A continuous batching and feeding integrated system for cement production

A feeding and cement technology, applied in the field of cement production equipment, can solve the problems of heavy workload, difficult cleaning, adverse effects of calcination, etc., and achieve the effect of reducing the stability coefficient, reducing the weight difference, and improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

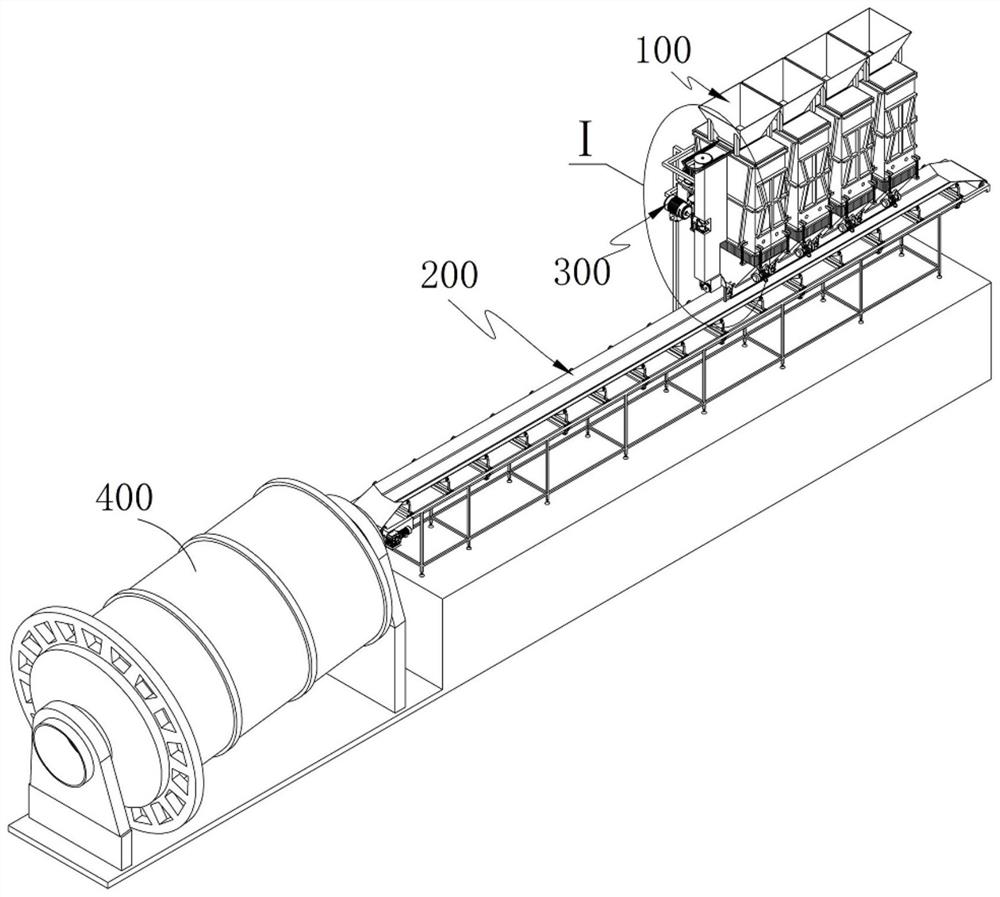

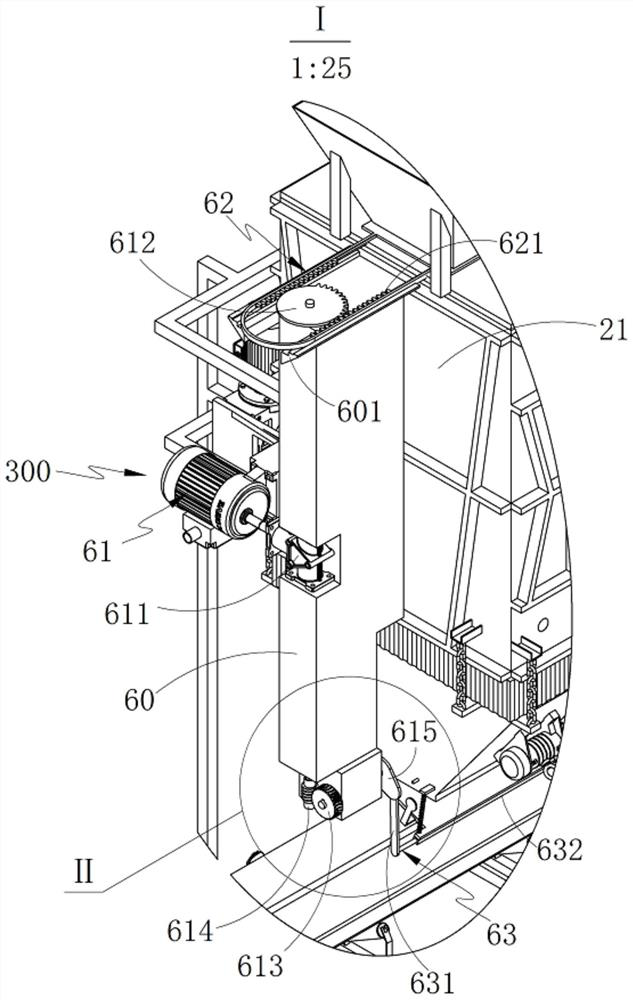

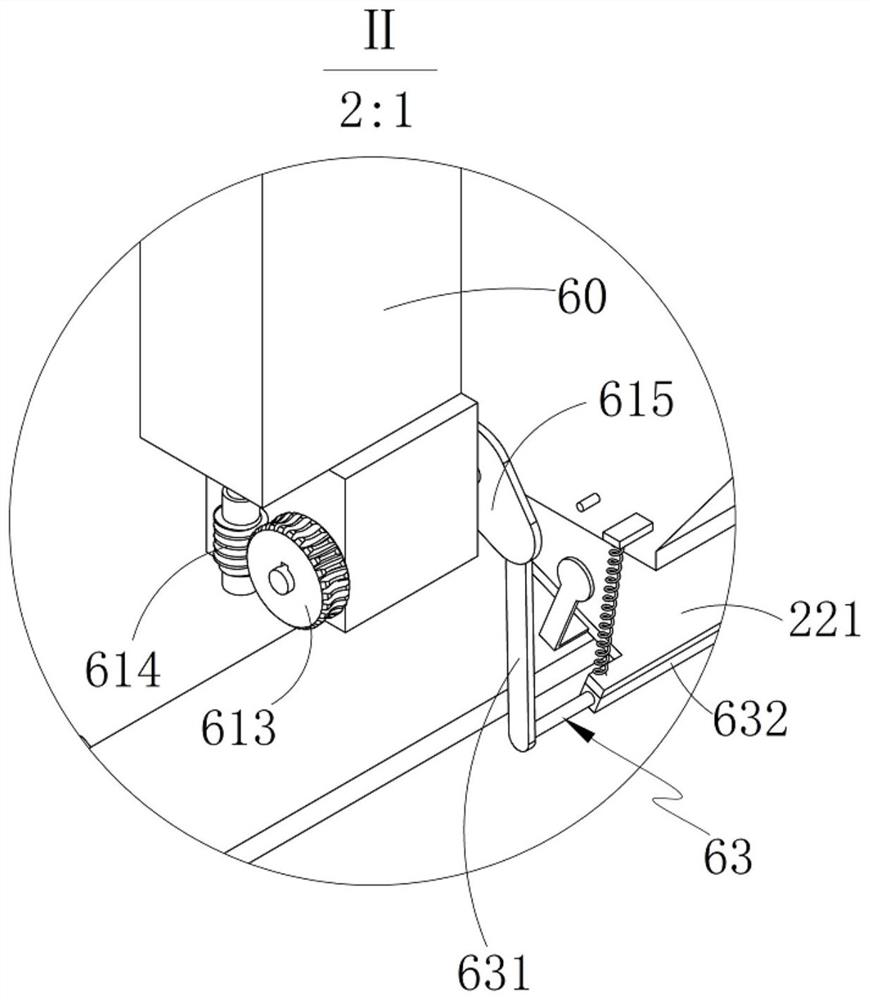

[0060] Such as figure 1 As shown, a continuous batching and feeding integrated system for cement production includes a conveying unit 200, and several raw material batching stations 100 arranged sequentially above the conveying unit 200 and used to control several raw material batching stations 100 The raw material batching station 100 realizes the feeding control unit 300 of intermittent feeding; the raw material batching station 100 includes a hopper unit 2 with an upper and lower split structure, and the hopper unit 2 includes an upper hopper 21 and a lower hopper 22; the lower hopper 22 is hoisted below the upper hopper 21 through a flexible part 23; the bottom outlet of the lower hopper 22 is hingedly provided with a baffle 221; wherein the flexible part 23 can be selected from a nylon belt, a belt, a chain, etc., preferably a chain; The connection between the upper hopper 21 and the lower hopper 22 is connected by a dustproof cloth 24, which solves the problem that dust ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com