Starch composition, preparation method thereof and pulp using the starch composition

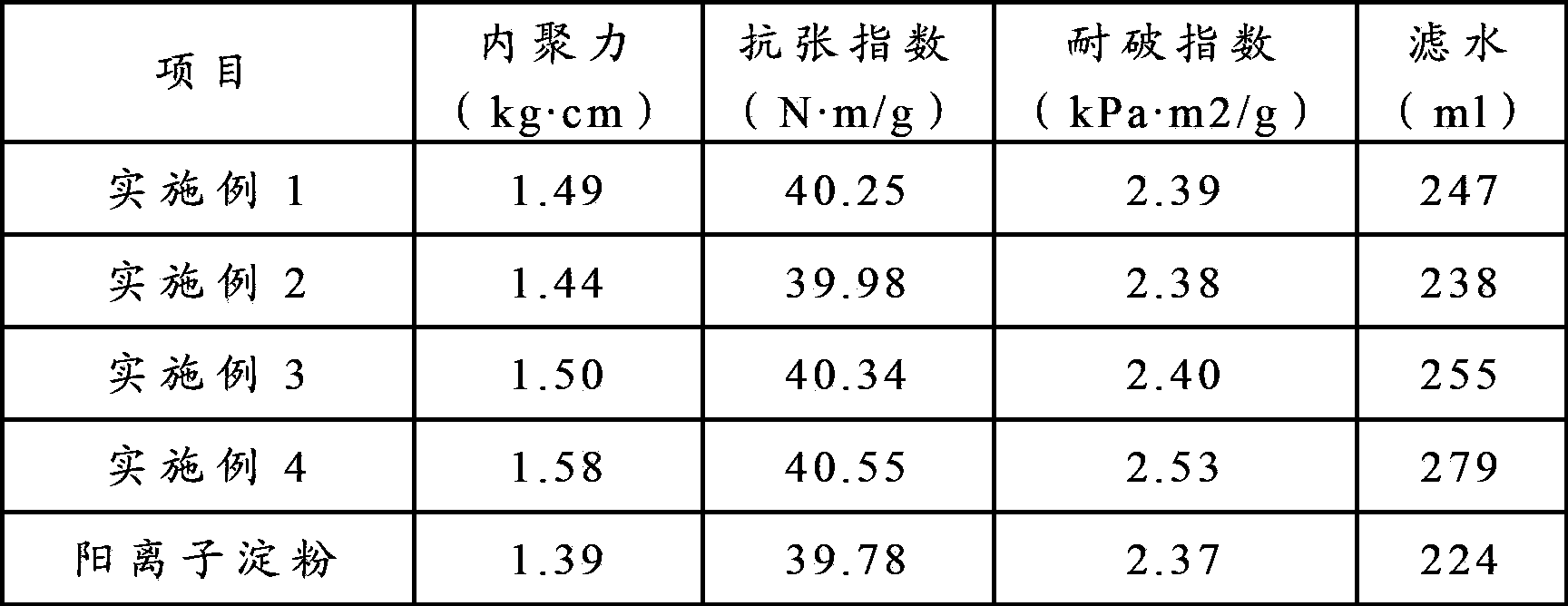

A technology of composition and starch, which is applied in the direction of non-fibrous pulp addition, fiber raw material treatment, retention aid addition, etc., can solve the problems of retention and drainage, and paper strength is not obvious, so as to improve pulp retention and The effects of water filtration performance, burst resistance index improvement, and ash retention improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

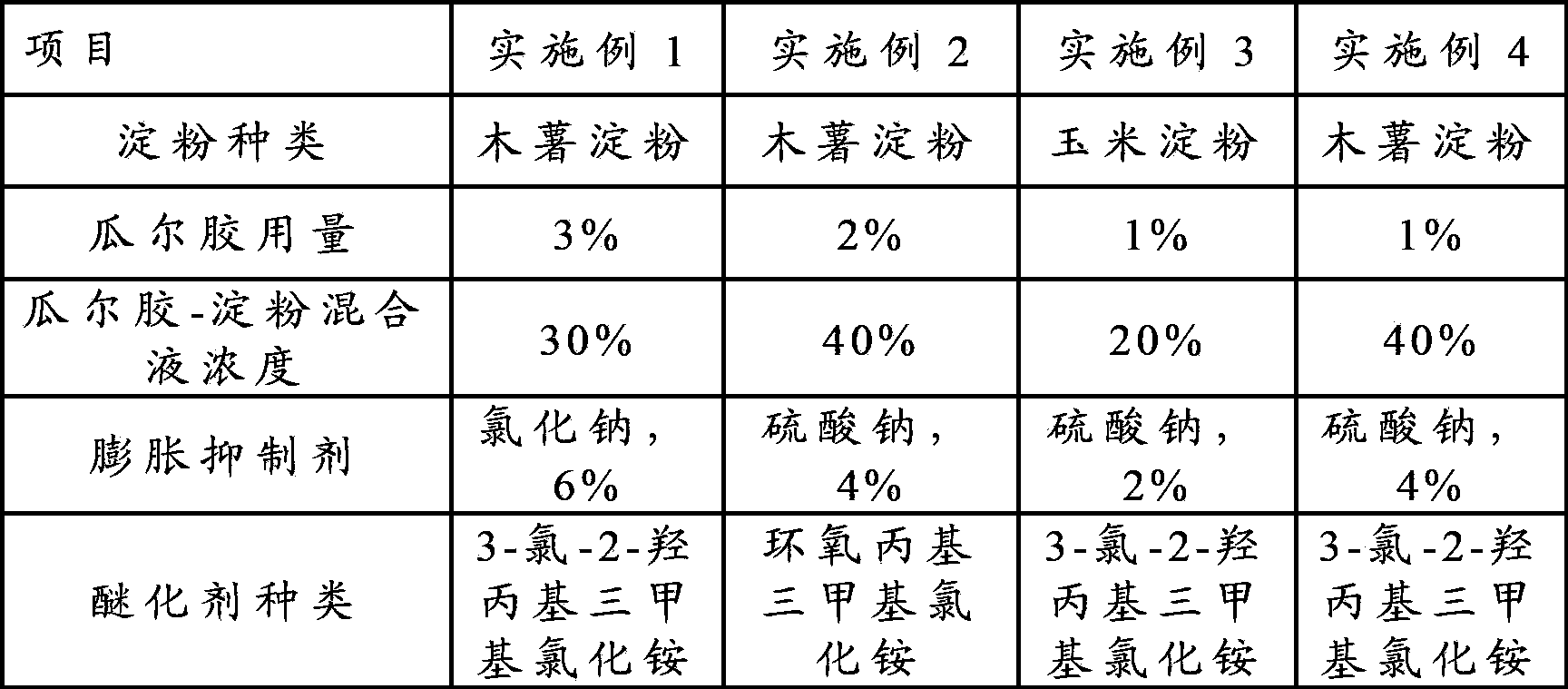

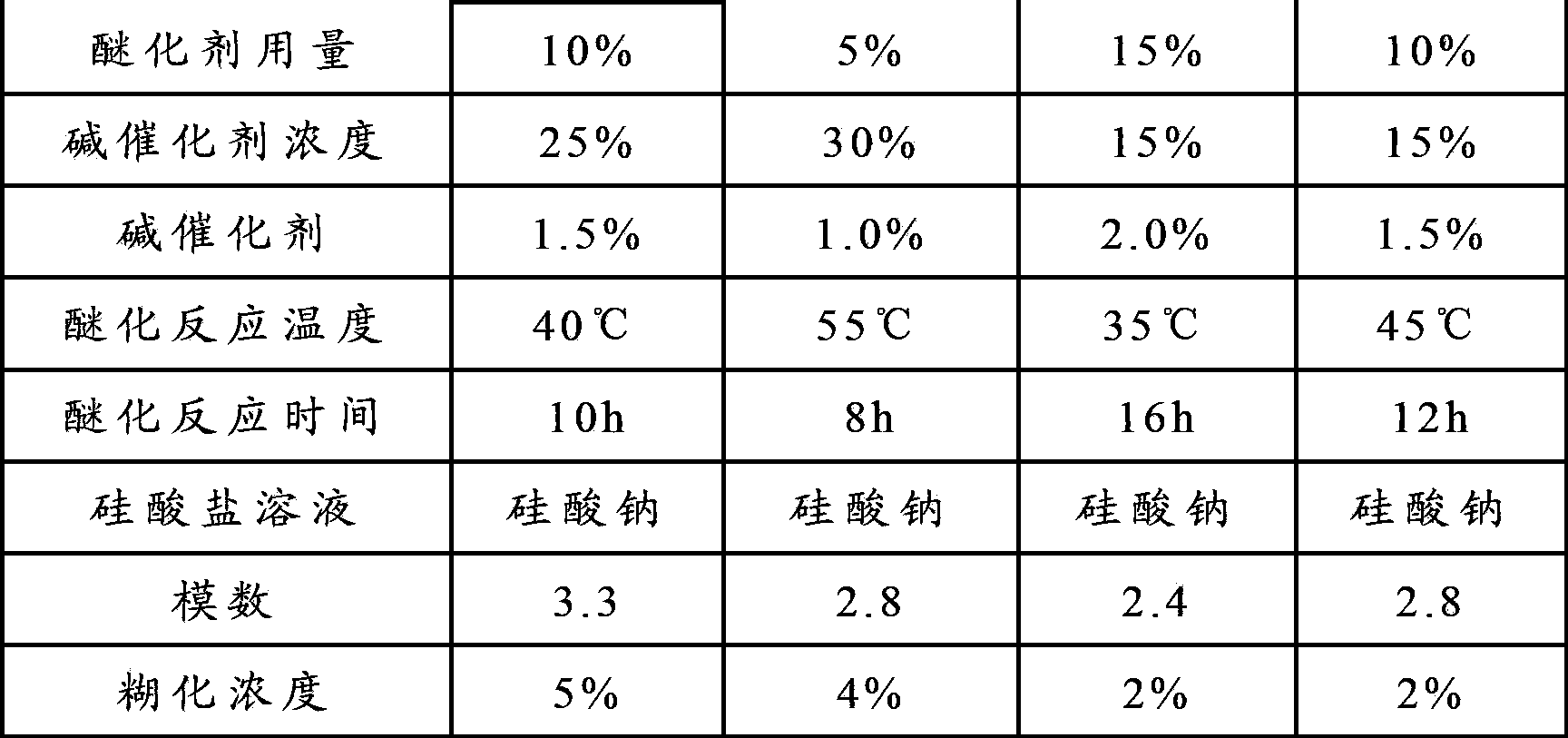

[0017] The preparation method of this modified starch composition, it comprises the steps:

[0018] (1) Take a certain amount of guar gum and raw starch, add water and mix evenly to form a starch-guar gum mixture, wherein the dry weight of the guar gum is 1.0%-3.0% of the dry weight of the raw starch. The solid content of the starch-guar gum mixture is 20%-40%.

[0019] The native starch may preferably be at least one of tapioca starch, corn starch, potato starch, and wheat starch, but not limited to the above-mentioned several, as long as it is native starch. The order of adding the guar gum and the original starch is not limited, it can be that the original starch is added first and then the guar gum is added, or the guar gum is added first and then the original starch is added, or the guar gum and the original starch are mixed together and added to the water .

[0020] Guar gum and starch are a two-phase system. From the perspective of its chemical structure, guar gum has...

Embodiment 1

[0042] Weigh 9g guar collagen powder (moisture content 12%), add it into 577g water under stirring state, after being uniformly dispersed, continue to add 300g tapioca starch (moisture content 14%) and stir evenly to obtain a concentration of 30% starch and Guar gum mixture. Add 15.5g of NaCl expansion inhibitor to the uniformly dispersed above mixed solution, stir evenly, then add 3-chloro-2-hydroxypropyltrimethylammonium chloride preactivated by 25% sodium hydroxide solution solution (concentration is 70%), wherein the sodium hydroxide solution consumption is 15.9g, the etherification agent 3-chloro-2-hydroxypropyltrimethylammonium chloride solution consumption is 38.0g, after stirring at room temperature for 30min, the temperature is raised to React at 40°C for 10h. After the reaction is over, add a certain amount of water to dilute the above mixed solution to a concentration of 5%, and then add 152g of sodium silicate aqueous solution to the diluted solution (the effectiv...

Embodiment 2

[0044] Weigh 6g of guar collagen powder (moisture content 12%), add it into 352g of water under stirring, after being uniformly dispersed, continue to add 300g of tapioca starch (moisture content 14%) and stir evenly to obtain a concentration of 40% starch and Guar gum mixture. Add 10.3g of Na to the uniformly dispersed above mixed solution 2 SO 4 Swelling inhibitor, stir evenly, then add glycidyltrimethylammonium chloride solution (concentration is 70%) preactivated by 30% sodium hydroxide solution, wherein the sodium hydroxide solution consumption is 8.8g, ether The dosage of the oxidation agent glycidyltrimethylammonium chloride solution was 18.8 g, and after stirring at room temperature for 30 min, the temperature was raised to 55° C. for 8 h. After the reaction, add a certain amount of water to dilute the above mixed solution to a concentration of 4%, and then add 75.2g of sodium silicate aqueous solution to the diluted solution (the effective concentration of sodium si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com