Patents

Literature

36results about How to "Reduce poor quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

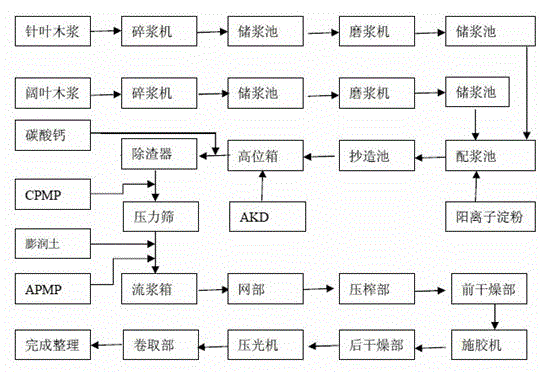

Method for producing highly quantitative two-side offset paper

ActiveCN103603225AImprove water filtration performanceReduce poor qualityChemical/chemomechanical pulpPaper-making machinesSulfatePulp and paper industry

The invention belongs to papermaking technologies and relates to a method for producing highly quantitative two-side offset paper. The method comprises the following steps: sequentially performing pulping, size mixing, sizing, manufacturing paper with pulp, pre-drying, surface sizing, after-drying, press polish and rolling on basic raw materials such as bleached sulfate needlebush pulp and bleached sulfate broadleaf wood pulp, and finally finishing into paper; and allowing the materials in the pulping process to sequentially pass through a pulper, a pulp storage pool, a pulp grinder and the pulp storage pool according to a material transfer sequence, wherein in the pulping process, the pulping beating degree of the bleached sulfate needlebush pulp in the basic raw materials is required to be 25-320SR, and the pulping beating degree of the bleached sulfate broadleaf wood pulp is required to be 24-330SR. According to the method, the highly quantitative two-side offset paper can be manufactured with pulp, and the manufactured paper is high in surface strength, high in internal binding force, high in smoothness and small in two-side difference.

Owner:ZHENJIANG DADONG PULP & PAPER

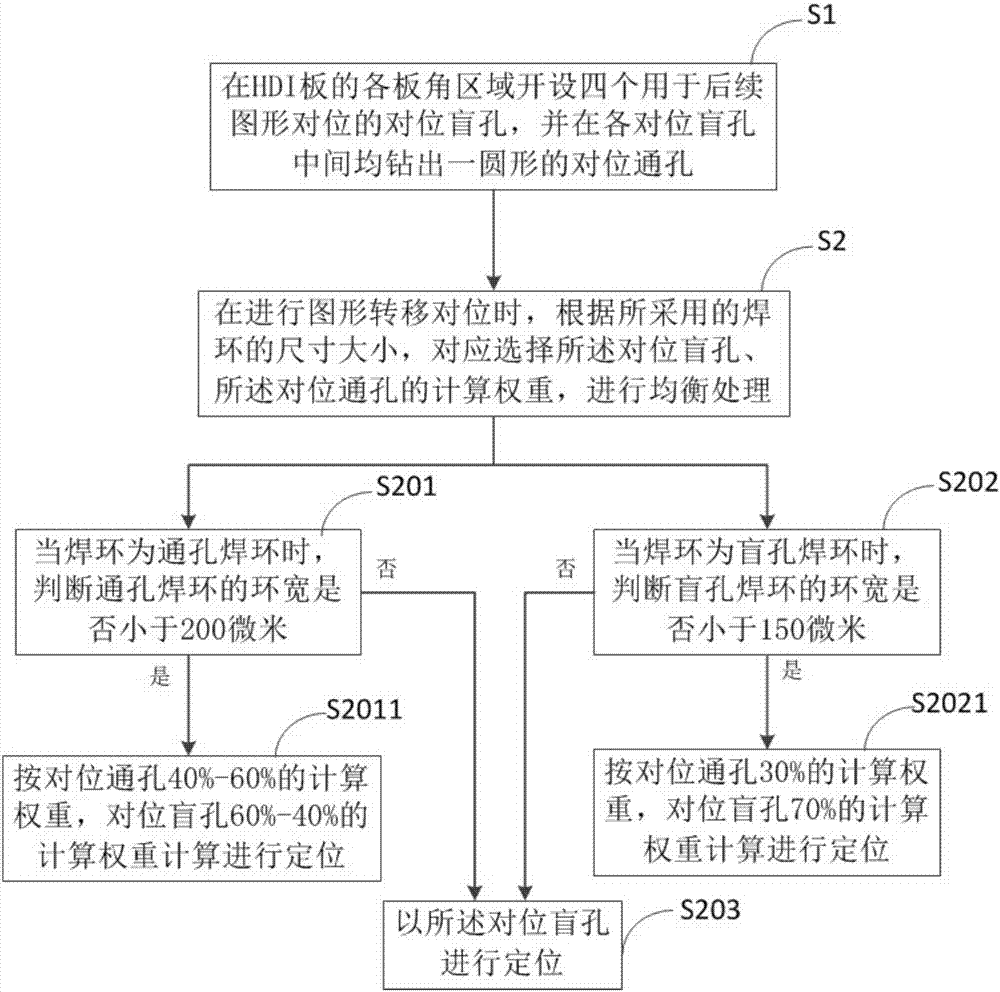

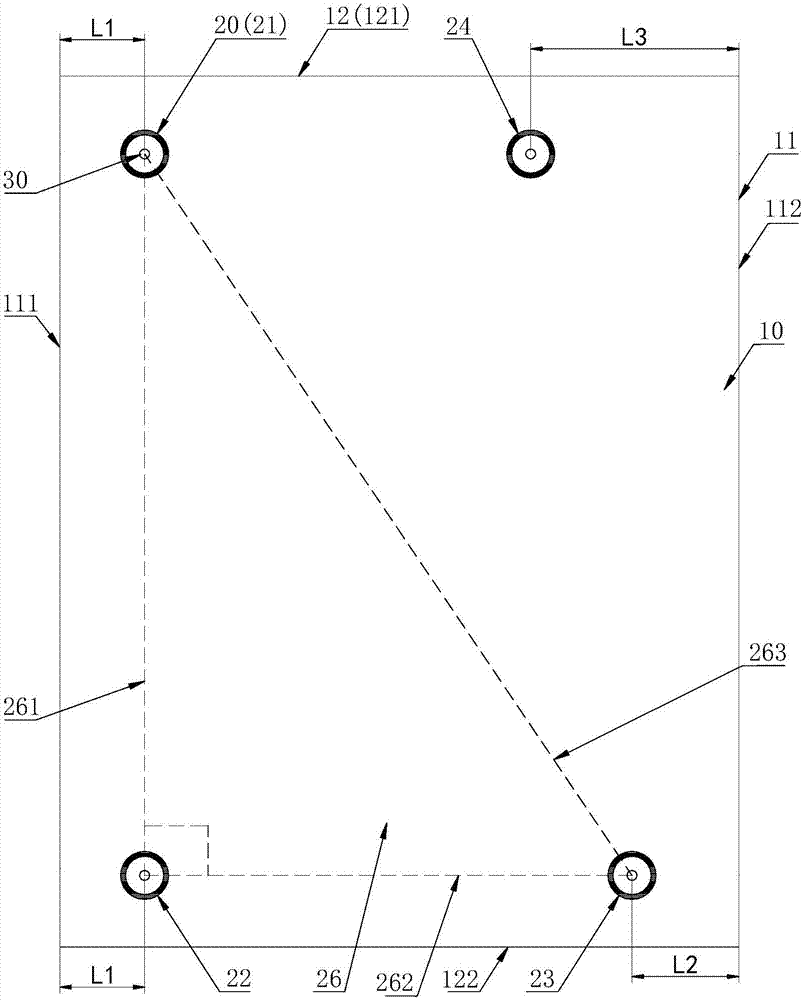

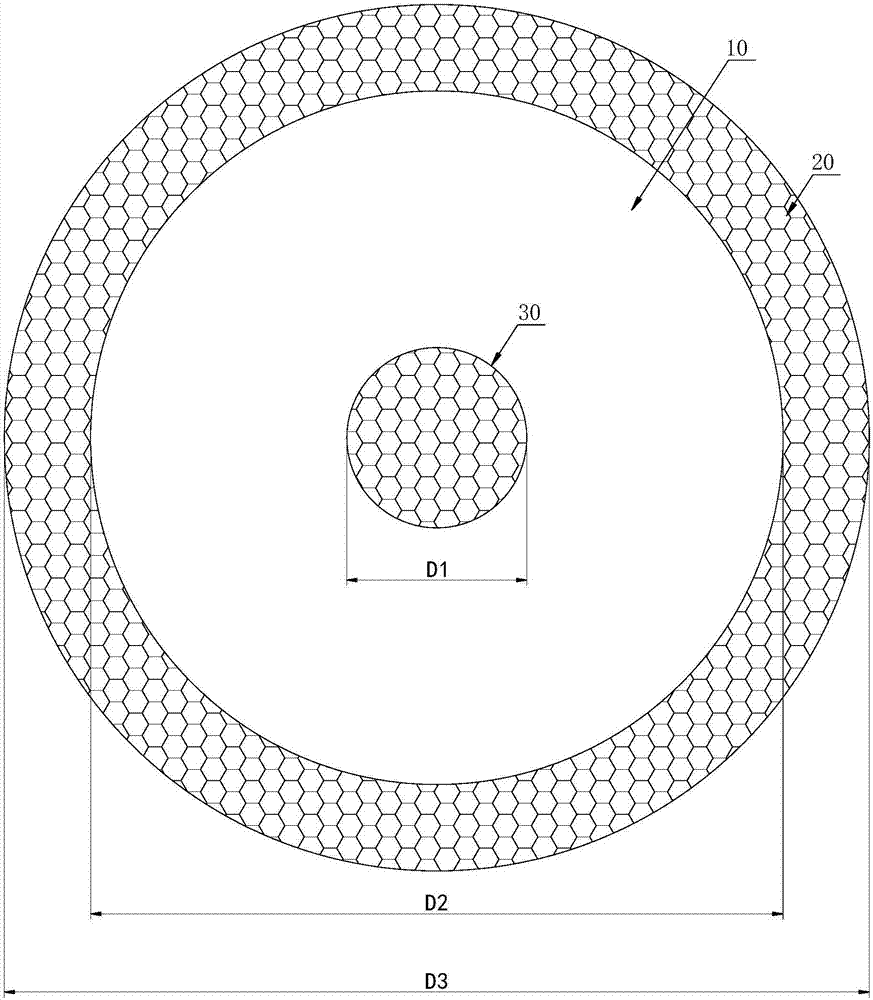

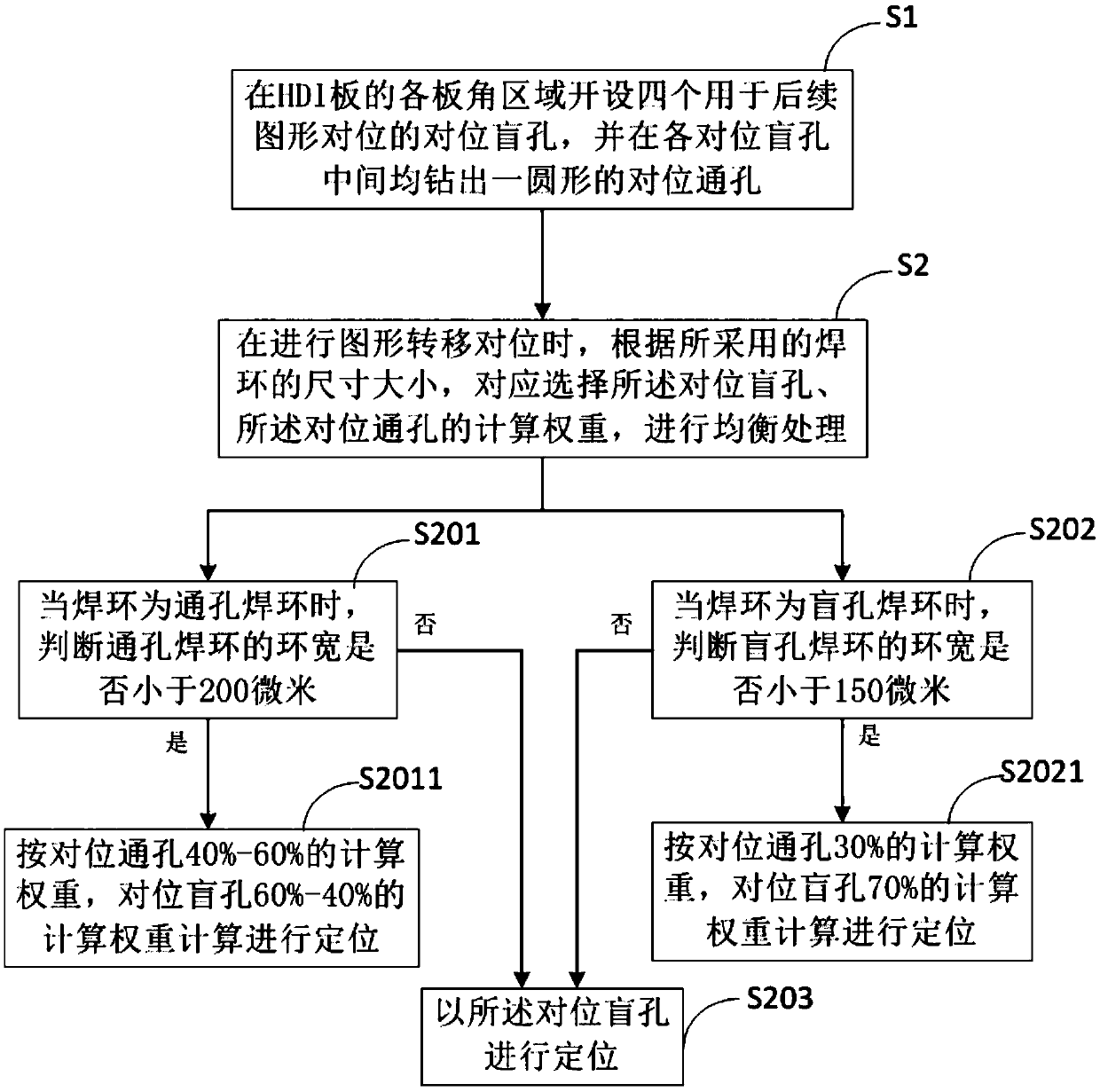

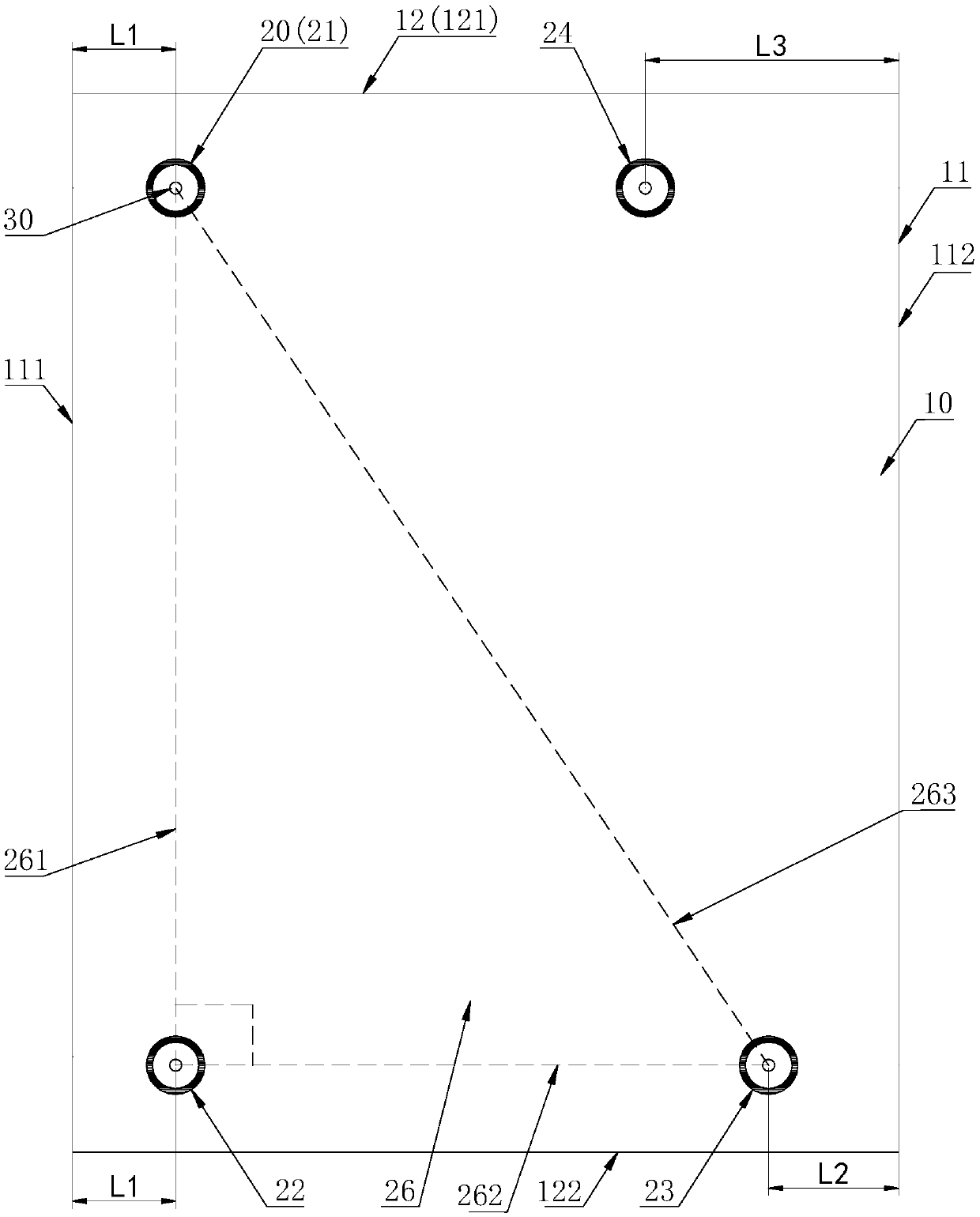

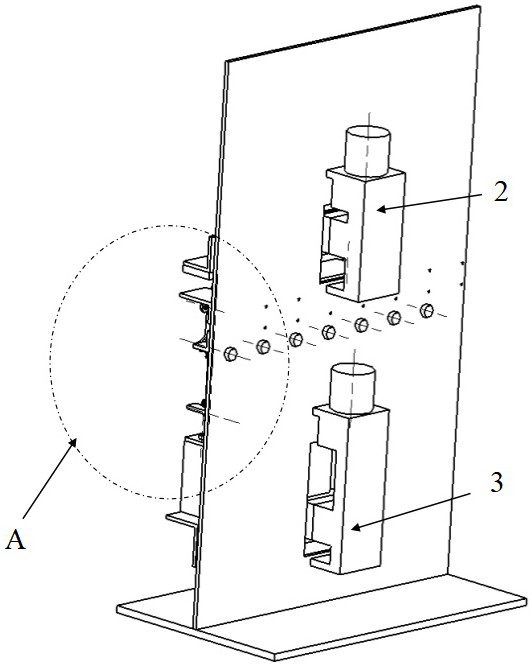

Pattern compound alignment method

ActiveCN107295751AImprove alignment efficiencyReduce poor qualityInspection/indentification of circuitsPrinted circuit manufactureEngineeringPoor quality

The invention discloses a pattern compound alignment method, and the method comprises the steps: four alignment blind holes for following pattern alignment are arranged on corner areas of an HDI board, a circular alignment through hole is arranged on each center of the alignment blind holes, when pattern transferring alignment is performed, calculation weights of the alignment blind holes and the alignment through holes are correspondingly selected according to sizes of adopted welding rings, and balanced-processing is performed, wherein the welding rings include blind hole welding rings and through hole welding rings. According to the invention, through hole alignment targets and blind hole alignment targets are mixed in alignment targets, when pattern alignment is performed, two kinds of alignment targets are captured to balance alignment bias caused by two kinds of hole types, the pattern alignment efficiency is greatly improved, poor quality is reduced, alignment precision is improved, a pattern target fused with plate edge design of an HDI product is added to a design operation module, and automatic operation is realized.

Owner:MEIZHOU ZHIHAO ELECTRONICS TECH

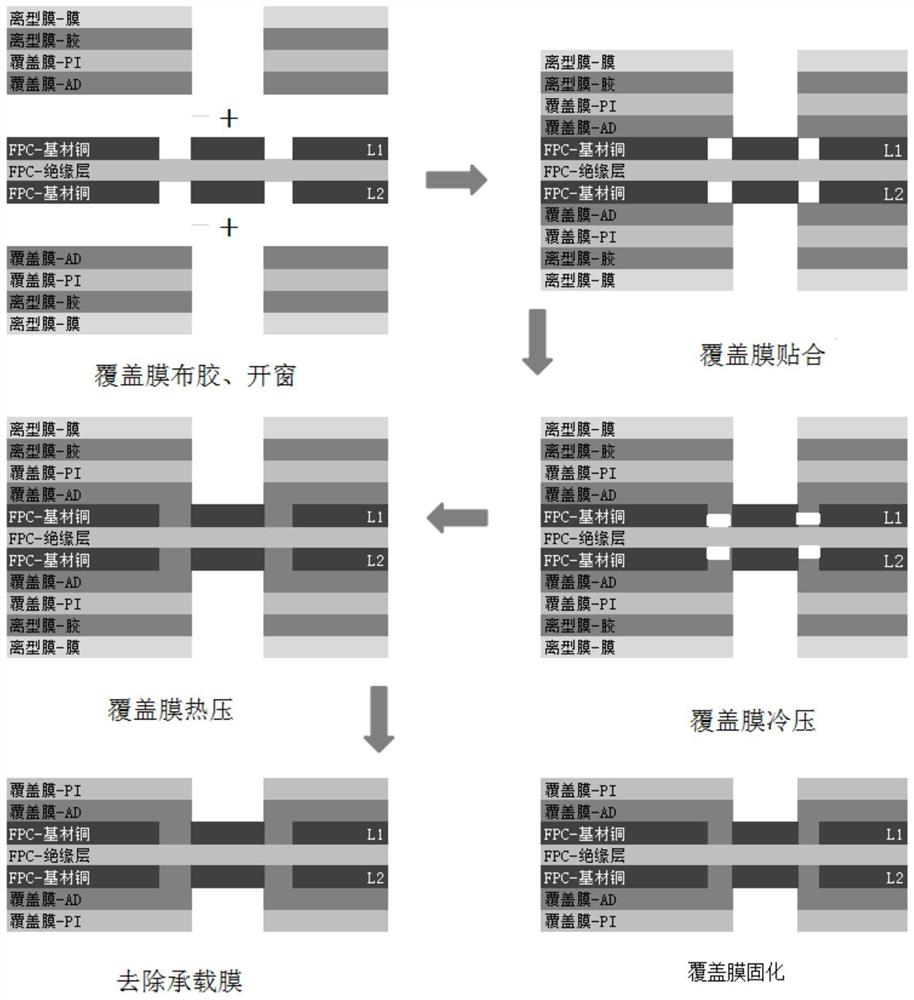

Wireless charging coil plate surface cover film laminating method

InactiveCN112074087AHigh precisionMinimize deflection issuesPrinted circuit manufactureCopper foilEngineering

The invention discloses a wireless charging coil plate surface cover film laminating method, which comprises the following steps: 1) material preparation: preparing a soft copper foil substrate to belaminated with a film and a cover film with a corresponding size, wherein the cover film comprises a PI layer and an AD layer; 2) cover film glue distribution: performing cold-pressing on a layer of transparent bearing film ion the cover film PI layer; 3) cover film windowing: punching and windowing the cover film and the bearing film together through a die; 4) laminating a cover film: taking downthe cover film, removing the release paper on the cover film, sleeving the PIN, and carrying out alignment lamination; 5) cover film cold pressing: performing vacuum cold pressing on the cover film;6) cover film hot pressing: performing hot pressing on the cover film; and 7) cover film curing: tearing off the transparent bearing film on the surface of the PI layer of the cover film, and baking and curing to obtain a semi-finished FPC board. The laminating precision of the cover film is improved, and the problems of laminating deviation and poor sol of the ultrathin cover film are solved.

Owner:江西一诺新材料有限公司

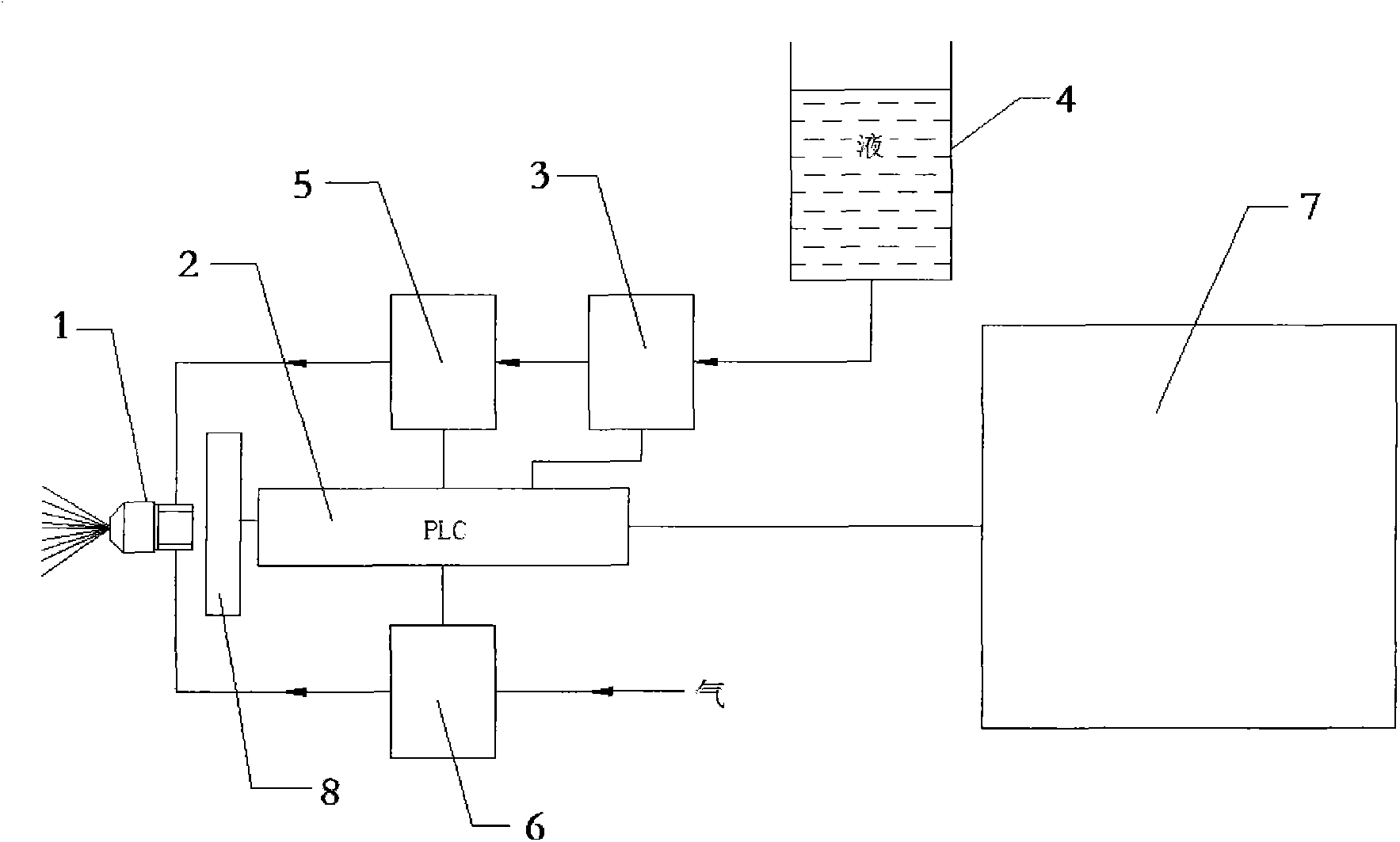

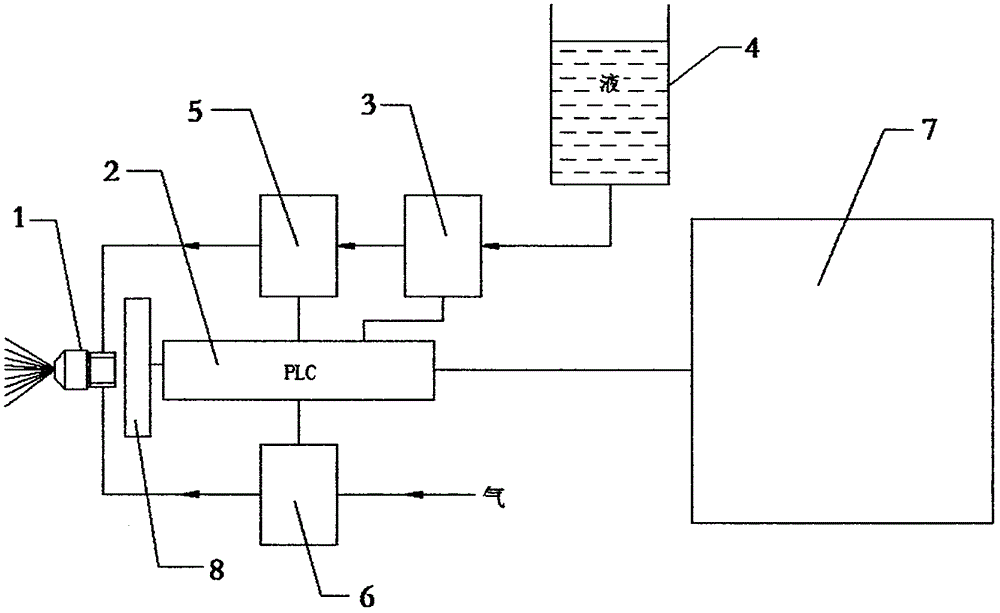

Automatic diluent adding instrument used in precision industrial silk-screen printing

The invention discloses a precision industrial silk-screen printing instrument and particularly relates to an automatic diluent adding instrument used in precision industrial silk-screen printing. With the automatic diluent adding instrument used in precision industrial silk-screen printing, the timed cost is effectively saved, the adding precision is improved, and the processing technology is stabilized. The automatic diluent adding instrument comprises a miniature mist air spray nozzle, a gas-liquid electromagnetic valve, a PLC (Programmable Logic Controller), a water pump, an intermediate relay and a container tank, wherein the container tank is used for storing a diluent, a liquid inlet, an air inlet and a spray opening are formed in the miniature mist air spray nozzle, the gas-liquid electromagnetic valve comprises a liquid valve assembly and a gas valve assembly, and the intermediate relay is used for calculating sprinkling time and spaced time; the container tank is communicated with the liquid inlet through the water pump, the liquid valve assembly is arranged between the water pump and the liquid inlet, and the air inlet is communicated with the gas valve assembly; the PLC is connected with the intermediate relay, the water pump, the liquid valve assembly and the gas valve assembly.

Owner:BLTY HUNAN TECH

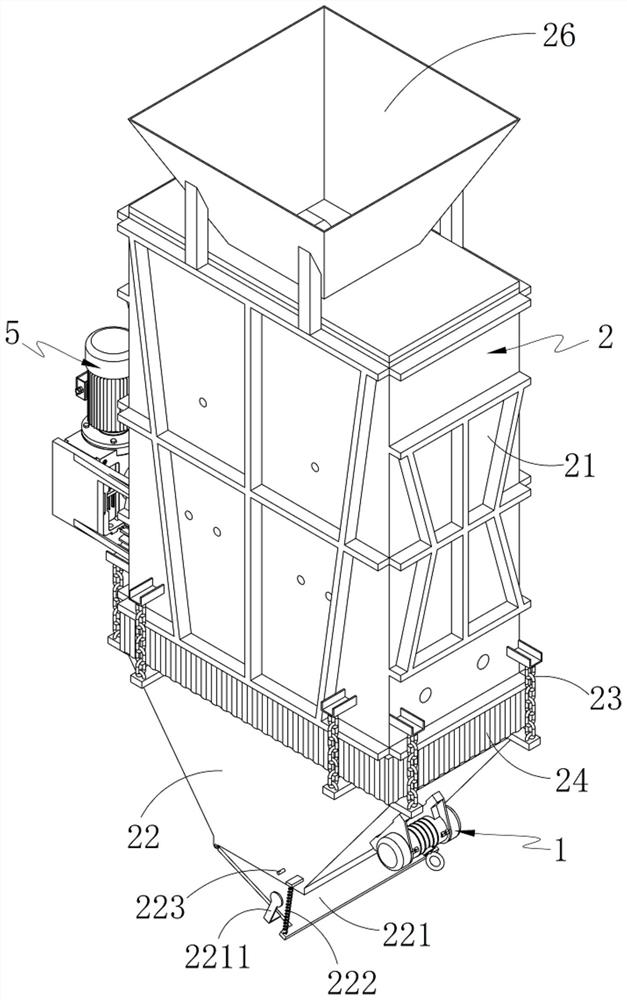

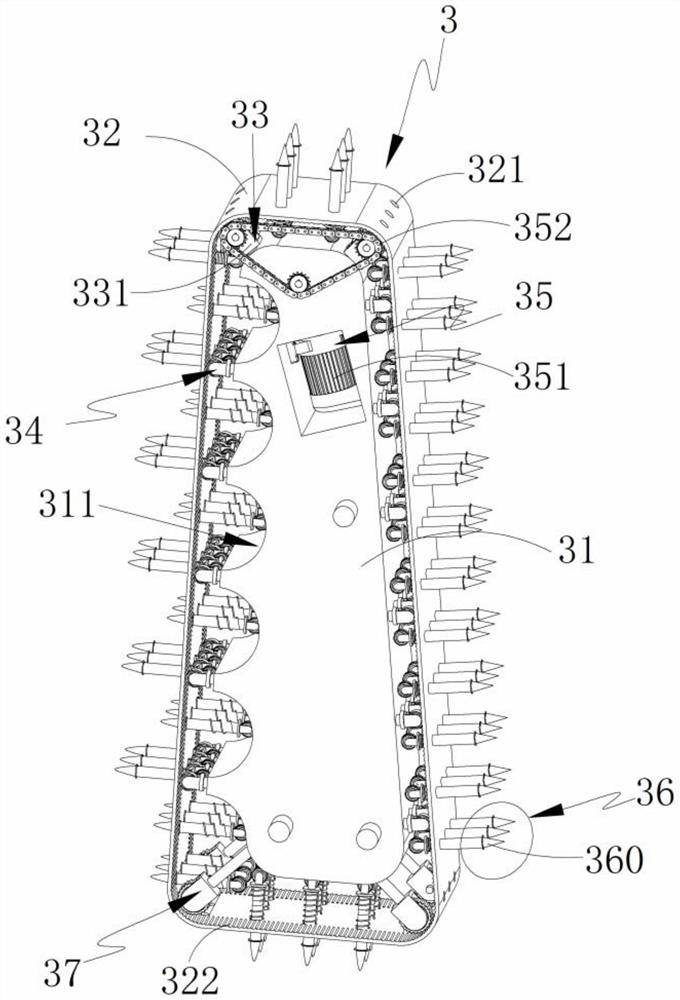

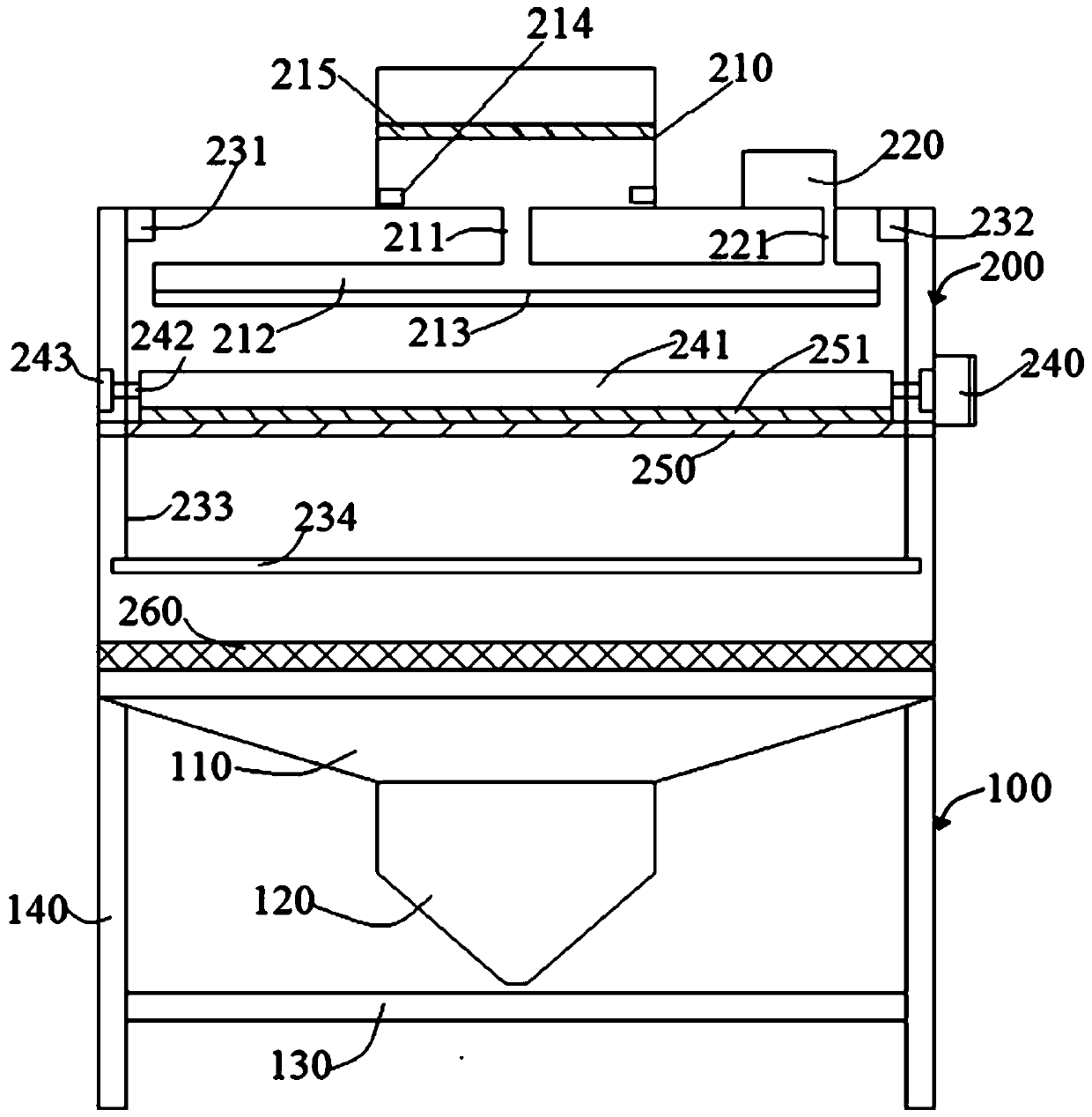

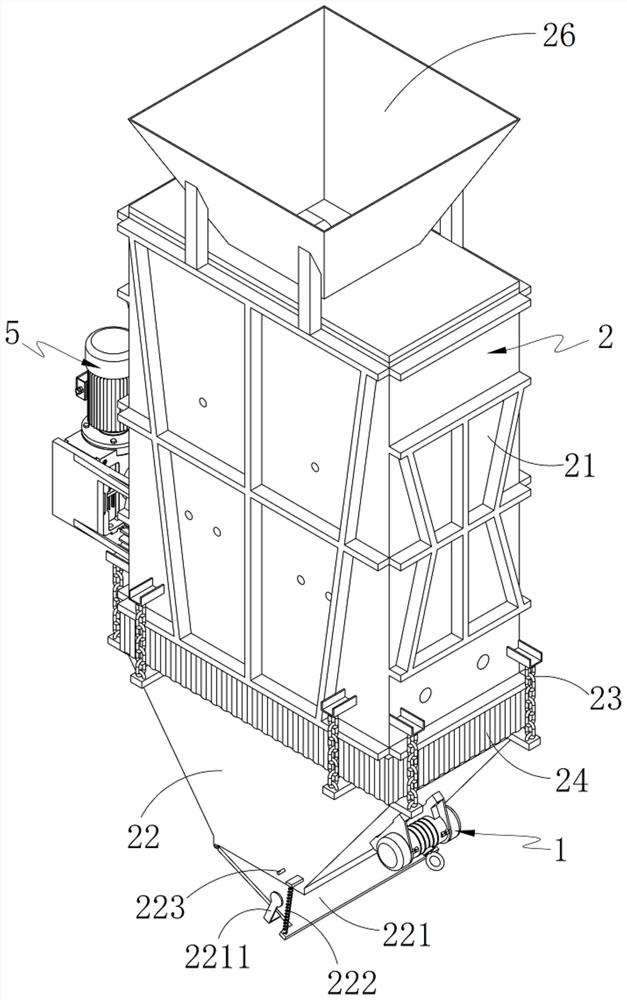

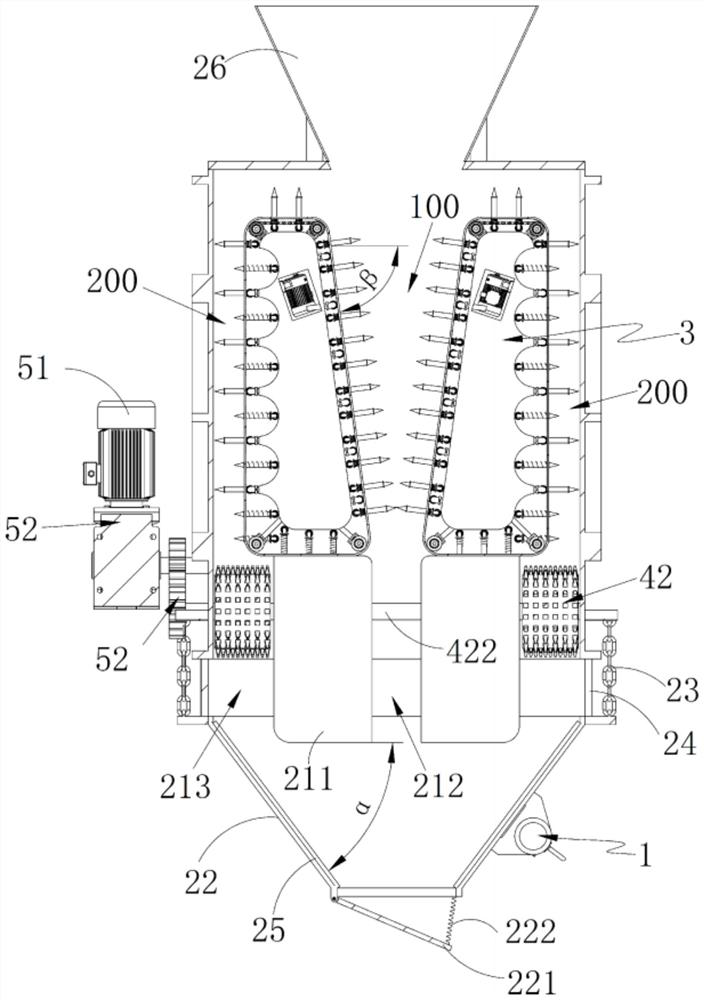

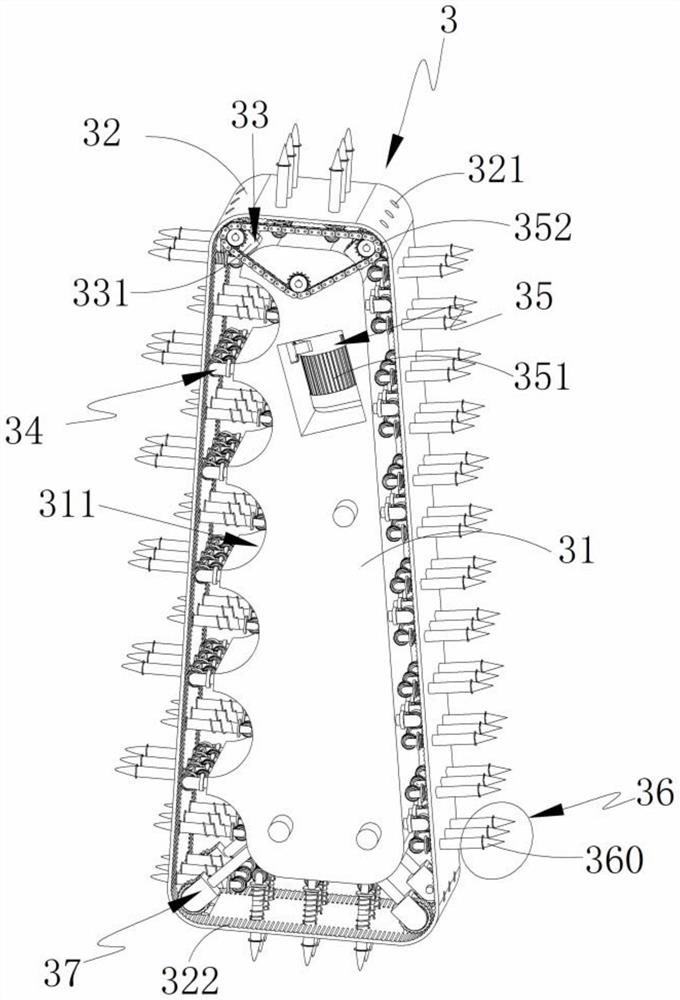

Raw material batching station with stable batching function

ActiveCN112275360AUniform sizeReduced weight differenceGrain treatmentsElectric machineryProcess engineering

The invention provides a raw material batching station with a stable batching function. The raw material batching station comprises a hopper unit, pre-crushing units and secondary crushing assemblies.When materials are located in a primary screening and crushing space, the screening and pre-crushing units are used for lifting and screening the materials, so that the primary crushing effect is achieved; and when the materials are conveyed to secondary crushing spaces, the secondary crushing assemblies are used in cooperation with concave-convex tracks arranged on screening mounting frames in the descending process, large materials are subjected to secondary crushing multiple times, crushing units arranged below the secondary crushing spaces are used for crushing the materials which are notcrushed in a tertiary mode, and it is guaranteed that the particle size of the flowing-out material is uniform and consistent. Due to the split design of the hopper unit and a vibration motor on oneside of the hopper, the problem of material accumulation is effectively solved, it is guaranteed that the mass of the materials falling per unit area is equal during continuous discharging, thus, it is guaranteed that the final proportion meets the technological requirement, the yield of cement clinker is increased, and the production efficiency is improved.

Owner:广德独山南方水泥有限公司

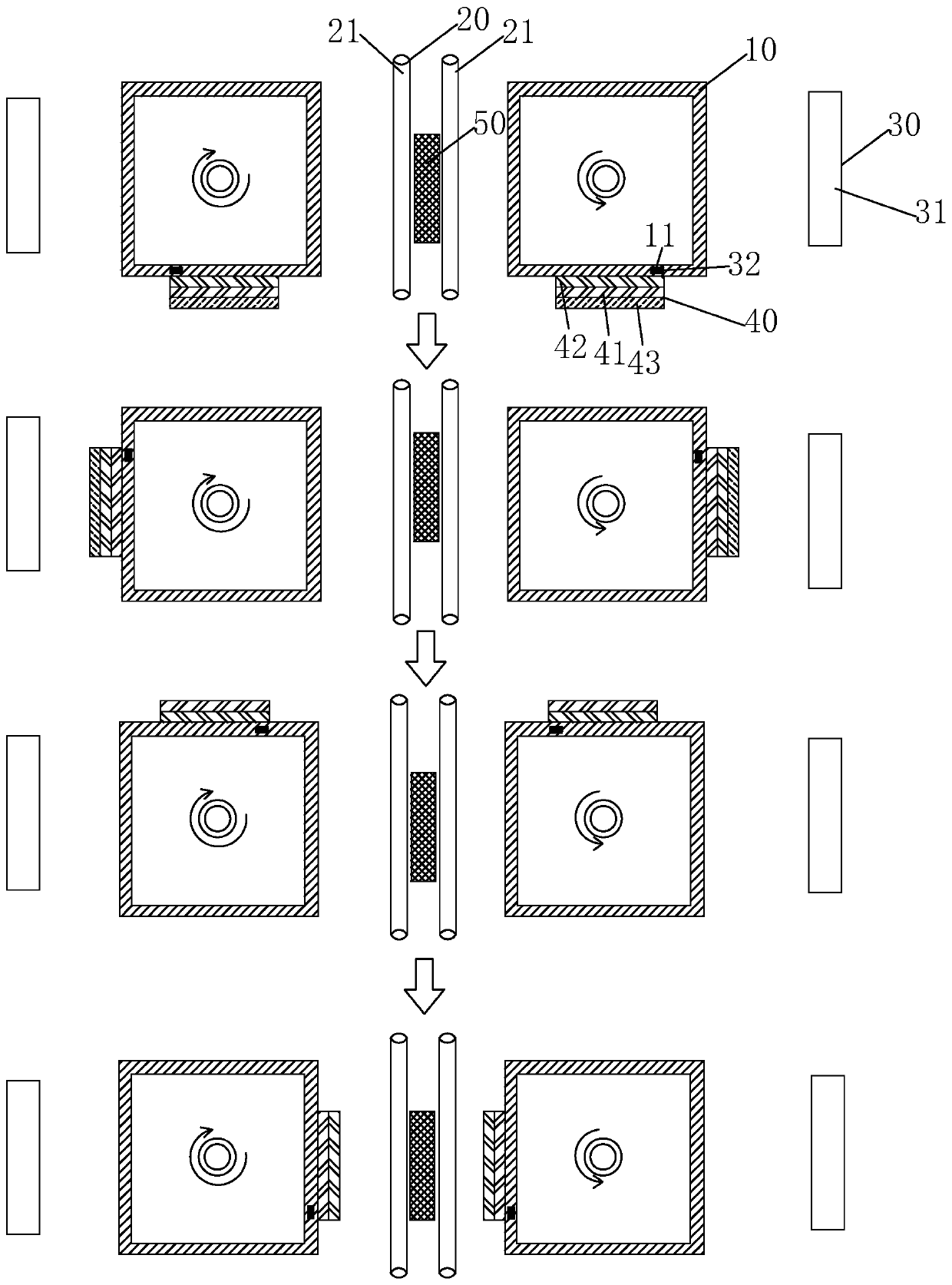

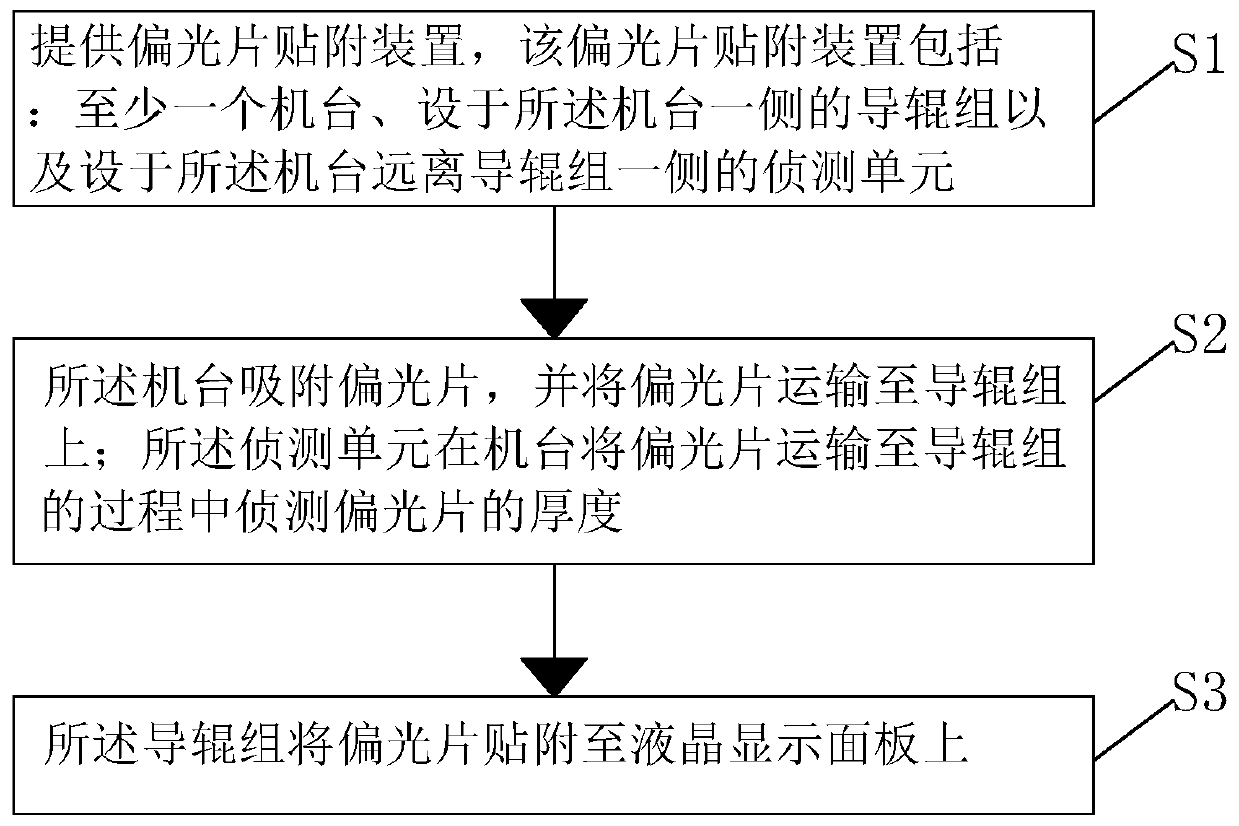

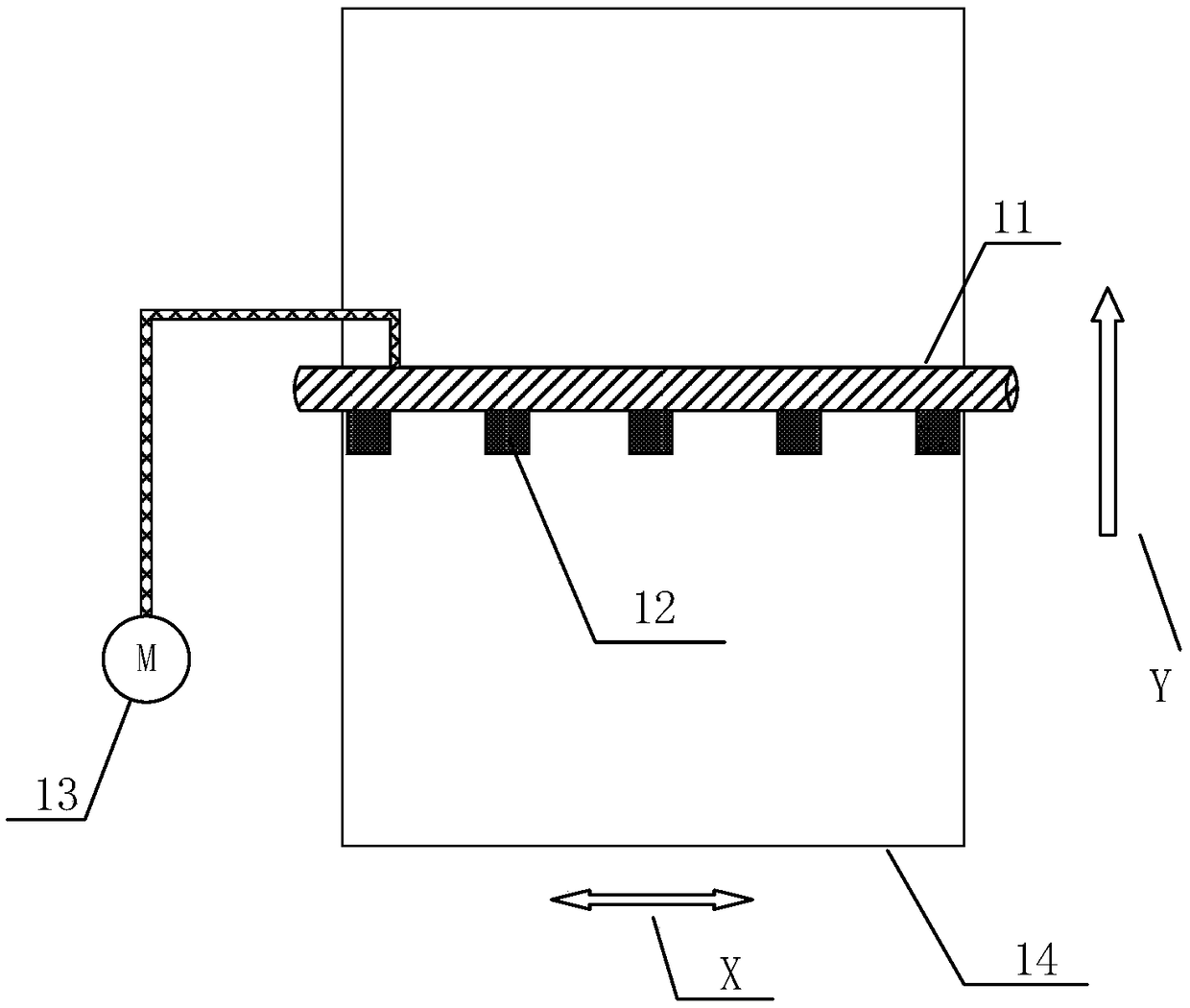

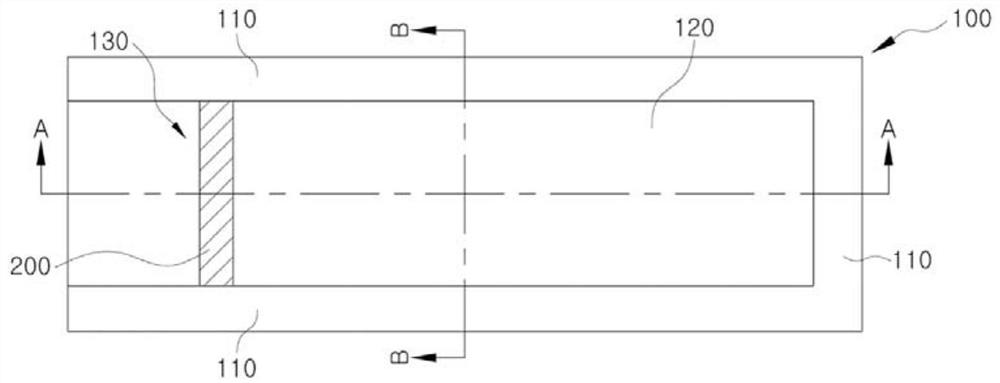

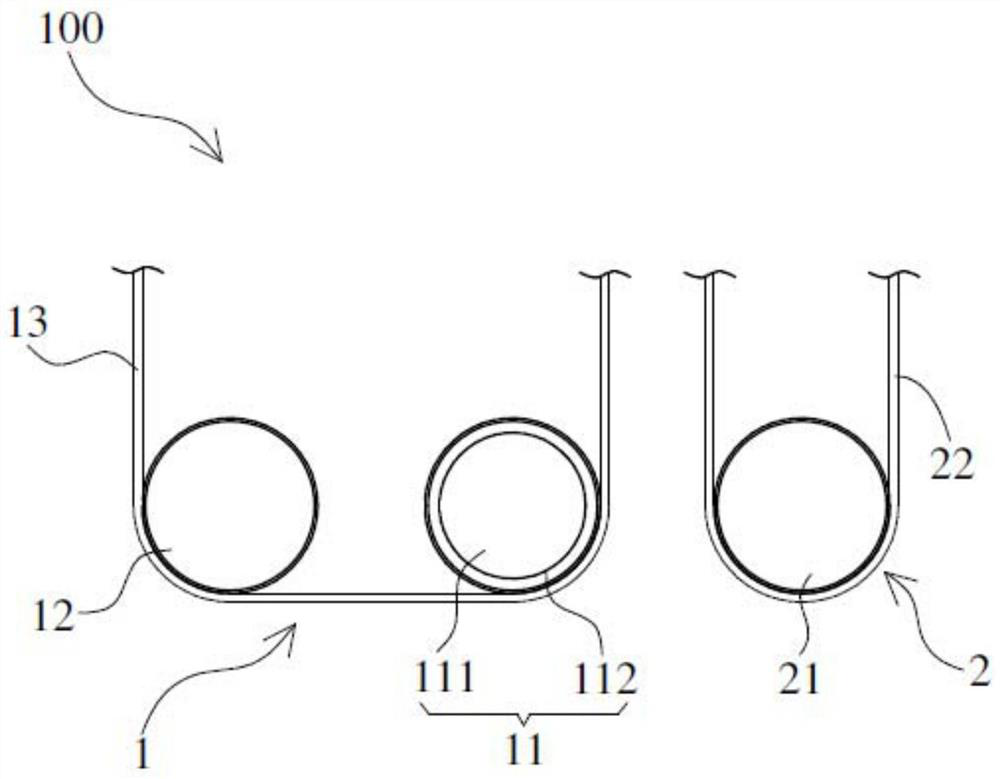

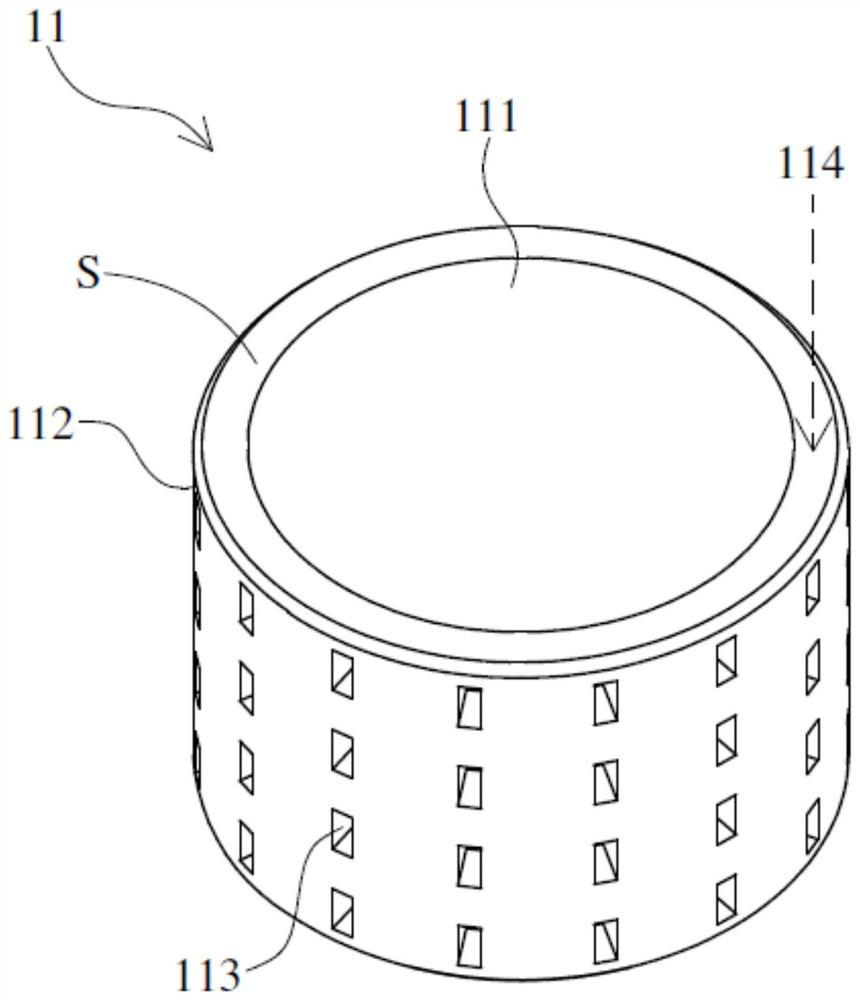

Polaroid attaching device and polaroid attaching method

InactiveCN109856826AIncrease the chance of being stoppedReduce poor qualityNon-linear opticsLiquid-crystal displayPoor quality

The invention provides a polaroid attaching device and a polaroid attaching method. The polaroid attaching device comprises at least one bench, guide roller set arranged at one side of the bench, anda detection unit arranged at one side, away from the guide roller set, of the bench. The bench is used for absorbing a polaroid and conveying the polaroid to the guide roller set. The guide roller setis used for absorbing the polaroid to a liquid crystal display panel. The detection unit is used for detecting the thickness of the polaroid during the process of conveying the polaroid to the guideroller set on the bench. Therefore, the number of the polaroids absorbed by the bench can be detected effectively, so that the stopping-checking probability of selecting multiple ones from the polaroids is increased and thus the poor quality phenomenon is reduced. According to the provided method, the number of the polaroids absorbed by the bench can be detected effectively; the stopping-checkingprobability of selecting multiple ones from the polaroids is increased; and the poor quality phenomenon is reduced.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

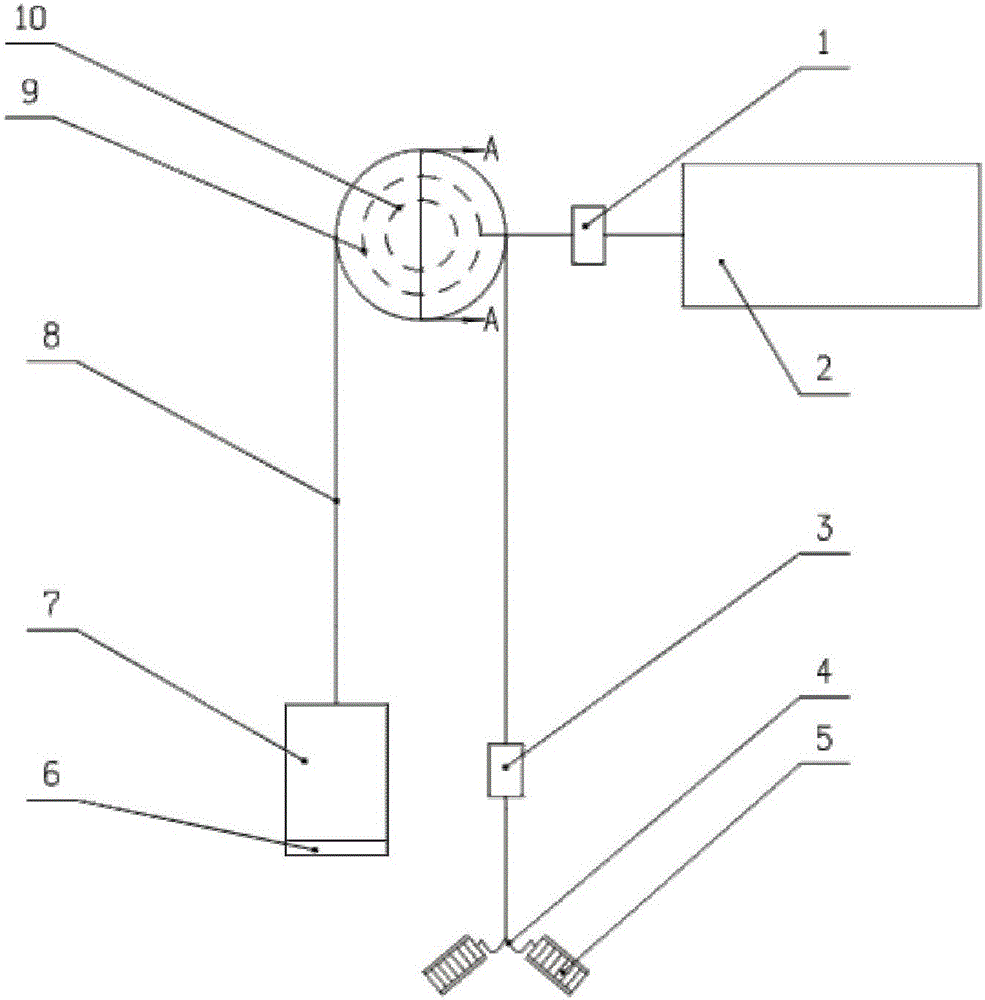

Automatic balance weight energy-saving control system for elevator

InactiveCN105712134AImprove running stabilityReduce torqueElevatorsSustainable buildingsControl systemEngineering

The invention relates to an automatic balance weight energy-saving control system for an elevator. A control mechanism is connected with a pressure sensor. The pressure sensor is located at the lower portion of a bottom plate of an elevator car. When an elevator door is closed, the elevator is electrified to enter a working state. Pressure data signals of the pressure sensor are transmitted to the control mechanism. The control mechanism receives the data of the pressure sensor. Balance weight assemblies are matched with an eight-claw hook so that a give balance weight value given by the control mechanism is selected; and the elevator car is connected with a motor and a clutch through a traction steel rope, and the motor, the clutch and a fixed balance weight are connected with the eight-claw hook through a traction steel rope. An electric storing device is connected with the control mechanism. The control system selects the balance weight assembly with the matched weight through cooperation of an automatic balance weight device and the control mechanism, the mass difference between the elevator car and the balance weight is reduced, and the variable balance weight is effectively achieved; and the balance weight assembly is used for achieving mutual conversion of gravitational potential energy in the elevator running process, and electric energy consumption is reduced on the basis that stable operation of the elevator is guaranteed.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

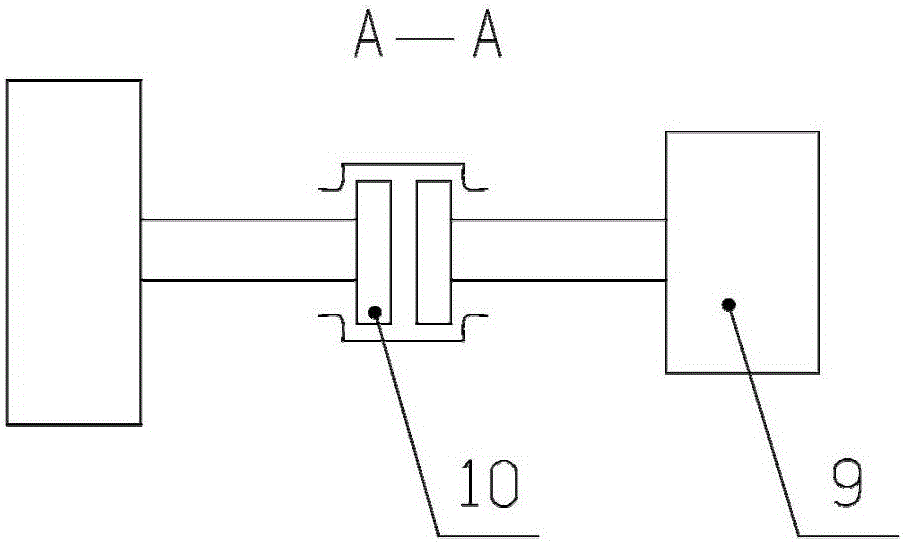

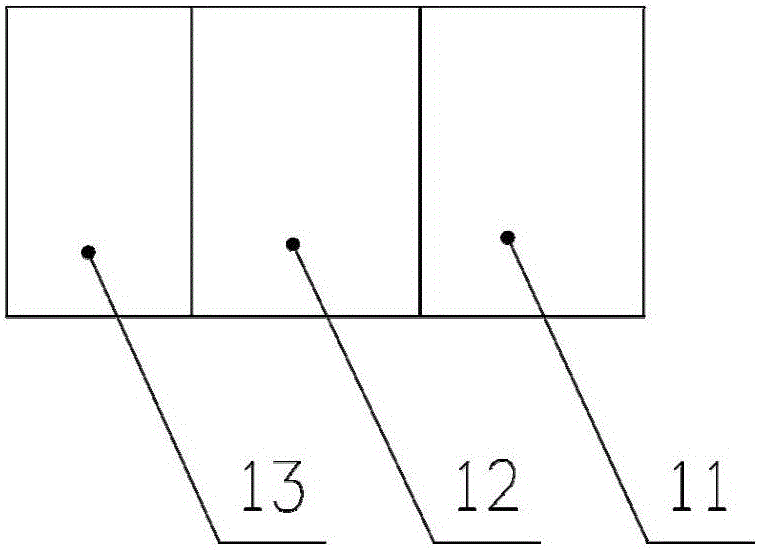

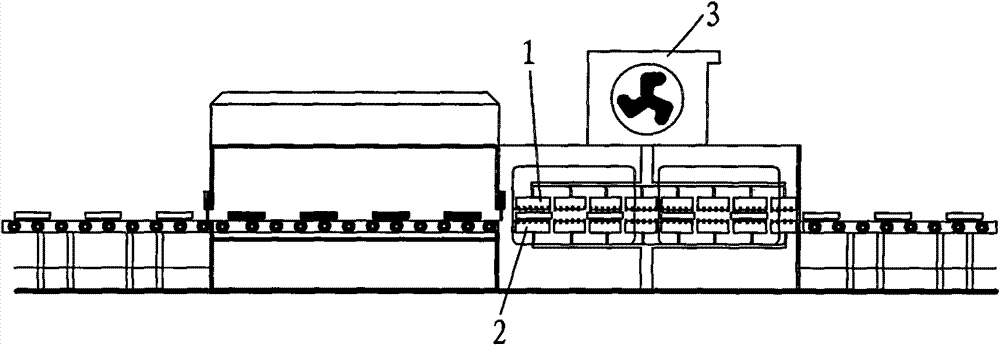

Heat treatment enhanced glass air cushion bed device

ActiveCN101671112BReduce poor qualityCool evenlyGlass tempering apparatusGlass productionEngineeringToughened glass

The invention discloses a heat treatment enhanced glass air cushion bed device, comprising an upper blowing device and an air cushion bed; wherein the upper blowing device and the inner part of the air cushion bed are hollow, and upper blowing device and the air cushion bed are respectively provided with at least one air inlet which is connected with an air duct of a blower, the upper blowing device and the air cushion bed are arranged up and down in parallel, the bottom surface of the upper blowing device is opposite to the top surface of the air cushion bed, and a plurality of air outlets are uniformly distributed on the top surface and the bottom surface, and a space for leading glass o pass through is kept between the top surface and the bottom surface. The device can eliminate all disadvantages of the glass with a transmission type cooling way, the purpose of realizing super-flat and spotless horizontal tempering glass is realized, and the surface quality of the tempering glass is greatly improved.

Owner:信义超薄玻璃(东莞)有限公司

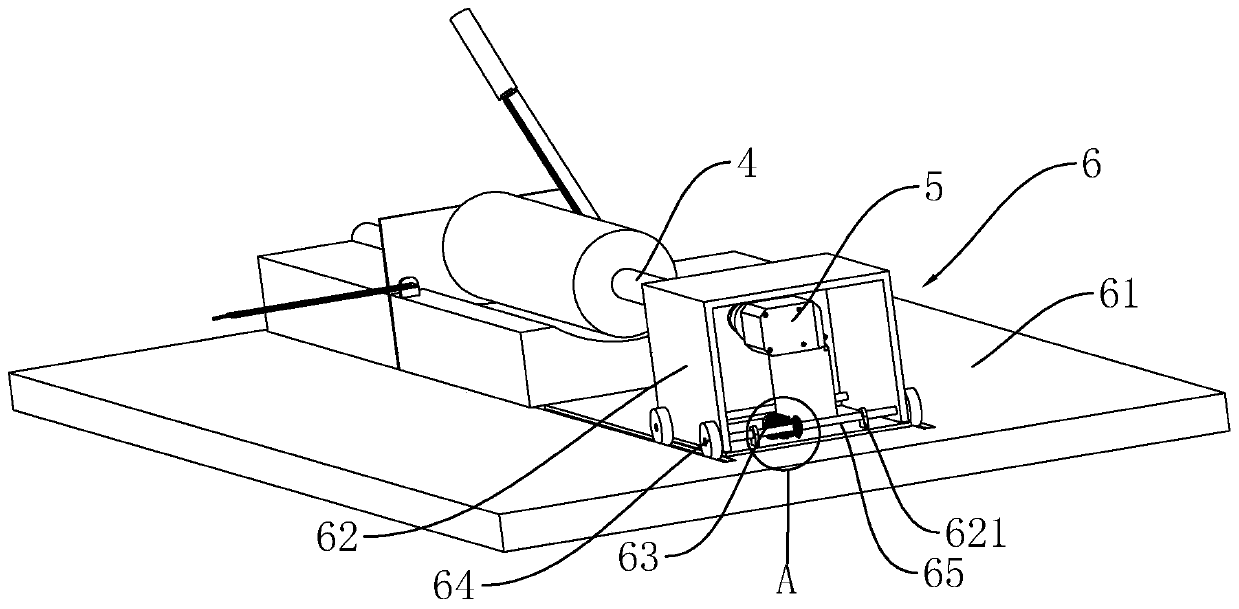

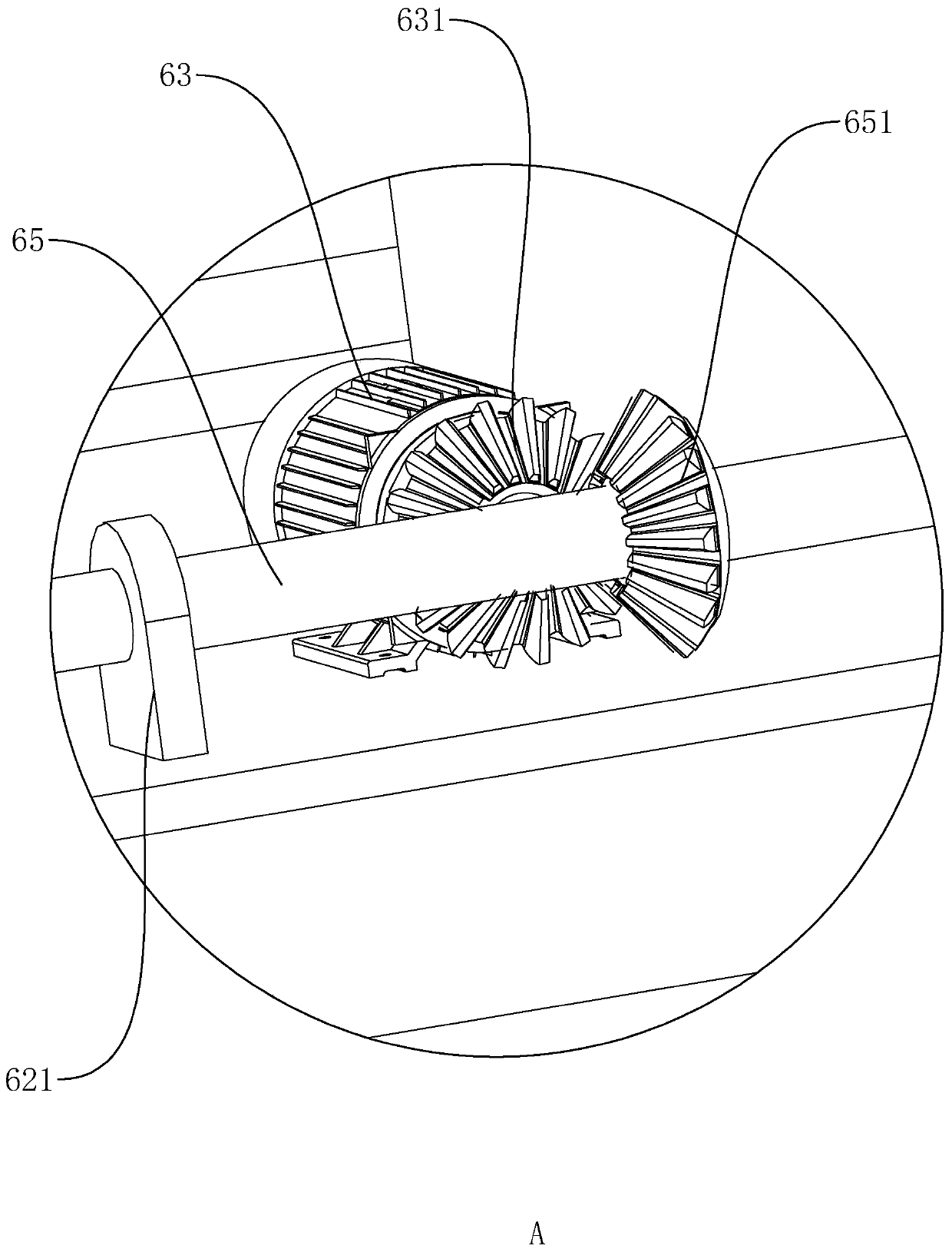

Glue coating machine for wallpaper

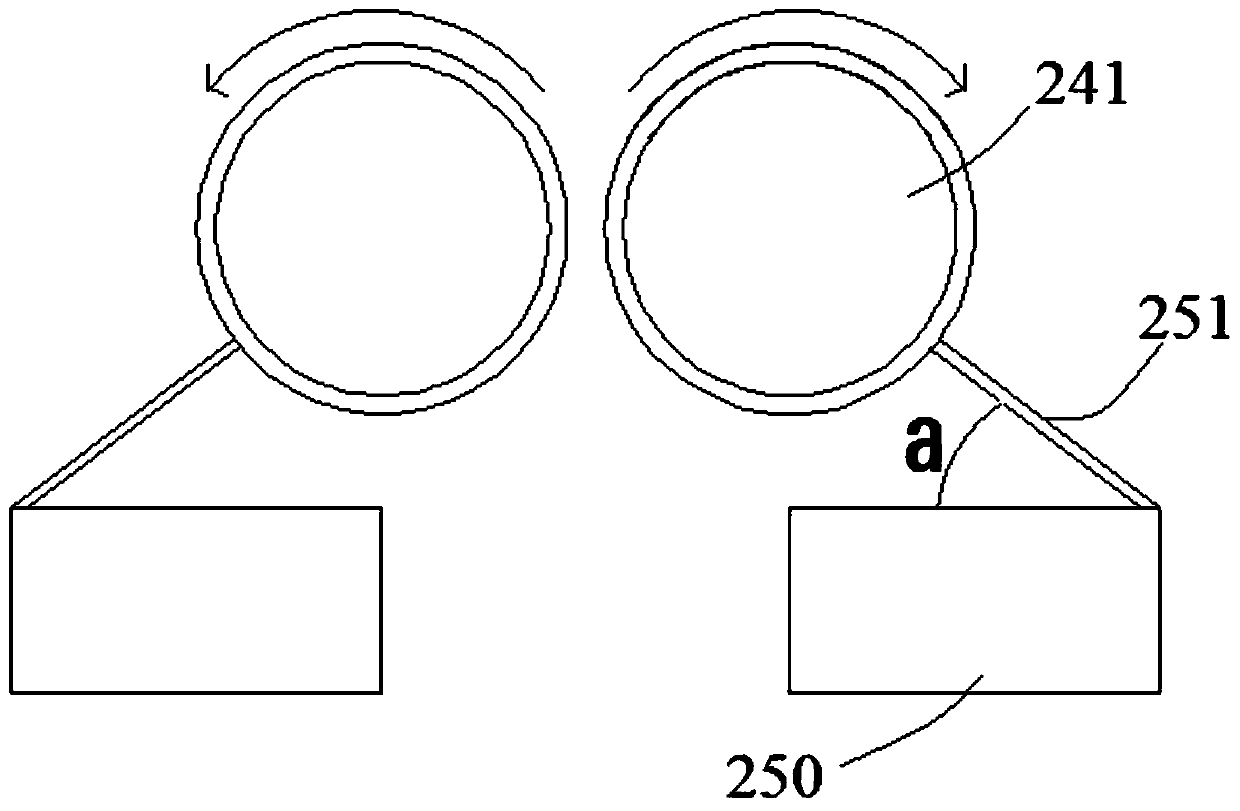

InactiveCN111535073AUniform materialReduce poor qualityPaper/cardboardApplied substance rearrangementRolling-element bearingEngineering

The invention discloses a glue coating machine for wallpaper. The glue coating machine comprises a base and a gluing device body installed on the base. The gluing device comprises a driving motor IIIarranged on the side surface; the driving motor III is connected with a glue rolling shaft group through a belt; the glue rolling shaft group comprises two glue rolling shafts which are arranged in parallel; the two sides of the rolling shaft are in rolling connection with the side wall of the gluing device through rolling bearings; the glue rolling shaft is connected with a belt through a rollingshaft; glue scraping fixing rods are arranged under the two glue rolling shafts; an inclined glue scraping sheet is arranged on the glue scraping fixing rod; the glue scraping sheet is contacted withthe lower side surface of the glue rolling shaft; the included angle alpha between the glue scraping sheet and the glue scraping fixing rod is 30-60 degrees; the glue scraping sheet which is obliquely arranged scrapes and removes redundant glue on the glue applying shaft, so that the glue applying shaft can smear the glue on the wallpaper more uniformly, uneven wallpaper materials caused by uniform smearing of the glue on the wallpaper due to glue accumulation on the glue applying shaft are prevented, and the situation that the quality of the wallpaper is poor is reduced.

Owner:ANHUI SOYA DECORATIVE MATERIALS

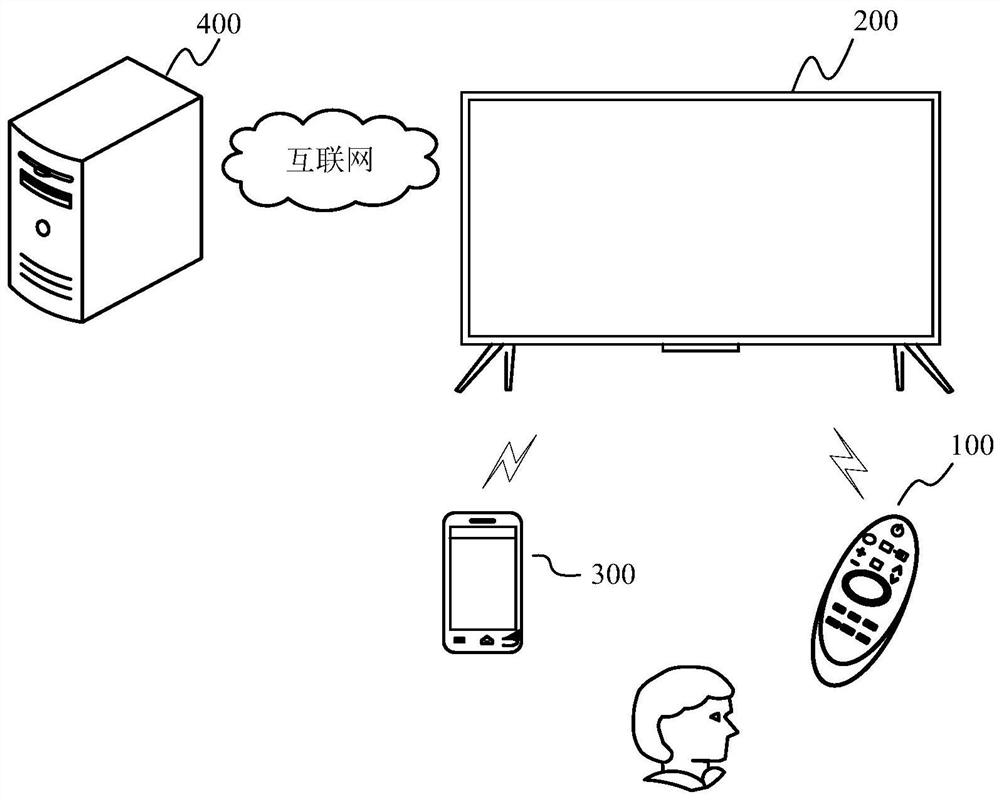

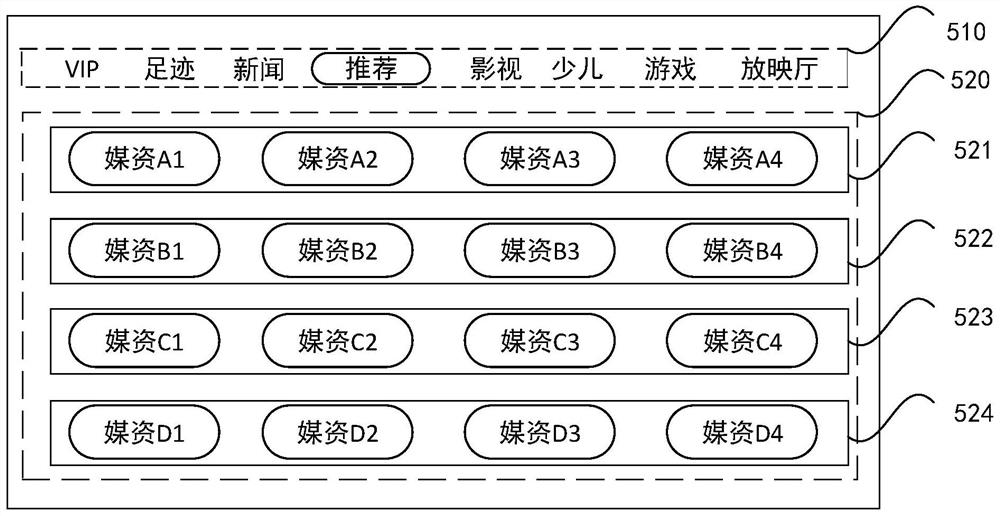

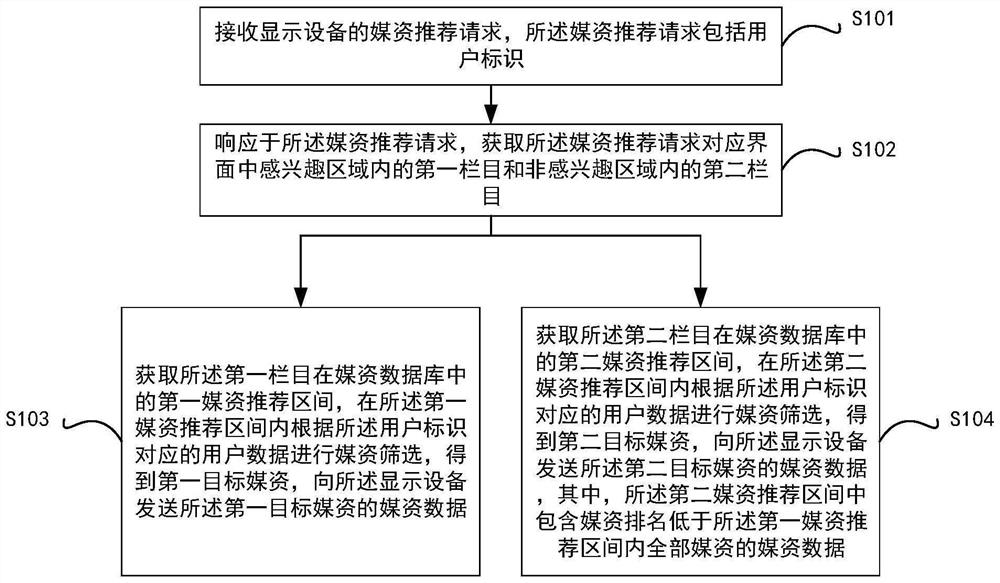

Server and media asset recommendation method

PendingCN114513687AImprove recommendation efficiencyReduce the poor quality of media assetsSelective content distributionDisplay deviceData library

The invention provides a server and a media asset recommendation method. The server is configured to receive a media asset recommendation request of a display device; responding to the media asset recommendation request, and obtaining a first column in an interested area and a second column in a non-interested area in an interface corresponding to the media asset recommendation request; obtaining a first media resource recommendation interval of the first column in a media resource database, performing media resource screening in the first media resource recommendation interval according to the user data to obtain a first target media resource, and sending media resource data of the first target media resource to a display device; obtaining a second media asset recommendation interval of the second column in the media asset database, performing media asset screening in the second media asset recommendation interval according to the user data to obtain second target media assets, and sending media asset data of the second target media assets to the display device, the second media asset recommendation interval comprises media asset data of which the media asset ranking is lower than that of all media assets in the first media asset recommendation interval. According to the invention, the media asset quality of media asset recommendation is improved.

Owner:青岛聚看云科技有限公司

Manufacturing method of roast mutton chops

The invention discloses a manufacturing method of roast mutton chops, and belongs to the technical field of food processing. The method specifically comprises the following steps: (1) unfreezing treatment; (2) slicing treatment; (3) soaking solution preparation; (4) soaking treatment; and (5) roasting mutton chops. By use of the manufacturing method disclosed by the invention, the appearances such as the color and the tenderness of the mutton chops before roasting can be effectively improved, a problem that the roasted product of the frozen mutton chops in the existing method is poor in quality is effectively improved, the entire treatment time is short, the efficiency is well promoted, the finally roasted mutton chops is unique in flavor, tender in taste, and high in appearance; and the manufacturing method is suitable for industrial batch production.

Owner:ANHUI BAIYI FOOD

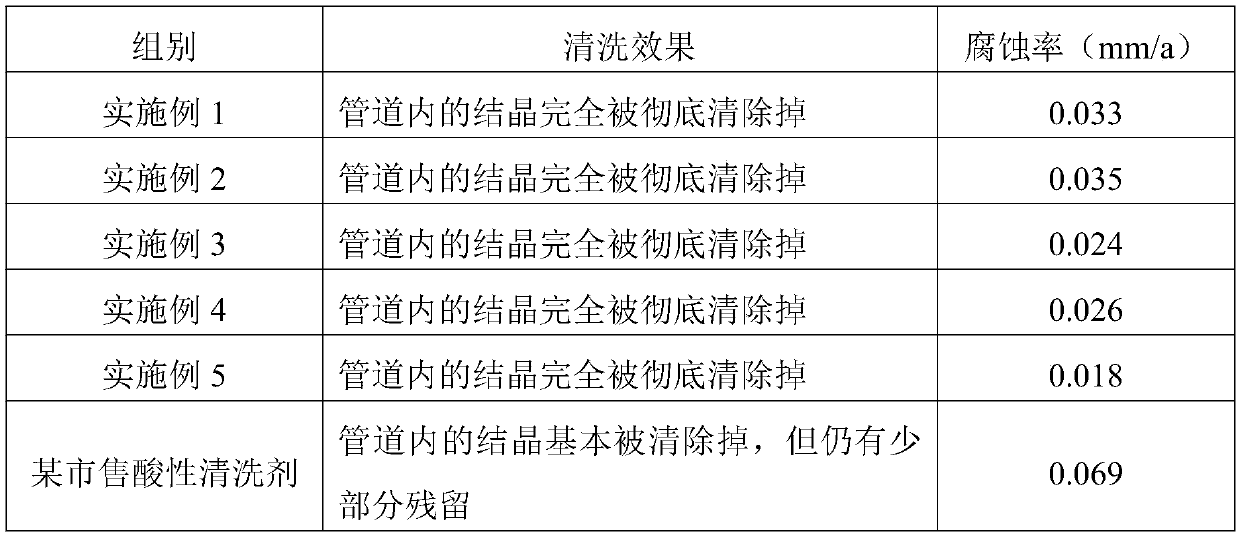

Glass etching industry pipe washing agent and washing method thereof

InactiveCN109576068AReduce corrosionExtended service lifeInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsAlcoholTime cost

The invention discloses a glass etching industry pipe washing agent. The glass etching industry pipe washing agent comprises the following components in parts by weight: 15-30 parts of inorganic acid,2-6 parts of alcohol amine, 1-3 parts of diethylenetriaminepenta(methylene-phosphonic acid), 0.3-0.6 parts of alkyl thioglycolic acid and 3-8 parts of an anionic surfactant. The provided pipe washingagent is capable of, through the synergistic effect of several substances of the inorganic acid, the alcohol amine, the diethylenetriaminepenta(methylene-phosphonic acid), the alkyl thioglycolic acidand the anionic surfactant, effectively cleaning crystal substances on the inner wall of a pipe, wherein the cleaning effect is good and corrosion to the pipe is smaller compared with a traditional acidic washing agent, and effectively prolonging service life of the pipe; and compared with artificial pipe cleaning, greatly saving labor cost and time cost. The invention further provides a method for washing the pipe by the glass etching industry pipe washing agent. The washing method is simple, short in washing time, high in efficiency, and no residual washing agent after washing.

Owner:UNITECH OPTRONICS TECH HUBEI

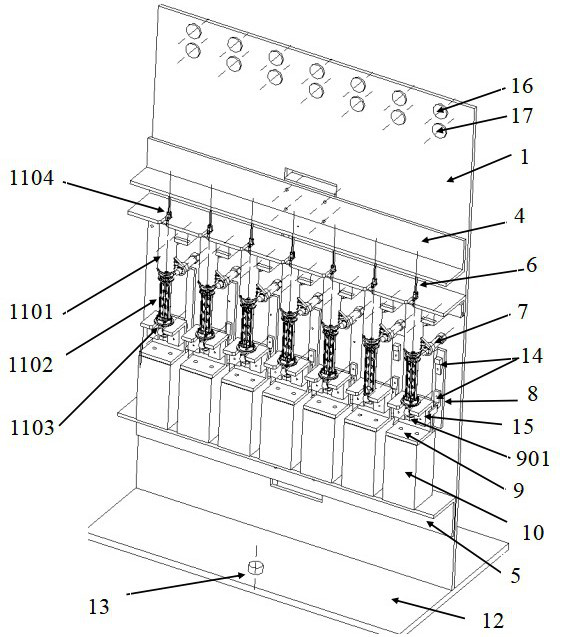

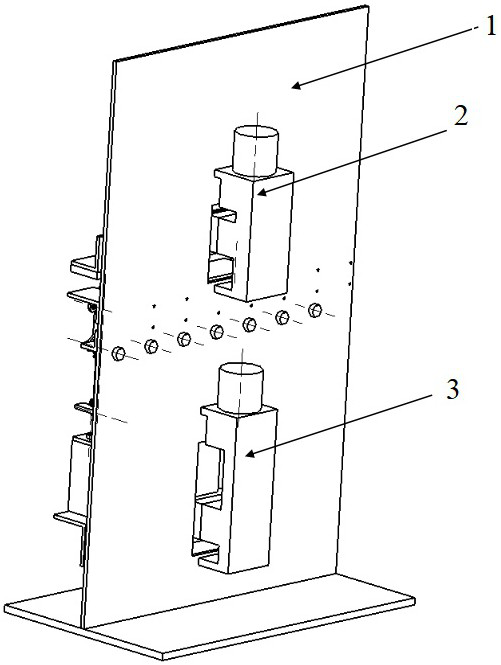

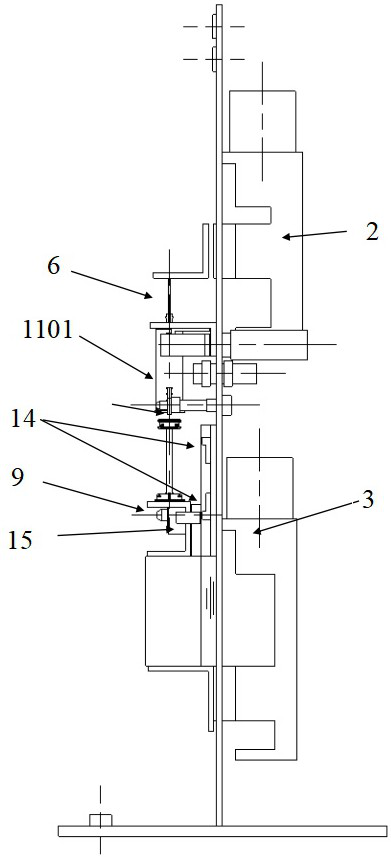

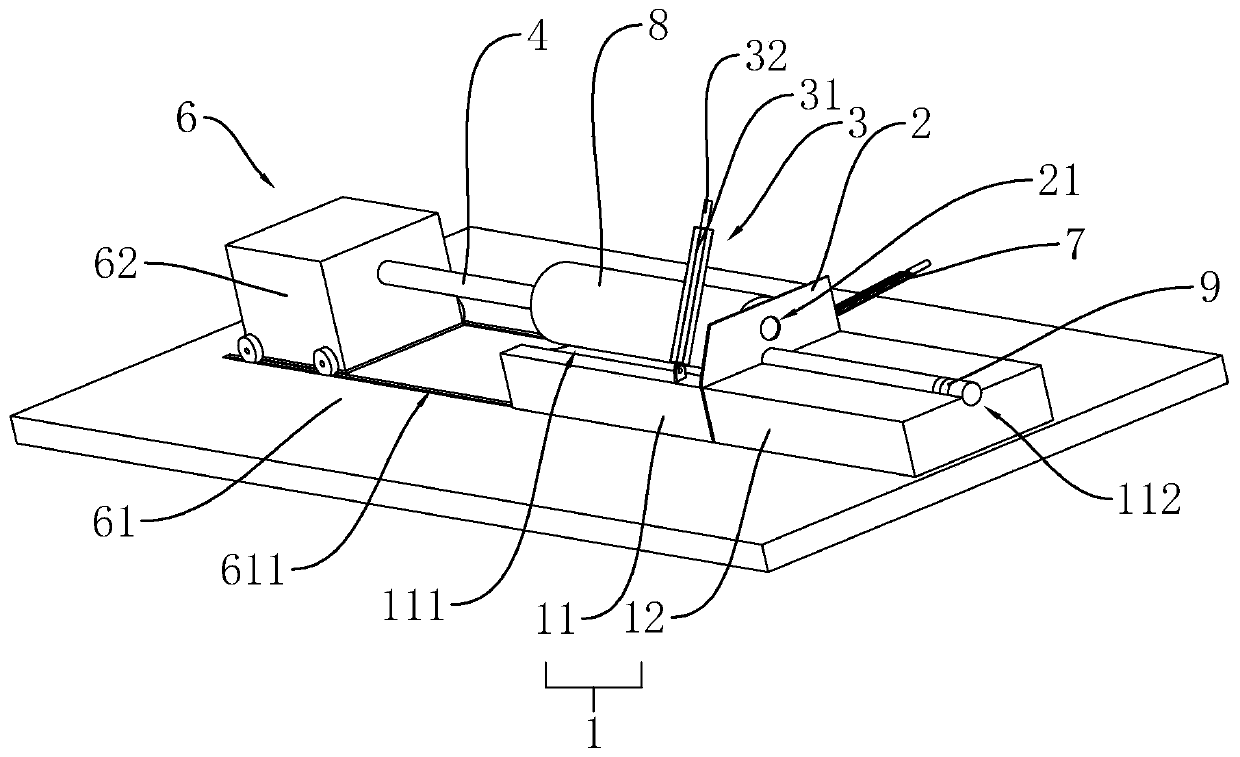

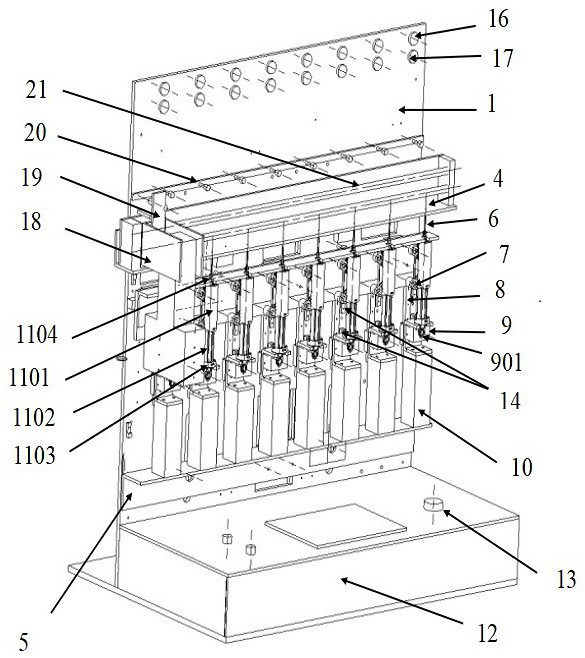

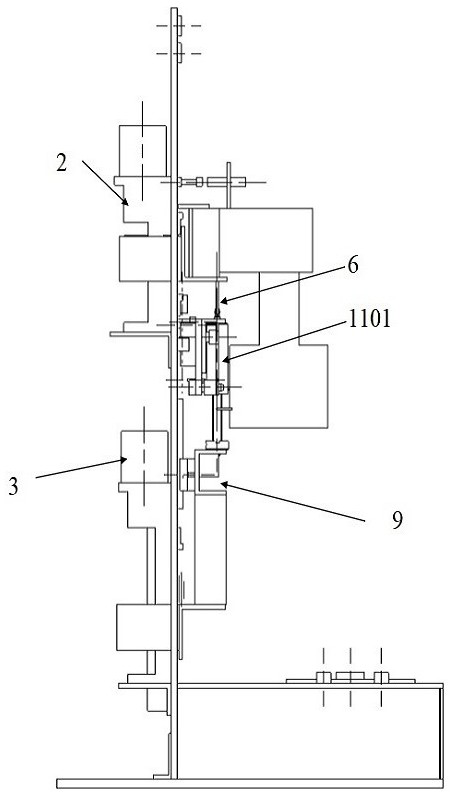

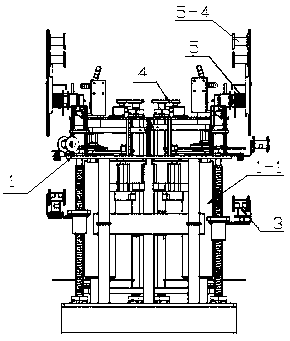

Automatic assembling and testing device for damper

PendingCN113500363AImprove assembly efficiencyReduce poor qualityMachine part testingMetal working apparatusDamperControl theory

The invention relates to an automatic assembling and testing device for a damper. The automatic assembling and testing device comprises an upper electric sliding table, a lower electric sliding table, an upper push plate, a lower push plate, an ejector pin, a guide rail, a balancing weight, a sensing piece, a sensor and an indicator lamp. After being powered on and started, the upper electric sliding table drives the upper push plate to move downwards, and meanwhile, the ejector pin pushes an air inlet plug of the damper to enter the tail of the damper and reset after being clamped to the tail of a damper cylinder; the lower electric sliding table drives the lower push plate and the balancing weight to move upwards in the direction of the guide rail and pushes a pull rod and a cylinder cover to enter the damper cylinder, and the cylinder cover is clamped to the damper cylinder; and after the damper is assembled, the balancing weight drives the pull rod of the damper to move downwards while the lower push plate is reset, the sensing piece passes through the upper sensor and the lower sensor, the induction time difference of the upper sensor and the lower sensor is the damping time value of the damper, and therefore a cycle of assembling and testing of the damper is completed.

Owner:上海琦天汽车零部件有限公司

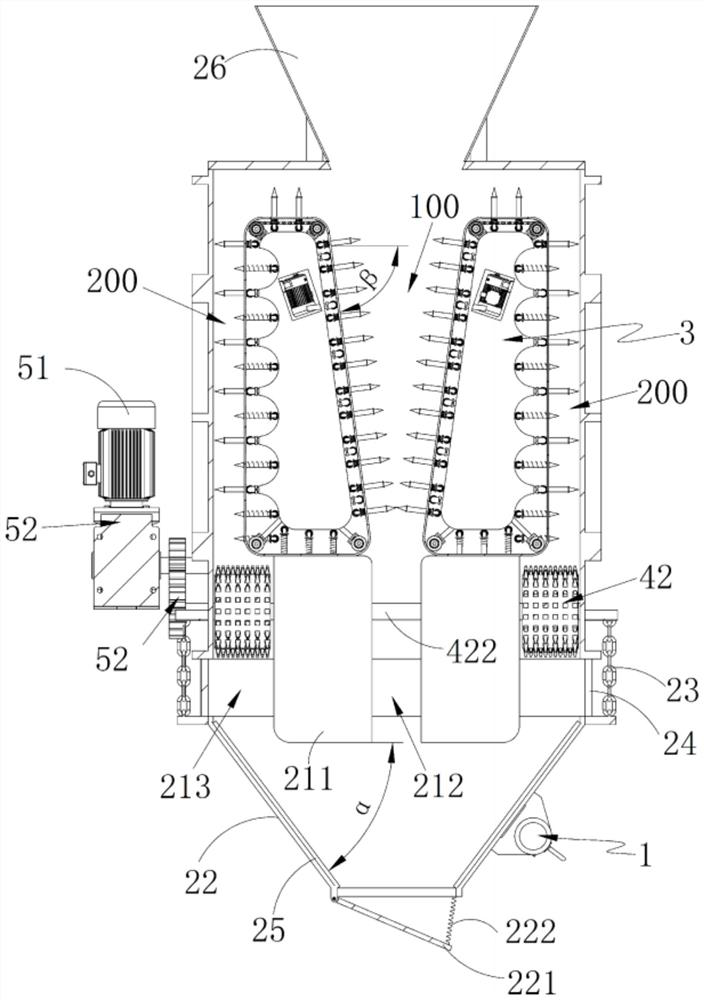

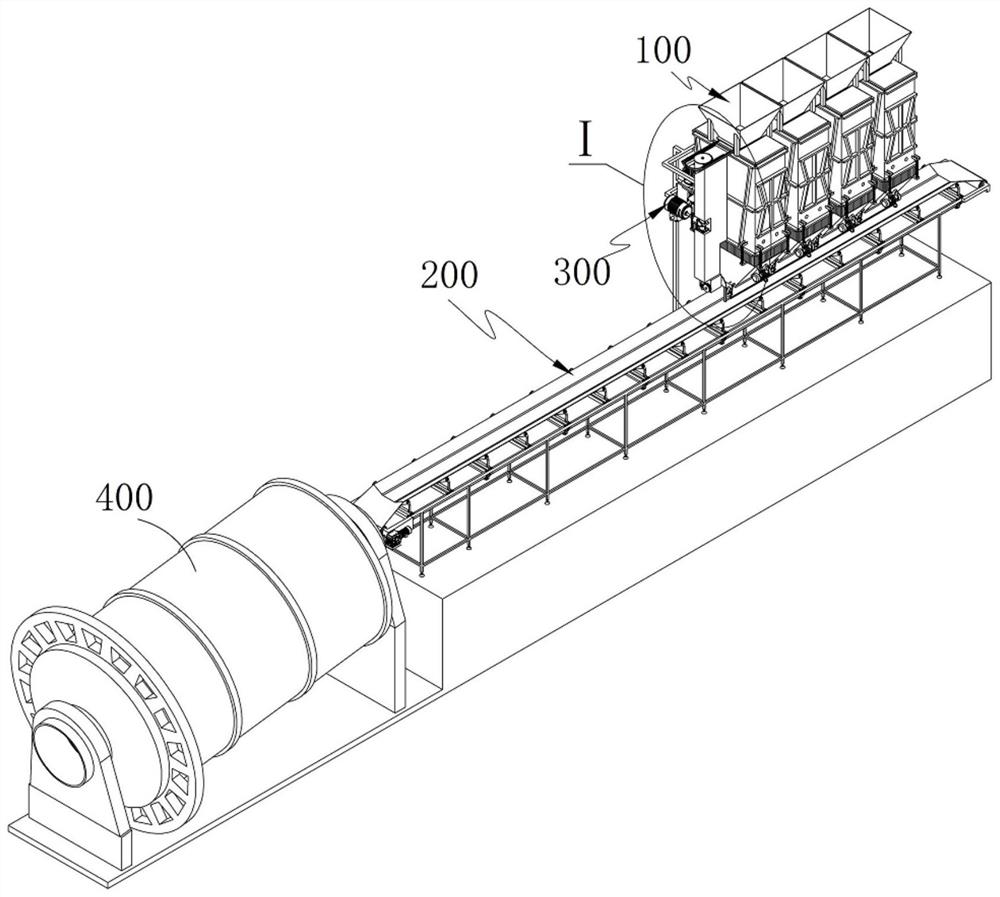

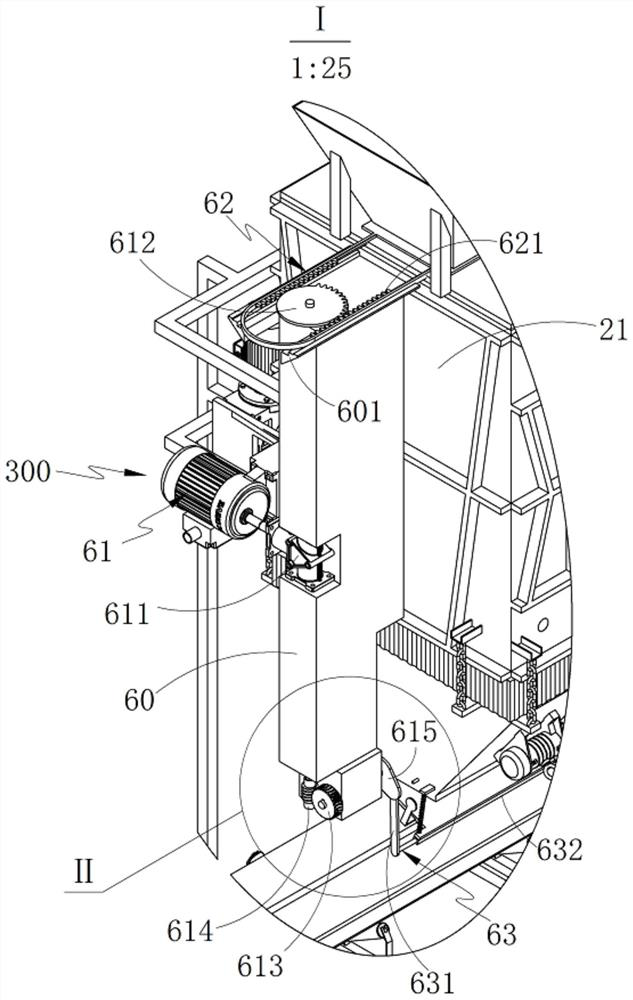

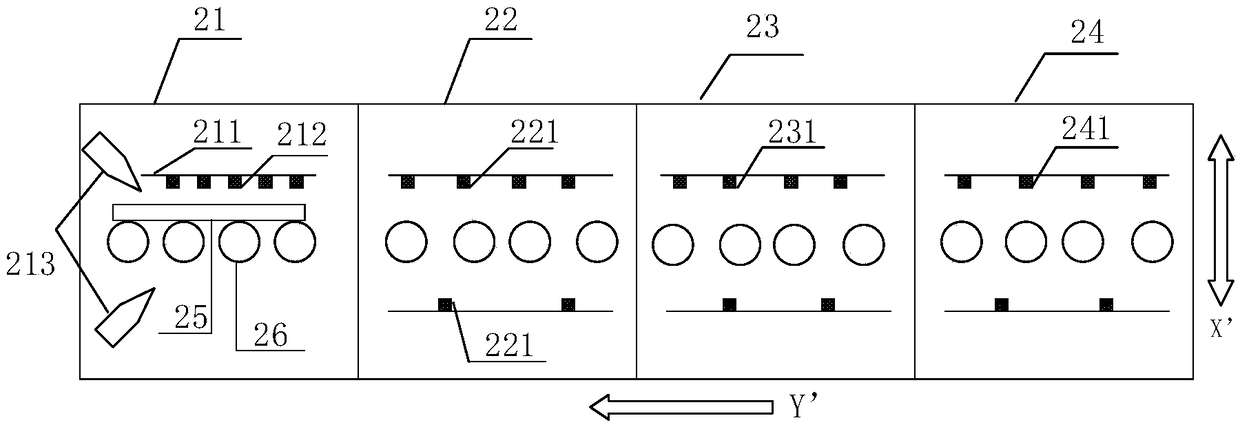

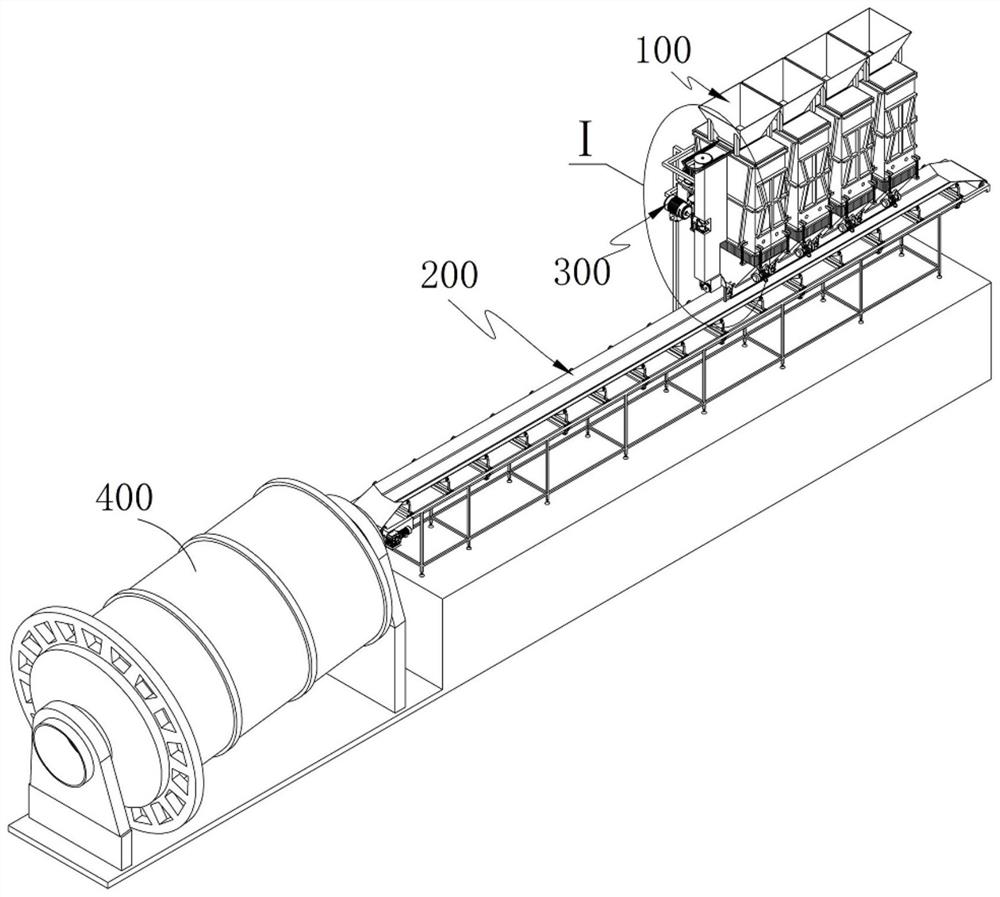

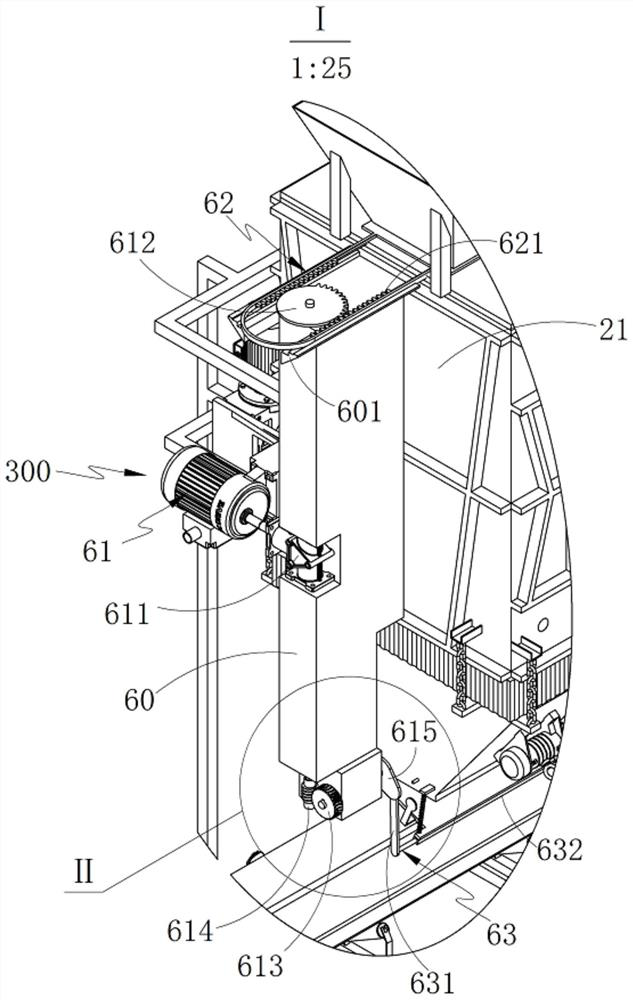

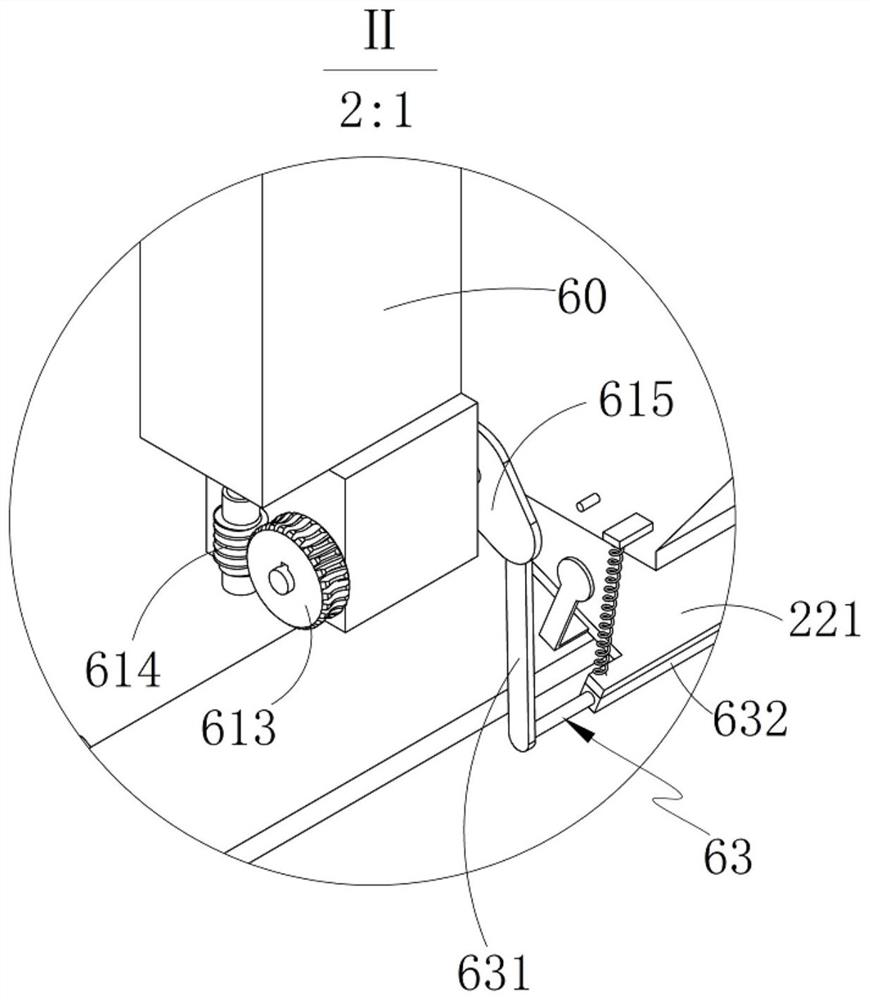

Continuous batching and feeding integrated system for cement production

ActiveCN112317095ASatisfied with the ratioThe ratio meets the process requirementsGrain treatmentsSynchronous controlElectric machinery

The invention provides a continuous batching and feeding integrated system for cement production. The continuous batching and feeding integrated system comprises a conveying unit, four raw material batching stations and a feeding control unit. The feeding control unit is used for synchronously controlling intermittent feeding and discharging of the four raw material batching stations, it is guaranteed that the crushing process of materials entering the raw material batching stations is smoothly carried out, and material blockage caused by material accumulation is avoided; a screening pre-crushing unit, a secondary crushing assembly and a crushing unit in the raw material batching stations are used for carrying out three-stage crushing on materials, so that the size consistency of particlesflowing out of the materials is improved, and it is guaranteed that the weights of the materials flowing out in unit time are equal; and by means of a hopper unit and a vibration motor which are designed in a split mode, materials are prevented from being accumulated on the inner surface of a discharging hopper, the discharging effect is prevented from being affected, it is guaranteed that the mass of the materials falling per unit area is equal during continuous discharging, and therefore it is guaranteed that the final proportion meets the technological requirement, the yield of cement clinker is increased, blocking is reduced, and production efficiency is improved.

Owner:广德独山南方水泥有限公司

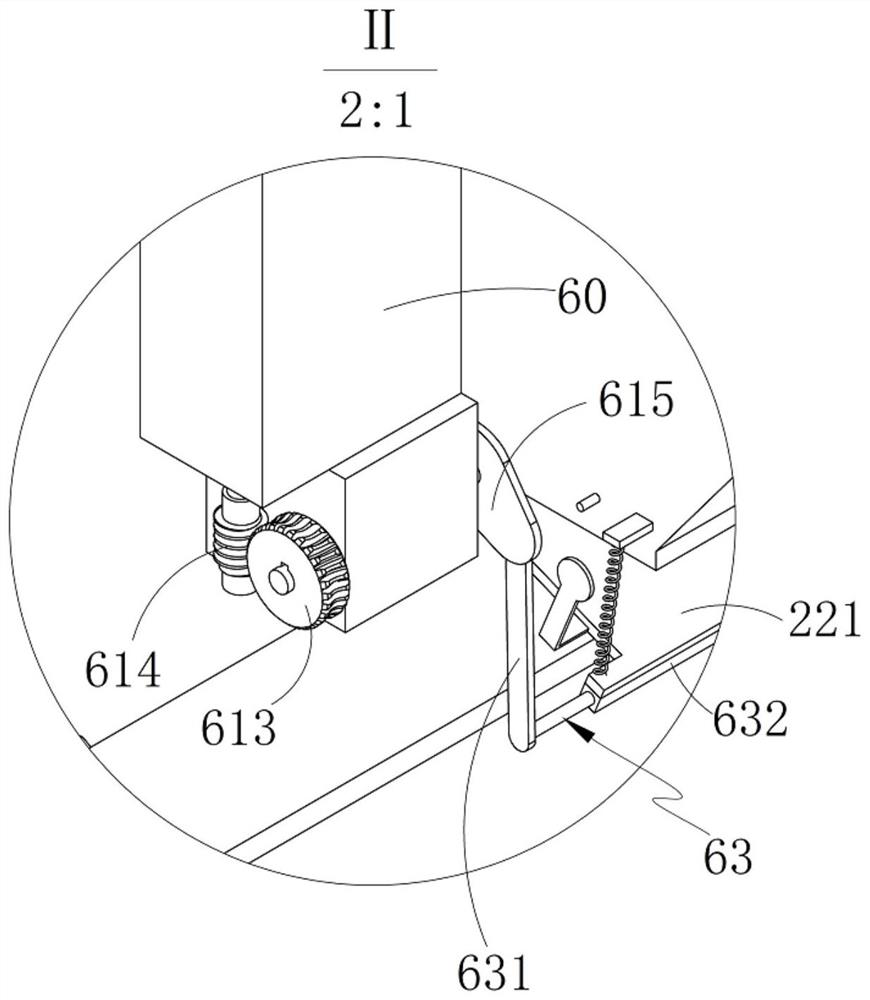

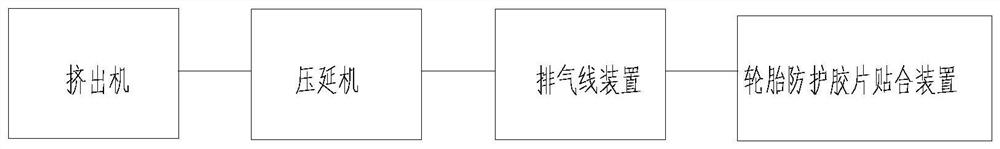

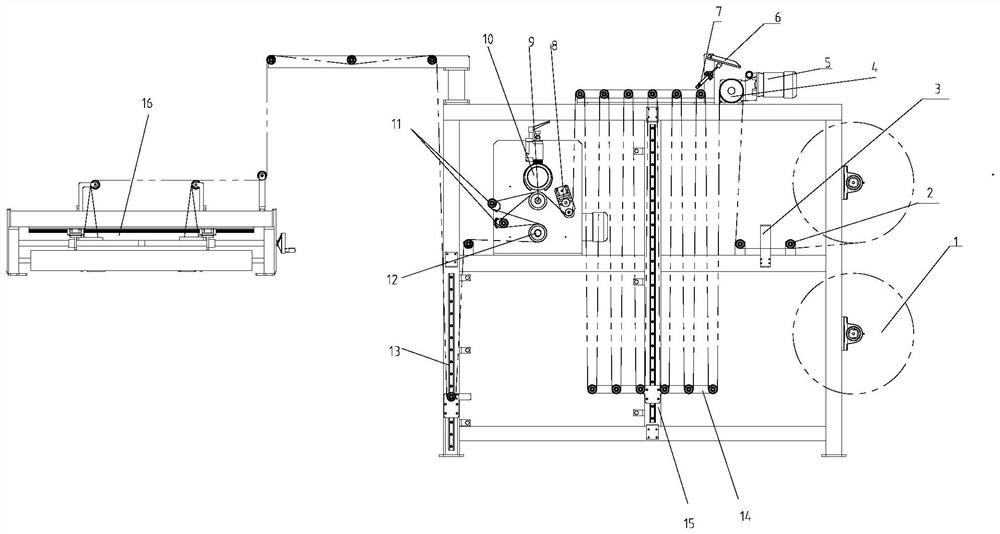

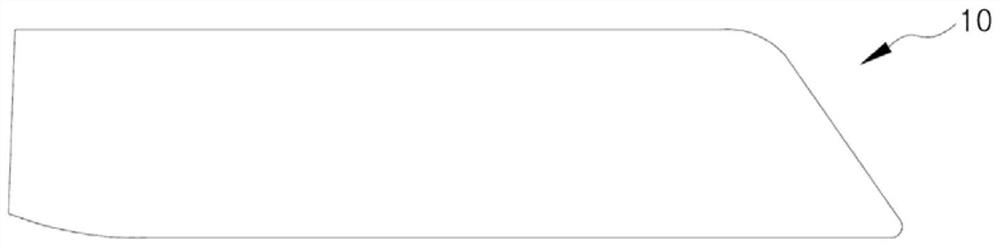

Transition layer production line and rubber sheet attaching method

ActiveCN112109294ASolve the problem of cumbersome fittingIncrease productivityTyresProduction lineEngineering

The invention belongs to the field of tire part production, and particularly relates to a transition layer production line and a rubber sheet attaching method. The transition layer production line andthe rubber sheet attaching method are applied to an online attaching process of a lining layer engineering steel wire wrapping protection rubber sheet. The transition layer production line comprisesan extruder, wherein the extruder is used for extrusion, a calender is used for extrusion molding, and an exhaust line is pressed under the pressing of an exhaust line device; and the transition layerproduction line is characterized in that a tire protection rubber sheet attaching device is arranged on a transition layer main machine receiving conveying belt behind the exhaust line device, and the tire protection rubber sheet attaching device carries out positioning on a transition layer and attaches a rubber sheet to the transition layer. The problem that bubbles are generated due to the fact that rubber sheet sizing materials are prone to accumulate when the protection rubber sheet is attached to the end part of a protection steel wire and punctures the lining layer is solved.

Owner:SHENYANG HEPING ZIWUXIAN TIRE MFG CO LTD

A raw material batching station with stable batching function

ActiveCN112275360BUniform particle sizeReduce weight differenceGrain treatmentsElectric machineryProcess engineering

The invention provides a raw material batching station with stable batching function, which includes a hopper unit, a pre-crushing unit and a secondary crushing component. Primary crushing effect: When the material is transferred to the secondary crushing space, the secondary crushing component is used to cooperate with the screening of the concave and convex tracks set on the mounting frame during the descending process, so that the bulk material is crushed by the secondary crushing multiple times. The crushing unit below the crushing space crushes the uncrushed material three times to ensure that the particle size of the outflowing material is uniform; the split-type hopper unit and the vibration motor on one side of the hopper effectively solve the problem of material accumulation. Ensure that the quality of materials falling per unit area is equal during continuous discharge, so as to ensure that the final ratio meets the process requirements, improve the yield of cement clinker, and improve production efficiency.

Owner:广德独山南方水泥有限公司

A Method of Composite Alignment of Graphics

ActiveCN107295751BImprove alignment efficiencyReduce poor qualityInspection/indentification of circuitsPrinted circuit manufactureGraphicsEngineering

The invention discloses a pattern compound alignment method, and the method comprises the steps: four alignment blind holes for following pattern alignment are arranged on corner areas of an HDI board, a circular alignment through hole is arranged on each center of the alignment blind holes, when pattern transferring alignment is performed, calculation weights of the alignment blind holes and the alignment through holes are correspondingly selected according to sizes of adopted welding rings, and balanced-processing is performed, wherein the welding rings include blind hole welding rings and through hole welding rings. According to the invention, through hole alignment targets and blind hole alignment targets are mixed in alignment targets, when pattern alignment is performed, two kinds of alignment targets are captured to balance alignment bias caused by two kinds of hole types, the pattern alignment efficiency is greatly improved, poor quality is reduced, alignment precision is improved, a pattern target fused with plate edge design of an HDI product is added to a design operation module, and automatic operation is realized.

Owner:MEIZHOU ZHIHAO ELECTRONICS TECH

An automatic diluent adding device in precision industrial screen printing

The invention discloses a precision industrial silk-screen printing instrument and particularly relates to an automatic diluent adding instrument used in precision industrial silk-screen printing. With the automatic diluent adding instrument used in precision industrial silk-screen printing, the timed cost is effectively saved, the adding precision is improved, and the processing technology is stabilized. The automatic diluent adding instrument comprises a miniature mist air spray nozzle, a gas-liquid electromagnetic valve, a PLC (Programmable Logic Controller), a water pump, an intermediate relay and a container tank, wherein the container tank is used for storing a diluent, a liquid inlet, an air inlet and a spray opening are formed in the miniature mist air spray nozzle, the gas-liquid electromagnetic valve comprises a liquid valve assembly and a gas valve assembly, and the intermediate relay is used for calculating sprinkling time and spaced time; the container tank is communicated with the liquid inlet through the water pump, the liquid valve assembly is arranged between the water pump and the liquid inlet, and the air inlet is communicated with the gas valve assembly; the PLC is connected with the intermediate relay, the water pump, the liquid valve assembly and the gas valve assembly.

Owner:BLTY HUNAN TECH

Substrate cleaning device, developing machine and substrate cleaning method

InactiveCN108787672AIncrease the fluidity of water film and the uniformity of water film thicknessReduce poor qualityFlexible article cleaningCleaning using liquidsPoor qualityEngineering

The invention discloses a substrate cleaning device, a developing machine and a substrate cleaning method. The substrate cleaning device comprises an output pipeline of the cleaning liquid, and a plurality of liquid outlet nozzles are arranged on one side, opposite to the substrate to be cleaned, of the output pipeline, the substrate cleaning device further comprises a driving device, the drivingdevice is connected with the output pipeline and used for driving the output pipeline to move in the set direction according to the set frequency. According to substrate cleaning device, the fluidityof the water film on the surface of the glass substrate and the thickness uniformity of the water film are improved, so that poor quality caused by nonuniform water films can be reduced.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

A continuous batching and feeding integrated system for cement production

ActiveCN112317095BSatisfied with the ratioThe ratio meets the process requirementsGrain treatmentsSynchronous controlElectric machinery

The invention provides a continuous batching and feeding integrated system for cement production, which includes a conveying unit, four raw meal batching stations and a feed control unit, and the feed control unit is used to synchronously control the four raw meal batching stations. Intermittent feeding and discharging ensure the smooth progress of the crushing process of materials entering the raw material batching station and avoid material blockage caused by material accumulation; use the screening pre-crushing unit, secondary crushing components and crushing The unit performs three-stage crushing on the material, so that the particle size consistency of the material outflow is improved, and the weight of the outflow material per unit time is guaranteed to be equal; the use of the split-type design of the hopper unit and the vibration motor prevents the material from accumulating on the inner surface of the lower hopper, which affects the discharge. The effect is to ensure that the quality of the falling materials per unit area is equal during continuous discharge, so as to ensure that the final proportion meets the process requirements, improve the yield of cement clinker, reduce the occurrence of clogging, and improve production efficiency.

Owner:广德独山南方水泥有限公司

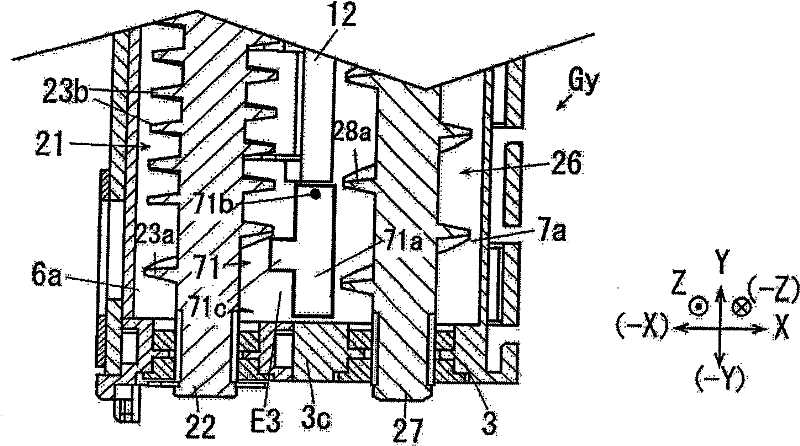

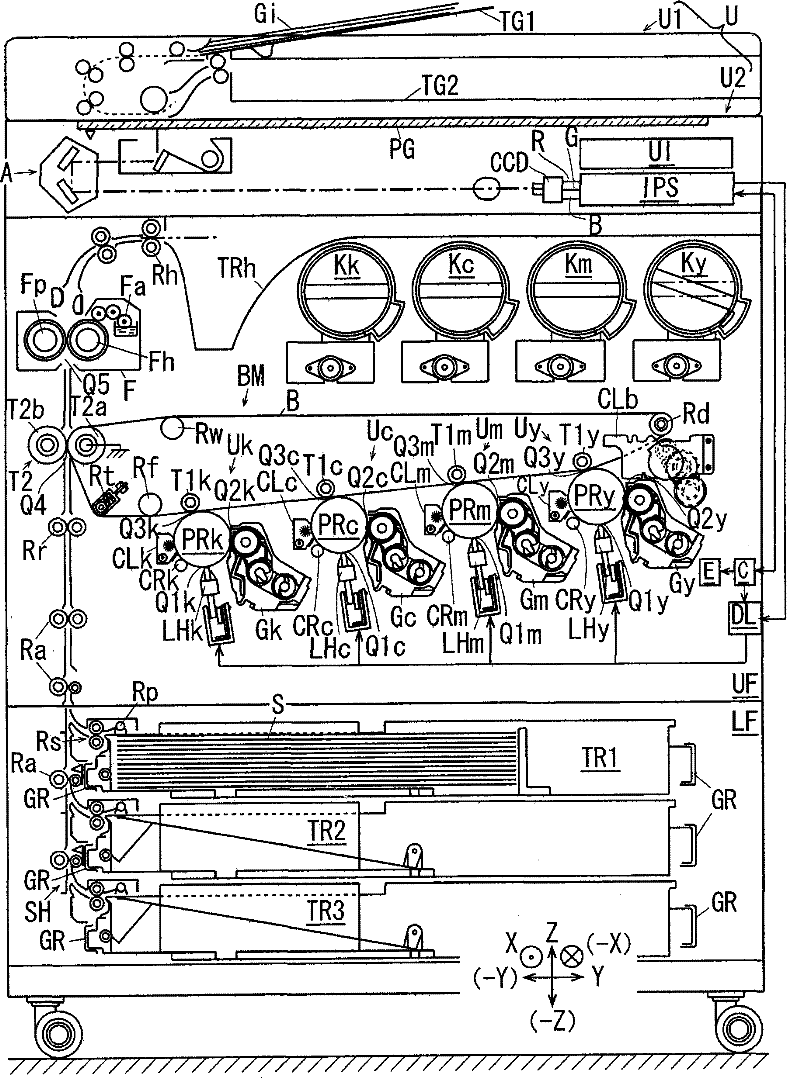

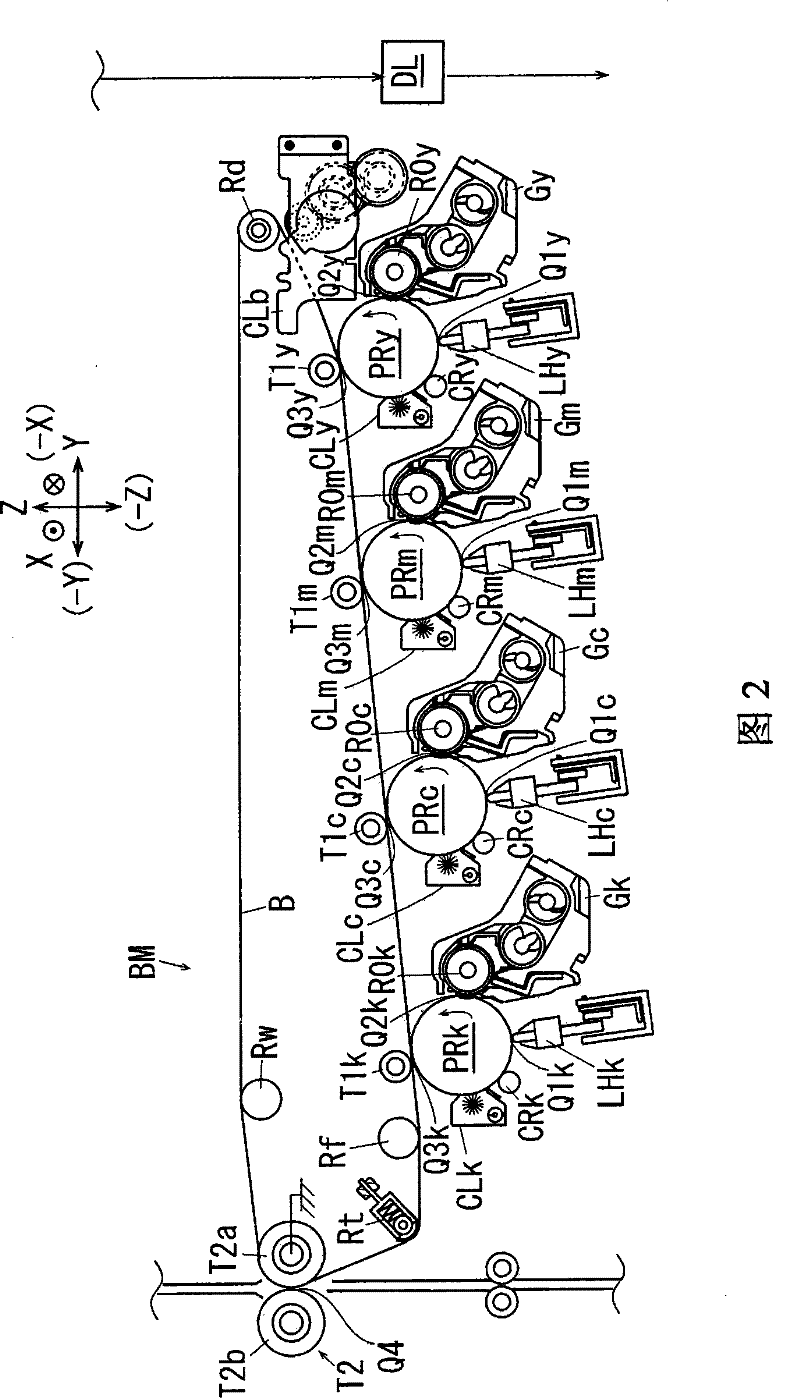

Developing device and image forming device

ActiveCN101436022BReduce retentionImprove crushing effectElectrographic process apparatusSoftware engineeringImage formation

Owner:FUJIFILM BUSINESS INNOVATION CORP

Measuring device for soil in moisture content test

PendingCN109900535AEasy to sampleAccurate samplingPreparing sample for investigationEngineeringMoisture

The invention relates to a measuring device for soil in a moisture content test. The device comprises a working table. A soil baffle perpendicular to the top surface of the working table is fixedly arranged on the working table; and a via hole is formed in the soil baffle. The soil baffle divides the working table into a cutting table and a receiving table; a three-joint switch blade for cutting undisturbed soil on the cutting table is hinged to one side of the cutting table; a hollow tube capable of measuring the undisturbed soil along the length of the cutting table is arranged at one end, away from the receiving table, of the cutting table; and the axis of the hollow tube and the circle center of the via hole are located at the same horizontal line. Besides, a mandril for pushing cylindrical soil measured in the hollow steel tube out of the via hole to the receiving table is arranged in the hollow tube. The measuring device has advantages of accurate sampling and high work efficiency.

Owner:BEIJING G&M ENG CONSTR CO LTD

Automatic coding, assembling and testing device for damper

PendingCN113532822AImprove assembly efficiencyReduce poor qualityMachine part testingTypewritersElectrical and Electronics engineeringMechanical engineering

The invention relates to an automatic coding, assembling and testing device for a damper, which comprises a main board, an upper electric sliding table, a lower electric sliding table, an upper push plate, a lower push plate, an ejector pin, a positioning pin shaft, a guide rail, a mounting seat, a balancing weight, a sensor, a sensing piece, an indicator lamp, a coding sliding guide rail, a coding machine, a coding sensor and a sensing head. On the basis of an existing device, a coding function is added. The structure is characterized in that the coding sliding guide rail is fixed to the upper portion of the upper push plate; the coding machine is fixed to a sliding block of the coding sliding guide rail and can reciprocate left and right along with the sliding block; the coding sensor is fixed on the coding machine; and the sensing head is fixed to the front face of the main board and located below the coding sensor. According to the automatic coding, assembling and testing device for a damper, the production efficiency can be improved, and the assembly cost can be reduced.

Owner:上海琦天汽车零部件有限公司

Frame for molding curved glass, and method for molding curved glass by using same

InactiveCN111836788AInhibit deteriorationReduce poor qualityGlass reforming apparatusGlass press-moulding apparatusPolymer sciencePolymer chemistry

One embodiment of a frame for molding curved glass comprises: a support region for supporting glass so that glass is loaded thereon; and a heating block arranged in the support region so as to come inat least partial contact with one surface of the glass in the bending portion of the glass when the glass is loaded on the support region, wherein the heating block can be formed from a material having a higher thermal conductivity than the glass and the support region.

Owner:科思斯格特电子有限公司

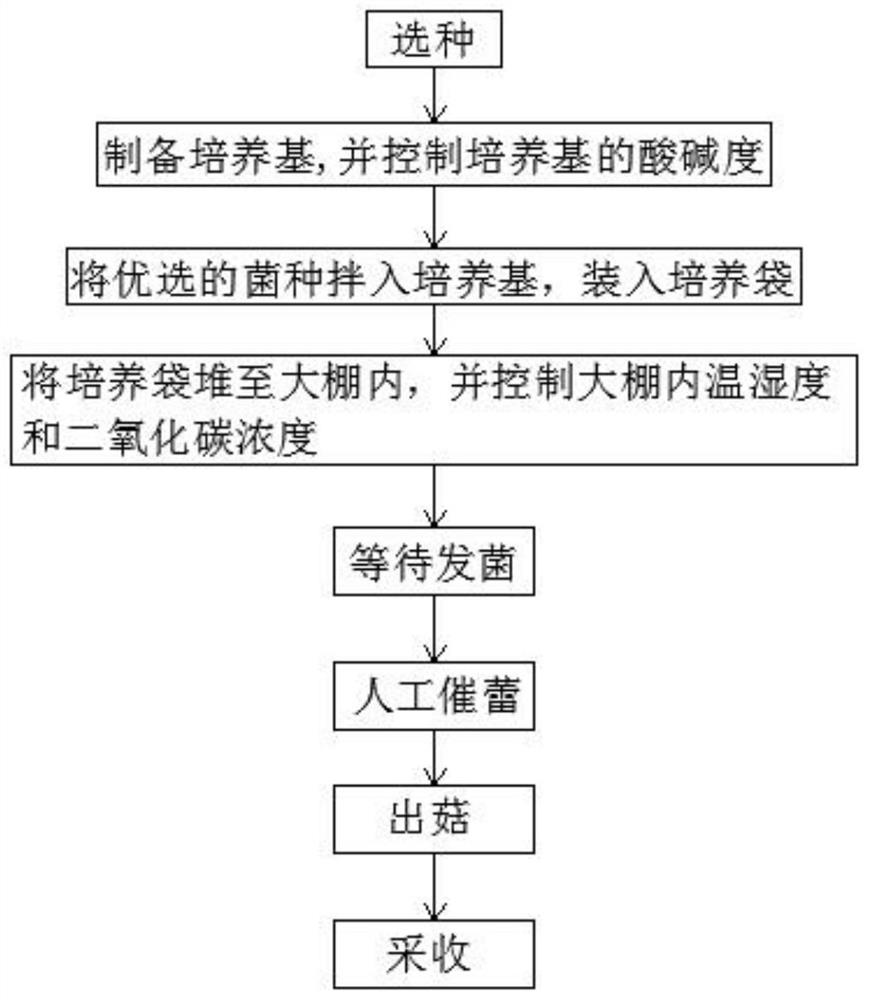

Large-scale high-yield hypsizygus marmoreus cultivation technology

PendingCN114679996AReduce poor qualitySpeed up germination timeCultivating equipmentsMushroom cultivationHyphaCulture mediums

The invention belongs to the technical field of hypsizygus marmoreus cultivation, and particularly relates to a hypsizygus marmoreus cultivation large-scale high-yield technology which comprises the following steps: 1, selecting seeds; 2, preparing a culture medium, and controlling the pH value of the culture medium; 3, mixing the optimized strain into the culture medium, and putting the culture medium into a culture bag; 4, the culture bags are stacked in a greenhouse, and the temperature, humidity and carbon dioxide concentration in the greenhouse are controlled; 5, waiting for spawn running, ventilating for 3-4 times per day and 25-30 minutes per time, and waiting for 30-35 days until the culture bag is full of hyphae; 6, artificial bud pressing; step 7, fruiting; according to the method, high-quality strains are selected in advance, so that products with poor quality during fruiting are reduced, and selling is facilitated; meanwhile, in the application document, a special culture medium preparation method and a raw material ratio are adopted, the hypsizygus marmoreus spawn running time is shortened, and meanwhile, artificial bud pressing is adopted, so that the production efficiency of hypsizygus marmoreus is improved.

Owner:福建省建宁大川生物菌业有限公司

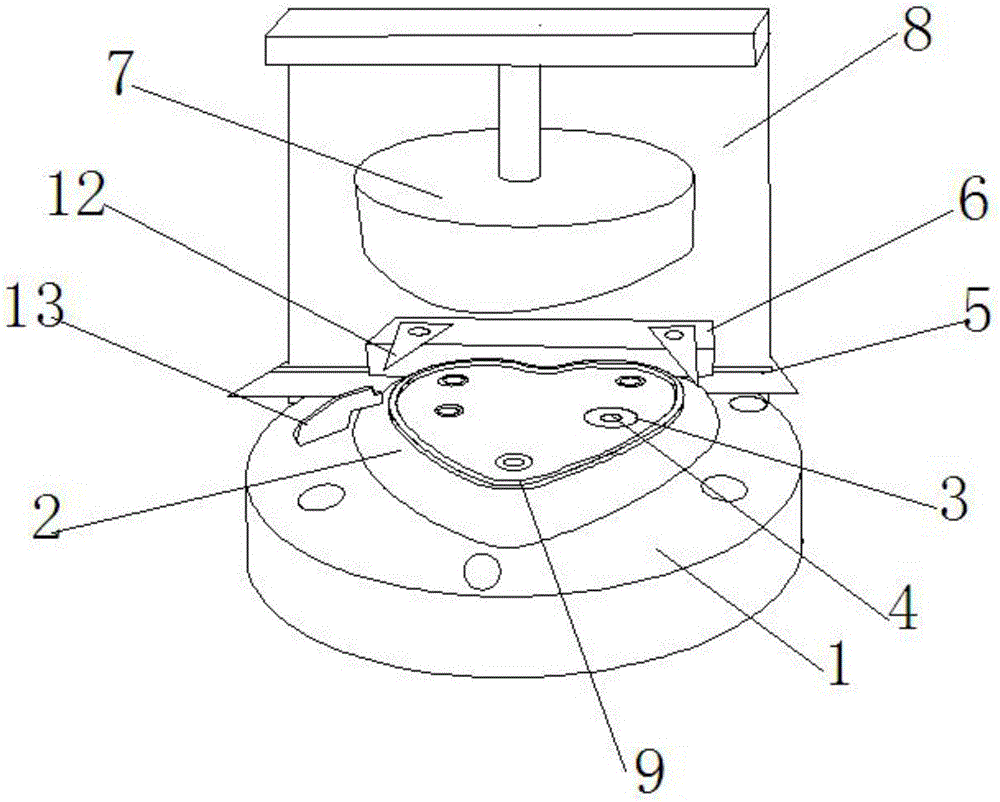

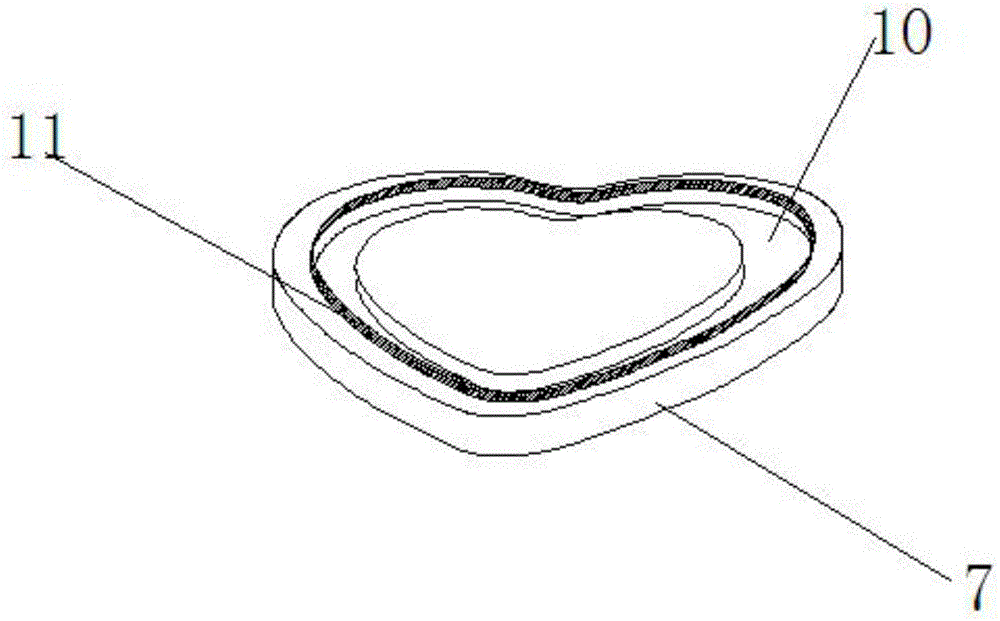

Heart-shaped box cover forming tool

ActiveCN106424337ASuitable for useSimple mechanical structureShaping toolsHollow articlesEngineeringMechanical engineering

The invention discloses a heart-shaped box cover forming tool. The heart-shaped box cover forming tool comprises an upper die, a lower die and a main machine. The bottom of the lower die is a base. The base is provided with a lower die block. Holes are formed in the lower die block and internally provided with movable rods. A sliding groove is formed in the part, on the edge of the lower die block, of the base and provided with a sliding block. The upper die comprises an upper die block connected to the main machine. The upper die block is right opposite to the lower die block. The lower die block is provided with a protruding stop edge, the upper die block is provided with a groove, the groove corresponds to the protruding stop edge in position, and the groove and the protruding stop edge are consistent in size. A blade is arranged on the outer side of the part, close to the edge of the upper die block, of the groove. A heart-shaped box cover is manufactured in a heart-shaped upper die and lower die extrusion cutting mechanical mode, production continuity is guaranteed through a simple mechanical structure, the situation of quality lowering caused by human factors is reduced, the heart-shaped box cover forming tool is suitable for being used in small factories, and benefits are increased.

Owner:ANHUI ZHONGKE AUTOMATION

Two-channel vertical type edge curling machine

PendingCN108689228AReduce poor qualityReduce the number of replacementsFilament handlingEngineeringGravitation

The invention provides a two-channel vertical type edge curling machine. The two-channel vertical type edge curling machine is characterized by comprising rubber rollers and a paper tube, the rubber rollers are symmetrically installed on the two sides of a support, rubber is arranged on the surfaces of the rubber rollers, the rubber rollers are driven by a motor A to rotate along rotating shafts of the rubber rollers, and the paper tube is parallel to the rubber rollers, is in tight contact with the surfaces of the rubber rollers and is driven by the rubber rollers to rotate to enable edge strips to be wound around the surface of the paper tube. According to a vertical type compression roller, the problem that due to the self gravity of the rubber rollers, vibration is generated in the rolling process, and the poor film roll quality is caused is solved, vibration is decreased to enable the service life of all parts to be effectively prolonged, the number of times of maintenance and repairing is reduced, and the using rate and efficiency are accordingly improved. Meanwhile, the roll diameter measuring function is increased, the problem that roll diameter detaching is difficult due to the too large roll diameter can be effectively solved, the unique two-channel design enables the volume of the edge strips collected each time to be larger, the film roll replacing frequency is reduced, time is saved, and the production capacity is improved.

Owner:DALIAN ALTMA IND CO LTD

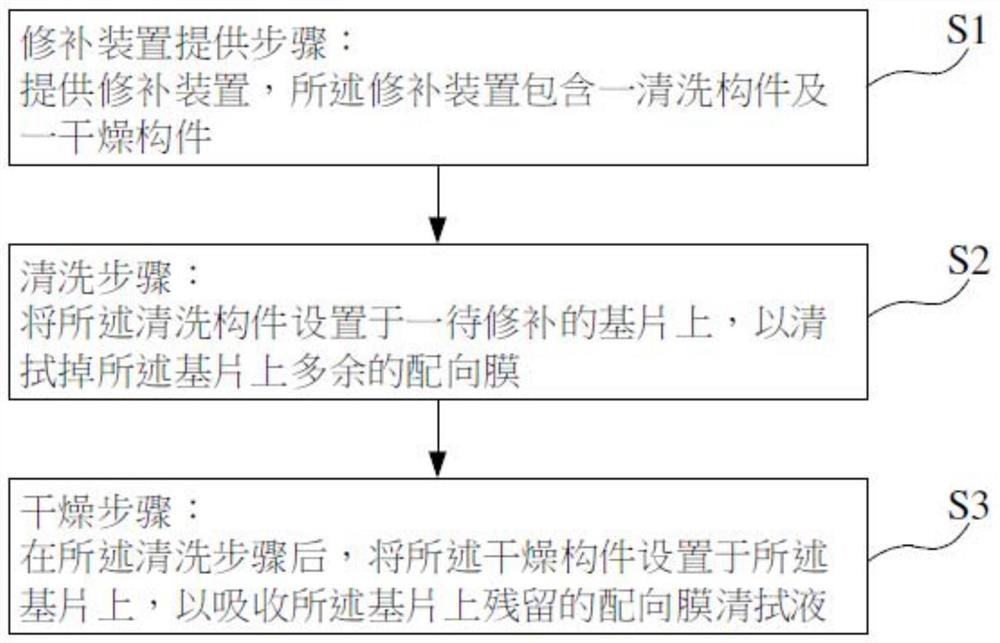

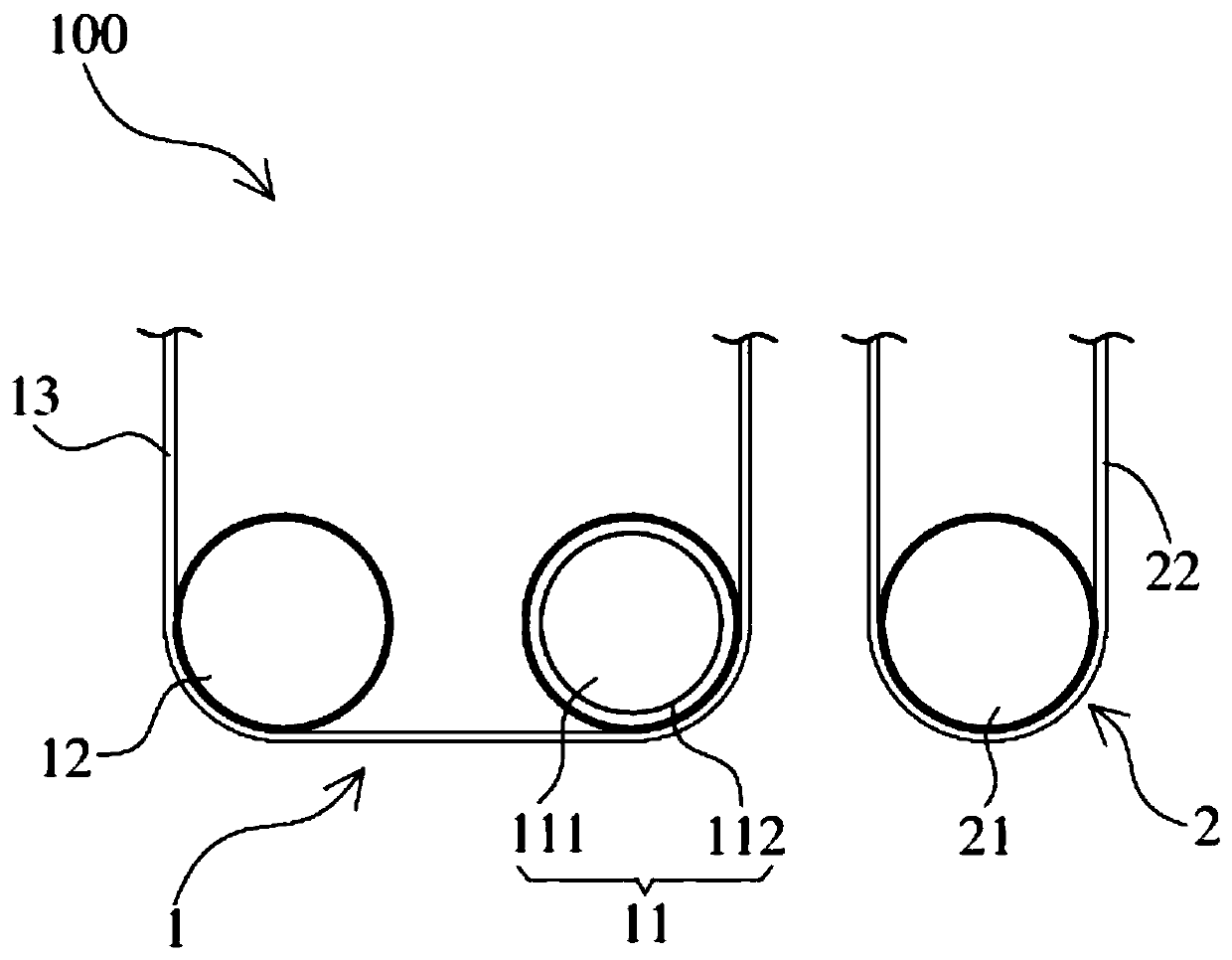

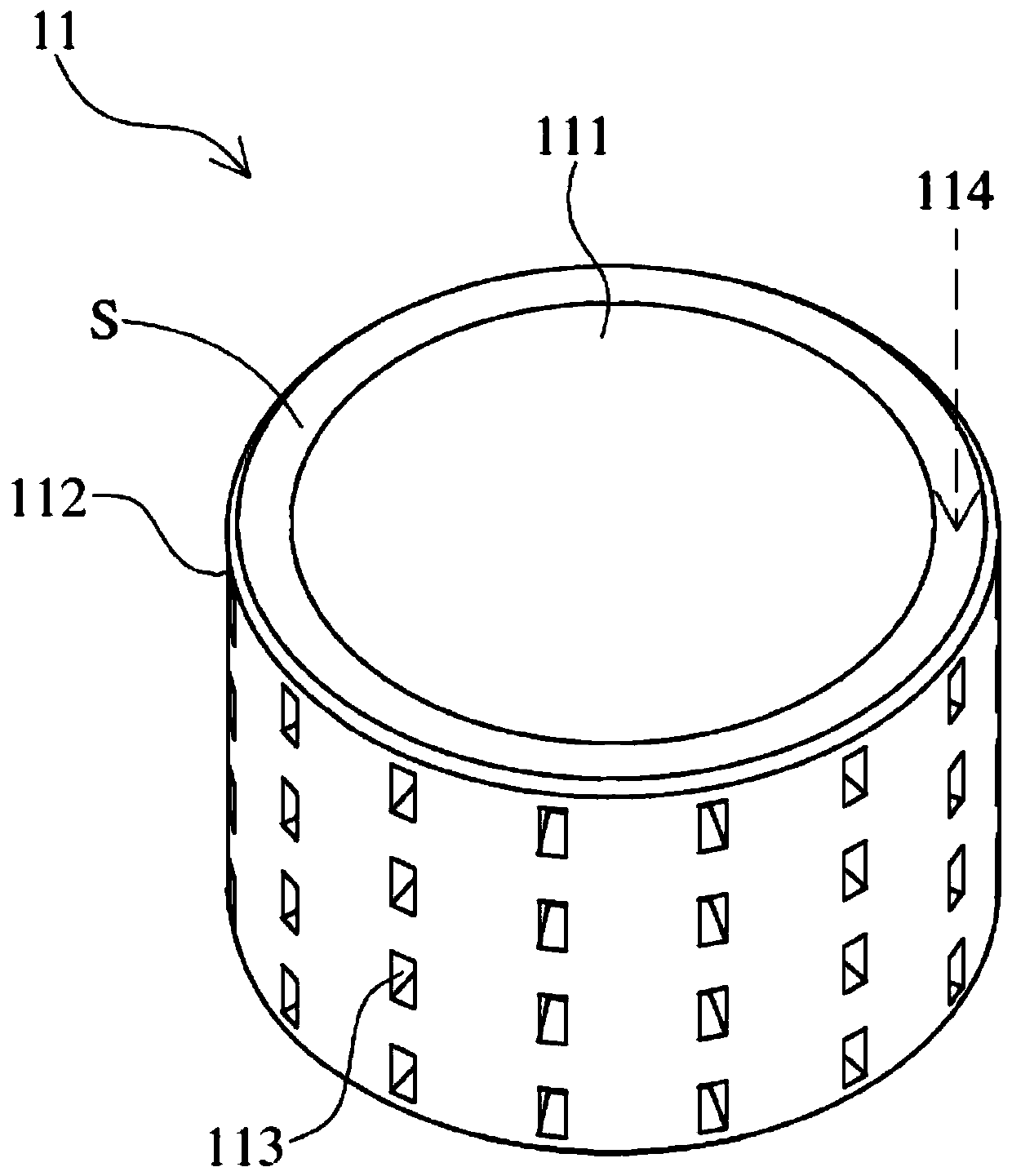

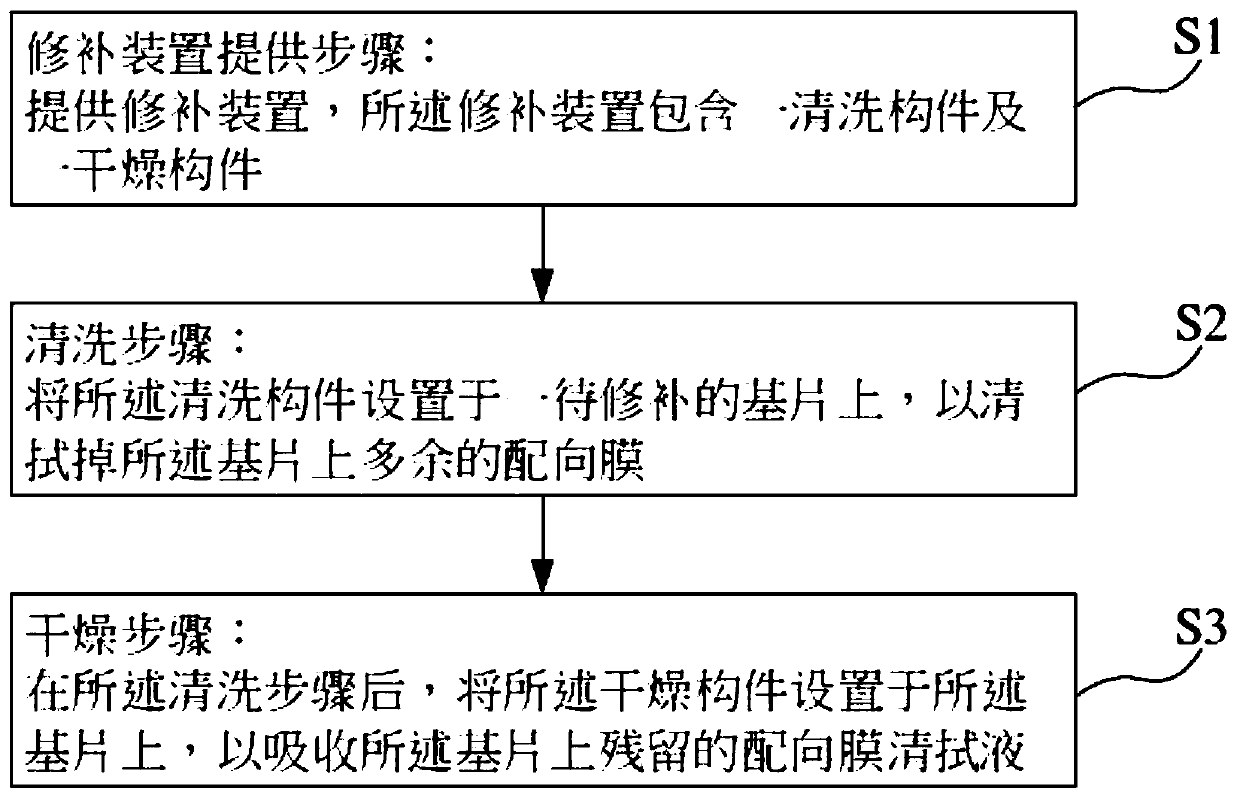

Repairing device for liquid crystal alignment film and method for repairing liquid crystal alignment film

ActiveCN110687703BPrecision exception avoidanceReduce poor qualityNon-linear opticsEngineeringConveyor belt

The invention discloses a repairing device for a liquid crystal alignment film, comprising a cleaning component and a drying component. The cleaning component includes a liquid supply rotating part, a traveling rotating part and an alignment film cleaning conveyor belt. The liquid supply rotating member and the traveling rotating member are driven to drive the alignment film cleaning conveyor belt to drive along a cleaning conveying path, so that the alignment film cleaning liquid contained in the alignment film cleaning conveyor belt can wipe off the excess alignment on the substrate. membrane. The drying component includes a traveling rotating part and a residual liquid cleaning conveyor belt. The traveling rotating part is driven to drive the residual liquid cleaning conveyor belt to drive along the cleaning and wiping conveying path, so as to absorb the residual alignment on the substrate through the residual liquid cleaning conveyor belt. The film cleaning solution can not only repair the area with abnormal precision on the substrate, but also simplify the repair of the alignment film.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Device for repairing liquid crystal alignment film and method for repairing liquid crystal alignment film

ActiveCN110687703APrecision exception avoidanceReduce poor qualityNon-linear opticsConveyor beltLiquid crystal

The invention discloses a device for repairing a liquid crystal alignment film. The device comprises a cleaning member and a drying member, the cleaning member comprises a liquid supply rotating member, a traveling rotating member, and an alignment film cleaning conveyor belt, and the liquid supply rotating member and the traveling rotating member are driven to cause the alignment film cleaning conveyor belt to move along a cleaning conveying path, so as to wipe off excessive alignment films on a substrate through alignment film cleaning liquid contained on the alignment film cleaning conveyorbelt. The drying member comprises a traveling rotating member and a residual liquid cleaning conveyor belt, and the traveling rotating member is driven to cause the residual liquid cleaning conveyorbelt to move along the cleaning conveying path to absorb the residual alignment film cleaning liquid on the substrate through the residual liquid cleaning conveyor belt. Therefore, an area with abnormal precision on the substrate can not only be repaired, and the repair of the alignment film is better simplified.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

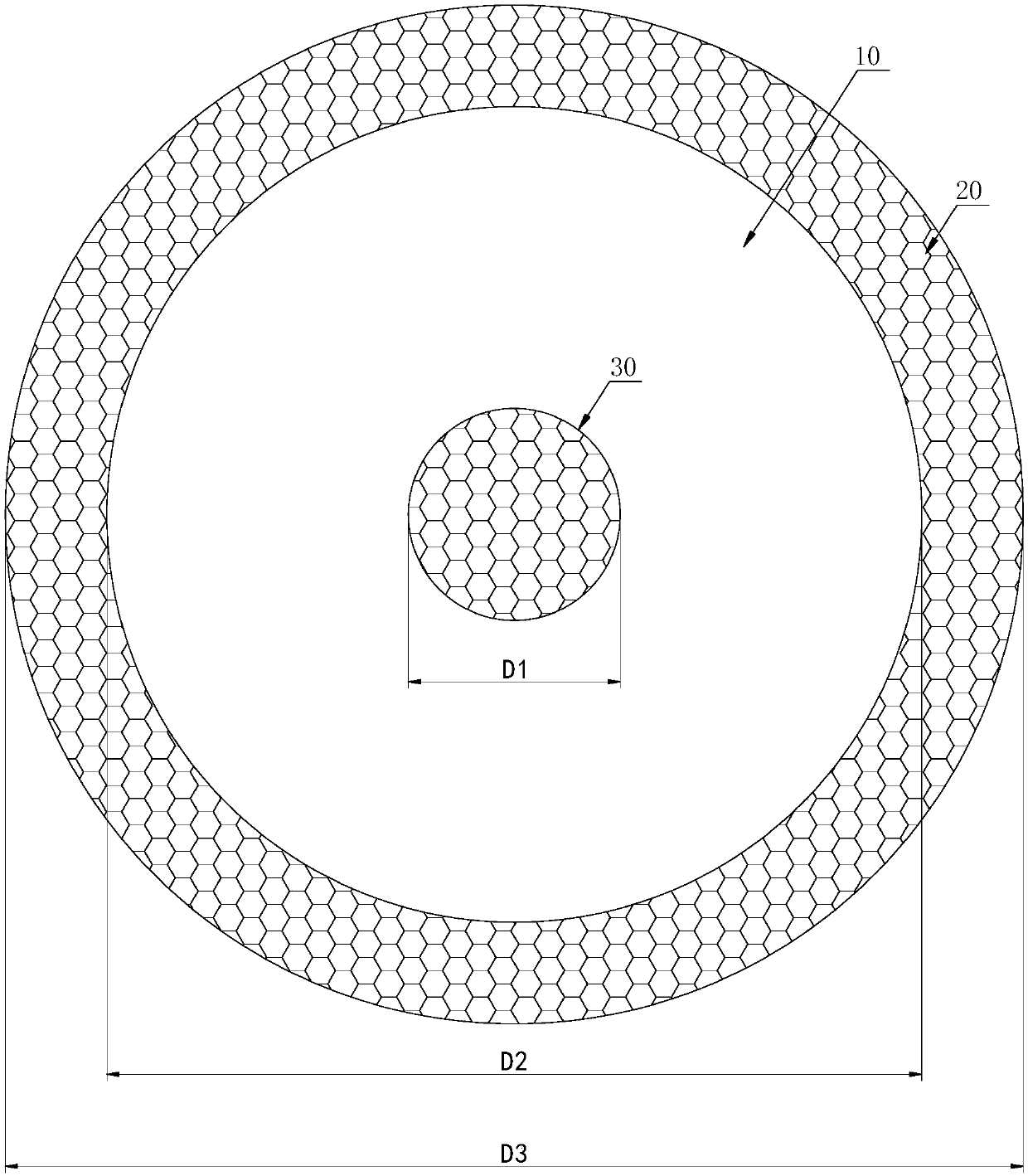

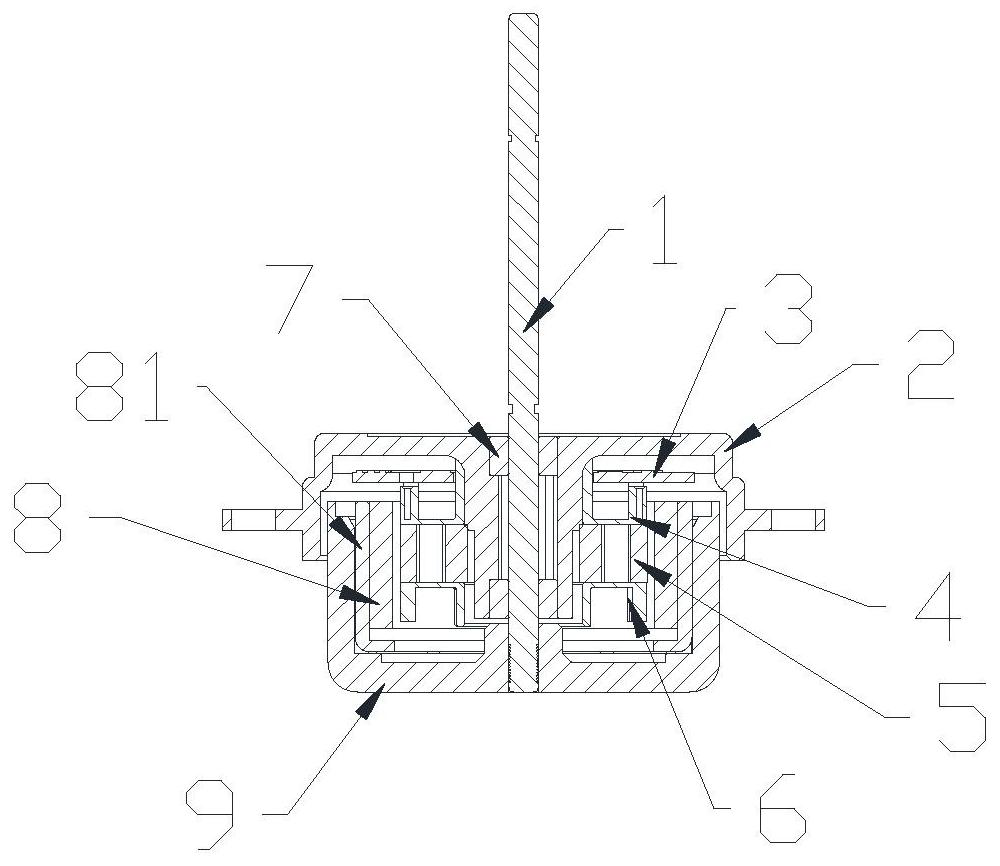

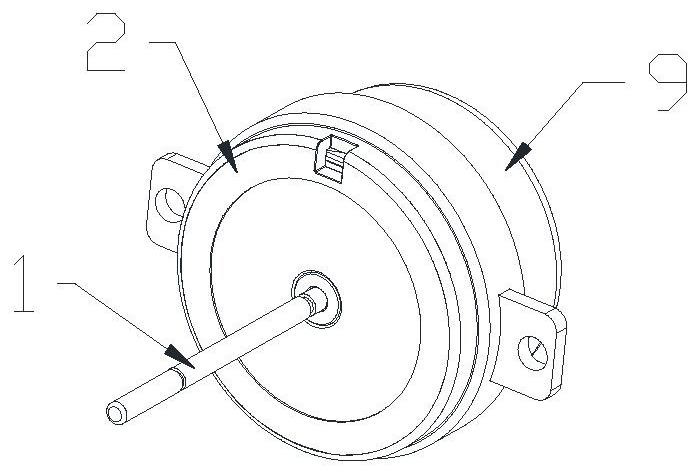

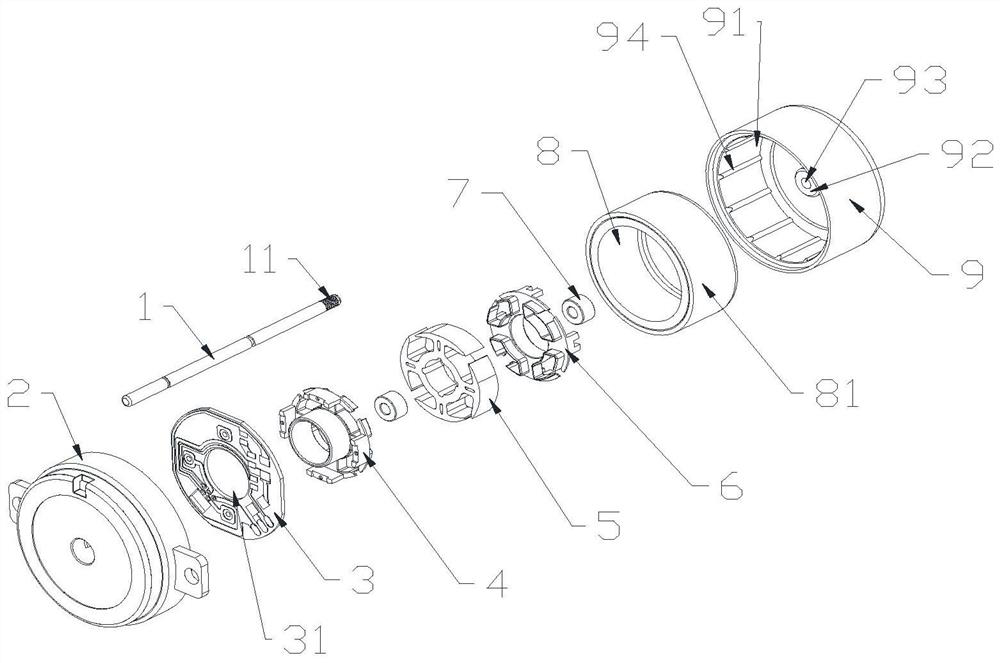

Direct-current outer rotor water fetching motor bracket and motor

PendingCN112737179AStable structureReduce poor qualityWindings insulation shape/form/constructionMagnetic circuit rotating partsElectric machineEngineering

The invention disclose a direct-current outer rotor water fetching motor bracket and a motor. The direct-current outer rotor water fetching motor comprises a motor support, a support inner groove is formed in the motor support, an installation column is arranged in the support inner groove, an installation hole is formed in the installation column, a stress boss is arranged in the installation hole, and oil bearings are arranged at the two ends of the stress boss. The oil bearings are internally provided with motor rotating shafts together. A circuit board is arranged in the support inner groove, a stator lower insulation frame and a stator upper insulation frame are arranged on one side of the circuit board, a stator is arranged between the stator lower insulation frame and the stator upper insulation frame, annular magnetic rings are arranged on the outer sides of the stator lower insulation frame, the stator upper insulation frame and the stator, and a rotor iron shell is arranged on the outer sides of the annular magnetic rings. And a rotor rubber shell is arranged outside the rotor iron shell. The motor bracket is reliable in structure, capable of effectively reducing poor quality caused by large bearing coaxiality in the motor assembling process, high in stability, good in motor lubricating effect, capable of effectively reducing friction damage to a motor rotating shaft, good in rotating flatness and capable of reducing running noise.

Owner:合肥珺安机电设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com