washed out is in the AgNO 3Until there is no white precipitate under titration, the filter cake obtained by suction filtration is dried in a vacuum oven at 50°C for 30 minutes to obtain organically modified bentonite;

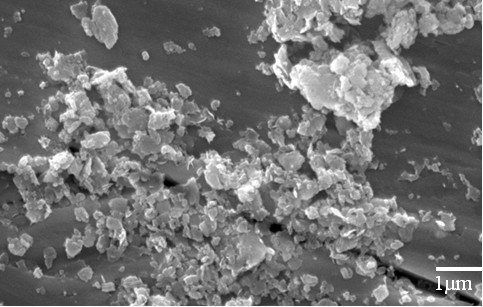

[0036] (3) Put the organically modified bentonite in step (2) in the ball mill tank of the planetary ball mill an...

Embodiment 2

[0039] (1) Disperse 5g of bentonite with a 200-mesh sieve in 100ml of water, stir on a magnetic stirrer for 1 hour, and place it in an ultrasonic instrument for 20 minutes of ultrasound to fully disperse the bentonite into a suspension in water;

[0040] (2) Take 30g of surfactant STAB and add 100ml of distilled water to make a solution, add 30% of the surfactant relative to the mass of bentonite to the pretreated bentonite suspension, stir for 10 minutes, and then place it in a water bath at 90°C After 2 hours of reaction, take it out, place it in a Bourg-style funnel, and rinse it with distilled water several times under a hydraulic suction filter until the filtrate washed out is in the AgNO 3 Titrate until there is no white precipitate, and dry the filter cake obtained by suction filtration in a vacuum oven at 30°C for 60 minutes;

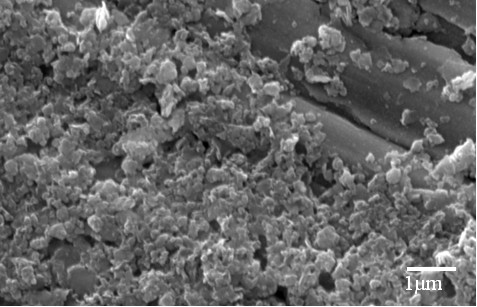

[0041] (3) Put the organically modified bentonite in the ball mill tank of the planetary ball mill and mill for 2 hours. The mass ratio of the ...

Embodiment 3

[0044] (1) Take a certain amount of bentonite, pass it through a 200-mesh sieve, take 5g of the sieved bentonite and disperse it in 100ml of water, stir it on a magnetic stirrer for 0.5h, put it in an ultrasonic instrument for 10min, and make the bentonite fully dispersed in water into a suspension liquid;

[0045] (2) Take 40g of surfactant STAB and add 100ml of distilled water to make a solution, add 25% of surfactant relative to the mass of bentonite to the pretreated bentonite suspension, stir for 5 minutes, and then place in a water bath at 70°C After reacting for 3 hours, take it out, place it in a Buchner funnel, and wash it with distilled water several times under the hydraulic suction filter until the filtrate washed out is in the AgNO 3 Titrate until there is no white precipitate, and dry the filter cake obtained by suction filtration in a vacuum drying oven at 80°C for 30 minutes;

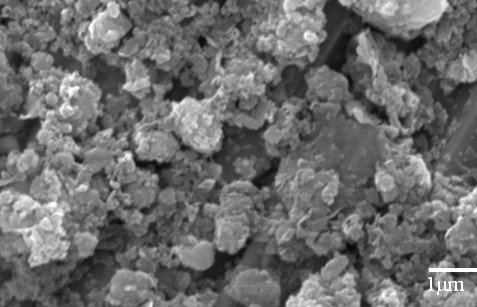

[0046] (3) Put the organically modified bentonite in the ball mill tank of the plan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| lattice spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com